VAC TZIDC, TZIDC-200 Configuration And Parameterization Instruction

Con guration-, Parameteri zation Ins truc tion C OI/T ZIDC /TZI DC-2 00 -EN

TZIDC, TZIDC-200

Digital Positioner

Software revision 5.0

VALVE ACCESSORIES & CONTROLS

2 COI/TZIDC/TZIDC-200- EN | TZIDC, TZIDC- 200

Short product description

Digital positioner for the positioning of pneumatically controlled

actuators.

Device rmware version: 05.00.00

Further information

A

dditional documentation on TZIDC, TZIDC-200 is available to

download free of charge at www.abb.com/positioners.

A

lternatively simply scan this code:

Manufacturer

A

BB Automation Products GmbH

Process Automation

Schillerstr. 72

32425 Minden

Germany

Tel: +49 571 830-0

Fax: +49 571 830-1806

Customer service center

Tel: +49 180 5 222 580

Mail: automation.service@de.abb.com

Change from one to two columns

TZIDC, TZIDC- 200 | COI/TZIDC/TZIDC-200-EN 3

Contents

1 Safety ............................................................................... 5

1.1 General information and instructions .................... 5

1.2 Warnings ............................................................. 5

1.3 Intended use ........................................................ 5

1.4 Improper use ....................................................... 5

1.5 Warranty provisions ............................................. 5

2 Operatio n ......................................................................... 6

2.1 Safety instru ctions ............................................... 6

2.2 Parameterization of the device ............................. 6

2.2.1 Menu navigation .................................................. 6

2.3 Menu levels .......................................................... 7

2.4 Operating modes ................................................. 7

2.4.1 Operating mode 1.0: Control with adaptation ....... 7

2.4.2 Operating mode 1.1: Control without adaptation .. 7

2.4.3 Operating mode 1.2: Manual adjustment in the

stroke ra nge ........................................................ 8

2.4.4 Operating mode 1.3: Manual adjustment in the

sensor range ........................................................ 8

2.5 Inhibiting operation .............................................. 8

3 Congurat ion ................................................................... 9

3.1 General information .............................................. 9

3.2 Example .............................................................. 9

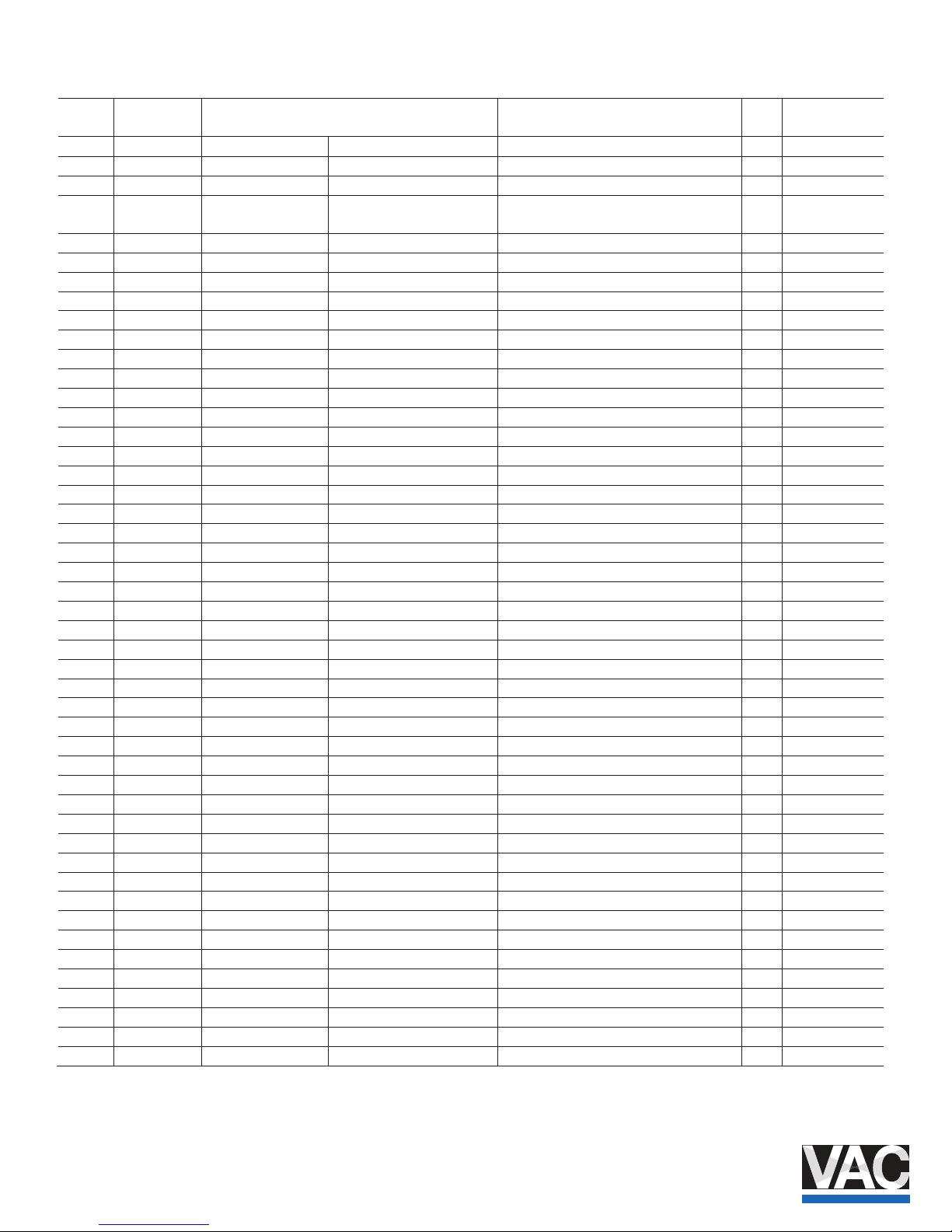

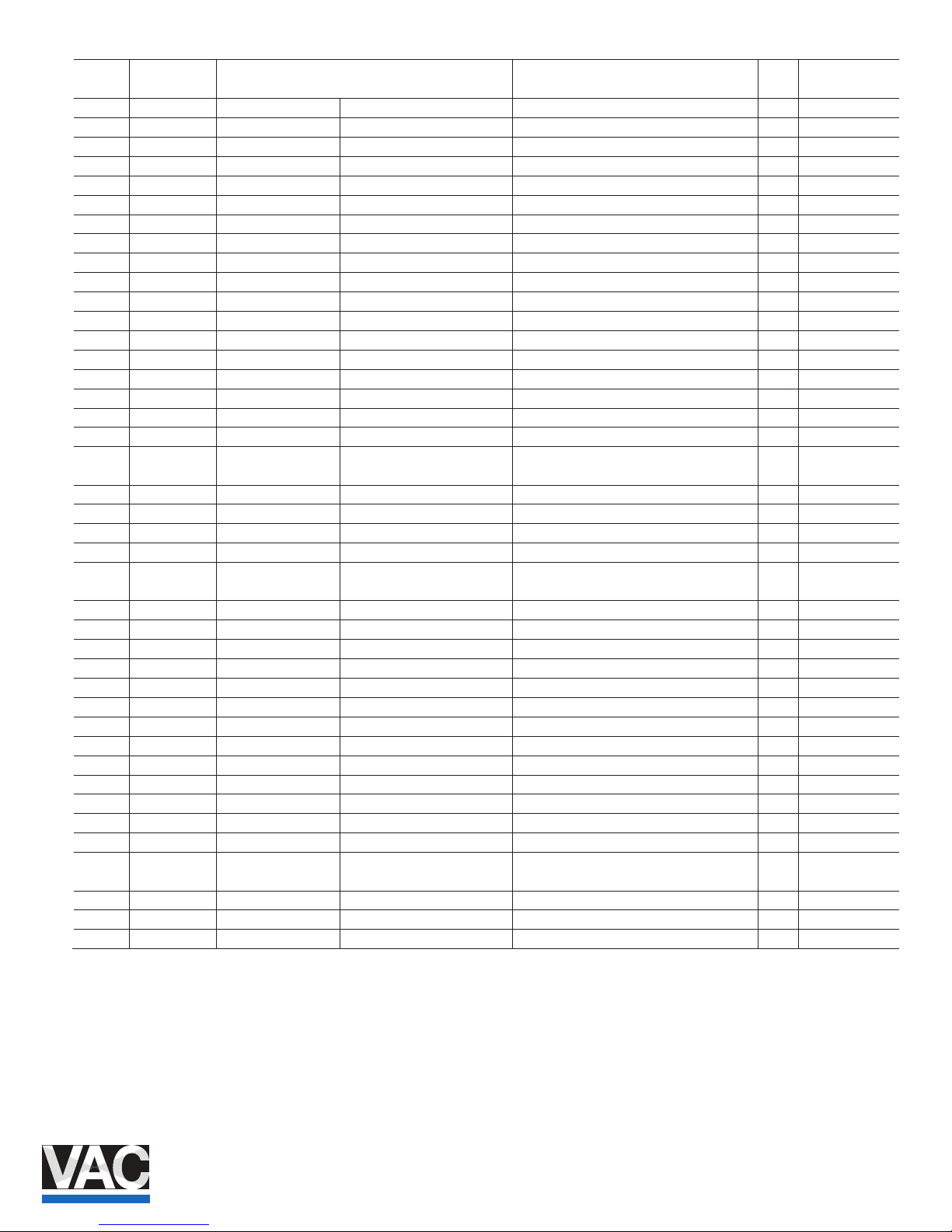

3.3 HART parameter description .............................. 10

3.4 HART parameter over view (graphic) ................... 12

3.5 Parametergroup 1: Standard ............................. 12

3.5.1 ACTUATOR – Actu ator type ............................... 12

3.5.2 AUTO_ADJ – automatic adjustment ................... 12

3.5.3 ADJ_MODE – Automatic adjustment mode ........ 13

3.5.4 TEST – Te st ....................................................... 14

3.5.5 FIND_DEV – Find device .................................... 14

3.5.6 EXIT – Return to op erating level ......................... 14

3.6 Parameter group 2: Setpoint .............................. 15

3.6.1 MIN_RGE – Setpoint range min. ........................ 15

3.6.2 MAX_RGE – Setpoint range max........................ 15

3.6.3 CHARACT – Character istic curve ....................... 15

3.6.4 ACTION – Direction of action (setpoint signal) ..... 15

3.6.5 SHUT_CLS – Shut-o value 0% ......................... 16

3.6.6 SHUT-OPN – Shut -o value 100%..................... 16

3.6.7 RAMP UP – Setpoint ramp (up) .......................... 16

3.6.8 RAMP DN – Setpoint ramp (down) ..................... 16

3.6.9 EXIT – Return to op erating level ......................... 17

3.7 Parameter group 3: Operating range .................. 17

3.7.1 MIN_RGE – Operatin g range min. ...................... 17

3.7.2 MAX_RGE – Operatin g range ma x. .................... 17

3.7.3 ZERO_POS – Zero position ................................ 18

3.7.4 EXIT – Return to op erating level ......................... 18

3.8 Parameter group 4: Messa ges ........................... 18

3.8.1 TIME_OUT – Dead band time limit ...................... 18

3.8.2 POS_SW1 – Switchin g point SW1 ..................... 18

3.8.3 POS_SW2 – Switchin g point SW2 ..................... 19

3.8.4 SW1_ACTV – Active direction SW1 .................... 19

3.8.5 SW2_ACTV – Active direction SW2 .................... 19

3.8.6 EXIT – Return to op erating level.......................... 19

3.9 Parameter group 5: Alarms ................................ 20

3.9.1 LEAKAGE – Leakage at actuator ........................ 20

3.9.2 SP_RGE – Setpoint monitoring .......................... 20

3.9.3 SENS_RGE – Operatin g range exceeded ........... 20

3.9.4 CTRLER – Contro ller inactive ............................. 20

3.9.5 TIME_OUT – Dead band time limit ...................... 20

3.9.6 STRK_CTR – Moveme nt counter ....................... 20

3.9.7 TRAVEL – Travel counter ................................... 21

3.9.8 EXIT – Return to op erating level.......................... 21

3.10 Parameter group 6: Ma nual adjustment ............. 21

3.10.1 MIN_VR – Operatin g range mi n. ......................... 21

3.10.2 MAX_VR – Operatin g range ma x. ....................... 22

3.10.3 ACTUATOR – Actu ator type ............................... 22

3.10.4 SPRNG_Y2 – Spring action (Y2) ......................... 22

3.10.5 DANG_DN – Dead Angle Close .......................... 23

3.10.6 DANG_UP – Dead Angle Open .......................... 23

3.10.7 BOLT_POS – Actua tor position .......................... 23

3.10.8 EXIT – Return to op erating level.......................... 23

3.11 Parameter group 7: Co ntrol parameters ............. 24

3.11.1 KP UP – KP va lue (up) ....................................... 24

3.11.2 KP DN – KP value (down) ................................... 24

3.11.3 TV UP – TV va lue (up) ........................................ 24

3.11.4 TV DN – TV va lue (down) ................................... 25

3.11.5 Y-OFS UP – Y oset (up) .................................... 25

3.11.6 Y-OFS DN – Os et (down) ................................. 25

3.11.7 TOL_BAND – Toler ance band ............................ 26

3.11.8 DEADBAND – Dead band .................................. 26

3.11.9 DB_APPR – Dead ba nd approach ..................... 26

3.11.10 DB_CALC – Dead-band determination ............... 26

3.11.11 LEAK_SEN – Leakage sensitivity ........................ 27

3.11.12 EXIT – Return to op erating level.......................... 27

3.12 Parameter group 8: Analog output ..................... 27

3.12.1 MIN_RGE – Current range min. .......................... 27

3.12.2 MAX_RGE – Current range max. ........................ 27

3.12.3 ACTION – Characteris tic curve action ................ 27

3.12.4 ALARM – Alarm ................................................. 28

3.12.5 RB_CHAR – Count back characteristic curve ..... 28

3.12.6 TEST – Te st ....................................................... 28

3.12.7 ALR_ENAB – Alarm vi a analog ou tput ................ 28

3.12.8 CLIPPING – Extending the signal output range ... 28

3.12.9 EXIT – Return to op erating level.......................... 28

4 COI/TZIDC/TZIDC-200- EN | TZIDC, TZIDC- 200

3.13 Parameter group 9: digital output ....................... 29

3.13.1 ALRM_LOG – Alarm ou tput logic ....................... 29

3.13.2 SW1_LOG – Logic ............................................. 29

3.13.3 SW2_LOG – Logic ............................................. 29

3.13.4 EXIT – Return to op erating level ......................... 29

3.14 Parameter group 10: digital input ....................... 30

3.14.1 FUNCTION – Digital input function selection ....... 30

3.14.2 EXIT – Return to op erating level ......................... 30

3.15 Parameter group 11: Safe positi on ..................... 31

3.15.1 FAIL_POS – Safe position .................................. 31

3.15.2 FACT_SET – Fac tory setting .............................. 31

3.15.3 IP-TYP – Type of the I/P module ........................ 32

3.15.4 IP_COMP – IP Co mpensation ............................ 32

3.15.5 HART_REV – HART versio n ............................... 32

3.15.6 EXIT – Return to op erating level ......................... 32

4 Diagnosis / erro r message s .......................................... 33

4.1 Error codes ........................................................ 33

4.2 Alarm co des ...................................................... 35

4.3 Message co des ................................................. 36

4.4 Error hand ling .................................................... 37

4.4.1 Positioner vibrates ............................................. 37

4.4.2 Positioner without function ................................. 38

TZIDC, TZIDC- 200 | COI/TZIDC/TZIDC-200-EN 5

1 Safety

Change from one to two columns

1.1 General information and instructions

These instructions are an impo rtant part of the product and

must be retained for future reference.

Installation, commissioning, and maintenance of the product

may only be performed by trained specialist personnel who

have been authorized by the plant operator accordingly. The

specialist personnel must have read and understood the

manual and must comply with its instructions.

For additional information or if specic problems occur that are

not discussed in these instruct ions, contact the manufacturer.

The content of these instructions is neither part of nor an

amendment to any previous or ex

isting agreement, promise or

legal relationship.

Modications and repairs to the product may only be

performed if expressly permitted by these instructions.

Information and symbols on the product must be observed.

These may not be removed and must be fully legible at all

times.

The operating company must stri ctly observe the applicable

national regulations relating to the installation, function testing,

repair and maintenance of electrical products.

1.2 Warnings

The warnings in these instructio ns are structured as follows:

DANGER

The signal word "DANGER" indicates an imminent danger.

Failure to observe this informat ion will result in death or

severe injury.

WARNING

The signal word "WARNING" in dicates an imminent danger.

Failure to observe this informat ion may result in death or

severe injury.

CAUTION

The signal word "CAUTION" in dicates an imminent danger.

Failure to observe this informat ion may result in minor or

moderate injury.

NOTE

The signal word "NOTE" in dicates useful or important

information about the product.

The signal word "NOTE" is n ot a signal word indicating a

danger to personnel. The signal word "NOTE" can also refer

to material damage.

1.3 Intended use

Positioning of pneumatically controlled actuators; designed for

mounting on linear and part-turn actuators.

The device is designed for use exclusively within the stated

values on the name plate and in the data sheet.

— The maximum operating temperature must not be

exceeded.

— The permissible ambient temperature must not be

exceeded.

— The housing protection ty pe must be observed.

1.4 Improper use

The following are considered to be instances of improper use

of the device:

— For use as a climbing aid, e.g. for mounting purposes

— For use as a support for extern al loads, e.g. as a support

for piping, etc.

— Material application, e.g. by painting over the name plate

or welding/soldering on parts.

— Material removal, e.g. by spot drilling the housing.

1.5 Warranty provisions

Usin

g the device in a manner that does not fall within the

scope of its intended use, disregarding this manual, using

underqualied personnel, or making unauthorized alterations

releases the manufacturer from liability for any resulting

damage. This renders the manufacturer's warranty null and

void.

6 COI/TZIDC/TZIDC-200- EN | TZIDC, TZIDC- 200

2 Operation

2.1 Safety instructions

CAUTION

Risk of injury due to incorrect parameter values!

Incorrect parameter values can cause the valve to move

unexpectedly. This can lead to process failures and result in

injuries.

— Before recommissioning a positioner that was previously

in use at another location, always reset the device to its

factory settings.

— Never start Auto Adjust before restoring the factory

settings.

If there is a chance that safe op eration is no lo nger possible,

take the device out of operation and secure it against

unintended startup.

2.2 Parameterization of the device

The LCD display features operat ing buttons which enable the

device to be operated with the housing cover open.

2.2.1 Menu navigation

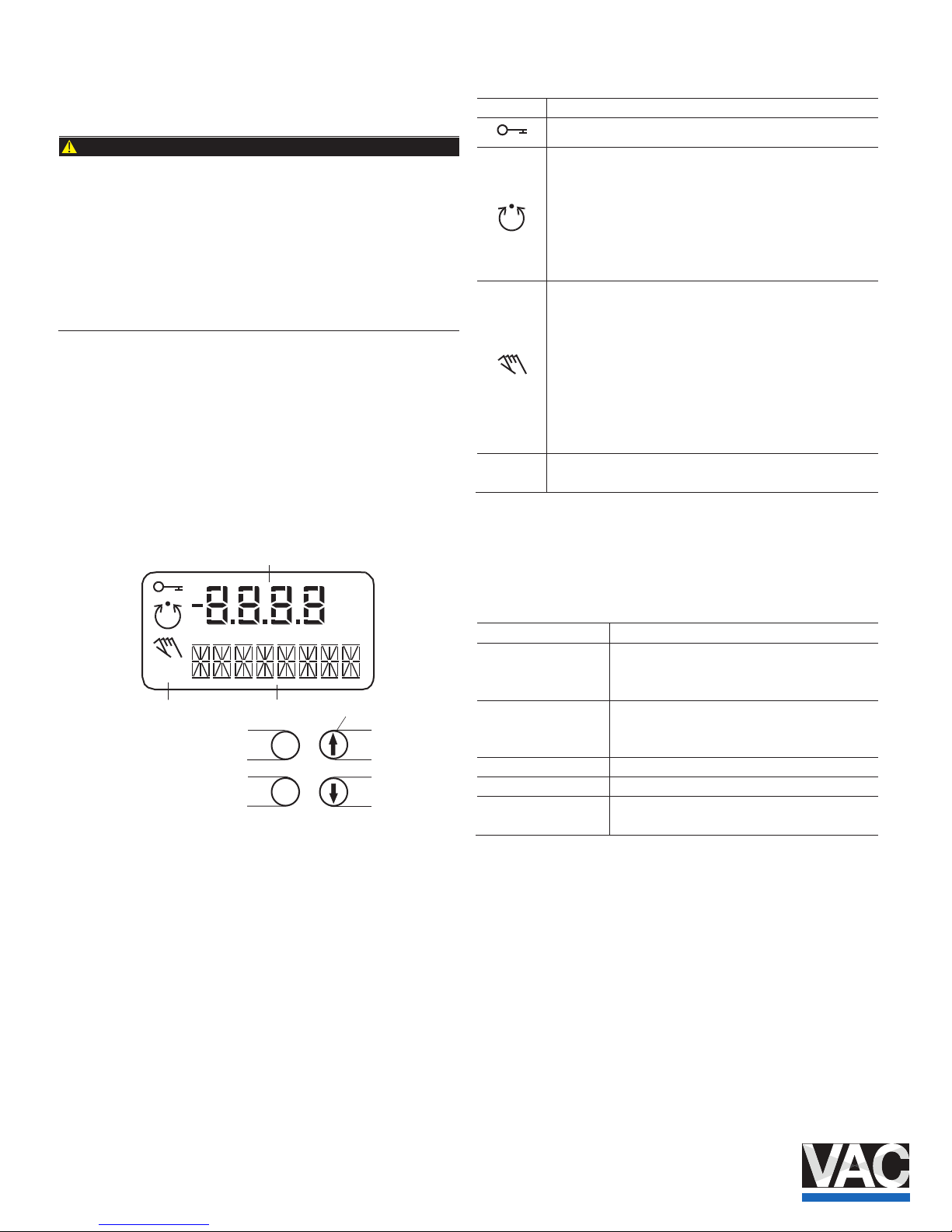

Fig. 1: LCD display with operating buttons

1 Value display with unit 2 Symbol display

3 Designator display 4 Operating buttons for menu navigation

Value display with unit

This 7-segment display with four digits indicates parameter

values or parameter reference numbers. For values, the

physical unit (°C, %, mA) is also displayed.

Designator display

This 14-segment display with eigh

t digits indicates the

designators of the parameters with their status, of the

parameter groups, and of the operating modes.

Description of symbols

Symbol Description

Operation or access is restricted.

Control loop is active.

The symbol is displayed when the positioner is in operating

mode 1.0 CTRL_ADP (adaptive control) or 1.1 CTRL_FIX

(xed control) at operating level. On the conguration level

there are test functions for which the controller will be active

as well. The control loop symbol will also be displayed when

these functions are active.

Manual adjustment.

The symbol is displayed when the positioner is in operating

mode 1.2 MANUAL (manual adjustment within the stroke

range) or 1.3 MAN_SENS (manual adjustment within the

measuring range) at operating level. At conguration level,

manual adjustment is active when setting the valve range

limits (parameter group 6 MIN_VR (min. of valve range) and

6 MAX_VR (max. of valve range)). The symbol will also be

displayed when these parameters are being set.

The conguration icon indicates that the positioner is at the

conguration level. The control operation is inactive.

The four operating buttons ENTER , MODE , and are

pressed individually or in cer tain combinations according to

the function desired.

Operating button functions

Control button

Meaning

ENTER — Acknowledge message

— Start an action

— Save in the non-volatile memory

MODE — Choose operating mode (operating level)

— Select parameter group or parameter

(conguration level)

nottub noitcerid PU

nottub noitcerid NWOD

Press and hold all four

buttons for 5 s

Reset

M10980

conf

mA

%

C

o

E

M

4

1

2

3

conf

TZIDC, TZIDC- 200 | COI/TZIDC/TZIDC-200-EN 7

2.3 Menu levels

The positioner has two operating levels:

Operating level

On the operating level the positioner operates in

one of four possible operating modes (two for

automatic control and tw o for manual mode).

Parameters cannot be changed or saved on this

level.

Conguration level

On this level most of the parameters of the

positioner can be changed locally. The PC is

required to change the limit values for the

movement counter, the travel counter, and the

user-dened characteristic curve.

On the conguration level the active operating

mode is deactivated. The I/P module is in neutral

position. The control operation is inactive.

NOTE

Property damage

During external conguration via a PC, the positioner no

longer responds to the setpoi nt current. This may lead to

process failures. Prior to extern al conguration, always move

the actuator to the safety position and activate manual

adjustment.

2.4 Operating modes

2.4.1 Operating mode 1.0: Control with adaptation

Controlling operation with automatic adaptation of the

control parameters

When the P1.0CTRL_ADP positioner is operated in "Adaptive

Mode", the control parameters are automatically optimized to

the operating conditions in small increments. This is especially

helpful if valves and ttings could not be operated with

reference conditions while the Auto Adjust function was in

progress.

Since self-optimization in "A daptive Mode" is subject to

several factors during operatio n and mismatches could result

over a longer period, we recommend that this operating mode

only be activated over severa l hours and be followed by the

mode P1.1 CTRL_FIX .

The valve position is indicated as a percentage of the

operating range (from 0 ... 100%).

2.4.2 Operating mode 1.1: Control without adaptation

Controlling operation with xed parameters

This is the normal recommended operating mode.

In contrast to the operating mode P1.0 CTRL_ADP , the

control parameters are not automatically adjusted.

The valve position is indicated as a percentage of the

operating range (from 0 ... 100%).

In both control modes 1.0 and 1.1 , several values can be

displayed besides the current actuator position:

Setpoint display

1. Press and hold the button.

The setpoint is displayed.

2. Briey press ENTER .

The setpoint display is toggled between the setpoint current at

the input terminals i

n mA and the setpoint as a percentage of

the stroke range.

Temperature display

1. Press and hold the button.

The temperature inside the case is displayed.

2. Briey press ENTER .

3. The temperature display is toggled between °C and °F.

Display of control deviation

1. Press and hold the and button.

The control deviation is displayed as a percentage (%) of the

stroke range.

conf

mA

%

C

°

conf

mA

%

C

°

conf

mA

%

C

°

conf

mA

%

C

°

conf

mA

%

C

°

conf

mA

%

C

°

conf

mA

%

C

°

8 COI/TZIDC/TZIDC-200- EN | TZIDC, TZIDC- 200

2.4.3 Operating mode 1.2: Manual adjustment in the

stroke range

The valve is adjusted manually using the direction buttons

and within the stroke range.

1. Press and hold the button for the desired direction.

2. To activate the high speed mode in the manual mode,

press the second arrow button.

CAUTION

If air escapes due to a leakag e, the position will not be

readjusted.

Congured stroke limit positions and stroke times are not

eective in manual mode.

In this operating mode the valv e position is indicated as a

percentage (%) of the stroke range.

2.4.4 Operating mode 1.3: Manual adjustment in the

sensor range

See operating mode 1.2

Unlike step 1.2, this operating mode is used to determine

whether the available detection ra nge of the position sensor is

used correctly after mounting the positioner to the actuator. In

this mode, the valve position is indicated in angular degrees

with respect to the sensor range (i.e.,0 ... 140 °).

2.5 Inhibiting operation

Positioner operation can be inhibited completely or partially via

the digital input and the FUNCTION parameter in parameter

gro

up 10 ( DIG_IN (digital input)).

This allows the user to prevent or restrict operating actions of

unauthorized personnel as desired. When operation is

disabled in this way, the key symb ol is indicated in the display.

The following levels of conf iguration locks are possible:

Inhibiting the local conguration

Local operation on the operating level and remote operation

and conguration via a PC are still possible.

Inhibiting all local operating functions

No local operating actions can be executed. Both the

operating level and the conguration level are locked. Remote

operation and setting of parameters via a PC is still possible.

Inhibiting local operation and remote conguration

It is not possible to operate or congure the positioner locally

or congure it using a PC.

NOTE

This inhibit function can only be deactivated when a voltage

of 12 ... 24 V is applied at the digital input of the positioner

(see Function selection in parameter group 10 on page 30).

conf

mA

%

C

°

conf

mA

%

C

°

conf

mA

%

C

°

conf

mA

%

C

°

TZIDC, TZIDC- 200 | COI/TZIDC/TZIDC-200-EN 9

3 Conguration

3.1 General information

Most parameters for the position er can be set locally, meaning

that conguration only needs to be performed via the local

communication interface (LCI) or FSK modem and PC in

exceptional cases.

You may also deny or restrict local modication and saving of

parameters by completely or partially blocking access to the

conguration level (see Chapter "Inhibiting operation" on page

8 and the description of the Function parameter on page 30).

To simplify the process, the di erent parameters are grouped

as follows:

ID Designator Name

P1._ STANDARD Standard

P2._ SETPOINT Setpoint

P3._ ACTUATOR Actuator

P4._ MESSAGES Events

P5._ ALARMS Alarms

P6._ MAN_ADJ Manual adjustment

P7._ CTRL_PAR Control parameters

P8._ ANLG_OUT Analog output

P9._ DIG_OUT Digital output

P10._ DIG_IN Digital input

P11._ FS / IP Factory setting, I/P type

The following sections provide an overview (in tabular and

graphical format) of the overa ll structure of the parameter

groups and parameters.

Change from two to one column

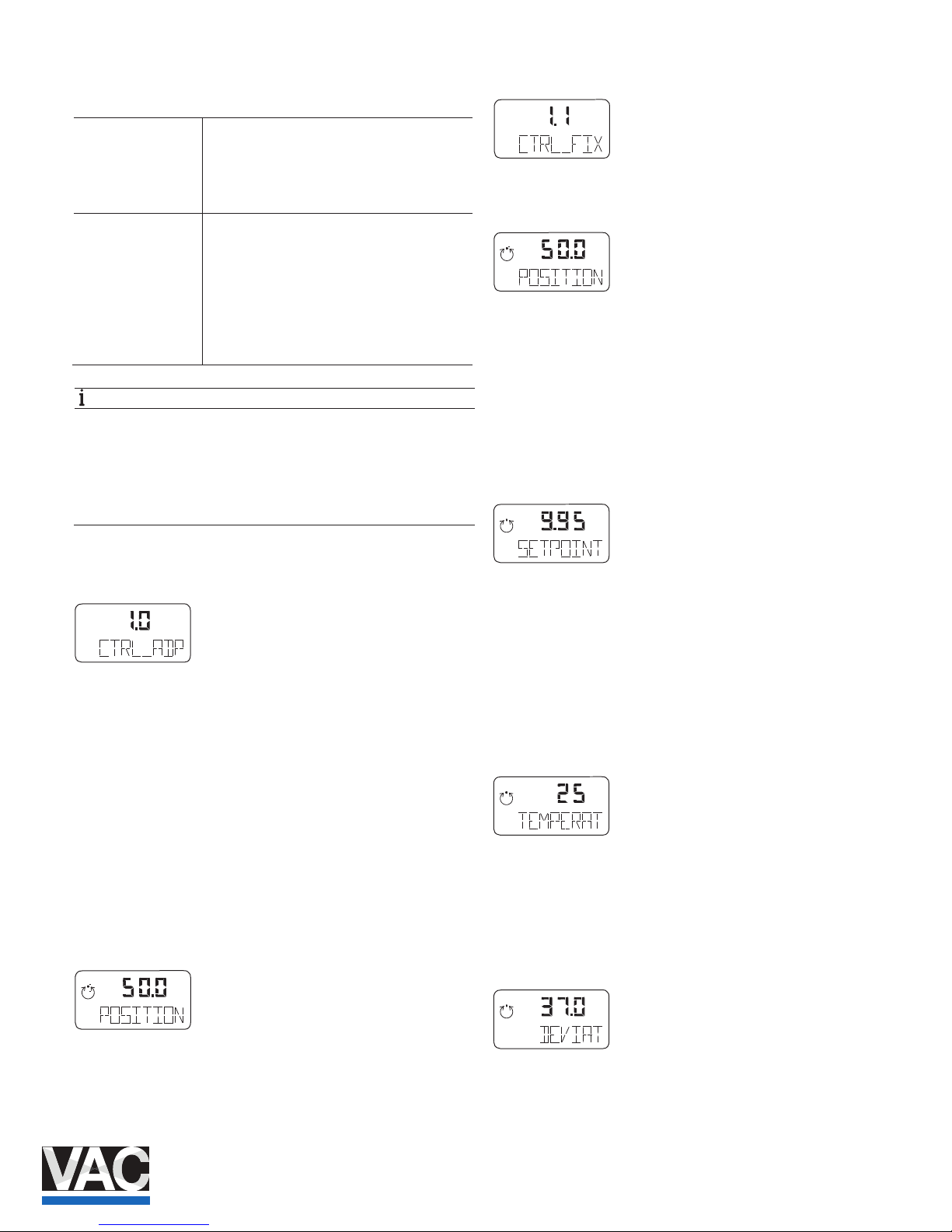

3.2 Example

Parameter (1st line in

display)

Indicator (2nd line in

display)

Function Possible parameter settings Unit Factory Setting

P1._ STANDARD

P1.0 ACTUATOR Actuator type LINEAR, ROTARY - LINEAR

P1.1 AUTO_ADJ Autoadjust Command / Function is being

run

- -

P1.2 ADJ_MODE Automatic adjustment mode FULL, STROKE, CTRL, PAR,

ZERO_POS, LOCKED

- FULL

P1.3 TEST gnieb si noitcnuF / dnammoC tseT

run

- INACTIV

P1.4 EXIT Return to operating level Command / Function is being

run

- NV_SAVE

P2._ SETPOINT

conf

10 COI/TZIDC/TZIDC-200- EN | TZI DC, TZIDC-200

3.3 HART parameter description

Parame

ter

Display Function Possible parameter setting Unit Factory setting

P1._ STANDARD

P1.0 ACTUATOR RAENIL --- YRATOR ,RAENIL epyt rotautcA epyt rotautcA

P1.1 AUTO_ADJ --- --- noitcnuF tsujdaotuA tsujda otuA

P1.2 ADJ_MODE Auto adjust mode Automatic adjustment mode FULL,STROKE,CTRL_PAR, ZERO_POS,

LOCKED

FULL

P1.3 TEST EVITCANI --- noitcnuF tseT tseT

P1.4 FIND_DEV Find device Find device DISABLE, ONE TIME, CONTINOUS --- DISABLE

P1.5 EXIT EVAS_VN --- noitcnuF level gnitarepo ot nruteR nruteR

P2._ SETPOINT

P2.0 MIN_RGE 0.4 Am 4.81 … 0.4 egnar tnioptes .niM egnar tnioptes niM

P2.1 MAX_RGE 0.02 Am 6.5 … 0.02 egnar tnioptes .xaM egnar tnioptes xaM

P2.2 CHARACT Charact. curve Characteristic curve LINEAR, 1:25, 1:50, 25:1, 50:1, USERD --- LINEAR

P2.3 ACTION Valve action Eective directio TCERID --- ESREVER ,TCERID n

P2.4 SHUT_CLS 0.1 % 0.54 … 1.0 ,FFO % 0 eulav ffo-tuhS %0 eulav ffo-tuhS

P2.5 SHUT_OPN Shut o value 100% Shut-o FFO % FFO ,0.001 … 0.55 % 001 eulav

P2.6 RAMP UP Set point ramp, up Setpoint ra FFO --- 002 … 0 ,FFO )pu( pm

P2.7 RAMP DN FFO --- 002 … 0 ,FFO )nwod( pmar tniopteS nwod ,pmar tniop teS

P2.8 EXIT EVAS_VN --- noitcnuF level gnitarepo ot nruteR nruteR

P3._ ACTUATOR

P3.0 MIN_RGE 0.0 % 0.09 … 0.0 .nim ,egnar gnitarepO egnar ekorts fo .niM

P3.1 MAX_RGE 001 % 0.01 … 0.001 .xam ,egnar gnitarepO egnar ekorts fo .xaM

P3.2 ZERO_POS Zero position Zero position CLOC KWISE, CTCLOCKWISE --- CTCLOCKWISE

P3.3 EXIT EVAS_VN --- noitcnuF level gnitarepo ot nruteR nruteR

P4._ MESSAGES

P4.0 TIME_OUT Control time out Dead FFO --- 002 … ,FFO timil emit dnab

P4.1 POS_SW1 Position switch 1 0.0 % 0.001 … 0.0 1WS tniop gnihctiwS

P4.2 POS_SW2 Position switch 2 0.001 % 0.001 … 0.0 2WS tniop gnihctiwS

P4.3 SW1_ACTV LEB_LLAF --- DEECXE ,LEB_LLAF 1WS noitcerid evitcA elbane 1 tniophctiwS

P4.4 SW2_ACTV DEECXE --- DEECXE ,LEB_LLAF 2WS noitcerid evitcA elbane 2 tniophctiwS

P4.5 EXIT EVAS_VN --- noitcnuF level gnitarepo ot nruteR nruteR

P5._ ALARMS

P5.0 LEAKAGE EVITCANI --- EVITCANI ,EVITCA rotautca ot egakaeL noitceted egakaeL

P5.1 SP_RGE EVITCANI --- EVITCANI ,EVITCA egnar tnioptes eht edistuO rotinom gnr tniopteS

P5.2 SENS_RGE EVITCANI --- EVITCANI ,EVITCA dedeecxe egnar gnitarepO rotinom egnar .sneS

P5.3 CTRLER Controller monitor Controller inactive ACTIVE, INACTI EVITCANI --- EV

P5.4 TIME_OUT EVITCANI --- EVITCANI ,EVITCA timil emit dnab daeD tuo emit lortnoC

P5.5 STRK_CTR Stroke counter Movement counter ACTIVE, INACTIVE EVITCANI ---

P5.6 TRAVEL EVITCANI --- EVITCANI ,EVITCA retnuoc levarT retnuoc levarT

P5.7 EXIT EVAS_VN --- noitcnuF level gnitarepo ot nruteR nruteR

P6._ MAN_ADJ

P6.0 MIN_VR 0 % 0.001 … 0.0 .nim ,egnar gnitarepO egnar evlav .niM

P6.1 MAX_VR 001 % 0.001 … 0.0 .xam ,egnar gnitarepO egnar evlav .xaM

P6.2 ACTUATOR RAENIL --- YRATOR ,RAENIL epyt rotautcA epyt rotautcA

P6.3 SPRNG_Y2 Spring action (Y2) Spring action (Y2) CL OCKWISE, CTCLOCKWISE --- CTCLOCKWISE

P6.4 DANG_DN 0.0 % 0.54 … 0.0 % 0 elgna daeD esolc elgna daeD

P6.5 DANG_UP 0.001 % 0.001 … 0.55 % 001 elgna daeD nepo elgna daeD

P6.6 BOLT_POS REVEL --- METS ,REVEL noitisop rotautcA noitisop tloB

P6.7 EXIT EVAS_VN --- noitcnuF level gnitarepo ot nruteR nruteR

TZIDC, TZIDC- 200 | COI/TZIDC/TZIDC-200-EN 11

Parame

ter

Display Function Possible parameter setting Unit Factory setting

P7._ CTRL_PAR

P7.0 KP UP 0.5 --- 0.021 … 1.0 )pu( eulav PK pu ,eulav PK

P7.1 KP DN 0.5 --- 0.021 … 1.0 )nwod( eulav PK nwod ,eulav PK

P7.2 TV UP TV value, up TV value 002 --- 054 ... 01 )pu(

P7.3 TV DN 002 --- 054 ... 01 )nwod( eulav VT nwod ,eulav VT

P7.4 Y-OFS UP 0.84 % 0.001 … 0.0 )pu( tesffo Y pu ,tesffo Y

P7.5 Y-OFS DN 0.84 % 0.001 … 0.0 )nwod( tesffo Y nwod ,tesffo Y

P7.6 TOL_BAND 5.1 % 0.01 … 3.0 )enoz( dnab ecnareloT )enoz( dnab ecnareloT

P7.7 DEADBAND 01.0 % 00.01 … 01.0 dnab daeD dnabdaeD

P7.8 DB_APPR Deadband Approach Dead-band ap TSAF ,MUIDEM ,WOLS hcaorp

P7.9 TEST EVITCANI --- noitcnuF tseT tseT

P7.10 DB_CALC NO --- FFO ,NO noitanimreted dnab-daeD .taluclac dnabdaeD

P7.11 LEAK_SEN Leakage sensivity Leakag 03 S 0027 … 1 ytivitisnes e

P7.12 CLOSE_UP Pos. time out Po 0.03 % 0.001 … 0.0 gnirotinom noitis

P7.13 EXIT EVAS_VN --- noitcnuF level gnitarepo ot nruteR nruteR

P8._ ANLG_OUT

P8.0 MIN_RGE 0.4 Am 4.81 … 0.4 egnar tnerruc .niM egnar .niM

P8.1 MAX_RGE 0.02 Am 7.5 … 0.02 egnar tnerruc .xaM egnar .xaM

P8.2 ACTION Action Direction of action of

characteristic curve

TCERID --- ESREVER ,TCERID

P8.3 ALARM Alarm current Alarm message HI RUC_HGIH --- RUC_WOL ,RUC_HG

P8.4 RB_CHAR TCERID CLACER ,TCERID sretcarahc detrevnoC .retcarahc kcabdaeR

P8.5 TEST ENON --- noitcnuF tseT tseT

P8.6 ALR_ENAB NO --- FFO ,NO tuptuo golana aiv mralA delbane noitcnuf mralA

P8.7 CLIPPING Current signal

Signal clipping range

Extension of signal output to

3.8 … 20.5 mA

4.0 … 20.0; 3.8 … 20.5 mA mA 4.0 … 20.5

P8.8 EXIT --- --- noitcnuF level gnitarepo ot nruteR nruteR

P9._ DIG_OUT

P9.0 ALRM_LOG Alarm logic Alarm output logic ACTIVE_HI, ACTIVE_LO --- ACTIVE_HI

P9.1 SW1_LOG Switchpoint 1 logic Logic SW1 ACTIVE_HI, ACTIVE_LO --- ACTIVE_HI

P9.2 SW2_LOG Switchpoint 2 logic Logic SW2 ACTIVE_HI, ACTIVE_LO --- ACTIVE_HI

P9.3 TEST ENON --- noitcnuF tseT tseT

P9.4 EXIT EVAS_VN --- noitcnuF level gnitarepo ot nruteR nruteR

P10._ DIG_IN

P10.0 FUNCTION Function select Function selection NONE, POS_0 %, POS_100 %, POS_HOLD --- NONE

P10.1 EXIT --- --- noitcnuF level gnitarepo ot nruteR nruteR

P11._ FS / IP

P11.0 FAIL_POS EVITCANI --- EVITCANI ,EVITCA noitisop efaS noitisop evaS

P11.1 FACT_SET TRATS --- noitcnuF gnitteS yrotcaF gnittes yrotcaF

P11.2 IP-TYP I/P module type Type of l/P mo dule NO_F_POS,F_SAFE_1,F_SAFE_2,

F_FREEZE1, F_FREEZE2

--- [CUSTOM]

P11.3

1)

IP_COMP NO --- FFO ,NO noitasnepmoc PI noitasnepmoc PI

P11.4 HART_REV 5 --- 7 ;5 noisiveR TRAH noisiver TRAH

P11.5 EXIT EVAS_VN --- noitcnuF level gnitarepo ot nruteR nruteR

1) Activation only by A BB Service

12 COI/TZIDC/TZIDC-200- EN | TZI DC, TZIDC-200

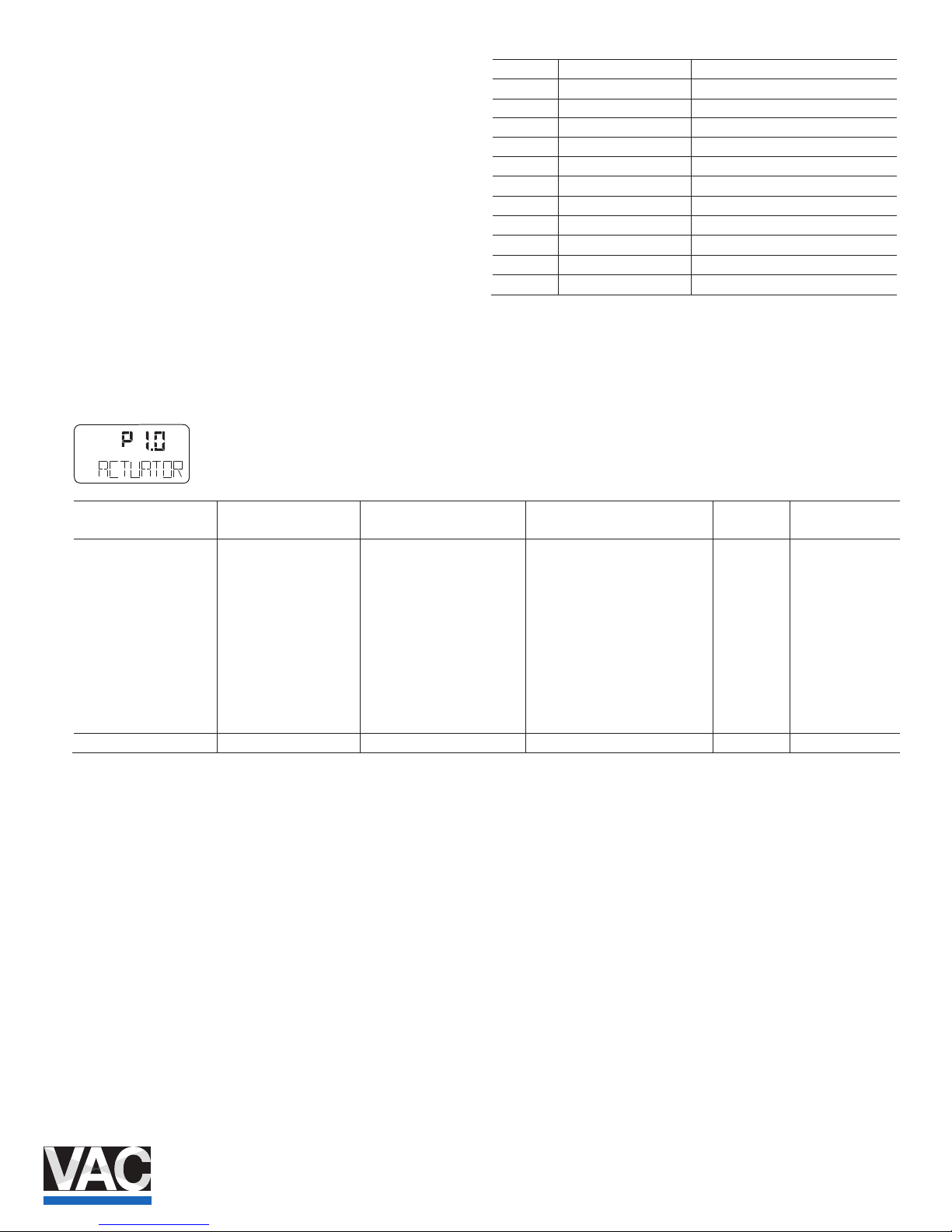

3.4 HART parameter overview (graphic)

Fig. 2

Change from one to two columns

3.5 Parametergroup 1: Standard

3.5.1 ACTUATOR – Actuator type

With this parameter you can congure the positioner for

operation on a linear actuator (sensor range ±30°) or on a

part-turn actuator (sensor ra nge ±45°). No mechanical

modications to the positioner are required.

NOTE

After changing the actuator type , it is recommended that you

run automatic adjustment to prevent linearity errors.

Selection

LINEAR Linear actuator

ROTARY Part-turn actuator

3.5.2 AUTO_ADJ – automatic adjustment

The following values are determined during Auto Adjust:

— Direction of action of the actuator

— Direction of action of the reset spring

— Actuator travel of the multi-turn actuator / nal control

element

— Stroke time for both directions

— Control parameters

— Oset for the I/P module

NOTE

The mode and scope of the automatic adjustment function

can be selected using parameter

A

DJ_MODE .

M10487

I.3

conf

mA

%

C

°

conf conf con f conf conf conf conf con f conf

ENTER

MODE

ENTER

(3 ... 0)

(3 ... 0)

conf

I.0

CTRL_ADP

CTRL_FIX

I.2

MANUAL

MAN_SENS

I.I

ENTER

Parameter “EXIT”

(NV_SAVE)

P1.0

P1.1

P1.2

P1.3

P1.4

P1.5

P4.0

P4.1

P4.2

P4.3

P4.4

P4.5

P2.0

P2.1

P2.2

P2.3

P2.4

P2.5

P2.6

P2.7

P2.8

P3.0

P3.1

P3.2

P3.3

P5.0

P5.1

P5.2

P5.3

P5.4

P5.5

P5.6

P5.7

P6.0

P6.1

P6.2

P6.3

P6.4

P6.5

P6.6

P6.7

P7.0

P7.1

P7.2

P7.3

P7.4

P7.5

P7.6

P7.7

P7.8

P7.9

P7.10

P7.11

P7.12

P8.0

P8.1

P8.2

P8.3

P8.4

P8.5

P8.6

P8.7

P8.8

P9.0

P9.1

P9.2

P9.3

P9.4

P10.0

P10.1

P11.0

P11.1

P11.2

P11.3

P11.4

P11.5

conf

conf

conf

P1._

STANDARD

P2._

SETPOINT

P3._

ACTUATOR

P4._

MES

P5._

ALARMS

P6._

MAN_ADJ

P7._

CTRL_PAR

P8._

ANLG_OUT

P9._

DIG_OUT

P10._

DIG_IN

P11._

FS/IP

MODE

MODE

Configuration level

Operating level

P7.13

conf

conf

conf

mA

%

C

°

Loading...

Loading...