VAC Phi 30 User Manual

F

30/30

The VAC Phi Thirty/Thirty

Stereophonic Triode Power Amplifier

Operation & Maintenance Information

Valve Amplification Company

Manual issued 02/24/2003

PLEASE READ CAREFULLY

Your Phi Thirty/Thirty is fitted with a thermal sensor circuit. It works in conjunction with the individual

indicator lights located on the front panel. It serves two purposes:

1)If the idle current of a 300B output tube should drop below nominal limit, the light

corresponding to that tube will light green. This indicates that the tube should be replaced

at your convenience, but it is safe to continue operating the amplifier.

The exact idle current of each tube may be tested by means of the meter and the test

switches. Typical readings are near the dot in the center of the meter. When no test switch

is selected, the meter indicates the incoming ac voltage (wall voltage).

Note: These lights will also be green when the amplifier is first switched on, and will

extinguish when the bias resistors have reached normal operating temperature after several

minutes. The threshold between green and no illumination is not precise; do not be overly

concerned if some positions take longer to extinguish. The condition of individual tubes

may be checked with the built in meter.

Note: a strong air current could cause the lights to remain green even in normal operation.

2)Should any output tube draw excessive idle current (a “run away” tube or a tube

with an internal short):

A)The high voltage supply in the amplifier will shut down automatically.

B)The light corresponding to the bad 300B tube will glow red. The red light will stay

on until the power switch is turned off. This tube must be replaced.

The lights for the other tubes will show green after a few minutes...this should be

disregarded.

This protection feature normally will operate with much greater speed than the AC line fuse,

and provides a high degree of protection against elevated temperature or fire due to a

major failure in an output tube. However, completely failsafe methods are not possible. As

with any high power electrical device, do not leave the amplifier running unattended. Turn

the amplifier off immediately if you smell any strong odor, or if you see any parts glowing

orange through the ventillation holes between the tubes.

To minimize difficulties, always source the highest quality tubes, avoiding inexpensive or generic

300B tubes. We recommend obtaining replacement tubes from VAC, stating that they are for use

in the Phi Thirty/Thirty.

CAUTION

THE AMPLIFIER AND POWER SUPPLY CONTAIN NO USER SERVICEABLE PARTS. DO NOT REMOVE THE

BOTTOM PLATES OR CHASSIS COVERS. LETHAL VOLTAGES ARE PRESENT WITHIN THE CHASSIS. DO

NOT OPERATE THE UNITS IF THEY ARE WET.

VACUUM TUBES BECOME HOT ENOUGH TO CAUSE SERIOUS BURNS. NEVER TOUCH A TUBE WHEN

THE UNIT IS ON. IT MAY TAKE SEVERAL MINUTES FOR THE TUBES TO COOL DOWN AFTER THE UNIT

IS SWITCHED OFF. IT IS STRONGLY RECOMMENDED THAT THE TUBE COVERS BE LEFT IN PLACE AT ALL

TIMES.

THE TUBE COVERS WILL BECOME HOT IN NORMAL OPERATION. DO NOT SET OR SPRAY ANYTHING

ON THEM.

THE AMPLIFIER AND POWER SUPPLY ARE HEAVY. IT IS ADVISABLE TO HAVE ASSISTANCE IN

UNPACKING, MOVING, AND SETTING UP. BE SURE TO USE PROPER LIFTING TECHNIQUES TO AVOID

BACK STRAIN AND INJURY. BE CERTAIN TO INSTALL IT IN A SECURE LOCATION FROM WHICH IT CAN

NOT FALL OR TIP OVER.

INDEX

Introduction

Unpacking & Assembly

Installation

Input connectors

Operation

Illuminated Logo

Installing New Output Tubes

Checking Output Tube Condition

Replacement of Low Level Tubes

Care Of Chassis

Tips and Advice

A Word About Tubes in General

Output Tubes

Low Level Tubes

Impedance Matching

Feedback

Grounding

Tuning Your System

Specifications

Footnotes

Warranty & Registration Form

1

INTRODUCTION

The Phi Thirty/Thirty is a unique power amplifier. It allies purist amplifying devices with the power and

solidity required to control modern audiophile loudspeakers. Extreme linearity is achieved without

resorting to loop negative feedback, for a more natural, dimensional sound.

The most noticeable feature of this amplifier is the 300B filamentary triode output tube. Originally

designed by Western Electric in 1935 (Footnote 1), it has several extremely desirable features that

have kept it in continuous production since that time. An examination of its dynamic curves (Figure

1) reveals it to be a naturally linear device, more so than any transistor device. It gives this superb

performance with voltages on the order of 450 VDC, not the 1000-1500 VDC required by other

output triodes like the 211 or 845. This lower voltage and lower output impedance allows superior

output transformer design, control of the loudspeaker, and safety.

Each 300B tube has its own separate heater power supply and independent cathode self-bias

network. This has several major advantages. No user adjustment of any kind is necessary to maintain

proper balance of the amplifier. The stabilizing action of this technique upon the idle current (bias

point) of each tube is exceptionally strong, and self corrects for large mismatches among tubes or

drift with age. This circuit also results in real-world output capability much greater than the testbench rating would indicate (Footnotes 2,3,4).

A total of four 300B are used in Class A1; that is, they are not operated into cutoff (as in Class AB

or B) or driven into grid current (suffix “2" operation) in normal operation. This is the purest, most

linear technique known.

The input circuitry of the Phi Thirty/Thirty is derivative of the unique Williamson circuit, which

provides pure, direct coupled, inherently balanced input amplification and phase splitting. Type

6SN7/5692 octal twin triodes do the honors.

The superb VAC output transformers provide superb voltage/current translation, allowing

impedances from eight ohms to as low as one ohm to be driven.

The main chassis is machined from thick aluminum. The separate power supply allows e.m.f. fields,

switching transients, and mechanical vibration to be isolated from the audio circuits. The high

voltage supply dual choke pi filtering for extremely low noise.

The Phi Thirty/Thirty is designed not to the latest fad but to substance, for the highest possible

sound quality. Time spent familiarizing yourself with this manual will be well rewarded.

2

UNPACKING & ASSEMBLY

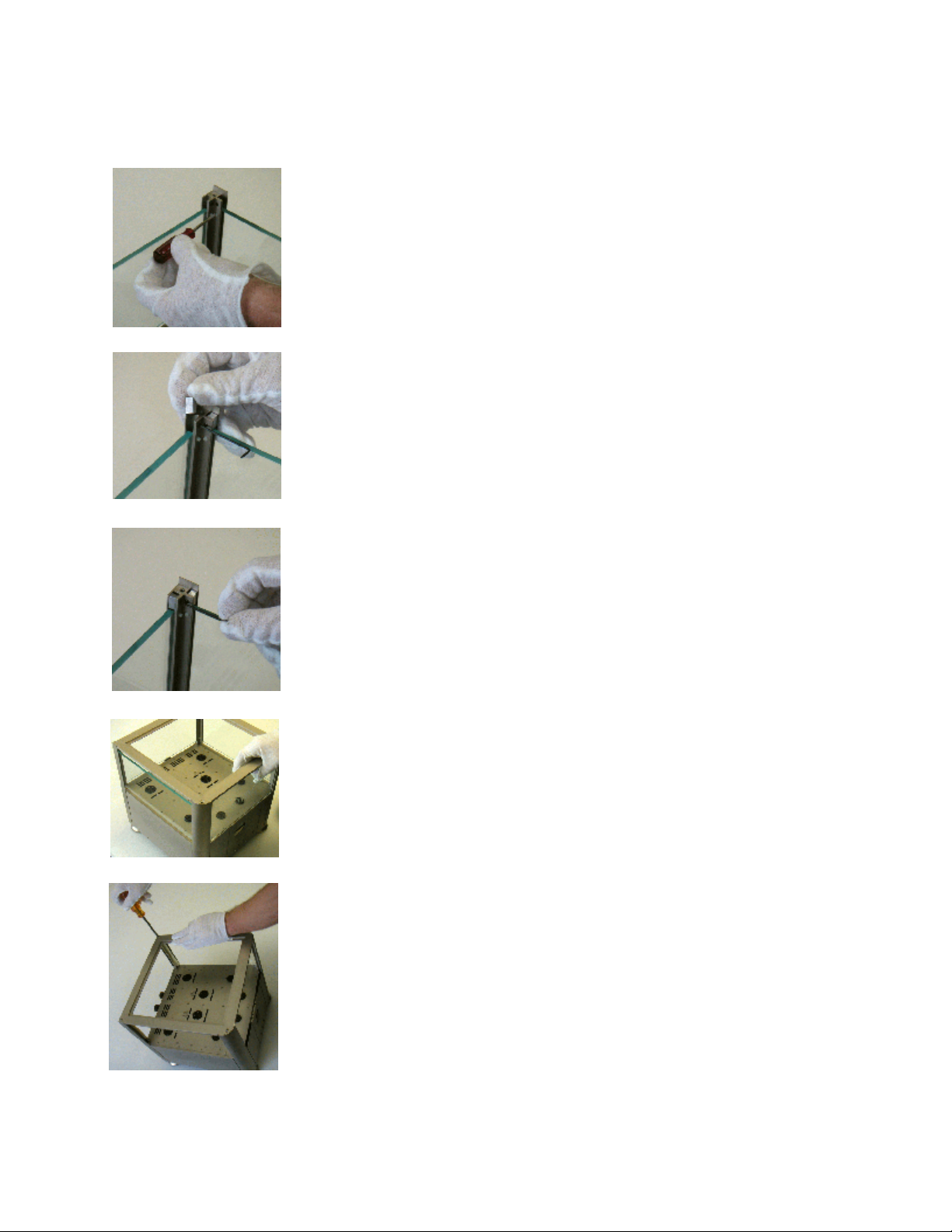

The vacuum tubes and glass covers are packed individually to prevent damage, and must be fitted

to the amplifier before installation can proceed.

Remove the four screws that secure the aluminum top frame to the chassis

pillars using the tool provided. Turn counterclockwise to remove.

Wear the supplied cotton gloves to minimize the chance of fingerprinting

the nickel plated chassis. Wipe any oils off immediately.

Take care to prevent the tool from scratching the chassis.

Remove the top frame.

From each of the four columns remove the tape, which prevented the

nylon setscrews from coming loose during shipment.

Slide the side and rear glass plates into the pillars’ channels.

Note that the rear glass is slightly wider than the side glasses.

The glass will not go all the way to the chassis top, but has a gap at the

bottom for air flow.

Take care not to scratch or break the glass.

3

The front glass has the etched VAC logo. Install this between the front pillars.

Take great care not to scratch this glass.

The front glass fits into a small channel in the front plate.

Tighten the white nylon setscrews that secure the rear glass and side

glasses. Turn clockwise to tighten.

There are four setscrews for each glass plate.

Do not tighten the setscrews for the front glass yet.

Install the six aluminum blocks at the top of the rear glass and side glasses.

If there is a ‘dimple’ in the block, it should face the outside of the amplifier.

Tighten the metal setscrews that secure each block using the allen key

supplied. Turn clockwise to tighten.

Replace the aluminum top frame.

Ensure that the front glass fits into the groove in the top frame.

Ensure that the top frame sits flush in the pillars.

Replace the four screws that secure the top frame. Turn clockwise to

tighten.

(Note: photo does not show the tubes or glass, which should be installed

by this time.)

4

Loading...

Loading...