VAC PHI-2.0 Owners manual

F

2.0

The VAC Phi 2.0 Master Control

Triode Preamplifier

Operation & Maintenance Information

Valve Amplification Company

Manual issued 02/24/2003

Revised 05/16/2005

CAUTION

THE PREAMPLIFIER AND POWER SUPPLY CONTAIN NO USER SERVICEABLE PARTS. DO NOT

REMOVE THE BOTTOM PLATES OR CHASSIS COVERS. LETHAL VOLTAGES ARE PRESENT

WITHIN THE CHASSIS. DO NOT OPERATE THE UNITS IF THEY ARE WET.

VACUUM TUBES BECOME HOT ENOUGH TO CAUSE SERIOUS BURNS. NEVER TOUCH A TUBE

WHEN THE UNIT IS ON. IT MAY TAKE SEVERAL MINUTES FOR THE TUBES TO COOL DOWN

AFTER THE UNIT IS SWITCHED OFF. IT IS STRONGLY RECOMMENDED THAT THE TUBE COVERS

BE LEFT IN PLACE AT ALL TIMES.

THE GLASS COVERS WILL BECOME HOT IN NORMAL OPERATION. DO NOT SET OR SPRAY

ANYTHING ON THEM.

THE AMPLIFIER AND POWER SUPPLY ARE HEAVY. IT IS ADVISABLE TO HAVE ASSISTANCE IN

UNPACKING, MOVING, AND SETTING UP. BE SURE TO USE PROPER LIFTING TECHNIQUES TO

AVOID BACK STRAIN AND INJURY. BE CERTAIN TO INSTALL IT IN A SECURE LOCATION FROM

WHICH IT CAN NOT FALL OR TIP OVER.

CONTENTS

Introduction

Unpacking, Assembly/Disassembly

Installation

Inputs (back panel)

Outputs & Grounding Switch (back panel)

Operation

Fuses

Front Panel Controls

Remote Control

Replacement of Tubes

Care of Chassis

A Word About Tubes In General / Locating a Defective Tube

Warranty / Registration Form

1

INTRODUCTION

The Phi Preamplifier is the world's finest audio preamplifier and an absolutely unique

component. Its unusual topology, premium parts, and flexibility make it a pleasure to hear

and operate.

The line stage is, in effect, a small Class A1 power amplifier, capable of driving loads as low

as a few hundred ohms. This is a stark contrast to normal preamplifiers, which claim a low

output impedance but completely collapse when asked to deliver current. The Phi circuit

is loafing with a normal load in the 10,000 to 200,000 ohm range, delivering an effortless,

musical performance.

There is no loop feedback and no coupling capacitors in the line section. All active elements

are triode tubes, the purest, most linear amplifying devices yet invented. Output matching

is accomplished by way of superb output transformers. As a side benefit, different output

grounding configurations are possible, optimizing performance into either balanced or

single-ended loads, and allowing ground loops to be broken.

The optional phono stage uses triode tubes operating without loop feedback. Gain is

moderately high, with a very low noise floor. Low output MC cartridges are accommodated

by means of high quality matching transformers, which contribute voltage gain without noise,

resulting in detail that emerges from a remarkably dark and neutral background.

Remote volume control is implemented via a motorized mechanical device. This provides

two major advantages. First, the control is completely intuitive to use. Second, we avoid the

sound degradation attendant with VCAs, transistor switches, and switched resistor arrays.

The main chassis is machined from thick aluminum. The separate power supply allows e.m.f.

fields, switching transients, and mechanical vibration to be isolated from the audio circuits.

The high voltage supply dual choke pi filtering for extremely low noise.

The Phi 2.0 is designed not to the latest fad but to substance, for the highest possible sound

quality. Time spent familiarizing yourself with this manual will be well rewarded.

2

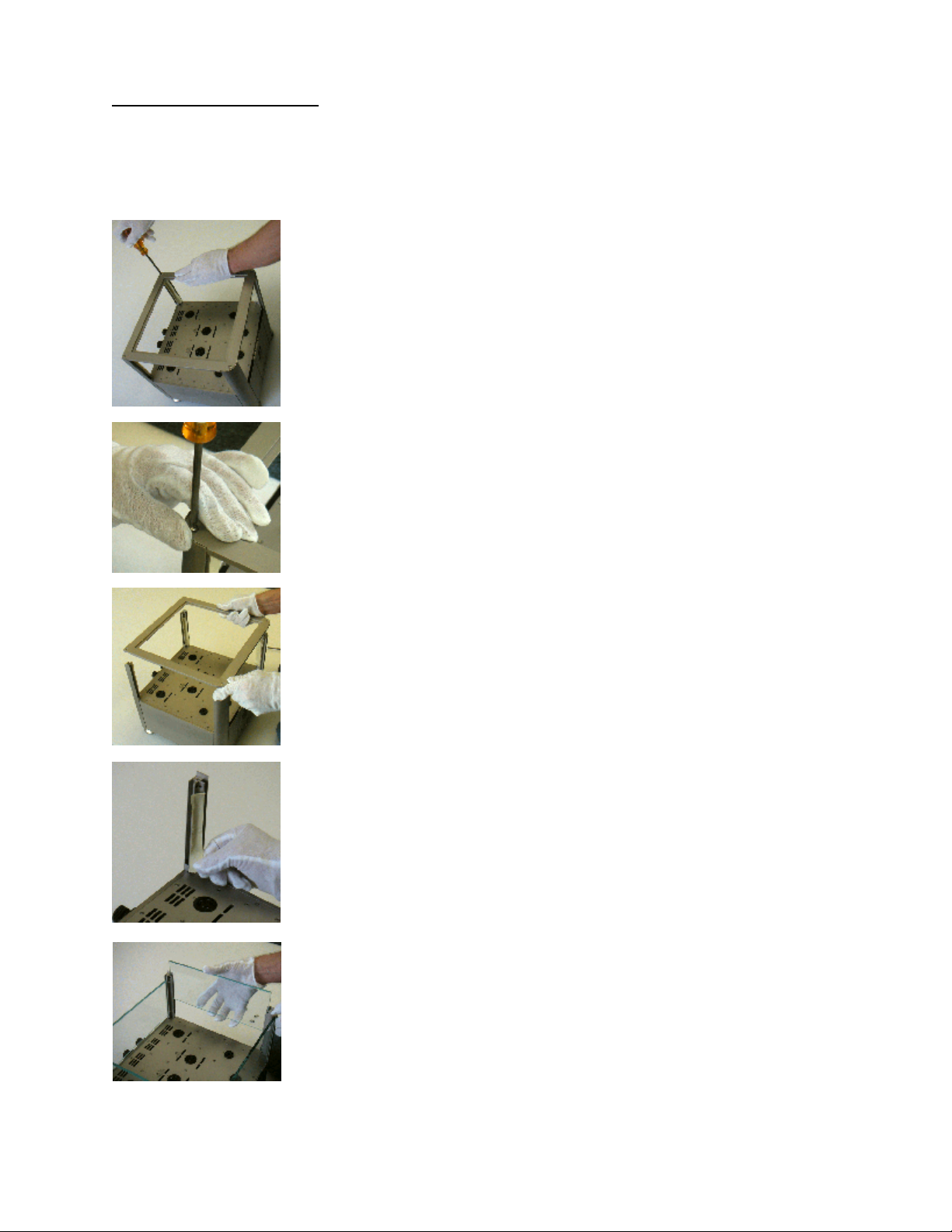

UNPACKING & ASSEMBLY

The Phi 2.0 is shipped with the vacuum tubes and glass covers installed. Should the need

ever arise, the following directions illustrate how to install the glass; follow these steps in

reverse order to remove the glass.

Remove the four screws that secure the aluminum top frame to the

chassis pillars using the tool provided. Turn counterclockwise to

remove.

Wear the supplied cotton gloves to minimize the chance of

fingerprinting the nickel plated chassis. Wipe any oils off immediately.

Take care to prevent the tool from scratching the chassis.

Remove the top frame.

From each of the columns remove the tape, which prevented the

nylon setscrews from coming loose during shipment.

Slide the side glass plates into the pillars’ channels.

The glass will not go all the way to the chassis top, but has a gap at

the bottom for air flow.

Take care not to scratch or break the glass.

3

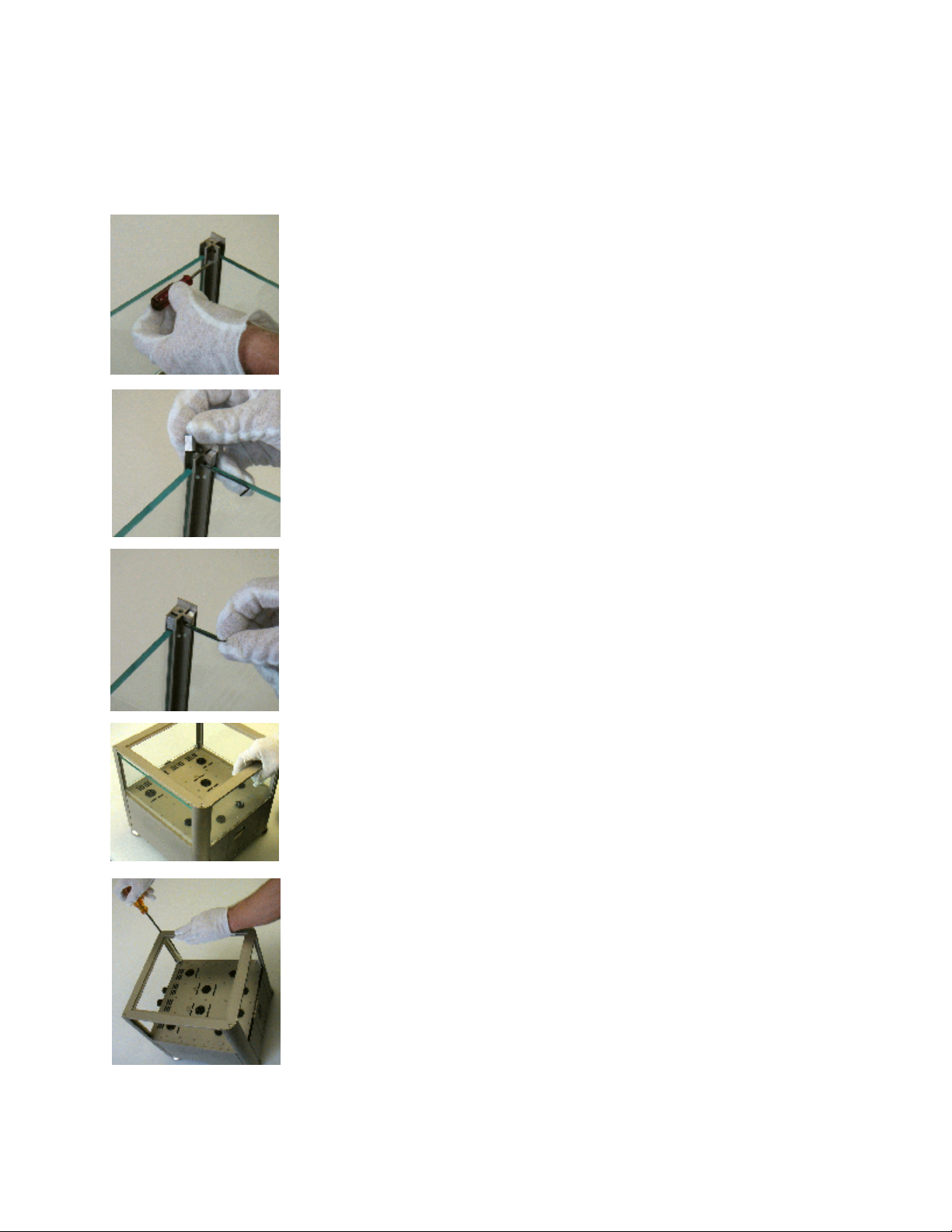

The front glass has the etched VAC logo. Install this between the front pillars.

Take great care not to scratch this glass.

The front glass fits into a small channel in the front plate.

Tighten the white nylon setscrews that secure the rear glass and side

glasses. Turn clockwise to tighten.

There are four setscrews for each glass plate.

Do not tighten the setscrews for the front glass yet.

Install the aluminum blocks at the top of the side glasses.

If there is a ‘dimple’ in the block, it should face the outside of the

amplifier.

Tighten the metal setscrews that secure each block using the allen key

supplied. Turn clockwise to tighten.

Replace the aluminum top frame.

Ensure that the front glass fits into the groove in the top frame.

Ensure that the top frame sits flush in the pillars.

Replace the four screws that secure the top frame. Turn clockwise to

tighten.

(Note: photo does not show the tubes or glass.)

4

Loading...

Loading...