Page 1

ATTUATORE ELETTROMECCANICO IRREVERSIBILE

PER CANCELLI A BATTENTE

IRREVERSIBLE ELECTROMECHANICAL ACTUATOR

FOR SWING GATES

OPERATEUR ELECTROMECANIQUE IRREVERSIBLE

POUR PORTAILS BATTANTS

OPERADOR ELECTROMECÁNICO IRREVERSIBLE

PARA CANCELAS BATIENTES

ACTUADOR ELECTROMECÂNICO IRREVERSÍVEL

PARA PORTÕES DE BATENTE

NICHT UMKEHRBARER ELEKTROMECHANISCHER

ANTRIEB FÜR FLÜGELTORE

ELEKTROMECHANISCHE, ONOMKEERBARE

LINEAIRE MOTOR VOOR HEKKEN MET VLEUGELS

I

GB

F

E

P

D

NL

CALYPSO

IL n. 186

EDIZ. 04/03/2010

V2 S.p.A.

Corso Principi di Piemonte, 65/67

12035 RACCONIGI (CN) ITALY

tel. +39 01 72 81 24 11 - fax +39 01 72 84 050

info@v2home.com - www.v2home.com

Page 2

7

IMPORTANT REMARKS

For any installation problem please contact our Customer Service

at the number +39-0172.812411 operating Monday to Friday

from 8:30 to 12:30 and from 14:00 to 18:00.

V2 has the right to modify the product without previous

notice; it also declines any responsibility to damage or

injury to people or things caused by improper use or

wrong installation.

Please read this instruction manual very carefully

before installing and programming your control unit.

• This instruction manual is only for qualified technicians, who

specialize in installations and automations.

• The contents of this instruction manual do not concern the

end user.

• Every programming and/or every maintenance service should

be done only by qualified technicians.

AUTOMATION MUST BE IMPLEMENTED IN COMPLIANCE

WITH THE EUROPEAN REGULATIONS IN FORCE:

EN 60204-1 (Machinery safety electrical equipment of

machines, part 1: general rules)

EN 12445 (Safe use of automated locking devices, test

methods)

EN 12453 (Safe use of automated locking devices,

requirements)

• The installer must provide for a device (es. magnetotermical

switch) ensuring the omnipolar sectioning of the equipment

from the power supply.

The standards require a separation of the contacts of at

least 3 mm in each pole (EN 60335-1).

• The plastic case has an IP55 insulation; to connect flexible

or rigid pipes, use pipefittings having the same insulation

level.

• Installation requires mechanical and electrical skills,

therefore it shall be carried out by qualified personnel only,

who can issue the Compliance Certificate concerning the

whole installation (Machine Directive 2006/42/CEE, Annex IIA).

• The automated vehicular gates shall comply with the

following rules: EN 13241-1, EN 12453, EN 12445 as well as

any local rule in force.

• Also the automation upstream electric system shall comply

with the laws and rules in force and be carried out

workmanlike.

• The door thrust force adjustment shall be measured by

means of a proper tool and adjusted according to the max.

limits, which EN 12453 allows.

• We recommend to make use of an emergency button, to be

installed by the automation (connected to the control unit

STOP input) so that the gate may be immediately stopped

in case of danger.

• The appliance is not to be used by children or persons with

reduced physical, sensory or mental capabilities, or lack of

experience and knowledge, unless they have been given

supervision or instruction.

• Children being supervised do not play with the appliance.

• For correct installation of the system, we recommend

following the instructions issued by UNAC very carefully,

which can be consulted at the following web site:

www.v2home.com

EC DECLARATION OF INCORPORATION FOR

PARTLY COMPLETED MACHINERY

(Directive 2006/42/EC, Annex II-B)

The manufacturer V2 S.p.A., headquarters in

Corso Principi di Piemonte 65, 12035, Racconigi (CN), Italy

Under its sole responsibility hereby declares that:

the partly completed machinery model(s):

CALYPSO400-230V, CALYPSO500-230V

CALYPSO400-120V, CALYPSO500-120V

Identification number and year of manufacturing: typed on

nameplate

Description: electromechanical actuator for gates

- is intended to be installed on gates, to create a machine

according to the provisions of the Directive 2006/42/EC.

The machinery must not be put into service until the final

machinery into which it has to be incorporated has been

declared in conformity with the provisions of the Directive

2006/42/EC (annex II-A).

- is compliant with the applicable essential safety requirements

of the following Directives:

Machinery Directive 2006/42/EC (annex I, chapter 1)

Low Voltage Directive 2006/95/EC.

Electromagnetic Compatibility Directive 2004/108/EC.

The relevant technical documentation is available at the national

authorities’ request after justifiable request to:

V2 S.p.A., Corso Principi di Piemonte 65,

12035, Racconigi (CN), Italy

The person empowered to draw up the declaration and to

provide the technical documentation:

Cosimo De Falco

Legal representative of V2 S.p.A.

Racconigi, 11th January 2010

ENGLISH

Page 3

ENGLISH

8

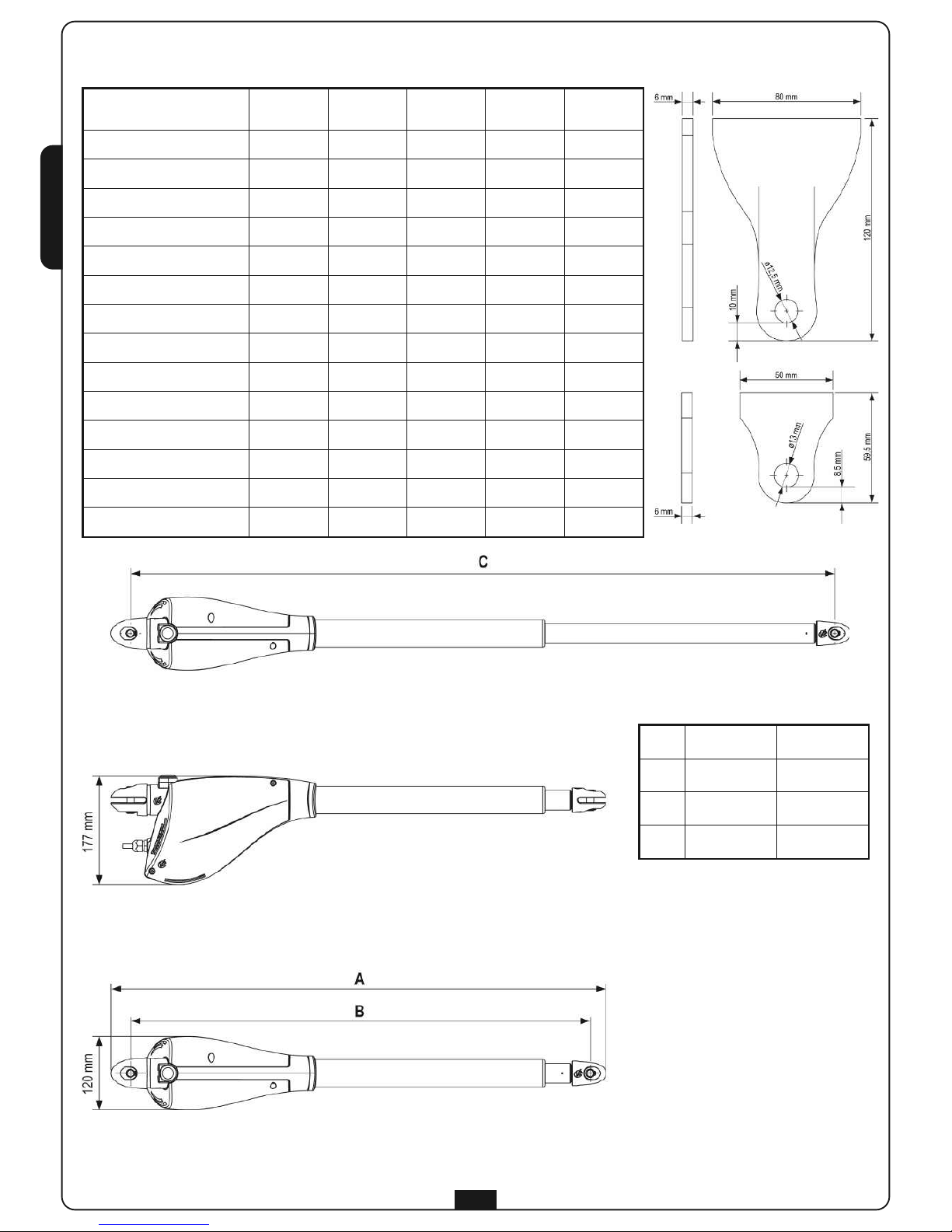

TECHNICAL DATA

Calypso400 Calypso500

Calypso

400-120V

Calypso

500-120V

Max. leaf lenght m 2,5 3 2,5 3

Max. leaf weight Kg 400 500 400 500

Power supply VAC - Hz 230 - 50 230 - 50 120 - 60 120 - 60

Idling current A 1 1 2 2

F

ull load current

A 1

,4

1

,4

2

,8

2

,8

Maximum Power W 300 300 300 300

Capacitor µF 8 8 25 25

Max travel mm 400 500 400 500

Operating speed m/s 0,016 0,016 0,018 0,018

Maximum thrust N 2600 2600 2600 2600

Working temperature °C -30 ÷ +60 -30 ÷ +60 -30 ÷ +60 -30 ÷ +60

Protection IP 44 44 44 44

Working cycle % 30 30 30 30

Motor weight Kg 6,5 6,8 6,5 6,8

Calypso400 Calypso500

A 819 944

B 762 887

C 1162 1387

Page 4

9

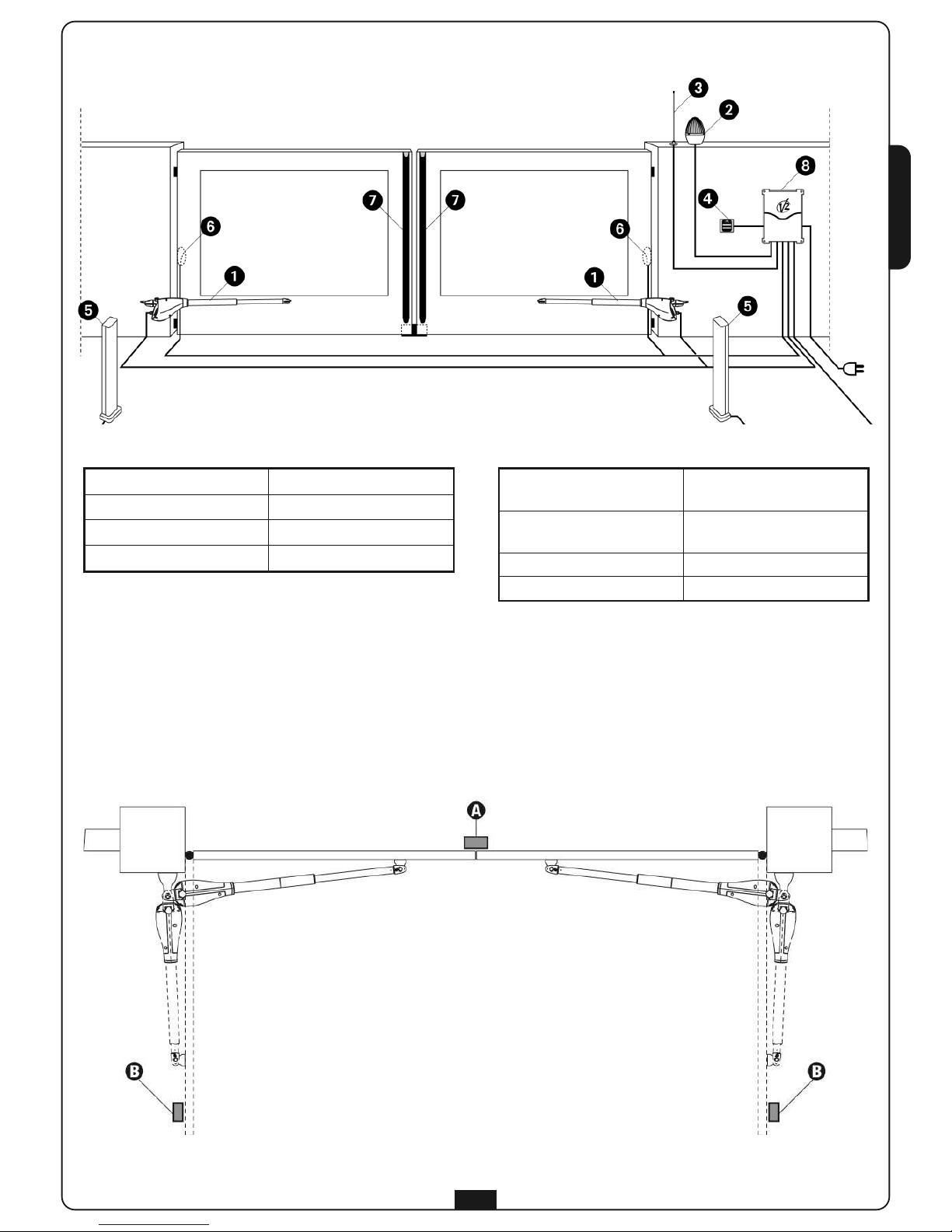

INSTALLATION LAYOUT

CALYPSO actuator

cable 4 x 1 mm

2

Blinker

cable 2 x 1,5 mm

2

Aerial

cable RG-58

Key or digital selector

cable 2 x 1 mm

2

Internal photocells

cable 4 x 1 mm2(RX)

cable 2 x 1 mm2(TX)

External photocells

cable 4 x 1 mm2(RX)

cable 2 x 1 mm2(TX)

Safety edge (EN 12978)

-

Control unit

cable 3 x 1,5 mm

2

PREPARATORY STEPS

The new series of actuadors CALYPSO, has been devised to serve gates up to 500 Kg with leaf up to 3 meters wide (look at the table

technical data). Before proceeding with the installation, please make sure that your gate opens and closes freely, and that:

• Hinges and pins are in optimum condition and properly greased.

• No obstacles are within the moving area.

• There is no friction with the ground or between the leaves.

• Your gate shall be equipped with central and side stops, which are fundamental for the good system operation.

ENGLISH

Page 5

10

INSTALLATION MEASURES

To carry out a proper installation of the operator parts as well as

to ensure the best automation performance, the measurement

levels shown in the following table shall be complied with.

Change the gate structure to adapt it to one of the cases in the

table, if necessary.

WARNING: In the case of leaf longer than 2 metres,

an electric lock must be fitted to ensure an efficent closig.

CALYPSO 400

γ

A [mm] B [mm] C [mm] F [mm]

90°

20 130 130 1010

40 150 140 1000

60 170 150 990

80 190 150 980

100 200 150 980

120 210 140 980

140 250 120 1010

100°

20 130 170 970

40 150 180 960

60 170 180 960

80 190 170 970

100 210 140 990

110°

20 130 190 950

40 150 180 960

50 160 170 970

CALYPSO 500

γ

A [mm] B [mm] C [mm] F [mm]

90°

20 130 170 1200

40 150 180 1190

60 170 180 1190

80 190 190 1180

100 210 190 1170

120 230 190 1170

140 250 180 1170

160 270 190 1170

180 290 170 1180

100°

20 130 160 1210

40 150 170 1200

60 170 170 1200

80 200 180 1190

100 210 170 1190

120 230 190 1170

140 250 180 1180

160 270 160 1200

170 280 160 1200

110°

20 130 170 1200

40 150 180 1190

60 170 180 1190

80 190 190 1180

100 210 200 1170

110 220 200 1170

ENGLISH

Page 6

11

ACTUATOR FIXING

Choose measures referring to the table you can find in the

previous page, mark them on the pillars and continue as follows:

• Fix the clamps to the pillar and to the gate soldering

directly; if the material does not allow it, it is necessary to

solder the clamps to plates to be fixed to the gate and the

pillars by screws.

• Close the swing.

• Unlock the actuators.

• Position CALYPSO on the brackets and fix the pins no. 1 and

no. 2 with seeger (see the picture).

• Open and close the swings repeatedly manually to verify the

absence of frictions between gate and ground.

WARNING: in order to avoid damage to the actuator,

please adhere to the following conditions:

• The brackets must be installed at the same height.

• The maximum stroke of arm A should not exceed 456 mm

for CALYPSO400 and 556 mm for CALYPSO500 (in case of

gate completely closed).

• The minimum stroke of arm B must be more than 56 mm (in

case of gate completely open).

ENGLISH

Page 7

ENGLISH

12

TO CONNECT CALYPSO WITH CONTROL UNIT

WARNING: always remember to connect the earth

according to current standards (EN 60335-1, EN 60204-1).

Avoid tension in the cable during open and close operations

.

EMERGENCY RELEASE

In case of a blackout, the gate can be operated

directly from the motor. Insert the key supplied

in the lock, perform 1/2 of a turn.

To restore the automation, simply rotate the key

in closed position and insert the provided plastic

cover onto the lock.

YELLOW - GREEN GND

BLUE (230V mod.)

WHITE (120V mod.)

COMMON

BLACK CLOSING

BROWN OPENING

Loading...

Loading...