Page 1

200mW Radio Port

Installation Manual

WLL-200mW-RP-IN-1.0

July 25, 2000

Page 2

2

200mW RP Installation RPC/RP Manual

Compiled by (Joseph) Guangping Zhang

Copyright 2000 UTStarcom Inc. All Rights Reserved.

This manual has been prepared for UTStarcom customers, UTStarcom personnel,

and licensees. The information contained herein is the property of UTStarcom

Inc. and shall be neither reproduced nor utilized in any form or by any means,

electronically or mechanically, in whole or in part, without prior written approval

from UTStarcom Inc.

WLL-200mW-RP-IN-1.0 25July2000

Page 3

RPC/RP Manual 200mW RP Installation

!

Important Safety Instructions

• The sign on the top right corner is intended to alert the user the presence of important

operation and maintenance (service) instructions in the literature accompanying the product.

Also notice warnings such as “WARNING!” or “CAUTION.”

• When installing, operating, or maintaining the system, please follow the basic safety

procedures in order to reduce the risk of fire, electric shock, and injury to persons, as listed

below:

• Read and understand all instructions.

3

• Follow all warnings and instructions marked on this product.

• For information on proper mounting instructions, consult the Installation Manual provided

with this product.

• Install only equipment identified in the Installation Manual provided with this product. Use

of other equipment may result in improper connection of circuitry leading to fire or injury to

persons.

• The telecommunication interfaces should not leave the building unless connected to

telecommunication devices providing primary and secondary protection, as applicable.

• This product should only be operated from the type of power source indicated on the marking

label.

• This equipment must be provided with a readily accessible disconnect device as part of the

building installation.

• Installation must include an independent frame ground drop to building ground. Refer to

installation instructions.

• Do not use this product near water, for example in a wet basement.

• Do not place this product on an unstable cart, stand, or table. The product may fall, causing

serious damage to the product.

25July2000 WLL-200mW-RP-IN-1.0

Page 4

4

• Use caution when installing or modifying telecommunications lines.

• Never install telecommunications wiring during a lightning storm.

• Never install telecommunications in wet locations.

• Never touch uninsulated telecommunications wires or terminals unless the

• Never touch uninsulated telecommunications wires or terminals carrying direct current or

• Never push objects of any kind into this product through slots as they may touch dangerous

• Slots and openings in the unit are provided for ventilation, to protect it from overheating.

200mW RP Installation RPC/RP Manual

telecommunications line has been disconnected at the network interface.

ringing current or leave this wiring exposed. Protect and tape such wiring and terminals to

avoid risk of fire, electric shock, and injury to service personnel.

voltage points or short-out parts that could result in a risk of fire or electrical shock. Never

spill liquids of any kind on this product.

These openings must not be blocked or covered. This product should not be placed in a

built-in installation unless proper ventilation is provided.

• To reduce the risk of an electrical shock, do not disassemble this product. Service should be

performed by trained personnel only. Opening or removing covers and/or circuit boards may

expose you to dangerous voltages or other risks. Incorrect re-assembly can cause electrical

shock when the unit is subsequently used.

• This equipment is intended for installation in restricted access locations where access is

controlled or where access can only be gained by service personnel with a key or tool.

Access to this equipment is restricted to qualified service personnel.

Save These Instructions!

WLL-200mW-RP-IN-1.0 25July2000

Page 5

RPC/RP Manual 200mW RP Installation

Table of Contents

1 Equipment Description...............................................................................................................................................6

1.1 200mW RP..........................................................................................................................................................6

1.1.1 List of Component Parts...............................................................................................................................6

1.1.2 Appearance of 200mW RP and Component Parts........................................................................................8

1.1.2.1 200mW RP............................................................................................................................................8

1.1.2.2 Mounting Plate

1.1.2.3 M4 Screw.............................................................................................................................................10

1.1.2.4 M6 Screw.............................................................................................................................................11

1.1.2.5 M6 Spring Washer...............................................................................................................................11

1.1.2.6 M6 Plane Washer.................................................................................................................................11

1.1.2.7 M6 Nut.................................................................................................................................................12

1.2 Joint Box............................................................................................................................................................12

1.2.1 List of Component Parts.............................................................................................................................12

1.2.2 Joint Box Unpacking..................................................................................................................................12

1.2.3 Joint Box and Component Parts.................................................................................................................14

1.2.3.1 Joint Box..............................................................................................................................................14

1.2.3.2 Hexagon Socket Head Screw...............................................................................................................15

1.2.3.3 M6 Spring Washer...............................................................................................................................15

1.2.3.4 M6 Plane Washer.................................................................................................................................15

1.2.3.5 M6 Nut.................................................................................................................................................15

2 Wiring Cables to the Joint Box.................................................................................................................................15

2.1 Opening the Joint Box Cover............................................................................................................................15

2.2 Making Connections..........................................................................................................................................17

2.3 Names of the Connection Joints........................................................................................................................18

2.4 Connecting the AC Power Cables and FG Cables.............................................................................................19

2.5 Connecting the Line Cables............................................................................................................................... 21

2.6 Fixing the AC Power Cables and FG Cables.....................................................................................................22

2.7 Fixing the Line Cables.......................................................................................................................................24

2.8 Waterproof Treatment of the Line Cables.........................................................................................................25

2.9 Closing the Joint Box Cover..............................................................................................................................27

3 Opening/Closing Cover of 200mW RP....................................................................................................................28

3.1 Opening the Top Cover.....................................................................................................................................28

3.2 Fixing the 200mW RP to the Mounting Plate....................................................................................................30

3.3 Closing the Top Cover................................................................................................................................... 3-31

Appendix................................................................................................................................................................. 3-33

A.1 200mW RP Cable Length............................................................................................................................. 3-33

A.2 The Exchange of the Fuse............................................................................................................................. 3-34

A.3 Electric Connection ...................................................................................................................................... 3-35

A.4 Example of Layout ....................................................................................................................................... 3-36

A.5 Suitable Size of the Local Cable................................................................................................................... 3-37

A.6 Tape Wrapping............................................................................................................................................. 3-38

A.7 Water Proof of Antenna Cable...................................................................................................................... 3-39

A.8 Grounding Protective Earthing Cable........................................................................................................... 3-40

A.9 Installation Image......................................................................................................................................... 3-42

.................................................................................................................................10

5

25July2000 WLL-200mW-RP-IN-1.0

Page 6

6

200mW RP Installation RPC/RP Manual

1 Equipment Description

This chapter describes all the components involved in the 200mW RP installation,

including the 200mW RP and the joint box.

1.1 200mW RP

This section represents the 200mW RP installation.

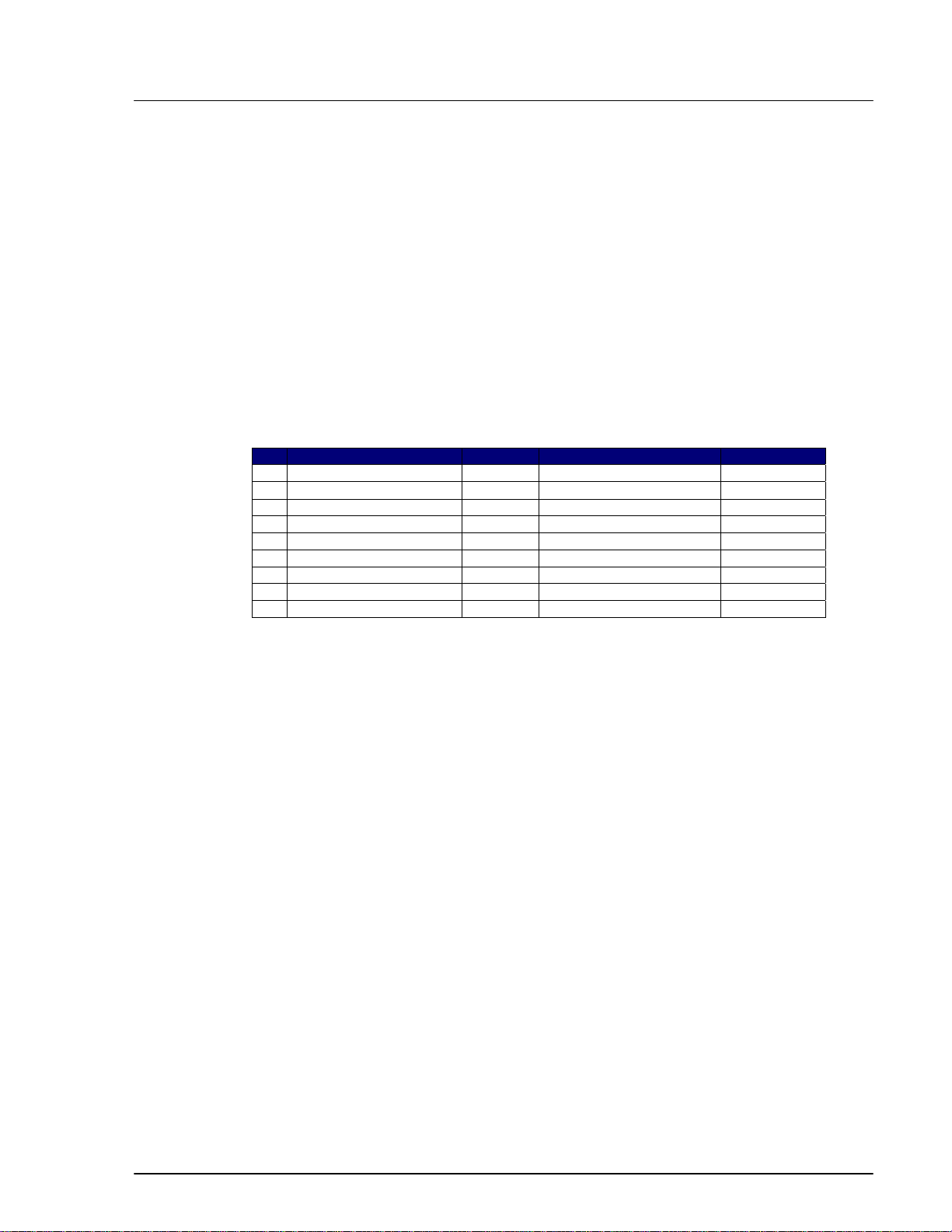

1.1.1 List of Component Parts

Items Quantity Model No. and DWG No. Company

1 200mWRP Main Unit 1 EA-7T56 PANASONIC

2 Screw for CS installation 1 XYN4•F18V PANASONIC

3 Mounting Plate 1 1B14449C PANASONIC

4 Screw for Mounting Plate 4 3Z10076A PANASONIC

5 Spring Washer 4 XWA6V PANASONIC

6 Plane Washer 4 XWG6V PANASONIC

7 Nut 4 XNG6AV PANASONIC

8 Spare Fuse 2 TSC3A PANASONIC

9 Spare Fuse 1 TSC6.3A PANASONIC

Table 1: Component Parts

! NOTE: No. 8 and No. 9 are spare fuses. The spare fuse must be inserted in the

right place.

WLL-200mW-RP-IN-1.0 25July2000

Page 7

RPC/RP Manual 200mW RP Installation

7

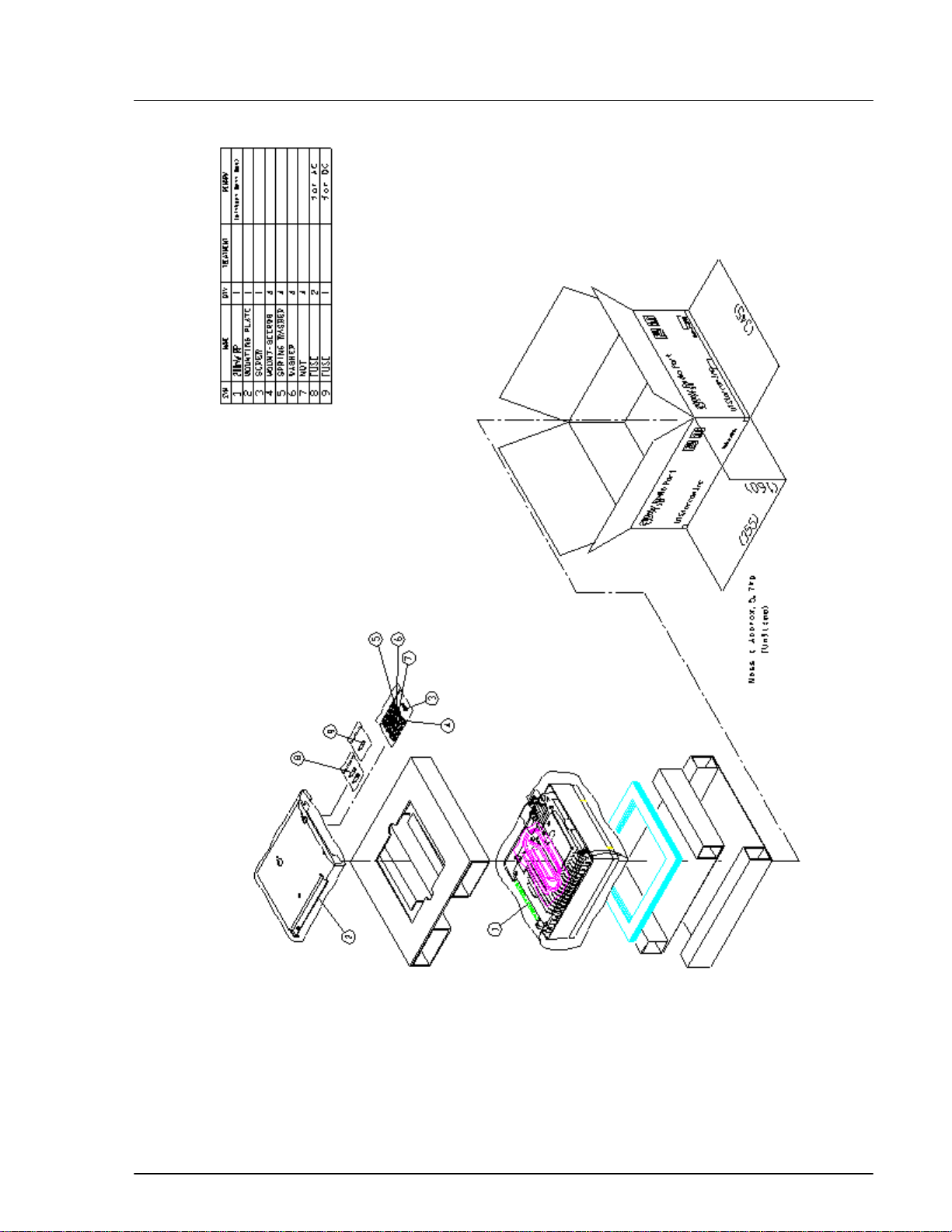

Figure 1: 200mW RP Unpacking

25July2000 WLL-200mW-RP-IN-1.0

Page 8

8

200mW RP Installation RPC/RP Manual

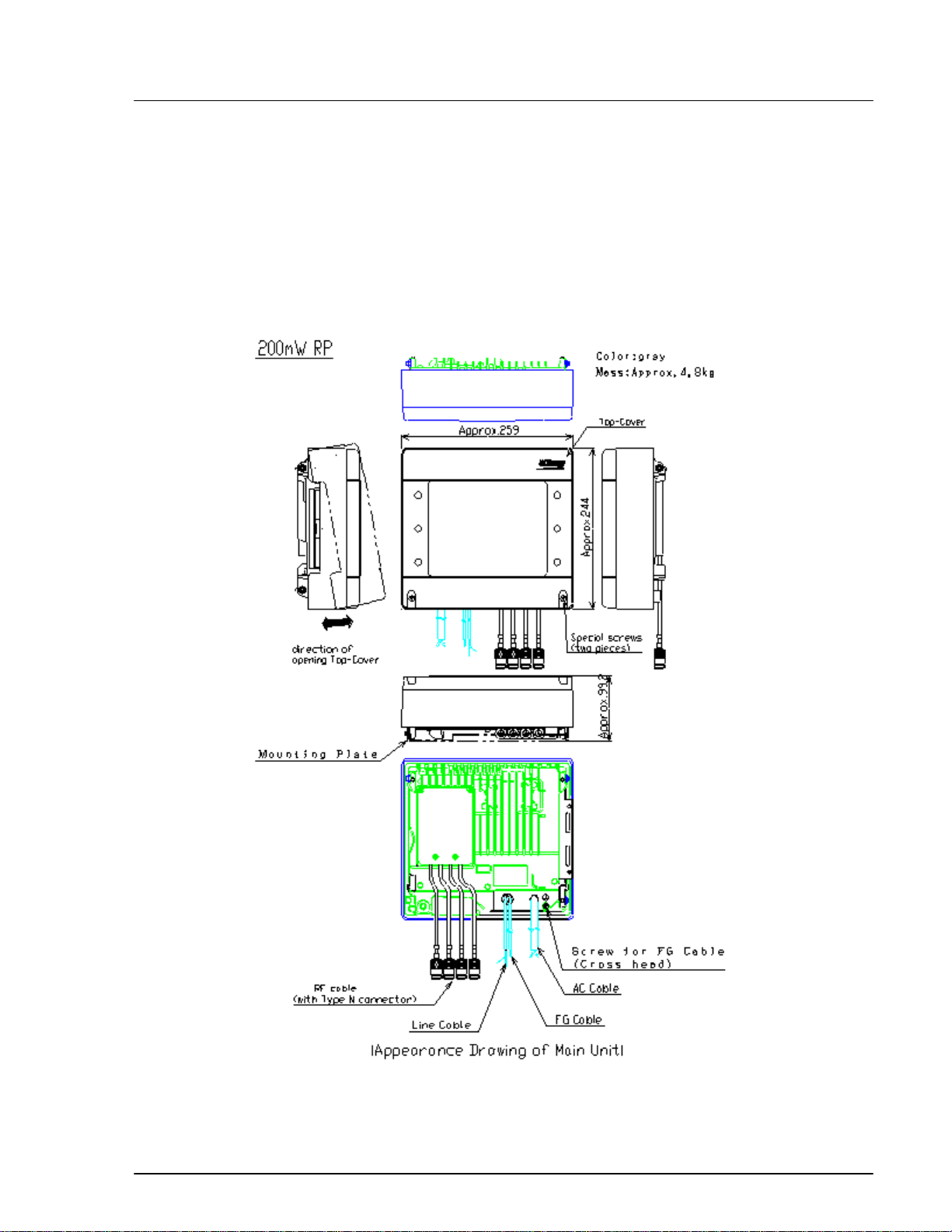

1.1.2 Appearance of 200mW RP and Component Parts

This section displays the main unit of the 200mW RP and the mounting parts.

Scales are not indicated in the diagrams.

1.1.2.1 200mW RP

Figure 2: 200mW RP Main Unit

WLL-200mW-RP-IN-1.0 25July2000

Page 9

RPC/RP Manual 200mW RP Installation

9

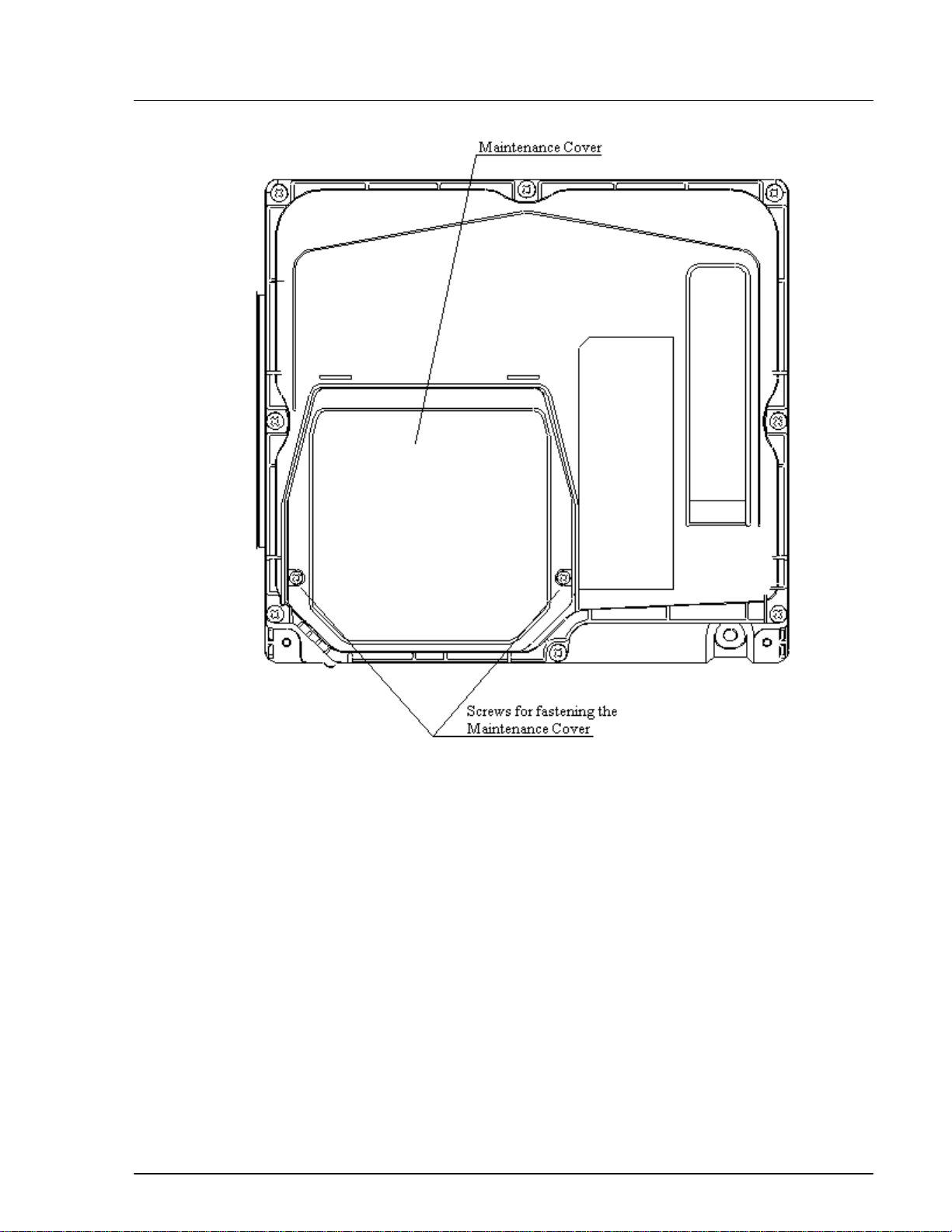

Figure 3: Front View of the Main Unit (without the Top Cover)

25July2000 WLL-200mW-RP-IN-1.0

Page 10

10

200mW RP Installation RPC/RP Manual

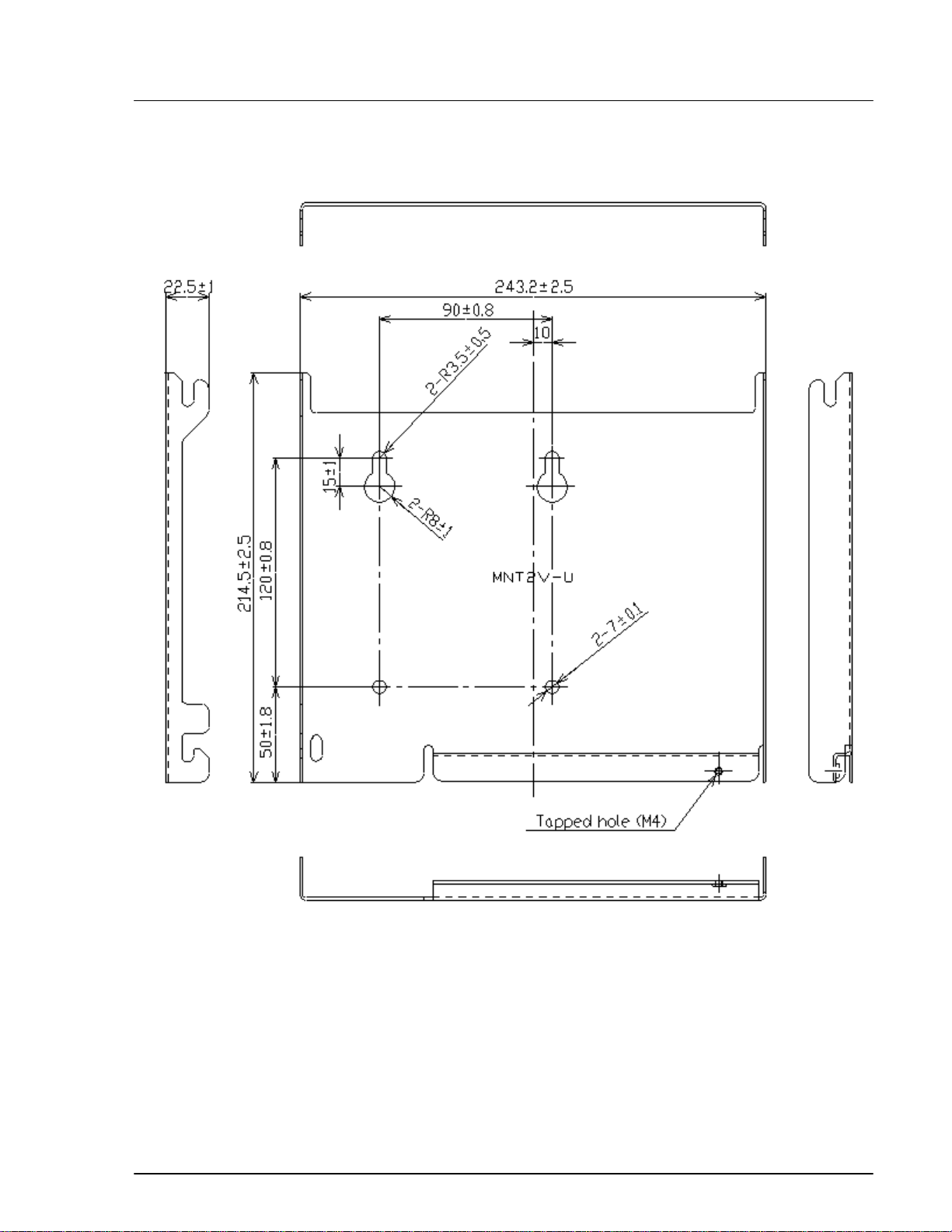

1.1.2.2

Mounting Plate

Figure 4: 200mW RP Mounting Plate (RP Mounting Base)

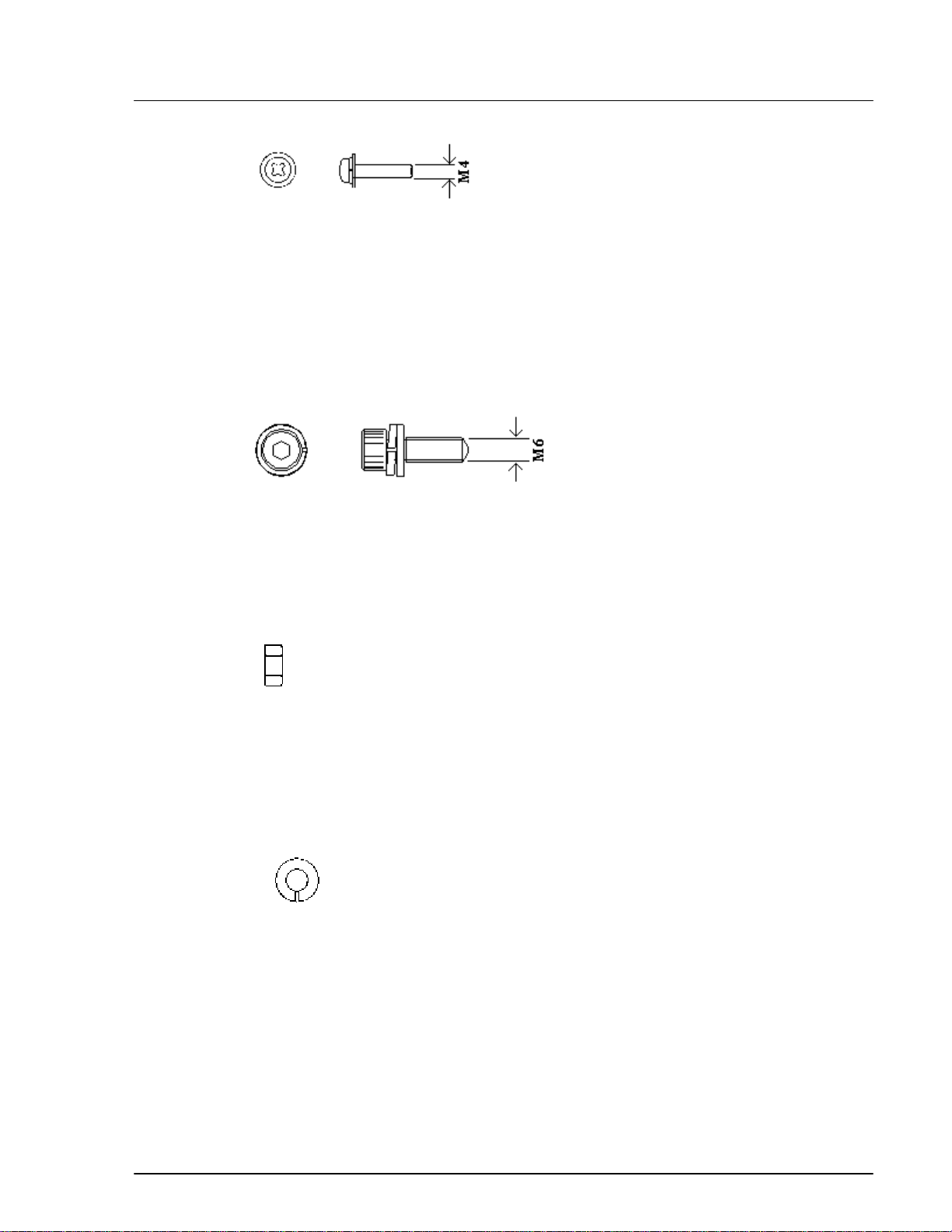

1.1.2.3 M4 Screw

The M4 screw is used to fix the RP onto the Mounting Plate

WLL-200mW-RP-IN-1.0 25July2000

Page 11

RPC/RP Manual 200mW RP Installation

Figure 5: M4 Screw and Its Cross Head

1.1.2.4 M6 Screw

The M6 screw is used to mount the Mounting Plate onto the wall.

Figure 6: M6 Screw and Its Socket Head

11

1.1.2.5 M6 Spring Washer

Figure 7: M6 Spring Washer

1.1.2.6 M6 Plane Washer

Figure 8: M6 Plane Washer

25July2000 WLL-200mW-RP-IN-1.0

Page 12

12

200mW RP Installation RPC/RP Manual

1.1.2.7 M6 Nut

Figure 9: M6 Nut

1.2 Joint Box

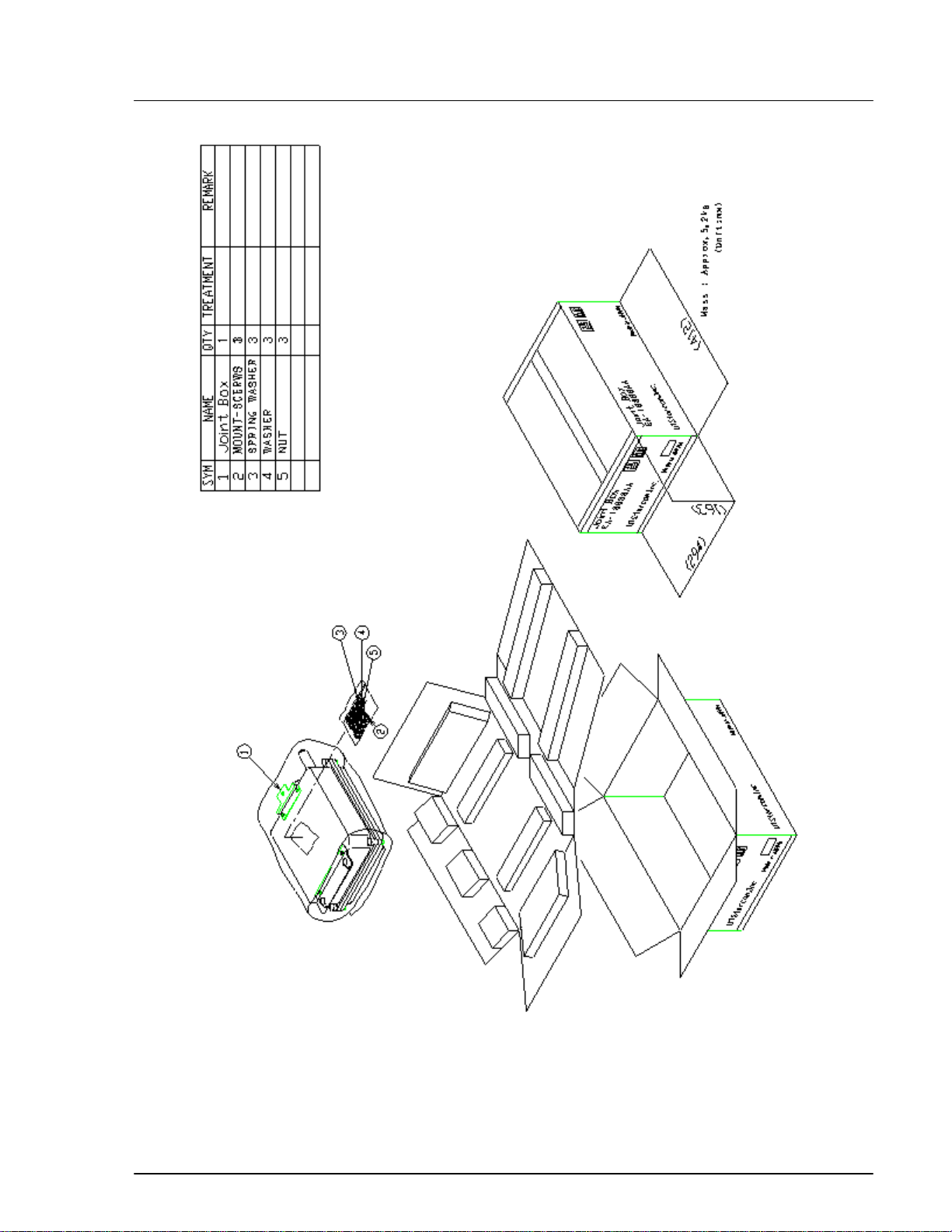

1.2.1 List of Component Parts

Items Quantity Model No. And DWG No. Company

1 Joint Box 1 EA-Z16092AZ PANASONIC

2 Screw for Joint Box installation 3 3Z10076A PANASONIC

3 Spring Washer 3 XWA6V PANASONIC

4 Plane Washer 3 XWG6V PANASONIC

5 Nut 3 XNG6AV PANASONIC

Table 2: Joint Box Component Parts

1.2.2 Joint Box Unpacking

WLL-200mW-RP-IN-1.0 25July2000

Page 13

RPC/RP Manual 200mW RP Installation

13

Figure 10: Joint Box Unpacking

25July2000 WLL-200mW-RP-IN-1.0

Page 14

14

200mW RP Installation RPC/RP Manual

1.2.3 Joint Box and Component Parts

This diagrams in this section display the joint box and the component parts.

Please note that the scales are not indicated in the diagrams.

1.2.3.1 Joint Box

Figure 11 shows the joint box. The color is gray and the weight is about 4.1 kg.

Figure 11: Joint Box and Open Direction

WLL-200mW-RP-IN-1.0 25July2000

Page 15

RPC/RP Manual 200mW RP Installation

1.2.3.2 Hexagon Socket Head Screw

The screw is used to fix the joint box to the wall.

Figure 12: Hexagon Socket Head Screw

1.2.3.3 M6 Spring Washer

Refer to Figure 7.

15

1.2.3.4 M6 Plane Washer

Refer to Figure 8.

1.2.3.5 M6 Nut

Refer to Figure 9.

2 Wiring Cables to the Joint Box

2.1 Opening the Joint Box Cover

Use a hexagon socket screw key to loosen the four hexagon socket head screws

on the four corners of the Joint Box, as displayed in Figure 13. The screws will

not drop off from the cabinet.

25July2000 WLL-200mW-RP-IN-1.0

Page 16

16

200mW RP Installation RPC/RP Manual

Figure 13: Loosing the Screws

As shown in the figure below, open the cover slowly to ensure that the hinges are

not damaged. Remove the pad.

Figure 14: Opening the Cover

WLL-200mW-RP-IN-1.0 25July2000

Page 17

RPC/RP Manual 200mW RP Installation

2.2 Making Connections

Wire each cable as shown in the figure below.

17

Figure 15: Standard Wiring Figure

! CAUTION: Make sure to install the 2A Circuit Breaker for safety.

25July2000 WLL-200mW-RP-IN-1.0

Page 18

18

200mW RP Installation RPC/RP Manual

! WARNING:

• Keep Commercial Circuit Breakers OFF when installing or reinstalling

devices

• Connect the power source cables completely

• Do not drop hardware into the openings in the interface

• Do not work with wet hands

• Do not wet the inside of the devices when installing

• Ground the instrument properly (Improper grounding may cause an

electric shock)

2.3 Names of the Connection Joints

WLL-200mW-RP-IN-1.0 25July2000

Page 19

RPC/RP Manual 200mW RP Installation

19

Figure 16: Terminals on the Joint Box

2.4 Connecting the AC Power Cables and FG Cables

! CAUTION: The diameter of the cable connected to this terminal is

mm for single wire.

1. Loosen bushings and put the Power and FG cables through each bushing.

25July2000 WLL-200mW-RP-IN-1.0

φ

1.2 to 2.0

Page 20

20

200mW RP Installation RPC/RP Manual

2. Peel off the cable coating to the length that corresponds to the strip gauge on

the terminal, as indicated in Figure 17.

Figure 17: Strip Gauge on the Terminal

3. Insert the cables firmly until they come to the end.

Figure 18: Inserting the Cable

4. If the cable is connected wrongly, use a proper tool to press down the button

of the terminal and pull out the attached cable. Then insert it again. The

proper tools that can be used for the purpose include:

• Regular screwdriver (shaft diameter: 6, nose width: 6)

• Phillips screwdriver (shaft diameter: 4)

WLL-200mW-RP-IN-1.0 25July2000

Page 21

RPC/RP Manual 200mW RP Installation

Figure 19: Tools for Disconnecting the Cable

2.5 Connecting the Line Cables

21

! CAUTION: The diameters of the cable connected to this terminal are

mm for single wire and φ 0.3 to 1.25 mm for twisted wire.

1. Put the Line cable through the bushing.

2. Peel off the cable coating to the length that corresponds to the strip gauge on

the terminal, as indicated in Figure 20.

φ

0.4 to 1.6

Figure 20: Strip Gauge on the Terminal

25July2000 WLL-200mW-RP-IN-1.0

Page 22

22

200mW RP Installation RPC/RP Manual

3. Insert the cables firmly until they come to the end.

Figure 21: Inserting the Cable

4. If the cable is connected wrongly, use a proper tool to press down the button

of the terminal and pull out the attached cable. Then insert it again. The

proper tool that can be used for the purpose is a regular screwdriver (shaft

diameter: 3, nose width: 2.6)

Figure 22: Tools for Disconnecting the Cable

2.6 Fixing the AC Power Cables and FG Cables

Tighten the Power and FG cables' Bushings (3 places) firmly at the torque

indicated in Figure 23 or until the interval becomes less than 2mm.

WLL-200mW-RP-IN-1.0 25July2000

Page 23

RPC/RP Manual 200mW RP Installation

23

Figure 23: Power and FG Cable Fixing

25July2000 WLL-200mW-RP-IN-1.0

Page 24

24

200mW RP Installation RPC/RP Manual

2.7 Fixing the Line Cables

As for the line cables, adjust their wiring margin as shown in

fix them with Insulock Tie (tie band). Cut off the surplus length of Insulock Tie with

nipper, etc.

Figure 24

, and bundle and

Figure 24: Line Cable Fixing

! NOTE: If the local line cables cannot be wired, use vinyl tape to seal the holes

through which the line cables are supposed to come in.

WLL-200mW-RP-IN-1.0 25July2000

Page 25

RPC/RP Manual 200mW RP Installation

2.8 Waterproof Treatment of the Line Cables

1. Make sure that the cables are properly wired.

2. To shrink the cables, put your finger into the loop of the spiral core and pull it,

as displayed in Figure 25. Pull it around the cable, making sure that the spiral

core will not get tangled up with the cables. When the spiral core is pulled out

a contraction tube sticks fast around the cables.

3. Make sure that the spiral core is removed completely.

25

Figure 25: Shrinking the Cables

25July2000 WLL-200mW-RP-IN-1.0

Page 26

26

200mW RP Installation RPC/RP Manual

! NOTE: If the local line cables cannot be wired, use vinyl tape to seal the holes

through which the line cables are supposed to come in.

4. Wrap the self-bonding tape half-lapping and elongate 1.8 to 2.0 times its

original length. Don’t over elongate, or it will show signs of cracking.

5. Wrap the protective adhesive PVC tape around the self-bonding tape.

Figure 26: Wrapping the Tape

WLL-200mW-RP-IN-1.0 25July2000

Page 27

RPC/RP Manual 200mW RP Installation

2.9 Closing the Joint Box Cover

Close the cover as shown in the figure below. Take care not to drop the waterproof

1.

tube around the lower case.

27

Figure 27: Closing the Joint Box Cover

2. Tighten the screws on the four corners. At first, balance the tightening of all

the four screws. Then tighten them firmly as indicated in Figure 28.

25July2000 WLL-200mW-RP-IN-1.0

Page 28

28

200mW RP Installation RPC/RP Manual

Figure 28: Tightening the Screws

3 Opening/Closing Cover of 200mW RP

3.1 Opening the Top Cover

1. Open the caps on the top cover and loose the special screws with a special

screwdriver. The screws will not drop off from the top cover.

WLL-200mW-RP-IN-1.0 25July2000

Page 29

RPC/RP Manual 200mW RP Installation

Figure 29: Opening the Top Cover

29

Pull the bottom edge of the top cover towards yourself and remove it. The top edge

2.

has a hinge.

Figure 30: Removing the Cover

25July2000 WLL-200mW-RP-IN-1.0

Page 30

30

200mW RP Installation RPC/RP Manual

3.2 Fixing the 200mW RP to the Mounting Plate

Hook the upper pins of the main unit onto the upper U-notches of the mount plate.

Then lift the main unit and fit the lower pins onto the lower U-notches. Finally,

fix the 200mW RP main unit onto the mounting plate by tightening the M4 screw.

Figure 31: Mounting the 200mW RP

WLL-200mW-RP-IN-1.0 25July2000

Page 31

RPC/RP Manual 200mW RP Installation

3.3 Closing the Top Cover

1. Hook the top cover to the main unit and push it into place slowly, as shown in

Figure 32.

3-31

Figure 32: Closing the Top Cover

2. Tighten the two special screws with the special screwdriver and close the cap.

Figure 33: Tightening the Screws

25July2000 WLL-200mW-RP-IN-1.0

Page 32

3-32

200mW RP Installation RPC/RP Manual

! NOTE: Do not use an electric screwdriver to fasten the screws. Fasten the

screws with 12 kg.cm – 15 kg.com torque.

WLL-200mW-RP-IN-1.0 25July2000

Page 33

RPC/RP Manual 200mW RP Installation

Appendix

A.1 200mW RP Cable Length

Each cable length is shown in Figure 34. The unit is “mm”.

3-33

Figure 34: Cable Length

25July2000 WLL-200mW-RP-IN-1.0

Page 34

3-34

200mW RP Installation RPC/RP Manual

A.2 The Exchange of the Fuse

The Spare fuses must be inserted in the right place, as indicated in Figure 35.

Figure 35: Spare Fuse Location

WLL-200mW-RP-IN-1.0 25July2000

Page 35

RPC/RP Manual 200mW RP Installation

A.3 Electric Connection

3-35

Figure 36: Electric Connection

25July2000 WLL-200mW-RP-IN-1.0

Page 36

3-36

200mW RP Installation RPC/RP Manual

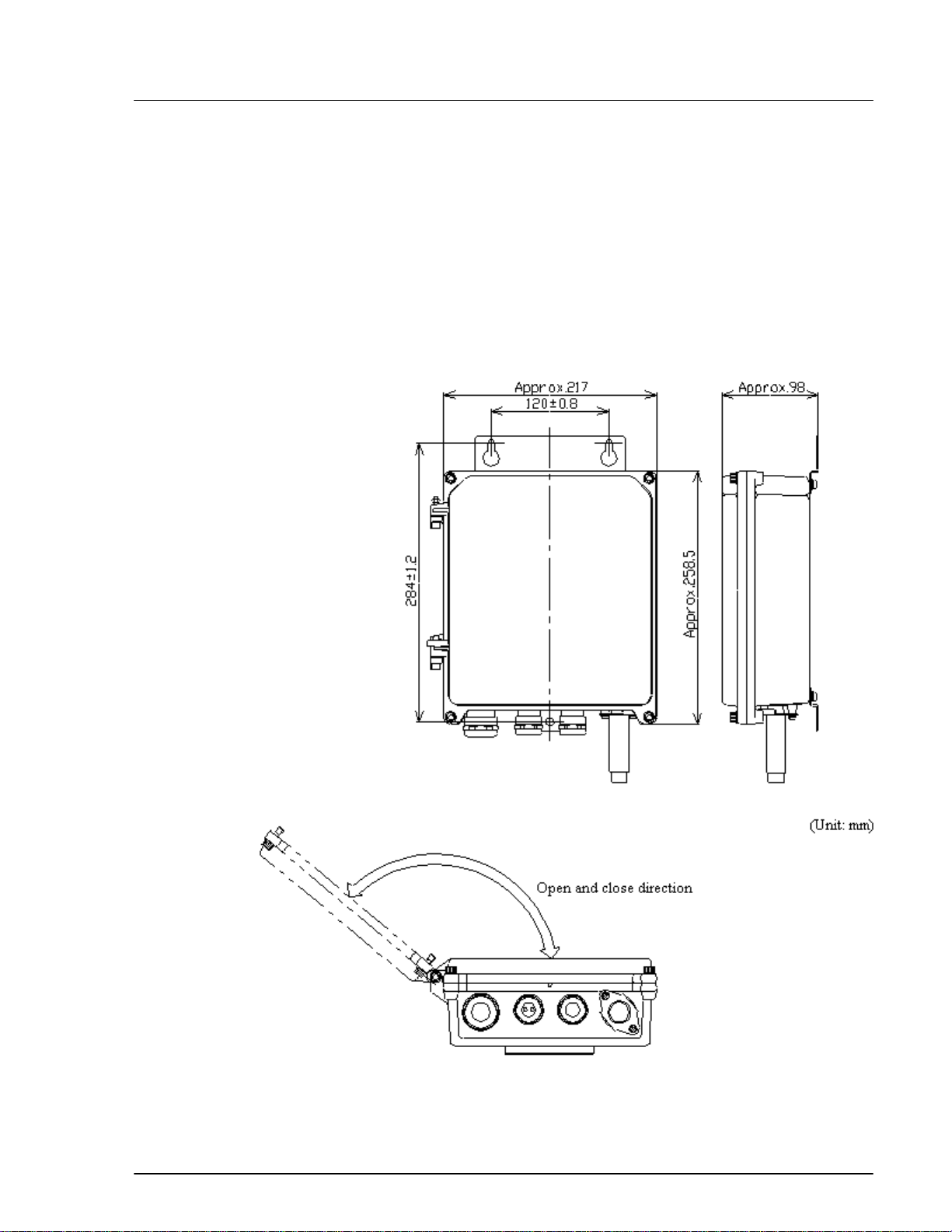

A.4 Example of Layout

Figure 37 illustrates the layout dimension for 200mW RP and the Joint Box.

Figure 37: Layout Dimension

WLL-200mW-RP-IN-1.0 25July2000

Page 37

RPC/RP Manual 200mW RP Installation

A.5 Suitable Size of the Local Cable

3-37

Figure 38: Local Cable Size

25July2000 WLL-200mW-RP-IN-1.0

Page 38

3-38

200mW RP Installation RPC/RP Manual

A.6 Tape Wrapping

If there is something wrong with the bushing, wrap the self-bonding tape and the

adhesive PVC tape as shown in the figures below.

Figure 39: Wrapping For Broken Spiral-core and Shrinking-tube

WLL-200mW-RP-IN-1.0 25July2000

Page 39

RPC/RP Manual 200mW RP Installation

A.7 Water Proof of Antenna Cable

3-39

Figure 40: Water Proof of Antenna Cable

25July2000 WLL-200mW-RP-IN-1.0

Page 40

3-40

200mW RP Installation RPC/RP Manual

Figure 41: Water Proof of Antenna Cable (Continued)

A.8 Grounding Protective Earthing Cable

Ground the PROTECTIVE EARTHING cable. Earth impedance is less than

100Ω.

WLL-200mW-RP-IN-1.0 25July2000

Page 41

RPC/RP Manual 200mW RP Installation

3-41

Figure 42: Cable Grounding

25July2000 WLL-200mW-RP-IN-1.0

Page 42

3-42

200mW RP Installation RPC/RP Manual

A.9 Installation Image

Figure 43: Pole Installation (1)

WLL-200mW-RP-IN-1.0 25July2000

Page 43

RPC/RP Manual 200mW RP Installation

3-43

Figure 44: Pole Installation (2)

25July2000 WLL-200mW-RP-IN-1.0

Page 44

3-44

200mW RP Installation RPC/RP Manual

Figure 45: Rooftop Installation

WLL-200mW-RP-IN-1.0 25July2000

Page 45

RPC/RP Manual 200mW RP Installation

3-45

25July2000 WLL-200mW-RP-IN-1.0

Loading...

Loading...