Page 1

P

r

e

l

i

m

i

n

a

r

y

FlexPacket ATCA PP50 Packet Processor

User Manual

CC06786-11B

Continuous Computing, the Continuous Computing logo, Create | Deploy | Converge, Flex21,

FlexChassis, FlexCompute, FlexCore, FlexDSP, FlexPacket, FlexStore, FlexSwitch, Network ServiceReady Platform, Quick!Start, TAPA, Trillium, Trillium+plus, Trillium Digital Systems, Trillium On Board,

TAPA, and the Trillium logo are trademarks or registered trademarks of Continuous Computing

Corporation. Other names and brands may be claimed as the property of others.

This document is confidential and proprietary to Continuous Computing Corporation. No part of this

document may be reproduced, stored, or transmitted in any form by any means without the prior written

permission of Continuous Computing Corporation.

Information furnished herein by Continuous Computing Corporation, is believed to be accurate and

reliable. However, Continuous Computing Corporation assumes no liability for errors that may appear in

this document, or for liability otherwise arising from the application or use of any such information or for

any infringement of patents or other intellectual property rights owned by third parties, which may result

from such application or use. The products, their specifications, and the information appearing in this

document are subject to change without notice.

The information contained in this document is provided “as is” without any express representations on

warranties. In addition, Continuous Computing Corporation disclaims all statutory or implied

representations and warranties, including, without limitations, any warranty of merchantability, fitness for a

particular purpose, or non-infringement of third-party intellectual property rights.

To the extent this document contains information related to software products you have not licensed from

Continuous Computing Corporation, you may only apply or use such information to evaluate the future

licensing of those products from Continuous Computing Corporation. You should determine whether or not

the information contained herein relates to products licensed by you from Continuous Computing

Corporation prior to any application or use.

Contributors: Continuous Computing Development Team, Naveen D’cruz, Kevin MacDowell.

Printed in U.S.A.

Copyright 2011 by Continuous Computing Corporation. All rights reserved.

Page 2

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device mus t accept

any interference received, including interference that may cause undesired operation.

The user manual or instruction manual for an intentional or unintentional radiator shall caution

the user that changes or modifications not expressly approved by the party responsible for

compliance could void the user's authority to operate the equipment. In cases where the manual is

provided only in a form other than paper, such as on a computer disk or over the Internet, the

information required by this section may be included in the manual in that alternative form,

provided the user can reasonably be expected to have the capability to access information in that

form.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment generates,

uses and can radiate radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a parti cu lar installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one or more of

the following measures:

-- Reorient or relocate the receiving antenna.

-- Increase the separation between the equipment and receiver.

-- Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

-- Consult the dealer or an experienced radio/TV technician for help.

Page 3

P

r

e

l

i

m

i

n

a

r

y

Contents

1 Introduction 19

1.1 Part Numbers and Options.......................................................................... 20

1.1.1 Part Numbers ................................................................................ 20

1.1.2 Basic Configurations ..................................................................... 21

1.1.3 RTM ............................................................................................... 21

1.1.4 Accessories ................................................................................... 21

1.2 Glossary ...................................................................................................... 22

1.3 Additional Documentation ........................................................................... 25

2 Technical Overview 27

2.1 Main Features ............................................................................................. 28

2.1.1 RMI Processor Subsystem ............................................................ 28

2.1.2 Ethernet Switch Module ................................................................ 28

2.1.3 RTM Interface ................................................................................ 28

2.2 Hardware Overview..................................................................................... 29

2.2.1 Front Panel Ports .......................................................................... 29

2.2.2 Backplane Interface ....................................................................... 29

2.2.3 Connectors .................................................................................... 30

2.2.3.1 Internal Connectors ....................................................... 30

2.2.3.2 External Connectors ..................................................... 30

2.2.3.3 ATCA Connectors ......................................................... 30

2.2.4 Graphical Overview ....................................................................... 31

2.2.5 RMI Processor CPU Subsystem ................................................... 33

2.2.5.1 PSRAM (Flight Recorder Memory) ............................... 34

2.2.6 Fabric and Base Switch Modules .................................................. 36

2.2.7 Optional TCAM Mezzanine ........................................................... 38

2.2.8 RTM interface ................................................................................ 38

Page 5

CC06786-11B

Confidential and Proprietary

Page 4

FlexPacket ATCA PP50 Packet Processor

P

r

e

l

i

m

i

n

a

r

y

2.2.9 Management Subsystem ............................................................... 40

2.2.10 Front Panel .................................................................................... 40

2.2.10.1 LEDs ............................................................................. 40

2.2.10.2 Handle Switch ............................................................... 42

2.2.10.3 Management Port ......................................................... 42

2.2.10.4 Console Port ................................................................. 42

2.2.10.5 10GBASE-X Port .......................................................... 42

2.2.11 Jumpers ......................................................................................... 43

2.2.11.1 Default Jumper Settings ............................................... 43

2.2.11.2 Force Power On Jumper: J116 ..................................... 44

2.2.11.3 Console Mux Bypass Jumpers: J112, J113 .................. 45

2.2.11.4 Spare Serial Config Jumper: J111 ................................ 45

2.2.11.5 Alt Boot Bank Select Jumpers: J117, J118 ................... 45

2.2.11.6 Reserved Jumpers ........................................................ 46

2.2.12 Power Design ................................................................................ 46

2.2.13 Mean Time Between Failures ........................................................ 46

2.3 Component Integration Overview................................................................ 47

2.3.1 Firmware ....................................................................................... 47

2.3.2 IPMI ............................................................................................... 48

2.3.3 IPMC ............................................................................................. 48

2.3.4 IPMC and XLR Software Domains ................................................ 49

2.3.5 XLR Watchdog Timers .................................................................. 49

2.3.6 XLR Software ................................................................................ 49

2.3.7 XLR and IPMC Messaging ............................................................ 51

2.3.8 Power Domains ............................................................................. 53

2.4 Specifications .............................................................................................. 55

2.4.1 CPU / Memory ............................................................................... 55

2.4.2 Input/Output ................................................................................... 55

2.4.3 Expansion Options ........................................................................ 55

2.4.4 Software ........................................................................................ 55

2.4.5 Mechanical & Environmental Compliance ..................................... 55

2.4.6 Fuses ............................................................................................. 56

2.4.7 Certifications .................................................................................. 56

2.4.7.1 Planned Certifications ................................................... 56

2.4.8 Power Consumption ...................................................................... 56

3 Board Installation 57

3.1 Precautions ................................................................................................. 58

3.1.1 Environmental Requirements ........................................................ 58

3.1.2 Heat Dissipation and Dust Prevention ........................................... 58

3.1.3 Electrostatic Prevention ................................................................. 58

3.1.4 Other Precautions ......................................................................... 59

3.2 Unpacking the PP50 ................................................................................... 60

3.2.1 Compact Flash .............................................................................. 60

Page 6

User Manual

Continuous Computing Corporation

Page 5

Contents

P

r

e

l

i

m

i

n

a

r

y

3.2.2 Board Identification ........................................................................ 61

3.2.2.1 Serial Number ............................................................... 61

3.2.2.2 MAC Address ................................................................ 62

3.2.2.3 Part Number ................................................................. 63

3.2.2.4 MAC Address Location ................................................. 63

3.2.2.5 IPMI Manufacturing Info ................................................ 63

3.3 Installing PP50s into the Chassis................................................................ 64

3.3.1 Where to Install the PP50 .............................................................. 64

3.3.2 Board Insertion .............................................................................. 65

3.3.3 Air Blocker Modules in Vacant Slots ............................................. 69

4 Board Access, Bootup, and Shutdown 71

4.1 Serial Console Access ................................................................................ 72

4.1.1 Connect to the Serial Console ....................................................... 72

4.1.2 How to Switch Between Serial Consoles (IPMC, XLRs) ............... 73

4.2 IPMC Telnet Access.................................................................................... 75

4.2.1 Setting eth0 IP Address Manually ................................................. 75

4.2.2 Setting eth0.4094 IP Address Manually ........................................ 75

4.2.3 Setting the DNS Manually ............................................................. 76

4.3 Console Access for Development ............................................................... 77

4.3.1 Development Adapter (Hydra) Cable ............................................ 77

4.4 Board Shutdown.......................................................................................... 79

4.4.1 Using the IPMI Command to Shutdown ........................................ 79

4.4.2 Using the Handle Latch to Shutdown ............................................ 79

4.5 Board Reset ................................................................................................ 80

4.5.1 IPMI Cold Reset Command ........................................................... 80

4.5.2 IPMC (CNode) Reboot .................................................................. 80

1

4ABAB

5 Using the XLR SDK 81

5.1 Installing RMI Source Code & Development Tools ..................................... 82

5.2 Installing Continuous Computing Software ................................................. 83

5.3 Build the Linux Kernel ................................................................................. 84

5.3.1 Apply Kernel Patches to the RMI SDK Kernel Source .................. 84

5.3.1.1 Example of Using the Patch ......................................... 84

5.3.2 Build the Patched Linux Kernel ..................................................... 84

5.4 Cross Compiling Linux Applications using the RMI SDK Crosscompiler .... 86

6 Booting the XLRs 87

6.1 XLR Boot Methods ...................................................................................... 88

6.1.1 Network Boot ................................................................................. 88

6.1.1.1 Boot Server setup ......................................................... 88

6.1.1.2 PP50 Setup ................................................................... 88

6.1.1.3 Network Boot Example ................................................. 89

6.1.2 XLR Bootloader Commands .......................................................... 90

Page 7

CC06786-11B

Confidential and Proprietary

Page 6

FlexPacket ATCA PP50 Packet Processor

P

r

e

l

i

m

i

n

a

r

y

6.1.3 Compact Flash Boot ...................................................................... 91

6.1.3.1 Formatting Compact Flash ........................................... 92

6.1.3.2 Booting from Compact Flash ........................................ 92

6.2 Automating XLR boot .................................................................................. 94

6.2.1 Continuous Computing Multiboot .................................................. 94

6.2.1.1 Key Values (KV) ........................................................... 94

6.2.1.2 KV Variable Syntax ....................................................... 95

6.2.1.3 Access to Multiple Boot Method ................................... 96

6.2.1.4 Boot Method Syntax ..................................................... 96

6.2.1.5 Specifying Boot file ....................................................... 97

6.2.1.6 Specifying Boot command ............................................ 97

6.2.1.7 Specifying Boot Arguments .......................................... 98

6.2.1.8 Watchdog Feature ........................................................ 98

6.2.1.9 Initializing Multiboot ...................................................... 99

6.2.1.10 Multiboot Example ...................................................... 101

6.2.2 Autobooting Using Environment Variables .................................. 101

6.3 XLR Utility ................................................................................................. 102

6.3.1 Installing Linux Utilities ................................................................ 102

6.3.1.1 RMI Linux .................................................................... 102

6.3.1.2 WR Linux .................................................................... 102

6.3.2 XLR Commands Available From the BootLoader ....................... 103

6.3.2.1 kv ................................................................................ 103

6.3.2.2 showboot .................................................................... 104

6.3.2.3 rollboot ........................................................................ 104

6.3.3 XLR Commands Available From Linux ....................................... 104

6.3.3.1 NTP client ................................................................... 104

6.3.3.2 kv ................................................................................ 104

6.3.3.3 showboot .................................................................... 104

6.3.3.4 rollboot ........................................................................ 105

6.3.3.5 ipmi_setwd .................................................................. 105

6.3.3.6 fswcmd ........................................................................ 105

6.3.3.7 upgrade ....................................................................... 106

6.3.3.8 bswcmd ....................................................................... 106

6.3.3.9 getcpuid ...................................................................... 106

6.3.3.10 net_config ................................................................... 107

6.3.3.11 ipmi_setwd .................................................................. 107

6.3.3.12 ux_diag ....................................................................... 108

7 Intelligent Platform Management Controller 109

7.1 FRU Support ............................................................................................. 110

7.1.1 FRU State .................................................................................... 110

7.1.2 FRU Hot swap Sensors ............................................................... 111

7.1.3 FRU Data .................................................................................... 111

7.1.3.1 Example of FRU Data using Pigeon Point ShMc ........ 111

7.2 Sensors ..................................................................................................... 114

7.3 Link Descriptors ........................................................................................ 118

Page 8

User Manual

Continuous Computing Corporation

Page 7

Contents

P

r

e

l

i

m

i

n

a

r

y

7.3.1 PP50 with 10G Fabric Link Descriptors (shelf manager) ............ 120

7.3.2 PP50 with 4*1G Fabric Link Descriptors (shelf manager) ........... 120

7.4 Key Value (KV) Database ......................................................................... 122

7.4.1 KV Keys ....................................................................................... 122

7.4.2 To List All Key Value Entries ....................................................... 132

7.5 IPMI and PICMG Commands.................................................................... 134

7.5.1 IPMI Device Global Commands .................................................. 135

7.5.2 BMC Watchdog Timer Commands .............................................. 135

7.5.3 Chassis Device Commands ........................................................ 135

7.5.4 Event Commands ........................................................................ 136

7.5.5 Sensor Device Commands .......................................................... 136

7.5.6 FRU Device Commands .............................................................. 138

7.5.7 SDR Device Commands ............................................................. 138

7.5.8 SEL Device Commands .............................................................. 138

7.5.9 ATCA (PICMG 3.0) Commands .................................................. 139

7.5.9.1 FRU Control Command .............................................. 140

7.5.10 OEM API Commands .................................................................. 141

7.5.10.1 Get Payload CPU-Reset ............................................. 141

7.5.10.2 Set Payload CPU-Reset ............................................. 143

7.5.10.3 Get Payload Active Flash Bank .................................. 143

7.5.10.4 Set Payload Active Flash Bank ................................... 144

7.5.10.5 Get Self Payload ID .................................................... 145

7.5.10.6 Get Payload ID for Watchdog Commands .................. 146

7.5.10.7 Set Payload ID for Watchdog Commands .................. 148

7.5.10.8 Get IPMC Key N ......................................................... 149

7.5.10.9 Get IPMC Key-Value .................................................. 150

7.5.10.10 Set IPMC Key-Value ................................................... 151

7.5.10.11 Get IPMC Key-Value Extended .................................. 153

7.5.10.12 Set IPMC Key-Value Extended ................................... 154

7.5.10.13 Sensor Thresholds and Hysteresis Overview ............. 155

7.5.11 IPMI Command Completion Codes ............................................. 158

7.6 Error Logging ............................................................................................ 160

7.7 Behavior of IPMI Resets ........................................................................... 161

7.7.1 IPMI Cold Reset .......................................................................... 161

7.7.2 IPMI Watchdog Reset ................................................................. 161

7.7.2.1 Linux Application Level ............................................... 161

7.7.2.2 Hardware Level ........................................................... 161

7.7.3 IPMI Firmware Upgrade Reset .................................................... 162

7.8 IPMC Command Line Interface................................................................. 163

7.8.1 bmc_watchdog ............................................................................ 164

7.8.2 commit ......................................................................................... 164

7.8.3 debuglevel ................................................................................... 165

7.8.4 getactivebank .............................................................................. 165

7.8.5 getresetstatus .............................................................................. 166

7.8.6 help .............................................................................................. 166

7.8.7 kv ................................................................................................. 167

1

4ABAB

Page 9

CC06786-11B

Confidential and Proprietary

Page 8

FlexPacket ATCA PP50 Packet Processor

P

r

e

l

i

m

i

n

a

r

y

7.8.8 listdev .......................................................................................... 168

7.8.9 listfwdev ....................................................................................... 168

7.8.10 listpay .......................................................................................... 168

7.8.11 localaddress ................................................................................ 169

7.8.12 quit ............................................................................................... 169

7.8.13 resetdev ....................................................................................... 169

7.8.14 restore ......................................................................................... 169

7.8.15 sel ................................................................................................ 170

7.8.16 sendcmd ...................................................................................... 170

7.8.17 setactivebank .............................................................................. 171

7.8.18 setresetstatus .............................................................................. 171

7.8.19 version ......................................................................................... 171

8 Network Configuration 173

8.1 Fabric Switch Models ................................................................................ 175

8.2 Fabric Switch Management....................................................................... 176

8.2.1 Managing the Fabric Switch with fswcmd ................................... 176

8.2.1.1 autopause ................................................................... 177

8.2.1.2 reload .......................................................................... 177

8.2.1.3 show stats ................................................................... 178

8.2.1.4 clear ............................................................................ 178

8.2.1.5 route ............................................................................ 178

8.2.1.6 set port ........................................................................ 178

8.2.1.7 enable/disable port ..................................................... 179

8.2.1.8 enable/disable port e-keying ....................................... 179

8.2.1.9 enable/disable ingress vlan ........................................ 180

8.2.1.10 enable/disable accept untagged port .......................... 180

8.2.1.11 set port default ............................................................ 180

8.2.1.12 add vlan ...................................................................... 180

8.2.1.13 del vlan ....................................................................... 181

8.2.1.14 show ........................................................................... 181

8.2.1.15 SFP Commands ......................................................... 181

8.2.1.16 show Commands ........................................................ 181

8.2.1.17 cfgreg .......................................................................... 182

8.2.1.18 dump ........................................................................... 182

8.2.1.19 show version ............................................................... 182

8.2.1.20 dump ........................................................................... 182

8.2.1.21 enable | disable mac-learning ..................................... 182

8.2.1.22 enable | disable flooding broadcast ............................ 182

8.2.1.23 high and low watermark range .................................... 183

8.2.1.24 enable | disable protocol-traps .................................... 183

8.2.1.25 show link ..................................................................... 183

8.2.1.26 MAC aging .................................................................. 184

8.2.2 fswcmd Start Up File ................................................................... 184

8.2.3 FIBM Mode .................................................................................. 185

8.2.3.1 Enabling FIBM Mode .................................................. 186

Page 10

User Manual

Continuous Computing Corporation

Page 9

Contents

P

r

e

l

i

m

i

n

a

r

y

8.3 Base Switch Management and Port Connectivity ..................................... 187

8.3.1 Default Behavior .......................................................................... 187

8.3.1.1 Broadcom Management Tag (BMT) ........................... 188

8.3.1.2 Register Initialization in u-boot .................................... 189

8.3.2 Configurable Behavior ................................................................. 191

8.3.3 Alternate bswitch Behavior .......................................................... 194

8.3.4 Configuration ............................................................................... 194

8.3.4.1 num_of_fakes: .......................................................... 194

8.3.4.2 vlan_method .............................................................. 194

8.3.5 Design Overview ......................................................................... 195

8.3.5.1 VLAN mode ............................................................... 196

8.3.5.2 BMT Mode ................................................................. 196

8.3.6 Key Value Database Syntax ........................................................ 197

8.3.7 Examples ..................................................................................... 197

8.3.7.1 VLAN method ............................................................ 197

8.3.7.2 Mask Method ............................................................ 198

8.3.8 Front Mode .................................................................................. 198

8.3.9 RTM Mode ................................................................................... 198

8.4 Ethernet Ports on the RTM ....................................................................... 199

8.5 Fabric and Base Switch Management....................................................... 199

8.6 CNode Base Switch (bswcmd) Command ................................................ 200

8.6.1 Binding bswcmd to the CNODE's IP ........................................... 200

8.6.2 bswcmd Usage Examples ........................................................... 200

8.6.2.1 Common bswcmd Commands .................................... 200

8.6.3 Fabric Switch ............................................................................... 202

8.7 Configuring XLR Network Interfaces using KV.......................................... 203

8.7.1 Configuring XLR Network Interfaces Example ............................ 204

1

4ABAB

9 Using Wind River Linux on the PP50 205

9.1 Overview ................................................................................................... 206

9.1.1 CCPU/WindRiver Release Compatibility ..................................... 206

9.1.2 Installation Requirements ............................................................ 207

9.1.2.1 For WindRiver PNE LE 2.0 ......................................... 207

9.2 Installing the Template and Patch............................................................. 208

9.2.1 Installation Steps for WindRiver PNE 2.0 .................................... 208

9.3 Building the Kernel and NFS..................................................................... 209

9.3.1 Installing the Boot Kernel and NFS ............................................. 217

9.3.2 Booting the Target Blade ............................................................. 217

9.4 Memory Map Setup................................................................................... 218

9.5 Linux Setup ............................................................................................... 218

9.6 Linux Command Line Options................................................................... 219

9.6.1 linux_cpu_mask=<cpu_mask> .................................................... 219

9.6.2 kseg0_start=<address> ............................................................... 219

9.6.3 kseg0_size=<size> ...................................................................... 219

9.6.4 kumem=<size@addr> ................................................................. 220

9.6.4.1 Examples of Using kumen .......................................... 220

Page 11

CC06786-11B

Confidential and Proprietary

Page 10

FlexPacket ATCA PP50 Packet Processor

P

r

e

l

i

m

i

n

a

r

y

9.6.5 kuseg_start_hi=<hi_address> ..................................................... 221

9.6.6 kuseg_start_lo=<lo_address> ..................................................... 221

9.6.7 kuseg_size_hi=<hi_size> ............................................................ 221

9.6.8 kuseg_size_lo=<lo_size> ............................................................ 221

9.6.9 app_sh_mem_sz=<hex_size> .................................................... 222

9.6.10 shared_core ................................................................................ 222

9.7 Linux Loader Applications ......................................................................... 223

9.7.1 userapp ....................................................................................... 223

9.7.1.1 load ............................................................................. 223

9.7.1.2 stop ............................................................................. 224

9.7.1.3 status .......................................................................... 224

9.7.1.4 showmem ................................................................... 224

9.7.1.5 shmem ........................................................................ 225

9.8 Building an RMIOS application ................................................................. 226

9.8.1 Building KSEG0 applications ....................................................... 226

9.8.2 Stop and Re-load support ........................................................... 226

10 Rear Transition Modules 227

10.1 Standard RTM ........................................................................................... 228

10.1.1 Standard RTM Features .............................................................. 228

10.1.2 Specifications and Features ........................................................ 228

10.1.2.1 General ....................................................................... 228

10.1.2.2 Mechanical .................................................................. 228

10.1.2.3 Power .......................................................................... 229

10.1.2.4 Management .............................................................. 229

10.2 COP50 RTM.............................................................................................. 230

10.2.1 COP50 Features ......................................................................... 230

10.2.2 Important COP50 Terms Definitions ........................................... 231

10.2.3 COP50 RTM Overview ................................................................ 232

10.2.3.1 Bypass protection ....................................................... 234

10.2.4 COP50 Specifications and Features ........................................... 234

10.2.4.1 General ....................................................................... 234

10.2.4.2 Mechanical .................................................................. 234

10.2.4.3 Power .......................................................................... 234

10.2.4.4 Management .............................................................. 235

10.2.4.5 Bypass protection ...................................................... 236

10.2.4.6 IPMC Firmware .......................................................... 236

10.2.5 Installation and Usage ................................................................. 236

10.2.5.1 Initial Installation ......................................................... 236

10.2.5.2 PP50 IPMC Bootup and the COP50 ........................... 237

10.2.5.3 RTM Insertion ............................................................. 238

10.2.5.4 Upgrading the COP50 RTM CPLD ............................. 238

10.2.5.5 RTM Removal ............................................................. 239

10.2.5.6 Auto-Arm versus Managed Re-Arming ....................... 239

10.2.5.7 Software Specifications .............................................. 239

10.2.5.8 COP50 Usage Example .............................................. 243

Page 12

User Manual

Continuous Computing Corporation

Page 11

Contents

P

r

e

l

i

m

i

n

a

r

y

11 Firmware Upgrades 245

11.1 CPLD Upgrade .......................................................................................... 245

11.1.1 CPLD Upgrade Examples ........................................................... 246

11.2 XLR bootloader Upgrade .......................................................................... 247

11.2.1 Get Image File ............................................................................. 247

11.2.1.1 Upgrade Boot Flash Via Network ............................... 247

11.2.1.2 Get Bootloader Image File from TFTP Server ............ 247

11.2.2 Loading Image Files .................................................................... 247

11.2.2.1 Ping-Pong Upgrade Method ....................................... 248

11.2.2.2 Factory Golden Upgrade Method ............................... 249

11.3 Upgrading the PP50 IPMC ........................................................................ 252

11.3.1 Upgrading Versions 2.3.x or Later to a Higher Version ............... 252

11.3.2 Upgrading Versions 2.2.x or Earlier to a Higher Version ............. 253

11.3.3 Showing, Switching, and Rebooting Boot Banks ........................ 255

11.4 Linux Bootloader Upgrade Tool ................................................................ 257

11.4.1 In WR Linux ................................................................................. 257

11.4.2 In RMI Linux ................................................................................ 258

11.5 XLR Fabric Switch Configuration Utility, Installation ................................. 259

1

4ABAB

12 Diagnostics and Troubleshooting 261

12.1 Overview ................................................................................................... 261

12.2 Running Diagnostic Tests from Raw CLI .................................................. 262

12.2.1 IPMC Raw CLI Diagnostic Commands ....................................... 262

12.2.2 XLR Raw CLI Diagnostic Commands ......................................... 263

12.3 Running Diagnostic Tests using KV Settings ............................................ 265

12.3.1 Running IPMC Diagnostic tests with KV settings ........................ 266

12.3.1.1 IPMC U-boot command for short/long POST tests ..... 266

12.3.1.2 IPMC Linux utility for POST/BIST tests ...................... 267

12.3.2 Running XLR Diagnostic Tests with KV settings ......................... 269

12.3.2.1 XLR Commands for Short/Long POST tests .............. 269

12.3.2.2 XLR RMI Linux Utility for POST/BIST Tests ............... 271

12.4 Indicating XLR’s POST/BIST Status Using LEDs ..................................... 275

12.5 Determining Board Build ........................................................................... 276

13 Product Repair and Returns 277

13.1 Customer Support ..................................................................................... 277

13.2 Warranty.................................................................................................... 277

13.2.1 RMA Procedure ........................................................................... 278

13.2.2 Non-Warranty Repairs ................................................................. 278

13.2.3 Shipping ...................................................................................... 278

13.2.4 Expedite Option for Repairs ........................................................ 278

14 Revision History 279

Page 2-13

CC06786-11B

Confidential and Proprietary

Page 12

FlexPacket ATCA PP50 Packet Processor

P

r

e

l

i

m

i

n

a

r

y

Page 2-14

User Manual

Continuous Computing Corporation

Page 13

P

r

e

l

i

m

i

n

a

r

y

Figures

Figure 2-1 PP50 Overview Photo .................................................................................... 27

Figure 2-2 Front Panel ..................................................................................................... 29

Figure 2-3 Overall Hardware Block Diagram. .................................................................. 31

Figure 2-4 Base and Fabric Connection Diagram. ........................................................... 32

Figure 2-5 RMI Processor CPU Subsystem .................................................................... 33

Figure 2-6 Switch Module ................................................................................................ 36

Figure 2-7 RTM interface in Chassis ............................................................................... 38

Figure 2-8 RTM Panel ...................................................................................................... 39

Figure 2-9 Front Panel LEDs ........................................................................................... 40

Figure 2-10 IPMC Overview ............................................................................................. 48

Figure 2-11 XLR Software Overview ............................................................................... 49

Figure 2-12 XLR and IPMC Messaging ........................................................................... 51

Figure 2-13 XLR and IPMC Boot Messaging ................................................................... 51

Figure 2-14 XLR and IPMC Telnet Messaging ................................................................ 52

Figure 2-15 XLR and IPMC IPMI Messaging ................................................................... 52

Figure 2-16 Virtual Switches ............................................................................................ 53

Figure 2-17 Power Domains, Startup ............................................................................... 54

Figure 3-1 ESD Wrist Strap ............................................................................................. 59

Figure 3-2 PP50 Unpacking ............................................................................................. 60

Figure 3-3 Serial Number Location .................................................................................. 61

Figure 3-4 Part Number Location ..................................................................................... 63

Figure 3-5 MAC Address Location ................................................................................... 63

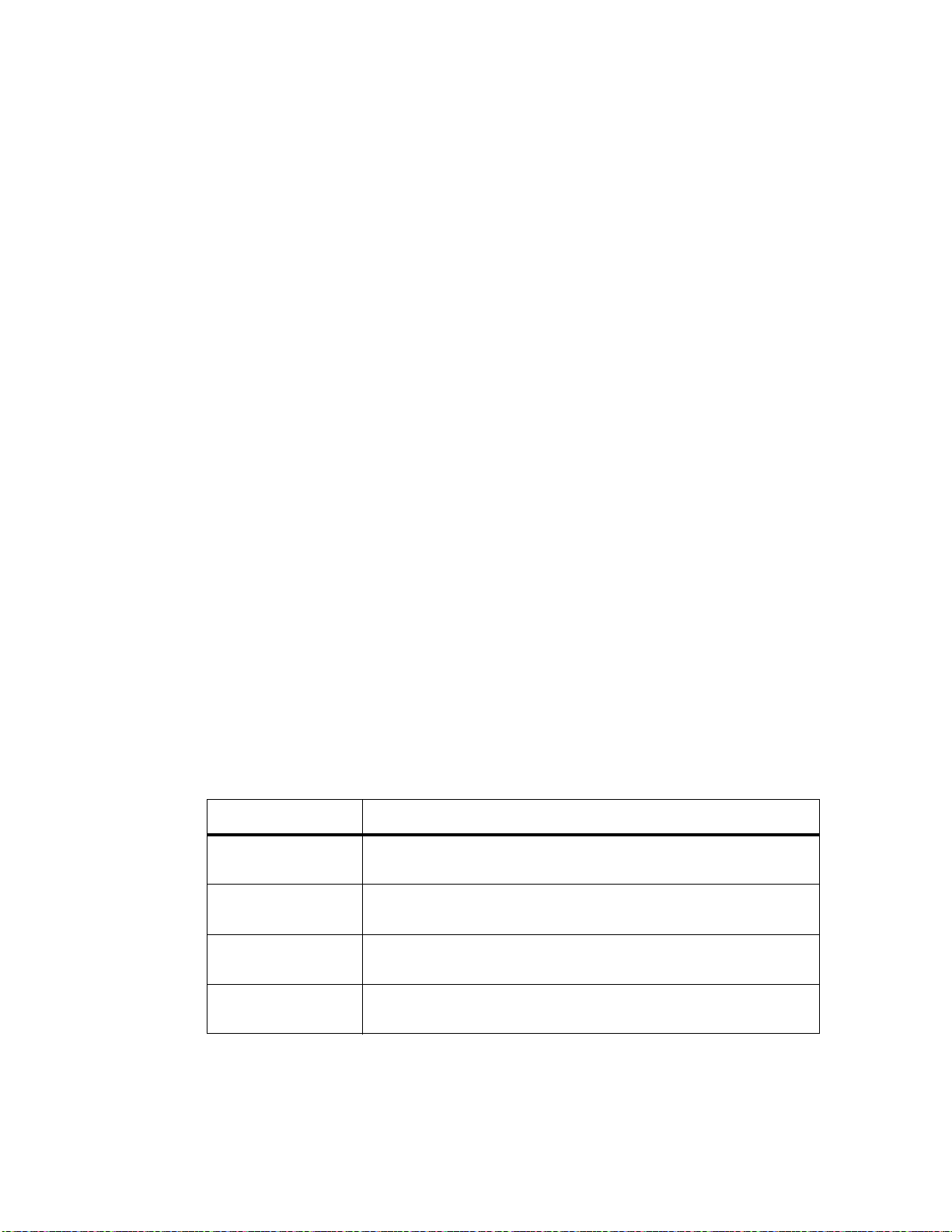

Figure 3-6 5U Chassis Slots ............................................................................................ 64

Figure 3-7 12U Chassis Slots .......................................................................................... 64

Figure 3-8 Latch Handle .................................................................................................. 65

Figure 3-9 Opening the Latch Handle, Lever Release ..................................................... 66

Figure 3-10 Opened Latch Handle ................................................................................... 66

Figure 3-11 Installation - Locator Pins ............................................................................. 67

Figure 3-12 Installation - Board Insertion ......................................................................... 68

Page 15

CC06786-11B

Confidential and Proprietary

Page 14

FlexPacket ATCA PP50 Packet Processor

P

r

e

l

i

m

i

n

a

r

y

Figure 3-13 PP50 Installation - Board Insertion, Latch Closure ....................................... 69

Figure 4-1 Serial Console Cable ...................................................................................... 72

Figure 4-2 Connecting Computer to the Serial Console .................................................. 72

Figure 4-3 Hydra Cable for Multiple Simultaneous Connection ....................................... 77

Figure 4-4 Hydra Cable Jumpers (J111 and J113) .......................................................... 78

Figure 7-1 Get Payload Active Flash Bank Response Data .......................................... 144

Figure 7-2 Set Payload Active Flash Bank Request Data ............................................. 145

Figure 7-3 Set Payload Active Flash Bank Response Data .......................................... 145

Figure 8-1 Networking Components Diagram ............................................................... 174

Figure 8-2 Fulcrum In Band Management (FIBM) ......................................................... 185

Figure 8-3 PP50 Channel A and B Networks ................................................................ 188

Figure 8-4 Selective-mask bswitch Ingress Masks ........................................................ 190

Figure 8-5 BMT Mode eth0 egress ................................................................................ 191

Figure 8-6 BMT Mode eth1 egress ................................................................................ 192

Figure 8-7 BMT Mode eth1 ingress ............................................................................... 192

Figure 8-8 VLAN Mode eth0 egress .............................................................................. 193

Figure 8-9 VLAN Mode eth1 egress .............................................................................. 193

Figure 8-10 sysctl tree ................................................................................................... 195

Figure 9-1 WindRiver PNE LE 2.0 Files for CCPU Release 1.3 .................................... 207

Figure 9-2 Create a New Project ................................................................................... 209

Figure 9-3 Input the Name ............................................................................................. 210

Figure 9-4 Select Board ................................................................................................. 211

Figure 9-5 Static Analysis .............................................................................................. 212

Figure 9-6 Project Name ................................................................................................ 212

Figure 9-7 Linux Kernel Configuration ........................................................................... 213

Figure 9-8 Package Configuration ................................................................................. 214

Figure 9-9 Build WindRiver Linux Kernel ....................................................................... 215

Figure 9-10 Build WindRiver Linux NFS ........................................................................ 216

Figure 10-1 Standard RTM ............................................................................................ 228

Figure 10-2 COP50 RTM ............................................................................................... 230

Figure 10-3 COP50 Front View ..................................................................................... 232

Figure 10-4 RTM-COP50 Block Diagram ...................................................................... 233

Figure 10-5 cop50d daemon’s Internal State Model ...................................................... 240

Figure 11-1 Ping-Pong Upgrade Flow Diagram ............................................................. 249

Figure 11-2 Factory Golden Upgrade Flow Diagram ..................................................... 251

Figure 12-1 Diagnostic Tests Tree ................................................................................ 261

Page 16

User Manual

Continuous Computing Corporation

Page 15

P

r

e

l

i

m

i

n

a

r

y

Tables

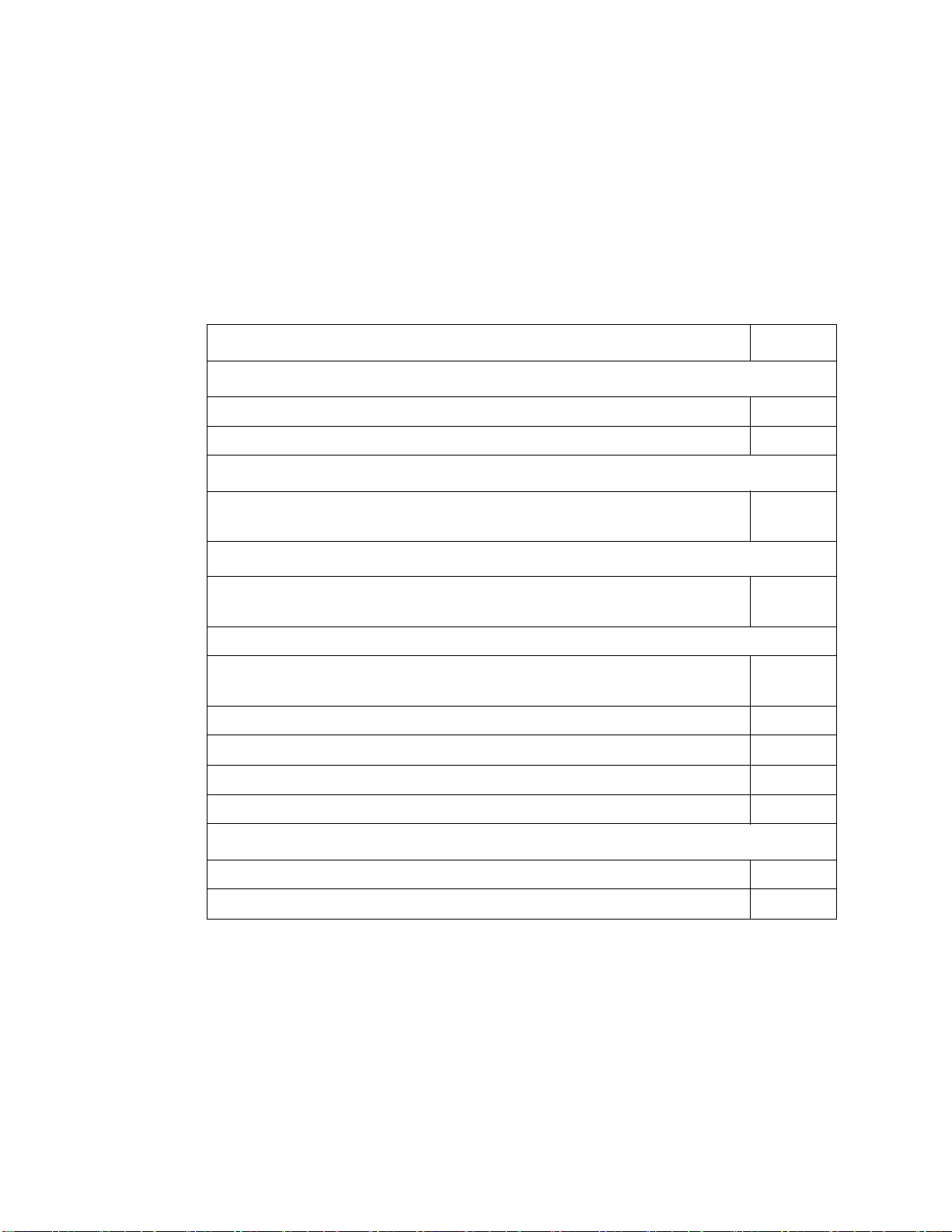

Table 1-1 PP50 and Accessory Part Numbers ........................................................ 20

Table 1-2 Terms Used in this Document.................................................................. 22

Table 2-1 RMI XLR Family Configurations............................................................... 33

Table 2-2 Ethernet Switch Operating Modes ........................................................... 37

Table 2-3 Ethernet Switch Port Usage..................................................................... 37

Table 2-4 LED Description....................................................................................... 41

Table 2-5 PP50 Jumper Information ........................................................................ 43

Table 2-6 Console Debug Bypass ........................................................................... 45

Table 2-7 Debug Mode – Triple MUX Modes........................................................... 45

Table 2-8 Reserved Jumpers................................................................................... 46

Table 2-9 PP50 Major Firmware Categories............................................................ 47

Table 2-10 Fuse Specification.................................................................................... 56

Table 3-1 MAC Address Ports ................................................................................. 62

Table 6-1 Network Boot Options.............................................................................. 89

Table 7-1 PP50 Sensor List ................................................................................... 114

Table 7-2 Factory default settings of thresholds and hysteresis............................ 116

Table 7-3 Link Records on PP50 with 10G Fabric ................................................ 118

Table 7-4 Table 7-2: Link Records on PP50 with 4*1G Fabric ............................. 118

Table 7-5 Key Value Database .............................................................................. 122

Table 7-6 IPMI Device Global Commands............................................................. 135

Table 7-7 BMC Watchdog Timer Commands ........................................................ 135

Table 7-8 Chassis Device Commands................................................................... 135

Table 7-9 Event Commands .................................................................................. 136

Table 7-10 Sensor Device Commands .................................................................... 136

Table 7-11 FRU Device Commands ........................................................................ 138

Table 7-12 SDR Device Commands........................................................................ 138

Table 7-13 SEL Device Commands......................................................................... 138

Table 7-14 AdvancedTCA Commands .................................................................... 139

Table 7-15 OEM Request and Response CodeBytes.............................................. 141

Page 17

CC06786-11B

Confidential and Proprietary

Page 16

FlexPacket ATCA PP50 Packet Processor

P

r

e

l

i

m

i

n

a

r

y

Table 7-16 Get Payload CPU-Reset Request Data................................................. 141

Table 7-17 Get Payload CPU-Reset Response Data.............................................. 142

Table 7-18 Set Payload CPU-Reset Request Data. ................................................ 143

Table 7-19 Set Payload CPU-Reset Response Data .............................................. 143

Table 7-20 Get Payload Active Flash Bank Request Data ...................................... 144

Table 7-21 Get Self Payload ID Request Data ........................................................ 146

Table 7-22 Get Self Payload ID Response Data ..................................................... 146

Table 7-23 Get Payload ID for Watchdog Commands Request Data...................... 147

Table 7-24 Get Payload ID for Watchdog Commands Response Data................... 147

Table 7-25 Set Payload ID for Watchdog Commands Request Data...................... 148

Table 7-26 Set Payload ID for Watchdog Commands Response Data ................... 148

Table 7-27 Get IPMC Key N Request Data ............................................................. 149

Table 7-28 Get IPMC Key N Response Data .......................................................... 149

Table 7-29 Get IPMC Key-Value Request Data ...................................................... 150

Table 7-30 Get IPMC Key-Value Response Data.................................................... 150

Table 7-31 Set IPMC Key-Value Request Data....................................................... 151

Table 7-32 Set IPMC Key-Value Response Data .................................................... 152

Table 7-33 Get IPMC Key-Value Extended Request Data ...................................... 153

Table 7-34 Get IPMC Key-Value Extended Response Data ................................... 153

Table 7-35 Set IPMC Key-Value Extended Request Data....................................... 154

Table 7-36 Set IPMC Key-Value Extended Response Data.................................... 155

Table 7-37 Command: 50h Sub-command: 23h Request data ............................ 156

Table 7-38 Command: 50h Sub-command: 23h Response data............................. 156

Table 7-39 Command: 50h Sub-command: 24h Request data ............................... 157

Table 7-40 Command: 50h Sub-command: 24h Response data............................. 157

Table 7-41 Command: 50h Sub-command: 25h Request data ............................... 157

Table 7-1 IPMI Command Completion Codes ....................................................... 158

Table 7-42 Command: 50h Sub-command: 25h Response data............................. 158

Table 8-1 Virtual Broadcast Domains .................................................................... 187

Table 8-2 VLAN assignment to ingress packets.................................................... 189

Table 8-3 Selective-mask bswitch Ingress Masks ................................................. 189

Table 8-4 cnswmode Values.................................................................................. 194

Table 8-5 BMT mode Flood Ports.......................................................................... 196

Table 8-6 BMT mode Flood Ports.......................................................................... 196

Table 8-7 XLR Ethernet ports and their corresponding key values ....................... 203

Table 9-1 CCPU/WindRiver Release Compatibility ............................................... 206

Table 9-2 Boot Target Blade Network Configuration ............................................. 217

Table 12-1 IPMC Raw CLI Diagnostic (Hardware) Tests ........................................ 262

Table 12-2 XLR Raw CLI Diagnostic (Hardware) Tests .......................................... 264

Table 12-3 POST/BIST KV Keys ............................................................................. 265

Table 12-4 xx_bootmode Settings (xx: cn, s0, s1)................................................... 265

Table 12-5 Diagnostic types and test mask string assignment................................ 266

Table 12-6 kv_diag Usage and Options................................................................... 269

Table 12-7 XLR Diagnostic Tests ............................................................................ 272

Table 12-8 Determining Board Build by Revision Number ...................................... 276

Table 14-1 User Manual Revision History ............................................................... 279

Page 18

User Manual

Continuous Computing Corporation

Page 17

1

P

r

e

l

i

m

i

n

a

r

y

1Introduction

This manual provides instructions for installing and using Continuous Computing’s

FlexPacket PP50 (PP50) high-performance packet processing blade.

The PP50 provides deep-packet inspection capabilities that support advanced content-aware routing and security functions required by multi-service IP networks.

The blade is for next-generation infrastructure applications, including IPTV, radio

network controllers (RNC), security gateways, session border controllers, WiMAX

base station aggregation, and wireless xGSNs.

The PP50 includes one or two discrete multi-core MIPS64 packet processors. Each

processor provides 8 multi-threaded cores and contains a built-in security coprocessor capable of handling up to 10Gbps of bulk encryption/decryption (20Gbps per

blade).

Each processor with up to 8Gb of memory (16Gb per blade), as well as access to a

TCAM and content-based processors via mezzanines. TCAM is especially important

for very high performance IPv6 routing platforms. For a list of orderable configurations, accessories and their part numbers please see Section1.1.4, "Accessories" for

more information.

The PP50 interconnects the processors, I/O, and backplane fabrics using a nonblocking 10 Gigabit Ethernet (10GbE) switch. Each XLR processor has two 10GbE

ports to the switch, providing full duplex 10GbE capabilities. External I/O is supported over a dual redundant 10GbE backplane fabric (PICMG 3.1.9). Direct

connection to 10GbE and 1GbE ports on the front or rear supports specific cabling

requirements.

When used with Continuous Computing's FlexTCA systems and software, the PP50

provides the fastest path from application development to deployment revenue.

From IPTV to Wireless Core Networks, the PP50 can deploy a wide range of high

performance, scalable telecom applications.

Page 1-19

CC06786-11B

Confidential and Proprietary

Page 18

FlexPacket ATCA PP50 Packet Processor

P

r

e

l

i

m

i

n

a

r

y

1.1 Part Numbers and Options

1.1.1 Part Numbers

Part numbers below are the standard Continuous Computing part numbers. Customer-specific configurations may be assigned a unique part number.

Table 1-1: PP50 and Accessory Part Numbers

Description Part #

PP50 Boards

PP50, baseboard, dual 1GHz XLR732, four 1-GB 667 MHz memory 0-11126

PP50, baseboard, dual 1GHz XLR732, four 2-GB 667MHz memory 0-11127

Adapter Cable for Development

DB9 to micro-DB9 adapter cable used for development (6 feet). See

Section4.1, "Serial Console Access" for details.

PP50 Rear Transition Module

RTM, Ten 1GbE and two 10GbE (SFP/SFP+ cages only, excludes

modules). Only compatible with PP50

SFP/SFP+ Modules (for both FM40 and PP50)

Optical 10GbE 850nm SFP+ SR transceiver with “Limiting” receiver

output signal.

Optical 1GbE/2GbE, SFP-SX, 850nm, 550m reach, Ethernet/FC 5-02515

Copper SFP, 1000Base-T 5-02673

1.25/1.0625Gbps SFP 1310nm Fp Transceiver, Hot Pluggable 5-02714

10G SFP+ 1310nm Limiting, Hot Pluggable 5-02784

PP50 TCAM Mezzanines

PP50, 36 Mbit TCAM mezzanine 0-11760

PP50, 72 Mbit TCAM mezzanine 0-11761

5-02138

0-11024

5-02491

Page 1-20

User Manual

Continuous Computing Corporation

Page 19

P

r

e

l

i

m

1.1.2 Basic Configurations

The PP50 is shipped in the following configurations.

•2G per XLR

• 4G per XLR

• 8G per XLR

All use 667MHz DRAM.

1.1.3 RTM

One RTM works for all configurations. It supports two 10GbE and ten 1GbE ports.

It does not include SFP or SFP+ modules as standard.

1.1.4 Accessories

An optional TCAM mezzanine may be factory installed. Two sizes are offered:

Introduction

i

n

a

r

y

1

4ABAB

•36Mbit

•72Mbit

SFP or SFP+ modules can be ordered as required and they will be pre-integrated

Special serial cables (hydra cables) used for development are also available as a separate line item. See Section4.3.1, "Development Adapter (Hydra) Cable" for more

information about the cables.

Page 1-21

CC06786-11B

Confidential and Proprietary

Page 20

FlexPacket ATCA PP50 Packet Processor

P

r

e

l

i

m

i

n

a

r

y

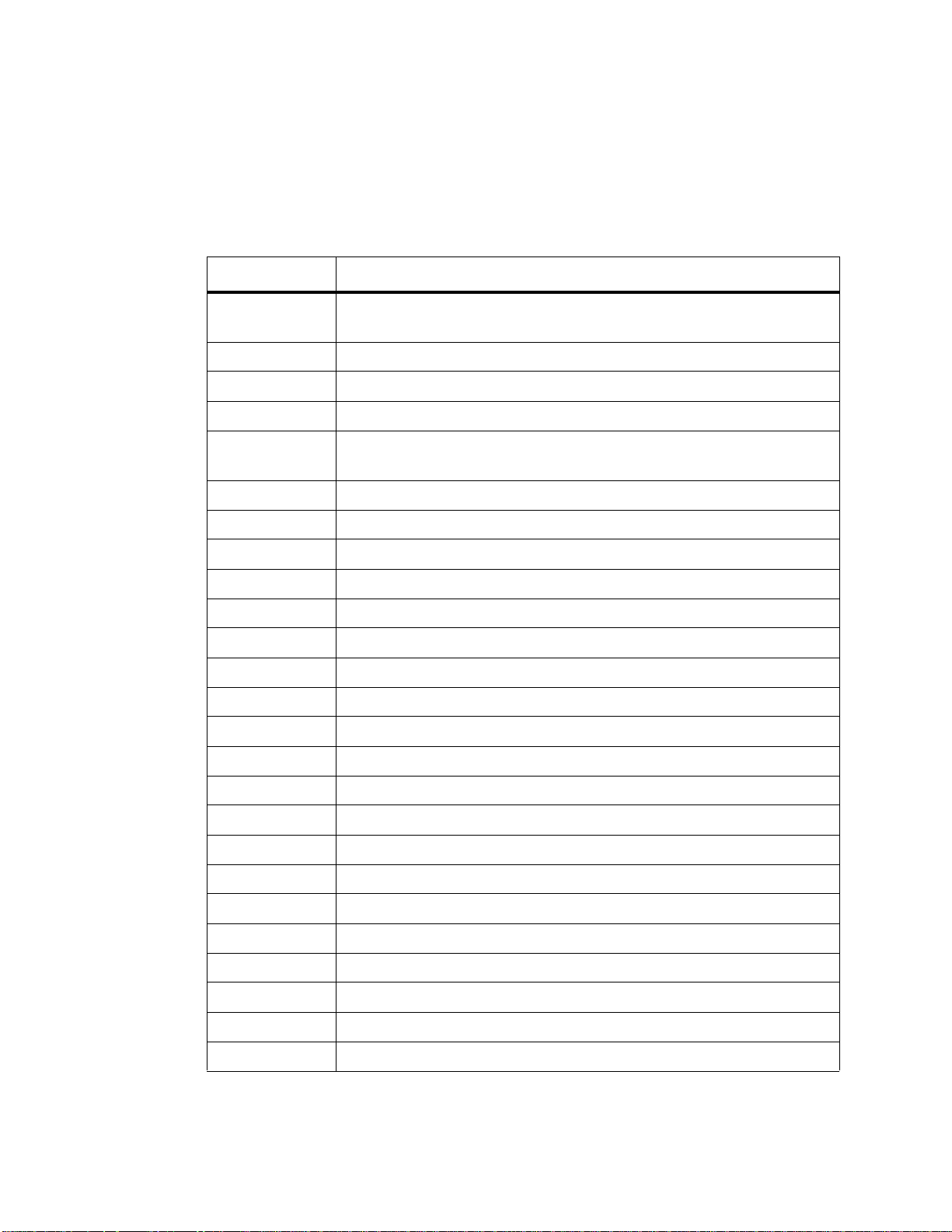

1.2 Glossary

The following table lists definitions for acronyms used in this document.

Table 1-2: Terms Used in this Document

Term Definition

SHMC A software package for acting as a Shelf Manager

10GbE Ten Gigabit Ethernet

1GbE One Gigabit Ethernet

BSWITCH Base Switch

CNODE The PPC 405+FPGA+FLASH+switch with whatever software

packages are running on it

CPLD Complex Programmable Logic Device

DDR2 Double Data Rate 2 (memory interface)

DHCP Dynamic Host Configuration Protocol

DIMM Dual In-Line Memory Module

FIFO First In First Out

FSWITCH Fabric Switch

I2C, IIC or I2CInter-IC Bus

IMS IP Multimedia Subsystem

IPMB Intelligent Platform Management Bus

IPMC Intelligent Platform Management Controller

IPMI Intelligent Platform Management Interface

JTAG Joint Test Action Group

NSE Network Search Engine

NFS Network File System

QDR Quad Data Rate

RAM Random Access Memory

RMCP Remote Management Control Protocol

ROM Read Only Memory

RTM Rear Transition Module

SCL I2C Bus Serial Clock

Page 1-22

User Manual

Continuous Computing Corporation

Page 21

P

r

e

l

i

m

i

n

a

Table 1-2: Terms Used in this Document

Introduction

r

y

1

Term Definition

TCA Telecommunications Computing Architecture

TCAM Ternary Content Addressable Memory

TFTP Trivial File Transfer Protocol

UART Universal Asynchronous Receiver Transmitter

VFAT Linux file system that is compatible with Windows FAT

XLR RMI’s multi-core CPU

4ABAB

Page 1-23

CC06786-11B

Confidential and Proprietary

Page 22

FlexPacket ATCA PP50 Packet Processor

P

r

e

l

i

m

i

n

a

r

y

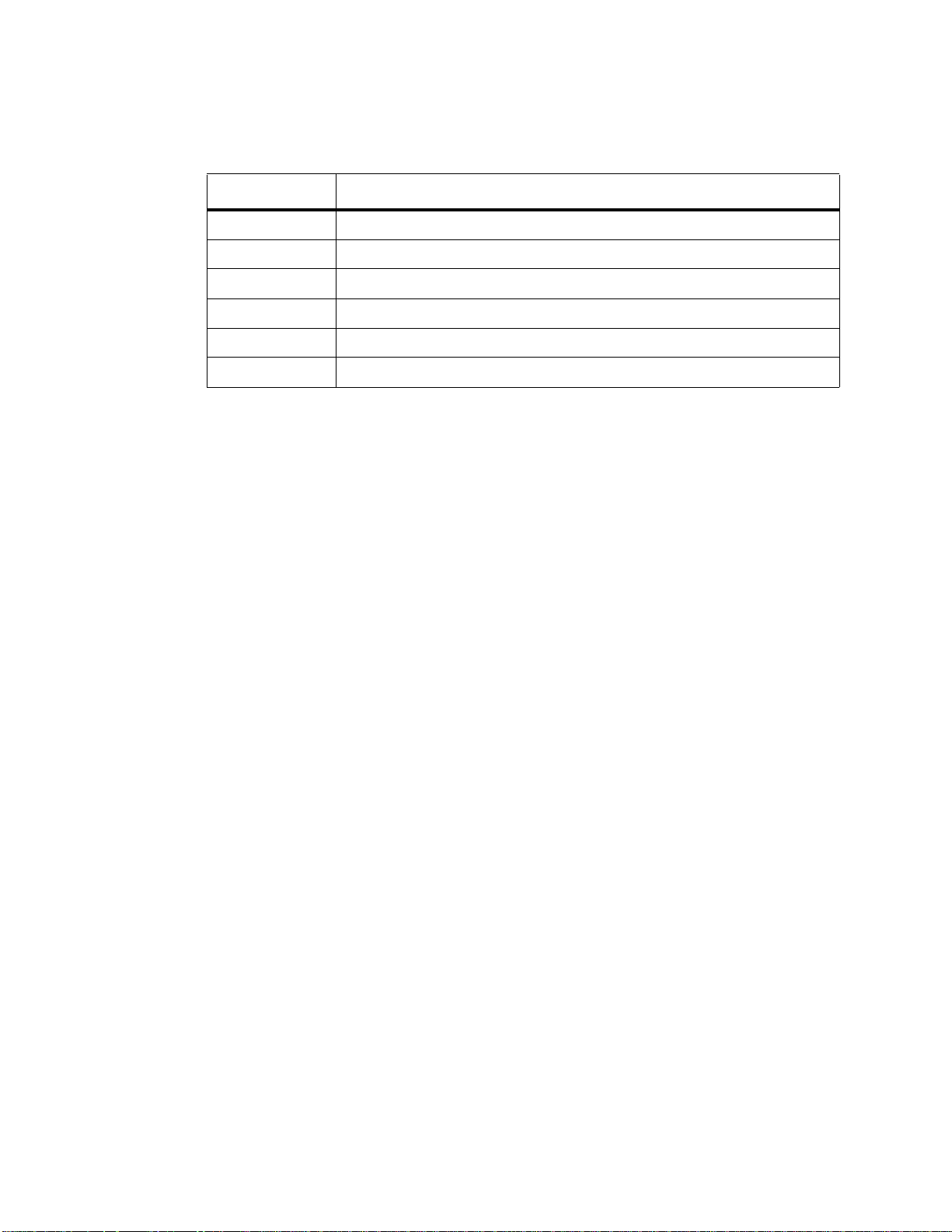

Notations

This table displays the notations used in this document:

Notation Explanation Examples

Arial Titles 1.1 Title

Book Antiqua Body text This is body text.

Bold Highlights information Loose coupling, tight coupling,

upper layer interface

Italics Document names,

emphasis

Command line input and output, and code is indicated by Courier New type and a

blue background as shown below.

PP50-1 $ iobus

IOBus Devices:

BaseAddr Size(KB) ChipSel Device

=============================================================================

0xbc000000 16384 0 cfiflash_0

Also note this document uses PDF page numbering compared to traditional number

schemes.

FlexPacket ATCA PP50 Packet

Processor

This must be installed.

Page 1-24

User Manual

Continuous Computing Corporation

Page 23

P

r

e

l

i

m

i

n

1.3 Additional Documentation

a

Introduction

r

y

1

This manual assumes you are familiar with the following documentation from RMI.

• RMI SDK Software Developer's Guide (referred to as “the RMI SDK Guide” in

this document)

• XLR Processor Family Programming Reference Manual

• TCAM User Manual (PN CC07478)

This document does not cover topics discussed in the above documents unless the

information is different for the PP50 platform.

You may also find it necessary to reference the MIPS 64 Architecture manuals, available for download from www.mips.org.

Finally, this manual assumes basic familiarity with setting up DHCP, TFTP, and

NFS servers, building Linux kernels, installing RPMs and tarballs, and using crosscompile tool chains.

4ABAB

Page 1-25

CC06786-11B

Confidential and Proprietary

Page 24

FlexPacket ATCA PP50 Packet Processor

P

r

e

l

i

m

i

n

a

r

y

Page 1-26

User Manual

Continuous Computing Corporation

Page 25

2

P

r

e

l

i

m

i

n

a

r

y

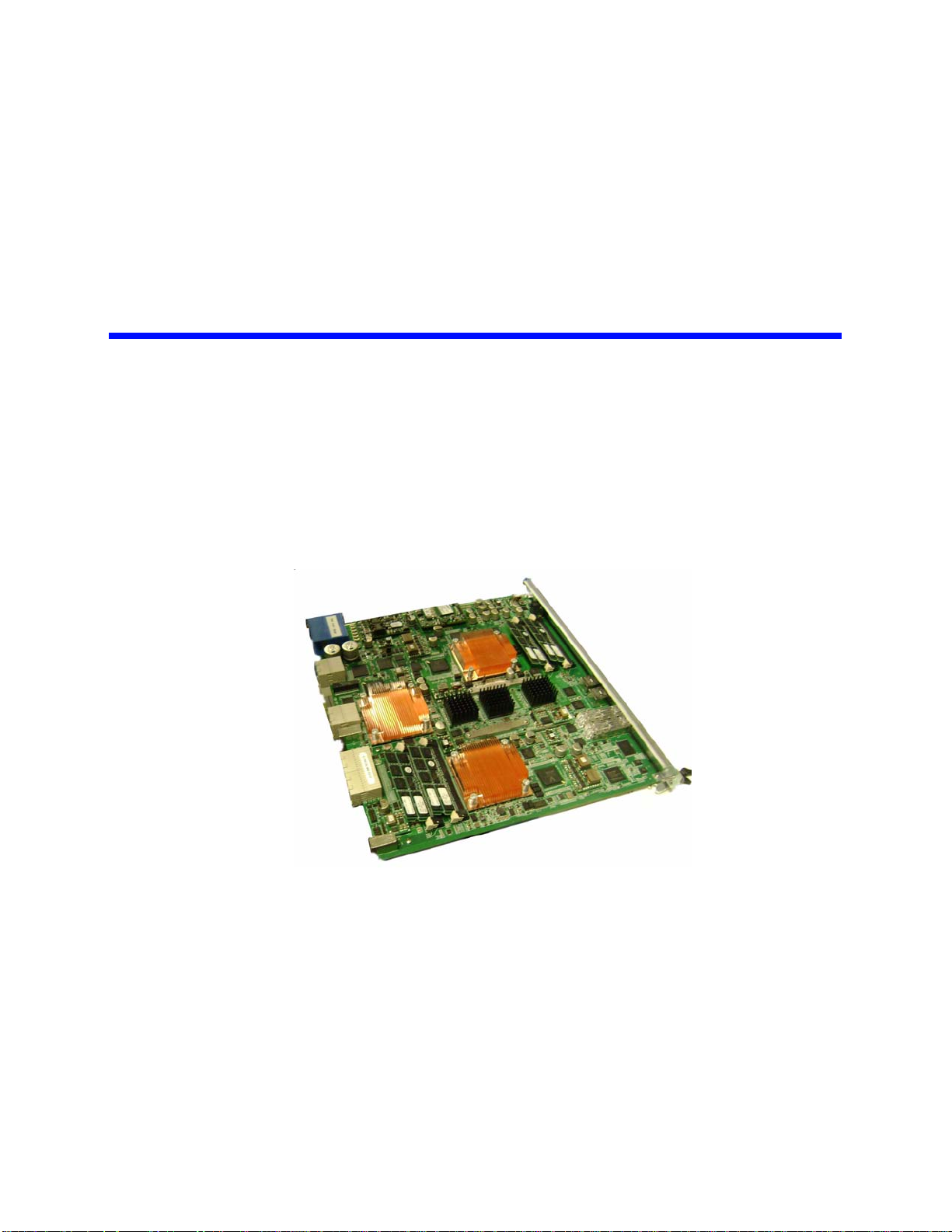

2Technical Overview

This chapter describes PP50 main features and gives an overview of the hardware

and software.

Figure 2-1: PP50 Overview Photo

Page 2-27

CC06786-11B

Confidential and Proprietary

Page 26

FlexPacket ATCA PP50 Packet Processor

P

r

e

l

i

m

i

n

a

r

y

2.1 Main Features

The PP50’s major subsystems are described in this section.

2.1.1 RMI Processor Subsystem

The RMI processor subsystem includes dual RMI XLR7xx BGA1605 CPU sites; a

PP50 can support any CPU in any of those families with the proper assembly

changes. See Section2.2.5, "RMI Processor CPU Subsystem" for processor subsystem details.

The RMI XLR processors support up to eight MIPS 64 bit RISC cores, each having 4

individual execution threads for a total of 32 execution threads.

See Table 2-1 "RMI XLR Family Configurations" for a reduced feature parts as list

for this processor family.

The PP50 supports reduced configurations based on these parts, but the default configuration is two XLR732s fully populated devices.

2.1.2 Ethernet Switch Module

FM2112/FM3112 (Fulcrum Microelectronics) Ethernet switch module, described in

detail in Section2.2.6, "Fabric and Base Switch Modules". The onboard fabric

Ethernet and base Ethernet switches facilitate connectivity. The fabric switch is a

layer 2 device that provides 10GbE connectivity for the CPUs as well as multiple

1GbE data paths. The base switch facilitates communication between the two XLR

CPUs, IPMC controller and two base interfaces.

2.1.3 RTM Interface

The PP50 supports a rear transition module (RTM) that includes a protected power

supply, a management interface to the IPMC, ten 1GbE interfaces and two 10GbE

interfaces.

Page 2-28

User Manual

Continuous Computing Corporation

Page 27

P

OOS

IS

ATTN

H/S

LNK and ACT

LEDs

Ports

10G 1

10G 2

CPU1

CPU2

CONSOLE

r

2.2 Hardware Overview

e

l

i

m

Technical Overview

i

n

a

r

y

1

2.2.1 Front Panel Ports

• 10GE.1: SFP+ port (IEEE 802.3 10GBASE-X)

• 10GE.2: SFP+ port (IEEE 802.3 10GBASE-X)

• CPU.1: RJ45 Connector to XLR 0

• CPU.2: RJ45 Connector to XLR 1

See Section2.2.10.1, "LEDs"for a description the LED indicators.

4ABAB

Figure 2-2: Front Panel

2.2.2 Backplane Interface

The PP50 is designed as a node board in an ATCA system. Its backplane interface is

compatible with the PICMG3.0 R2.0 specification.

Confidential and Proprietary

Page 2-29

CC06786-11B

Page 28

FlexPacket ATCA PP50 Packet Processor

P

r

e

l

i

m

i

n

a

r

y

2.2.3 Connectors

2.2.3.1 Internal Connectors

J15 - XLR CPU 2 Memory Channel AB Mini-DIMM Connector

J17 - XLR CPU 2 Memory Channel CD Mini-DIMM Connector

J18 - XLR CPU 1 Memory Channel AB Mini-DIMM Connector

J21 - XLR CPU 1 Memory Channel CD Mini-DIMM Connector

J52 - XLR CPU 2 CF card connector

J53 - XLR CPU 1 CF card connector

J54 - Extended JTAG connector from JTAG CPLD

J56 - JTAG connector for JTAG CPLD

J100 - Internal Mezzanine card connector

J101 - Internal Mezzanine card connector

J102 - JTAG connector for XLR CPU 1

J103 - JTAG connector for XLR CPU 2

J110 - JTAG connector for IPMC

2.2.3.2 External Connectors

J11 - Micro-DB9 Console Port

J104 - RJ45 Connector for XLR Module 1 (XLR0)

J105 - RJ45 Connector for XLR Module 2 (XLR1)

J109 - Two 10G SFP plus Ports connector

2.2.3.3 ATCA Connectors

P10 - ATCA Zone 1 Power Connector

J20 / J23 - ATCA Zone 2 connectors

J26 / J27 - ATCA Zone 3 connectors to RTM

Page 2-30

User Manual

Continuous Computing Corporation

Page 29

P

CF Flash

PSRAM

XLR732

)

DDRII DIMM

Four

GE MAC

Two 72bit

DRAM

interface

Two

10GE MAC

Local BUS

PCI- X BUS

Boot

Flas h

SRAM /

LA-1

HT BUS

CF Flash

PSRAM

XLR732

DDRII DIMM

Four

GE MAC

Two 72bit

DRAM

interface

L ocal BUS

Boot

Flash

SRAM /

LA-1

Two

10GE MAC

FM 2112

Core Switch

P1

P2

P24

Host Interfa ce

P9

P4

P6

P3

P8

P5

P7 P13

P11

P15

P21

P19

P23

P22

P20

P18

P17

P10

P16

P14

P12

RGMII

TCAM or QDRII

Mezzanine

HT Co- processor

Mezzanine

LA-1

LA-1

HT 8bit

PM8380

MUX

SPF+

Module

PM8380

MUX

XUAI

XUAI

MUX

or Resistor

RESISTOR

XUAI or

1000 BASE-X

XUAI or

1000 BASE-X

1000BASE-X

1000BASE-X

SPF+

Module

S

F

I

S

F

I

XUAI

XUAI

RTM

2

x

1

0

G

E

10 x 1GE

Fabric

10GE

(or 4x GE)

10GE

(or 4x GE)

Channel 2

Channel1

BCM5389

Base Switch

P

P

P

P

P

P

P

P

VSC7280

Dual

XGMII-XAUI PHY

XGMII

VSC7280

Dual

XGMII-XAUI PHY

XGMII

XUAI

XUAI

XUAI

XUAI

X

U

A

I

X

U

A

I

Base

Channel 1

Channel 2

BCM5482

1000 BASE-T

RJ45

RJ45

1000 BASE-T

1000 BASE-T

1000 BASE-X

1000 BASE-X

MII

I2C MDIO

I2C

MDIO

From IPMC

From IPMC

BCM5482

Dual PHY

BCM5482

Dual PHY

RGMII

BCM5482

Dual PHY

BCM5482

Dual PHY

AEL2005

BCM8706

16bit bus

405EZ

IPMC

Managed

by IPMC

IPMB A

IPMB B

FPGA

CRAM

FW2112

r

e

l

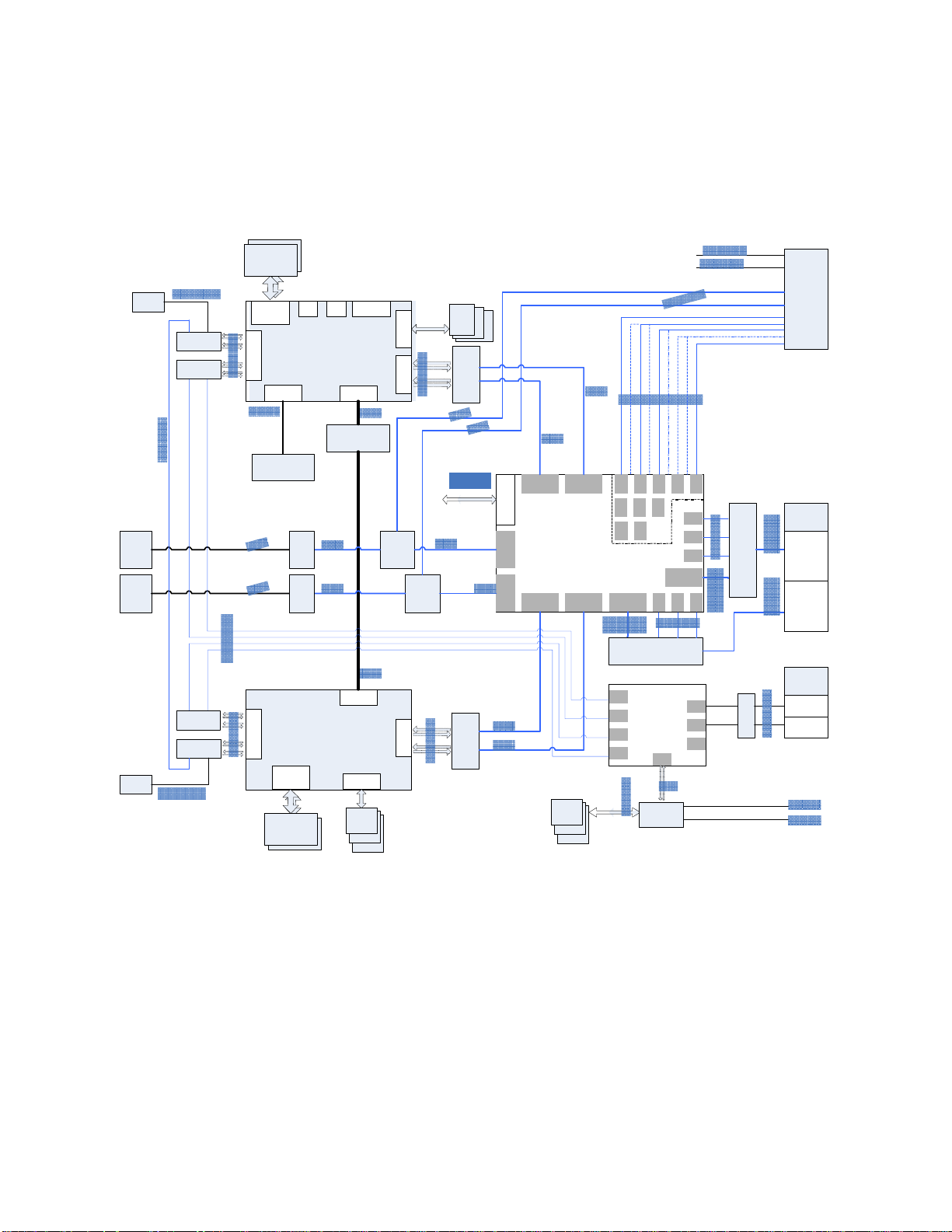

2.2.4 Graphical Overview

The following diagram provides a graphical overview the PP50’s hardware. The

zoom tool in your viewer may be used to magnify sections of interest.

i

m

Technical Overview

i

n

a

r

y

1

4ABAB

Page 2-31

Confidential and Proprietary

CC06786-11B

Figure 2-3: Overall Hardware Block Diagram.

Page 30

FlexPacket ATCA PP50 Packet Processor

P

r

e

l

i

m

i

n

a

r

y

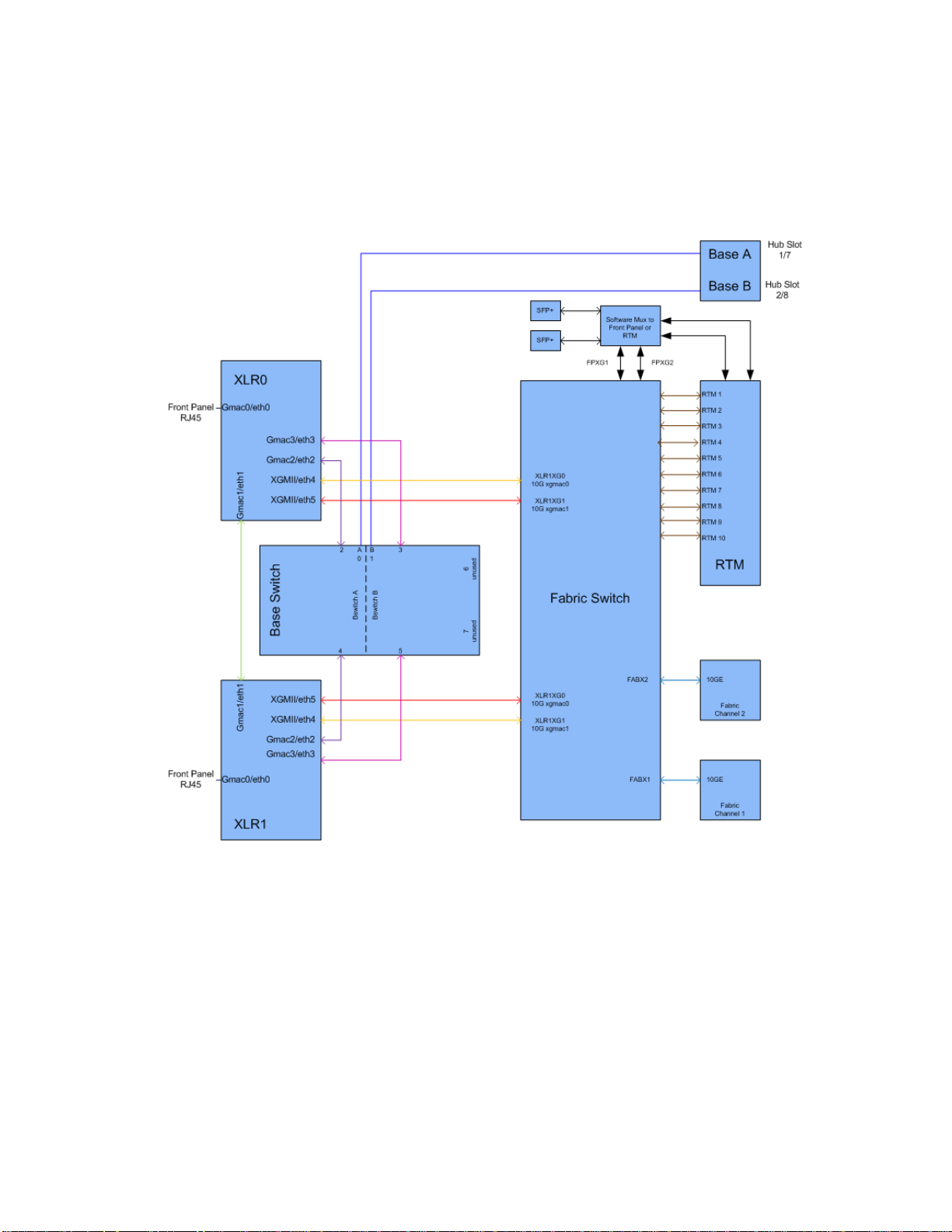

The diagram below shows connections between the PP50’s Base and Fabric

components.

Page 2-32

User Manual

Continuous Computing Corporation

Figure 2-4: Base and Fabric Connection Diagram.

Page 31

P

C ompact

Flash

CORE5

THREAD 17

THREAD 18

THREAD 19

THREAD 20

ICache

DCache

CORE6

THREAD 21

THREAD 22

THREAD 23

THREAD 24

ICache

DCache

CORE7

THREAD 25

THREAD 26

THREAD 27

THREAD 28

ICache

DCache

CORE8

THREAD 29

THREAD 30

THREAD 31

THREAD 32

ICache

DCache

To TCAM

Mezzanine

DDR2 DIMMDDR2 DIMM

RGMII A

RGMII B

RGMII C

RGMII D

GE MAC

GE MAC

GE MAC

GE MAC

SRAM /

LA-1

MEM AB MEM CD

10 GE

MAC

10 GE

MAC

XGMII A

XGMII B

Local

BUS

PCI-X

BUS

UART 1

UART 2

HT BUS

Boot

Flash

Console Serial Port

Command Serial Port

CPU sub- system

To Co- Processor

Mezzanine

VSC7280

Dual XGMII- XAUI

XAUI A XAUI B

I2C

CORE1

THREAD 1

THREAD 2

THREAD 3

THREAD 4

ICache

DCache

CORE2

THREAD 5

THREAD 6

THREAD 7

THREAD 8

ICache

DCache

CORE3

THREAD 9

THREAD 10

THREAD 11

THREAD 12

ICache

DCache

CORE4

THREAD 13

THREAD 14

THREAD 15

THREAD 16

ICache

DCache

RAZA XLR

8bit

8bit

PSRAM

10/100/

1000 base-T

1000BASE-X

1000BASE-X

1000BASE-X

To Front

Panel

To the other

CPU module

To Base

Switch

To Core Switch To Core Switch

To Base

Switch

C ontrol

CPLD

(XLR1 Only

)

BCM5482

Dual PHY

BCM5482

Dual PHY

r

e

l

i

m

i

n

a

r

y

2.2.5 RMI Processor CPU Subsystem

Technical Overview

1

4ABAB

Figure 2-5: RMI Processor CPU Subsystem

The PP50 uses two XLR7xx CPU sites. They are identical, except that the XLR at site

1 can access the co-processor mezzanine through the bus. The features of the CPU

subsystems are described below and shown in Figure 2-5 "RMI Processor CPU

Subsystem".

• RMI XLR7xx BGA1605 CPU sites; the PP50 can support any CPU in any of

those families with the proper assembly changes. They include the following

XLR Family of CPUs:

Table 2-1: RMI XLR Family Configurations

Part x32

XLR7xx 8 Cores, 32threads four 1GbE; two 10GbE

• Two 244 pin DDR2 Mini-DIMM sockets supporting standard 1.8V DDR2 MiniDIMMs

- One DIMM on memory channel A/B

- One DIMM on memory channel C/D

- Up to 800MHz DDR2 data rates

-Up to 4GB for each DIMM

Page 2-33

CC06786-11B

Confidential and Proprietary

Page 32

FlexPacket ATCA PP50 Packet Processor

P

r

e

l

i

m

i

n

a

r

y

•LA-1 Interface

- Connected to a mezzanine for TCAM add on options