UTMC 5962R9684504VXC, 5962R9684504VXA, 5962R9684504QYX, 5962R9684504QYC, 5962R9684504QYA Datasheet

...

FEATURES

q 45ns and 55ns maximum address access time

q Asynchronous operation for compatibility with industry-

standard 4K x 8/9 dual-port static RAM

q CMOS compatible inputs, TTL/CMOS compatible output

levels

q Three-state bidirectional data bus

q Low operating and standby current

q Radiation-hardened process and design; total dose

irradiation testing to MIL-STD-883 Method 1019

- Total-dose: 1.0E6 rads(Si)

- Memory Cell LET threshold: 85 MeV-cm2/mg

- Latchup immune (LET >100 MeV-cm2/mg)

q QML Q and QML V compliant part

q Packaging options:

- 68-lead Flatpack

- 68-pin PGA

q 5-volt operation

q Standard Microcircuit Drawing 5962-96845

INTRODUCTION

The UT7C138 and UT7C139 are high-speed radiationhardened CMOS 4K x 8 and 4K x 9 dual-port static RAMs.

Arbitration schemes are included on the UT7C138/139 to

handle situations when multiple processors access the same

memory location. Two ports provide independent,

asynchronous access for reads and writes to any location in

memory. The UT7C138/139 can be utilized as a stand-alone

32/36-Kbit dual-port static RAM or multiple devices can be

combined in order to function as a 16/18-bit or wider master/

slave dual-port static RAM. For applications that require

depth expansion, the BUSY pin is open-collector allowing

for wired OR circuit configuration. An M/ S pin is provided

for implementing 16/18-bit or wider memory applications

without the need for separate master and slave devices or

additional discrete logic. Application areas include

interprocessor/multiprocessor designs, communications,

and status buffering.

Each port has independent control pins: chip enable (CE),

read or write enable (R/ W), and output enable (OE). BUSY

signals that the port is trying to access the same location

currently being accessed by the other port.

Standard Products

UT7C138/139 4Kx8/9 Radiation-Hardened

Dual-Port Static RAM with Busy Flag

Data Sheet

January 2002

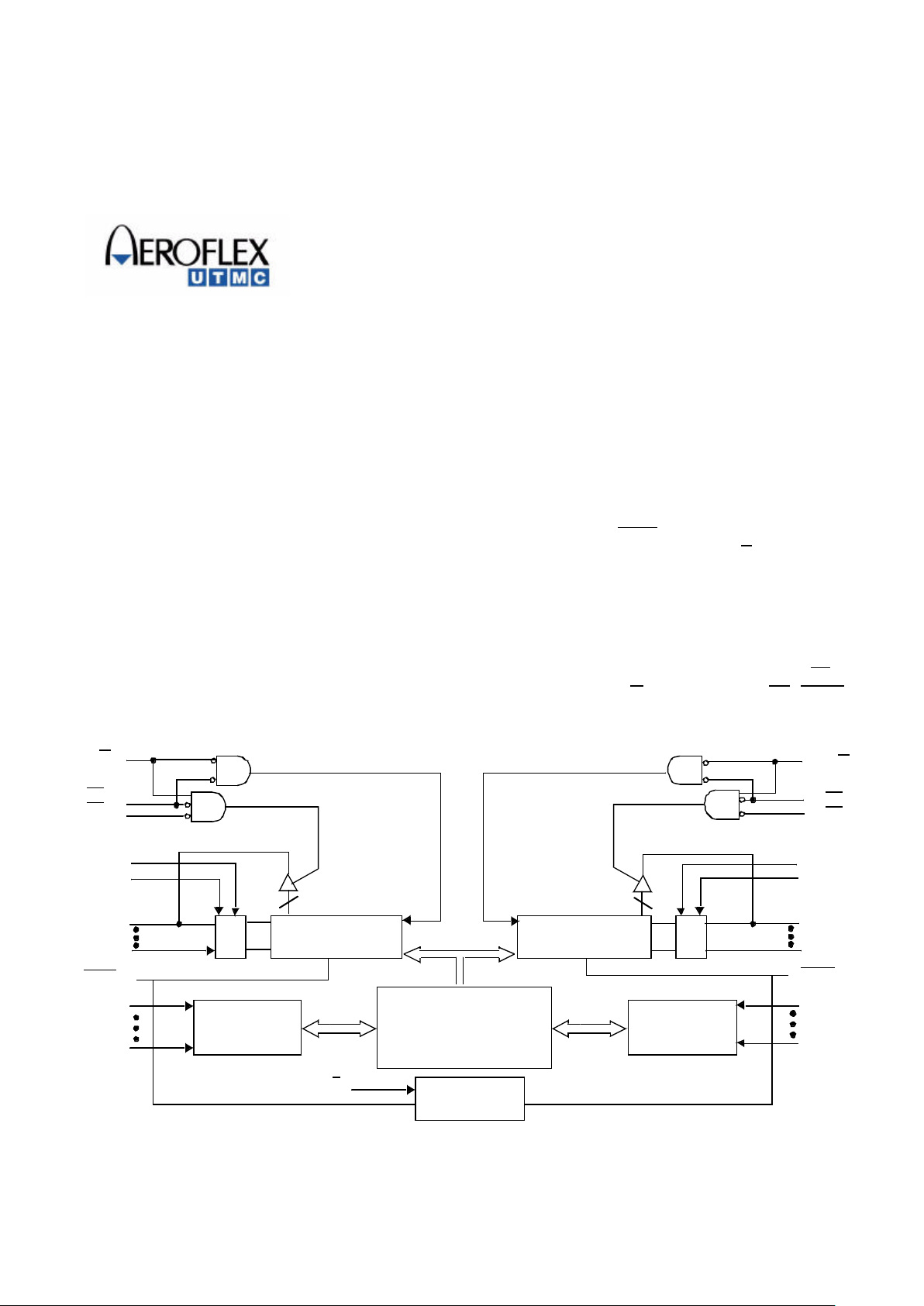

Figure 1. Logic Block Diagram

MEMORY

ARRAY

ROW

SELECT

ROW

SELECT

COL

SEL

COL

SEL

COLUMN

I/O

COLUMN

I/O

R/W

L

CE

L

OE

L

A

11L

A

10L

A

9L

A

0L

R/W

R

CE

R

OE

R

A

11R

A

10R

A

9R

A

0R

I/O

7L

I/O8L (7C139)

I/O

7R

I/O8R (7C139)

I/O

0L

I/O

0R

ARBITRATION

BUSY

L

BUSY

R

M/S

2

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

9

8

7

6

5

4

3

2

1

68

67

66

65

64

63

62

61

7C138/139

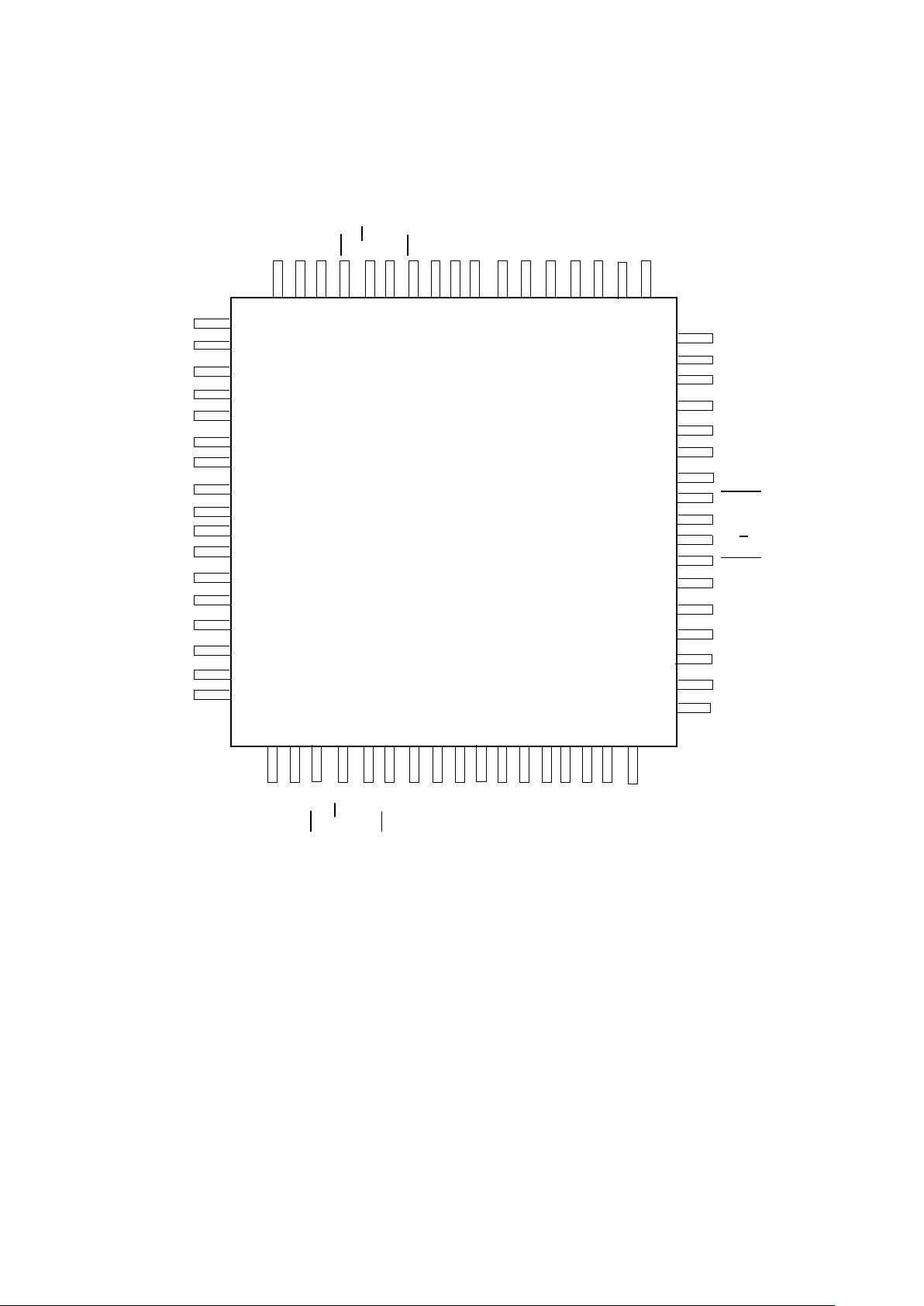

Figure 2a. DPRAM Pinout (68-Flatpack)

(top view)

A

5L

A

4L

A

3L

A

2L

A

1L

A

0L

NC

BUSY

L

GND

M/S

BUSY

R

NC

A

0R

A

1R

A

2R

A

3R

A

4R

I/O

7R

NC

(1)OER

R/WRNC

CERNC

NC

GND

NC

A

11RA10RA9RA8RA7RA6RA5R

I/O1LI/O0LNC

(2)

OE

R/WLNC

CELNC

NC

VDDNC

A11LA10LA9LA8LA7LA6

L

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

I/O

2L

I/O

3L

I/O

4L

I/O

5L

GND

I/O

6L

I/O

7L

V

DD

GND

I/O

0R

I/O

1R

I/O

2R

V

DD

I/O

3R

I/O

4R

I/O

5R

I/O

6R

Notes:

1. I/O8R on the7C139

2. I/O8L on the 7C139

3

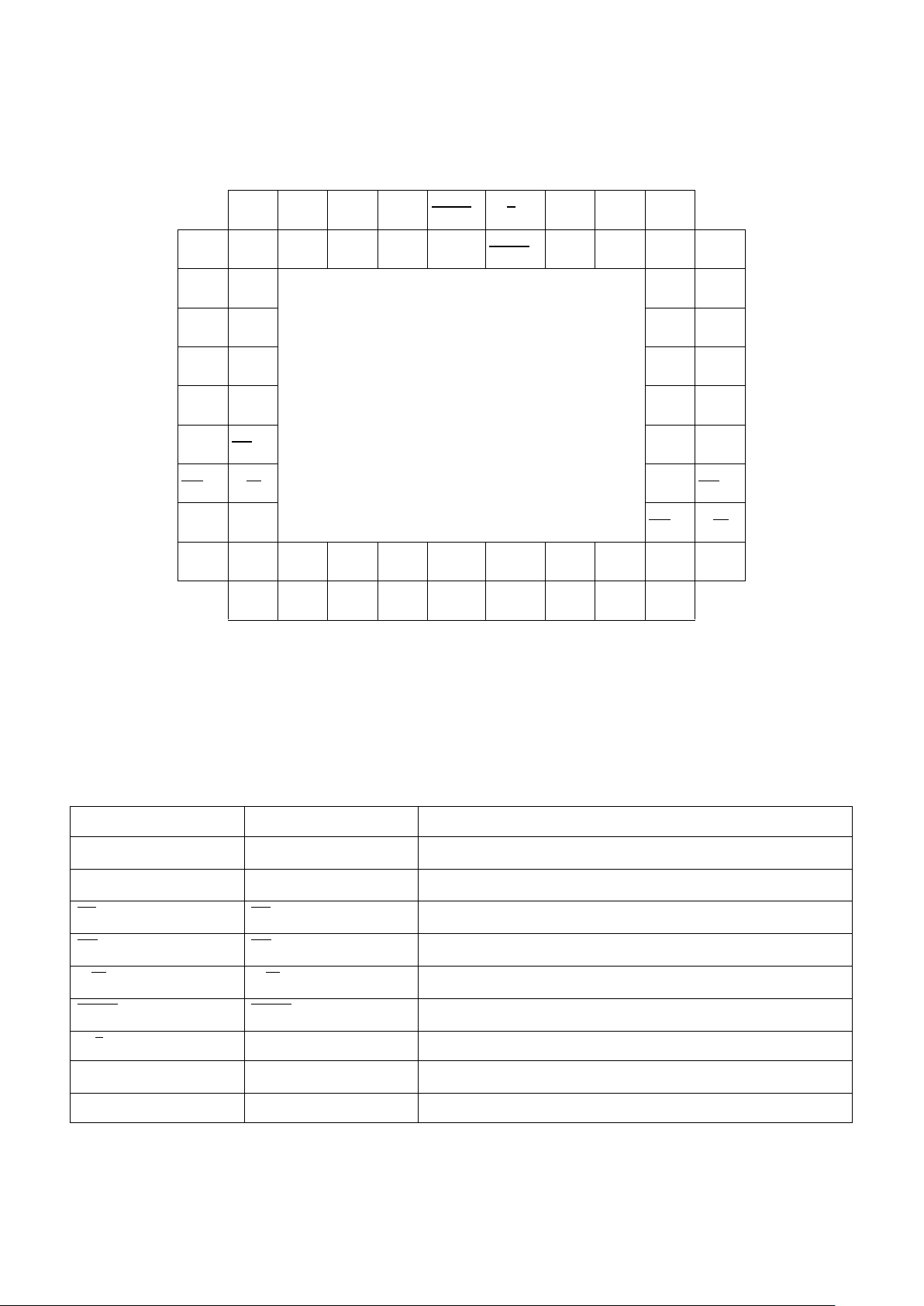

Figure 2b: DPRAM Pinout (68 PGA)

(top view)

Notes:

1. I/O8R on the7C139

2. I/O8L on the 7C139

PIN NAMES

B11

A

5L

C11

A

4L

D11

A

2L

E11

A

0L

F11

BUSY

L

G11

M/S

H11NCJ11

A

1R

K11

A

3R

A10

A

7L

B10

A

6L

C10

A

3L

D10

A

1L

E10NCF10

GND

G10

BUSY

R

H10

A

0R

J10

A

2R

K10

A

4R

L10

A

5R

A9

A

9L

B9

A

8L

K9

A

7R

L9

A

6R

A8

A

11L

B8

A

10L

K8

A

9R

L8

A

8R

A7

V

DD

B7

NC

K7

A

11R

L7

A

10R

A6

NCB6NC

K6

GNDL6NC

A5

NCB5CE

L

K5NCL5

NC

A4

OE

L

B4

R/W

L

K4NCL4

CE

R

A3

I/O

0L

B3

NC

(2)

K3

OE

R

L3

R/W

R

A2

I/O

1L

B2

I/O

2L

C2

I/O

4L

D2

GNDE2I/O

7L

F2

GNDG2I/O

1R

H2

V

DD

J2

I/O

4R

K2

I/O

7R

L2

NC

(1)

B1

I/O

3L

C1

I/O

5L

D1

I/O

6L

E1

V

DD

F1

I/O

0R

G1

I/O

2R

H1

I/O

3R

J1

I/O

5R

K1

I/O

6R

LEFT PORT RIGHT PORT DESCRIPTION

I/O

0L-7L(8L)

I/O

0R-7R(8R)

Data Bus Input/Output

A

0L-11L

A

0R-11R

Address Lines

CE

L

CE

R

Chip Enable

OE

L

OE

R

Output Enable

R/W

L

R/W

R

Read/Write Enable

BUSY

L

BUSY

R

Busy Flag Input/Output

M/S Master or Slave Select

V

DD

Power

GND Ground

7C138/139

11

10

9

8

7

6

5

4

3

2

1

A B C D E F H J K LG

4

The UT7C138/139 consists of an array of 4K words of 8 or 9

bits of dual-port SRAM cells, I/O and address lines, and control

signals (CE, OE, R/W). These control pins permit independent

access for reads or writes to any location in memory. To handle

simultaneous writes/reads to the same location, a BUSY pin is

provided on each port. With the M/S pin, the UT7C138/139 can

function as a master (BUSY pins are outputs) or as a slave

(BUSY pins are inputs). Each port is provided with its own

output enable control (OE), which allows data to be read from

the device.

WRITE CYCLE

A combination of R/W less than VIL (max), and CE less than

VIL (max), defines a write cycle. The state of OE is a “don’t

care” for a write cycle. The outputs are placed in the high-

impedance state when either OE is greater than VIH (min), or

when R/W is less than VIL (max).

WRITE OPERATION

Write Cycle 1, the Write Enable-controlled Access shown in

figure 4a, is defined by a write terminated by R/W going high

with CE active. The write pulse width is defined by t

PWE

when

the write is initiated by R/W, and by t

SCE

when the write is

initiated by CE going active. Unless the outputs have been

previously placed in the high-impedance state by OE, the user

must wait t

HZOE

before applying data to the eight/nine

bidirectional pins I/O(0:7/0:8) to avoid bus contention.

Write Cycle 2, the Chip Enable-controlled Access shown in

figure 4b, is defined by a write terminated by CE going inactive.

The write pulse width is defined by t

PWE

when the write is

initiated by R/ W, and by t

SCE

when the write is initiated by CE

going active. For the R/ W initiated write, unless the outputs have

been previously placed in the high-impedance state by OE, the

user must wait t

HZWE

before applying data to the eight/nine

bidirectional pins I/O(0:7/0:8) to avoid bus contention.

If a location is being written by one port and the opposite port

attempts to read that location, a port-to-port flow through delay

must be met before the data is read on the output. Data will be

valid on the port wishing to read the location (t

BZA

+ t

BDD

) after

the data is written on the other port (see figure 5a).

READ OPERATION

When reading the device, the user must assert both the OE and

CE pins. Data will be available t

ACE

after CE or t

DOE

after OE

is asserted (see figures 3a and 3b).

MASTER/SLAVE

A M/ S pin is provided in order to expand the word width by

configuring the device as either a master or a slave. The BUSY

output of the master is connected to the BUSY input of the slave.

Writing of slave devices must be delayed until after the BUSY

input has settled. Otherwise, the slave chip may begin a write

cycle during a contention situation. When presented as a HIGH

input, the M/S pin allows the device to be used as a master and,

therefore, the BUSY line is an output. BUSY can then be used

to send the arbitration outcome to a slave. When presented as a

LOW input, the M/S pin allows the device to be used as a slave,

and, therefore, the BUSY pin is an input.

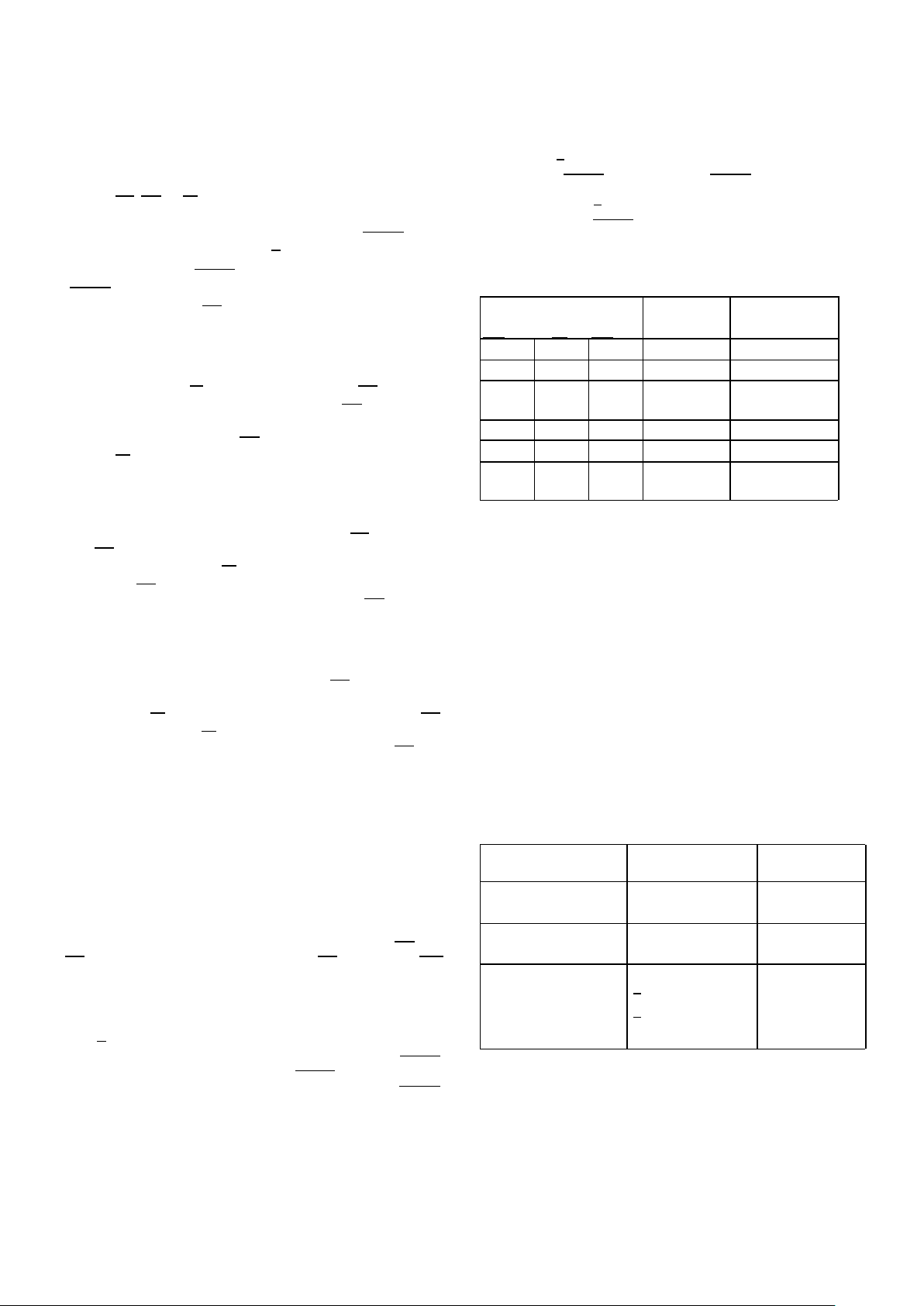

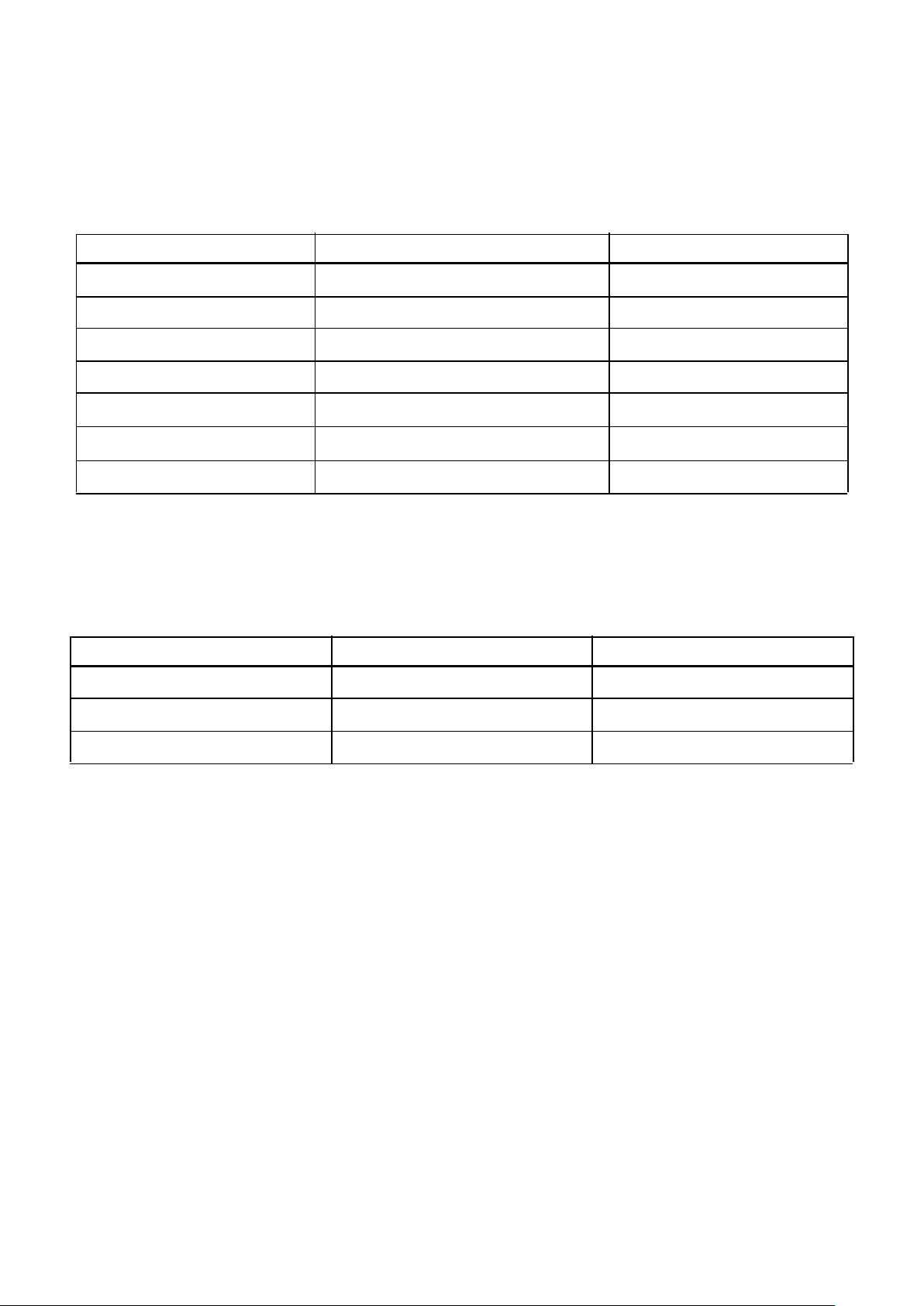

Table 1. Non-Contending Read/Write

RADIATION HARDNESS

The UT7C138/139 incorporates special design and layout

features which allow operation in high-level radiation

environments. UTMC has developed special low-temperature

processing techniques designed to enhance the total-dose

radiation hardness of both the gate oxide and the field oxide

while maintaining the circuit density and reliability. For

transient radiation hardness and latchup immunity, UTMC

builds all radiation-hardened products on epitaxial wafers using

an advanced twin-tub CMOS process. In addition, UTMC pays

special attention to power and ground distribution during the

design phase, minimizing dose-rate upset caused by rail

collapse.

Table 2. Radiation Hardness

Design Specifications

1

Notes:

1. The DPRAM will not latchup during radiation exposure under recommended

operating conditions.

2. Not tested for CMOS technology.

INPUTS OUTPUTS

CE R/W OE I/O

0-7

OPERATION

H X X High Z Power Down

X X H High Z I/O Lines

Disabled

L H L Data Out Read

L L X Data In Write

L X X --- Illegal

Condition

Total Dose 1.0E6 rads(Si)

LET Threshold 85

MeV-cm2/mg

Neutron Fluence

2

3.0E14

n/cm

2

Memory Device

Cross Section @ LET

= 120MeV-cm2/mg

< 1.376E-2 (4Kx8)

< 1.548E-2 (4Kx9)

cm

2

5

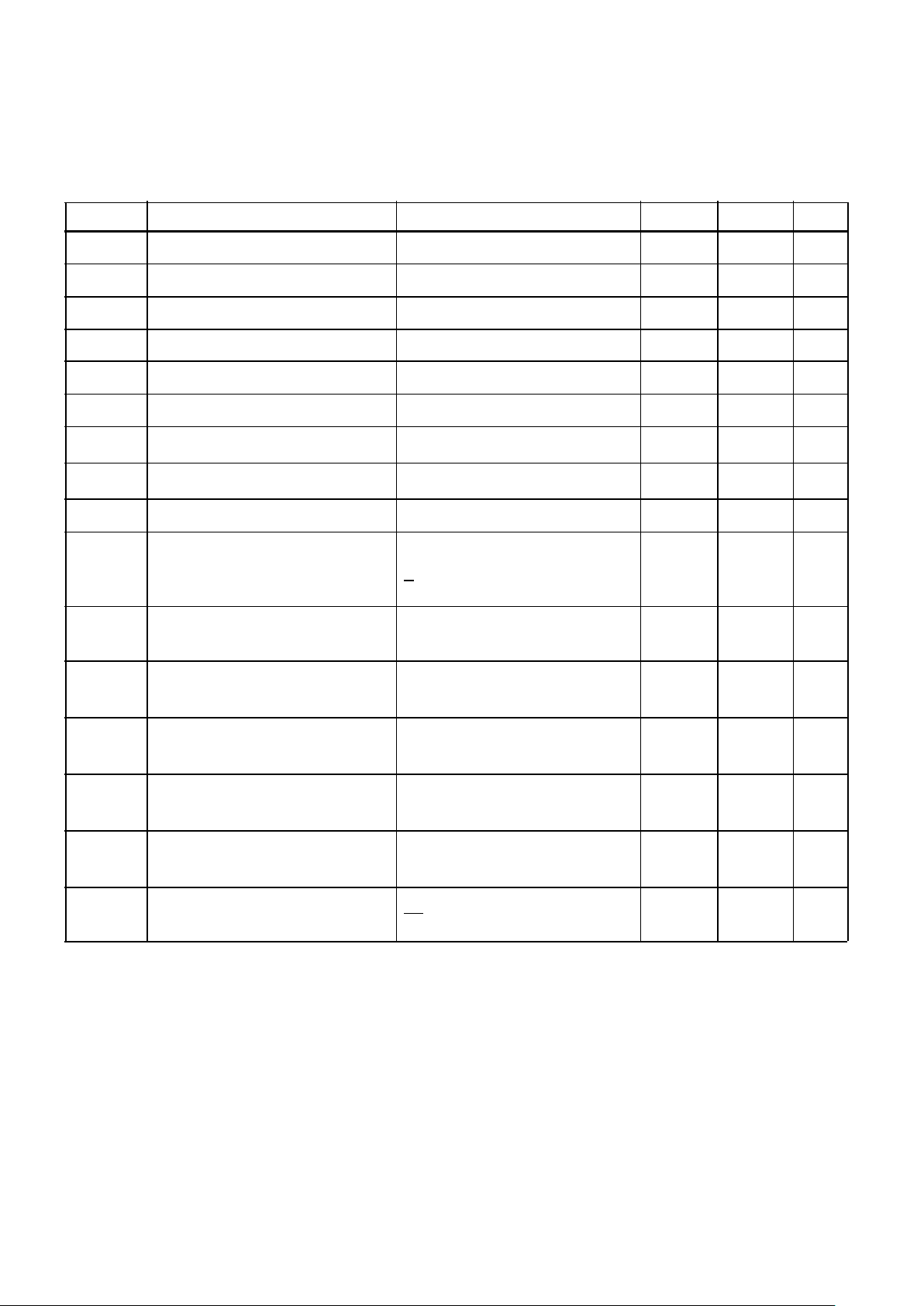

ABSOLUTE MAXIMUM RATINGS

1

(Referenced to VSS)

Notes:

1. Stresses outside the listed absolute maximum ratings may cause permanent damage to the device. This is a stress rating only, and functional operation of the device

at these or any other conditions beyond limits indicated in the operational sections of this specification is not recommended. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

2. Maximum junction temperature may be increased to +175°C during burn-in and steady-static life.

3. Test per MIL-STD-883, Method 1012, infinite heat sink.

RECOMMENDED OPERATING CONDITIONS

SYMBOL PARAMETER LIMITS

V

DD

DC supply voltage -0.5 to 7.0V

V

I/O

Voltage on any pin -0.5 to (V

DD

+ 0.3)V

T

STG

Storage temperature -65 to +150 °C

P

D

Maximum power dissipation 2.0W

T

J Maximum junction temperature

2

+150°C

Θ

JC Thermal resistance, junction-to-case

3

3.3°C/W

I

I

DC input current

±10 mA

SYMBOL PARAMETER LIMITS

V

DD

Positive supply voltage 4.5 to 5.5V

T

C

Case temperature range -55 to +125°C

V

IN

DC input voltage 0V to V

DD

6

DC ELECTRICAL CHARACTERISTICS (Pre/Post-Radiation )*

(VDD = 5.0V ±10%; -55°C < TC < +125 °C)

Notes:

* Post-radiation performance guaranteed at 25°C per MIL-STD-883 Method 1019.

1. Measured only for initial qualification and after process or design changes that could affect input/output capacitance.

2. Supplied as a design limit but not guaranteed or tested.

3. Not more than one output may be shorted at a time for maximum duration of one second.

4. VIH = 5.5V, VIL = 0V.

5. IDD (OP) derates at 6.4mA/MHz.

6. IDD (OP) derates at 3.4mA/MHz.

SYMBOL PARAMETER CONDITION MIN MAX UNIT

V

IH

High-level input voltage (CMOS) 0.7V

DD

V

V

IL

Low-level input voltage (CMOS) 0.3V

DD

V

V

OL

Low-level output voltage IOL = 8mA, V

DD

= 4.5V (TTL) 0.4 V

V

OL

Low-level output voltage IOL = 200µA, VDD = 4.5V (CMOS) 0.05 V

V

OH

High-level output voltage IOH = -4mA, VDD = 4.5V (TTL) 2.4 V

V

OH

High-level output voltage IOH = -200µA, VDD = 4.5V (CMOS) 4.45 V

C

IN

1

Input capacitance ƒ = 1MHz @ 0V 25 pF

C

IO

1

Bidirectional I/O capacitance ƒ = 1MHz @ 0V 25 pF

I

IN

Input leakage current VIN = VDD and V

SS

-10 10 µA

I

OZ

Three-state output leakage current VO = VDD and V

SS

VDD = 5.5V

G = 5.5V

-10 10 µA

I

OS

2,3

Short-circuit output current VDD = 5.5V, VO = V

DD

VDD = 5.5V, VO = 0V

-90

90 mA

mA

IDD(OP)

4,5

Supply current operating (both ports)

@ 22.2MHz

CMOS inputs (I

OUT

= 0)

VDD = 5.5V

300 mA

IDD(OP)

4,6

Supply current operating (single port)

@ 22.2 MHz

CMOS inputs (I

OUT

= 0)

VDD = 5.5V

150 mA

IDD(OP)

4,5

Supply current operating (both ports)

@ 18.2MHz

CMOS inputs (I

OUT

= 0)

VDD = 5.5V

275 mA

IDD(OP)

4,6

Supply current operating (single port)

@ 18.2 MHz

CMOS inputs (I

OUT

= 0)

VDD = 5.5V

138 mA

IDD(SB)

4

Supply current standby CMOS inputs (I

OUT

= 0)

CE = V

DD

- 0.5, V

DD

= 5.5V

1 mA

7

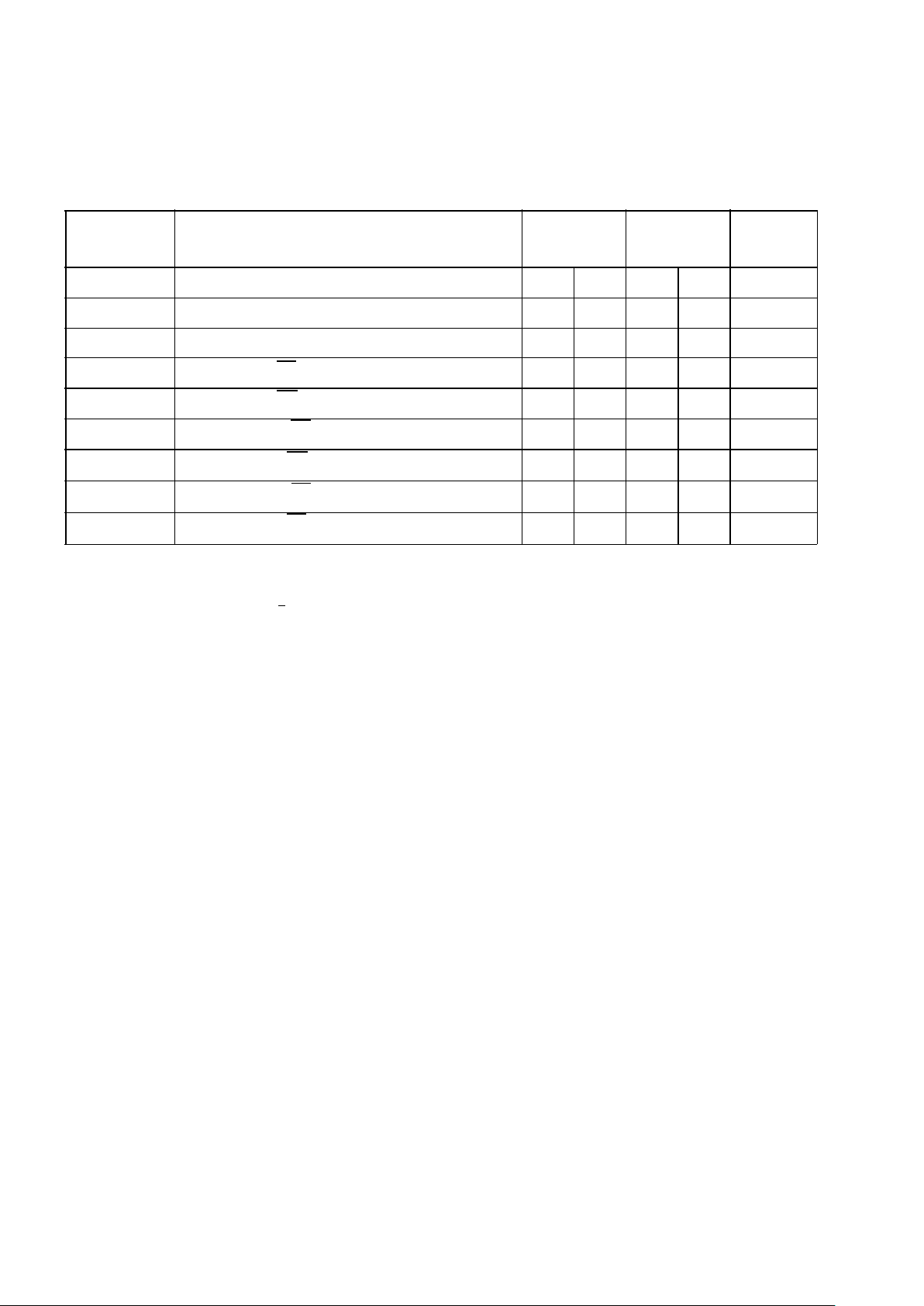

AC CHARACTERISTICS READ CYCLE

1,2

(VDD = 5.0V±10%)

Notes:

1. Test conditions assume signal transition time of 5ns or less, timing reference levels of VDD/2, input pulse levels of 0.5V to VDD-0.5V, and output

loading of the specified IOL/IOH and 50-pF load capacitance.

2. AC test conditions use VOH/VOL=VDD/2 + 500mV.

SYMBOL PARAMETER

7C138 - 45

7C139 - 45

MIN MAX

7C138 - 55

7C139 - 55

MIN MAX

UNIT

t

RC

Read cycle time 45 55 ns

t

AA

Address to data valid

2

45 55 ns

t

OHA

Output hold from address change 5 5 ns

t

ACE

CE LOW to data valid

2

45 55 ns

t

DOE

OE LOW to data valid

2

20 20 ns

t

LZOE

OE LOW to low Z 0 0 ns

t

HZOE

OE HIGH to high Z 20 20 ns

t

LZCE

CE LOW to low Z 0 0 ns

t

HZCE

CE HIGH to high Z 20 20 ns

8

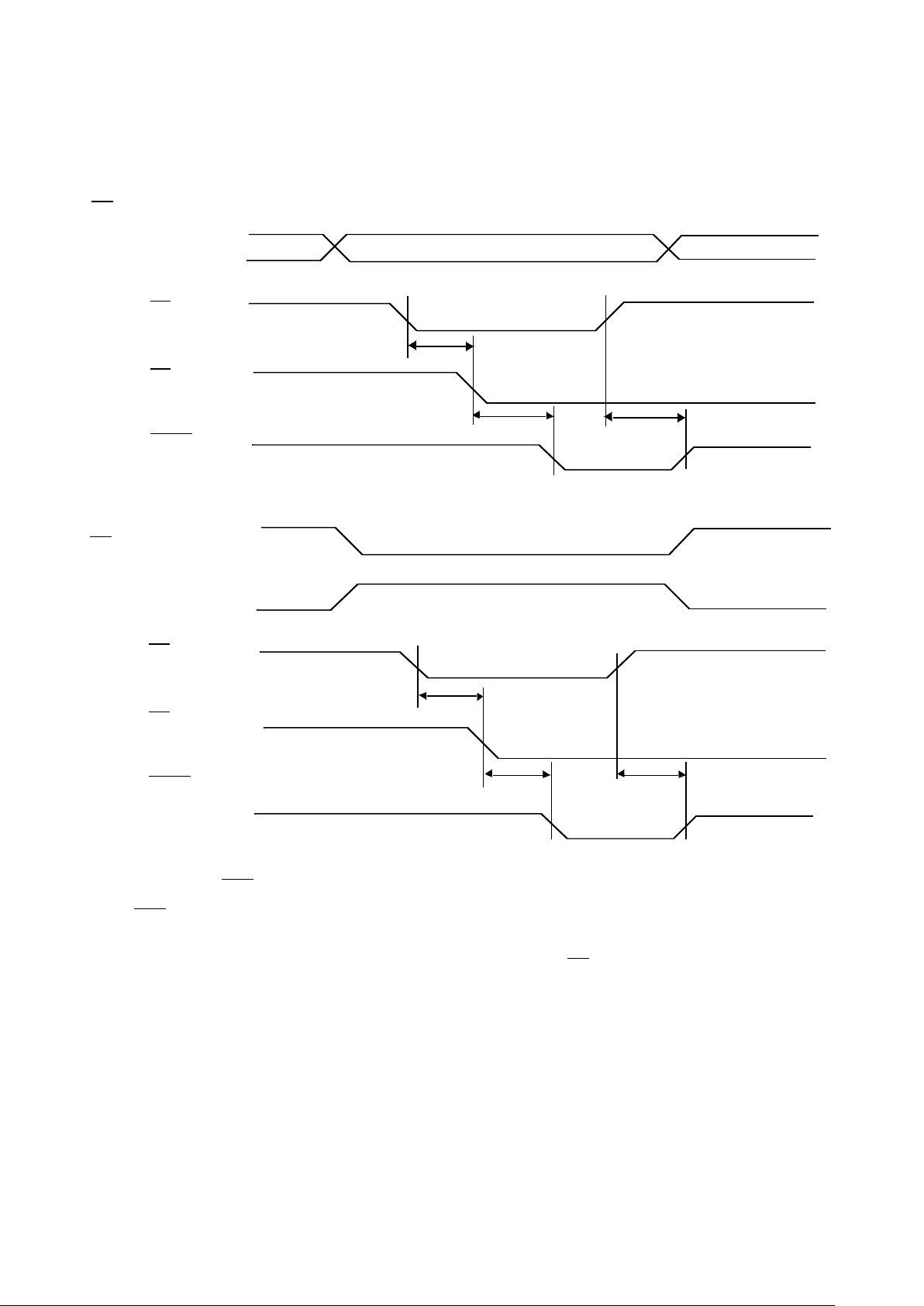

Figure 3b. Read Cycle 2

CE

OE

Data Out

t

LZCE

t

LZOE

t

DOE

t

ACE

t

HZOE

t

HZCE

Figure 3c. Read Timing with Port-to-Port Delay

Address

R/W

R

Data

INR

Address

L

DATA

OUTL

t

WC

MATCH

t

PWE

t

SD

t

HD

VALID

MATCH

VALID

t

DDD

t

WDD

Assumptions:

1. Address valid prior to or coincident with CE transition LOW

2. R/W is HIGH for read cycle

Assumptions:

1. BUSY = HIGH for the writing port

2. CEL = CER = LOW

Address

Data Out

Figure 3a. Read Cycle 1

t

RC

t

OHA

t

AA

Data Valid

Assumptions:

1.R/W is HIGH for read cycle

2.Device is continuously selected CE=LOW and OE=LOW

Previous Data Valid

9

AC CHARACTERISTICS WRITE CYCLE

1

(VDD = 5.0V±10%)

Notes:

1. For information on part-to-part delay through DPRAM cells from writing port to reading port, refer to Read Timing with Port-t o-Port Delay waveform (see figure 3c).

SYMBOL PARAMETER

7C138 - 45

7C139 - 45

MIN MAX

7C138 - 55

7C139 - 55

MIN MAX

UNIT

t

WC

Write cycle time 45 55 ns

t

SCE

CE LOW to write end 40 50 ns

t

AW

Address set-up to write end 40 50 ns

t

HA

Address hold from write end 0 0 ns

t

SA

Address set-up to write start 0 0 ns

t

PWE

Write pulse width 40 50 ns

t

SD

Data set-up to write end 40 50 ns

t

HD

Data hold from write end 0 0 ns

t

HZWE

R/W LOW to high Z 20 20 ns

t

LZWE

R/W HIGH to low Z 0 0 ns

t

WDD

Write pulse to data delay 95 105 ns

t

DDD

Write data valid to read data valid 95 105 ns

t

WHWL

Write disable time 5 5 ns

10

Address

CE

R/W

Data in

OE

Data out

t

WC

t

SCE

t

AW

t

PWE

t

HA

t

SA

t

SD

t

HZOE

t

LZOE

DATA VALID

HIGH IMPEDANCEHIGH IMPEDANCE

t

HD

Assumptions:

1. The internal write time of memory is defined by the overlap of CE

LOW and R/W LOW. Both signals must be LOW to initiate a write,

and either signal can terminate a write by going HIGH. The data input

set-up and hold timing should be referenced to the rising edge of the

signal that terminates the write.

2. If OE is LOW during a R/W controlled write cycle, the write pulse

width must be the larger of t

PWE

or (t

HZWE

+ tSD) to allow the I/O

drivers to turn off and data to be placed on the bus for the required tSD.

If OE is HIGH during a R/W controlled write cycle (as in this example), this requirement does not apply and the write pulse can be as

short as the specified t

PWE

.

3. R/W must be HIGH during all address transactions.

Figure 4a. Write Cycle 1: OE Three-States Data I/Os (Either Port)

11

Address

CE

R/W

Data in

t

WC

t

SCE

t

AW

t

PWE

t

SA

t

SD

DATA VALID

t

HA

t

LZWE

t

HD

t

HZWE

HIGH IMPEDANCE

Figure 4b. Write Cycle 2: R/W Three-States Data I/Os (Either Port)

Assumptions:

1. The internal write time of memory is defined by the overlap of CE

LOW and R/ W LOW. Both signals must be LOW to initialize a write,

and either signal can terminate a write by going HIGH. The data input

set-up and hold timing should be referenced to the rising edge of the signal that terminates the write.

2. R/W must be HIGH during all address transactions.

3. Data I/O pins enter high impedance even if OE is held LOW during

write.

Data out

t

WHWL

12

AC CHARACTERISTICS BUSY CYCLE

1

(VDD = 5.0V±10%)

Notes:

1. Test conditions assume signal transition time of 5ns or less, timing reference levels of VDD/2, input pulse levels of 0.5V to VDD-0.5V, and output

loading of the specified IOL/IOH and 50-pF load capacitance.

2. Violation of tPS (with addresses matching) results in at least one of the two busy output signals asserting, only one port remains busy.

3. When violating tPS, the busy signal asserts on one port or the other; there is no guarantee on which port the busy signal asserts.

SYMBOL PARAMETER

7C138 - 45

7C139 - 45

MIN MAX

7C138 - 55

7C139 - 55

MIN MAX

UNIT

t

BLA

BUSY LOW from address match 25 30 ns

t

BZA

BUSY HIGH-Z from address mismatch 25 30 ns

t

BLC

BUSY LOW from CE LOW 25 30 ns

t

BZC

BUSY HIGH from CE HIGH 25 30 ns

t

PS

2,3

Port set-up for priority 5 5 ns

t

WB

R/W LOW after BUSY LOW 0 0 ns

t

WH

R/W HIGH after BUSY HIGH 40 50 ns

t

BDD

BUSY HIGH to data valid 45 55 ns

13

Address

R

R/W

R

Data In

R

Address

L

BUSY

L

Data

OUTL

t

WC

t

PWE

t

SD

t

HD

t

PS

t

BLA

t

BZA

t

DDD

t

WDD

VALID

MATCH

MATCH

VALID

Figure 5a. Read Timing with BUSY (M/S=HIGH)

Assumptions:

1. CEL = CER = LOW

t

BDD

BUSY

R/W

t

PWE

t

WB

t

WH

Figure 5b. Write Timing with BUSY (M/S=LOW)

14

Address

L,R

CE

L

CE

R

BUSY

R

Address

L,R

CE

R

CE

L

BUSY

L

ADDRESS MATCH

ADDRESS MATCH

t

PS

t

BLC

t

BZC

t

PS

t

BLC t

BZC

Figure 5c. BUSY Timing Diagram No. 1 (CE Arbitration)

CEL Valid First:

CER Valid First:

Assumptions:

1. If tPS is violated, the BUSY signal will be asserted on

one side or the other, but there is no guarantee on which

side BUSY will be asserted.

15

Address

L

Address

R

BUSY

R

Address

R

Address

L

BUSY

L

ADDRESS MATCH ADDRESS MISMATCH

ADDRESS MATCH ADDRESS MISMATCH

t

PS

t

BZA

t

RC or tWC

t

RC or tWC

t

PS

t

BLA

t

BLA

t

BZA

Figure 5d. BUSY Timing Diagram No. 2 (Address Arbitration)

Right Address Valid First:

Left Address Valid First:

Assumptions:

1. If tPS is violated, the BUSY signal will be asserted on

one side or the other, but there is no guarantee on which

side BUSY will be asserted.

16

DATA RETENTION CHARACTERISTICS (Pre-Radiation)

(TC = 25°C)

Notes:

1. CE equals V

DR,

all other inputs equal VDR or VSS.

2. Guaranteed but not tested.

SYMBOL PARAMETER MINIMUM MAXIMUM

V

DD

@

2.5V

UNIT

V

DR

VDD for data retention 2.5 -- V

I

DDR

1

Data retention current -- 400 µA

t

EFR

1,2

Chip deselect to data retention time 0 ns

t

R

1,2

Operation recovery time t

WC

or t

RC

ns

V

DD

CE

DATA RETENTION MODE

t

R

4.5V

4.5V

VDR 2.5V

Figure 6. Low VDD Data Retention Waveform

t

EFR

V

DR

V

IN

< 1.5V CMOS

Notes:

1. 50pF including scope probe and test socket.

2. Measurement of data output occurs at the low to high or high to low transition mid-point

(CMOS input = VDD/2).

90%

Figure 7. AC Test Loads and Input Waveforms

Input Pulses

10%

< 5ns < 5ns

460 ohms

VDD/2

50pF

CMOS

0.5V

VDD-0.5V

17

Figure 8. 68-lead Flatpack

Notes:

1. All package finishes are per MIL-PRF-38535.

2. Letter designations are for cross-reference to MIL-STD-1835.

3. All leads increase max limit by 0.003 measured at the center of the

flat, when lead finish A (solder) is applied.

4. ID mark: Configuration is optional.

5. Lettering is not subject to marking criteria.

6. Total weight is approximately 4.5 grams.

18

L

K

J

H

G

F

E

D

C

B

A

1 2 3 4 5 6 7 8 109 11

11 10 9 8 7 6 5 4 23 1

L

K

J

H

G

F

E

D

C

B

A

Figure 9. 68-pin PGA

Notes:

1. All packages finishes are per MIL-PRF-38535.

2. True position applies at base plane (Datum C).

3. True position applies at pin tips.

4. Letter designations are for cross-reference to MIL-STD-1835.

5. Total weight is approximately 7.0 grams.

19

ORDERING INFORMATION

UT7C138/UT7C139 Dual-Port SRAM: SMD

Lead Finish:

(A) = Solder

(C) = Gold

(X) = Optional

Case Outline:

(X) = 68-pin PGA

(Y) = 68-lead Flatpack

Class Designator:

(Q) = Class Q

(V) = Class V

Device Type

(01) = 4Kx8, CMOS Compatible Inputs, 45ns

(02) = 4Kx9, CMOS Compatible Inputs, 45ns

(03) = 4Kx8, CMOS Compatible Inputs, 55ns

(04) = 4Kx9, CMOS Compatible Inputs, 55ns

Drawing Number: 96845

Total Dose:

(H) = 1E6 rads(Si)

(G) = 5E5 rads(Si)

(F) = 3E5 rads(Si)

(R) = 1E5 rads(Si)

Federal Stock Class Designator: No options

5962 * 96845 * * * *

Notes:

1. Lead finish (A, C, or X) must be specified.

2. If an “X” is specified when ordering, part marking will match the lead finish and will be either “A” (solder) or “C” (gold).

3. Total dose radiation must be specified when ordering. QML Q and QML V not available without radiation hardening.

20

UT7C138/UT7C139 Dual-Port SRAM

UT **** *** - * * * * * *

Total Dose:

( ) = None

Lead Finish:

(A) = Solder

(C) = Gold

(X) = Optional

Screening:

(C) = Military Temperature Range flow

(P) = Prototype flow

Package Type:

(G) = 68-lead PGA

(W) = 68-lead Flatpack

Access Time:

(45) = 45ns access time

(55) = 55ns access time

Device Type Modifier:

(C) = CMOS-compatible Inputs, 5.0V operation

Device Type:

(7C138) = 4Kx8 Dual-Port SRAM

(7C139) = 4Kx9 Dual-Port SRAM

Notes:

1. Lead finish (A,C, or X) must be specified.

2. If an “X” is specified when ordering, then the part marking will match the lead finish and will be either “A” (solder) or “C” (gold).

3. Military Temperature Range flow per UTMC Manufacturing Flows Document. Radiation characteristics are neither tested nor guaranteed and may

not be specified.

4. Prototypes are produced to UTMC’s prototype flow and are tested at 25°C only. Radiation characteristics are neither tested nor guaranteed. Lead finish

is GOLD only.

UTMC Main Office European Sales Office Boston Sales Office

4350 Centennial Blvd. 1+719-594-8166 40 Mall Road, Suite 203

Colorado Springs, CO 80907-3486 1+719-594-8468 FAX Burlington, MA 01830

800-MIL-UTMC http://www.utmc.com 781-221-4122

800-645-8862

http://www.utmc.com

Melbourne Sales Office South LA Sales Office

1901 S. Harbor City Blvd., Suite 802 101 Columbia Street, Suite 130

Melbourne, FL 32901 Aliso Viejo, CA 92656

407-951-4164 714-362-2260

DUALPORT-2-12-97

Copyright 1996 & 1997 by UTMC Microelectronic Systems Inc.

All rights reserved

UTMC Microelectronic Systems Inc. (UTMC) reserves the right to make changes to any products and services herein at any time without notice. Consult UTMC

or an authorized sales representative to verify that the information in this data sheet is current before using this product. UTMC does not assume any responsibility

or liability arising out of the application or use of any product or service described herein, except as expressly agreed to in writing by UTMC; nor does the purchase,

lease, or use of a product or service from UTMC convey a license under any patent rights, copyrights, trademark rights, or any other of the intellectual rights of

UTMC or of third parties.

Loading...

Loading...