Instruction manual

Model: UM-U42

Read and understand all of the instructions and

safety information in this manual before operating

or servicing this tool.

UTILCO Lineman Tools

4730 Madison Road

Cincinnati OH 45227

www.utilco.com

Phone:

800-776-9775

513-533-6200

Pg. 2

UM-U42

Table of Contents

1.

Warranty and Servicing/Safety Symbols Page 3

2. General Safety Information Page 4

3.

Techinical Specications Page 5

4.

Tool Parts Labeled Page 6

5.

Operating Instructions Page 7

6.

Tool Maintenance Page 8

7.

Head Assembly Breakdown and Parts List Page 9

8.

Tool Parts Breakdown Page 10

9.

Parts List Page 11

THANK YOU...

for buying a UTILCO Lineman Tool. Our mission is to bring product innovation and exceptional

customer service to the marketplace. This tool line is reliable, dependable, and durable for our

customer’s needs.

Please read this instruction manual carefully before using the product. If you have any questions

about our product please reach out to our customer service department (see back cover). No part

of the contents of this manual may be reproduced, transmitted or circulated in any form or by any

means without the prior written authorization of UTILCO Lineman Tools.

Pg. 3

UM-U42

Description of Safety Symbols:

Do not dispose

of product.

Please recycle

Electric Shock

Hazard- use

proper protective

equipment

Attention!

Risk of

cutting injury

Never use

with unlocked

workhead

Read the operating

instructions

before use

Wear protective

goggles

1. Warranty and Servicing

UtilPro™ 5-Year Tool Service Protection Program

Introducing the industry’s best service & support program for all your UTILCO hydraulic crimping

and cutting tools. All UTILCO tool buyers are automatically registered in the UtilPro Service

Protection Program and will receive free tool repairs for defects in material or workmanship on their

tool(s) for ve years after their original purchase date. (Excludes abuse, non-intended use, tampered

with or normal wear and tear.)

UtilPro Tool 5 Day Repair Pledge

If your tool(s) need repair at any time within ve years of your original purchase date, our UtilPro

service network will repair your registered tools within ve business days of receipt.

UtilPro Tool Loaner Program

If you need a replacement tool during any repair, our UtilPro network can typically provide a

comparable loaner tool to registered tool owners while your tool is being repaired.

FREE Tool Reconditioning

Your rst reconditioning is on us!

To Find a UtilPro Service Partner

Call UTILCO for assistance in solving tool performance issues or for any of your service needs.

UTILCO tool owners will be oered options to solve any tool replacement, parts or repair

issues.

Call 513-533-6200 or 800-776-9775

Monday to Friday

8:00AM to 5:00PM Eastern Time (ET)

Pg. 4

UM-U42

2. General Safety Information

Read all safety warnings, instructions provided with this tool. Failure to follow all

instructions listed below may result in electric shock, re and/or serious injury. Save all

warnings and instructions for future reference.

WORK AREA SAFETY

• Keep work area clean and well lit. Cluttered or dark areas invite accidents.

• Keep children and bystanders away while operating a hydraulic tool. Distractions can

cause you to lose control.

PERSONAL SAFETY

• Stay alert, watch what you are doing and use common sense when operating a

hydraulic tool. Do not use a hydraulic tool while you are tired or under the inuence

of drugs, alcohol, or medication. A moment of inattention while using hydraulic tools

may result in serious personal injury.

• Use personal protective equipment. Always wear eye protection. Protective

equipment such as rubber gloves, non-skid safety shoes, hard hat or hearing

protection used for appropriate conditions will reduce personal injuries.

• Do not overreach. Keep proper footing and balance at all times. This enables better

control of the tool in unexpected situations.

• Do not let familiarity gained from frequent use of hydraulic tools allow you to

become complacent and ignore tool safety principles. A careless action can cause

severe injury within a fraction of a second.

SERVICE

• Have your tool serviced by a qualied repair person using only identical replacement

parts. This will ensure that the safety of the hydraulic tool is maintained.

Pg. 5

UM-U42

3. Technical Specications

Force developed: 12 tons

Jaw Opening: 1.65 in.

Hydraulic oil: Shell Tellus S2 V 15

Dimensions: 23 in. x 8.75 in. x 3 in. (L x W x H)

Weight: 14.5 lbs.

Crimp Capacity

CU code wire: 1000 kcmil - #8

AL code wire: 750 kcmil - #8

23 in. (584 mm)

8.75 in. (222 mm)

Pg. 6

UM-U42

Die release buttons

Stationary handle

Pump handle

Release button

y Serial number

4. Tool Parts Labeled

NOTE: Includes durable plastic carrying case.

Pg. 7

UM-U42

5. Operating Instructions

Be sure to read instructions carefully, wear safety goggles, and keep ngers away from cutting

head.

ADVANCING & RETRACTING

1. To advance the tool, lift and lower the pump handle.

2. To retract the tool, twist pump handle completely, then push handles together until ram is

fully retracted.

CRIMPING

1. Make sure the ram is fully retracted.

2. Insert dies by pressing die release buttons and sliding die into ram, then releasing the buttons

until the die clicks into place.

3. Place the connector between the dies.

4. Advance the ram by lifting and lowering the pump handle so that the connector is held

between the dies and insert conductor into the terminal.

5. Advance the tool until the compression is completed. You will know that compression is

completed by the pop when the tool hits full pressure, and the pump handle giving less

resistance.

6. Retract the tool by twisting the pump handle completely, then pushing handles together

until ram is fully retracted.

7. Remove dies when crimp is complete by pressing die release buttons.

NOTE: Your tool is equipped with with a safety bypass. When maximum pressure is

achieved, you will hear a pop.

Pg. 8

UM-U42

6. Tool Maintenance

Daily maintenance:

• After each crimping cycle wipe the crimping head jaws free of metal shavings.

• Wipe down all steel parts with WD-40.

• Store the tool in a non-humid environment.

The tool should provide many years of service when given the proper maintenance and care.

Should you experience any diculty with the operation and maintenance of this tool, contact our

customer service department (see back cover).

Pg. 9

UM-U42

7. Head Assembly Breakdown and Parts List

# Part # Part Description Qty

8 700883 COUNTERSUNK SCREW 1

9 705806 FILTER DISC 1

10 714160 PRESSURE DISC 1

11 707044 O-RING SEAL 1

12 711962 COMPRESSION SPRING 1

13 714164 STUD 1

14 714159 PISTON 1

1

14

13

12

11

10

9

8

7

6

5

4

3

2

# Part # Part Description Qty

1 711065 C-HEAD 1

2 712496 UNLOCKING BOLT 4

3 101595 NEEDLE ROLLER 2

4 712497 CLAMPING BOLT 2

5 714089 COMPRESSION SPRING 2

6 711018 COURSER 1

7 711017 SLOT NUT 1

2

2

3

4

5

Pg. 10

UM-U42

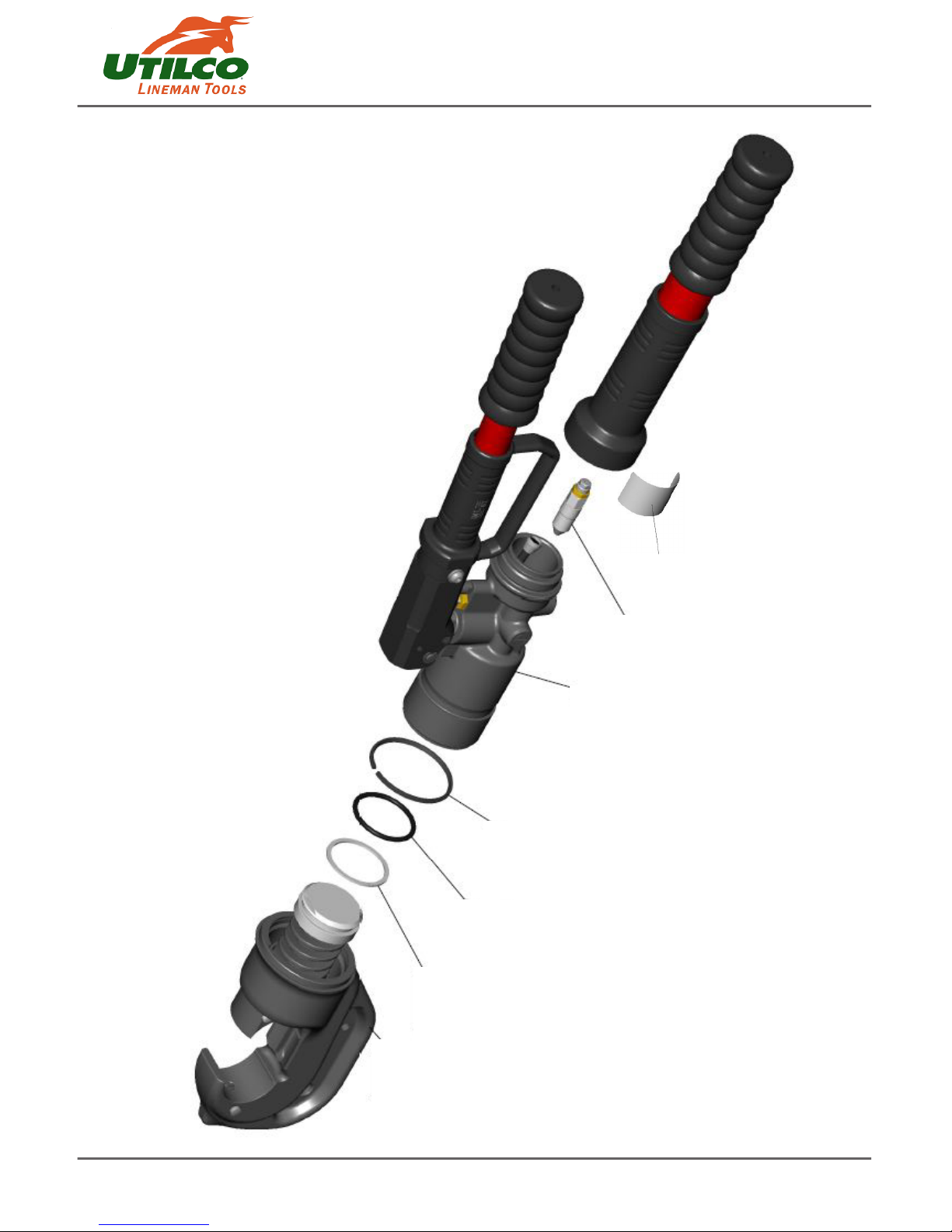

8. Tool Parts Breakdown

1

9

8

6

5

5

4

3

2

7

Pg. 11

UM-U42

# Part Number Part Description Qty

1 E711020 CRIMPING HEAD MNT 1

2 730749 SUPPORT RING 1

3 730787 O-RING SEAL 1

4 711200 SPRING RING 1

5 E710498 HAND OPERATED HYDRAULIC TOOL MNT 1

6 713795 PRESSURE CONTROL VALVE 1

7 LABEL 1

9. Parts List

Pg. 12

UM-U42

Notes:Notes:

Pg. 13

UM-U42

Notes:

Pg. 14

UM-U42

Notes:

Pg. 15

UM-U42

Notes:

Service:

Date: 07/17 Version 1

UTILCO Lineman Tools

4730 Madison Rd.

Cincinnati, OH 45227

Phone: 800-776-9775

513-533-6200

www.utilco.com

Loading...

Loading...