Utica Boilers UB95M-200 Brochure

UB95M-200

There Are Some Things You Can Always Depend On...

UB95M-200

92.5% AFUE Residential Gas Fired Modulating Condensing Boiler

• High Efciency Cast Aluminum Monoblock Heat Exchanger

with low pressure drop.

• Microprocessor Based Modulating Control.

- Monitors the supply and return water temperature, adjusting the

boiler ring rate to match the building load conditions.

• Hi-Limit Control with LED display and self diagnostic features.

• Low Water Cut Off.

• Boiler Temperature Reset.

- Lowers the boiler supply water temperature depending on outdoor

air temperature. Saves fuel without sacricing comfort.

• Domestic Hot Water Priority.

• Easy to Install & Service.

- Intake and ue gasses can be piped with readily available

3” PVC up to 100 equivalent feet.

- Option of left, right, or rear exit for return plumbing and gas piping.

- Piping connections facilitate multiple boiler installations.

- Integral Condensate Trap.

• Limited 15 Year Warranty.

• Made In the USA.

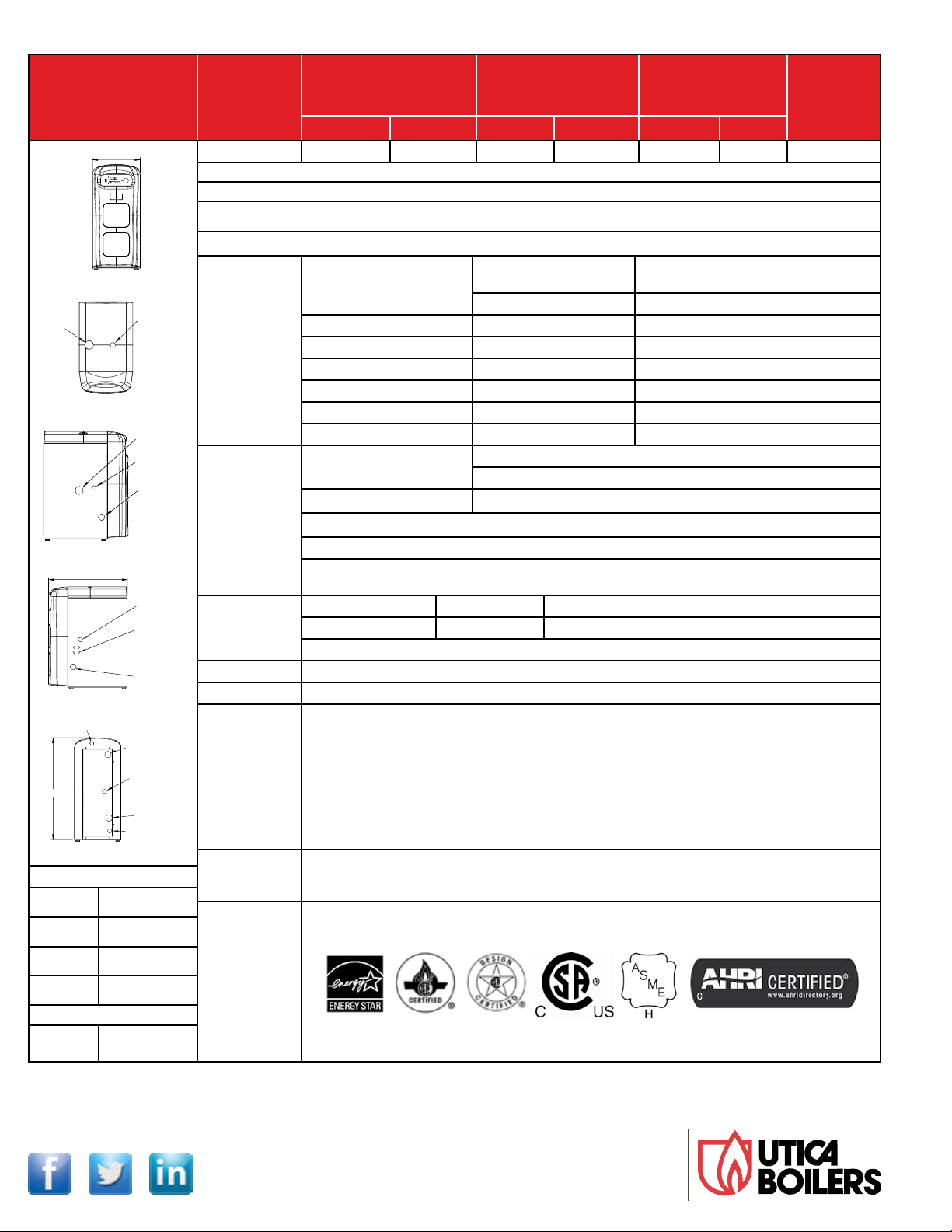

Utica UB95M-200 Natural or Propane Gas-Fired Modulating Condensing Hot Water Boiler

Net AHRI

Rating, Water

(MBH)

3” Pipe

15 Ft. (4.6 m)

(1) (3)

Service

AFUE %

(5)

Dimensions/Weights Model

18"

UB95M-200 200 80 182 73 158 63 92.5

(1) 1000 Btu/hr (British Thermal Units Per Hour)

(2) Heating Capacity and AFUE (Annual Fuel Utilization Efciency) are based on DOE (Department of Energy) test procedures.

(3) Net AHRI Ratings based on piping and pickup allowance of 1.15. Contact Technical Support before selecting boiler for installations having unusual piping and

pickup requirements, such as intermittent system operation, extensive piping systems, etc.

General Information (See Installation, Operation and Maintenance Manual for complete instructions)

Clearances

(4) Required

distances

measured from

boiler.

(5) Service, proper

operation clearance

recommendation.

Note: May be

installed on

combustible

ooring

(No Carpets).

Combustion

Air & Vent Pipe

Equivalent

Length

OPENING FOR

VENT TEE

EXHAUST (2" CVPC)

front

top

STANDARD SUPPLY OPENING

1 1/4 NPT CONNECTIONS

PROVIDED INSIDE BOILER

CABINET.

AIR VENT INTAKE

OPENING 2" PVC

(OPTIONAL)

GAS SUPPLY

OPENING 1/2 NPT

(OPTIONAL)

WATER RETURN OPENING

1 1/4 NPT CONNECTION

(OPTIONAL)

left

30 7/8"

GAS SUPPLY OPENING

1/2 NPT (OPTIONAL)

ELECTRICAL CONNECTION

39 3/8"

right

OPENING FOR RELIEF

VALVE DISCHARGE PIPE

FOR 120V POWER & 24 V

THERMOSTAT LEADS

WATER RETURN OPENING

1 1/4 NPT CONNECTION

(OPTIONAL)

AIR VENT INTAKE OPENING

2" PVC (OPTIONAL)

GAS SUPPLY OPENING

1/2 NPT (OPTIONAL)

WATER RETURN OPENING

1 1/4 NPT CONNECTION

(OPTIONAL)

CONDESATE DRAIN

OPENING 1/2" PVC

Connections

Electrical 120 Volts AC, 60 hertz, 1 phase, Less than 12 amps (15 amp circuit recommended)

Water Content 2.6 Gallons

Standard

Equipment

back

Options

Certications

Width

Height

Depth

Flue

Diameter

Ship Wgt.

Dimensions

457.2 mm

39.375”

1000.1 mm

30.875”

784.2 mm

76.2 mm

Weights

284 lbs.

128.8 kg

18”

3”

Boiler Input Rate

(MBH)

Max. Min.

Top

(1)

Heating

Capacity

(MBH)

(1)(2)

Max. Min. Max. Min.

Combustible Materials

(Required)

1” (26 mm) 8” (204 mm)

(4)

Left Side 1” (26 mm) 24” (610 mm)

Right Side 1” (26 mm) N/A

Front 0” (0 mm) 24” (610 mm)

Back 6” (153 mm) N/A

Bottom Combustible N/A

Combustion Air/Vent Piping 0” (0 mm) N/A

Min. Length

Max. Length 100 Ft. (30.5 m)

Vent Pipe - First 2.5’ (.762 m) is Schedule 80 2” CPVC (provided), then Schedule 40 3” PVC.

Air Intake - Schedule 40 3” PVC.

Notes: 3” Pipe Min. Venting - 15 ft. equivalent length, 3” Pipe Max. Venting - 100 ft. equivalent length.

Reduce the maximum vent length by 5’ per each 90° elbow. Refer to IOM for additional piping details.

Return/Supply Water Gas In Condensate Drain

1-1/4” NPT 1/2” NPT 1/2” PVC

Note: Option of left, right, or rear exit for return plumbing and gas piping.

Boiler Control Module: Microprocessor based Modulating Control, Hi-Limit Control.

User Display Interface: Temperature Display. Outdoor temperature sensor with cover included.

Heat Exchanger: Cast Aluminum Monoblock.

Combustion: Modulating Automatic Gas Valve, Modulating Burner, Direct Spark Igniter,

LP Conversion Kit included. Modulating Blower, Manual Reset Casting Temperature Switch,

Air Proving/Blocked Vent Safety Assembly, Air Purge Vent.

Electrical: Service Switch, Service Receptacle Outlet.

Other: Circulator (Taco 007 or Grundfos), Manual Reset Low Water Cutoff, Pressure Gauge, 30 PSI

Safety Relief Valve, Integral Condensate Trap, Combination Painted Metal and Durable Plastic Jacket.

Concentric Vent Kit (3”), AMB Multiple Boiler Control (For Multiple Boiler Applications - Includes

outdoor reset, priority override and lead boiler run time rotation. Available in two sizes - AMB4 and

AMB8 to allow stage ring of up to 8 boilers).

50 psi MAWP

(2)

All ratings and specications subject to change.

Contractor

Assistance: 800.325.5479

Utica, New York 13504

tel: 315.797.1310

www.uticaboilers.com

PN 240006151 Rev. 10/13

P.O. Box 4729

• fax: 315.797.3762

Loading...

Loading...