Utica Boilers UB95M-200 Operation and Installation Manual

UB95M-200

Gas-Fired Direct Vent

Modulating Hot Water Boiler

Model

UB95M-200

INSTALL ATION, OPER ATION &

MAINTENANCE MANUAL

An ISO 9001-2008 Certied Company

Manufactured by:

ECR International, Inc.

2201 Dwyer Avenue, Utica NY 13501

web site: www.ecrinternational.com

P/N# 240006103U, Rev. E [02/2014]

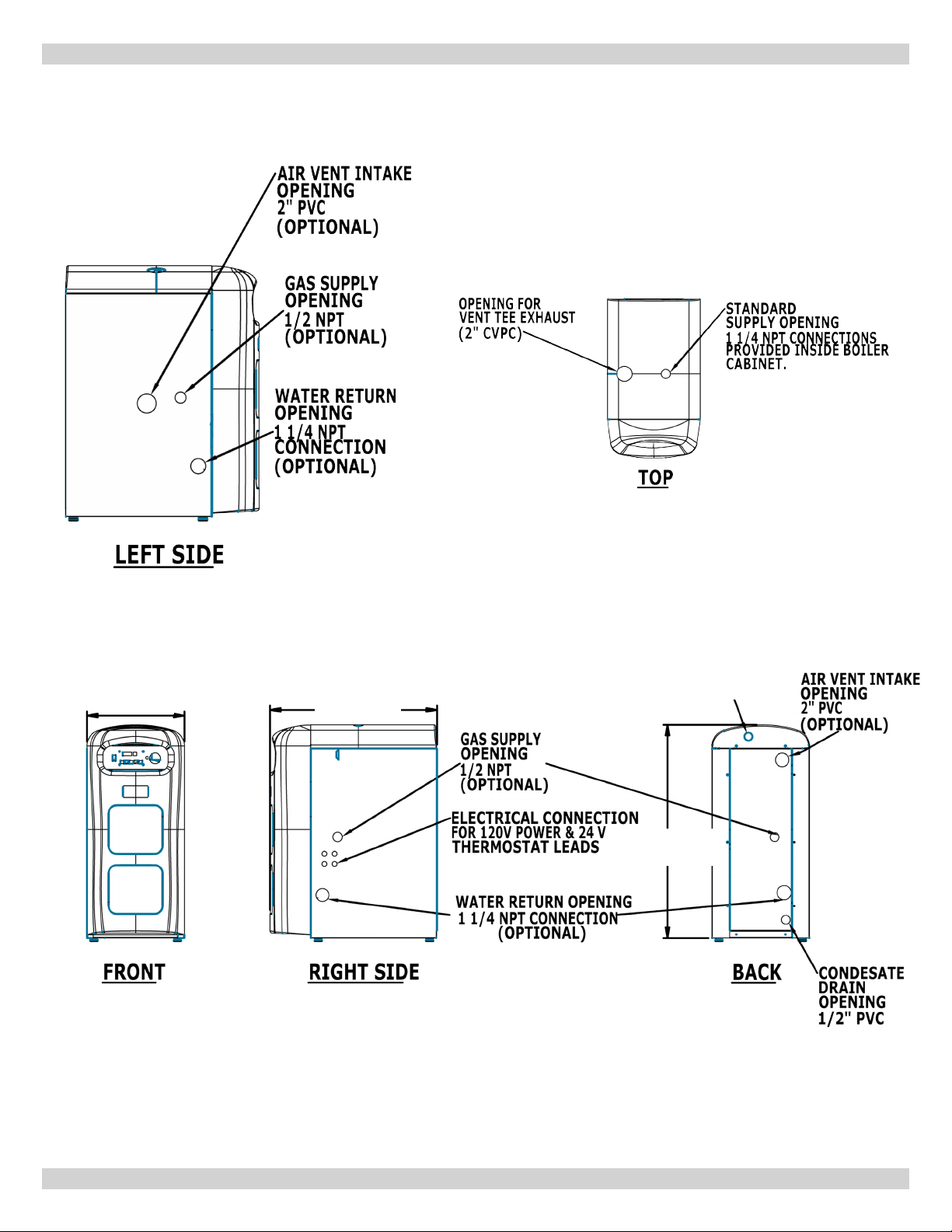

1 - DIMENSIONS

18”

(458mm)

30⅞”

(785mm)

OPENING FOR

SAFETY

RELIEF VALVE

DISCHARGE PIPE

39⅜”

(1.1m)

2

2 - INTRODUCTION

1 - Dimensions .............................................................................................................. 2

2 - Introduction ............................................................................................................. 3

3 - Important Safety Information ..................................................................................... 4

4 - Boiler Ratings & Capacities ......................................................................................... 5

5 - Before Installing The Boiler ........................................................................................6

6 - Locating The Boiler ...................................................................................................7

7 - Near Boiler Piping ..................................................................................................... 9

8 - Combustion Air And Vent Pipe .................................................................................. 12

9 - Gas Supply Piping ................................................................................................... 17

10 - Electrical Wiring .................................................................................................... 19

11 - Controls And Accessories ....................................................................................... 21

12 - Boiler Startup ....................................................................................................... 23

13 - Operating Instructions ........................................................................................... 24

14 - Maintenance And Cleaning ..................................................................................... 25

Appendix A - Boiler Piping And Wiring ............................................................................ 27

Appendix B - Water Quality, Water Treatment and Freeze Protection ................................... 45

2.1 Introduction

• Boiler is certied in accordance with ANSI Z21.13

American National Standards Institute) and CSA

(Canadian Standards Association) 4.9.

• This appliance is a gas-red direct vent modulating cast

aluminum hot water boiler.

• Cast aluminum monoblock heat exchanger allows better

heat transfer and thermal storage than similarly sized

cast iron boilers resulting in higher efciency.

• The heating system water absorbs large amounts of

heat from the cast aluminum heat exchanger, cooling

ue gases and causing condensation.

• Sealed combustion, premix gas burner, and low ame

temperature means reduced CO and NOx emissions,

which contribute to cleaner and healthier environment.

• This appliance takes its combustion air directly from

outdoors (sealed combustion) and does not compete

with building occupants for fresh air.

• Sealed combustion (also known as “direct vent”)

is safest and best way to obtain plenty of clean

combustion air.

• Forced draft fan draws in outside combustion air, takes

cooler ue gases from boiler unit and provides positive

removal of ue gases from the building through readily

available PVC and CPVC pipes. Canada use ULC S636

Material.

• These low pressure gas-red hot water boilers are

design certied by CSA International for use with

natural gas and propane gas.

• Boilers are constructed and hydrostatically tested

for maximum working pressure of 50 psig (pounds

per square inch gage) in accordance with A.S.M.E.

(American Society of Mechanical Engineers) Boiler and

Pressure Vessel Code Section IV Standards for heating

boilers.

3

3 - IMPORTANT SAFETY INFORMATION

3.1 General

Boiler installation shall be completed by qualied agency.

See glossary for additional information.

WARNING

!

Fire, explosion, asphyxiation and electrical shock

hazard. Improper installation could result in death or

serious injury. Read this manual and understand all

requirements before beginning installation.

Keep this manual near boiler

Retain for future reference

Become familiar with symbols identifying

potential hazards.

This is the safety alert symbol. Symbol alerts you to

potential personal injury hazards. Obey all safety messages

following this symbol to avoid possible injury or death.

!

DANGER

Indicates a hazardous situation which, if not avoided,

WILL result in death or serious injury

!

WARNING

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

3.2 Installation shall conform to requirements of

authority having jurisdiction or in absence of such

requirements:

•

United States

• National Fuel Gas Code, ANSI Z223.1/NFPA 54

• National Electrical Code, NFPA 70.

• Canada

• Natural Gas and Propane Installation Code, CAN/CSA

B149.1. and .2

• Canadian Electrical Code, Part I, Safety Standard for

Electrical Installations, CSA C22.1

3.3 Where required by authority having jurisdiction,

installation shall conform to Standard for Controls

and Safety Devices for Automatically Fired Boilers,

ANSI/ASME CSD-1.

Additional manual reset low water cutoff and/or manual

reset high limit may be required.

3.4 Requirements for Commonwealth of

Mas sachusetts:

Boiler installation must conform to Commonwealth of

Massachusetts code 248 CMR which includes but is not

limited to:

• Installation by licensed plumber or gas tter.

Installers - Follow local regulations with respect to

installation of CO (Carbon Monoxide) Detectors. Follow

maintenance recommendations “Maintenance And

Cleaning” Section 14 page 25.

.

!

CAUTION

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

NOTICE

Used to address practices not related to personal

injury.

4

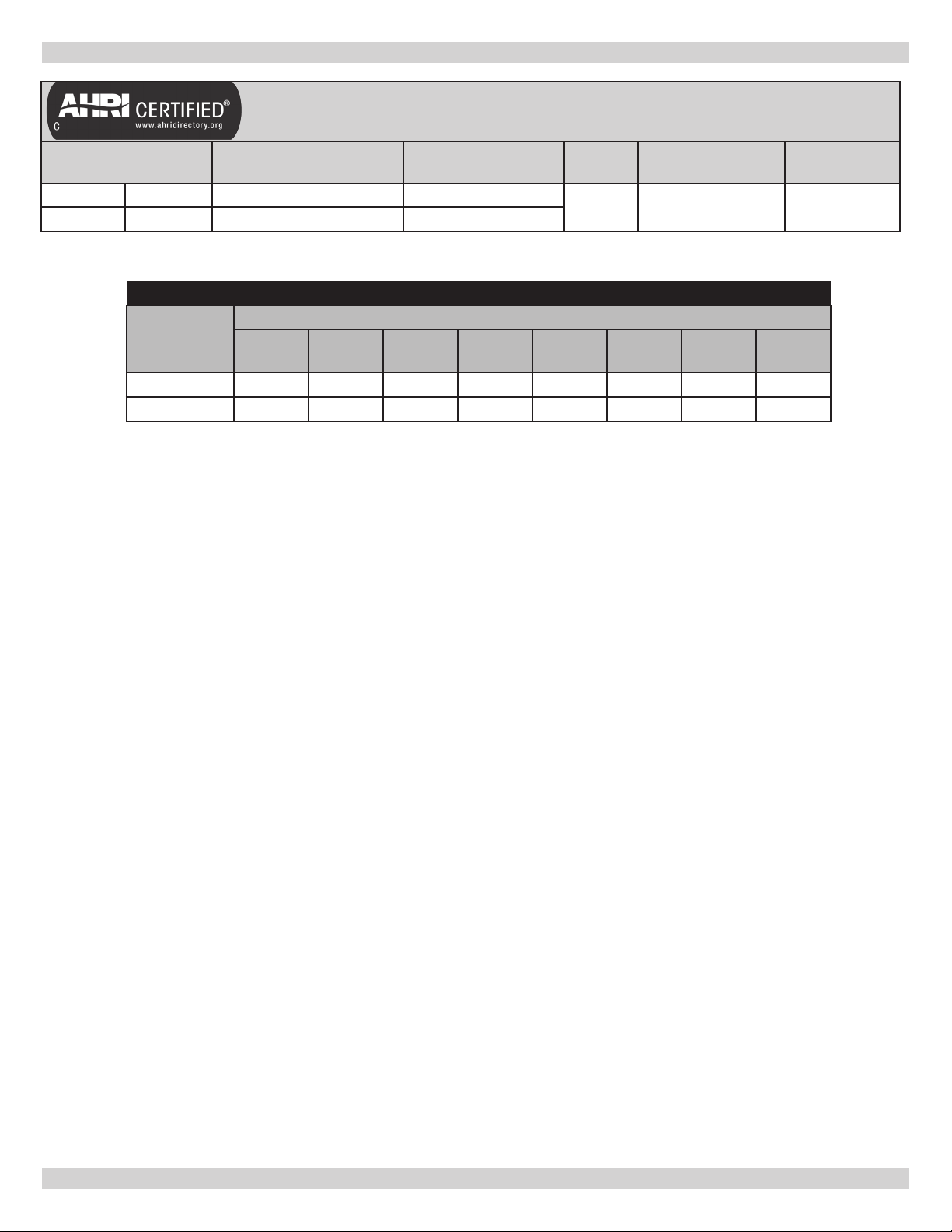

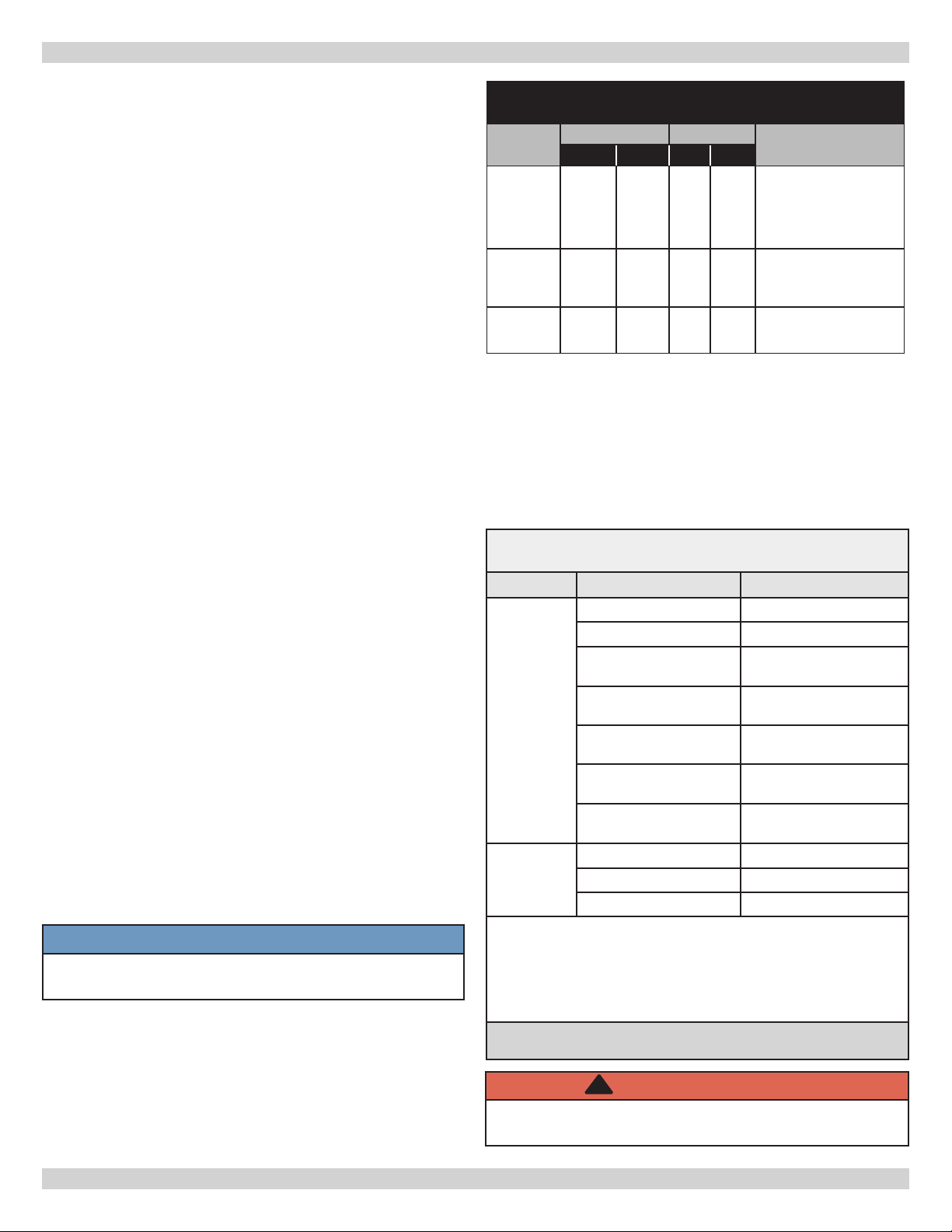

4 - BOILER RATINGS & CAPACITIES

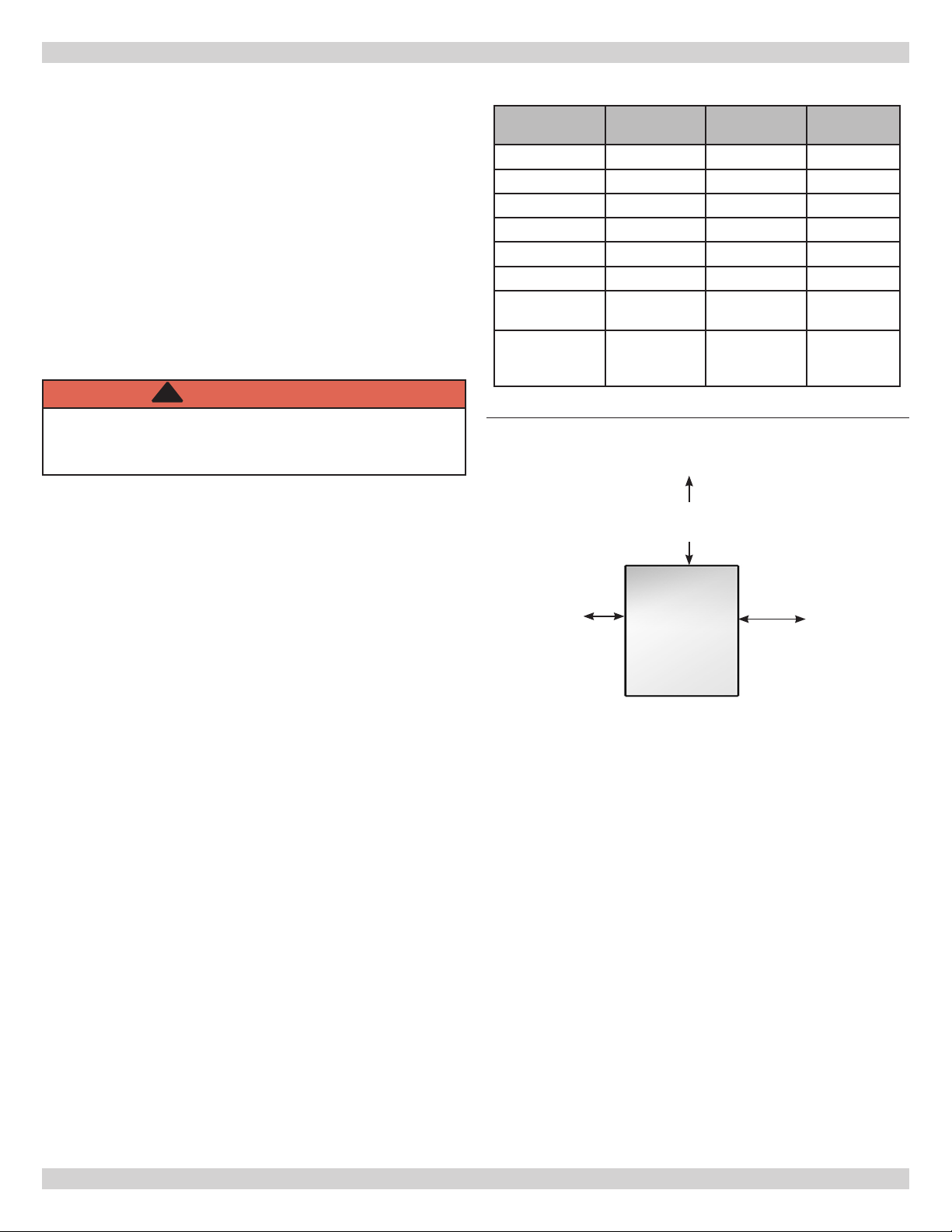

TABLE 1: SEA LEVEL RATINGS - NATURAL AND PROPANE GASES

Input (MBH)

(1)

Heating Capacity

(MBH)

(1)(2)

Net AHRI Rating

(MBH)

(1)

AFUE

(2)

Flue Diameter Shipping Wt.

High Fire 200 182 158

Low Fire 80 73 63

(1)

1 MBH = 1,000 BTUH (British Thermal Units Per Hour)

(2)

Heating Capacity and AFUE (Annual Fuel Utilization Efciency) are based on DOE (Department of Energy) test procedures.

92.5% 2” CPVC & 3” PVC 284 lbs.

TABLE 2: 95M-200 HIGH ALTITUDE DERATE CHART

Input

(MBH)

3,000

(2)

4,000

(2)

5,000

Altitude (In Feet)

(3)

6,000 7,000 8,000 9,000 10,000

High Fire 196 192 177 174.5 172 169 168 167

Low Fire 78.4 76.8 115 113.5 112 110 109 108

1)

Boiler Input Rate is determined at minimum vent length. The rate will decrease as vent length increases.

2)

Parameter 17 is set to 2,250 at elevations of 2,000 feet and below.

3)

Parameter 17 must be raised to 3,200 at altitudes or elevations of 2,000 feet and above.

• Heating Capacity indicates amount of heat available after subtracting losses up the stack. Most of this heat is available

to heat water. Small portion is heat loss from jacket and boiler surfaces, and it is assumed this heat stays in the

structure.

• Net AHRI Rating represents portion of remaining heat that can be applied to heat radiation or terminal units (i.e.,

nned tube baseboard, cast iron radiators, radiant oor, etc.) Difference between Heating Capacity and Net AHRI

Rating, called piping and pickup allowance, establishes reserve for heating volume of water in the system and

offsetting heat losses from piping.

• Net AHRI Ratings shown are based on piping and pickup factor of 1.15 in accordance with AHRI Standard. Net AHRI

Rating of selected boiler should be greater than or equal to calculated peak heating load (heat loss) for building or

area(s) served by boiler and associated hot water heating systems. Consult manufacturer before selecting boiler for

installations having unusual piping and pickup requirements.

5

5 - BEFORE INSTALLING THE BOILER

5.1 Before Boiler Installation

1.

Boiler is equipped for residential installations. If

used for commercial applications, additional code

requirements must be adhered to for installation. This

may require additional controls including but not limited

to a low water cut off, a manual reset high temperature

limit, and wiring and/or piping modications.

2.

Never vent products of combustion from this boiler to

enclosed space. Always vent to outdoors. Never vent to

another room or to inside building.

3.

Keep boiler area clean of debris and free of combustible

and ammable materials.

4.

Proper through wall or through roof combustion venting

shall be in accordance with materials and methods

described in this manual. Installation must comply with

local codes.

5.2 Boiler Sizing

• Verify you have selected boiler with proper capacity

before continuing installation. AHRI Rating of selected

boiler should be greater than or equal to calculated

peak heating load (heat loss) for the building or area(s)

served by boiler and associated hot water heating

systems. See Sea Level Ratings - Natural and Propane

Gases” Section 4.

• Heat loss calculations should be based on approved

industry methods.

5.3 Considerations for Boiler Location

Before selecting boiler location consider following.

• Supplied with correct type of gas (natural gas or

propane).

• Connected to suitable combustion air intake piping

system to supply correct amounts of fresh (outdoor) air

for combustion (15’ minimum equivalent length/100’

maximum equivalent length).

• Connected to suitable venting system. (15’ minimum

equivalent length/100’ maximum equivalent length).

• Connected to suitable hot water heating system.

• Supplied with suitable electrical supply for all boiler

motors and controls.

• Connected to properly located thermostat or operating

control (not included with boiler).

!

WARNING

Fire hazard. Do not install on carpeting. Failure to

follow these instructions could result in death or

serious injury.

• Placed on level surface (must NOT be installed on

carpeting).

• Pitch condensate drain line down to oor drain or

external condensate pump with reservoir at ¼” per foot

(wood frame or blocks may be used to raise boiler).

6

6 - LOCATING THE BOILER

6.1 Locating the Boiler

1.

Place crated boiler as close to selected location as

possible and un-crate boiler. Boiler may be moved into

position with appliance dolly or 2 wheel hand truck.

Insert dolly or hand truck under right hand side of

boiler. It is possible to slide boiler for short distance on

smooth oor or surface.

2.

Select level location central to piping systems served

and as close to vent and air intake terminals as

possible.

3.

Accessibility clearances, if more stringent (i.e. larger

clearances) than required re protection clearances,

must be used for boiler installation. Accessibility

clearances may be achieved with use of removable

walls or partitions.

!

WARNING

Fire hazard. Do not install on carpeting. Failure to

follow these instructions could result in death or

serious injury.

4.

Boiler is approved for installation in closets and on

combustible oors. Boiler shall NOT be installed on

carpeting.

5.

Clearances shown in Table 3 indicate required

clearances per CSA listing. Minimum 1” (26mm)

clearance must be maintained between combustible

construction and each of the right, top and back

surfaces of the boiler. Allow at least 24” (610mm) at

front and left side and 8” (204mm) at top for servicing.

No combustible clearances are required to venting or

combustion air intake piping.

6.

Install equipment in location which facilitates operation

of venting and combustion air intake piping systems as

described in this manual.

7.

Advise owner to keep venting and combustion air

intake passages free of obstructions. Both venting

and combustion air intake piping systems connected

to outdoors must permit ow through piping systems

without restrictions for boiler to operate.

8.

Install boiler so automatic gas ignition system

components are protected from water (dripping,

spraying, rain, etc.) during operation and service

(circulator replacement, control replacement, etc.).

9.

Keep boiler area clean of debris and free of ammable

and combustible materials, vapors and liquids.

10.

Locate boiler where ambient room temperatures

(minimum possible temperatures where boiler is

installed assuming boiler is not in operation and

therefore contributes no heat to space) are always

at or above 32°F (0°C) to prevent freezing of liquid

condensate.

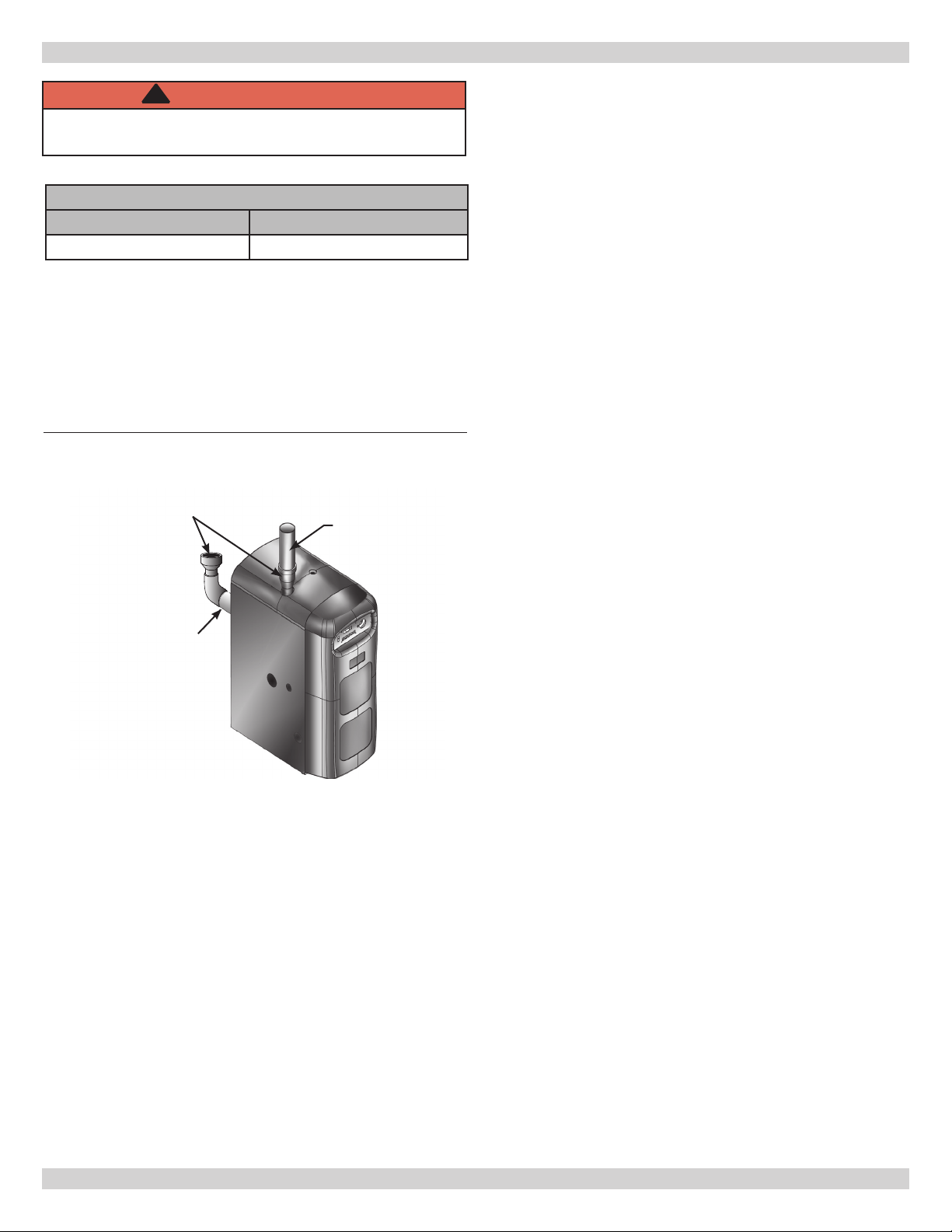

TABLE 3: BOILER CLEARANCES

Dimension

Top

Left Side

Right Side

Base

Front

Back

Intake/Vent

Piping

Near Boiler

Hot Water

Piping

Figure 1 - Minimum Clearances To Combustible

Combustible

Construction

1” (26mm) 8” (204mm) 8” (204mm)

1” (26mm) 24” (610mm) 24” (610mm)

1” (26mm) - -

Combustible - -

0 24” (610mm) 24” (610mm)

6” (153mm) - -

0 - -

1” (26mm) - -

Construction

Accessibility/

Cleaning

Service

6”

(153mm)

8”

1”

(26mm)

Left Side

Rear

Boiler

Front

Right Side

1”

(26mm)

0”

(0mm)

7

6 - LOCATING THE BOILER

6.2 Combustion Air and Vent Pipe Requirements

• This boiler requires dedicated direct vent system.

• In direct vent system all air for combustion is taken

directly from outside atmosphere, and all ue products

are discharged to outside atmosphere.

• Combustion air and vent pipe connections must

terminate together in same atmospheric pressure

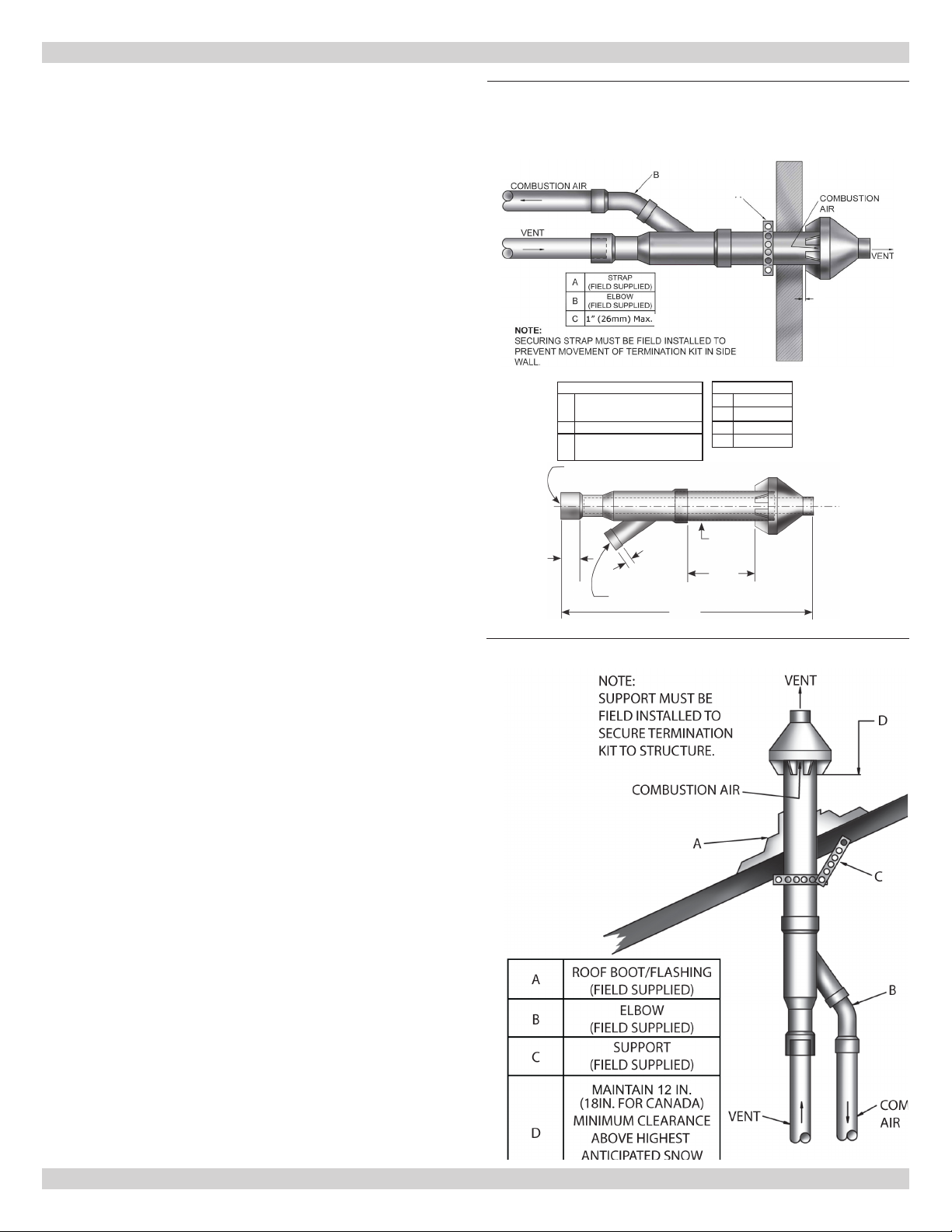

zone, either through roof or sidewall (roof termination

preferred). See Figures 5 and 6 for required clearances.

For proper set up of concentric vent termination see

Figure 7 and Figure 8.

!

WARNING

Solvent cements are combustible. Keep away from

heat, sparks, and open ame. Use only in well

ventilated areas. Avoid breathing in vapor or allowing

contact with skin or eyes. Failure these instructions

could result in re, personal injury, or death.

• Locate combustion air inlet as far away as possible

from swimming pool and swimming pool pump house.

• All combustion air and vent pipes must be airtight and

watertight. Combustion air and vent piping must also

terminate as shown in “Combustion Air and Vent Pipe”

section.

• Vent connections serving appliances vented by

natural draft shall not be connected into any portion

of mechanical draft systems operating under positive

pressure.

• Covering non-metallic vent pipe and ttings with

thermal insulation shall be prohibited.

6.3 Condensate Drain Requirements

• Condensate trap provided with boiler, an additional

trap is not required and should not be used.

• Pitch condensate drain line down to oor drain at

minimum of ¼” per foot. External condensate pump

(not furnished) may be used if oor drain is not

available.

• Condensate pump must be designed for ue gas

condensate application.

• Wood frame or blocks may be used to raise boiler

to maintain drain pitch or to be above external

condensate pump reservoir.

• If boiler is not level, condensate drain lines will not

function properly. Adjustable feet are located on boiler

to make up for minor surface irregularities or tilt.

• 115 volt AC receptacle provided on control panel to

provide power for external condensate pump if used.

6.4 Removal of Existing Boiler From Common

Vent System

When an existing boiler is removed from a common

venting system, the common venting system is likely to be

too large for proper venting of the appliances remaining

connected to it. At the time of removal of an existing boiler,

the following steps shall be followed with each appliance

remaining connected to the common venting system

placed in operation, while the other appliances remaining

connected to the common venting system are not in

operation.

1.

Seal any unused openings in the common venting

system.

2.

Visually inspect the venting system for proper size and

horizontal pitch and determine there is no blockage, or

restrictions, leakage, corrosion and other deciencies

which could cause an unsafe condition.

3.

In-so-far as is practical, close all building doors and

windows and all doors between the space in which the

appliances remaining connected to the common venting

system are located and other spaces of the building.

Turn on clothes dryer and any appliance not connected

to the common venting system. Turn on any exhaust

fans, such as range hoods and bathroom exhaust, so

they will operate at maximum speed. Do not operate a

summer exhaust fan. Close re dampers.

4.

Place in operation the appliance being inspected.

Follow the lighting instructions. Adjust thermostat so

appliances will operate continuously.

5.

Test for spillage at the draft hood relief opening after 5

minutes of main burner operation. Use the ame of a

match or candle, or the smoke from a cigarette, cigar

or pipe.

6.

After it has been determined that each appliance

remaining connected to the common venting system

properly vents when tested as outlined above, return

doors, windows, exhaust fans, re place dampers,

and any other gas-burning appliance to their previous

condition of use.

7.

Any improper operation of the common venting system

should be corrected so the installation conforms with

the National Fuel Code, NFPA-54/ANSI -Z223.1 and/or

the Natural Gas and Propane Installation Code, CAN/

CSA B149.1. When re-sizing any portion of common

venting system, common venting system should be resized to approach minimum size as determined using

appropriate tables in Chapter 13 of the National Fuel

Gas Code, NFPA-54/ANSI- Z223.1 and/or the Natural

Gas and Propane Installation Code, CAN/CSA B149.1.

8

7 - NEAR BOILER PIPING

7.1 Clean System First

Before

system thoroughly. Verify system is free of sediment, ux

and any residual boiler water additives.

Systems having antifreeze not recommended must be

completely ushed to insure no old antifreeze remains. In

older systems obviously discolored, murky or dirty water;

or pH reading outside acceptable range (between 7.0 and

8.0) are indications system should be cleaned or treated.

Thoroughly ush system with clean water to remove any

sediment or contaminants. Sludge and iron oxide deposits

can cause rapid breakdown of inhibitors.

Flushing with clean water. If chemical cleaners are used,

use only those recommended for use with aluminum

boilers. Follow chemical cleaner manufacturer’s instructions

completely.

DO NOT

connecting boiler to heating system, clean and ush

mix different manufacturer’s products.

• When boiler installation is for new heating system,

install all of radiation units (panels, radiators,

baseboard, or tubing) and supply and return mains.

• After all heating system piping and components have

been installed, make nal connection of system piping

to boiler.

• Hot water boiler installed above radiation level, or as

required by the Authority having jurisdiction, must be

equipped with low water cut off device. This boiler is

factory equipped with manual reset probe type low

water cutoff.

• Periodic inspection is necessary per low water cut off

manufacturers specic instructions.

7.2 Supply & Return Lines

See Appendix A for piping examples.

• Packaged boiler set to receive 1¼” NPT return piping

from rear of unit with option for left or right return

connections.

• Use two furnished dielectric unions at boiler supply and

return connections between copper system piping and

boiler. Do not install copper supply and return piping

directly into aluminum boiler casting due to galvanic

corrosion between dissimilar metals.

• 1¼” NPT supply piping exits boiler jacket at top of unit.

• Some boilers supplied with circulator pump and

isolation valves are furnished in a carton inside boiler

cabinet and can be installed at installer preferred

location.

9

7 - NEAR BOILER PIPING

GATE VALVE

REDUCED PRESSURE

BACKFLOW PREVENTER

FEED

WATER

PRESSURE

REDUCING VALVE

AIR SCOOP

DIAPHRAGM TYPE

EXPANSION TANK

SUPPLY PIPING

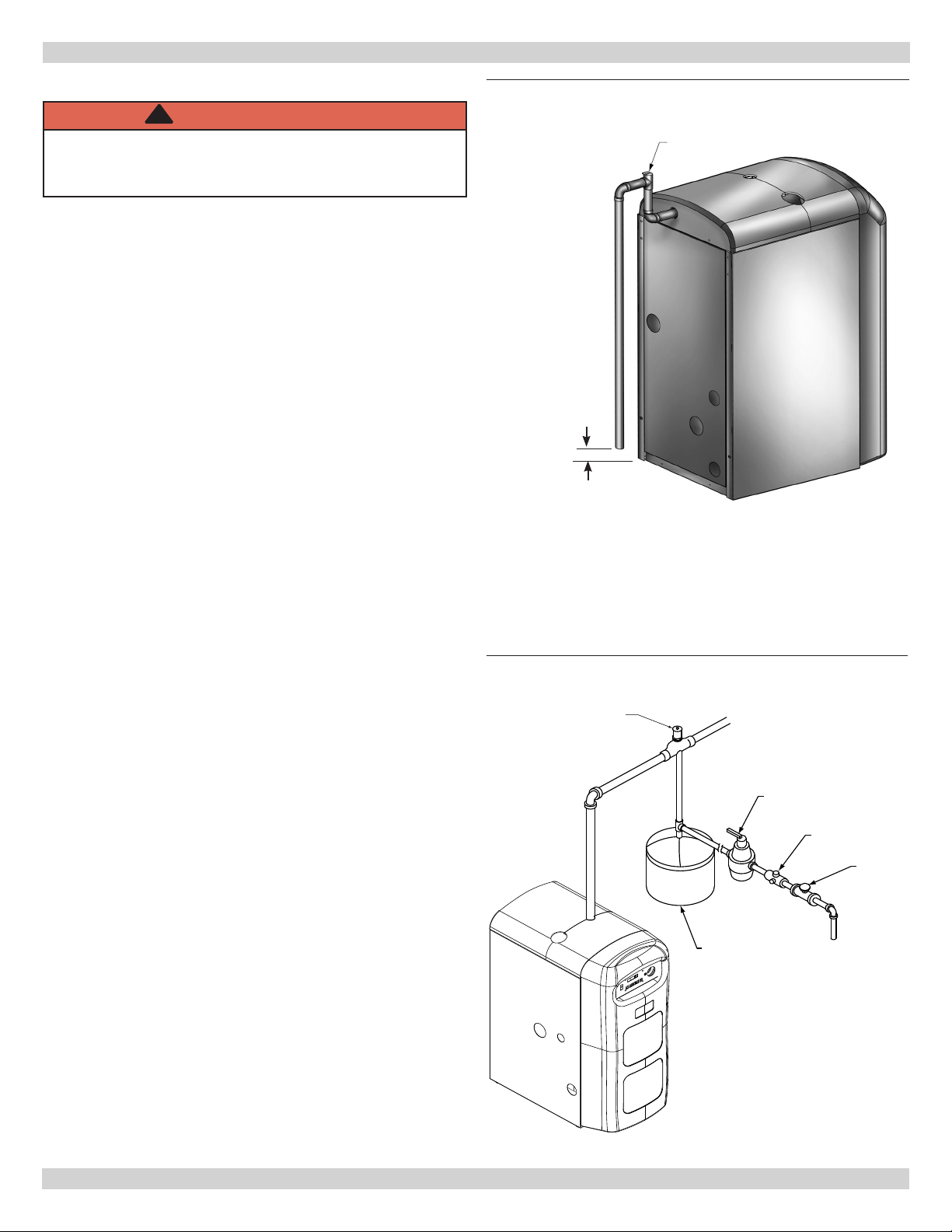

7.3

Safety Relief Valve / Temperature Pressure Gauge

!

WARNING

Burn and scald hazard. Safety relief valve could

discharge steam or hot water during operation.

Install discharge piping per these instructions.

Installation of (supplied) safety relief valve shall conform to

ANSI/ASME Boiler and Pressure Vessel Code, Section IV.

• Install furnished safety relief valve using 3/4” pipe

ttings provided with boiler. See Figure 2.

• Install safety relief valve with spindle in vertical

position.

• Do not install shutoff valve between boiler and safety

relief valve.

• Install discharge piping from safety relief valve. See

Figure 2.

• Use ¾” or larger pipe.

• Use pipe suitable for temperatures of 375°F (191°C) or

greater.

• Individual boiler discharge piping shall be independent

of other discharge piping.

• Size and arrange discharge piping to avoid reducing

safety relief valve relieving capacity below minimum

relief valve capacity stated on rating plate.

• Run pipe as short and straight as possible to location

protecting user from scalding.

• Install union, if used, close to safety relief valve outlet.

• Install elbow(s), if used, close to safety relief valve

outlet and downstream of union (if used).

• Terminate pipe with plain end (not threaded).

Figure 2 - Safety Relief Valve Discharge Piping

Safety Relief Valve

Check local codes

for maximum

distance from

oor.

FLOOR

Figure 3 -

Diaphragm Type Expansion Tank Piping

7.4 Expansion Tank & Make-up Water

• Determine required system ll pressure, system design

temperature, and system water content.

• Boiler contains 2.6 gallons (US). Size expansion tank

accordingly.

• Consult expansion tank manufacturer for proper sizing

information. Connect properly sized expansion tank

(not furnished) as shown in Figure 3 for diaphragm

type expansion tank.

• Adjust tank air pressure on diaphragm type expansion

tanks to match system ll pressure.

• Install air vent (furnished) as shown for diaphragm

type expansion tank system only.

• Install make-up water connections as show.

• If pressure reducing valve is used, adjust to match

system ll pressure.

• Verify clean water supply is available when connecting

cold make-up water supply to boiler.

• Use sand strainer at pump if water supply is from well

or pump.

10

7 - NEAR BOILER PIPING

7.5 Condensate Drain Piping

Boiler is factory equipped with a condensate trap.

Additional trap is not required and should NOT be used.

• Use supplied 1/2” PVC tee, transition to ½” pipe and

ttings for PVC condensate drain line.

• The ½” diameter schedule 40 PVC or CPVC condensate

drain and pipe ttings must conform to ANSI standards

and ASTM D 1785 or D2846.

• Schedule 40 PVC or CPVC cement and primer must

conform to ASTM D2564 or F493. In Canada, use

CSA or ULC certied schedule 40 PVC drain pipe and

cement.

• Condensate pump with reservoir (not furnished) to

remove condensate to drain line (sanitary line) above

boiler if oor drain is not available or is inaccessible.

7.6 Filling Condensate Trap with Water

On initial start up manually ll condensate trap with water.

Following are steps required to initially ll condensate trap

for start up. Steps are only required at initial start up or if

maintenance requires draining of condensate trap.

1.

Remove vent drain line from CPVC vent pipe. Pour

about 1 cup of cold tap water into vent drain line.

2.

Excess water should go through overow and out

through condensate drain line. Verify proper operation

of drain line (or external condensate pump if used).

3.

Reinstall vent drain line.

7.7 Chilled Water Piping

Install Boiler, when used in connection with refrigeration

system, so chiller medium is piped in parallel with boiler

with appropriate valves to prevent chilled medium from

entering boiler.

Piping system of hot water boiler connected to heating coils

located in air handling units where they may be exposed

to refrigerated air circulation must be equipped with ow

control valves or other automatic means to prevent gravity

circulation of boiler water during cooling cycle.

11

8 - COMBUSTION AIR AND VENT PIPE

8.1 Connections And Termination

Boilers for connection to gas vents or chimneys, vent

installations shall be in accordance with “Venting of

Equipment” of the National Fuel Gas Code, ANSI Z223.1/

NFPA 54, or “Venting Systems and Air Supply for

Appliances”, of the Natural Gas and Propane Installation

Code, CAN/CSA B149.1, or applicable provisions of local

building codes.

Provisions for combustion and ventilation air must be

in accordance with section, Air For Combustion and

Ventilation, of the National Fuel Gas Code, ANSI 2223.1/

NFPA54, National Gas and Propane Installation Code, CAN/

CGA-B 149.1, in absence of such requirements to the

Authority having jurisdiction.

Boilers require dedicated direct vent system. All air for

combustion is taken directly from outdoors through

combustion air intake pipe. All ue products are discharged

to outdoors through vent pipe.

1.

See Figures 5 and 6 for two pipe combustion air

and vent pipe roof and sidewall termination. Roof

termination is preferred. Combustion air and vent pipes

must terminate together in same atmospheric pressure

zone as shown.

2.

Use of concentric vent termination see Figures 7-9for

proper setup.

3.

For Canadian installations all plastic venting material

must be listed to ULC S636.

4.

Construction through which vent and air intake pipes

may be installed is maximum 24 inches, minimum ¼”

thickness.

5.

See Table 5 for combustion air and vent pipe ttings

approved material and standards.

6.

Canada construct all combustion air and vent pipes

for this unit of ULC S636 listed schedule-40 CPVC,

schedule-40 PVC, PVC-DWV or ABS-DWV pipe and pipe

cement. SDR pipe is not approved in Canada.

• First 3 feet (900mm) of venting must be readily

available for visual inspection.

• Specied primers and glues of certied vent

system must be from single manufacturer, and not

intermixed with other manufacturer’s vent system

parts.

• Components of the certied system must not be

interchanged with other vent systems, or unlisted pipe

and/or ttings.

Length of pipe is counted from end of supplied 2” CPVC

pipe exiting boiler. Termination is not counted in “Total

Equipment Length.”

TABLE 4

HDT

Material

PVC 158 70 – –

CPVC 210 100 – –

ABS 180 82 – –

°F °C °F °C

Maximum Allowable Temperatures

Of Typical Non-Metallic Vent Material

RTI

Standard

ASTM F 891 *

ASTM D2665 **

ASTM D1785 **

ASTM D2241 **

ASTM D2846 **

ASTM F441 **

ASTM F442 **

ASTM D2661 ***

ASTM F628 ***

* Allowable temperatures based on Classications covered in ASTM

D4396 [Deection Temperatures under Load (264psi) (1819 KPa)].

** Allowable temperatures based on Classications covered in ASTM

D1784 [Deection Temperatures under Load (264psi) (1819 KPa)].

*** Allowable temperatures based on Classications covered in ASTM

D3965 [Deection Temperatures under Load (264psi) (1819 KPa)].

Table 5 - Combustion air and vent pipe ttings

must conform with the following:

Item Material Standards

PVC schedule 40 ANSI/ASTM D1785

PVC - DWV ANSI/ASTM D2665

ANSI/ASTM D1784/

F441

UL 1738

ULC S636-08

Vent Pipe

and Fittings

Pipe

Cement/

Primer

CPVC schedule 40

SDR-21 & SDR-26 PVC ANSI/ASTM D2241

ABS-DWV ANSI/ASTM D2661

Schedule 40ABS ANSI/ASTM F628

PP (Polypropylene)

Pipe and Components

PVC ANSI/ASTM D2564

CPVC ANSI/ASTM F493

Schedule 40 ABS ANSI/ASTM D2235

NOTICE

Transition from 2” pipe to 3” pipe must be made in

vertical run.

7.

Boiler combustion air and vent pipe connections are 2”

but must increase to 3”. Due to potential for ue gas

temperatures above 155°F, rst 30” of supplied vent

pipe is CPVC while remaining vent pipe can be PVC. Any

replacement of rst 30” of vent pipe must be made with

CPVC.

8.

Covering non-metallic vent pipe and ttings with thermal

insulation shall be prohibited.

• IPEX is approved vent manufacturer in Canada listed

to ULC-S636.

• IPEX System 636 Cements and Primers are approved

in Canada listed to ULC-S636.

Use of cellular core PVC (ASTM F891), cellular core CPVC, or Radel® ,

(Polyphenolsulfone) in venting systems shall be prohibited.

!

WARNING

Use of cellular core PVC for venting ue gas could

result in death, or serious injury.

12

8 - COMBUSTION AIR AND VENT PIPE

!

WARNING

Covering non-metallic vent pipe and ttings with

thermal insulation shall be prohibited.

Allowable Vent and Air Intake Lengths

3” Pipe Min. Length 3” Pipe Max. Length

15 ft. equivalent length 100 ft. equivalent length

Length of pipe is counted from end of supplied 2” CPVC

pipe exiting boiler. Termination is not counted in “Total

Equivalent Length.”

Reduce maximum vent/air intake length by 5 feet per each

90° elbow.

Figure 4 - Combustion Air & Vent Piping

FIELD INSTALL 2” BY 3”

TRANSITION IN THE

VERTICAL POSITION

ONLY (2 REQ’D, NOT

FURNISHED)

2” (50.8MM)

COMBUSTION AIR

INTAKE PIPING

(FURNISHED)

9.

Combustion air must be clean outdoor air. Do not take

combustion air from inside structure because that air

is frequently contaminated by halogens, which includes

uorides, chlorides, phosphates, bromides and iodides.

These elements are found in aerosols, detergents,

bleaches, cleaning solvents, salts, air fresheners, paints,

adhesives, and other household products.

10.

Locate combustion air inlet as far away as possible from

swimming pool and swimming pool pump house.

11.

All combustion air and vent pipes must be airtight and

watertight.

12.

Pitch exhaust air piping back to boiler at minimum ¼” per

foot from vent terminals so all moisture in vent piping

drains to boiler. Pitch pipes with no sags or low spots

where moisture can accumulate and block ow of ue gas.

13.

Vent connections serving appliances vented by

natural draft shall not be connected into any portion

of mechanical draft systems operating under positive

pressure.

3” INTAKE AND

EXHAUST

TERMINATIONS

2” (50.8MM)

CPVC

VENT PIPING

(FURNISHED &

REQUIRED)

8.2 Vent/Air Intake Termination Location

Consider following when determining appropriate location

for termination of combustion air and vent piping.

A. Position termination where vent vapors will not

damage plants/shrubs, air conditioning equipment, or

siding on the house.

B. Position termination so it will not be effected by wind

eddy, air born leaves, snow, or recirculated ue gases.

C. Position termination where it will not be subjected to

potential damage by foreign objects, such as stones,

balls, etc.

D. Position termination where vent vapors are not

objectionable.

E. Put vent on wall away from prevailing winter wind.

Locate or guard vent to prevent accidental contact

with people or pets.

F. Terminate vent above normal snow-line. Avoid locations

where snow may drift and block vent. Ice or snow may

cause boiler to shut down if vent becomes obstructed.

G. Under certain conditions, ue gas will condense,

forming moisture, and may be corrosive. In such

cases, take steps to prevent building materials at

vent from being damaged by exhaust of ue gas.

H. United States - Terminate vent system at least 4

feet (1.22 m) horizontally from, and in no case

above or below, unless a 4 feet (1.22 m) horizontal

distance is maintained, from electric meters, gas

meters, regulators and relief equipment.

I. Canada - Terminate vent system at least 6 feet

(1.83m) horizontally from, and in no case above

or below, unless 6 feet (1.83m) horizontal distance

is maintained, from electric meters, gas meters,

regulators and relief equipment.

J. Terminate venting system at least 3 feet (0.3m)

above any forced air inlet (except boiler’s

combustion air inlet) within 10 feet (3m).

K. Terminate venting system at least 12 inches

(300mm) from any air opening into any building.

L. Locate bottom of vent at least 12 inches (300mm)

above grade.

M. Terminate vent not less than 7 feet (2.1m) above

adjacent public walkway.

N. Vent terminal shall not be installed closer than 3 feet

(0.9m) from inside corner of L shaped structure.

O. Termination of vent should be kept at least 3 feet

(0.9m) away from vegetation.

P. If multiple terminations are used, minimum of

12 inches (300 mm) between exhaust of one

termination and air intake of next termination. See

pages 14 & 15.

Q. All eld installed vent pipe must be 3”.

13

8 - COMBUSTION AIR AND VENT PIPE

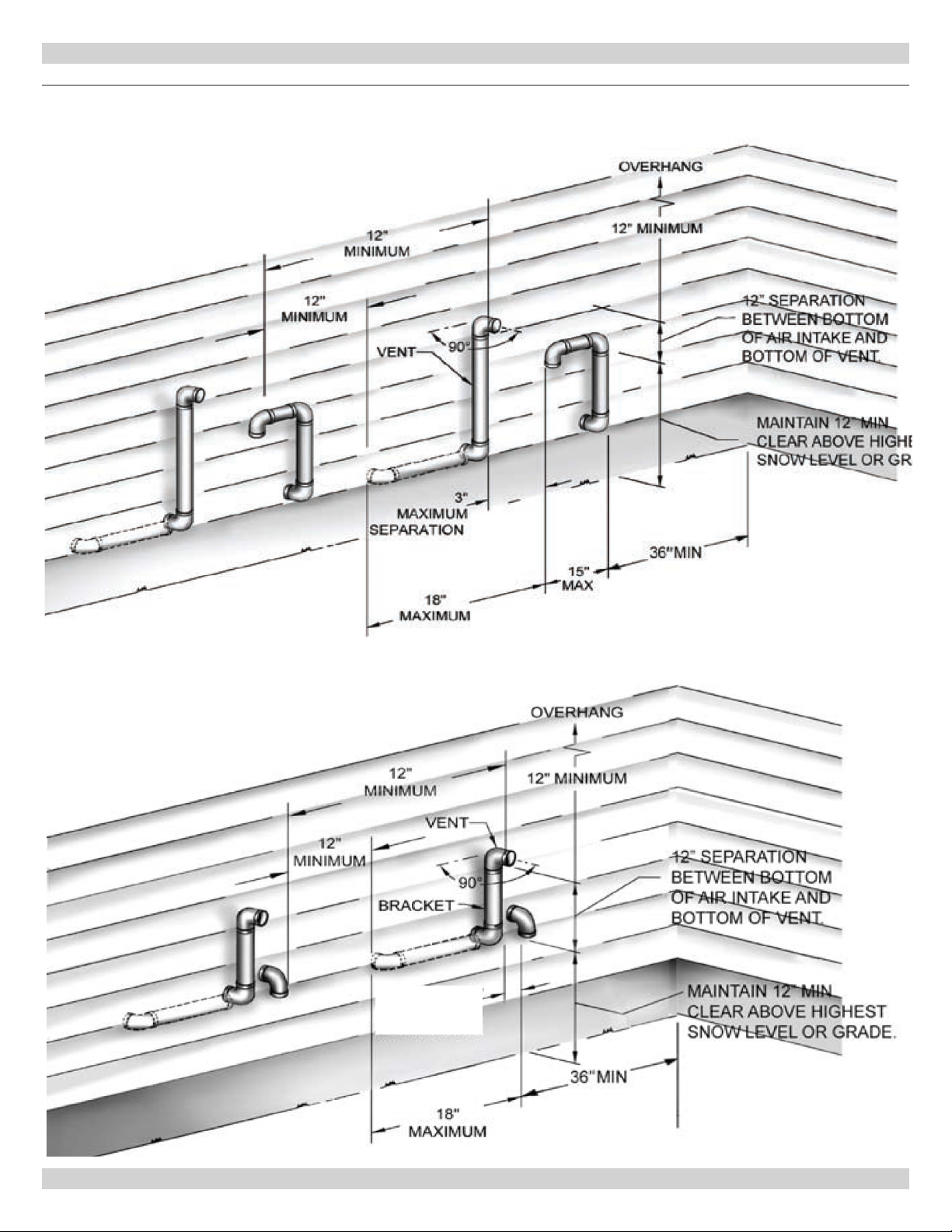

Figure 5 - Side Wall Vent / Intake terminations - Less Than 12” Clearance Above Grade

3” MIN

SEPARATION

14

8 - COMBUSTION AIR AND VENT PIPE

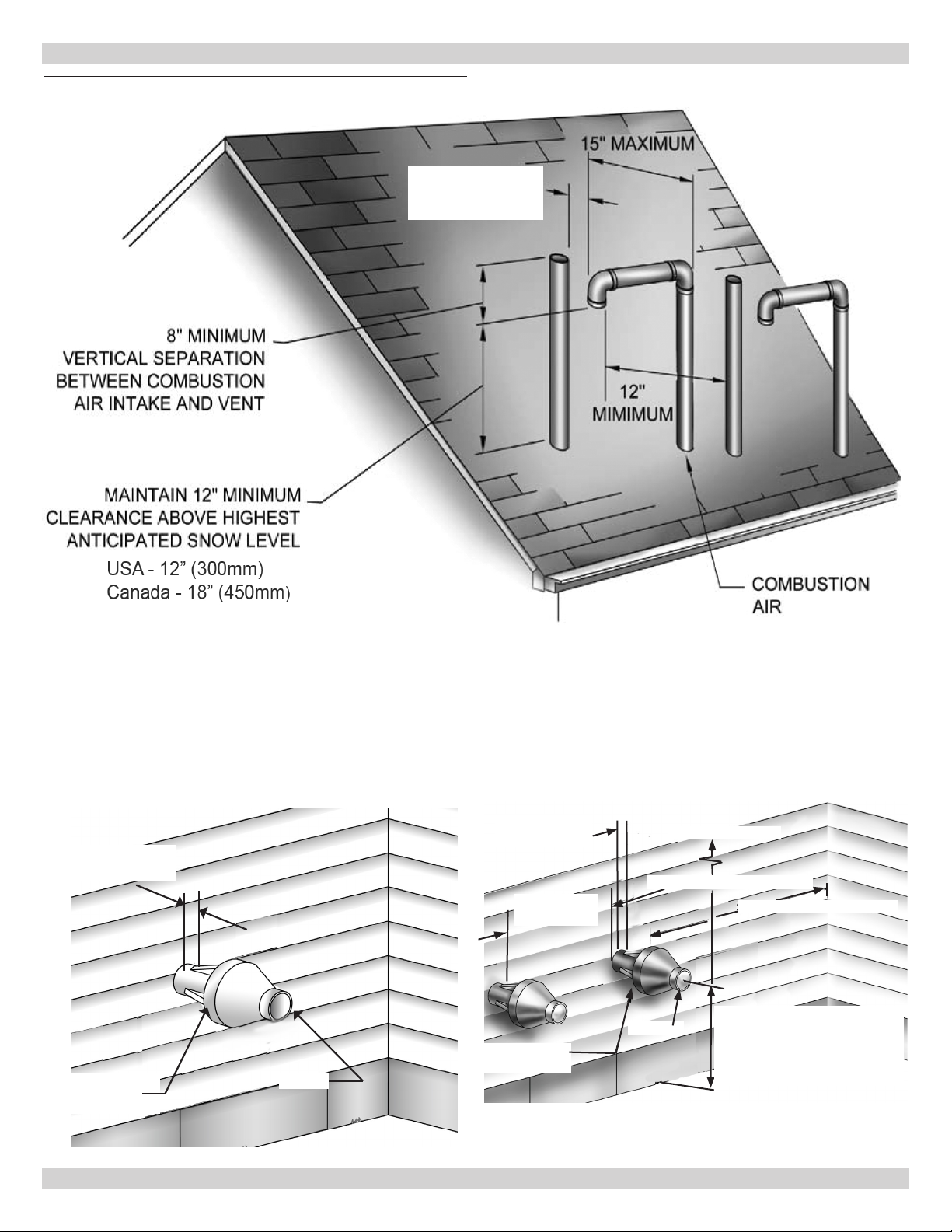

Figure 6 -Roof Vent / Intake Terminations

3” MINIMUM

SEPARATION

Figure 7 - Concentric Vent Terminations

1" (26mm)

Maximum

Combustion

Vent

Air

1" (26mm)

Maximum

* See Note

Below

Combustion

Air

Roof Overhang

12" (300mm) Minimum

36"(915mm) Minimum

Maintain 12"(300mm)

Vent

clearance above highest

anticipated snow level or

grade

*Must be less than 4" (102mm) or greater than

24"(610mm) Horizontal distance between end bells of each

air intake to prevent ue gas recirculation.

15

8 - COMBUSTION AIR AND VENT PIPE

MAINTAIN 12 IN.

8.3 Installation

When transitioning from CPVC to PVC use Weld-On CPVC

724 or other cement approved for CPVC to PVC. In Canada

ULC S636 approved cement must be used.

1.

Recommend all pipes be cut, prepared, and preassembled before permanently cementing any joint.

2.

Rigid supports cause excess noise in vent piping.

3.

Attach combustion air intake piping to supplied 2”

piping on CVI gas valve. Attach vent piping to furnished

2” CPVC preformed exhaust pipe. Use 2” x 3” adapter

in vertical position on both air intake and vent pipe.

4.

All pipe joints are to be water tight.

5.

Working from boiler to outside, cut pipe to required

length(s).

6.

Deburr inside and outside of pipe. Remove all chips and

shavings.

7.

Chamfer outside edge of pipe for better distribution of

primer and cement.

8.

Clean and dry all surfaces to be joined.

9.

Check dry t of pipe and mark insertion depth on pipe.

10.

After pipes have been cut and pre-assembled, apply

cement primer to pipe tting socket and end of pipe to

insertion mark. Quickly apply approved cement to end

of pipe and tting socket (over primer). Apply cement

in light, uniform coat on inside of socket to prevent

buildup of excess cement. Apply second coat.

11.

While cement is still wet, insert pipe into socket with

¼ turn twist. Be sure pipe is fully inserted into tting

socket.

12.

Wipe excess cement from joint. Continuous bead of

cement will be visible around perimeter of properly

made joint.

13.

Handle pipe joint carefully until cement sets.

14.

Support combustion air and vent piping minimum of

every 5 feet using pre-formed metal hanging straps. Do

not rigidly support pipes. Allow for movement due to

expansion and contraction.

15.

Slope combustion air and vent pipes toward boiler

minimum of ¼” per linear foot with no sags between

hangers.

16.

Use appropriate methods to seal openings where vent

and combustion air pipes pass through roof or side

wall.

Figure 8 - Concentric Vent w/ Dimensions

A

C

B

E

Dimension

D

E

F

4½” Dia.

G

G

F

³⁄16

1

46¾”

31⅞”

”

Dimension

3” Diameter PVC

A

Vent/Exhaust

B

C

Intake/Combustion Air

A

B

1½”

3” Diameter PVC

D

C

Figure 9 - Concentric Vent Roof Installation

16

Loading...

Loading...