Page 1

SW SERIES 2

OIL FIRED DIRECT EXHAUST

CAST IRON BOILER

Model

SW3065

SW4100

SW5125

INSTALLATION, OPERATION &

MAINTENANCE MANUAL

An ISO 9001-2008 Certified Company

Tested For 75 psig

ASME Working Pressure

Manufacturedby:

ECRInternational,Inc.

2201 Dwyer Avenue, Utica NY 13501

web site: www.ecrinternational.com

P/N# 240009678, Rev . B [ 0 2/20 13 ]

Page 2

DIMENSIONS

A

LENGTH OF FLUSH

BOILER

NO.

SW3065 17 7/8" 11 1/4" 4"

SW4100 21 1/2" 12 5/8" 4"

SW5125 25 1/8" 14 1/4" 4"

JACKET

FRONT OF CASTING

TO CENTER LINE OF

FLUE OUTLET

B

DIAMETER OF FLUE

OUTLET

C

2

Page 3

TABLE OF CONTENTS

!

Dimensions ................................................................................................................................. 2

Safety Symbols ..........................................................................................................................3

Installation ................................................................................................................................ 4

Connecting Supply And Return Piping ............................................................................................. 5

Recommended Piping For Boilers Equipped With A P3 Or T4 Tankless Heater ........................................ 9

Options Utilizing 3/4" Tapping ......................................................................................................10

Oil Tank And Piping .....................................................................................................................11

Electrical Wiring .........................................................................................................................12

Sequence Of Operation................................................................................................................14

Operating Instructions .................................................................................................................15

Instructions To Obtain Proper Operation Of The Boiler-Burner Unit ....................................................16

Preventive Maintenance ...............................................................................................................17

Instructions For Opening And Closing Burner Swing Door .................................................................17

Ratings and Data ........................................................................................................................18

Service Check List ......................................................................................................................19

KEEP THIS MANUAL NEAR BOILER

RETAIN FOR FUTURE REFERENCE

IMPORTANT: Read the following instructions

COMPLETELY before installing.

Safety Symbols & Warnings

The following defi ned symbols are used throughout this

manual to notify the reader of potential hazards of varying

risk levels.

!

DANGER

Indicates a hazardous situation which, if not avoided,

WILL result in death or serious injury

!

WARNING

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

!

CAUTION

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

NOTICE

Used to address practices not related to personal

injury.

Boiler installation shall be completed by qualifi ed agency.

!

WARNING

Keep boiler area clear and free from combustible

materials, gasoline and other fl ammable vapors

and liquids.

DO NOT obstruct air openings to the boiler room.

Modifi cation, substitution or elimination of factory

equipped, supplied or specifi ed components may

result in personal injury or loss of life.

TO THE OWNER - Installation and service of this

boiler must be performed by a qualifi ed installer.

TO THE INSTALLER - Leave all instructions with

boiler for future reference.

!

WARNING

Fire, explosion, asphyxiation and electrical shock

hazard. Improper installation could result in death

or serious injury. Read this manual and understand

all requirements before beginning installation.

NOTICE

When this product is installed in the Commonwealth

of Massachusetts installation must be performed by

a Licensed Plumber or Licensed Gas Fitter.

3

Page 4

INSTALLATION

!

WARNING

Improper installation, adjustment, alteration, service

or maintenance could result in death or serious

injury.

Installation

Installation shall conform to requirements of authority

having jurisdiction or in the absence of such requirements,

NFPA 31: Installation Code for Oil Burning Equipment.

Where required by authority having jurisdiction, installation

shall conform to standard for Controls and Safety Devices

for Automatically fi red boilers, ANSI/ASME CSD-1.

Locate boiler in front of fi nal position before removing

crate. Provide level solid base as near to vent outlet

as possible and centrally located with respect to heat

distribution system as practical.

Allow 24 inches in front and top for servicing and cleaning,

or removing tankless water heating coil.

Fire hazard. Do not install boiler on combustible fl ooring

or carpeting. Failure to follow these instructions could

result in death or serious injury.

FOR INSTALLATION ON NON-COMBUSTIBLE FLOORS ONLY

- The boiler must not be installed on carpeting or vinyl

fl ooring. Minimum clearances to combustible construction

are:

Minimum clearances to combustible construction are:

TOP .................................................0 IN.

FRONT .... ......................................24 IN.*

FLUE CONNECTOR .............................2 IN.

REAR ...............................................6 IN.

LEFT SIDE ........................................0 IN.

RIGHT SIDE ......................................0 IN.

Recommended clearance for service access should exceed

fi re protection clearance.

!

WARNING

* "FOR ALCOVE INSTALLATION"

When installed in utility room, door should be wide enough

to allow largest boiler part to enter, or permit replacement

of another appliance such as water heater.

TOP ...............................................24 IN.

FRONT ...........................................24 IN.

FLUE CONNECTOR .............................9 IN.

REAR ...............................................6 IN.

LEFT SIDE ......................................10 IN.

RIGHT SIDE ......................................6 IN.

Remove crate and plastic protective wrapper and inspect

for damage.

Our responsibility ceases upon delivery of the crated boiler

to the carrier in good condition. Any claims for damage or

shortage in shipment must be fi led immediately against

carrier by consignee. Move boiler to permanent position by

sliding or walking.

4

Page 5

CONNECTING SUPPLY AND RETURN PIPING

Circulators in following illustrations are mounted on

system supply side, mounting on system return side is also

acceptable practice.

Figure 1 - Typical Installation Using Circulators

Figure 2 - Typical Installation Using Zone Valves

5

Page 6

CONNECTING SUPPLY AND RETURN PIPING

1.

Typical installation using circulators shown in

1

.

2.

Typical installation using zone valves shown in

.

2

3.

Hot water boilers installed above radiation level must

be provided with low water device either as part of

boiler or at time of boiler installation.

Figure

Figure

• Method used to protect systems using radiant

panels and material they are encased in from high

temperature supply water from boiler. See

3

.

• Method used to protect boilers from condensate

forming due to low temperature return water.

Generally noticed in large converted gravity systems

or other large water volume systems. See

Figure

Figure 4

.

4.

When boiler is connected to heating system utilizing

multiple zoned circulators, each circulator must be

supplied with fl ow control valve to prevent gravity

circulation.

• Reduced pressure back fl ow preventer must be

present under provisions required by Environmental

Protection Agency (EPA).

5.

Bypass piping is an option which gives ability to adjust

supply boiler water temperature to fi t system or

condition of installation. This method of piping is not

typically required for baseboard heating systems.

Figure 3

• Method used to protect boilers from condensate

forming as well as protecting heating system from

high water temperature. See

6.

When using bypass piping, adjust valves A and B until

desired system temperature is obtained.

7.

Bypass loop piping must be same size piping for supply

and return.

8.

Connect supply and return piping as suggested in

Figure 6

refrigerated systems:

, when boiler is used in connection with

Figure 5

.

Check local codes for maximum

from fl oor or allowable safe point of

discharge

6

Page 7

Figure 4

CONNECTING SUPPLY AND RETURN PIPING

Figure 5

Check local codes for maximum

from fl oor or allowable safe point of

discharge

Check local codes for maximum

from fl oor or allowable safe point of

discharge

7

Page 8

CONNECTING SUPPLY AND RETURN PIPING

A. Chilled medium must be in parallel with the boiler.

B. Use appropriate valves to prevent chilled medium

from entering heating boiler.

9.

During heating cycle open valves A and B, close valves

C and D.

10.

During heating cooling cycle open valves C and D, close

valves A and B.

A. Maintain minimum clearance of one inch to hot

water pipes.

In air handling units where they may be exposed to

refrigerated air circulation, boiler piping system MUST be

supplied with fl ow control valves or other automatic means

to prevent gravity circulation of boiler water during cooling

cycle.

!

WARNING

Burn and scald hazard. Safety relief valve could

discharge steam or hot water during operation.

Install discharge piping from safety relief valve.

• Use ¾” or larger pipe.

• Use pipe suitable for temperatures of 375°F (191°C)

or greater.

• Individual boiler discharge piping shall be independent

of other discharge piping.

• Size and arrange discharge piping to avoid reducing

safety relief valve relieving capacity below minimum

relief valve capacity stated on rating plate.

• Run pipe as short and straight as possible to location

protecting user from scalding and properly drain

piping.

• Install union, if used, close to safety relief valve outlet.

• Install elbow(s), if used, close to safety relief valve

outlet and downstream of union (if used).

• Terminate pipe with plain end (not threaded).

Figure 6

Check local codes for maximum

from fl oor or allowable safe point of

discharge

8

Page 9

RECOMMENDED PIPING FOR BOILERS EQUIPPED WITH A P3 OR T4 TANKLESS HEATER

!

DANGER

Burn, scald hazard. Water temper atures ex ceeding

125º F will cause severe burns instantly or death by

scalding.

• An automatic mixing valve must be installed on the

outlet of the domestic coil. Installation must comply

with the valve manufacture’s recommendations, and

instructions.

• Do not remove the bolts or limit at the time of

installation.

• Pipe in accordance with the installation manual.

• Due to varying water conditions, an adjustable fl ow

restrictor must be installed in the cold water inlet of

this coil.

Figure 7 Recommended Piping For Boilers Equipped With A P3 Or T4 Tankless Heater

9

Page 10

OPTIONS UTILIZING 3/4" TAPPING

Figure 8 -

Optional Location For Air Vent

Figure 9 -

Optional Location For Expansion Tank (Non-Diaphragm Type)

10

Page 11

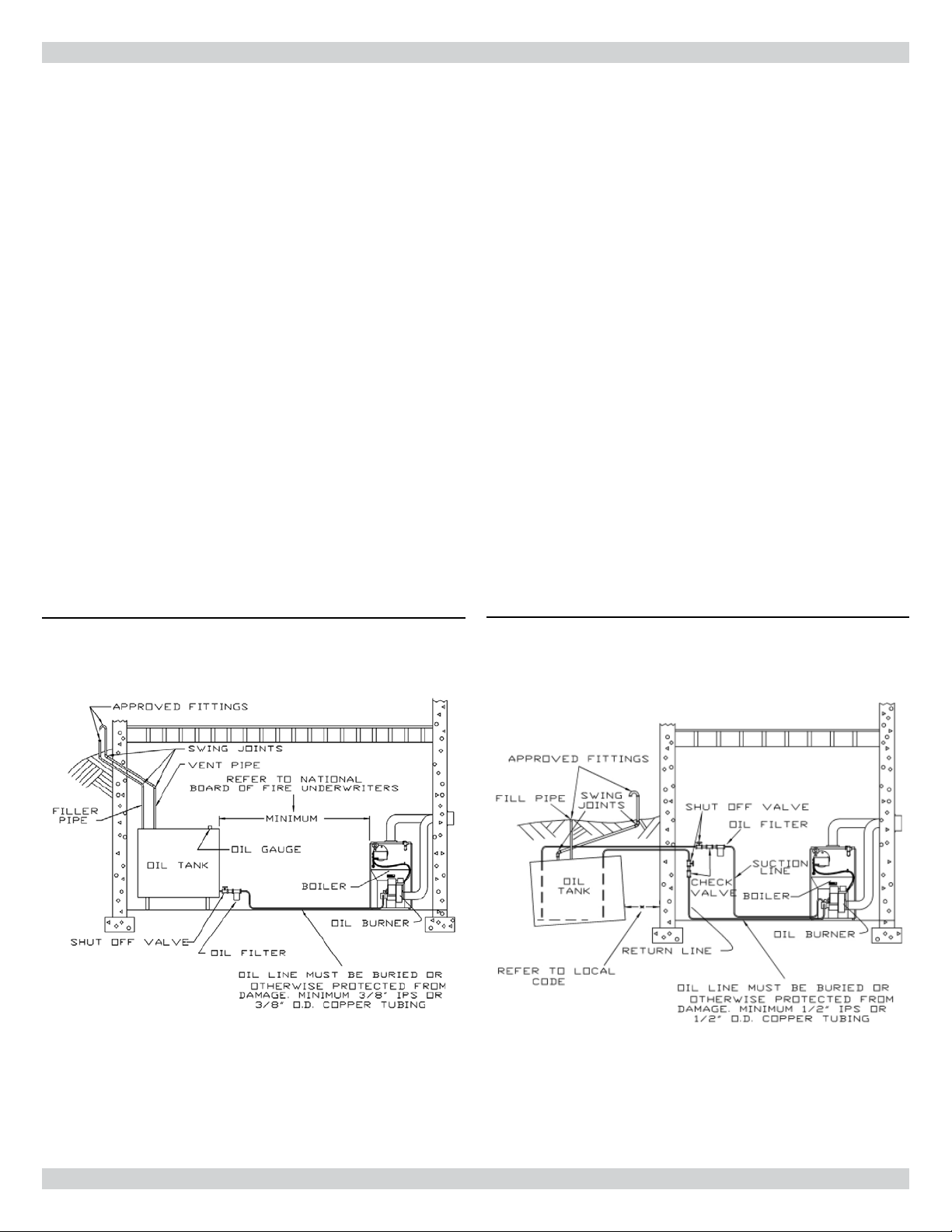

OIL TANK AND PIPING

Install Oil tank and piping in accordance with the

National Board of Fire Underwriters and in absence of such

regulations in accordance with authority having jurisdiction.

Oil storage tank, vent, fi ll pipe and caps should be in

accordance with the authority having jurisdiction.

A. In no case should vent pipe be smaller than 1-1/4"

I.P.S.

B. Fill pipe should not be less than 2" I.P.S.

• Suction line from tank to burner should be one

continuous piece of tubing to prevent air entering line.

Suction line, must be 3/8" O.D. copper tubing for runs

of 50 feet or less, and 1/2" O.D. for longer runs.

• Oil return line, same size as suction line, must be used

on any installation where bottom of tank is below fuel

unit of burner.

• Oil lines should be buried or otherwise protected from

mechanical injury.

• Flare fi ttings on all oil lines are recommended.

• Compression fi ttings on suction line often allow air to

be drawn into fuel pump, making it diffi cult to maintain

oil pressure at nozzle.

• Do not run overhead fuel lines from tank to oil burner.

• Fuel pump connections and by-pass should be made

according to instructions attached to fuel pump. If

tank is more than 20' from the boiler, a two stage

fuel unit should be installed in place of single stage

pump supplied as standard equipment with burner.

Make certain rotation and speed are same and pump is

suitable for burner horsepower rating.

• Oil line fi lter and shut-off valve should be installed in

suction line.

• Shut-off valves should be installed in both suction

and return lines at burner for convenience in servicing

burner.

• Allow extra tubing at burner so burner may be removed

from boiler for cleaning without disconnecting tubing.

Figures 10 & 11

(See

• A UL approved fl exible oil line may be used.

).

Figure 10 System

Typical Installation Single Pipe Oil

Figure 11 System

Typical Installation Two Pipe Oil

11

Page 12

ELECTRICAL WIRING

Install electrical wiring in accordance with

requirements of authority having jurisdiction, or

in the absence of such requirements, NFPA 70:

Electrical Code.

• Separate electrical circuit should be run from entry

box with fused disconnect switch in this circuit.

• See wiring diagrams in

suggested circuitry and fi eld wiring see Normal

Sequence of Operation in this manual.

• Wiring for zone valve installations are furnished with

zone valve packages.

Figure 12 -

Wiring Diagram For Oil Fired Boilers Less Tankless Heater And Beckett Burner

Figures 12 & 13

for

12

Page 13

ELECTRICAL WIRING

Figure 13 -

Wiring Diagram For Oil Fired Boilers With Tankless Heater And Beckett Burner

13

Page 14

ELECTRICAL WIRING

Thermostat Installation

1.

Install thermostat on inside wall about four feet above

fl oor.

2.

Never install thermostat on outside wall.

3.

Do not install thermostat where it will be affected by:

A. Drafts

B. Hot or cold pipes

C. Sun light

D. Lighting fi xtures

E. Television sets

F. A fi replace or chimney

SEQUENCE OF OPERATION

Sequence of Operation - Non-Tankless

• Thermostat calls for heat.

• Circulator turns on.

• Limit checks boiler water temperature. Burner ignition

delayed until limit determines call for heat cannot be met

by residual heat in boiler and heat distribution system.

See limit literature for additional information.

• Burner and circulator operation continues until

thermostat stops call for heat.

4.

Check thermostat operation by raising and lowering

thermostat as required to start and stop burner.

5.

Instructions for fi nal adjustment of thermostat

are packaged with thermostat (adjusting heating

anticipator, calibration, ect.).

Sequence of Operation - Tankless

• Thermostat will activate, completing circuit to limit

control.

• Circulator motor starts and power is switched to

limit. If limit circuit is closed burner motor circuit is

energized.

• Burner motor starts prepurge and approximately 15

seconds after solenoid valve opens and ignition system

is activated, ignition will begin.

• In event boiler water temperature exceeds high limit

setting on boiler mounted limit control; Power will be

interrupted between limit control and ignition system.

Burner motor will continue to run in post purge mode

for approximately 2 min. or until water temperature

drops below high limit setting. Circulator will continue

to operate under this condition until thermostat is

satisfi ed.

• When thermostat is satisfi ed power is interrupted to

boiler mounted limit control and burner will run in post

purge mode for 2 minutes.

14

Page 15

OPERATING INSTRUCTIONS

Venting system should be inspected at start of each heating

season.

• Check vent pipe from boiler to termination cap for

signs of deterioration by rust or cracked silicone joints.

Repair if necessary.

• Lever of safety relief valve, shown in Figure 17, on

page 18, on boiler should be operated periodically to

Instruments are only reliable method to determine proper

air adjustments. Improperly adjusted burner causes soot

and high fuel bills because of incomplete combustion of fuel

oil. This in turn may require excessive boiler maintenance,

service costs. Consult competent service mechanic to make

proper adjustments with smoke tester, CO

draft gauge. Bacharach or Dwyer test kits include these

instruments.

make sure it is functioning properly. Pressure relief

valve should open before water pressure exceeds

30 psi. reading on gauge. If pressure is exceeded

• 1/4" diameter slot is provided in inspection cover plate

and pressure relief valve leaks water when boiler is

operating at normal pressures, immediately replace.

• 3/8" hole is provided in vent appliance adapter to take

Corrosion can build up rapidly at valve seat preventing

it functioning as safety device.

• Adjust air dial on oil burner to obtain trace of smoke.

Start-up and adjustment of oil burner (See oil burner

instructions for nozzle and electrode setting).

• Check draft over fi re and in vent, normal readings will

A. Check oil burner nozzle to make certain it is tight in

adapter. Burner mounting bolts should be tight.

B. Check electrode setting, as they may have been

jarred out of position during transportation.

Table page 17 is provided as guideline for initial startup. Final adjustments MUST be made using combustion

instruments as previously mentioned.

C. Lubricate burner motor and circulator motor if

required. Some circulators are water lubricated and

do not require oiling.

D. Set room thermostat to call for heat.

E. Open all oil line valves.

F. Turn service switch on. Burner should start.

G. On one pipe fuel systems only, vent pump as soon

as burner starts. Allow oil to run until all traces of

air in the suction line disappear.

H. Turn “OFF” burner and install pressure gauge in

port on pump.

I. Start burner again and check oil pressure for 140

psi. Adjust if necessary.

indicator and

2

to take draft reading in combustion chamber.

draft, CO2, smoke, and temperature readings.

Measure CO2 at this point and increase air setting until

CO2 = 1-1.5% lower than reading at trace point.

be positive (+.01 Over-fi re & +.02 In Vent) W.C.

15

Page 16

INSTRUCTIONS TO OBTAIN PROPER OPERATION OF THE BOILER-BURNER UNIT

Check Safety Control Circuit after burner adjustments

have been made for satisfactory performance.

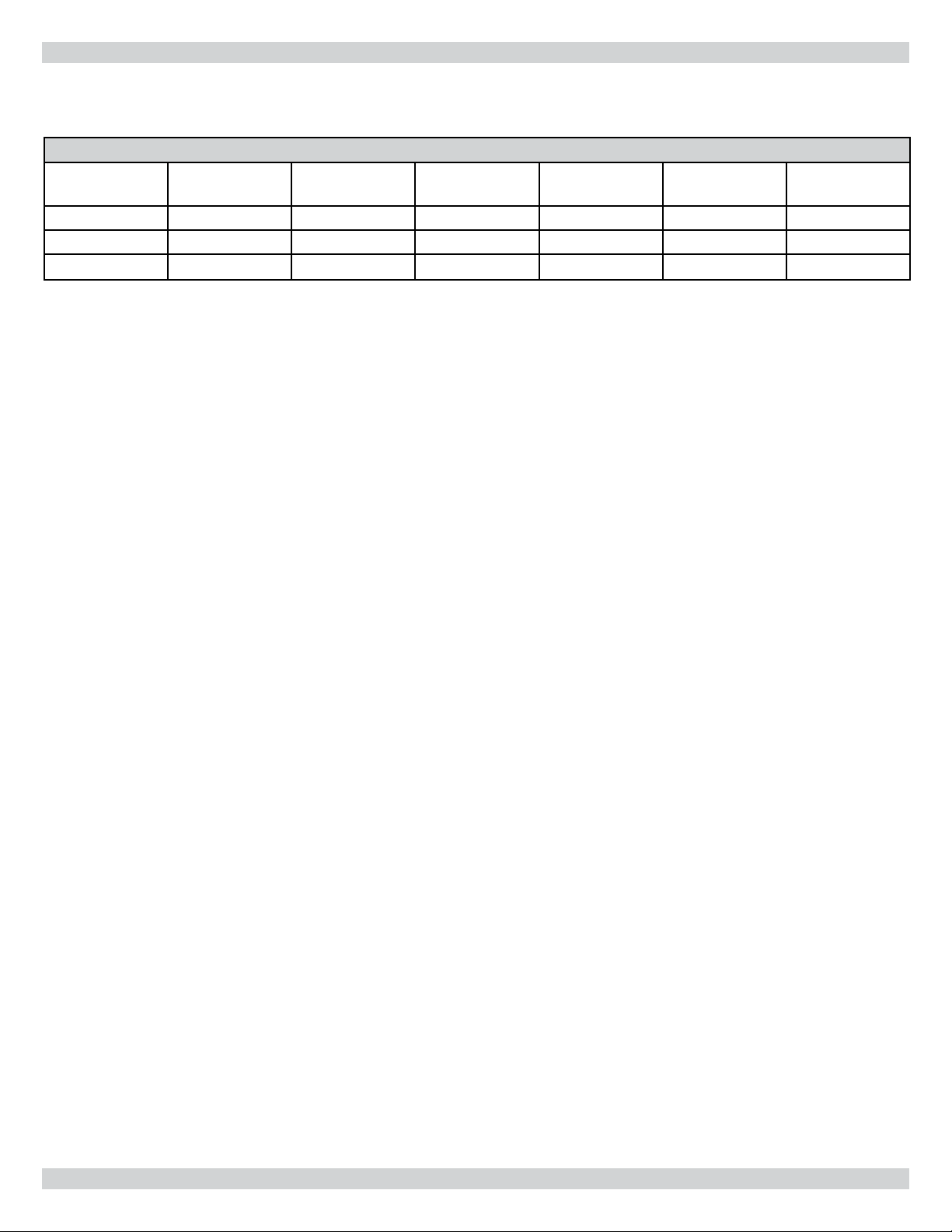

BECKETT SETTINGS

Boiler

No.

SW3065 AFII 100 3.25 3 140 PSI HLX 6 .60 45B

SW4100 AFII 100 7.50 5 140 PSI HLX 6 .85 45B

SW5125 AFII 150 5.00 8 140 PSI HLX 6 1.10 45B

Burner

No.

Air

Damp

Pin

Pump

Pressure

Head

Nozzle

Furnished

A. HIGH LIMIT CONTROL: remove cover and note

temperature setting. See fi gure 15 on page 15. With

burner operating, decrease this setting to minimum

point. When boiler water temperature exceeds this

set point, high limit switch will open, shutting off

power to oil burner and starting post purge cycle for

approximately 2 minutes. Return setting to desired

high limit point. Burner should restart.

B. PRIMARY CONTROL AND FLAME SENSOR:

To Check:

• Flame failure - simulate by shutting off oil supply

with hand valve while burner is on. 15 seconds after

fl ameout, safety switch locks out, ignition stops,

motor stops and oil valve closes. To restart, open oil

supply valve and reset safety switch.

• Ignition failure - with burner off, unplug electrical

disconnect on burner harness. Disconnect one wire

from transformer and put wire nut on disconnected

wires . Restore power and run through start-up

procedure, safety switch should lockout as fl ame

failure. Reconnect wires after this procedure is

complete.

• Power failure - Turn off main power supply switch

while burner is operating. When burner stops, restore

power and burner should start.

If operation is not as described as above, check wiring and

controls.

16

Page 17

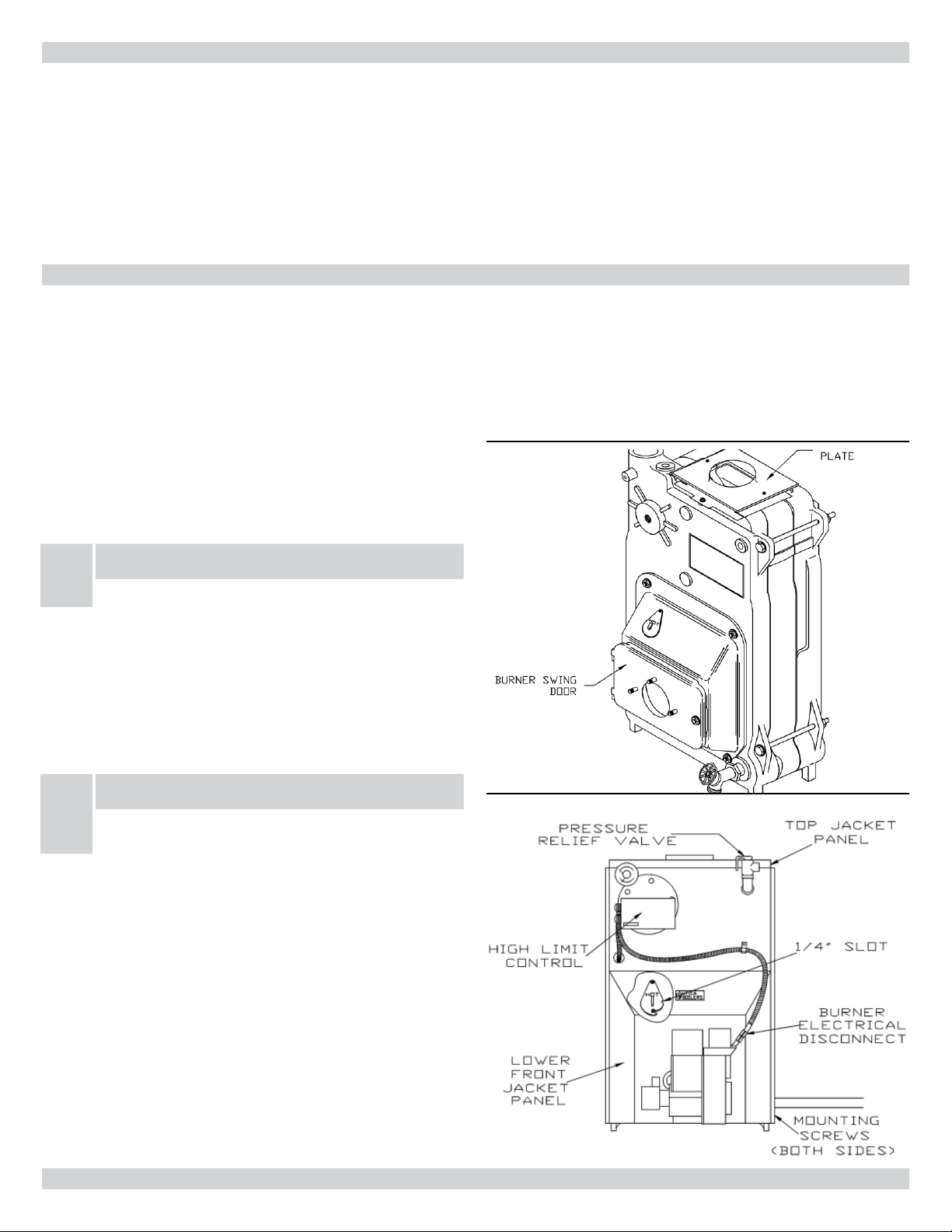

PREVENTIVE MAINTENANCE

Preventive Maintenance of oil fi red boiler reduces op-

erating costs. Boiler and vent pipe should be inspected for

accumulation of soot or scale deposits periodically but at

least once every year before start of each heating season.

When soot is present on section walls and fl ueways, im-

proper combustion will result, causing additional sooting

and scaling until fl ueways are completely closed. To remove

soot and scale from fl ueways, remove top jacket panel, top

clean-out plate, and open burner swing door. (

Figure 14

).

INSTRUCTIONS FOR OPENING AND CLOSING BURNER SWING DOOR

Instructions for Opening Burner Swing Door

1.

Turn off power to boiler.

2.

Allow boiler to cool down.

3.

Disconnect power cable at factory supplied burner

electrical disconnect. See

4.

Loosen screws on sides of lower front jacket panel. See

Figure 15

5.

Pull bottom part of lower front panel forward.

6.

Lift lower front panel up and off boiler. See

7.

Close oil valve. See

8.

Disconnect oil line from burner.

.

Figure 15

Figures 10 and 11

.

Figure 15

.

.

Periodic Inspection and tightening of tankless heater/

cover plate bolts will reduce risk of leaks.

3.

Replace oil line to burner.

4.

Replace inlet air pipe.

5.

Replace lower jacket panel, and tighten screws.

6.

Connect power cable at factory supplied burner

electrical disconnect.

7.

Turn on power to boiler.

8.

Bleed oil line.

Figure 14

NOTICE

Do not try to swing door with oil line attached

9.

Disconnect inlet air pipe from side of burner.

10.

Remove nut from swing door stud on right hand side of

door.

11.

Swing open burner and door to left.

12.

Using fl ue brush, brush soot and scale into combustion

space where it can be removed through swing door

opening.

NOTICE

Use caution when vacuuming in the chamber area.

Damage to chamber could result.

Recommend to replace nozzle at start of each heating

season. Lubricate burner motor and circulator motor - if

required - with few drops of good grade light motor oil.

Do not over oil. Have competent service person service

burner, check controls and check electrodes for carbon or

cracks in insulators. Burners should be adjusted to produce

conditions shown in Start-up and Adjustment of Oil Burner

procedure.

Figure 15

Instructions for Closing Burner Swing Door

1.

Swing burner and door to right until insulation is

slightly compressed and stud is exposed.

2.

Attach nut to stud and tighten it until built in stop

contacts mounting door.

17

Page 18

RATINGS AND DATA

RATINGS AND DATA

AHRI NET

RATINGS

WATER

MBH

(2)

A.F.U.E.

RATING

BOILER

MODEL

NUMBER

OIL BURNER INPUT

G.P.H. MBH MBH*

(1)

HEATING

CAPACITY

SW3065 .65 91 78 68 85.0

SW4100 1.00 140 120 104 85.0

SW5125 1.25 175 150 130 85.0

NOTES:

1. AHRI burner input is based on an oil heating value of 140,000 Btu/gal.

2. Net AHRI Water Ratings shown are based on a piping and pickup allowance of 1.15. Consult

manufacturer before selecting boiler for installations having unusual piping and pickup requirements,

such as intermittent system operation, extensive piping.

3. 120 Volts, 15 Amps, & 60 Hz. required to operate this boiler.

STANDARD EQUIPMENT: Crated Boiler, Flush Jacket, Oil Burner, Target Wall/Liner, Circulator-1 1/4",

Safety Relief Valve, Temperature Pressure Gauge, Drain Valve, Wiring Harness, Burner Electrical

Disconnect, Plastic Cover, Supply Tapping 2", Return Tapping 1¼", High Limit and Circulator

Control, Primary Control. For Tankless Heater Units-add Tankless Hot Water Coil, Flow Restrictor

and Combination High Limit, Low Limit, and Circulator Control.

BOILER

MODEL

NUMBER

SW3065

SW4100

SW5125

TANKLESS WATER HEATER CAPACITIES

INPUT

RATE

G.P.H.

TANKLESS

HEATER

NUMBER

TANKLESS

HEATER CAPACITY

INTERMITTENT DRAW

G.P.M.

BOILER

WATER

CONTENT

GALS.

.65 P3 CAPACITY AVAILABLE ON REQUEST 10.5

1.00 T4 3.25 13.5

1.25

T4 3.75 16.5

18

Page 19

SERVICE CHECK LIST

Pump Pressure/Vacuum

Line Voltage/Motor Amps

Smoke Test

Draft Over-fi re/In Flue

CO

or O

2

2

Flue Gas Temperature

Proper Light-Off (Hot & Cold)

Controls and Safety Devices

Inspect Chimney and Flue pipe

Inspect and Clean Appliance

Inspect Oil Line - Size/Leaks

Inspect Electrical Connections

Install New Filter

Room Make-up Air

Electrode setting

Nozzle-Size, Angle, Type

Measure with Instruments and Record results on chart provided below.

Pump Flue

Date Nozzle Pressure Smoke Dra CO2 or O2 Temperature

Size Angle Type PSI NO. O.F. INF

o

F

19

Page 20

SW

OIL FIRED DIRECT EXHAUST

CAST IRON BOILER

Loading...

Loading...