UTICA BOILERS Starfire 3 Installation Manual And Operating Instructions

STST

ST

STST

ARFIRE 3ARFIRE 3

ARFIRE 3

ARFIRE 3ARFIRE 3

WW

W

WW

OIL FIRED CAST IRON BOILER

AA

TERTER

A

TER

AA

TERTER

UCTIONSUCTIONS

UCTIONSUCTIONS

UCTIONS

TING INSTRTING INSTR

TING INSTRTING INSTR

TING INSTR

Utica Boilers • P.O. Box 4729 • Utica, NY 13504

AND OPERAAND OPERA

AND OPERAAND OPERA

AND OPERA

AL AL

AL AL

AL

TION MANUTION MANU

TION MANUTION MANU

TION MANU

ALLAALLA

ALLAALLA

ALLA

INSTINST

INSTINST

INST

TT

ABLE OF CONTENTSABLE OF CONTENTS

T

ABLE OF CONTENTS

TT

ABLE OF CONTENTSABLE OF CONTENTS

SAFETY SYMBOLS & WARNINGS ..................................................................... PAGE 1

INSTALLATION PROCEDURE ........................................................................... PAGE 2

VENTILATION AND COMBUSTION AIR ....................................................... PAGES 3-5

CONNECTING SUPPLY AND RETURN PIPING ........................................... PAGES 6-9

TANKLESS HEATER PIPING ............................................................................ PAGE 10

3/4" TAPPING OPTIONS ................................................................................... PAGE 11

VENTING SYSTEM INSPECTION & INSTALLATION ....................................... PAGE 12

OIL TANK PIPING .............................................................................................. PAGE 13

ELECTRICAL WIRING .....................................................................................PAGES 14

THERMOSTAT INSTALLATION........................................................................ PAGE 15

NORMAL SEQUENCE OF OPERATION ........................................................... PAGE 15

OPERATING INSTRUCTIONS .................................................................. PAGES 16-19

SERVICE CHECK LIST ..................................................................................... PAGE 20

REPLACEMENT PARTS LIST.....................................................................PAGES 21-28

RATINGS, DATA AND DIMENSIONS ........................................................... PAGE 29-30

KEEP THIS MANUAL NEAR BOILER. RETAIN FOR FUTURE REFERENCE

SERIES SFH 3

CAST IRON

OIL FIRED BOILER

INSTALLATION MANUAL AND OPERATING INSTRUCTIONS

PUBLISHED FEBRUARY 1996

PRINTED IN USA

MADE IN USA

TESTED FOR 100 LBS.

ASME WORKING PRESSURE

Safety SymbolsSafety Symbols

Safety Symbols

Safety SymbolsSafety Symbols

The following defined symbols are used throughout this manual to notify the

reader of potential hazards of varying risk levels.

DANGERDANGER

DANGER

DANGERDANGER

DANGER - Indicates an imminently hazardous situation which, if not avoided, WILL

result in death or serious injury.

WARNINGWARNING

WARNING

WARNINGWARNING

WARNING - Indicates a potentially hazardous situation which, if not avoided, COULD

result in death or serious injury

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

CAUTION - Indicates a potential hazardous situation which, if not avoided, MAY result

in minor or moderate injury. It may also be used to alert against unsafe practices.

IMPORIMPOR

IMPOR

IMPORIMPOR

1. Keep boiler area clear and free from combustible materials, gasoline and other

flammable vapors and liquids.

2. DO NOT obstruct air openings to the boiler room.

3. Modification, substitution or elimination of factory equipped, supplied or specified

components may result in property damage, personal injury or the loss of life.

4. To the owner: Installation and service of this boiler must be performed by a qualified

installer.

5. To the installer: Leave all instructions with the boiler for future reference.

6. When this product is installed in the Commonwealth of Massachusetts, the installation

must be performed by a licensed Plumber or Licensed Gas Fitter.

SHOULD BE DONE ONLY BY A QUALIFIED EXPERT AND INSHOULD BE DONE ONLY BY A QUALIFIED EXPERT AND IN

SHOULD BE DONE ONLY BY A QUALIFIED EXPERT AND IN

SHOULD BE DONE ONLY BY A QUALIFIED EXPERT AND INSHOULD BE DONE ONLY BY A QUALIFIED EXPERT AND IN

ACCORDANCE WITH THE APPROPRIATE UTICA BOILERS MANUAL.ACCORDANCE WITH THE APPROPRIATE UTICA BOILERS MANUAL.

ACCORDANCE WITH THE APPROPRIATE UTICA BOILERS MANUAL.

ACCORDANCE WITH THE APPROPRIATE UTICA BOILERS MANUAL.ACCORDANCE WITH THE APPROPRIATE UTICA BOILERS MANUAL.

INSTALLING OR VENTING A BOILER OR ANY OTHER GAS APPLIANCEINSTALLING OR VENTING A BOILER OR ANY OTHER GAS APPLIANCE

INSTALLING OR VENTING A BOILER OR ANY OTHER GAS APPLIANCE

INSTALLING OR VENTING A BOILER OR ANY OTHER GAS APPLIANCEINSTALLING OR VENTING A BOILER OR ANY OTHER GAS APPLIANCE

WITH IMPROPER METHODS OR MATERIALS MAY RESULT IN SERIOUSWITH IMPROPER METHODS OR MATERIALS MAY RESULT IN SERIOUS

WITH IMPROPER METHODS OR MATERIALS MAY RESULT IN SERIOUS

WITH IMPROPER METHODS OR MATERIALS MAY RESULT IN SERIOUSWITH IMPROPER METHODS OR MATERIALS MAY RESULT IN SERIOUS

INJURY OR DEATH DUE TO FIRE OR TO ASPHYXIATION FROMINJURY OR DEATH DUE TO FIRE OR TO ASPHYXIATION FROM

INJURY OR DEATH DUE TO FIRE OR TO ASPHYXIATION FROM

INJURY OR DEATH DUE TO FIRE OR TO ASPHYXIATION FROMINJURY OR DEATH DUE TO FIRE OR TO ASPHYXIATION FROM

POISONOUS GASES SUCH AS CARBON MONOXIDE WHICH ISPOISONOUS GASES SUCH AS CARBON MONOXIDE WHICH IS

POISONOUS GASES SUCH AS CARBON MONOXIDE WHICH IS

POISONOUS GASES SUCH AS CARBON MONOXIDE WHICH ISPOISONOUS GASES SUCH AS CARBON MONOXIDE WHICH IS

ODORLESS AND INVISIBLE.ODORLESS AND INVISIBLE.

ODORLESS AND INVISIBLE.

ODORLESS AND INVISIBLE.ODORLESS AND INVISIBLE.

TT

ANT!ANT!

T

ANT! READ ALL INSTRUCTIONS BEFORE INSTALLING.

TT

ANT!ANT!

WARNING:WARNING:

WARNING:

WARNING:WARNING:

WARNING:WARNING:

WARNING:

WARNING:WARNING:

ALL INSTALLATIONS OF BOILERS AND VENTINGALL INSTALLATIONS OF BOILERS AND VENTING

ALL INSTALLATIONS OF BOILERS AND VENTING

ALL INSTALLATIONS OF BOILERS AND VENTINGALL INSTALLATIONS OF BOILERS AND VENTING

PAGE 1

INSTINST

INST

INSTINST

WARNING:WARNING:

WARNING: Improper installation, adjustment, alteration, service or

WARNING:WARNING:

maintenance can cause property damage, personal injury or loss of life.

All installations must conform to the requirements of the authority having jurisdiction.

Such applicable requirements take precedence over the general instructions of this manual.

Where required by the authority having jurisdiction, the installation must conform to the

American Society of Mechanical Engineers Safety Code for Controls and Safety Devices

for Automatically Fired Boilers, ANSI/ASME No. CSD-1. In Canada all installations must

be in accordance with the authorities having jurisdiction and CSA B139.

LOCATE BOILER in front of final position before removing crate. Provide a level solid

base as near chimney as possible and centrally located with respect to the heat distribution

system as practical.

WARNING:WARNING:

WARNING: BOILER MAY NOT BE INSTALLED ON COMBUSTIBLE

WARNING:WARNING:

FLOORING.

Allow 24 inches in the front and top for servicing and cleaning, or removing tankless

water heating coil.

When installed in a utility room, the door should be wide enough to allow the largest

boiler part to enter, or to permit replacement of another appliance such as a water heater.

ALLAALLA

ALLA

ALLAALLA

TION PRTION PR

TION PR

TION PRTION PR

OCEDUREOCEDURE

OCEDURE

OCEDUREOCEDURE

FOR INSTALLATION ON NON-COMBUSTIBLE FLOORS ONLY. The boiler must not

be installed on carpeting or vinyl flooring. Minimum clearances to combustible construction

are:

TOP .............................................................. 24 IN.

FRONT ......................................................... 24 IN.

FLUE CONNECTOR ....................................... 9 IN.

REAR .............................................................. 6 IN.

SIDES ............................................................. 6 IN.

NOTE: CLEARANCE FOR ACCESS SHOULD EXCEED FIRE PROTECTION

CLEARANCE.

REMOVE CRATE and plastic protective wrapper and inspect for damage. All equipment

is carefully manufactured, inspected and packaged by experienced workers. Our responsibility

ceases upon delivery of the crated boiler to the carrier in good condition. Any claims for

damage or shortage in shipment must be filed immediately against the carrier by the

cosignee. Move boiler to permanent position by sliding or walking.

PAGE 2

VENTILAVENTILA

VENTILA

VENTILAVENTILA

WARNING:WARNING:

WARNING: AIR OPENINGS TO COMBUSTION AREA MUST NOT

WARNING:WARNING:

BE OBSTRUCTED. BY FOLLOWING THE CHART BELOW , ADEQUATE

COMBUSTION AIR CAN BE MAINTAINED.

TION & COMBTION & COMB

TION & COMB

TION & COMBTION & COMB

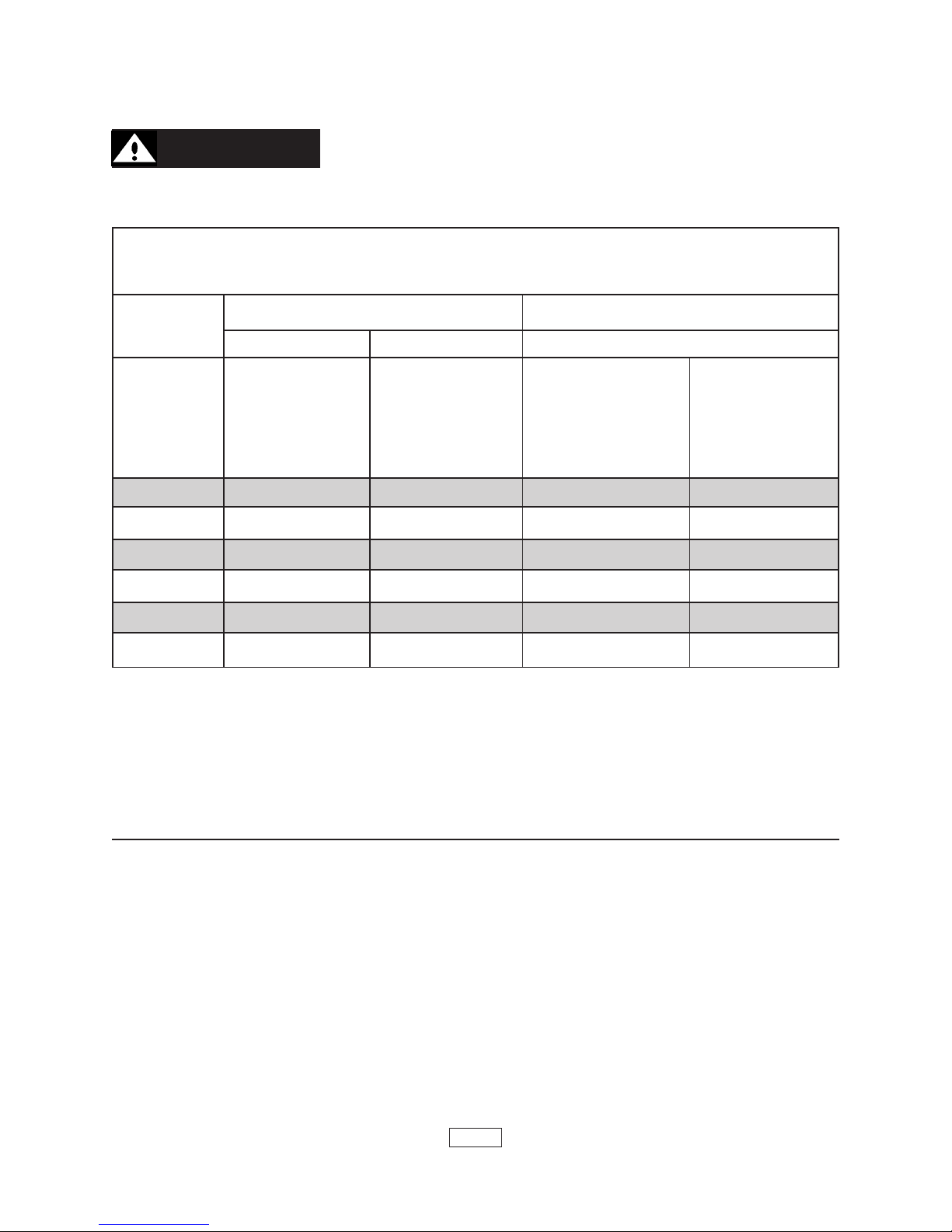

COMBUSTION AIR REQUIREMENTS

(Minimum Opening Requirements)

USTION USTION

USTION

USTION USTION

AIRAIR

AIR

AIRAIR

*UNCONFINED AREA **CONFINED AREA

Outside Inside Outside Combustion Air

Combustion Combustion VERT. DUCTS HORZ. DUCTS

BTU/HR Air 1 IN.

INPUT /5000 BTU/HR /1000 BTU/HR /4000 BTU/HR /2000 BTU/HR

(Paragraph 4) (See Fig 1) (See Fig 2 & 3 (See Fig 4

91,000 19 100 23 46

140,000 28 140 35 70

2

Air 1 IN.

(MIN. 100 IN2) Pages 5 & 6) Page 6)

2

1 IN.

2

1 IN.

2

175,000 35 175 44 88

210,000 42 210 53 106

245,000 49 245 61 122

280,000 56 280 61 140

*Unconfined area: A space whose volume is not less than 50 cubic feet per 1000

BTU per hour of all appliances installed in that space (cubic feet of space = height x

width x length).

**Confined area: A space whose volume is less than 50 cubic feet per 1000 BTU

per hour of all appliances installed in that space (cubic feet of space = height x width x

length).

1. Ventilation of boiler room must be adequate enough to provide sufficient air to

properly support combustion.

2. When a boiler is located in an unconfined space in a building of conventional

construction frame, masonry or metal, infiltration normally is adequate to provide air for

combustion and ventilation. However, in any building which has been altered to conserve

energy or to minimize infiltration, the boiler area should be considered as a CONFINED

SPACE. If there is any doubt, install air supply provisions for combustion and ventilation in

accordance with section 5.3, Air for Combustion and Ventilation, of the NFPA 54 1988 code,

the recommendations that follow, or applicable provisions of the local building codes.

3. When a boiler is installed in an unconfined space, in a building of unusually tight

construction, air for combustion and room ventilation must be obtained from outdoors or

from spaces freely communicating with the outdoors. A permanent opening or openings

PAGE 3

having a total free area of not less than 1 square inch per 5,000 BTU per hour of total input

rating of all appliances shall be provided. Ducts may be used to convey make-up air from

the outdoors and shall have the same cross-sectional area of the openings to which they

are connected.

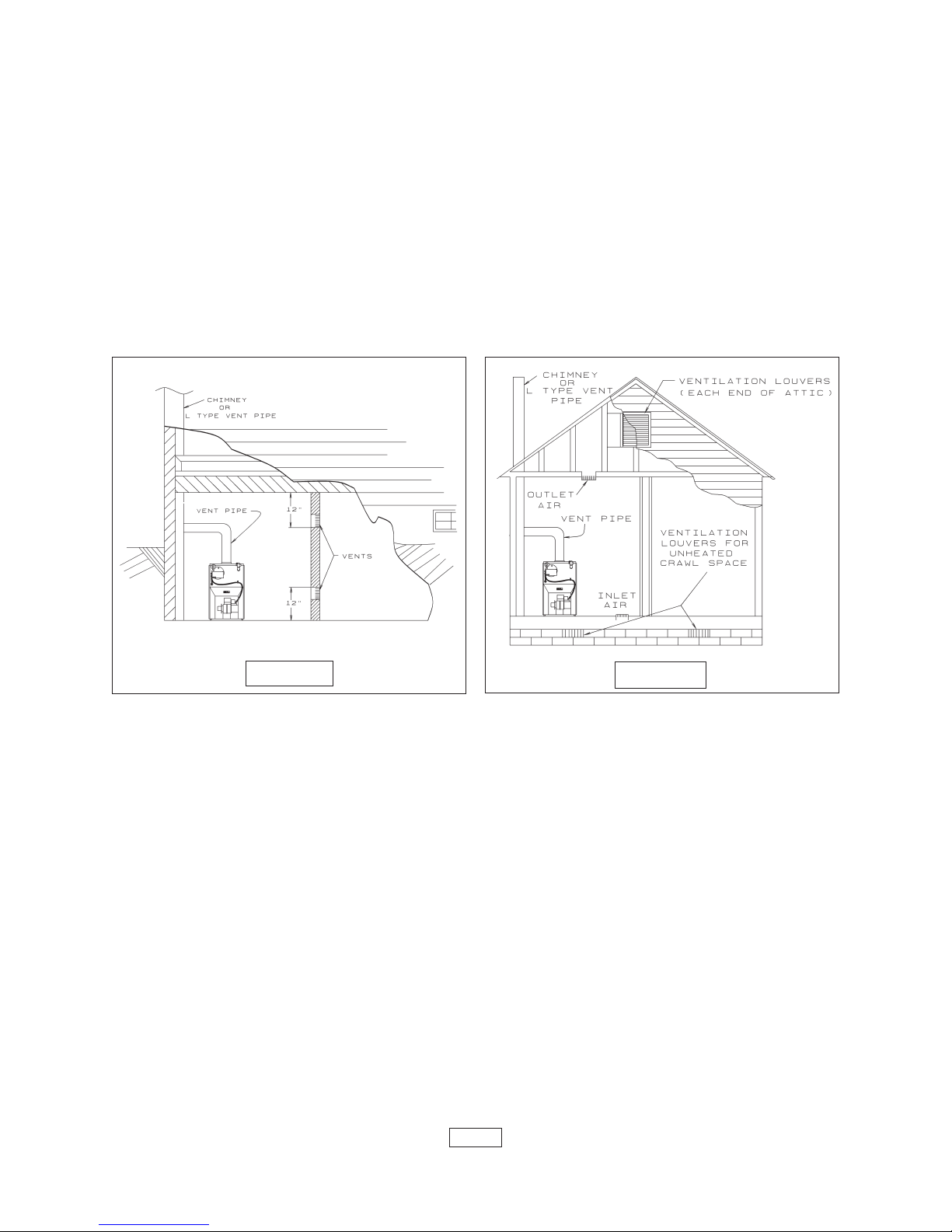

4. When air for combustion and room ventilation is from inside buildings, the confined

space shall be provided with two permanent openings, one starting 12 inches from the top

and one 12 inches from the bottom of the enclosed space. Each opening shall have a

minimum free area of 1 square inch per one thousand (1,000) BTU per hour of the total input

rating of all appliances in the enclosed space, but must not be less than one hundred (100)

square inches. These openings must freely communicate with the interior areas having

adequate infiltration from the outside. See figure 1 below.

FIGURE 1

FIGURE 2

5. When the boiler is installed in a confined space and all air is provided from the outdoors,

the confined space shall be provided with two permanent openings, one commencing within

12 inches from the top and one commencing 12 inches from the bottom of the enclosure. The

openings shall communicate directly, or by ducts, with the outdoors or spaces (crawl or attic)

that freely communicate with the outdoors. One of the following methods must be used to

provide adequate air for ventilation and combustion.

A. When directly communicating with the outdoors, each opening shall have a minimum

free area of 1 square inch per 4,000 BTU per hour of total input rating of all equipment in

the enclosure. See figure 2, above.

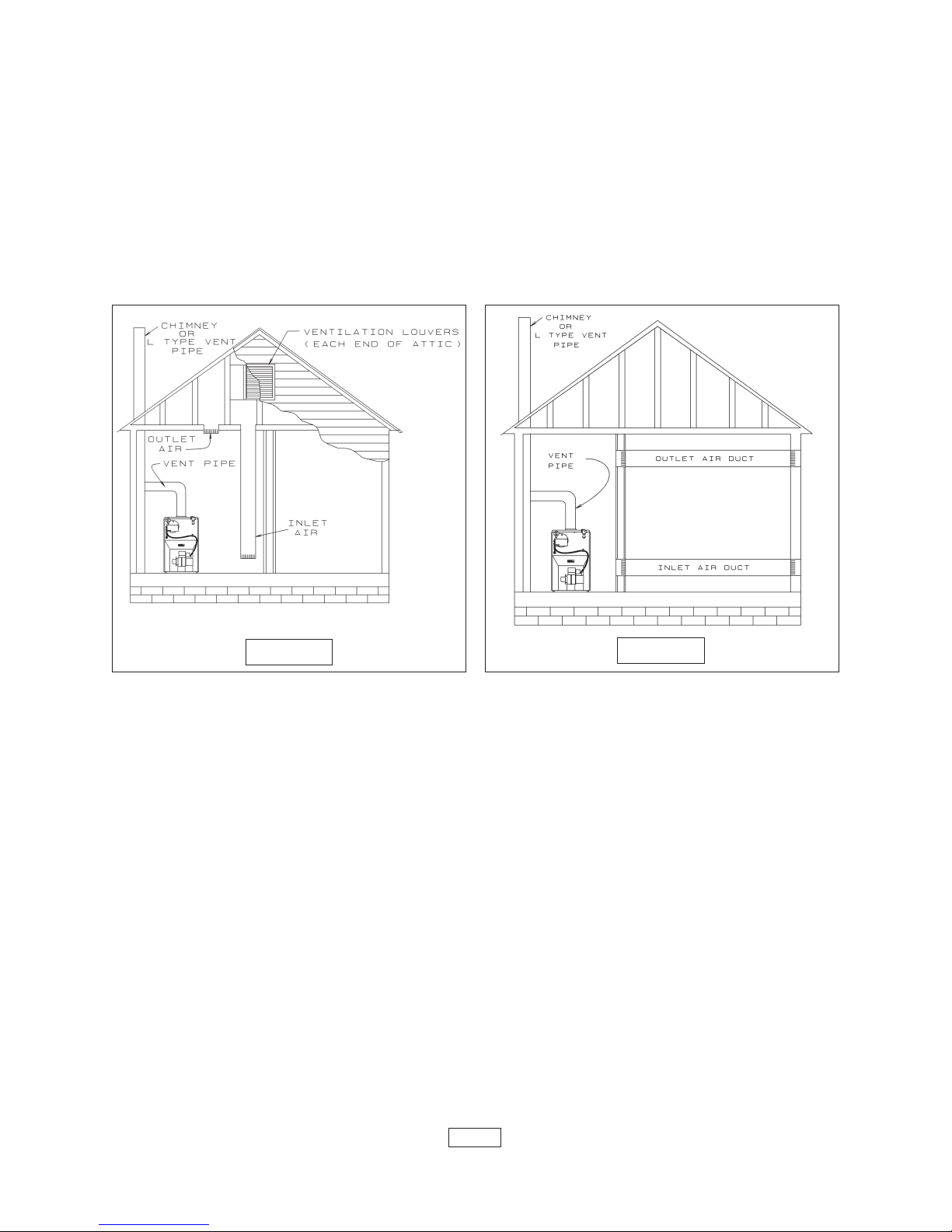

B. When communicating with the outdoors by means of vertical ducts, each opening

shall have a minimum free area 1 square inch per 4,000 BTU per hour of total input rating

of all appliances in the enclosed space. See figure 3 on page 5.

C. If horizontal ducts are used, each opening shall have a minimum free area 1 square

inch per 2,000 BTU per hour total input rating of all appliances in the enclosed space. See

figure 4, on page 5.

D. When ducts are used, they shall be of the same cross sectional area as the free area

of the area of the openings to which they connect. The minimum dimension of rectangular

PAGE 4

air ducts shall not be less than 3 inches.

6. In calculating free area using louvers, grills or screens for the above, consideration

shall be given to their blocking effect. Screens used shall not be smaller than 1/4 inch mesh.

If the free area through a design of louver or grill is known, it should be used in calculating

the size opening required to provide the free area specified. If the design and free area is

not known, it may be assumed that wood louvers will have 20-25% free area and metal

louvers and grills will have 60-75% free area. Louvers and grills shall be fixed in the open

position or interlocked with the boiler so that they are opened automatically during boiler

operation. See chart on page 4 for combustion air minimum opening requirements.

FIGURE 3

FIGURE 4

PAGE 5

CONNECTING SUPPLCONNECTING SUPPL

CONNECTING SUPPL

CONNECTING SUPPLCONNECTING SUPPL

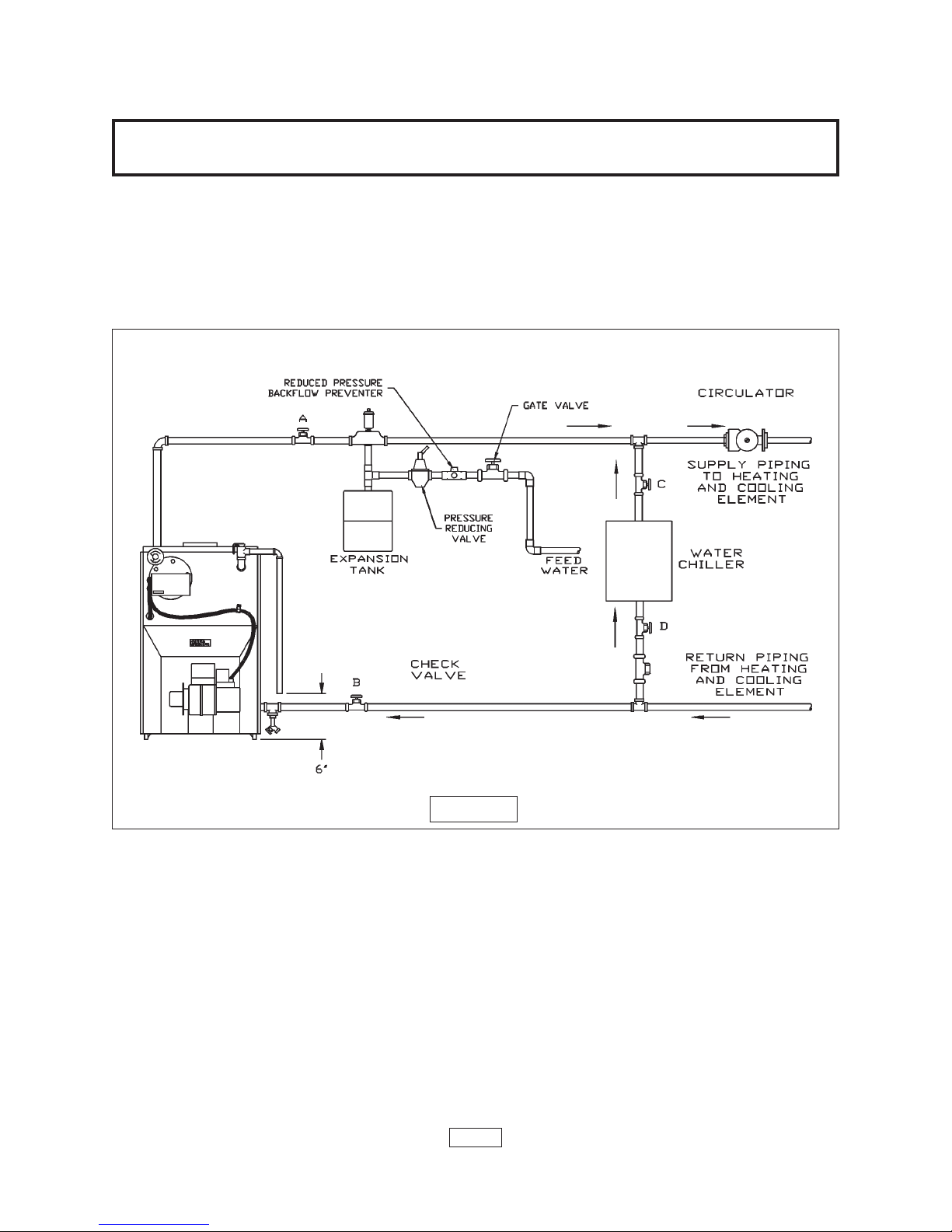

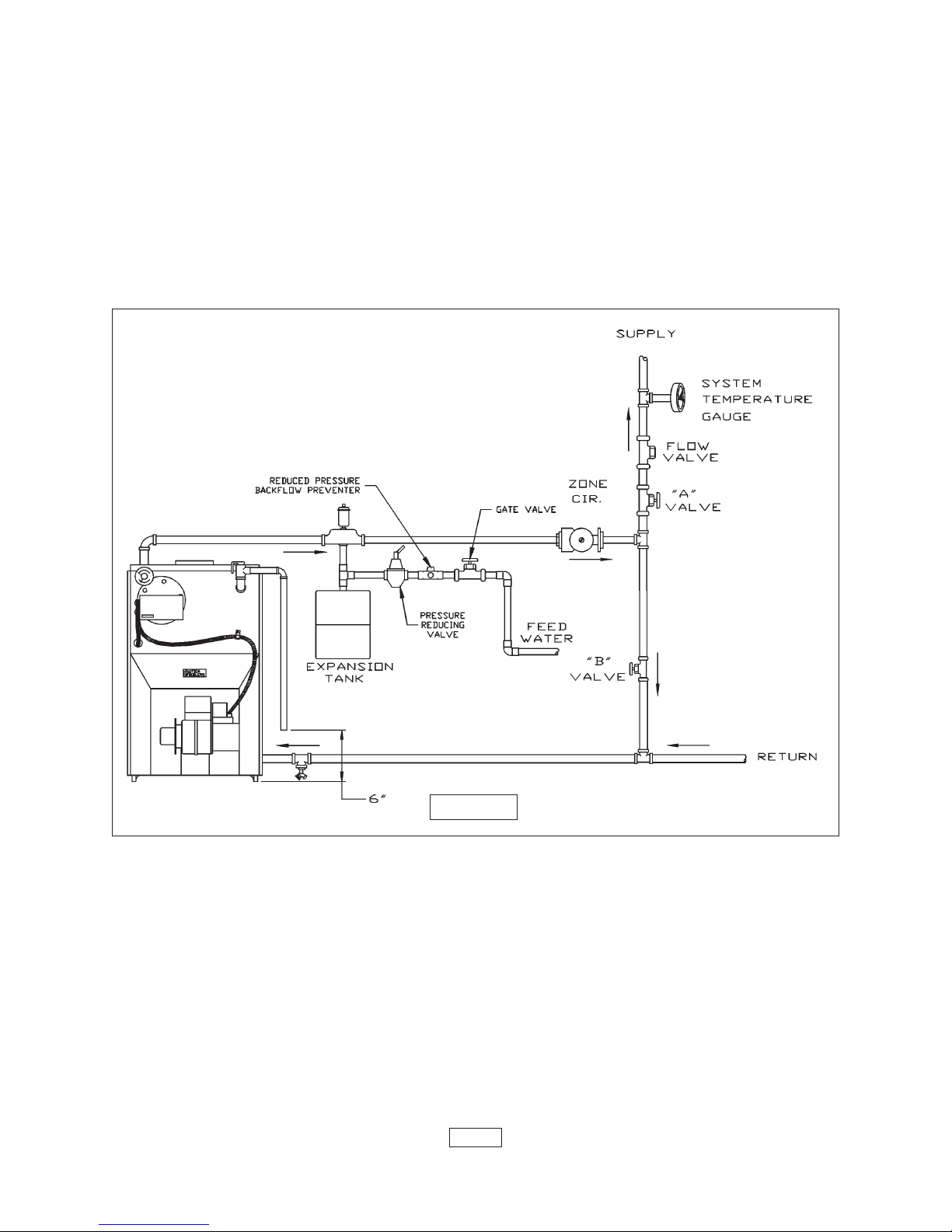

IMPORTANT: Circulators in the following illustrations are mounted on the system supply

side, but mounting on the system return side is also acceptable practice.

1. Connect supply and return piping as suggested in figure 5, below. When the boiler is

used in connection with refrigerated systems:

A. The chilled medium MUST BE IN PARALLEL with the boiler.

B. Use appropriate valves to prevent the chilled medium from entering the heating boiler.

Y Y

AND RETURN PIPINGAND RETURN PIPING

Y

AND RETURN PIPING

Y Y

AND RETURN PIPINGAND RETURN PIPING

2. During the heating cycle open valves A and B, close valves C and D.

3. During heating cooling cycle open valves C and D, close valves A and B.

A. Maintain a minimum clearance of one inch to hot water pipes.

In air handling units where they may be exposed to refrigerated air circulation, the

boiler piping system MUST be supplied with flow control valves or other automatic means

to prevent gravity circulation of the boiler water during the cooling cycle.

4. Hot water boilers installed above radiation level must be provided with a low water

device either as part of the boiler or at the time of boiler installation.

5. When a boiler is connected to a heating system that utilizes multiple zoned circulators,

each circulator must be supplied with a flow control valve to prevent gravity circulation.

FIGURE 5

PAGE 6

* Reduced pressure back flow preventer must be used under provisions required by the

Environmental Protection Agency, (EPA).

6. Bypass piping is an option which gives the ability to adjust the supply boiler water

temperature to fit the system or condition of the installation. Although, this method of

piping is not typically required for baseboard heating systems.

A. This method is used to protect boilers from condensate forming due to low temperature

return water. Generally noticed in large converted gravity systems or other large water volume

systems. See figure 6 below.

BYPASS PIPING

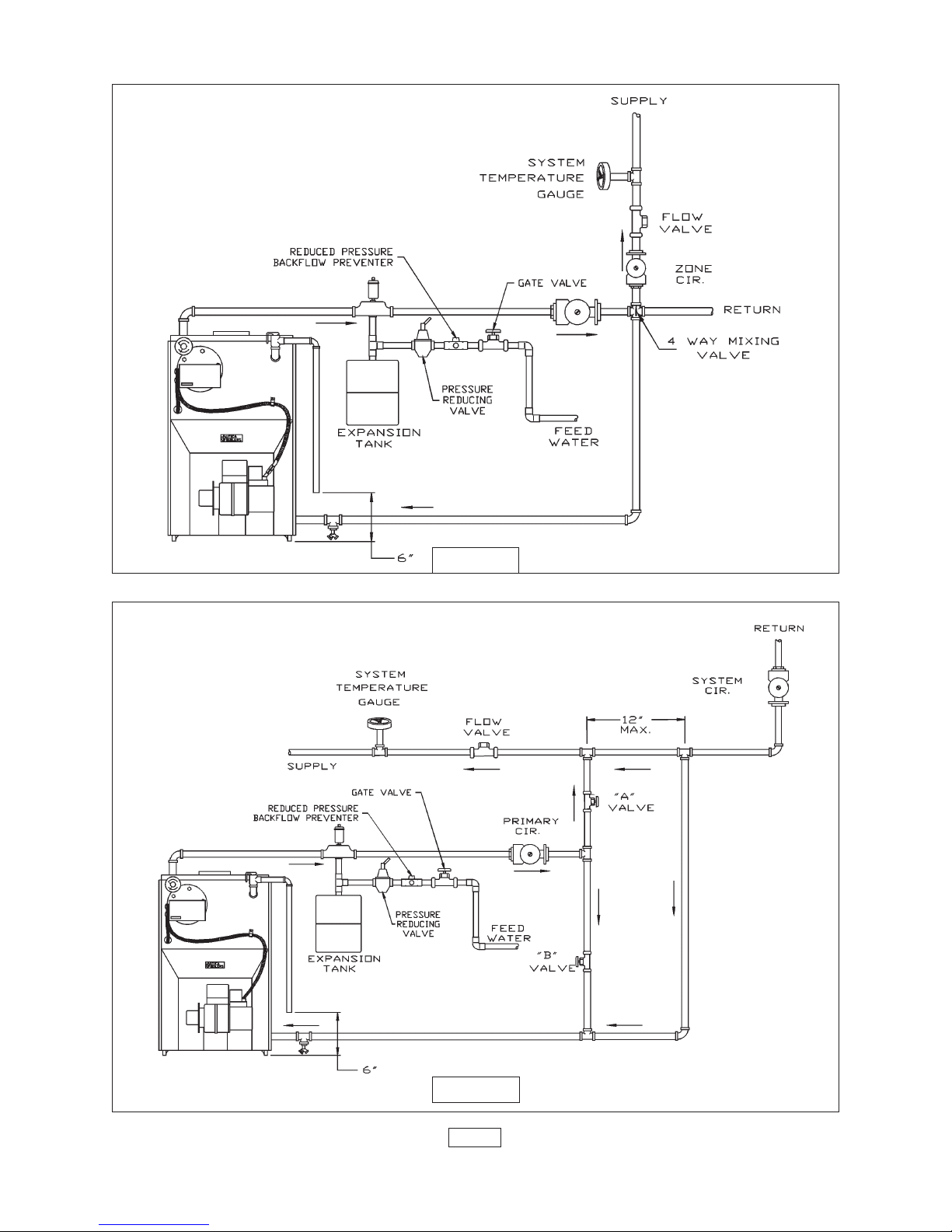

B. These methods are used to protect systems using radiant panels and the material

they are encased in from high temperature supply water from the boiler and protect the boiler

from condensation. See figures 7 and 8 on page 8.

C. This method is used to protect boilers from condensate forming as well as

protecting the heating system from high water temperature. See figure 8 on page 8.

7. Note: When using bypass piping, adjust valves A and B until desired system

temperature is obtained.

8. Bypass loop piping must be the same size piping for the supply and return.

FIGURE 6

PAGE 7

MIXING-VALVE PIPING

FIGURE 7

PRIMARY SECONDARY PIPING WITH BYPASS

FIGURE 8

PAGE 8

Loading...

Loading...