UTICA BOILERS TCI-150RA-3/8, TCI-250R, TCI-75FRN, CH-150, CH-75F Instruction Manual

...

Instruction Manual

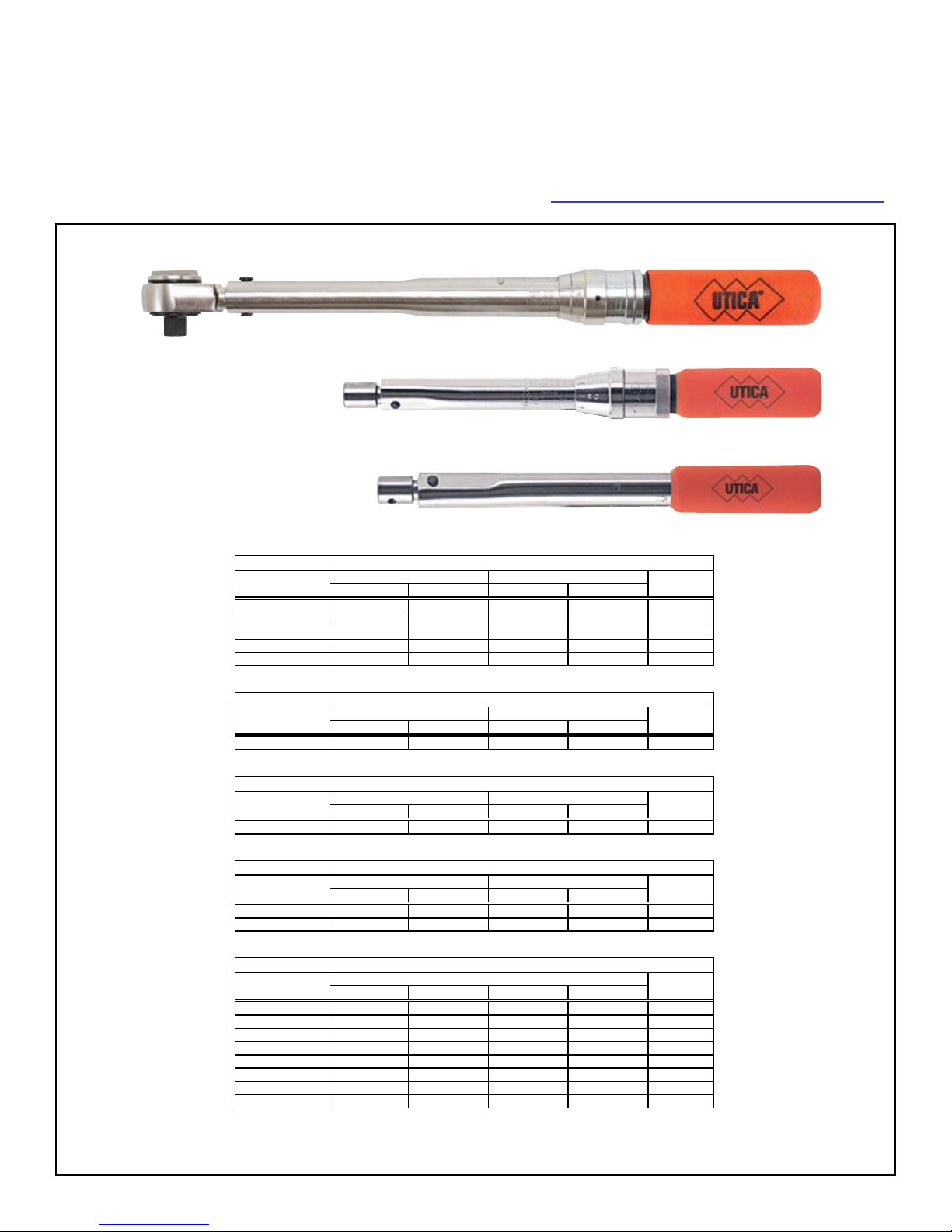

in.-lb. Nm in.-lb. Nm

TCI-150RA * 30-150 3.4-17.0 1.0 0 . 1 1 1/4"

TCI-150RA-3/8 * 30-150 3.4-17.0 1.0 0 . 1 1 3/8"

TCI-250R * 50-250 5.7-28.3 1.0 0 . 1 1 3/8"

TCI-750R 150-750 ------ 5.0 ------ 3/8"

TCI-750R-1/2 150-750 ------ 5.0 ------ 1/2"

* Note: Dual Scale Model

ft.-lb. Nm ft.-lb. Nm

TCI-75FRN * 15-75 20.3-102 0.5 0.7 3/8"

* Note: Dual Scale Model

in.-lb. Nm in.-lb. Nm

CH-150 * 30-150 3.4-17.0 1.0 0 . 1 1 --* Note: Dual Scale Model

ft.-lb. Nm ft.-lb. Nm

CH-75F *

15-75 20.3-102 0.5 0.7 --CH-150F * 30-150 40.7-203 1.0 1.4 --* Note: Dual Scale Model

in.-lb. Nm ft.-lb. cm-kg

CHA-6 10-50 1.2-6 0.9-4.5 12-60 --CHA-11 20-100 2.2-11 1.6-8 22-110 --CHA-23 40-200 4.6-23 3.4-17 46-230 --CHB-55 100-500 11-55 8-40 112-560 --CHB-85 150-750 17-85 12.5-62.5 172-860 --CHB-110 200-1000 22-110 16-80 224-1120 --CHB-170 300-1500 34-170 25-125 346-1730 --CHB-225 400-2000 45-225 33-165 460-2300 ---

Torque Range

Graduations

Drive Size

Single Setting (Preset) Wrench

Model No.

Drive Size

Torque Range

Model No.

Model No.

Torque Range

Graduations

Drive Size

Micrometer Adjustable Wrench (in.-lb. Graduations)

Model No.

Torque Range

Graduations

Drive Size

Micrometer Adjustable Wrench (ft.-lb. Graduations)

Model No.

Ratchet Head (in.-lb. Graduations)

Drive Size

Torque Range

Graduations

Ratchet Head (ft.-lb. Graduations)

45-8448

®

Utica

CH & TCI Series

Click Type Torque Sensing Wrenches

Ratchet Head

Micrometer Adjustable

Single Setting

Note: Single setting wrenches do not have a scale and must be set on a torque tester.

45-8448

Utica

®

“Click” Type Torque Sensing Wrenches

Micrometer Adjustable Torque Sensing Wrenches:

These torque sensing wrenches automatically signal by

SOUND and IMPULSE when the desired torque is reached.

These wrenches are calibrated for right hand (clockwise) and

left hand (counter clockwise) torque applications.

Setting a Torque:

Unlock: Pull back, fully, and hold the automatic lock collar.

While holding the lock collar, advance the handle up the barrel

by turning it in a clockwise direction or counter clockwise to

move down the barrel. The barrel is marked in even increments

of torque and one complete turn of the handle will change the

torque setting one complete barrel increment.

If the barrel is marked in increments of ten, each complete

turn of the handle would change the torque setting by ten.

The sleeve die is marked around the circumference with

intermediate increments.

The sleeve die markings start at 10 and are divided into ten

equal marks. Every other mark is numbered. To set at an even

barrel increment the zero marking on the sleeve die should line

up with the center of the barrel marking, see Figure 1.

Figure 1

Center

Line Barrrel

Marking

Barrel Die

Increment

Sleeve Die

Increment

By advancing the handle one sleeve die mark you have

increased the torque an amount equal to 1/10th the increase

between two barrel increments, see Figure 2.

Figure 2

Lock:

When you have lined up a sleeve die mark with the center

line barrel mark, you can release the lock collar and it will

automatically move forward and lock the handle to the barrel.

To Use:

Attach the appropriate socket wrench or adapter to the torque

wrench square drive and apply to the application. Hold the

torque wrench by the padded handle and tighten the fastener.

Apply force with a steady, smooth action.

Do not apply force by holding any part of the wrench, other

than the padded handle. Do not use an extension or other

lever aid on the handle. When the torque setting is reached,

the wrench will momentarily release with a feel impulse and

audible click. The wrench will move freely through a small arc

of approximately two (2) degrees. At this point the set torque

has been achieved and force on the handle must be released.

The wrench will automatically snap back to it’s original position

and is ready for the next torque application.

NOTE: When set at the lower torque range, the audible signal

will be much lower. However, there is an audible sound which

in conjunction with the feel impulse should present no difculty

in operating the wrench at the lower scale settings.

Torque Extensions:

When an extension is used on the drive end of the torque

wrench, the torque applied at the end of the extension is NOT

the same as the torque setting on the wrench. The method of

determining the actual torque produced using various types of

extensions is as follows:

Ta = Torque applied at the end of extension

Tw = Torque Wrench setting

L = Length of wrench (center of handle to drive)

A = Length of extension *

* Note: Dimension always taken parallel to the line of

the wrench regardless of extension conguration.

If the barrel increments are 10, 20, etc. and the original setting

was 30, by moving the handle on the sleeve die one increment

you increase the torque an amount equal to 1. Your new torque

setting would be 31. If you turned the handle four (4) sleeve die

marks in a clockwise direction from zero you have advanced

the torque four (4) increments and your new torque setting

would be 34, see Figure 3.

Figure 3

Figure 4

NOTE: To obtain the actual torque values as calculated, force

must be applied only at the center point of the handle.

Loading...

Loading...