Page 1

GE AccessSmart 313 Last Update July 6, 2005

GE AccessSmart 313 Last Update July 6, 2005

Table of Contents

1. IMPORTANT SAFTY INSTRUCTIONS Page 4

2. INTRODUCTION Page 6

2.1 IDENTIFYING SUPPLIED PARTS Page 6

2.2 INTRODUCTION Page 6

2.3 FEATURES Page 6

2.4 SPECIFICATIONS Page 7

3. PRODUCT OVERVIEW Page 8

3.1 FUNCTIONS Page 8

3.2 PRODUCT EXPLANATION Page10

3.2.1 FRONT PANEL DESCRIPTION Page10

3.2.2 CONNECTOR LAYOUT Page11

3.2.3 WIRE COLOR TABLE OF THE GE314 Page11

4. INSTALLATION TIPS & CHECK POINT Page 12

4.1 CHECK POINT BEFORE THE INSTALLATION Page 12

4.1.1 CABLE SELECTION Page 12

4.1.2 CABLE SELECTION TABLE Page 13

4.2 CHECK POINT DURING THE INSTALLATION Page 13

4.2.1 TERMINATION RESISTOR Page 13

4.2.2 HOW TO CONNECT TERMINATION RESISTOR Page 14

4.2.3 GROUND SYSTEM Page 14

4.2.4 REVERSE DIODE CONNECTION Page 15

5. INSTALLATION Page 15

5.1 WALL MOUNT DRAWING Page 15

5.2 BACKUP BATTERY SWITCH Page 16

5.3 SYSTEM INITIALIZATION Page 16

5.4 WALL MOUNT INSTALLATION Page 17

6. WIRING Page 17

6.1 POWER CONNECTION Page 17

6.2 INPUT CONNECTION Page 17

6.3 OUTPUT CONNECTION Page 18

6.4 EXTERNAL READER CONNECTION Page 18

6.5 RS232 PORT CONNECTION Page 19

6.6 RS485 PORT CONNECTION Page 20

6.6.1 RS485 CONNECTION (SINGLE UNIT) Page 20

6.6.2 RS485 CONNECTION (MUTIPLE UNITS) Page 20

6.7 TCP/IP CONNECTION (OPTIONAL) Page 21

1

2

Page 2

GE AccessSmart 314 Last Update July 6, 2005

7. BASIC SETTINGS Page 22

7.1 INITIALIZATION OF GE314 Page 22

7.2 HOW TO ENTER THE SETUP MENU Page 22

7.3 LANGUAGE SETTING Page 23

7.4 DATE/TIME SETTING Page 23

7.5 ID REGISTRATION Page 24

8. OPERATION Page 27

8.1 NORMAL OPERATION Page 27

8.2 DEFAULT SETTING Page 27

9. SETTING CHANGES Page 28

9.1 F1 SETUP MENU Page 29

9.2 F2 SETUP MENU Page 33

9.3 F3 SETUP MENU Page 37

9.4 F4 SETUP MENU Page 42

9.5 F5 SETUP MENU Page 47

9.6 F6 SETUP MENU Page 50

9.7 F7 SETUP MENU Page 53

9.8 F8 SETUP MENU Page 56

A. THE RELATION BETWEEN INPUT

9.9 F9 SETUP MENU Page 59

APPENDIX Page 61

AND OUTPUT (DEFAULT) Page 61

B. TROUBLE SHOOTING Page 63

FCC REGISTRATION INFORMATION Page 67

GE AccessSmart 314 Last Update July 6, 2005

1. IMPORTANT SAFETY INSTRUCTIONS

To prevent injuries to persons and damages to property, please read all instructions and follow them

whenever you deal with this product.

After reading, please put this instruction manual where it can be easily seen for the system operator.

ON INSTALLATION AND POWER

Use 12V DC power ONLY.

- Connecting to higher than 12V DC may result in a risk of electric shock, fire, or heavy damage of the unit.

Do NOT install this product at places with wet or metallic dust or that can be watered.

- There may be risks of electric shock and fire.

Do NOT install this product near electric motors running.

- The Unit may not operate normally.

Do NOT set this product near heaters or any thing that produces heat.

- There may be a risk of fire.

Be ALWAYS careful not to short-circuit any part of the circuitry with tools like a screwdriver.

- There may be a risk of fire or heavy damage of the unit.

ON MAINTENANCE

Do NOT use any kind of liquid for cleaning.

- There may be a risk of electric shock, fire or heavy damage of the unit. Use air spray, if needed.

Users are cautioned NOT to attempt repair of this product or modify the wirings set by the installer at their own

discretion.

- It may pose the risk of fire, hardware damages, or abnormal operations of the unit.

It is recommended not to use a flammable spray or something else easy flammable near this product.

- There may be the risk of an explosion or fire.

Keep the unit away from any unauthorized people.

- It may cause abnormal operations of the unit.

3

4

Page 3

GE AccessSmart 314 Last Update July 6, 2005

GE AccessSmart 314 Last Update July 6, 2005

NOTICE

Please contact a designated service center or the outlet at which the product was purchased when

A. Any liquid has been spilt or sprayed onto the product. In this case, cut the power off first.

B. The product seems to be operating abnormally.

C. The unit exhibits a distinct change in performance.

D. The unit has fallen to be broken down or damaged on its case.

* Repairing costs can be charged for troubles caused due to improper handling or negligence of users or the operator.

2. INTRODUCTION

2.1 IDENTIFYING SUPPLIED PARTS

Please unpack and check the contents of the box (Optional accessories, if purchased, may be included in the

package).

unit Wall mount Manual Diode

Main

( 1ea ) ( 1ea ) ( 1ea ) ( 2개 )

2.2 INTRODUCTION

The GE314 is ideal to use for Single Door Access Control and Time & Attendance. The GE314 has four input

ports, two Form-C relay outputs, two TTL outputs, RS232/RS485 communication port and optional TCP/IP

communication port to meet various customer requirements. This user-friendly device allows you to register up

to 1,000 Fingerprint Users (Optional 2,000/4,000 Fingerprint Users) and can be stored up to 20,000 event

transactions. All Events can be uploaded and saved to the database of the host PC and the software creates the

report to MS-Excel, HTML and Text files for the Time & Attendance purpose. The GE314 has a built-in

Fingerprint Module, proximity card reader with IDC 26-bit Wiegand format and it has 24 keypads (10 Numeric

keys, 2 Control keys and 12 Function keys) for wide applications. The GE314 allows to accessing the door with

any combination of Fingerprints, Proximity Card/PIN and/or Password. The GE314 has four external input ports

to be connected to an exit button, motion detector, door contact sensor and existing alarm system to prevent

unauthorized access. The GE314 has a door relay to control the door lock and an alarm relay to warn any error.

The graphic LCD display supports 6 different languages so that the unit can be operated anywhere in the world.

All setup menus can be programmed through the front keypads or via Windows-based software program. The

GE314 is a cost effective biometrics system to be used for Standalone or network. Dual tamper switches prevent

unauthorized access.

2.3 FEATURES

z Dual function for Access Control and Time & Attendance

z 8 bit and 16 bit Dual Microprocessors, 32 bit ARM9 Microprocessor for Fingerprint Module

z 1,000 Fingerprint Users (Optional 2,000/4,000 Fingerprint Users) and 20,000 Event Buffers

z Built-in Fingerprint Scanner, Module and Algorithm

z Built-in Proximity Reader and External Reader Port for T&A

z 24 Keypads including 12 Functional Keys

z Graphic LCD Display for 6 different Language Support

z Standalone or Network Communication via RS232/RS485 (max. 256ch)

z Optional TCP/IP Communication, Optional Automatic Touch Sensor (for Identification Mode)

z Independent 4 Inputs and 4 Outputs including 2 FORM-C Relay Outputs

z Output Time Setting for Individual ID(4 Levels – Longer Output Time for Handicap Person)

z Forced Door Open Alarm, Door Lock/Unlock by T/S and/or by registered ID

z Anti-pass Back, Duress Alarm Functions

5

6

Page 4

GE AccessSmart 314 Last Update July 6, 2005

GE AccessSmart 314 Last Update July 6, 2005

z Dual Tamper Alarm

z 10 Time schedules, 8 Days with 5 Individual Time intervals each

z 10 Holiday Schedules, 100 holidays each

z Operating Mode Selectable for Individual ID (Proximity/PIN Only Mode, Fingerprints Only Mode,

Proximity/PIN + Fingerprints Mode, Proximity/PIN + Password + Fingerprints Mode)

z Time Schedule Applied to Individual ID, Input Port, Output Port and Reader Mode

z Multiple Master ID/Fingerprints Registration

z 3 LED Indicators and Beeper for the System Status

2.4 SPECIFICATIONS

CPU 8 bit and 16bit Dual Microprocessors, 32bit ARM9 Microprocessor

Memory Program Memory: 2M bit ROM

Fingerprint User

Event Buffer

Operating Mode Operating mode can be programmed for Individual ID

FAR (False Acceptance Rate) 0.001%

FRR (False Reject Rate) 0.1%

Fingerprint Scanner Optical Scanner, LED Lighting

Resolution of Scanner 500dpi, CMOS CCD, 356 x 292 pixels

1:1 Verification Time < 1 sec.

1:N Identification Time < 3 sec. if ID found (Up to 4000 Fingerprint Users)

Reader Port 1 Internal and 1 External Reader Port

Read Range Up to 4” (10cm) with IDC170 Clamshell Card

Reader Data Format Standard IDC 26 bit Wiegand Format

Communication port RS232/RS485(up to 256 channels) Address Selectable

Input/Output 4 Input Ports, Rating DC12V/ 20mA max.

Keypad 24 keys with Back lighting (Sky Blue)

Self Diagnostic Yes

Reset Power On Reset and Watch-dog Timer Reset

Operating Status 3 LED (Red, Green, Yellow) indicators, Beeper

Data Memory: 4M bit FLASH memory

Fingerprint Module: 1M bytes FLASH memory (Optional 2M/4M bytes)

1,000 Fingerprint Users (Optional 2,000/4,000 Fingerprint Users)

20,000 Event Buffers

- Proximity ID/PIN Only Mode

- Fingerprints Only Mode (Up to 4000 Users, Identification Mode)

- Proximity ID/PIN + Fingerprints(Password) Mode

- Proximity ID/PIN + Password + Fingerprints Mode

8 bit Burst Format for Keypad Reader

9600(Default), 19200, 38400, 57600bps Communication Speed

2 Relay Outputs, DC12V~24V/ FORM-C Relay 2A max.

2 TTL Outputs, DC0 ~5V/ 20mA max.

- 10 Numeric Keys

- 2 Control Keys

- 12 Function Keys

Weight 1.62 lbs (735g)

Dimensions 7.56” x 6.42” x 1.97” (192mm x163mm x50mm)

LCD Display Module 128 x 64 dots, 2.85” x 1.56”(72.5mm x 39.5mm) View Area

Power DC 12V±10%, 550mA max.

Operating Environment 32°F ~ 149°F (0°C ~ +65°C), 0 ~ 90% Humidity None Condensing

Storage Environment -40°F ~ 158°F (-40 ~+70℃℃), 0 ~ 90% Humidity None Condensing

Mount Wall Mount or Electrical Gang Box Mount (U.S. and European/Asian)

Color Silver and Dark Gray Color

Optional

TCP/IP Module (Internal)

Connection

Automatic Touch Sensor Capacitance Touch Sensor for Identification Mode only

Fingerprint Module 2,000 Fingerprint Module, 4,000 Fingerprint Module

IIM7100A Internal Mounting Module for TCP/IP Communication

RJ45 Socket

3. PRODUCT OVERVIEW

3.1 FUNCTIONS

Stand-Alone Operation

The GE314 is capable of having 2 readers (1 Door Control). The unit receives card ID numbers from the

proximity readers and determines whether or not to unlock the door. When an input signal is entered, for

example from a Sensor activated or an Exit button pressed, the controller generates and logs an appropriate

response by input signals. All events are stored into the memory buffers and sent to the host computer. The

access controller is a true stand-alone device that, in the event of malfunction, will not affect other units when

used in conjunction with one another.

Operation with Host Computer

All event transactions can be managed via the host computer. The data transmitted from the controller can be

displayed and stored on the host PC.

Keypad

If the GE314 is not connected to a host PC, the integrated keypad and LCD display module can also be used

for the entire programming process.

Input/Output

The GE314 has 4 built-in inputs and 4 outputs (2 relay outputs and 2 TTL outputs) which can be used to

manipulate a wide variety of controls.

7

8

Page 5

GE AccessSmart 314 Last Update July 6, 2005

GE AccessSmart 314 Last Update July 6, 2005

Time Schedule Setup

You can program 10 time schedules and apply one time schedule to each User. Each time schedule has 8

different time zones from Monday-Sunday (7 time zones) and one holiday. Each time zone has 5 different

time codes so you can program 5 different time codes to each day. You can also program time schedules for

individual inputs and outputs. Note that the time schedule for input is activated time code for input device so

that the input is activated during the time code on this time schedule. Each time schedule is linked to one

holiday schedule and this linked holiday only validates to the holiday time code of the time schedule.

Holiday Schedule Setup

Excepting Sunday, you can program 100 holidays to one holiday schedule. Each holiday schedule is linked to

one time schedule which has a time code for holidays. You can program all holidays to a holiday schedule

and the time code for holidays is programmed to the holiday time zone of time schedule.

Example: A. Holiday schedule 01 linked to time schedule 01,

Holiday schedule 02 linked to time schedule 02

B. Holiday schedule 02 linked to time schedule 01,

Holiday schedule 01 linked to time schedule 03

Forced Door Open Alarm

When the door is opened by force, the door contact sensor will be activated. For this application, you have to

install the door contact sensor and properly set the door contact time and outputs to the alarm devices. The

Forced Door Open Alarm will be generated until the alarm is cleared.

Overtime Door Open Alarm

The Overtime Door Open Alarm will be generated when the door is open continusly, after the door is opened

by corrected process.

The Overtime Door Open Alarm will be generated until the door is closed.

Anti-Pass-Back

By using an additional proximity reader, the Anti-Pass-Back mode can be set. The Anti-pass-back mode

prevents entry or exit when the registered user did not properly followed one entry and one exit by the Anti-

pass-back rule. The same user can not enter twice with the entry card without properly using the exit before.

Duress Alarm

In case of duress, enter the 2 digits Duress Password and press the<ENT> key before the normal access

process. The door can be opened as normal, but the duress alarm is also generated at the same time. The

duress alarm output will be activated to the TTL output and an alarm event will be sent to the host PC.

3.2 PRODUCT EXPLANATION

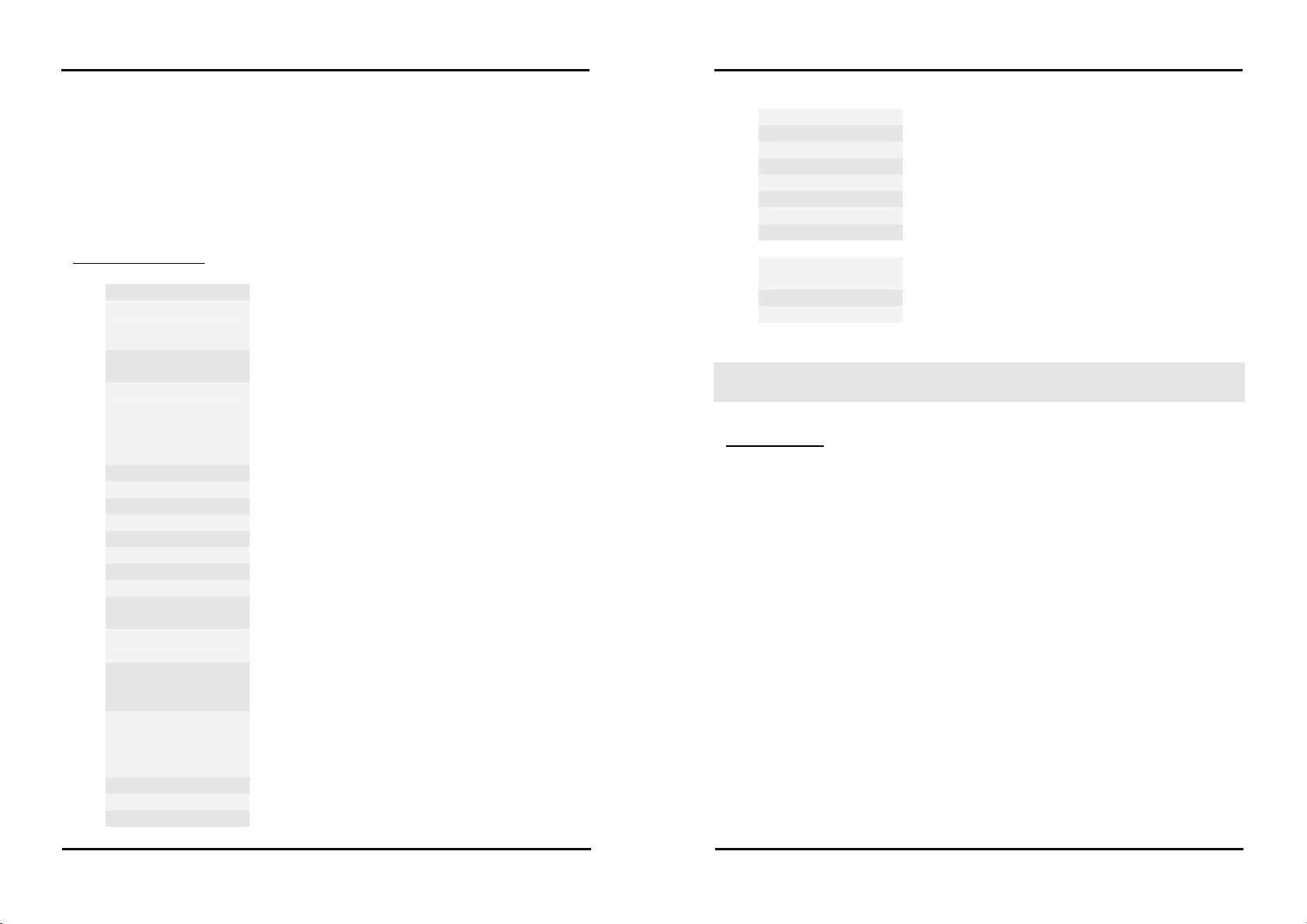

3.2.1 FRONT PANEL DESCRIPTION

System Operation

Status LED

LCD

24 key pad

Function key

Figure: Description of GE314 Front Panel

LCD Module:

LCD module display GE314 status.

System Operation Status LED:

When the power is applied to GE314, the red LED is turned on.

When the Relay #1 is operated, the green LED is turned on.

When the Relay #2 is operated, the yellow LED is turned on.

24 key pad:

You can operate GE314 manually by using the key pad.

Function key:

The GE314 has 12 Function keys ([F1] ~ [F12]).

Fingerprint

Scanner

9

10

Page 6

GE AccessSmart 314 Last Update July 6, 2005

GE AccessSmart 314 Last Update July 6, 2005

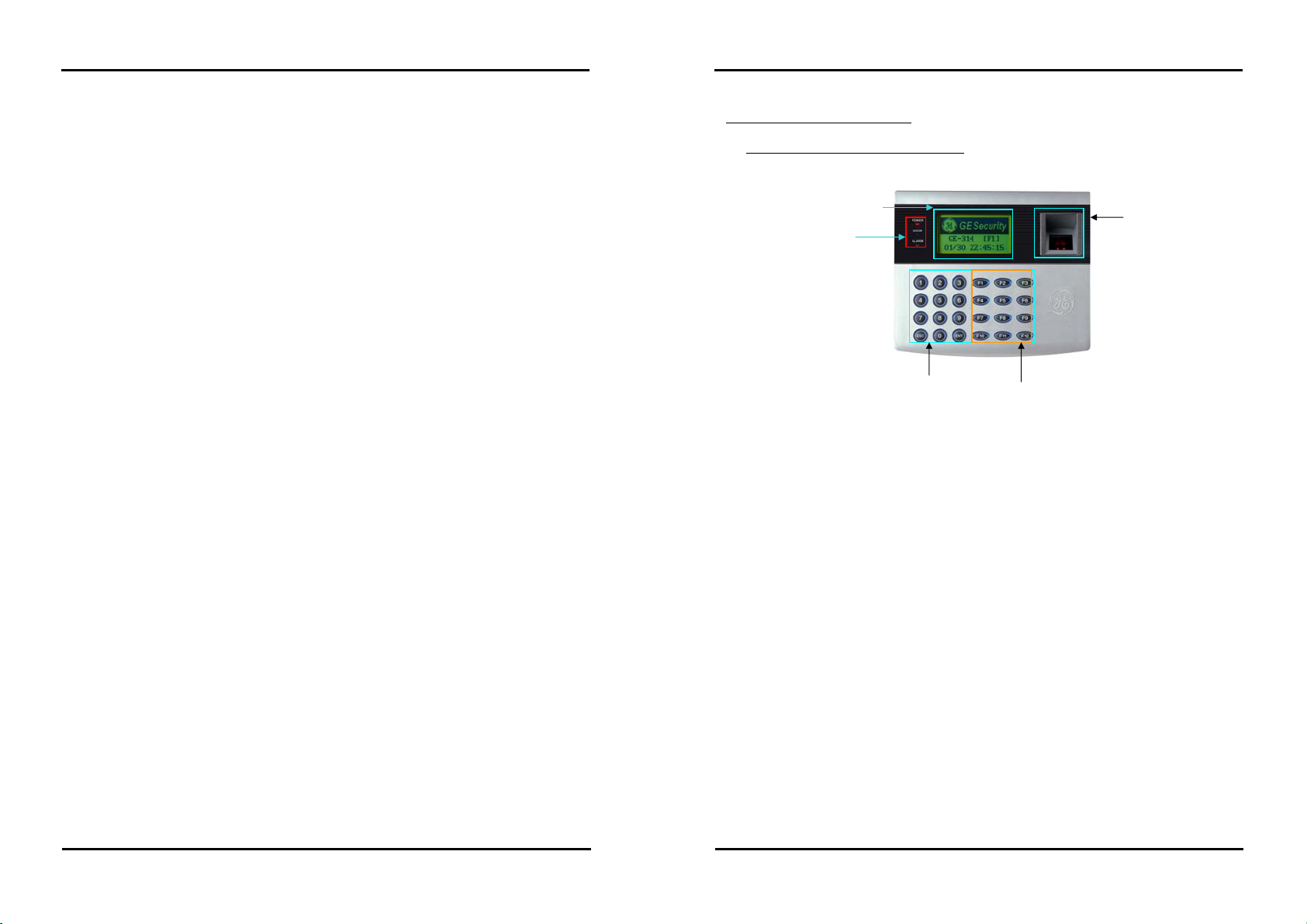

3.2.2 CONNECTOR LAYOUT

Figure: Connector Layout

3.2.3 WIRE COLOR TABLE OF THE GE314

I/O PORT NAME SIGNAL NAME WIRE COLOR

CNN-1: POWER

Main Power (+12V) +12V Red wire

Power Ground 0V Black wire

CNN-2:COMMUNICATION

RS485-RTX(+) RS485-A(+) Gray wire

RS485-RTX(-) RS485-B(-) Blue wire

RS232-TX TXD Red wire with white stripe

RS232-RX RXD Black wire with white stripe

RS232-GND GND Black wire

CNN-3: INPUT/OUTPUT

TTL OUTPUT #1 TTL#1, WD0 Brown wire

TTL OUTPUT #2 TTL#2, WD1 Yellow wire

Aux Input #1 IN#1 Pink wire

Aux Input #2 IN#2 Cyan wire

Wiegand DATA 0 DATA-0 Green wire

Wiegand DATA 1 DATA-1 White wire

CNN-4: INPUT/OUTPUT

Door RELAY(NC) NC(1) Gray wire with white stripe

Door RELAY(COM) COM(1) Green wire with white stripe

Door RELAY(NO) NO(1) White wire with red stripe

Alarm RELAY(NC) NC(2) Yellow wire with red stripe

Alarm RELAY(COM) COM(2) Brown wire with white stripe

Alarm RELAY(NO) NO(2) Blue wire with white stripe

Exit Button EXIT Orange wire

Door Sensor CONTACT Purple wire

CNN-5: TCP/IP RJ45 CONNECTOR

4. INSTALLATION TIPS & CHECK POINT

4.1 CHECK POINT BEFORE THE INSTALLATION

4.1.1 CABLE SELECTION

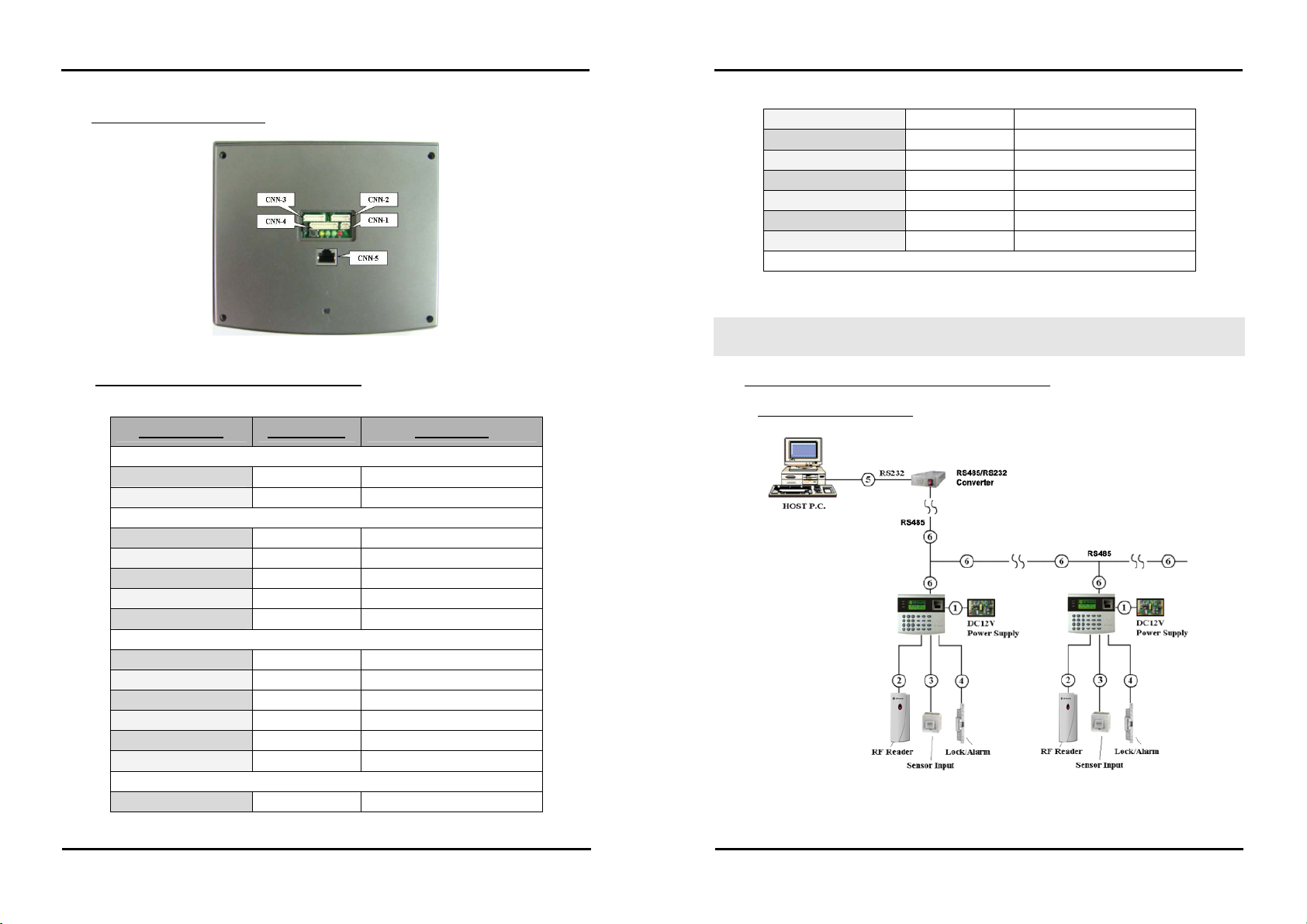

Figure: System Installation Layout

11

12

Page 7

GE AccessSmart 314 Last Update July 6, 2005

GE AccessSmart 314 Last Update July 6, 2005

4.1.2 CABLE SELECTION TABLE

Reference Description Cable Specification Maximum Distance

GE314 Power (DC12V)

①

②+

③

④

⑤

⑥

+

: Need thicker wire if you connect the reader with high current consumption.

DC Power -> GE314

Reader (Power and Data)

Exit Reader -> GE616

Door Contact

Exit Button

Sensor Input

Input -> GE314

Door Lock, Alarm Device

Lock (Alarm) -> GE314

RS232 Cable

Converter -> Host P.C.

RS485 Cable

GE314 -> GE314

GE314 -> Converter

Belden #9409, 18 AWG

2 conductor, unshielded

Belden #9512, 22 AWG

4 conductor, shielded

Belden #9514, 22 AWG

8 conductor, shielded

Belden #9512, 22 AWG

4 conductor, shielded

Belden #9514, 22 AWG

8 conductor, shielded

Belden #9409, 18AWG

2 conductor, unshielded

Belden #9829, 24 AWG

2-twisted pair, shielded

Belden #9829, 24 AWG

2-twisted pair, shielded

30m

150m

300m

300m

15m

1,200m

4.2 CHECK POINT DURING THE INSTALLATION

4.2.1 TERMINATION RESISTOR

Termination resistors are used to match impedance of the network to the impedance of the transmission line

being used. When impedance is mismatched, the transmitted signal is not completely absorbed by the receiver

and a portion of signal is reflected back into the transmission line. The decision whether or not to use termination

resistors should be based on the cable length and data rate used by the communication system. For example, if

you use 9,600 baud rate and 1,200m length of cable, the propagation velocity of cable is 0.66 x speed of light

(This value is specified by the cable manufacturer), if we assume the reflections will damp out in three round trip

up and down the cable length, the transmitted signal will stabilize 18.6us after the leading edge of a bit. Since the

data bit is captured in the middle of the bit which is approximately 52us after the leading edge of a bit. The

reflection stabilizing time 18.6us is much before the center of the bit therefore the termination resistors are not

required. However, if you install the cable to maximum length, the impedance of cable and network is

mismatched and the transmitted signal is overlapped by the reflected signal. In this case, it is recommended to

add termination resistors to the end of the receiver lines. A 120Ω resistor can be used for termination resistor in

parallel between the receiver lines “A” and “B” for 2 wires RS485 system. A termination resistor of less than

90Ω should not be used and no more than 2 terminations should be used in one networking system.

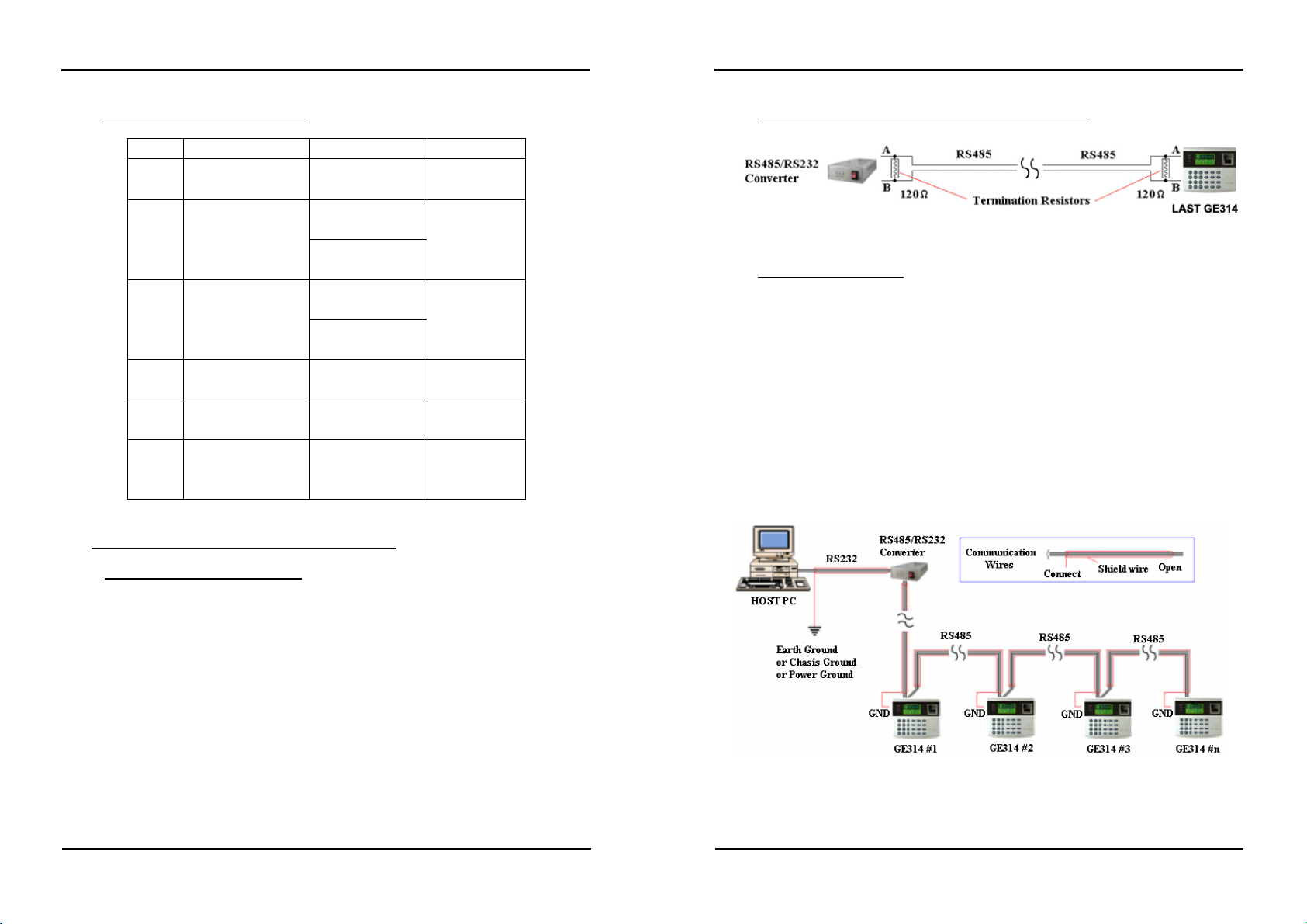

4.2.2 HOW TO CONNECT TERMINATION RESISTORS

Figure: Termination resistors for 2 wire RS485 communication system

4.2.3 GROUND SYSTEM

We recommend to using proper grounding system of the communication cable. The best method for grounding

system is to put the shield wire of the communication cable to the 1

easy to bring the earth ground to the communication cable and also the installation cost is raised.

There will be three grounding point where you can find during installation;

1) Earth Ground

2) Chassis Ground

3) Power Ground

The most important point for grounding system is not to connect both ends of shield wires to the grounding

system; in this case there will be a current flow through the shield wire when the voltage level of both ends of

shield wire is not equal and this current flow will create noise and interfere to communications. For the good

grounding, we recommend to connecting ONLY one end of shield wire of communication cable to grounding

system; If you find earth ground nearby, then connect one end of shield wire to earth ground; If you do not have

earth ground nearby, then find chassis ground and connect one end of shield wire to chassis ground; If you do

not find both earth ground and chassis ground, then connect one end of shield wire to power ground. (GND of

GE314) Note that if the chassis ground is not properly connected to the earth and floated from the ground level,

then grounding to the chassis ground will give the worst communication; in this case we recommend to using

power ground instead of chassis ground.

Figure: Grounding system

st

class earth grounding; however it is not so

13

14

Page 8

GE AccessSmart 314 Last Update July 6, 2005

GE AccessSmart 314 Last Update July 6, 2005

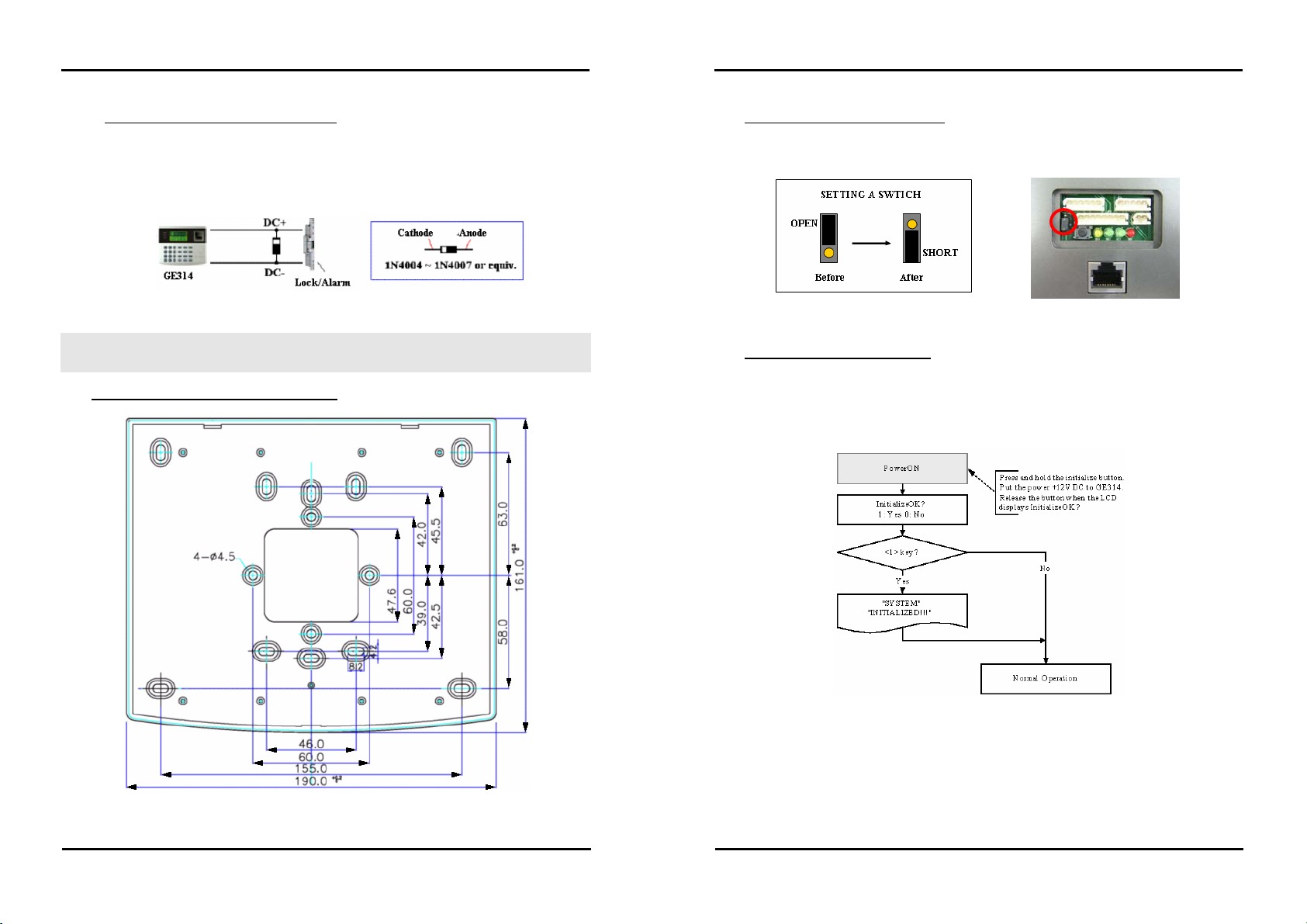

4.2.4 REVERSE DIODE CONNECTION

If you connect an inductor (Door Locks or Alarm device) to the output relays, there will be a high surge voltage

created while the inductor is turning on and off. If you do not connect reverse diode, the surge voltage will

transfer and damage to the electronic circuit of the controller. It is strongly recommended to add a reverse diode

between the inductor coils to absorb this surge voltage.

Figure: Reverse Diode connection

5. INSTALLATION

5.1 WALL MOUNT DRAWING (Unit: mm)

5.2 BACKUP BATTERY SWITCH

GE314 has a switch for the backup battery connection, which remains open circuit to prevent any current

consumption of the backup battery (Figure: Switch setting). Before the GE314 operation, it needs to be

connected so that the backup battery can retain the serial RTC(Date and Time data) during power failure.

Figure: SWITCH SETTING Figure: SWITCH LOCATION

5.3 SYSTEM INITIALIZATION

After the all installation and connections are completed, press and hold the Initialize button and put the power

(+12V DC) to GE314. The LCD will first display “Initialize OK? 0:No 1:Yes”. Press <1> key if you want to

initialize the system. After all Initialization process is completed, the system is operating on normal mode and

the LCD displays “GE Security, GE314 [F1], Date Time”.

Figure: Wall Mount Layout

15

16

Page 9

GE AccessSmart 314 Last Update July 6, 2005

GE AccessSmart 314 Last Update July 6, 2005

5.4 WALL MOUNT INSTALLATION

z Position the Wall Mount to the location where you install the unit and mark 4 x drilling position. Drill 6-

32 holes at least 4 mounting point.

z Drill 1/2” hole on the center of Wall Mount.

z Using 4 screws, install the Wall Mount to the proper location.

z Take out the cable through the center hole.

z After the wiring is done on the section 8, install the Main Unit to the Wall Mount using a screw to the

bottom of the Wall Mount.

6. WIRING

6.1 POWER CONNECTION

1. Connect (+) wire of DC 12V power Supply to the Red wire.

2. Connect GND (-) wire of DC 12V power Supply to the Black wire.

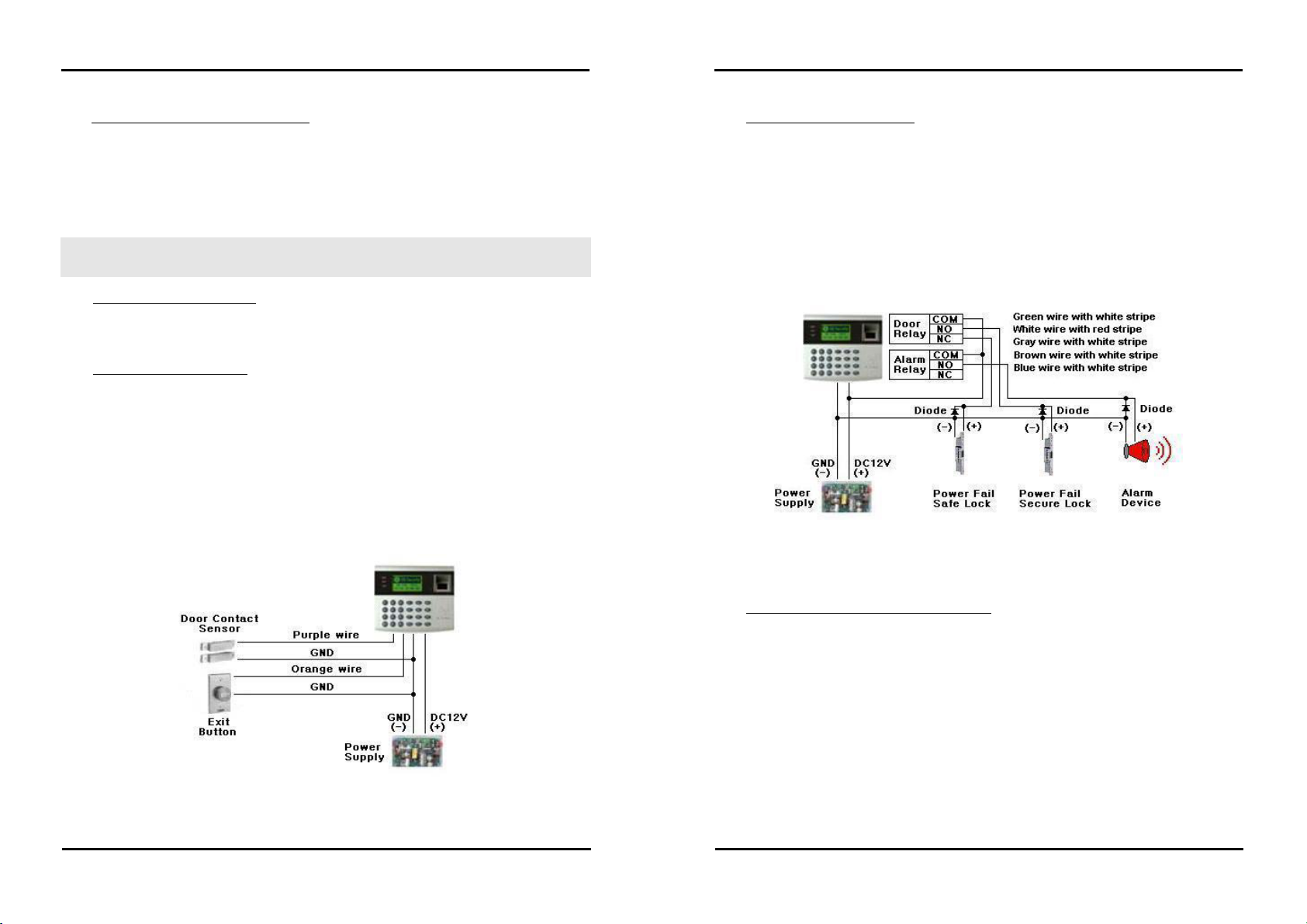

6.2 INPUT CONNECTION

Exit Button Connection

1. Connect one wire from an Exit Button to the Orange wire.

2. Connect the other wire from the Exit Button to the GND.

Door Contact Sensor Connection

1. Connect one wire from a Door Contact Sensor to the Purple wire.

2. Connect the other wire from the Door Contact Sensor to GND.

Auxiliary Input Connection

Applied to Aux Input #1(Pink wire), Aux Input #2(Cyan wire)

1. Connect one wire from an Auxiliary Input Device to one of the Aux Input #1 or Aux Input #2.

2. Connect the other wire from the Auxiliary Input Device to GND.

6.3 OUTPUT CONNECTION

Door Lock (Power Fail Safe) Connection (Door Relay)

1. Connect COM wire of Door Relay, the Green wire with white stripe to +12V.

2. Connect NC wire of Door Relay, the Gray wire with white stripe to (+) wire of door lock device.

3. Connect GND wire to (-) wire of door lock device.

Door Lock (Power Fail Secure) Connection (Door Relay)

1. Connect COM wire of Door Relay, the Green wire with white stripe to +12V.

2. Connect NO wire of Door Relay, the White wire with red stripe to (+) wire of door lock device.

3. Connect GND wire to (-) wire of door lock device.

Alarm Device Connection (Alarm Relay)

1. Connect COM wire of Alarm Relay, the Brown wire with white stripe to +12V.

2. Connect NO wire of Alarm Relay, the Blue wire with white stripe to (+) wire of Alarm device.

3. Connect GND port to (-) wire of Alarm device.

Figure: Door Lock, Alarm Device Connection

CAUTION: Must add REVERSE DIODE as shown above.

DIODE: Fast Recovery DIODE (current: min. 1A), 1N4004 ~ 1N4007 or similar.

6.4 EXTERNAL READER CONNECTION

Proximity Reader Connection

1. Connect (+) wire of the Proximity Reader to DC +12V.

2. Connect (-) wire of the Proximity Reader to GND.

3. Connect Data-0 wire of the Proximity Reader to the Green wire.

4. Connect Data-1 wire of the Proximity Reader to the White wire.

z Compatible Reader:

GE616: Standard IDC 26bit Wiegand Format Proximity Reader.

Figure: Input Device Connection

17

18

Page 10

GE AccessSmart 314 Last Update July 6, 2005

GE AccessSmart 314 Last Update July 6, 2005

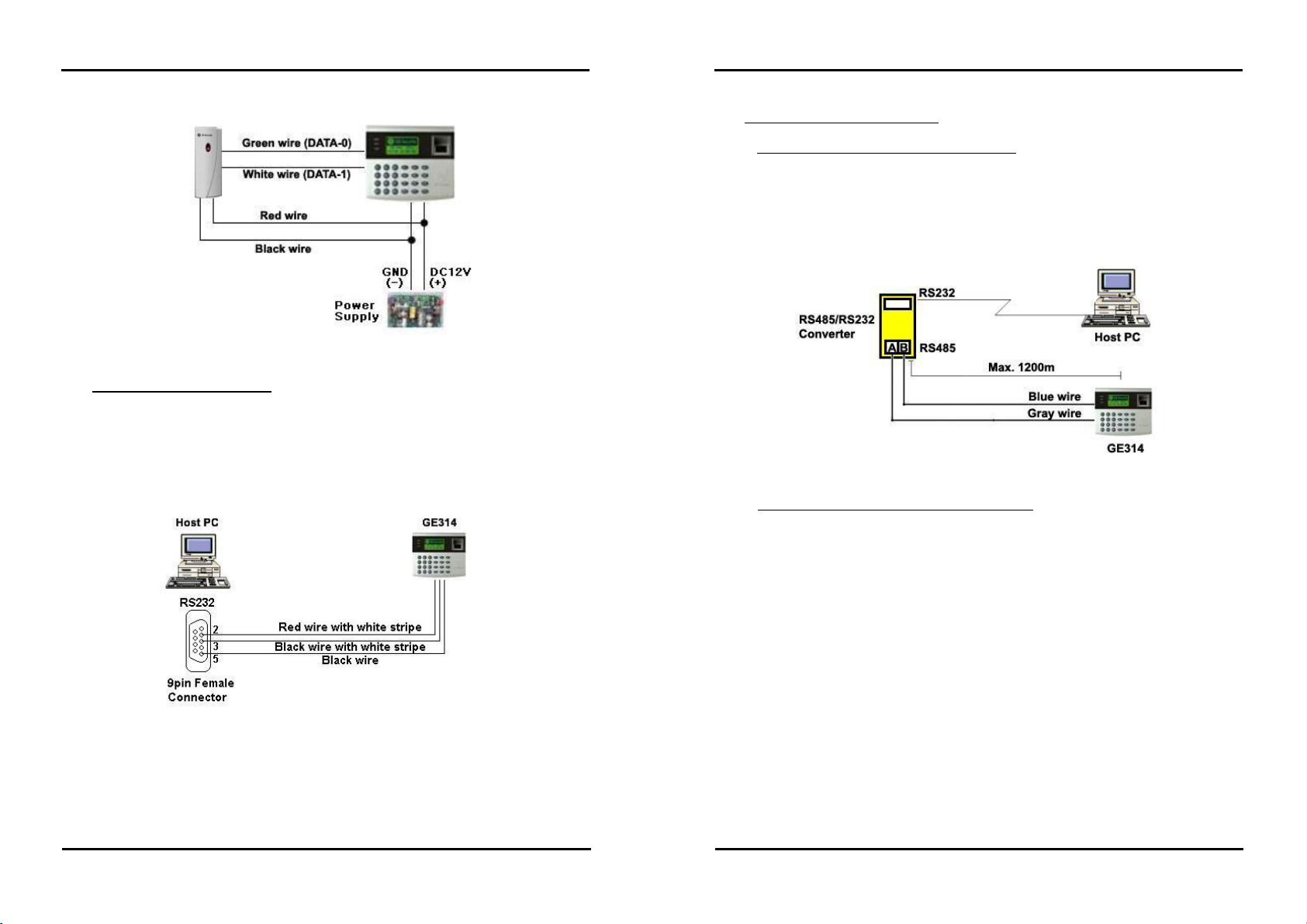

6.6 RS-485 PORT CONNECTION

6.6.1 RS-485 CONNECTION(SINGLE UNIT)

RS485/RS232 converter is required to use RS485 communication between the GE314 and a host PC.

Please follow the instructions.

1. Connect RS485-RTX(+), Grey wire to RS485-A port of the converter.

2. Connect RS485-RTX(-), Blue wire to RS485-B port of the converter.

3. Plug the RS232, 9-pin connector of the converter into the COM1 or COM2 Port of the host PC.

4. Install and run the GE314 Application Software.

Figure: External Reader Connection

6.5 RS232 PORT CONNECTIN

A 9-pin connector (Serial communication connector, female) is required to connect the GE314 to a host

computer via RS232 communication. Please follow the instructions.

1. Connect RS232-TX, Red wire with white stripe to the pin #2(RXD) of the 9-pin connector.

2. Connect RS232-RX, Black wire with white stripe to the pin #3(TX) of the 9-pin connector.

3. Connect GND, Black wire to the pin #5 of the 9-pin connector.

4. Plug in the 9-pin female connector to COM1 or COM2 Port of the host PC.

5. Install and run GE314 Application Software.

Figure: RS-232 COMMUNICATON

Figure: RS-485 Connection between GE314 and a host PC

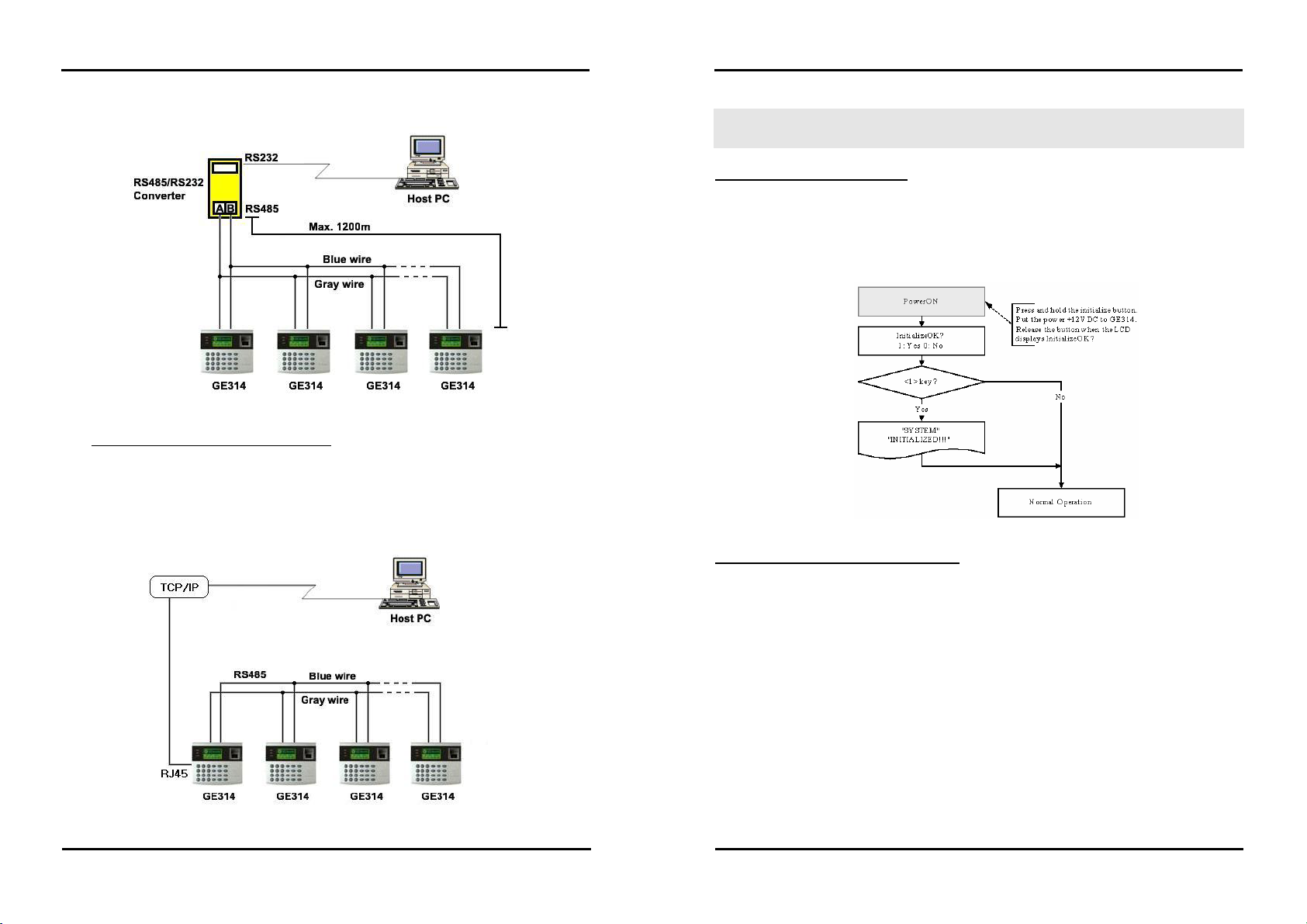

6.6.2 RS-485 CONNECTIN(MULTIPLE UNITS)

RS485/RS232 converter is required to use RS485 communication between multiple GE314 and a host PC.

Please follow the instructions.

First, you have to connect all RS485 port of GE314 in parallel. (max. 32 x GE314 Units)

1. Connect RS485-RTX(+), Grey wire of one GE314 to RS485-RTX(+), Grey wire of another GE314.

2. Connect RS485-RTX(-), Blue wire of one GE314 to RS495-RTX(-), Blue wire of another GE314.

3. Set a different COMM ID for each GE314.

Second, you have to connect one of RS485 port of GE314 to RS485/RS232 converter.

1. Connect RS485-RTX(+), Grey wire of one GE314 to RS485-A port of the converter.

2. Connect RS485-RTX(-), Blue wire of one GE314 to RS485-B port of the converter.

3. Plug the RS232, 9-pin connector of the converter into the COM1 or COM2 Port of the host PC.

4. Install and run the GE314 Application Software.

19

20

Page 11

GE AccessSmart 314 Last Update July 6, 2005

GE AccessSmart 314 Last Update July 6, 2005

7. BASIC SETTINGS

7.1 INITIALIZATION OF GE314

After the all installation and connections are completed, press and hold the Initialize button and put the power

(+12V DC) to GE314. The LCD will first display “Initialize OK? 1:YES, 0:NO”. Press <1> key if you want

to initialize the system. After all Initialization process is completed, the system is operating on normal mode

and the LCD displays “GE Security, GE314 [F1], Date Time”.

Figure: RS-485 Communication between multiple GE314 and a host PC

6.7 TCP/IP CONNECTION (OPTIONAL)

Optional TCP/IP Module is required for TCP/IP communication to the host PC.

1. Connect RJ45 plug, LAN cable of the network system to RJ45 jack of the GE314.

2. If you install multiple GE314 and only one TCP/IP port is available, you may connect one GE314 to

TCP/IP then connect all GE314 units to RS485 multiple communication shown above.

3. Set a different COMM ID for each GE314.

4. Install and run the GE314 Application Software.

Figure: TCP/IP Communication between multiple GE314 and a host PC

7.2 HOW TO ENTER THE SETUP MENU

To setup or to change the GE314 settings, you have to enter the SETUP MENU first. To do so, press <0> key

eight times (Default Master ID ‘00000000’) and <ENT> key from the Keypad. You now entered to the

SETUP MENU. There are 9 SETUP MENU and you first get into [F1 SETUP MENU]. You can move to

another SETUP MENU by pressing <F1> key to <F9> key button. For example, if you want to go to [F2

SETUP MENU] then press <F2> key, for [F5 SETUP MENU] then press <F5> key and so on. There are

several SUBMENU on each SETUP MENU and you can scroll up and down the SUBMENU by pressing

<4> and <6> key on each SETUP MENU. If you don’t press any key for 60 seconds or if you press <ESC>

key, GE314 will exit the SETUP MENU and return to normal operation mode. You can also change the

Master ID in the [F4 SETUP MENU].

21

22

Page 12

GE AccessSmart 314 Last Update July 6, 2005

GE AccessSmart 314 Last Update July 6, 2005

7.3 LANGUAGE SETTING

Select [LANGUAGE] in the [F2 SETUP MENU] then press <ENT> key to select the LANGUAGE. Please

follow the steps below for LANGUAGE setting and following procedure is for selecting CHINESE.

7.4 DATE/TIME SETTING

Select [SET DATE/TIME] in the [F2 SETUP MENU] and enter Year / Month / Date / Hour / Minute /

Second / Day (Total 15 digits) as shown below. The LCD will display the new Date and Time after the time

setting is completed but the year and day will not be displayed. GE314 has a 24 hours system and day codes

are 1 for Sunday, 2 for Monday, 3 for Tuesday, 4 for Wednesday, 5 for Thursday, 6 for Friday and 7 for

Saturday.

7.5 ID REGISTRATION

You can register the User ID into the GE314. Select [F4 SETUP MENU] -> [REGISTRATION] and follow

the steps below.

1. Registration by Card

2. Registration by Key

23

24

Page 13

GE AccessSmart 314 Last Update July 6, 2005

GE AccessSmart 314 Last Update July 6, 2005

1. Scanning… The reader is waiting for the ID number to be registered. The card number will appear with a

beep sound when you present the card. ID number is 8digit number.

2. ID: ID number consists of 4~8 digit. Enter 4~8digit ID number (PIN) and press <ENT> key on the field.

3. PW: PW is the password which can be used to access the doors with RF + Password operating mode. It is

necessary to enter a default password (‘0000’) when you register an ID.

4. TA: TA is the Time Schedule code (‘00’ ~ ‘10’) for the Reader#1 (Built-in Reader). When you present the

card to the Reader#1, the cardholder is only allowed the access of the door during the Time intervals of the

Time Schedule code entered to TA. To setup the Time intervals for each Time Schedule code, refer to the

Time Schedule Setup on the [F5 SETUP MENU]. If you want to access the door anytime for the cardholder

then enter the default Time Schedule code '00' for the value.

5. TB: TB is the Time Schedule code (‘00’ ~ ‘10’) for the Reader#2 (Exit Reader). When you present the

card to the Reader#2, the cardholder is only allowed the access of the door during the Time intervals of the

Time Schedule code entered to TB. To setup the Time intervals for each Time Schedule code, refer to the

Time Schedule Setup on the [F5 SETUP MENU]. If you want to access the door anytime for the cardholder

then enter the default Time Schedule code '00' for the value.

6. RD: RD is the Reader Assignment code for the cardholder. Code ‘0’ assigns for both readers (Built-in

Reader and Exit Reader), code ‘1’ only assigns Reader#1 (Built-in Reader) and code ‘2’ only assigns

Reader#2 (Exit Reader). If you put ‘1’ for RD (Only Reader#1 assigned) and try to exit through Reader#2

(Exit Reader) then GE314 generates an error message (“Access Door Error”) on the LCD display.

7. MA: MA is the Reader#1 (Built-in Reader) Operating Mode for the cardholder. If you put ‘1’ for MA,

Reader#1 is always operating on RF Only Mode.

‘0’ – System Operating Mode [F2 SETUP MENU]Æ [READER#1 MODE]

‘1’ – ID Only Mode

‘2’ – ID + Finger(Password) Mode

‘3’ – ID + Password + Finger Mode

8. MB: MB is the Reader#2 (Exit Reader) Operating Mode for the cardholder. If you put ‘1’ for MB,

Reader#2 is always operating on RF Only Mode.

‘0’ – System Operating Mode [F2 SETUP MENU]Æ [READER#2 MODE]

‘1’ – ID Only Mode

‘2’ – ID + Password Mode

9. LV: LV is the Output Operating Level for the cardholder. Output operating time can be set for each user.

To setup Output operating time for each level, refer to the Output Setting on the [F7 SETUP MENU].

‘0’ or ‘1’ – Level #1

‘2’ – Level #2

‘3’ – Level #3

‘4’ – Level #4

10. FP: FP is the Fingerprint Usage Flag (1 digit). You can assign the user who uses fingerprint or not.

‘0’ – User without Fingerprint

‘1’ – User with Fingerprint

3. How to put your finger to the scanner

When you enroll or verify your fingerprint, please place your finger to the scanner correctly.

Figure: How to put your finger to the scanner

25

26

Page 14

GE AccessSmart 314 Last Update July 6, 2005

GE AccessSmart 314 Last Update July 6, 2005

8. OPERATION

8.1 NORMAL OPERATION

Power on

When the power is applied to GE314, the Red LED is turned on.

Registered card reading

When a registered card (or PIN) is read and his/her fingerprint is verified, the Door (Relay#1) will open for 3

seconds (Default) with the Green LED on.

Exit Button

When the Exit button is pressed, the Door (Relay#1) will open for 3 seconds with the Green LED on.

Alarms

When an unregistered card is read or his/her fingerprint is not verified, the access is denied and the Alarm

(Relay#2) will be activated for 3 seconds with the Yellow LED on.

8.2 DEFAULT SETTING

When you operate the system for the first time or the system initialized, the factory setting values (default

settings) will be stored in the memory. You may change the settings for the desired application.

9. SETTING CHANGES

☞. To setup or to change the GE314 settings, you have to enter the SETUP MENU first. To do so, press <0> key

eight times (Default Master ID ‘00000000’) and <ENT> key from the Keypad. You now entered to the

SETUP MENU. There are 9 SETUP MENU and you first get into [F1 SETUP MENU]. You can move to

another SETUP MENU by pressing <F1> key to <F9> key button. For example, if you want to go to [F2

SETUP MENU] then press <F2> key, for [F5 SETUP MENU] then press <F5> key and so on. There are

several SUBMENU on each SETUP MENU and you can scroll up and down to SUBMENU by pressing <4>

and <6> key on each SETUP MENU. If you don’t press any key for 60 seconds or if you press <ESC> key,

GE314 will exit the SETUP MENU and return to normal operation mode. You can also change the Master ID

in the [F4 SETUP MENU].

27

28

Page 15

GE AccessSmart 314 Last Update July 6, 2005

GE AccessSmart 314 Last Update July 6, 2005

9.1 F1 SETUP MENU

9.1.1 VERSION CHECK

☞. The Firmware Version of the GE314 displays on the LCD.

Press <4> or <6> key to have a look for other menus on

[ F1 SETUP MENU]

9.1.2 INPUT TEST

. The ☞ 5digit shows the input status and “0” indicates that the input port is open circuit and “1” indicates that the

input port is short circuit to ground level.

9.1.3 OUTPUT TEST

☞. The first two tests are for the output relays (Door Relay and Alarm Relay) test. You can hear the mechanical

sound of relays and LED will blink. Following two tests are for TTL#1 and TTL#2 output testing. The last

test is for the Internal Buzzer test and you can hear two beep sounds.

9.1.4 LCD TEST

☞. The LCD will display all characters on the screen. When the test is done, the LCD will show “Last Update

Press any key”.

9.1.5 KEYPAD TEST

29

30

Page 16

GE AccessSmart 314 Last Update July 6, 2005

GE AccessSmart 314 Last Update July 6, 2005

☞. LCD will display all keys of the unit. Press each key from the keypad one by one, the depressed key will

disappear from the LCD. Note that ENT key is “#” and ESC key is “*” on the LCD.

9.1.6 READER TEST

☞. LCD will display “Scanning…” for reading the cards. Present the card to one of the readers.

☞. When the reader successfully read the card, LCD will display Reader number and 8digit card number on the

LCD.

9.1.7 MEMORY TEST

9.1.8 COMMUNICATION TEST

. ☞ Before this communication test, connect RS232-RX and RS232-TX wires together.

. ☞ This test is a loop test and GE314 sends a character to RS232-TX and check whether the RS232-RX receive

the same character or not. If you have an error, contact manufacturer for technical support.

☞. If the Data Memory has problems, LCD will show the memory block number with Memory failure message.

In this case, contact manufacturer for technical support.

31

32

Page 17

GE AccessSmart 314 Last Update July 6, 2005

GE AccessSmart 314 Last Update July 6, 2005

9.2 F2 SETUP MENU

9.2.1 LANGUAGE

☞. The default Language is in ENGLISH.

☞. There are 6 languages can be selected. (KOREAN, ENGLISH, CHINESE, JAPANESE, SPANISH,

PORTUGUESE)

9.2.2 DATE AND TIME SETTING

☞. Example: 200302101330152 => Feb. 10, 2003, 13:30:15, Monday

9.2.3 READER#1 MODE

Note: READER#1 is built-in proximity reader in the unit.

ID(PIN) ONLY: The door is accessible by just presenting the proximity card(or Press the ID Number).

ID+F/P(P/W): The door is accessible by presenting a card and verifying Fingerprint (or Password).

ID+P/W+F/P: The door is accessible by presenting a card and verifying Password and Fingerprint.

33

34

Page 18

GE AccessSmart 314 Last Update July 6, 2005

GE AccessSmart 314 Last Update July 6, 2005

9.2.4 READER#2 MODE

READER#2 MODE setting is the same as 9.2.3 READER#1 MODE setting.

Note: READER#2 is an external Exit reader of the unit.

ID(PIN) ONLY: The door is accessible by just presenting the proximity card(or Press the ID Number).

ID+ P/W: The door is accessible by presenting a card and Password.

9.2.5 READER#1 PIN INPUT

☞. This function is for USE/UNUSE the keypad inputs for the Reader#1. The default setting is UNUSE the

keypad inputs. If you want to access the door by entering the user ID by keypad, set this mode USE. You

have to set this mode USE when the unit is operating with Password.

9.2.6 READER#2 PIN INPUT

READER#2 PIN INPUT setting is the same as 9.2.5 READER#1 PIN INPUT setting.

9.2.7 COMMUNICATION ADDRESS SETTING

. ☞ The default Communication Address is “000” and set a different COMM Address for each unit in the loop.

9.2.8 BAUD RATE SETTING

☞. GE314 supports 9600, 19200, 38400 and 57600bps of Baud Rate and default Baud Rate is 9600bps. Wrong

Baud Rate setting will cause communication error and you have to set same Baud Rate for the same

communication network.

If you have communication problem, please check followings;

- Check Communication Address for both GE314 and the host PC (Software)

- Check Baud Rate for both GE314 and host PC

- Check Communication Port and Cable

- Check COM port setup of the host PC

Parity: None, Data Bit: 8 bit, Stop Bit: 1 bit

35

36

Page 19

GE AccessSmart 314 Last Update July 6, 2005

GE AccessSmart 314 Last Update July 6, 2005

9.3 F3 SETUP MENU

9.3.1 EVENT MEMORY

☞. ☞. You can select whether you will use event memory or not. When you select USE and in case of an event

memory, GE314 generates an error message and keeps all events stored in the memory. When you select

UNUSE, GE314 will not generate an error and new event overwrite into the event buffers. If you use GE314

for standalone (just for door access), select UNUSE.

9.3.2 ID DISPLAY

☞. This function is to set display mode. If you want to display user ID number on the LCD, select

ID+MESSAGE. MESSAGE: Text message and “********” characters will be displayed on the LCD and it

will not display user ID number. ID+MESSAGE: The user ID number will be displayed on the LCD with text

message. Default setting is MESSAGE only.

37

38

Page 20

GE AccessSmart 314 Last Update July 6, 2005

GE AccessSmart 314 Last Update July 6, 2005

9.3.3 TIME UNIT SETTING

. ☞ This menu is to define time unit for 5 output ports.

1sec: Output Time will be calculated by one second time unit for in/out definition.

0.1sec: Output Time will be calculated by 1/10 second time unit (100ms) for in/out definition

Ex) If you want to activate Door Relay (Relay #1, DR) for 3 second, you have to set as follow.

- Set Output Time Unit to 1 SEC.

- Set Door Relay (DR) Output Time to “03”

Ex) ) If you want to activate Door Relay (Relay #1, DR) for 0.5 second, you have to set as follow.

- Set Output Time Unit to 0.1 SEC.

- Set Door Relay (DR) Output Time to “05”

9.3.4 OUTPUT T/S+ID

☞. Output Time Schedule+ID is to unlock the door when the first user grants the access during the Time Interval

of the Time Schedule. The door will be locked just after the Time Interval period is over.

UNUSE: Door will unlock at the beginning of the Time Interval of the Time Schedule code.

USE: Door will unlock when the first user grants the access during the Time Interval of the Time Schedule.

9.3.5 ANTI-PASS BACK MODE

☞. The Anti-pass Back mode is only used when you installed Exit Reader. Do not set this mode in USE when

you installed Exit Button. You must install GE314 for entry and Exit Reader for Exit.

UNUSE: Anti-pass Back mode OFF

USE: Anti-pass Back mode ON

☞. ALL FLAG RESET: Allow the access only one time whatever the Anti-pass Back flag is.

9.3.6 DURESS MODE

☞. You can set Duress Mode for Reader#1. Default setting is UNUSE. If you select USE, LCD will display

default Duress Password ‘00’. Enter 2 digit Duress Password.

Note!!

If you are in Duress condition, enter 2 digit Duress Password and press <ENT> key prior to present the card.

Door will be opened as normal but the Duress Alarm will be generated and reported to the host PC.

9.3.7 WIEGAND OUTPUT

39

40

Page 21

GE AccessSmart 314 Last Update July 6, 2005

p

m

GE AccessSmart 314 Last Update July 6, 2005

☞. This is the function to use GE314 as a Reader and sends 26bit Wiegand Output through two TTL output ports.

Press <ENT> key and select USE by pressing <4> or <6> key then press <ENT> key for setting.

UNUSE: Normal TTL outputs will be activated.

USE: 26bit Wiegand output will be generated through TTL1 and TTL2 port.

When an registered card is read, the “CARD SCCANNING OK” message will appear on the LCD.

z TTL1 : Data 0 TTL2 : Data 1

9.3.8 DOOR OPEN ALARM TIME SETTING

☞. When the door is not closed after the door open time is over, you may set the delay time to generate Door

Open Alarm. To use this function, you have to install a Door Contact Sensor on the door and setup the alarm

time by Door Contact Sensor. ‘03’ sec. is default time.

00: Alarm if the door is not closed after the door open time (Door Relay time).

01~98: Alarm if the door is not closed after the door open time and over the alarm delay time. (01~98s)

99: No Door O

en Alar

9.4 F4 SETUP MENU

9.4.1 ID REGISTRATION

1. Registration by RF Card

41

42

Page 22

GE AccessSmart 314 Last Update July 6, 2005

GE AccessSmart 314 Last Update July 6, 2005

2. Registration by Keypad

1. Scanning… The reader is waiting for the ID number to be registered. The card number will appear with a

beep sound when you present the card. ID number is 8digit number.

2. ID: ID number consists of 4~8 digit. Enter 4~8digit ID number (PIN) and press <ENT> key on the field.

3. PW: PW is the password which can be used to access the doors with RF + Password operating mode. It is

necessary to enter a default password (‘0000’) when you register an ID.

4. TA: TA is the Time Schedule code (‘00’ ~ ‘10’) for the Reader#1 (Built-in Reader). When you present the

card to the Reader#1, the cardholder is only allowed the access of the door during the Time intervals of the

Time Schedule code entered to TA. To setup the Time intervals for each Time Schedule code, refer to the

Time Schedule Setup on the [F5 SETUP MENU]. If you want to access the door anytime for the cardholder

then enter the default Time Schedule code '00' for the value.

5. TB: TB is the Time Schedule code (‘00’ ~ ‘10’) for the Reader#2 (Exit Reader). When you present the

card to the Reader#2, the cardholder is only allowed the access of the door during the Time intervals of the

Time Schedule code entered to TB. To setup the Time intervals for each Time Schedule code, refer to the

Time Schedule Setup on the [F5 SETUP MENU]. If you want to access the door anytime for the cardholder

then enter the default Time Schedule code '00' for the value.

6. RD: RD is the Reader Assignment code for the cardholder. Code ‘0’ assigns for both readers (Built-in

Reader and Exit Reader), code ‘1’ only assigns Reader#1 (Built-in Reader) and code ‘2’ only assigns

Reader#2 (Exit Reader). If you put ‘1’ for RD (Only Reader#1 assigned) and try to exit through Reader#2

(Exit Reader) then GE314 generates an error message (“Access Door Error”) on the LCD display.

7. MA: MA is the Reader#1 (Built-in Reader) Operating Mode for the cardholder. If you put ‘1’ for MA,

Reader#1 is always operating on RF Only Mode.

‘0’ – System Operating Mode [F2 SETUP MENU]Æ [READER#1 MODE]

‘1’ – ID Only Mode

‘2’ – ID + Finger Mode

‘3’ – ID + Password + Finger Mode

8. MB: MB is the Reader#2 (Exit Reader) Operating Mode for the cardholder. If you put ‘1’ for MB,

Reader#2 is always operating on RF Only Mode.

‘0’ – System Operating Mode [F2 SETUP MENU]Æ [READER#2 MODE]

‘1’ – ID Only Mode

‘2’ – ID + Password Mode

9. LV: LV is the Output Operating Level for the cardholder. Output operating time can be set for each user.

To setup Output operating time for each level, refer to the Output Setting on the [F7 SETUP MENU].

‘0’ or ‘1’ – Level #1

‘2’ – Level #2

‘3’ – Level #3

‘4’ – Level #4

10. FP: FP is the Fingerprint Usage Flag (1 digit). You can assign the user who uses fingerprint or not.

‘0’ – User without Fingerprint

‘1’ – User with Fingerprint

9.4.2 ID DELETION

. ☞ Registered ID will be deleted in the controller by presenting the card or input the ID number from the keypad.

Present the card to be deleted. The ID number will appear on the LCD. If you don’t have the card, input 8digit

ID number and <ENT> key from the keypad. If the ID number is found, the ID will be deleted and display “ID

DELETED”. If the ID number is not found, the display will show “ UNREGISTERED ID”. You may repeat ID

DELETION many times.

43

44

Page 23

GE AccessSmart 314 Last Update July 6, 2005

GE AccessSmart 314 Last Update July 6, 2005

9.4.3 ID LIST

. LCD will display 5digit ID Index, 8digit I☞ D number, 4digit Password, T/S for Reader#1(TA) and

Reader#2(TB), accessible Readers(RD), operating mode for Reader#1(MA) and Reader#2(MB), the output

level(LV) and usage of Fingerprint(FP) for this user.

. ☞ “EMPTY” message will be displayed if there is no registered user ID.

. ☞ “FIRST ID” message will be displayed if the LCD displays the ID on the top of the list.

. ☞ “LAST ID” message will be displayed if the LCD displays the ID on the bottom of the list.

9.4.4 MASTER ID REGISTRATION

MASTER ID REGISTRATION BY CARD

MASTER ID REGISTRATION BY PIN

. ☞ The default Master ID ‘01’ is “00000000” and Fingerprint is not used.

There are total 10 Master IDs (from “01” to “10”) can be stored in the unit.

9.4.5 ID COUNT

☞. This menu displays the total number of registered user ID. It

automatically counts when you register or delete user IDs. The LCD

shows total 123 user IDs registered in the memory.

☞. Total number of user IDs is 1,000 user IDs (standard) or optional

2,000/4,000 user IDs can be stored in the unit.

9.4.6 EVENT COUNT

☞. This menu displays the total number of Event stored in the memory.

It automatically increases the count when the Event is stored in the

memory. The LCD shows total 12345 Events are stored in the

memory.

☞. Total number of Event is 20,000 Event buffers and the Event is

automatically deleted once the Event is successfully uploaded to the

host PC.

45

46

Page 24

GE AccessSmart 314 Last Update July 6, 2005

GE AccessSmart 314 Last Update July 6, 2005

9.5 F5 SETUP MENU

9.5.1 TIME SCHEDULE

☞. There are 10 Time Schedule Code available for the users. T/S Code “00” is a default and allows the access for

all users for all the time. (Access is granted 24 hours per day) The user can program the Time Schedule Code

from “01” to “10”. Each Time Schedule Code has 8 programmable days (Sun, Mon, Tue, Wed, Thu, Fri, Sat

and Holiday) and each day has 5 Time Intervals. (Shift time or Accessible time zone)

☞. LCD will show current T/S settings such as T/S Code, Day, Time Interval and time period.

Use <2> or <8> key to scroll up and down the Time Schedule Code (01~10) and a day of the week. (Mon ~

Sun and Holiday). Use <4> or <6> key to select Time Interval (1 ~ 5). The Holiday in this Time Schedule will

be linked to the Holiday Schedule Code.

Select one of the Time Schedule Code, Day and Interval then press <ENT> key to program the time period.

This system is based on 24 hours system and therefore the time 00:00 and 24:00 is the same time and 12:00 is

12 O’clock afternoon. Enter hour and minutes for start time and hour and minutes for end time of the Time

Interval then press <ENT> key to store T/S to the memory.

Press <ESC> key to return to the menu.

9.5.2 HOLIDAY SCHEDULE

☞. There are 10 Holiday Schedule Code available for the users. H/S Code “00” is a default and there is no

Holidays in this code. The user can program the Holiday Schedule Code from “01” to “10”. Each Holiday

Schedule Code has 100 programmable holidays.

☞. LCD will show current H/S settings such as H/S Code, Holiday number and Date.

Use <2> or <8> key to scroll up and down the Holiday Schedule Code (01~10) and use <4> or <6> key to

select Holiday number (001 ~ 100).

Select one of the Holiday Schedule Code and Holiday number then press <ENT> key to program holidays.

Enter month and date of holiday then press <ENT> key to store H/S to the memory.

Press <ESC> key to return to the menu.

47

48

Page 25

GE AccessSmart 314 Last Update July 6, 2005

y

GE AccessSmart 314 Last Update July 6, 2005

9.5.3 HOLIDAY CODE

☞. Holiday Code is to link the Holiday Schedule to the Time Schedule. T/S has 5 Time Intervals for holidays and

this Time Intervals are only applied to the dates of this Holiday Schedule. Default Holiday Schedule Code is

‘00’ which means no holidays are applied to T/S.

Use <4> or <6> key to scroll up and down the T/S Code (01~10) and press <ENT> key to enter 2digit Holiday

Schedule Code and press <ENT> key to store Holiday Index to the memory.

Press <ESC> ke

to return to the menu.

9.5.4 READER#1 MODE TIME SCHEDULE

☞. There are 3 system operating mode, RF Only Mode, RF+F/P Mode and RF+PW+F/P Mode. You can setup one

of the system operating mode from [F2 SETUP MODE]->[R1 MODE SETTING] menu. However, you want

to apply different operating mode for a certain Time Interval for all users. For example, you want to access the

door by just presenting the card for the time from 09:00 to 17:00 and you want to use Fingerprint verification

for the rest of the time. In this case, setup [R1 MODE SETTING] to RF+F/P Mode which is for the system

operating mode and program “01” T/S Code which includes a Time Interval 09:00-17:00 then link “01” T/S

Code to this function, R1 MODE T/S setting here.

To link a T/S Code (01~10) to Reader#1 Mode, press <ENT> key. Enter 2digit T/S Code and press <ENT>

key to store T/S Code to R1 MODE to the memory.

Press <ESC> key to return to the menu.

. There are 3 system operating mode, ☞ ID Only Mode, ID + Finger(Password) Mode and ID + PW + Finger

Mode.

You can select one of the system operating mode from [F2 SETUP MENU]->[READER#1 MODE SETTING]

however, you want to apply different operating mode

‘2’ – RF + Finger Mode

‘3’ – RF + PW + Finger Mode

9.5.5 READER#2 MODE TIME SCHEDULE

READER#2 MODE TIME SCHEDULE setting is the same as 9.5.4 READER#1 MODE T/S setting.

9.6 F6 SETUP MENU

49

50

Page 26

GE AccessSmart 314 Last Update July 6, 2005

GE AccessSmart 314 Last Update July 6, 2005

* Default Output Setting for Input Sources

Door

OUTPUT

[1] EXIT BUTTON 03 00 00 00 00

[2] DOOR CONTACT 00 99 00 00 00

[3] AUX Input #1 00 00 00 00 00

[4] AUX Input #2 00 00 00 00 00

[5] TAMPER ALARM 00 99 99 99 99

[6] DURESS ALARM 00 00 00 00 00

[7] OUTPUT TIME SCHEDULE 00 00 00 00 00

[8] INPUT TIME SCHEDULE 00 00 00 00 00

Relay

(DR)

Alarm

Relay

(AR)

TTL#1

(T1)

TTL#2

(T2)

Buzzer

9.6.1 EXIT BUTTON OUTPUT SETTING

. You can program ☞ OUTPUT activating time when the EXIT button pressed. The value put here is value x

second when the Time Unit set to 1 second and value/10 second when the Time Unit set to 0.1 sec.

You can set the time from 00 to 98 seconds (0.0 to 9.8 seconds if Time Unit set to 0.1 sec.) and if you put the

value “99”, the Output will activate forever until you reset the Output.

Press <4> or <6> key to select Input Sources then press <ENT> key to program the Output time.

DR: Door Relay Output

AR: Alarm Relay Output

T1: TTL#1 Output

T2: TTL#2 Output

BZ: Buzzer Output

9.6.2 DOOR CONTACT OUTPUT SETTING

9.6.3 AUX INPUT#1 OUTPUT SETTING

9.6.4 AUX INPUT#2 OUTPUT SETTING

9.6.5 TAMPER ALARM OUTPUT SETTING

9.6.6 DURESS ALARM OUTPUT SETTING

Output Time setting for above Input Sources are the same as 9.6.1 Exit Button Output setting.

(BZ)

9.6.7 OUTPUT TIME SCHEDULE SETTING

. You can ☞ link a T/S Code to each Output. The default T/S Code is “00” which means no T/S is applied to the

Outputs. This setting is very useful when you want to open the door for a Time Interval.

Press <ENT> key to link a T/S Code to the Output then enter 2digit T/S Code for each Output.

DR: Door Relay Output T/S Code

AR: Alarm Relay Output T/S Code

T1: TTL#1 Output T/S Code

T2: TTL#2 Output T/S Code

BZ: Buzzer Output T/S Code

9.6.8 INPUT TIME SCHEDULE SETTING

. You can ☞ link a T/S Code to each Input. The default T/S Code is “00” which means no T/S is applied to the

Inputs. This setting is very useful when you want to activate PIR sensor input for a Time Interval.

Press <ENT> key to link a T/S Code to the Input then enter 2digit T/S Code for each Input.

EX: EXIT Button Input T/S Code

DC: Door Contact Sensor Input T/S Code

I1: Aux Input#1 T/S Code

I2: Aux Input#2 T/S Code

TP: Tamper Switch Input T/S Code

51

52

Page 27

GE AccessSmart 314 Last Update July 6, 2005

: Buzzer Outpu

e

GE AccessSmart 314 Last Update July 6, 2005

9.7 F7 SETUP MENU

OUTPUT

[1] Reader#1 ID OK LV1 03 00 00 00 00

[2] Reader#1 ID OK LV2 05 00 00 00 00

[3] Reader#1 ID OK LV3 05 00 00 00 00

[4] Reader#1 ID OK LV4 05 00 00 00 00

[5] Reader#1 ID Error 00 03 00 00 00

[6] Reader#1 T/S Error 00 03 00 00 00

[7] Reader#1 APB Error 00 03 00 00 00

[8] Reader#2 ID OK LV1 03 00 00 00 00

[9] Reader#2 ID OK LV2 05 00 00 00 00

[10] Reader#2 ID OK LV3 05 00 00 00 00

[11] Reader#2 ID OK LV4 05 00 00 00 00

[12] Reader#2 ID Error 00 03 00 00 00

[13] Reader#2 T/S Error 00 03 00 00 00

[14] Reader#2 APB Error 00 03 00 00 00

Door

Relay

(DR)

Alarm

Relay

(AR)

TTL#1

(T1)

TTL#2

(T2)

Buzzer

(BZ)

9.7.1 OUTPUT SETTING FOR READER#1 ID OK LEVEL 1

* Default Output Setting for Input Circumstance

. You can program ☞ OUTPUT activating time when the user ID is granted the access from the Reader#1. The

value put here is value x second when the Time Unit set to 1 second and value/10 second when the Time Unit

set to 0.1 sec. This Output Time is applied for the users registered with Level#1 output.

You can set the time from 00 to 98 seconds (0.0 to 9.8 seconds if Time Unit set to 0.1 sec.) and if you put the

value “99”, the Output will activate forever until you reset the Output.

Press <4> or <6> key to select Input Sources then press <ENT> key to program the Output time.

DR: Door Relay Output Time

AR: Alarm Relay Output Time

T1: TTL#1 Output Time

T2: TTL#2 Output Time

BZ

t Tim

Output Time setting from 9.7.2 to 9.7.14 is the same as 9.7.1 RD1 ID OK LV1 Output setting.

53

54

Page 28

GE AccessSmart 314 Last Update July 6, 2005

GE AccessSmart 314 Last Update July 6, 2005

9.7.2 OUTPUT SETTING FOR READER#1 ID OK LEVEL 2

This Output Time is applied for the users registered with Level#2 output.

9.7.3 OUTPUT SETTING FOR READER#1 ID OK LEVEL 3

This Output Time is applied for the users registered with Level#3 output.

9.7.4 OUTPUT SETTING FOR READER#1 ID OK LEVEL 4

This Output Time is applied for the users registered with Level#4 output.

9.7.5 OUTPUT SETTING FOR READER#1 ID ERROR

This Output Time is applied if the user is not registered to Reader#1.

9.7.6 OUTPUT SETTING FOR READER#1 T/S ERROR

This Output Time is applied if the user is T/S error to Reader#1.

9.7.7 OUTPUT SETTING FOR READER#1 APB ERROR

This Output Time is applied if the user is APB error to Reader#1.

9.7.8 OUTPUT SETTING FOR READER#2 ID OK LEVEL 1

This Output Time is applied for the users registered with Level#1 output.

9.7.9 OUTPUT SETTING FOR READER#2 ID OK LEVEL 2

This Output Time is applied for the users registered with Level#2 output.

9.7.10 OUTPUT SETTING FOR READER#2 ID OK LEVEL 3

This Output Time is applied for the users registered with Level#3 output.

9.7.11 OUTPUT SETTING FOR READER#2 ID OK LEVEL 4

This Output Time is applied for the users registered with Level#4 output.

9.7.12 OUTPUT SETTING FOR READER#2 ID ERROR

This Output Time is applied if the user is not registered to Reader#2.

9.7.13 OUTPUT SETTING FOR READER#2 T/S ERROR

This Output Time is applied if the user is T/S error to Reader#2.

9.7.14 OUTPUT SETTING FOR READER#2 APB ERROR

This Output Time is applied if the user is APB error to Reader#2.

9.8 F8 SETUP MENU

9.8.1 SYSTEM INITIALIZE

☞. This operation will initialize the GE314. Press <ENT> key, if an initialization is needed (First time installation

or resetting in the event of a malfunction).

CAUTION: Initializing will erase all stored data in the memory.

☞. Press the <1> key to initialize or <0> key to cancel the operation.

☞. The “WAIT..”message appears while the system is being initialized.

After the initialization, GE314 will return to the Setup menu.

55

56

Page 29

GE AccessSmart 314 Last Update July 6, 2005

g

y

g

y

g

GE AccessSmart 314 Last Update July 6, 2005

9.8.2 EVENT CLEAR

☞. When the event memory is full or when you want to change ID COUNT, you can clear the event memory in

this menu. Press <ENT> key then press <1> key to clear event memory or <0> key to cancel the operation.

CAUTION: Before

host PC otherwise you may lose important data.

ou clear the events, make sure that the stored events is not necessary to upload to the

9.8.3 ID CLEAR

☞. When you want to delete all User IDs (Card IDs), you can clear all User IDs from the memory. Press <ENT>

key, then press the <1> key to clear all User IDs or <0> key to cancel the operation.

CAUTION: Before clearing all User IDs, make sure that the registered User ID is no lon

you may lose all registered User IDs.

er used otherwise

9.8.4 MASTER ID CLEAR

☞. When you want to delete all Master IDs, you can clear all Master IDs from the memory. Press <ENT> key,

then press the <1> key to clear all Master IDs or <0> key to cancel the operation.

CAUTION: Before clearin

otherwise you may lose all registered Master IDs.

all Master IDs, make sure that the registered Master ID is no longer used

9.8.5 TIME SCHEDULE CLEAR

☞. When you want to delete all Time Schedules (01~10), all Holiday schedules(01~10), Holiday code, Reader#1

Mode T/S code and Reader#1 Mode T/S code, you can clear them from the memory. Press <ENT> key and

press the <1> key to clear all T/S or <0> key to cancel the operation.

CAUTION: Before you clear all T/S, make sure that the stored T/S is no longer used, otherwise

lose all stored T/S in the memory.

ou may

9.8.6 DEFAULT SETTING

☞. When you want to delete all Default setting value, you can clear them from the memory. Press <ENT> key and

press the <1> key to reload all default setting value clear all T/S or <0> key to cancel the operation.

CAUTION: Before you clear all Default settin

stored system setting value is no longer used, otherwise you may lose all stored system setting value in

the memory.

value(Reader mode, Board ID etc..), make sure that the

57

58

Page 30

GE AccessSmart 314 Last Update July 6, 2005

g

g

GE AccessSmart 314 Last Update July 6, 2005

9.9 F9 SETUP MENU

9.9.1 GET FINGERPRINT SCANNER GAIN

. You can ☞ get the current brightness of the fingerprint scanner.

Higher gain is more darkness.

CAUTION : If you change the gain, it will result a bad fingerprint verification. Do not chan

needed.

9.9.2 SET FINGERPRINT GAIN

e unless

. You can ☞ set brightness of the fingerprint scanner. The value for the gain is 1, 2, 4 or 8. The default gain is 4.

CAUTION : If you change the gain, it will result a bad fingerprint verification. Do not chan

needed.

9.9.3 DUAL FINGERPRINT MODE

. ☞ In DUAL FINGERPRINT MODE, you can register two fingerprints for one user ID. Default is UNUSE.

But Dual Fingerprint Mode is higher False Acceptance Rate (FAR) measured.

9.9.4 ADAPTIVE MODE

.☞ In ADAPTIVE MODE, scanning quality is better than normal mode and also it checks latent finger..

But scanning speed is longer than normal mode. Def ault is USE.

9.9.5 AUTOMATCH MODE

. ☞ Automatch Mode is an IDENTIFICATION MODE, you can use 1:N Identification. You can Identify ID by

only putting finger to the scanner. Automatic Touch Sensor is optional purchase.

e unless

59

60

Page 31

GE AccessSmart 314 Last Update July 6, 2005

GE AccessSmart 314 Last Update July 6, 2005

APPENDIX

A. THE RELATION BETWEEN INPUT AND OUTPUT (DEFAULT)

* Default Output Setting for Input Sources

OUTPUT

INPUT

[1] EXIT BUTTON 03 00 00 00 00

[2] DOOR CONTACT 00 99 00 00 00

[3] AUX Input #1 00 00 00 00 00

[4] AUX Input #2 00 00 00 00 00

[5] TAMPER ALARM 00 99 99 99 99

[6] DURESS ALARM 00 00 00 00 00

[7] OUTPUT TIME SCHEDULE 00 00 00 00 00

[8] INPUT TIME SCHEDULE 00 00 00 00 00

Door

Relay

(DR)

* Index No. [1] ~ [6]:

The value indicates operation time (second) of each output for the input signal.

* Index No. [7]:

The value indicates time schedule code (index) that each output operation has to

be applied.

* Index No. [8]:

The value indicates the time schedule code (index) that each input #1(Exit

button) ~#5 operation has to be applied.

Alarm

Relay

(AR)

TTL#1

(T1)

TTL#2

(T2)

Buzzer

(BZ)

* Default Output Setting for Input Circumstance

OUTPUT

INPUT

[1] Reader#1 ID OK LV1 03 00 00 00 00

[2] Reader#1 ID OK LV2 05 00 00 00 00

[3] Reader#1 ID OK LV3 05 00 00 00 00

[4] Reader#1 ID OK LV4 05 00 00 00 00

[5] Reader#1 ID Error 00 03 00 00 00

[6] Reader#1 T/S Error 00 03 00 00 00

[7] Reader#1 APB Error 00 03 00 00 00

[8] Reader#2 ID OK LV1 03 00 00 00 00

[9] Reader#2 ID OK LV2 05 00 00 00 00

[10] Reader#2 ID OK LV3 05 00 00 00 00

[11] Reader#2 ID OK LV4 05 00 00 00 00

[12] Reader#2 ID Error 00 03 00 00 00

[13] Reader#2 T/S Error 00 03 00 00 00

[14] Reader#2 APB Error 00 03 00 00 00

Door

Relay

(DR)

Alarm

Relay

(AR)

TTL#1

(T1)

TTL#2

(T2)

* Index No. [1] ~ [14]:

The value indicates operation time (second) of each output for the input signal.

Buzzer

(BZ)

61

62

Page 32

GE AccessSmart 314 Last Update July 6, 2005

GE AccessSmart 314 Last Update July 6, 2005

B. TROUBLE SHOOTING

☞ When the power off and on after the time setting, the LCD displays “00/00 00:00:01”.

Cause Of that user mistake, or the system is defective of the device.

Solution 1. Check BAT connection S/W.

You have to short the S/W, and system initialize before system installation.

Figure: SWITCH SETTING Figure: SWITCH LOCATION

2. If the trouble remains after checking the above, contact a designated service center.

☞ A valid card became unregistered after batch-downloading IDs from PC.

Cause Wrong procedure during download or a component defect.

Solution 1. The card ID might be registered only to the controller and not registered in the PC. During the process

of downloading IDs, GE314 first erase the ID memory of the unit, therefore if the IDs from the PC

didn’t contain the card ID, this can happen.

2. Check whether the card ID is registered in the PC.

3. If not, please register the number and try downloading again.

4. If the trouble remains after the procedure above, contact a designated service center.

☞ It doesn’t enter the Setup Mode after entering the Master ID “00000000”.

Cause The Master ID might have been changed or components are defective.

Solution 1. Try changing the Master ID through the application S/W (It’ll be changed to “00000000”).

2. When it is not feasible, initialize the unit as following:

After the all installation and connections are completed, press and hold the Initialize button and put the

power (+12V DC) to GE314. The LCD will first display “Initialize OK? 0:No 1:Yes”. Press <1> key

if you want to initialize the system. After all Initialization process is completed, the system is operating

on normal mode and the LCD displays “GE Security, GE314 [F1], Date Time”.

3. If the trouble remains after the procedure above, contact a designated service center.

☞ No problem with accessing by card, but cannot access with the PIN input.

Cause An error in Setup or possible component defect.

Solution 1. Check whether a beep sound is generated when you press a key.

When a beep sound is generated, the problem may be an error in setup. Proceed like followings:

- Enter the Master ID (“00000000” default) to enter the Setup mode.

- Press <F2> key.

- [LANGUAGE] will appear on the LCD, then use the key <6> to choose [RD1_PIN_INPUT] and

select ‘USE’ as wanted.

2. When there is no beep sound or already enabled Key-in functions, contact a designated service center.

☞ The Setup mode suddenly goes back to the Normal operating mode.

Cause Time out error

Solution In the Setup mode, it is programmed to do so when there is no key-in or reading card within 60 seconds.

☞ Keeps making buzzer sound: “beep~ beep ~ beep” or “beeeeeeeep~~~~”.

Cause Error in Installation, Door status or Internal circuits.

Solution 1. Check the door status. It occurs in case that the door is opened over 3sec(Default) after the proper door

open time.

2. Check the door contact sensor type: it should be NO type.

3. Check in [7. OUTPUT T/S] of F6, the ten Time schedule code (01~10) value of output T/S. If the time

schedule code is set between 01 up to 10 and if the present time is included in the schedule.

If it is set to unintended value, change it to “00” ( Programmable via PC software)

4. Check in Tamper switch of GE314.

5. If the trouble remains after checking the above, contact a designated service center.

63

64

Page 33

GE AccessSmart 314 Last Update July 6, 2005

GE AccessSmart 314 Last Update July 6, 2005

☞ “SCHEDULE ERROR” message shows when RFID card is read.

Cause Error in RFID card registration, time schedule setting or the system itself.

Solution 1. If it was a properly operating unit before, there has been an electric shock that damaged the internal

memory and data. Please initialize the unit as instructed in the manual.

2. Check if ID information has been put in incorrectly during its registration.

* Register ID again checking the following points.

-In order to restrict access of the ID user for specific time zone as instructed in the manual, register time

schedule in advance and apply the time schedule code(1~10) in the registration of the user ID.

- In order to allow the user to access at all times, put in “00”.

3. Use software for time schedule setting in case it is connected to PC as the software manual.

4. If the trouble remains after checking the above, contact a designated service center.

☞ “ACCESS DOOR ERR” message shows when the RF ID card is read.

Cause Incorrect user setting or false of internal circuit.

Solution 1. If it was a properly operating unit before, there has been an electric shock that damaged the internal

memory and data. Please initialize the unit as instructed in the manual.

2. Check if ID information has been put in incorrectly during its registration.

* Register ID again and check the following points:

- Since the controller has two reader ports, define “RD” – door for the user to be allowed to access

(Reader1(Bilt-in reader) only: “1”, Reader 2(Extra reader) only: “2”, Reader 1 & 2 both: “0 or 3”)

- If RD is set as “1”, only when the card is read at Reader 1, the door opens but not at Reader2. If it is

read at Reader 2, “ACCESS DOOR ERROR” message shows up.

- If RD is set as “2”, only when the card is read at reader 2, the door opens but not at reader1. If it is read

at reader 1, “ACCESS DOOR ERROR” message shows up.

- If RD is set as “0 or 3”, reader 1 & 2 both open each door.

3. If the trouble remains after checking the above, contact a designated service center.

☞ The controller does not communicate with the Host-PC.

Cause A defective cable is used, errors in wiring, an error in setting COMM ID of the controller, or damage on

the communication port (either on PC side or on the controller side).

Solution 1. Please check the settings of the application S/W and the controller.

- Check if the controller’s COMM ID is listed on the application S/W.

- Set the different COMM ID when two or more controllers are installed.

- Check if the communication speed (9600bps default) is the same as the setting on the S/W.

- Make sure that the PC’s COM port is set correctly on the S/W.

- The parameters at the S/W should be set as following:

Parity bit : NONE

Data bit : 8bit

Stop bit : 1bit

2. Check the line connection for communication.

RS232 RS485 (mono)

GE313 PC GE314

RX TX RTX(-) RTX(-)

TX RX RTX(+) RTX(+)

GND GND

GE314 GE314

RX(-) RX(-) TX(-)

RX(+) RX(+) TX(+)

3. In case of setting RS485 communication, we recommend to use line-end resistors of 120 Ohm

between the RTX (+) and RTX (-) lines. Apply the same resistors to the converter RS485 lines.

Consult a service center or an electric technician if you are not sure how to do it.

4. When a multi-drop communication doesn’t work, test one-by-one communication first.

5. If the trouble remains after the procedure above, contact a designated service center.

RS485/232

Converter

RS485/232

Converter

RS485(Multi Drop)

The RS232 cable from

the converter

PC

The RS232 cable from

the converter

PC

65

66

Page 34

GE AccessSmart 314 Last Update July 6, 2005

FCC REGISTRATION INFORMATION

FCC REQUIREMENTS PART 15

Caution: Any changes or modifications in construction of this device which are not expressly approved by the

manufacturer for compliance could void the user's authority to operate the equipment.

NOTE: This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions;

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class A Digital Device, pursuant to Part 15

of the FCC Rules. These limits are designed to this equipment generates, uses, and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may cause harmful interference to radio

communications.

However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by turning the radio or television off and

on, the user is encouraged to try to correct interference by one or more of the following measures.

1. Reorient or relocate the receiving antenna.

2. Increase the separation between the equipment and receiver.

3. Connect the equipment into an outlet on another circuit.

4. Consult the dealer or an experienced radio/TV technician for help.

67

Loading...

Loading...