Page 1

60

60

60

PET Immune SAW PIR Motion Sensors Installation Sheet

• Supervisory signals transmitted every 64 minutes to the

Description

This is the Installation Sheet for SAW PIR and PET Immune

Motion Sensors. See Table 1.

Table 1: Motion Sensors

-807-95R Pet Immune SAW PIR Motion Sensor

-807-01-95R

-807-02-95R

A motion sensor (passive-infrared or PIR) detects movement

within a specific area by sensing the infrared energy emitted

from a body as it moves across the sensor’s field of view.

When this motion is detected, the sensor transmits an alarm

signal to the control panel.

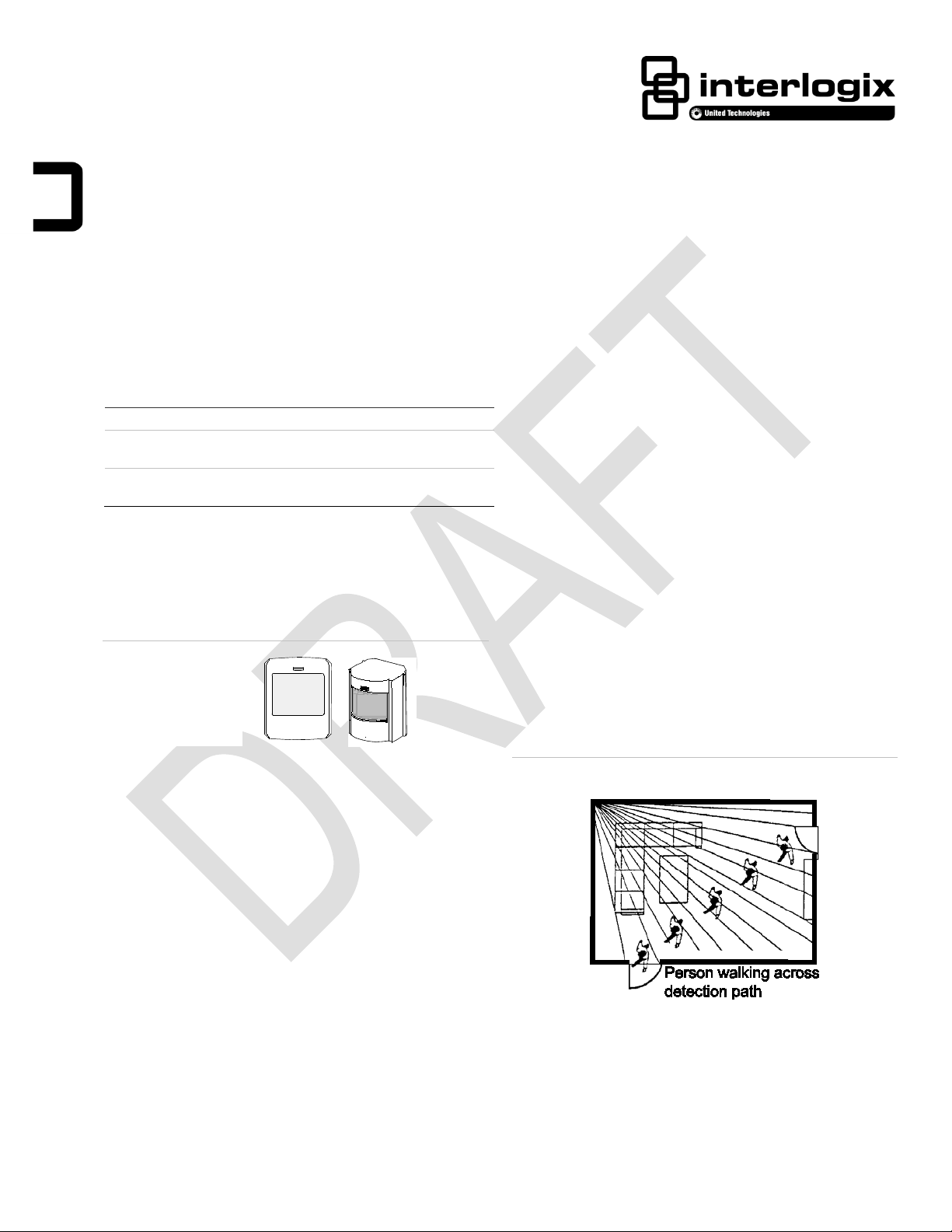

Figure 1: Pet Immune SAW PIR Motion Sensors

Pet Immune SAW PIR Motion Sensor with Lithium

Battery.

Pet Immune SAW PIR Motion Sensor with 1.5 V

Lithium Batteries.

control panel.

• Sensor low battery reports (trouble) to the control panel.

• Field-selectable sensitivity options.

Installation

Installation Guidelines

• Temporarily place the sensor in its intended mounting

location. Program and final test the sensor befor e

permanently mounting it.

• If possible, locate sensors within 100 ft. (30.5 m) of the

panel. While a transmitter may have a range of 500 ft.

(152 m) or more out in the open, the environment at the

installation site can have a significant effect on

transmitter range. Sometimes a change in sensor

location can help overcome adverse wireless conditions.

• The recommended mounting height is 7 1/2 ft.

Use these motion sensors to protect locations where

door/window sensors are impractical or not needed. For

example, use a motion sensor to protect large areas or open

floor plans. Motion sensors also provide backup protection for

door/window sensors.

The Pet Immune SAW PIR 60-807 utilizes advanced signal

processing, a new custom designed lens, and a new custom

designed sensing element. The combination of these

improvements provides false alarm immunity for pets with a

combined weight of up to 40 pounds while still providing

superior human catch performance.

These wireless motion sensors include the following features:

• 35 by 40 ft. (10.6 m by 12 m) coverage area.

• Three minute transmitter lockout time after an alarm that

helps extend battery life.

• Cover-activated tamper (optional wall-activated tamper is

included).

• Position the sensor to protect an area where an intruder

would be most likely to walk across the detection pattern

See Figure 2.

Figure 2: Overhead Detection Path

• Mount the motion sensor on a rigid surface which is free

from vibrations.

• Do not mount the sensor near duct work or other large

metallic surfaces which may affect the RF signals (see

RF Testing). Actual acceptable transmitter range should

be verified for each installation.

P/N 466-1725 • RevD.07 • 25Feb14 1 / 6

Page 2

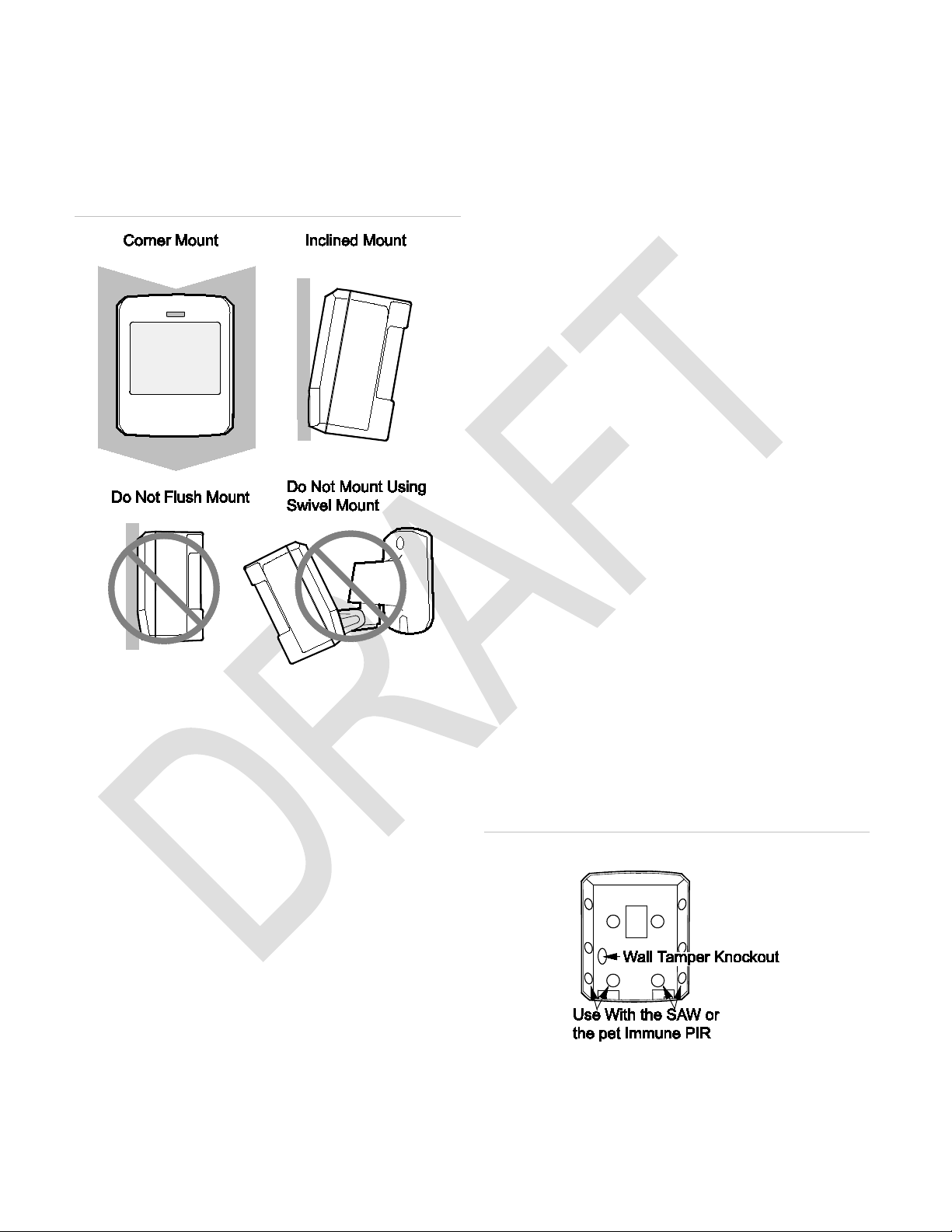

• Mount the sensor permanently on a flat wall or in a

corner. Do not set it on a shelf.

• Windows should be closed in any area which has an

armed motion sensor.

• The sensor must be incline-mounted at a mounting

height of 7.5 ft. See Figure 3.

Figure 3: Wall Mount Options

Final Testing

Final testing should be done to verify radio signal integrity

and confirm control panel programming and response. The

actual transmitter range can be determined by performing a

sensor test as follows:

1. With the PIR temporarily mounted at its intended

location, remove the PIR from its mounting plate and

activate the tamper switch to start the walk test mode.

2. Replace the sensor in its mounting plate.

3. Place the control panel in Sensor test mode. Move

across the detection pattern until the sensor’s LED turns

on. STOP your motion.

4. Listen for the appropriate system response. Refer to the

specific panel installation manual for details on system

response. If the system does not respond as expected,

proceed to the “Troubleshooting” section.

Mounting

The sensors must be incline-mounted on a wall surface or

incline-mounted in a corner at a mounting height of 7.5 ft.

(2.5 m).

• Room temperature must be kept between 60° and 120°F

(16° and 49° C).

• Position the sensor so it faces a solid reference point,

like a wall.

Programming

Refer to the panel documentation for information on

programming the sensor into the panel.

To Trip the Sensor

1. Set the panel to program mode.

2. Proceed to the Learn Sensors menu.

3. Remove the PIR from its mounting plate (activ at ing the

tamper switch).

To Mount the Sensor

1. Remove the mounting plate by depressing the button on

the top of the sensor body. With the opposite hand pull

the mounting plate away from the body of the sensor.

2 Punch out the mounting holes that best fit your

application. See Figure 3 for wall mount options.

3. See Figure 4 to determine which knockouts to use when

mounting the motion sensor. Use the lower-side holes

for corner mounting, or the lower-back holes for surface

mounting.

4. If wall-tamper functionality is desired, remove the walltamper knockout See Figure 4.

Figure 4: PIR Mounting Plate Knockouts

4. Select the appropriate sensor group and number .

5. Exit the panel’s programming mode.

6. Return the PIR to its mounting plate.

2 / 6 PET Immune SAW PIR Motion Sensors Installation Sheet

6. Mark the location of the required holes on the mounting

surface.

Page 3

7. Use wall anchors and screws to secure into place.

Attach the sensor to the mounting plate.

8. When testing is completed the PIR can be securely

attached to its mounting plate by screwing the smalle st

enclosed screw into the hole at the top of the mounting

plate.

Setting the Sensitivity

The PIR has two sensitivity settings (standard and high

sensitivity). The sensor is set to standard sensitivity at the

factory. This sensitivity is preferred for most applications and

provides the best immunity to false alarms.

Note: If the shorting jumper is not used or is placed

incorrectly, the sensor defaults to standar d sensitiv ity .

Figure 5: Sensitivity Pin Locations

Figure 6: Standard Sensitivity Setting

CAUTION: High sensitivity should only be used in

environments where the room temperature is very

stable.

1. Remove the mounting plate by depressing the button on

the top of the sensor body. With the opposite hand pull

the mounting plate away from the body of the sensor.

2. Remove the PIR cover by depressing the three tabs

3. Locate the sensitivity pins under the battery on the right

side of the PIR when looking at the front of the PIR.

4. To change to high sensitivity move the shorting jumper

to the pair of pins that are closer to the top of the PIR

See Figure 5.

5. Walk test the PIR to verify the sensitivity.

The difference between the two settings are indicated in

Figures 6 and 7.below.

Figure 7: High Sensitivity Setting

PET Immune SAW PIR Motion Sensors Installation Sheet 3 / 6

Page 4

60

60

60

Important information Regarding Sensitivity Settings

The sensitivity settings should be set as followed:

Standard Sense:

• Rooms < 25ft

• Pets < 40 pounds

High Sense:

• Rooms < 35ft

• Pets < 20 pounds

Testing

Walk Testing

Walk testing should be done to determine the sensor’s actual

coverage area. The edge of the coverage pattern is

determined by the first flash of the LED. This may change

slightly depending upon the sensitivity setting. Walk test the

unit from both directions to determine the pattern boundaries.

CAUTION: Excessive use of the walk test mode may

reduce battery life. Use only for initial setup and

maintenance testing.

1. Remove the sensor body from the mounted mounting

plate and then remount the body to activate the 60

second walk test mode.

2. Walk across the coverage pattern to determine the

coverage area, indicated by LED activation. Each

activation extends the walk test mode for an additional

60 seconds.

After 60 seconds without motion the walk test mode and the

LED will no longer activate when motion is detected.

Note: When the walk test mode has ended, an alarm can be

transmitted only after 3 minutes have passed since the

previous alarm. This 3 minute lockout time reduces

unnecessary RF transmissions in high traffic areas thereby

extending battery life.

Replacing the Batteries

When the system indicates the sensor has low batteries,

replace the batteries immediately. The sensors are powered

by the batteries shown in Table 2. Use only the batteries

indicated in Table 2 for the appropriate sensor. See the steps

listed after Table 2 for replacing the batteries.

Table 2: Battery Replacement

-807-95R Two AA Alkaline Batteries

-807-01-95R One AA Lithium Battery (#60-619).

-807-02-95R

Two 1.5 AA Lithium Iron Disulfide Batteries (#60-

931).

1. Remove the mounting plate by depressing the button on

the top of the sensor body. With the opposite hand pull

the mounting plate away from the body of the sensor.

See Figure 8.

2. Remove the PIR cover by depressing the three tabs.

See Figure 8.

3. Remove the old batteries and replace them with new

batteries as noted in Table 2 and Figure 8.

Note: Observe polarity when replacing the batteries. For

all units install the battery on the right side as shown in

Figure 8 with the positive end of the battery facing down

(near the tamper switch). For 60-807-95R and 60-80702-95R units with two batteries, install the second

battery on the left side with the positive end of the

battery facing up. See Figure 8.

If a battery is installed incorrectly the unit will not function

and the red LED will not light up. The sensor may be

damaged if a battery is installed incorrectly. For sensors

with two batteries, always replace both batteries.

4. Dispose of the batteries as required by local

requirements

5. Walk test the PIR to verify proper operation.

Note: When the battery is replaced, wait at least three

minutes after installing the battery before activating the

walk test mode.

Environment Testing

Figure 8: PIR Compon e nts, Battery Locations & Tamper Switch

Turn on all heating or air conditioning sources which would

normally be active during the protection peri od. Stand away

from the sensor and outside the coverage pattern and watch

for alarms. When testing the Pet Immune PIR also verify the

pets allowed in the coverage pattern do not trip the PIR.

Maintenance

At least once a year, the range and coverage should be

verified for proper operation. The end user should be

instructed to put the sensor in walk test mode and walk

through the far end of the coverage pattern to verify proper

detection.

4 / 6 PET Immune SAW PIR Motion Sensors Installation Sheet

Page 5

RF Frequency

Compatibility

Battery Type

Typical Battery Life

Operating

Temperature

Supervisory Interval

Relative Humidity

Storage Temperature

Range

Weight

Dimensions

(L x W x H )

RF

Compatibility

Battery Type

Typical Battery Life

Operating

Temperature

Supervisory Interval

Relative Humidity

Storage Temperature

Range

Weight

Dimensions

(L x W x H )

RF Frequency

Compatibility

Battery Type

Typical Battery Life

Operating

Temperature

Supervisory Interval

Relative Humidity

Storage Temperature

Range

Weight

Dimensions

(L x W x H )

Troubleshooting

Use the following guidelines if the system does not respond

correctly when the sensor final testing is conducted.

• Check programming and re-program sensor into panel if

necessary.

• Move the sensor to another location and test for correct

response.

• Check the mounting height and angle are according to

“Mounting” section.

To Relocate a Sensor

1. Test the sensor a few inches from the original position.

2. Increase the distance from the original position and

retest until an acceptable location is found.

3. Mount the sensor in the new location.

4. If no location is acceptable, test the sensor as described

below:

• Test a known good sensor at the same location.

• If the system does not respond, avoid mounting a sensor

at that location.

• If the replacement sensor functions, return the problem

sensor for repair or replacement.

Specifications

60-807-95R

319.5 MHz

Interlogix 319.5 MHz control panels/receivers

Two AA Alkaline Batteries

2 – 4 years at 68° F (20° C)

Range

0.3 lbs (0.136 kg)

32° to 110°F (0° to 43°C) Non-pet

applications

60° to 110°F (16° to 43°C) Pet applications

64 Minutes

0 – 90% non-condensing

-30 to 140°F (-34 to 60°C)

2.875 x 2.375 x 1.875 in.

(7.303 x 6.033 x 4.763 cm)

60-807-01-95R

Frequency 319.5 MHz

Interlogix 319.5 MHz control panels/receivers

Range

0.3 lbs (0.136 kg)

60-807-02-95R

319.5 MHz

Interlogix 319.5 MHz control panels/receivers

Range

0.3 lbs (0.136 kg)

One AA Lithium Battery

Interlogix part #60-619

4 – 6 years at 68° F (20° C)

32 to 120°F (0 to 49°C) Non-pet applications

60 to 120°F (16 to 49°C) Pet applications

64 Minutes

0 – 90% non-condensing

-30 to 140°F (-34 to 60°C)

2.875 x 2.375 x 1.875 in.

(7.303 x 6.033 x 4.763 cm)

Two 1.5V AA Lithium Iron Disulfide Batteries

(Interlogix part # 60-931, six pack of

batteries).

Note: Use only AA 1.5 Volt Lithium Iron

Disulfide batteries (part # 60-931) with this

product. Do not substitute any other

brand/type of batteries.

2-5 years at 68° F (20° C)

32 to 120°F (0 to 49°C) Non-pet applications

60 to 120°F (16 to 49°C) Pet applications

64 Minutes

0 – 90% non-condensing

-30 to 140°F (-34 to 60°C)

2.875 x 2.375 x 1.875 in.

(7.303 x 6.033 x 4.763 cm)

PET Immune SAW PIR Motion Sensors Installation Sheet 5 / 6

Page 6

Regulatory Information

This equipment has been tested and found to comply with the

limits for a Class B digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential

installation.

This equipment generates,uses and can radiate radio

frequency energy and, if not installed and used in accordance

with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that

interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct

the interference by one or more of the follow ing mea sure s:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equip ment and

receiver.

• Connect the equipment into an outlet on a circuit

different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician

for help.

Changes or modifications not expressly approved by UTC

Fire and Security could void the user’s authority to operate

the equipment.

This device complies with Industry Canada licence-exempt

RSS standard(s). Operation is subject to the following two

conditions: (1) this device may not cause interference,and (2)

this device must accept any interference, in clud ing

interference that may cause undesired operation of the

device.

© 2014 United Technologies Corporation. Interlogix is part of

UTC Building and Industrial Systems, a United Technologies

Corporation. All rights reserved. The Product Name and logo

are trademarks of United Technologies. Other trade names

used in this document may be trademarks or registered

trademarks of the manufacturers or vendors of the respective

products.

Limitation of Liability

To the maximum extent permitted by applicable law, in no

event will Interlogix be liable for any lost profits or business

opportunities, loss of use, business interruption, loss of data,

or any other indirect, special, incidental, or consequential

damages under any theory of liability, whether based in

contract, tort, negligence, product liability, or otherwise.

Because some jurisdictions do not allow the exclusion or

limitation of liability for consequential or incidental damages

the preceding limitation may not apply to you. In any event

the total liability of Interlogix shall not exceed the purchase

price of the product. The foregoing limitation will apply to the

maximum extent permitted by applicable law, regardless of

whether Interlogix has been advised of the possibility of such

damages and regardless of whether any remedy fails of its

essential purpose.

Installation in accordance with this ma nual , appli cab le code s,

and the instructions of the authority having jurisdiction is

mandatory.

While every precaution has been taken during the

preparation of this manual to ensure the accuracy of its

contents, Interlogix assumes no responsibility for errors or

omissions.

Cet appareil est conforme avec Industrie Canada exempts de

licence standard RSS (s). Son fonctionnement est soumis

aux deux conditions suivantes: (1) cet appareil ne doit pas

provoquer d'interférences et (2 ) cet appareil doit accepter

toute interférence, y compris celles pouvant causer un

mauvais fonctionnement de l'appareil.

In accordance with FCC requirements of human exposure to

radiofrequency fields, the radiating element shall be installed

such that a minimum separation distance of 20 cm is

maintained from the general population.

FCC: B4Z-680F-PIR

IC: 1175C-680PIR

This Class B digital apparatus complies with Canadian ICES3B.

Cet appareil numérique de la classe B est conforme à la

norme NMB-3B du Canada.

Contact Information

For general information, see www.interlogix.com. For

customer/technical support, see

www.interlogix.com/customer-support

8889.

or call +1 855 286

6 / 6 PET Immune SAW PIR Motion Sensors Installation Sheet

Loading...

Loading...