Page 1

5845GBW-OEM

Glass Break Detector

Product Introduction

The 5845GBW Glass Break Detector (product) is ideal for applications

where hardwired acoustic sensors are impractical, listens for actual

patterns of breaking glass using Pattern Recognition Technology™

across the full audio band. The factory set recognition patterns detect

breaking glass of framed perimeter windows in a building vs. a

drinking glass breaking within a room. This product features a 20-ft. (6

m) range from sensor to glass.

The product is suitable for use in quiet occupied areas on the perimeter

loop. The sensor’s low-profile housing conceals the wireless transmitter

and battery.

A simple hand clap feature lets the user confirm that the sensor is

operational, or a handheld tester can be activated at close range.

This wireless Glass Break Detector complies with the ANSI/UL 639

standard for Intrusion products. It is intended for residential indoor

dwelling unit applications and other areas approved by the authority

having jurisdiction (AHJ). It is not intended for use in industrial

applications.

This product operates in conjunction with your wireless Control Panel,

providing a local indication. Refer to the panel installation instructions

for revision verification details. Please contact Technical Support for any

questions regarding compatibility.

About This Guide

This User Guide describes how to install, the operation and

maintenance of this product. The User Guide is organized as you intent

to use this product with step by step instructions.

Keep this document in a handy location and refer to it when you have

questions about this product and its functions and features. Reading

this guide is the only way to learn how to use your product wisely and

to know how to react in the event of an alarm.

Attention: Please take a few minutes to thoroughly read this

guide which should be saved for future reference and passed on to

any subsequent owner.

1. General Information

Congratulations on purchasing your Glass Break Detector. This product is

designed to be used with a Control Panel as an intrusion signaling

device.

Install the sensor on a perimeter loop armed whenever the door and

window contacts are armed. Avoid 24-hour loop applications where

the sensor is armed all day and all night. The false-alarm technology

will be pushed to its limit in a 24-hour loop.

The sensor’s false-alarm immunity is best in rooms with only moderate

noise. Some sounds can duplicate the points on the glass break

pattern the sensor detects. The sensor may not consistently detect

cracks in glass, or bullets which break through the glass. Glass break

sensors should always be complemented with interior protection.

Parts List

One Glass Break Detector

One CR123 Lithium Battery

Mounting Screws and Anchors

User Guide

2. Mounting Guideline

This product is a member of a reliable, high-quality product family

using the latest technology available. Review the information in this

section to ensure you get the most out of the product.

Choosing an Installation Location

The sensor must always be in direct line of sight of all windows to be

protected. The sensor cannot consistently detect glass breaking around

corners or in other rooms. There is no required front, back, up or down

orientation.

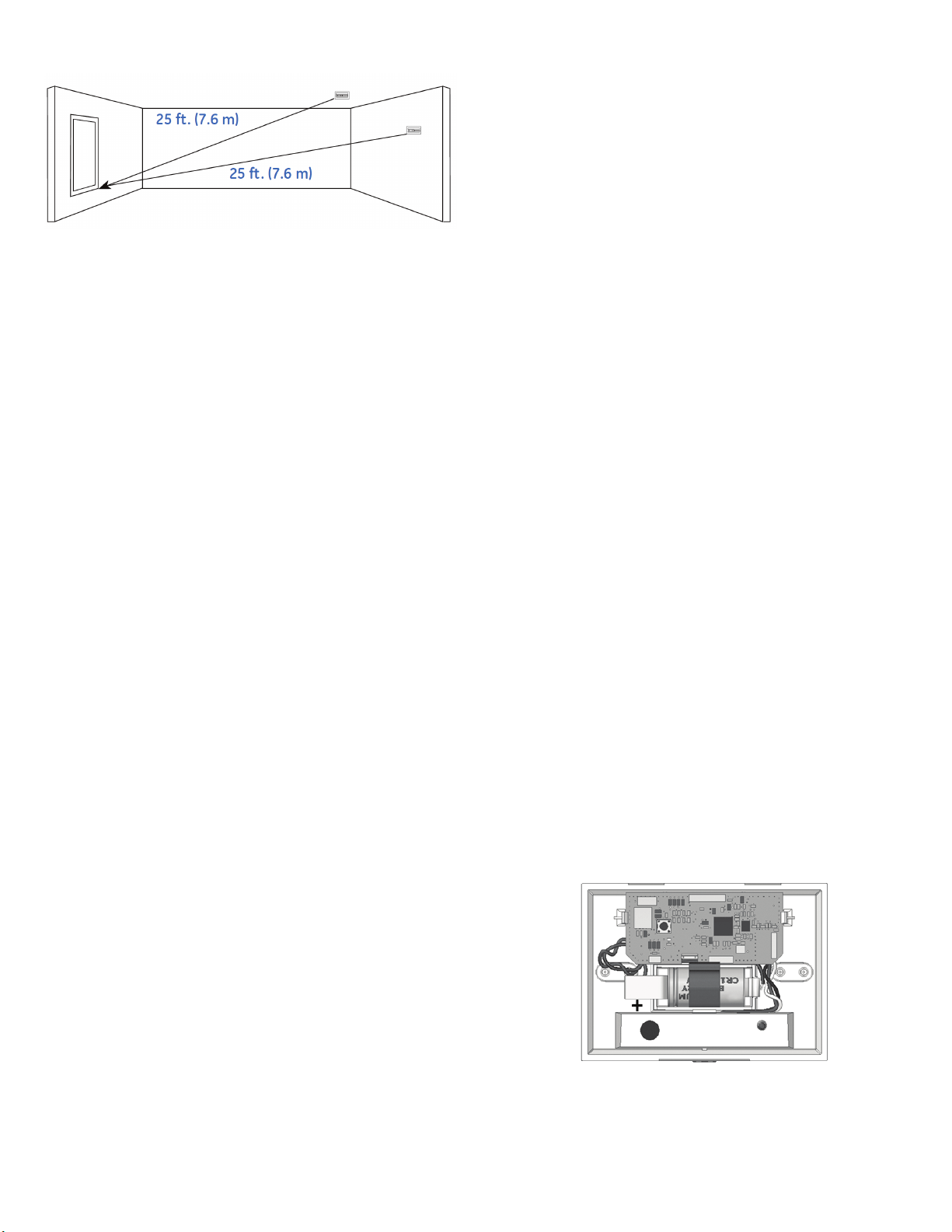

Wall mount…

The best wall-mount location is on the opposite wall, assuming the

glass to be protected is within the sensor’s range and line of sight. The

adjoining wall can also be used.

Ceiling mount…

Mount the sensor in a location that is in direct line of sight of the glass

to be protected. However, since sound travels directionally out from a

broken window, a position 8 ft. (2.4 m) into the room provides better

detection.

Use the following guidelines to determine the best mounting location:

o Mount the sensor at least 3.3 ft. (1 m) from the windows being

protected and at least 4 ft. (1.2 m) from noise sources such as

TVs, speakers, sinks, and doors.

o Mount the sensor in the direct line of sight of the glass to be

protected.

o Mount the sensor in a suitable environment: temperature

between 0 and 120°F (-18 and 50°C); and humidity between 10

and 90% non-condensing.

o Mount the sensor on a stable surface up to 25 ft. (7.6 m) from

the farthest point on the glass surface.

Recommended locations and Range

The sensor is omni-directional, providing 360° coverage. Coverage is

measured from the sensor to the point on the glass farthest from the

sensor. The sensor can be mounted as close as 3.3 ft. (1 m) from the

glass. The maximum range depends on the type of glass being

protected:

o Armor-coated glass - Mount sensor no more than 12 ft. (3.6 m)

from the glass.

o Plate, tempered, laminated, and wired glass - Mounted on

the ceiling or the opposite or adjoining wall, maximum range is

25 ft. (7.6 m).

UTC. All Rights Reserved. 1 P/N 0000000 – Rev. A – 06 Nov 12

Page 2

Locations to avoid

Improper location can affect the sensitive electronic components in this

product. To avoid causing damage to the product, to provide optimum

performance, and to prevent unnecessary nuisance alarms:

o Avoid rooms smaller than 10 x 10 ft. (3m x 3m).

o Avoid locations where lined, insulating, or sound-deadening

drapes or closed wooden shutters are used.

o Corner of a room.

o Do not install the sensor in humid rooms. Excess moisture on

the circuit board can eventually cause a short and a false

alarm.

o Avoid locations that expose the sensor to possible false alarm

sources such as:

− glass airlocks and vestibule areas

− kitchens

− corner mounting

− residential car garages

− small utility rooms

− stairwells

− bathrooms

− small acoustically live rooms.

− locations exposed to white noise, such as air

compressors, etc.

3. Mounting the Sensor

Note: Add the product to the Control Panel before physically mounting

the product in the desired location. This verifies RF performance prior to

permanently mounting the alarm. See “RF Communication Test”.

To mount the alarm:

This product can be wall mounted or ceiling mounted.

A. Disconnect alarm-notification appliances, service-release devices,

and extinguishing systems. Test communications between the

control panel and the product before permanently mounting as

follows:

− Hold the product where you plan to install it.

− Hold the glass break tester next to the glass break’s

microphone sensor and press the test button on the glass

break tester. The product sends a signal to the control panel.

− At the control panel, verify the signal was received and RF

signal strength is adequate. If no signal is received or the RF

signal is low, relocate the product and retest.

B. Using two supplied screws and anchors, mount the base of the

product as follows:

- Remove the screw located in the front.

- Remove the top cover by using a flat bladed tool in the screw

location to pry open the top cover.

- Locate the mounting location and drill holes in base per the

mounting impression in the base.

- Use the anchors and screws to secure the product to the

mounting surface.

C. Replace the product’s top cover:

− Snap the top onto the base.

− Replace the screw into the front location.

4. Basic Operations

This product is equipped with an intuitive normal mode operation.

Since the batteries are pre-installed, remove the battery pull tab to turn

ON power. The product shall search for a networked control panel to

pair with. During this time, Search Mode, the RF wireless module

transmits every ~ 5-seconds. Not pairing or enrolling into a control

panel within minutes of initial power up, places a large drain the

batteries. Failure to complete pairing results in dead batteries after 2-3

days time passes.

Normal Mode Operation

o In normal operation, the red LED remains OFF.

o In wake up, the red LED flashed ON with two quick flashes.

o In alarm mode, the red LED stays ON for 4 seconds. Sends an

alarm message to the control panel.

o In trouble or maintenance mode, the red LED does not activate

after a wake up test.

o In low battery mode, a message is sent to the control panel.

Note: the modes can be viewed from the Control Panel.

5. Installing / Replacing Battery

This product comes with one battery preinstalled. When you need to

replace the battery, use the following procedure.

Note: Place the control panel into sensor test mode prior to replacing

the batteries. If the control panel is not in sensor test mode during

battery replacement, an alarm/tamper condition may be indicated.

A. Remove the product top cover.

B. If replacing the battery, remove the old battery and properly

dispose of it as recommended by the battery manufacturer.

C. Install the new battery. Note the polarity illustration in the battery

compartment.

D. Replace the top cover.

E. Replace the front screw.

When replacing the battery, use one of the following approved brands:

o Duracell Ultra

UTC. All Rights Reserved. 2 P/N 0000000 – Rev. A – 06 Nov 12

Page 3

o Panasonic

Note: Use of a different battery may have a detrimental effect on the

product’s operation. Constant exposures to high or low humidity may

reduce battery life.

After installing or changing the batteries, reinstall the product’s top

cover. Test your product by a wake up test.

6. Adding to the Control Panel

Each product is programmed with a unique ID when manufactured.

The unique ID is enrolled into the control panel at the time of

installation, allowing the product to communicate with that specific

control panel.

A. Log in to the Settings app with an Installer code.

B. In the Settings menu, tap Sensors & Zones > Add a Sensor/Zone.

C. Place the product in Search mode and prepare it to be added to

the control panel (refer to the installation documentation for your

sensors). Available sensors meet the following requirements:

o Defaulted.

o Not currently paired with another control panel device.

o Currently in Search mode.

D. At the Locating Wireless Sensors screen, tap Next. A Done button

appears on the screen and the control panel searches for sensors

that are available to be added. As sensors are found, a grayed

icon appears for that sensor.

E. Fault each found sensor to pair it to the control panel. The icon for

each sensor is undarkened as it is faulted and the control panel

beeps. The sensor is paired to the control panel.

F. When all the sensors are found and paired, tap Stop. Any located

sensors that were not paired are released by the control panel

and can be added later. The Wireless Sensors Located screen

shows the number of wireless sensors found and paired.

G. Tap Next. The Configure Wireless Sensors screen shows icons of

the sensors that were found and paired.

H. Touch each sensor icon to configure the corresponding product.

The Add Sensor/Zone Modify screen appears.

I. To change the product Icon (if multiple options are available), tap

the currently selected value.

J. Tap Next. The Add Sensor/Zone Modify screen appears.

K. To modify a text field on the control panel, tap the field, use the

onscreen keyboard to enter your changes, and tap Done to save

your changes.

L. When all sensors are configured properly, tap Next in the

Configure Wireless Sensors screen.

M. If all of the sensors have not been configured, the Modify screen

appears for each sensor to let you review its details. Change the

details as needed or tap Next to cycle through all the sensors. The

sensors are marked as configured.

7. Testing the Product

This product may be tested during install or at anytime. It is

recommended the product be tested in place annually. This product is

sealed. The cover is not removable.

WARNING: The control panel must be placed into sensor test

mode while conducting any tests. Placing the control panel into sensor

test mode for all testing helps to protect against false alarms and

unintentional central station reporting.

This product has three test methods:

o Wake Up Test. A hand clap should wake up the glass break

detector.

o RF Communication Test. Tests the communication path with

the control panel.

o Glass Break Functional Test. Tests the functional operation of

the glass break sensing element.

Wake Up Test

To test the product locally is to clap your hands loudly above the sensor

and verify that the LED blinks twice. This test verifies that the product is

receiving power, and the microphone and circuit board are working

properly. It does not trip the sensor. The hand clap is only a momentary

test, so there is no significant affect on battery life.

Note: Room acoustics can artificially extend the range of a glass-break

sensor. The specified range of the sensor is set for worst-case

conditions. While it may work at extended range, it can miss a

minimum output break or room acoustics may change over time,

bringing sensor range back into normal 2-foot (6 m) conditions. Do not

exceed the rated range of the sensor, regardless of the tester results.

RF Communication Test

This section provides general guidelines for testing the product with the

control panel. For complete testing details, refer to the specific control

panel documentation.

A. Be sure the product is normal operation.

B. Set the control panel to sensor test mode to prevent an alarm

signal from being sent to the central-monitoring station if you

have a monitored system.

C. To generate a test alarm, remove the top cover generating a

tamper alarm. If the product is operating properly, an alarm

message is sent to the control panel.

D. The control panel beeps and shows the number of RF packets

received.

E. At the panel, exit sensor test mode.

Glass Break Functional Test

The product is designed to detect the breaking of framed glass

mounted in an outside wall. Testing the sensor with unframed lass,

broken bottles, etc., may not trip the sensor. The sensor typically does

not trip to glass breaking in the middle of the room. In rooms where

multiple sounds can reflect and duplicate the glass-break frequency

pattern. The Pattern Recognition Technology of the sensor ignores most

false alarm sounds, including glass break testers. To test the sensor,

use test mode. Test mode disables glass break pattern processing in

upper and lower frequencies. The sensor is then listening only for the

mid-range frequencies that the 5709C hand-held tester reproduces. It’s

the mid-range frequencies that determine sensor range.

Test Mode - To put the sensor in test mode, do the following:

A. Set the control panel to sensor test mode.

B. Use the 5709C handheld tester to put the sensor into test mode.

Set the tester to tempered glass and hold the tester on top of the

sensor.

C. Activate the tester. The sensor will alarm, then go into test mode

for one minute. In test mode, the LED will blink continuously. To

UTC. All Rights Reserved. 3 P/N 0000000 – Rev. A – 06 Nov 12

Page 4

extend test time, fire the tester at the sensor at least once a

+

RF LED

minute.

D. The control panel will beep and display the number of RF

packets received.

E. At the control panel, exit sensor test mode.

Sensor Test Mode - To put the sensor in sensor test mode, do the

following:

A. The tester has a different setting for each type of glass. Set the

tester for tempered or laminated glass unless you are certain

that all the glass to be protected is plate glass.

B. Hold the tester near the surface of the glass to be protected

and aim the speaker at the sensor. Be sure the tester is at the

point on the glass farthest from the detector. If closed drapes

or curtains are present, hold the tester behind them.

Press the test button on the tester. The LED on the sensor should stay

on for 4 seconds to indicate the glass is within detection range of the

sensor. If the LED does not stay on for 4 seconds, move the sensor and

retest.

If the sensor will not activate within its stated range of coverage, check

for battery strength in the tester. A new tester battery will likely restore

range. You may need to use additional sensors to achieve adequate

coverage.

The sensor will automatically change from test mode to normal mode

approximately one minute after it last hears the tester. In normal mode

the LED does not blink unless it hears a loud sound. In normal mode,

the sensor will not trip to the tester, unless the tester is held next to the

sensor. Each time the sensor alarms, it also goes into test mode for one

minute.

Room acoustics can artificially extend the range of a glass break

sensor. The specified range of the sensor has been established for

worst-case conditions. While the sensor will likely function at additional

range, it may miss a minimum output break, or room acoustics may

change at some future time, bringing the sensor range back into

normal 20 ft. (6 m) conditions. Do not exceed the rated range of the

sensor, regardless of what the tester shows.

8. Defaulting the Detector

This step should only be performed by a qualified service technician.

A. Remove the top cover from the product.

B. Remove the battery.

C. Press the enrollment switch in the RF circuit inside the product

and hold until you replace the batteries.

D. Replace the battery while still pressing the enrollment switch

then release the switch. The RF Module LED flashes three times

to signal the product is defaulted and not paired with a control

panel.

E. Replace the top cover.

9. Viewing Zone Event History

To view event history:

A. Tap the Security widget on the Home screen.

B. Tap the History tab. The Zone Event History shows the event

history.

10. Disabling Zones

The system can bypass a zone, so the zone is not monitored when the

system is armed. This is useful when a sensor is being repaired. You

can only change the Bypass state of a zone when the system is

disarmed.

The system continues to log the activity of bypassed zones in the Event

History (see “View Zone Event History,” above).

To bypass a zone:

A. With the system disarmed, tap the Security app on the Home

screen.

B. Tap the Turn Zone Off button for the smoke alarm. The Turn Zone

Off button changes to Turn Zone On.

C. When the system is disarmed, the Security Status header shows

that some zones have been bypassed.

11. Deleting the Product from the Control Panel

Deleting a sensor from the premises removes it from being monitored

by the customer’s system. This is not the same as disabling (bypassing)

a sensor. You should delete a sensor only:

o If the product is being removed from the premises

o To reset the product to factory default settings by deleting the

product and re-adding it immediately.

To delete a product from the system:

A. Contact Customer Care to obtain the Premise Passphrase for

the current customer account.

B. Perform steps A through D in Step 6, “Adding to the Control

Panel.”

C. When the Technician Settings menu appears, select Sensors

& Zones > Delete a Sensor/Zone. The Premise Passphrase

keyboard appears.

UTC. All Rights Reserved. 4 P/N 0000000 – Rev. A – 06 Nov 12

Page 5

D. Enter the Premise Passphrase and click Done. The currently

installed sensors/security zones appear.

E. Tap the zone you want to delete and follow the instructions

provided by the Control Panel to delete the sensor and

security zone from the current system.

12. Maintenance

This product is design for a long service life. Even though the control

panel indicates when to service this product, several annual and

random/as required checks are recommended.

Annual - Glass Break Functional Test

Random - visual check for LED flash during a Wake Up Test

- Wireless Signal Strength

The control panel indications are Trouble and Low Battery.

Trouble - the product has an internal fault indication, which

requires technical service.

Low Battery - batteries are low and must be replaced to maintain

proper operation.

In General

To keep your product in good working order:

o Vacuum the product cover once a month to remove

accumulated dust.

o Never use detergents or solvents to clean the product.

Chemicals can permanently damage or temporarily

contaminate the sensor.

o Avoid spraying air fresheners, hair spray, paint, or other

aerosols near the product.

o Do not paint the product. Paint will seal the sensor opening and

interfere with proper sensor operation.

Wireless Signal Strength

After adding the product to the control panel and installing this product,

test the signal strength between the control panel and its added

sensors/security zones:

A. Be sure steps A through D in Section 6, “Adding to the Control

Panel” have been performed.

B. When the Technician Settings menu appears, select Sensors &

Zones > Sensor Diagnostics.

C. When the currently installed sensors/ security zones appear,

tap the zone you want to test for connectivity and follow the

instructions from the control panel.

The Sensor Diagnostic for <Security Zone name> appears as the

system detects the current signal strength between the selected sensor

and the control panel.

Trouble

Refer to Section 13 for trouble shooting guidance.

Low Battery

Replace the batteries per Section 5 - Installing / Replacing Battery.

13. Troubleshooting

Product does not power up properly or reports low battery

o Be sure the battery is fully seated within the battery

compartment and the polarity is correct.

o Check the battery voltage (3.0 VDC nominal).

Control Panel does not respond

o Use a wireless RF Sniffer to confirm that the product is sending

messages for activation.

o Be sure the product is enrolled into the control panel properly.

o Be sure you are using a compatible control panel.

Tamper condition does not restore

o Be sure the product is installed properly onto the mounting

plate and the mounting plate has a magnet.

o Be sure there are no trouble indications at the detector.

o Be sure you are using a compatible control panel.

If a tamper alarm occurs

o Be sure you are using a compatible control panel.

o Be sure the control panel is in sensor test mode during sensor

testing.

Alarm/open condition does not restore

o Be sure the smoke or heat has cleared at the product.

o Be sure you are using a compatible control panel.

14. Specifications

Compatible panels -

Power One CR123 battery

Battery type

Standby Current

Battery Life 5 years (typically)

Glass Break Sensor Microphone Omni-directional 360o

Detection Range 20 ft. (6 m) x 360o

Min. Distance from Glass 4 ft. (1.2 m)

Glass Thickness

Plate

Tempered

Wired

Laminated

RF Wireless Frequency 2.4 GHz

Weight w/battery 0.28 lbs / 0.13 kg

Dimensions

Storage temperature -4 to 140°F (-20 to 60°C)

Operating environment 14 to 120°F (-10 to 50°C)

Relative Humidity 10 to 95% non-condensing

3.0 VDC Lithium

Duracell, Panasonic, Sanyo

25 µA (typically)

3/32 to 1/4 in. (2.4 to 6.4 mm)

1/8 to 1/4 in. (3.2 to 6.4 mm)

1/4 in. (6.4 mm)

1/8 to 1/4 in. (3.2 to 6.4 mm)

3.13"H x 4.25"W x 1.31”D

(80mm x 108mm x 33mm)

UTC. All Rights Reserved. 5 P/N 0000000 – Rev. A – 06 Nov 12

Page 6

15. Regulatory Information

This product is manufactured by Edwards, a UTC Fire and Security

Company, 8985 Town Center Parkway, Bradenton, FL 34202.

Manufacturer: UTC Fire & Security

WEEE Directive

2002/96/EC (WEEE directive): Products marked with this symbol cannot

be disposed of as unsorted municipal waste in the

European Union. For proper recycling, return this product to

your local supplier upon the purchase of equivalent new

equipment, or dispose of it at designated collection points.

For more information see: www.recyclethis.info.

RoHs Directive

2002/95/EC RoHS Compliant. Hereby, UTC Fire & Security declares that

this product does not contain lead, mercury, cadmium, hexavalent

chromium, polybrominated biphenyls (PBB) or polybrominated

depheny ethers (PBDE) in more than the percentage specified by EU

directive 2002/95/EC, except exemptions stated in EU directive

2002/95/EC annex.

UL Rating

ANSI/UL 639 Recognized

FCC Compliance

FCC ID: QPY-5845GB-Z

IC: 8303B-5845GB-Z

The device complies with part 15 of the FCC Rules as well as Industry

Canada Rules and Regulations license-exempt RSS standard(s).

Operation is subject to the following two conditions: (1) This device may

not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired

operation.

Conformité Réglementaire

Ce dispositif est conforme à la réglementation de la IC et (Partie 15) de

la FCC. Son fonctionnement est soumis à deux conditions : (1) ce

dispositif ne doit pas causer d’interférences nuisibles, et (2) ce dispositif

doit accepter toute interférence reçue, y compris les interférences

pouvant entraîner des conditions de fonctionnement indésirables.

WARNING: Changes to Section 15 – Regulatory Information is

strictly prohibited. Any changes or modification made to the product

without the permission of the manufacturer could void the user’s

authority to use this product.

16. Product Information

Disclaimer

This Glass Break Detector is not a complete alarm system, but only a

part of. Therefore UTC Fire & Security does not accept any responsibility

or liability for any damage that is claimed to be a result of an incorrect

functioning of the Glass Break Detector. UTC Fire & Security reserves the

right to change the specification without a prior notice.

Limitations of Security Products

Security products and alarm systems do not offer guaranteed

protection against burglary, fire, or other emergencies. They may fail to

warn for diverse reasons, including (but not limited to): power failure,

dead batteries, improper installation, coverage, coverage areas

overlooked during installation, defeat by technically sophisticated

intruders, component failure, or inadequate maintenance. Alarm

systems should be checked weekly to ensure that all devices are

working properly.

AN ALARM SYSTEM IS NOT A SUBSTITUTE FOR INSURANCE

Limited Warranty

Edwards is a brand of UTC Fire & Security. The manufacturer warrants

this product (except batteries) to be free from defects in material and

workmanship under conditions of normal use for a term of 3 years

from the date of manufacture.

During the warranty period, if a UTC Fire & Security product or any of its

components becomes defective, it will be repaired or replaced without

charge.

Out-of-warranty units will be repaired at the discretion of the

manufacturer or, if not, a card will be forwarded to the customer

suggesting a replacement unit and the cost of that unit.

This warranty does not apply to units which have been subject to

abuse,

misuse, negligence or accident, or to which any modifications,

alterations or repairs have been made or attempted.

This warranty is extended only to the original purchaser of the smoke

alarm and may be enforced only by such person. During the warranty

period, if the alarm or any warranted components thereof becomes

defective, it will be replaced or repaired without charge at the

manufacturer’s discretion if returned in accordance with the following

instructions:

Obtain a Return Authorization Number by calling the number below,

then carefully pack it in a well padded and insulated carton and return,

postal charges prepaid to:

Return units to: UTC – Climate, Controls & Security

325 N Main St

Pittsfield, ME 04967

Phone: 1-207-487-3104

A note should be included advising the nature of the malfunction. Care

must be exercised in the proper packing of alarms returned under this

warranty as UTC Fire & Security will not be responsible for warranty

repairs to equipment damaged because of improper packing.

The above warranty is in lieu of all other express warranties, and

implied warranties of merchantability and fitness for a particular

purpose are limited in duration for a period of THREE years from the

date of manufacture. Under no circumstances shall manufacturer be

liable to the purchaser or any other person for incidental or

consequential damages of any nature, including without limitation

damages for personal injury or damages to property, and however

occasioned, whether alleged as resulting from breach of warranty by

manufacturer, the negligence of manufacturer or otherwise.

Manufacturer’s liability will in no event exceed the purchase price of the

product. Some states do not allow limitations on how long an implied

warranty lasts, or the exclusion or limitation of incidental or

consequential damages, so the above limitations and exclusions may

not apply to you. Unless a longer period is required by applicable law,

any action against manufacturer in

connection with this smoke alarm must be commenced within one

year after the cause of action has occurred.

UTC. All Rights Reserved. 6 P/N 0000000 – Rev. A – 06 Nov 12

Page 7

No agent, employee or representative of the Manufacturer nor any

other person is authorized to modify this warranty in any respect.

Repair or replacement as stated above is the exclusive remedy of the

purchase hereunder. This warranty gives you specific legal rights and

you also have other rights which vary from state to state.

End of document

UTC. All Rights Reserved. 7 P/N 0000000 – Rev. A – 06 Nov 12

Loading...

Loading...