UST WP255, WP255 Owner’s Manual

WATER / SEMI TRASH PUMP

OWNER'S MANUAL

Model WP255

IMS (International Merchandising Services)

Warranty Information

Do Not Return To Store

One year Limited ManufactureCs Warranty.

Products are not to be returned to retailer

Service is available from a network of providers nationwide

To identify a provider in your area or for warranty information call toll free

866 797 2738

CONTENTS

( I ) SAFETY INFORMATIONS.................................... 2

(If) SAFETY LABEL LOCATION-S.............................. 2

(lli) NAMEOF EVERYPART .................................... 3

(IV) PRE STARTING OPERATION-.............................. ,t

(V) STARTING THE ENGINE.................................... 7

(V[) IJSINGMETHODOF WATERPIJMP ........................ 9

(\ll) STOPPIN(; THE ENGINE.................................... 10

(VIII) PERIODIC MAINTENANCE................................. 11

(IX) TRANSPORT/STORAGE....................................... 15

( X ) TROUBLESHOOTING.......................................... 17

(Xl) SPECIFICATION ............................................. 19

( I ) SAFETY INFORNATIONS

•To sure safety, don' t use water pump pump combustible,

caustic, brine(e.g, wine, boney, oil has been used), or

caustic liquid(e.g, gasoline and acid).

•To prevent fire, stop engine when refueling.

•To prevent fire, clean tt_e overflowing fuel.

•To prevent fire, never use the machine in flammable

conditions.

•place the machine in a place where pedestrians or

children are not likely to touch the machine.

•To prevent being poisoned and fire disease, when

exhausting, never point to building or appliance with

exhaust pipe.

•To prevent being poisoned, never operate the machine

indoors or any where witt_ air blocked.

•To avoid accident, please place tt_e water pump in tt_e

horizontal and solid position.

•To avoid accident, before you start the engine, please

check tt_e machine is safety.

•Before starting, please check tt_e oil is full.

(II) SAFETY LABEL LOCATIONS

Your water pump/petrol engine must be used witt_ care.

Therefore, decals have been place on the machine, to

remind you pictorially of main precautions to take

during use.

Should one become detached o1" unreadable, contact your

dealer for its replacement.

(III) NAMEOF EVERYPART

Muffler

Tention rod Fuel tank cap

Fuel valve

Choke rod_gutle t pipe

Starter grip___ '_''- Ftame

water filler cap

intake pipe

water drain plug

I _Engine oi filler cap

ngine switch

oil drain plug

air cleaner

0

filter

(IV) PRE-STARTING OPERATION

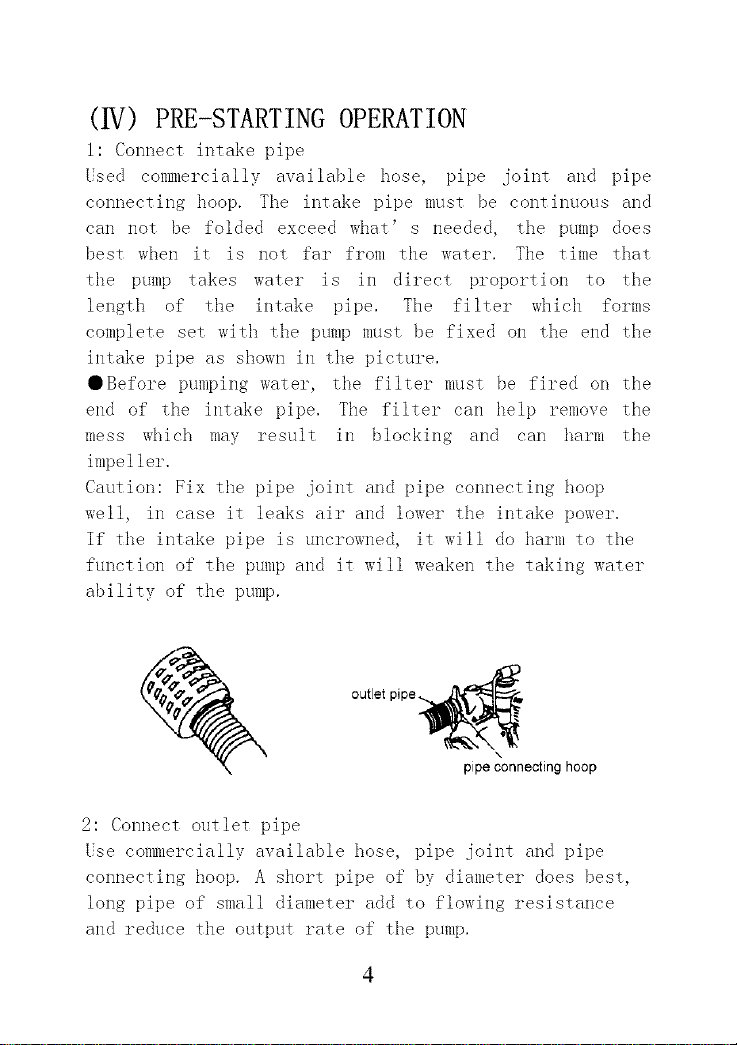

1: Connect intake pipe

Used conmlercially available bose, pipe joint and pipe

connecting hoop. The intake pipe must be continuous and

can not be folded exceed what' s needed, the pump does

best when it is not far from the water. The time that

the pump takes water is in direct proportion to the

length of the intake pipe. The filter which forms

complete set with the pump must be fixed on the end the

intake pipe as shown in the picture.

QBefore pumping water, the filter must be fired on the

end of the intake pipe. The filter can help remove the

mess which may result in blocking and can harm the

impeller.

Caution: Fix the pipe joint and pipe connecting hoop

well, in case it leaks air and lower the intake power.

If the intake pipe is uncrowned, it will do harm to the

function of the pump and it will weaken the taking water

ability of the pump.

out[et pipe__

\

pipe connecting hoop

2: Connect outlet pipe

[se conmlercially available bose, pipe _joint and pipe

connecting hoop. i short pipe of by diameter does best,

long pipe of small diameter add to flowing resistance

and reduce the output rate of the pump.

4

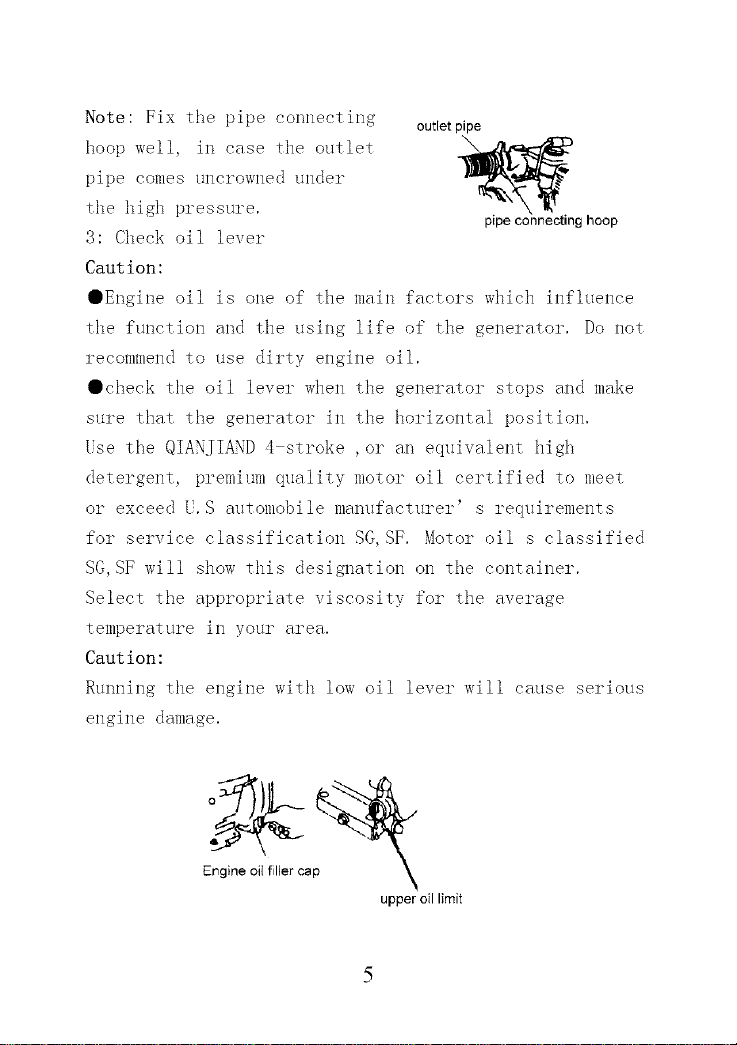

Note: Fix the pipe connecting

outlet pipe

hoop well, in case the outlet

pipe comes tll]crowl]edul]der

the high pressure.

3: Check oil lever

pipe connecting hoop

Caut ion:

SEngine oil is one of the main factors which influence

the function and the using life of the generator. Do not

recommend to use dirty engine oil.

Qcheck the oil lever when the generator stops and make

sure theft the generator in the horizontal position.

_se the QIANJIAND 4 stroke , or an equiw_lent high

detergent, premium qut_litymotor oil certified to meet

or exceed [.S automobile mal_t_facturer's reqt_irements

for service classification SG, SF. Motor oil s classified

SG, SF will show this designation on the container.

Select the appropriate viscosity for the average

temperature in your area.

Caut ion:

Running the engine with low oil lever will cause serious

engine d_mlage.

Engine oil filler cap

upper oil limit

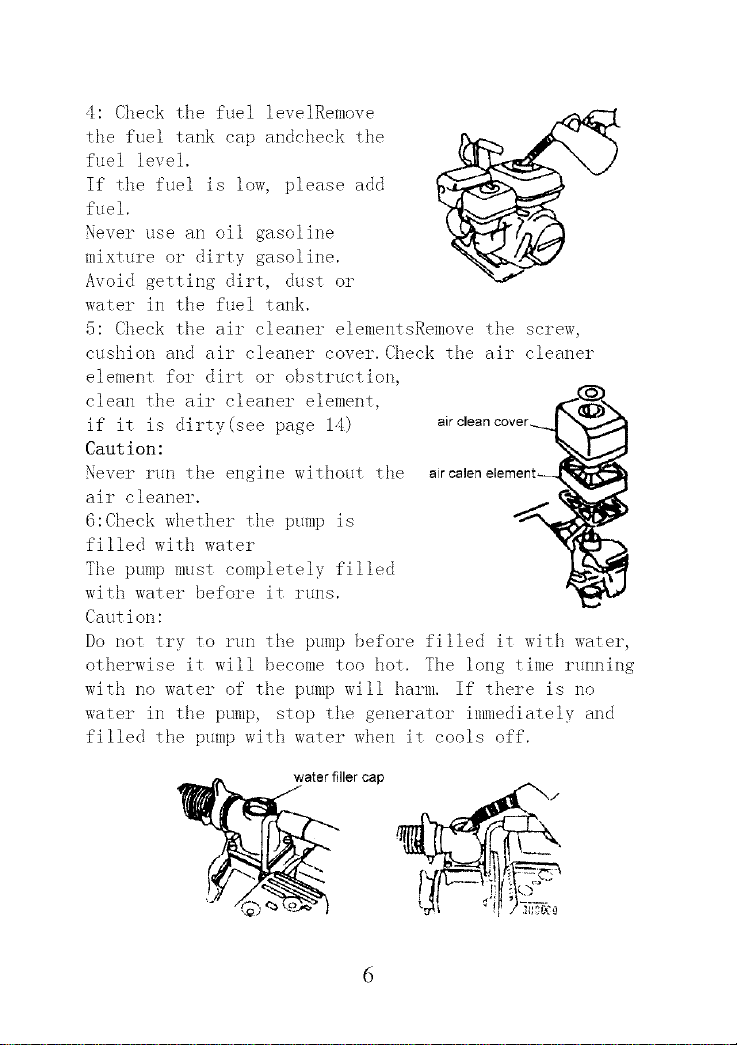

4: Check tilefuel levelRemove

the fuel tank cap andcheck tile

fuel level.

If the fuel is low, please add

fuel.

Never use all oil gasoline

mixture or dirty gasoline.

Avoid getting dirt, dust or

water illtilefuel tank.

5: Check tile air cleaner elementsRemove tile screw,

cushion and air cleaner cover. Check tileair cleaner

element for dirt or obstruction,

clean the air cleaner element,

if it is dirty(see page 14) aircleancover

Caut ion:

Never run tileengine without tile

_ir cleaner.

6:Check whether tile pump is

filled with water

The pump must completely filled

with water before it runs.

Cauti on :

Do not try to run tilepump before filled it with water,

otherwise it will become too hot. The long time running

with no water of tilepump will harm. If there is no

water illthe pump, stop the generator immediatelyand

filled tilepump with water when it cools off.

water filler cap

Loading...

Loading...