Page 1

Pre-drilled mounting holes

Tel: 877 55 US SUN (877-558-7786)

www.ussunlight.com

support@ussunlight.com

Rigid Tube Kit for Model 2014ST

Installation and Mounting Guide

The Rigid Tube Kit can be installed as a retrofit to the standard flex tube that has

already been installed, or as part of a new installation of the 2014ST. Please read the

entire installation guide before beginning your installation.

REQUIRED TOOLSBOX CONTENTS / PARTS LIST

1.

#8 Panhead

Screws

(3 each)

2.

Foil Tape

29 ft.

Crimped edge

14” Rigid Tube Lower Elbow

(with crimped bottom)

Part# 29-02-005

14” Rigid Tube Upper Elbow

Part# 29-02-004

Removal of the old ex tube material

Cut around edge to

expose retaining band.

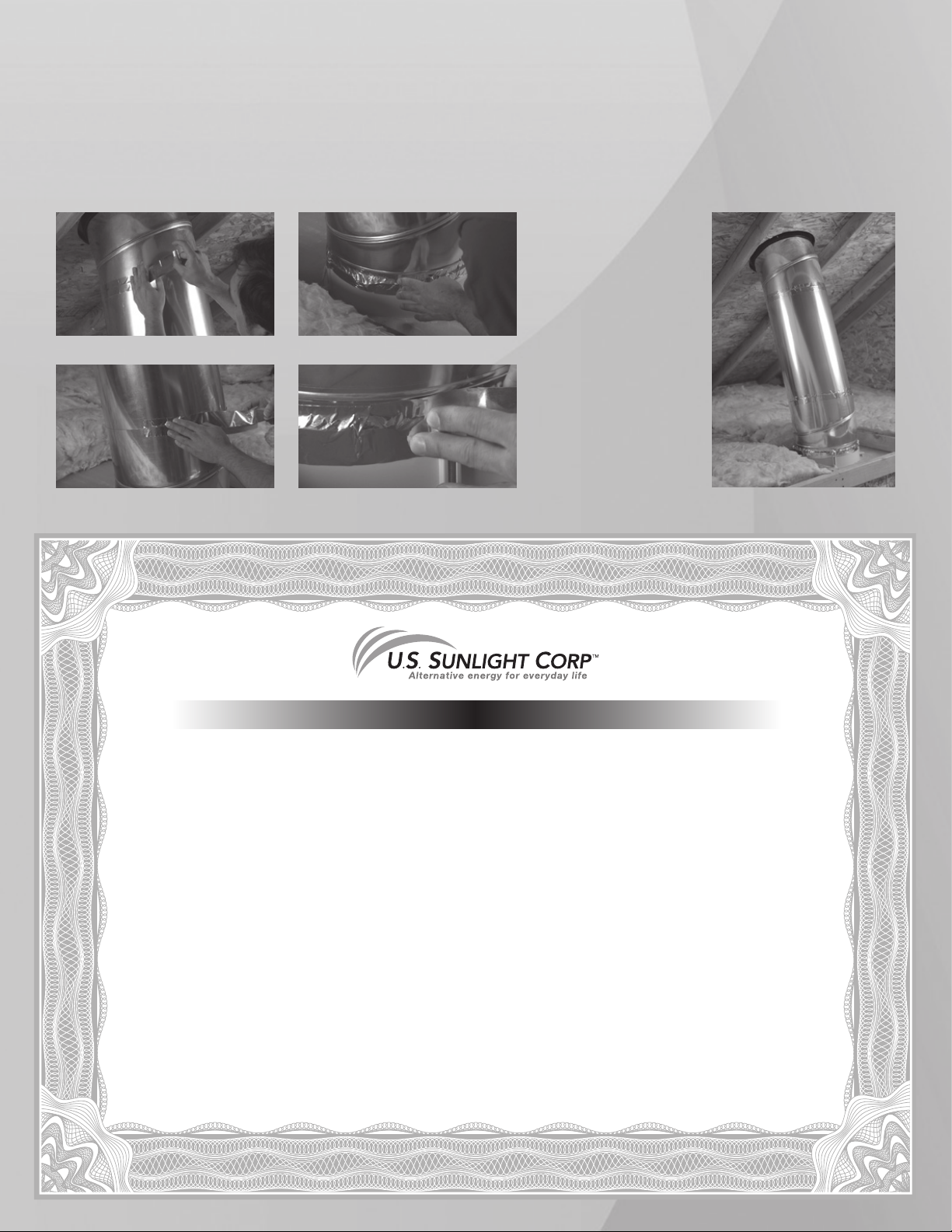

fig. 1 fig. 2 fig. 3 fig. 4

Step 1

You will need to remove the diffuser assembly and retaining

band from the diffuser housing first. Start by removing the trim

ring and diffuser assembly. (fig. 1)

Step 2

Using a utility knife, cut the flex material around the inside of

the housing to expose the retaining band. (fig. 2) If you have a

Light Kit installed you will need to remove that as well, consult

the Light Kit install instructions for removing.

2’ Straight Tube - 3 pieces

Part# 29-02-007

3. 4.

1. Tin Snips

2. Drill with a Phillips Bit

or a Phillips Screwdriver

3. Measuring Tape

4. Utility Knife

Step 3

Remove the retaining band from the housing by removing the

three nuts and washers from the screw posts. (fig. 3)

Step 4

From inside the attic, lift the flex tube out of the diffuser housing, make sure to compress it to clear the screw posts. (fig. 4)

© Copyright 2011 US Sunlight Corp, Inc. 2014ST-RT-C01_ver1

Page 2

Retaining

ring

fig. 5 fig. 6 fig. 7 fig. 8

Step 5

Raise the flex tube material up to the dome assembly so you

can see the aluminium retaining ring. (fig. 5)

Step 6

Using the lower edge of the retaining ring as a guide, cut the

material all the way around to separate it from the dome assembly. (fig. 6) Try to make the cut as smooth as possible.

Step 7

Expose the spiral wire, and using the tin snips, cut the wire away

as close to the edge as shown. (fig. 8)

Step 8

Push up any exposed wire or

tube material left behind.

(fig. 9)

(fig. 7)

Assemble the straight tube lengths

The Rigid Tube Kit comes with three 2 ft straight extension tubes. When installed with the Upper and Lower Elbows a

7.5 ft. total length may be achieved in most cases. You will need to measure the distance from the edge of the flange

at the dome opening, down to the top of the Diffuser Housing to find the total length. If your installation requires more

distance, you can order additional straight tubes on our website: www.ussunlight.com

Tube when

assembled

should have

a slight cone

shape.

Mark

at 3/8”

L

i

n

e

u

p

w

i

t

h

t

h

i

s

e

d

g

e

DOUBLE SIDED TAPE

outside of flat sheet

(reflective surface on the other side)

Mark

at 1”

L

i

n

e

u

p

w

it

h

t

h

i

s

e

d

g

e

fig. 9

fig. 10

Step 9

After determining how many straight tubes you require, you

will need to assemble them as follows: There should be scribe

marks on both sides of the outer surface where the double stick

tape is applied. (ill. a) If not, use a pen to mark the locations at

1 inch and 3/8 inch as shown in (fig. 10 & 11) then peel off the

backing tape. (fig. 12)

Step 10

Before continuing, cut a piece of the 2” foil tape about 24” in

length and have it nearby. (fig. 13) Turn the flat sheet on its

back (reflective surface up) and peel away about 2-3” of the

protective film on the side opposite the double sided tape.

Then form a cylinder and secure the first side at 3/8” (fig. 14)

Use the other hand to steady the cylinder in the center.

Then secure the other side at 1”. (fig. 15) IMPORTANT:

Firmly press on both sides (inside and out) of the entire

length of the tube to secure the double stick tape.

Now immediately apply the foil tape along the outside edge

down the entire length. (fig. 16) Press firmly in place up and

down the length to secure. (fig. 17)

Repeat step 10 for other tubes if necessary.

Line up the far edge (3/8”)

and press to hold.

ill. a

Cut a 24” strip.

fig. 12

Then line up the

near edge (1”)

and press to hold.

fig. 14 fig. 15

Press firmly

to secure.

fig. 16

fig. 11

fig. 13

fig. 17

Page 3

IMPORTANT:

Remove the protective lm

Before beginning the fitting and installation, peel off all of the

protective film on the inside of each component. Otherwise,

you won’t be able to peel the film after the tube is sealed.

(fig. 18 and 19).

fig. 18 fig. 19

Dry t the components before securing

It is important to “dry fit” the parts of the Rigid Tube Kit as close as possible to their final angles before securing. The

best method is to try to line up the Upper Elbow to the Lower Elbow by changing the tilt and rotation of each as they are

sitting in the Dome Flange and Diffuser Housing. The requirement is that they line up as much as possible prior to inserting the straight tube length(s). If you can, check with a yard stick or long level along both edges as shown in (fig. 20).

Retaining Ring

Rotating

the base

fig. 25

fig. 26

fig. 20

Flange

fig. 21

fig. 22

fig. 23

Tilting the Elbow

fig. 24

Step 11

The Upper Elbow fits inside the flange and rests against the retaining ring. (fig. 21) Fit the Upper Elbow into the flange and adjust the angle

to point at the Diffuser Housing (fig. 22) The crimped edge of Lower Elbow fits into the Diffuser Housing and rests on the three retaining band

posts (fig. 23) Both elbows adjust the same way as shown in (fig. 24 & 25). When satisfied with the initial adjustments, draw a registration

mark to indicate the desired angles. (fig. 26)

Secure the Upper Elbow

Step 12

With the Upper Elbow held securely against the retaining ring

in the final desired position, drive a Mounting Screw through

one of the pre drilled holes into the Flange. (fig. 27) Continue

until all three screws are installed. (fig. 28)

fig. 27 fig. 28

Fit the Straight Tube length(s)

Step 13

As you fit the Straight Tube(s) into position, the larger opening

of the tube(s) should always be at the top and should fit over

the preceeding tube or elbow (fig. 29) and then fit inside the

bottom component as you work your way down the installation. (fig. 30 & 31) Make final small adjustments to the Lower

Elbow if necessary. Overlap each component by no less than

1” and try to minimize any protruding areas to create smooth

transitions between each piece. (fig. 32)

Fit on the outside

of the top

components

Fit on the inside

of the bottom

components

fig. 29 fig. 30

Adjust for a tight,

smooth transition

fig. 31 fig. 32

Page 4

Apply Foil Tape to seal and secure

Step 14

Cut strips of the foil tape about 45” in length and apply to all transition areas starting from the Upper Elbow. (fig. 33 & 34)

When you get to the transition at the Diffuser Housing and Lower Elbow, cut a large piece of tape about 52” in length to

adequately cover the uneven surface as shown in (fig. 35 & 36). Try to form the tape around the surfaces without tearing

so that it will create a tight seal.

After you have taped

the transition areas,

your Rigid Tube Kit is

installed. (fig. 35)

Just replace the

Diffuser Assembly and

fig. 33

fig. 35

Trim Ring to complete

the process.

fig. 34

fig. 36 fig. 37

WARRANTY

Manufacturer’s Limited Warranty

U. S. Sunlight Corp. (“Manufacturer”) warrants that certain of its product components are free from defects of workmanship and/or materials

for a period of time commencing on the date of original purchase and continuing as noted hereafter: (a) roof ashing for a period of ten (10)

years (b) exible tubing for a period of ten (10) years (c) ceiling lens diffuser house for a period of ten (10) years.

Disclaimer

Except as expressly set forth herein, all Manufacturer’s products, including components thereof, are sold “AS IS” without warranty of

merchantability, tness for intended purpose, or other warranty, express or implied. In no event shall Manufacturer be liable for the loss of

prots, indirect, special, incidental, consequential or other similar damages, including but not limited to any claim or demand arising out of the

installation, furnishing, or functioning of a product or use by purchaser or any third party. The warranty terms and conditions detailed above

do not extend to misuse, neglect, abuse, alteration, exposure to extreme weather conditions, lightning strikes, physical damage to any

product, or damages caused by transportation or installation of any product. Manufacturer explicitly does not warrant any labor, shipping, or

service fees incurred by purchaser for the replacement, repair, or exchange of any product or product components claimed under the above

warranty terms and conditions.

Warranty Claims

Warranty claims shall be submitted in writing to Manufacturer at its principal place of business. Claims shall include a copy of the original

purchase invoice, purchaser’s name, address, telephone number, and e-mail address, and such other particulars as are necessary to

describe the claimed defect. If requested by Manufacturer, purchaser shall ship the claimed defective component(s) to Manufacturer’s

principal place of business, FOB destination, freight prepaid, for evaluation. As to any product component determined by Manufacturer to

contain a defect covered by its warranty, Manufacturer reserves the right, at its discretion, to repair or replace the defective component, or

rebate a portion of the purchase price prorated based on the balance of the warranty term.

General

This limited warranty contains all of the terms and conditions of Manufacturer’s warranty of the purchased product and its components. No

representation, arrangement, or agreement not appearing herein shall be binding on Manufacturer. This limited warranty is issued in and shall

be governed by the laws of the State of California.

Loading...

Loading...