Page 1

INSTALLATION AND

OPERATION MANUAL

“THE SUMMIT” ELECTRIC

CONVECTION OVEN

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

PLEASE READ ALL SECTIONS OF THIS MANUAL

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

INSTALLATION AND ELECTRICAL CONNECTION

MUST COMPLY WITH CURRENT CODES:

IN CANADA - THE CANADIAN ELECTRICAL

CODE PART 1 AND / OR LOCAL CODES.

IN USA – THE NATIONAL ELECTRICAL CODE

ANSI / NFPA – CURRENT EDITION.

ENSURE ELECTRICAL SUPPLY CONFORMS WITH

ELECTRICAL CHARACTERISTICS SHOWN ON

THE RATING PLATE.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

GARLAND COMMERCIAL INDUSTRIES, LLC

185 East South Street

Freeland, Pennsylvania 18224

Phone: (570) 636-1000

Fax: (570) 636-3903

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Enodis UK LTD.

Swallow eld Way, Hayes, Middlesex UB3 1DQ ENGLAND

Telephone: 081-561-0433

Fax: 081-848-0041

Part # 1955204 Rev 1 (01/08/09) © 2004 Garland Commercial Industries, LLC

Part # 1955204 Rev 1 (01/08/09) Page 1

Page 2

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the state of California to cause cancer and/or birth defects

or other reproductive harm. Installation and servicing of this product could expose you to airborne

particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers

is known to the state of California to cause cancer.

Keep appliance area free and clear of combustibles.

Part # 1955204 Rev 1 (01/08/09)Page 2

Page 3

TABLE OF CONTENTS

IMPORTANT INFORMATION .............2

DIMENSIONS AND SPECIFICATIONS,

MODEL SUME 100/200 .................4

DIMENSIONS AND SPECIFICATIONS,

MODEL SEM 100/200...................5

INTRODUCTION........................6

Rating Plate ..................................6

INSTALLATION .........................6

Clearances ...................................6

Installation Of Ovens Equipped With Casters . . 6

Installation of Double Deck Models ...........6

Electrical Connections ........................7

Power Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Summit 45 Electronic Control

With Cook-N-Hold And

Summit 45+ Electronic Control

With Cook-N-Hold & Core Probe ..............9

In O Mode .............................. 9

On Start Up .............................. 9

Controller Keys ........................... 9

Fahrenheit/Celsius....................... 10

Operating the Controls ..................10

Cook-N-Hold Operation ................. 11

Core Probe Operation ................... 11

Setting Setback Feature ................. 11

PERFORMANCE RECOMMENDATIONS ..12

PROBLEM/SOLUTIONS ................13

COOKING GUIDE ......................14

OPERATING INSTRUCTIONS.............8

Summit 20 Solid State Control with

Electromechanical Timer . . . . . . . . . . . . . . . . . . . . . 8

In O Mode .............................. 8

Start Up.................................. 8

Fan Speed ............................... 8

Lights .................................... 8

Cool Down............................... 8

Temperature ............................. 8

Timer .................................... 9

COOK AND HOLD .....................15

CLEANING AND MAINTENANCE ........16

Break-In Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Exterior Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Interior Cleaning ............................16

Fan Area Maintenance . . . . . . . . . . . . . . . . . . . . . . 16

Motor Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Part # 1955204 Rev 1 (01/08/09) Page 3

Page 4

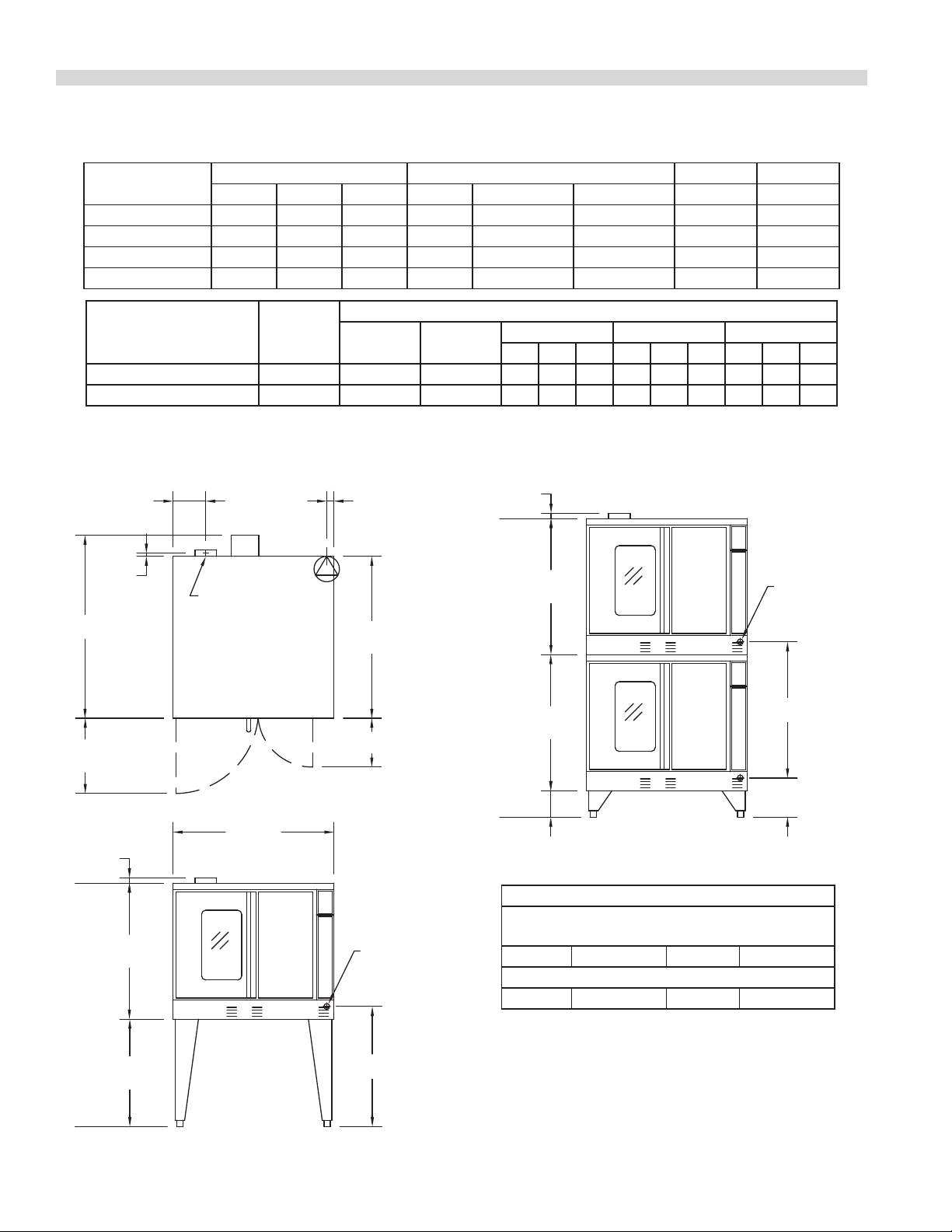

DIMENSIONS AND SPECIFICATIONS, MODEL SUME 100/200

7-3/4"

[197mm]

38-1/4"

[972mm]

3/4"

[19mm]

17-3/4"

[451mm]

38"

[965mm]

32-1/8"

[816mm]

25-3/8"

[645mm]

1-1/4"

[32mm]

32-1/8"

[816mm]

32-1/8"

[816mm]

6-1/4"

[159mm]

1-1/4"

[32mm]

11-1/2"

[292mm]

9-1/4"

[235mm]

32-1/8"

[816mm]

1-11/16"

[43mm]

28-3/8"

[721mm]

FLUE: 2-3/8" x 5"

[60mm x 127mm]

TOP VIEW

DOUBLE DECK

FRONT VIEW

SINGLE DECK

FRONT VIEW

"D" (includes

motor)

REAR CABLE

ENTRANCE

REAR CABLE

ENTRANCE

Model

Int. Dimensions :In (mm) Ext. Dimensions: In (mm) Ship Wt Ship Dim.

W H D W H D Lbs/kg Cubic Ft.

SUME-100S1 29 (736) 24 (610) 24 (610) 38 (965) 57-1/2 (1461) 39-1/4(997) 510/232 42

SUME-100D1 29 (736) 24 (610) 28 (711) 38 (965) 57-1/2 (1461) 43-1/4(1099) 510/232 42

SUME-200S1 29(736) 24(610) 24(610) 38(965) 70-1/2 (1791) 39-1/4(997) 1024/464 84

SUME-200D1 29(736) 24(610) 28 (711) 38(965) 70-1/2 (1791) 43-1/4(1099) 1024/464 84

Nominal Amperes Per Line, (includes 3/4 HP fan motor)

Model Tota kW

208V/1Ph 240V/IPh

208V/3Ph 240V/3Ph 460V/3Ph

X Y Z X Y Z X Y Z

Single Deck 10.4 50 43 30 30 28 26 26 24 14 14 13

Double Deck* each oven 10.4 50 43 30 30 28 26 26 24 14 14 13

* Double Deck Models are provided with individual power supply connections.

Electrical specications include motor requirements. 3/4, HP, 2-speed motor: 1725/1140 rpm, (60Hz); or 1440/950 rpm (50Hz)

Please specify electrical characteristics when ordering.

Instillation Notes:

CombustIble & Non-Combustible

Wall Clearances:

Sides 1" (25mm) Back 3" (76mm)

Entry Clearances: In (mm)

Crated 44-1/2 (1130) Uncrated 32-1/2 (826)

Many local codes exist and it is the responsibility of the

owner and installer to comply with those codes.

These appliances are intended for commercial use by

professionally trained personnel.

Part # 1955204 Rev 1 (01/08/09)Page 4

Page 5

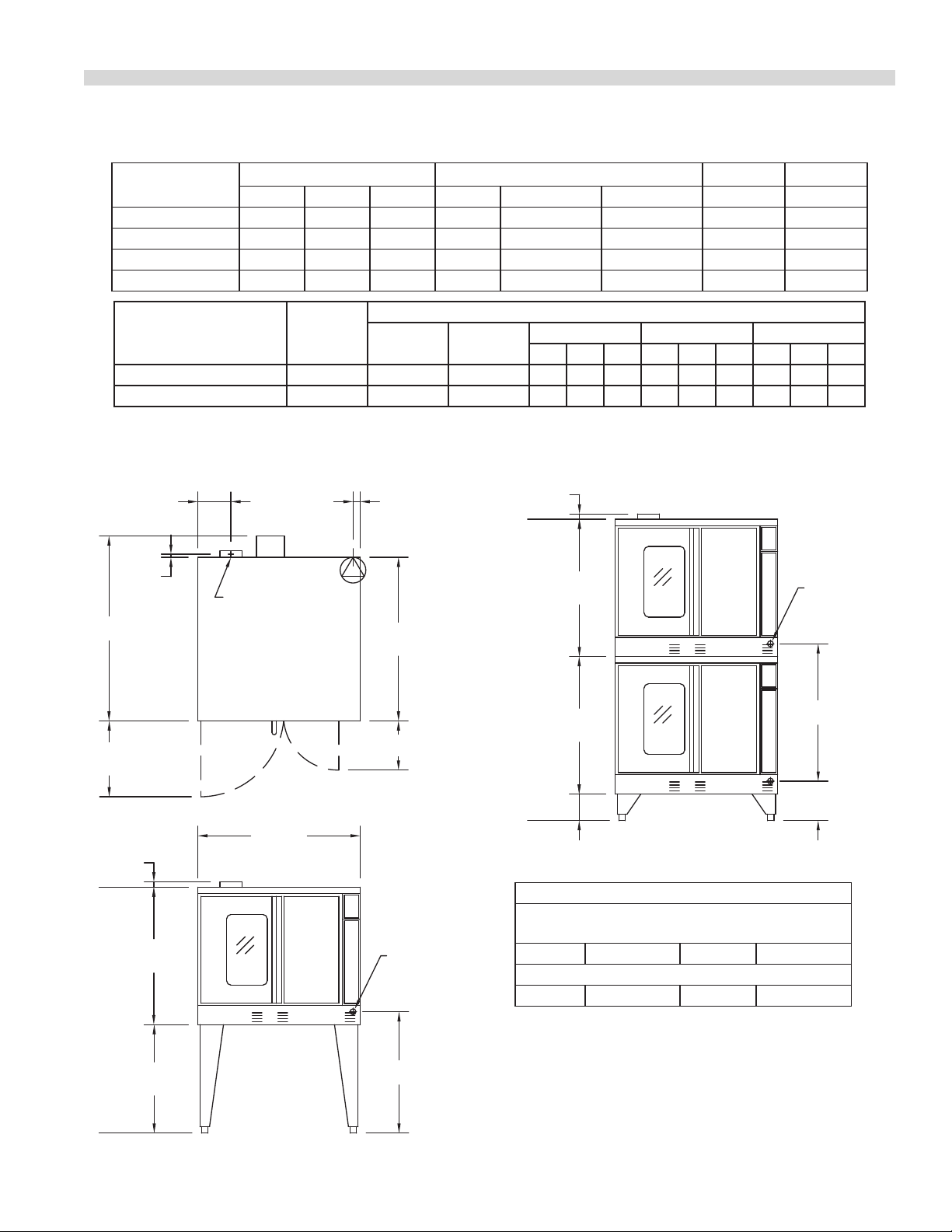

DIMENSIONS AND SPECIFICATIONS, MODEL SEM 100/200

7-3/4"

[197mm]

38-1/4"

[972mm]

3/4"

[19mm]

17-3/4"

[451mm]

38"

[965mm]

32-1/8"

[816mm]

25-3/8"

[645mm]

1-1/4"

[32mm]

32-1/8"

[816mm]

32-1/8"

[816mm]

6-1/4"

[159mm]

1-1/4"

[32mm]

11-1/2"

[292mm]

9-1/4"

[235mm]

32-1/8"

[816mm]

1-11/16"

[43mm]

28-3/8"

[721mm]

FLUE: 2-3/8" x 5"

[60mm x 127mm]

TOP VIEW

DOUBLE DECK

FRONT VIEW

SINGLE DECK

FRONT VIEW

"D" (includes

motor)

REAR CABLE

ENTRANCE

REAR CABLE

ENTRANCE

Model

Int. Dimensions :In (mm) Ext. Dimensions: In (mm) Ship Wt Ship Dim.

W H D W H D Lbs/kg Cubic Ft.

SEM-100S1 29 (736) 24 (610) 24 (610) 38 (965) 57-1/2 (1461) 39-1/4(997) 510/232 42

SEM-100D1 29 (736) 24 (610) 28 (711) 38 (965) 57-1/2 (1461) 43-1/4(1099) 510/232 42

SEM-200S1 29(736) 24(610) 24(610) 38(965) 70-1/2 (1791) 39-1/4(997) 1024/464 84

SEM-200D1 29(736) 24(610) 28 (711) 38(965) 70-1/2 (1791) 43-1/4(1099) 1024/464 84

Nominal Amperes Per Line, (includes 3/4 HP fan motor)

Model Tota kW

208V/1Ph 240V/IPh

208V/3Ph 240V/3Ph 460V/3Ph

X Y Z X Y Z X Y Z

Single Deck 10.4 50 43 30 30 28 26 26 24 14 14 13

Double Deck* each oven 10.4 50 43 30 30 28 26 26 24 14 14 13

* Double Deck Models are provided with individual power supply connections.

Electrical specications include motor requirements. 3/4, HP, 2-speed motor: 1725/1140 rpm, (60Hz); or 1440/950 rpm (50Hz)

Please specify electrical characteristics when ordering.

Instillation Notes:

CombustIble & Non-Combustible

Wall Clearances:

Sides 1" (25mm) Back 3" (76mm)

Entry Clearances: In (mm)

Crated 44-1/2 (1130) Uncrated 32-1/2 (826)

Many local codes exist and it is the responsibility of

the owner and installer to comply with those codes.

These appliances are intended for commercial use by

professionally trained personnel.

Part # 1955204 Rev 1 (01/08/09) Page 5

Page 6

INTRODUCTION

Like any other ne, precision built appliance, your oven

should be given regular care and maintenance. Periodic

inspections by your dealer or a qualied service agency is

recommended.

INSTALLATION

Clearances

Combustible and non-combustible wall clearances are: side,

1.0” (25mm) and rear, 3.0” (76mm).

NOTE: Adequate clearance must be provided for servicing

and proper operation.

Installation Of Ovens Equipped

With Casters

A. For an appliance equipped with casters, the installation

shall be made with a connector that complies with the

Standard for connectors for Movable Appliances, ANSI

Z21.69. Adequate means must be provided to limit the

movement of the appliance without depending on

connector wiring.

B. The front casters of the unit are equipped with brakes to

limit the movement of the oven without depending on

the connector wiring to limit the appliance movement.

C. The restraint can be attached to the unit near the

electrical inlet. If the restraint is disconnected, be sure to

reconnect the restraint after the oven has been returned

to its originally installed position.

Rating Plate

When corresponding with the factory or your local

authorized factory service center regarding service problems

or replacement parts, be sure to refer to the particular unit

by the correct model number (including the prex and sux

letters and numbers) and the warranty serial number. The

rating plate located behind the lower front panel (below the

oven doors) contains this information.

Installation of Double Deck Models

A. Position insert in bottom leg opening and tap insert up

into leg until it seats at collar. Attach six inch (6”, 152mm)

legs to lower oven section. Raise unit or lay on its left side.

Place the front legs on the oven so as to line up with four

(4) attaching bolt holes. Secure leg to oven frame using

four (4) 3/8-16 x 3/4 bolts and washers provided. Repeat

at rear of unit.

B. Remove lower front cover of top deck (located under

oven doors). Raise top deck into place and line up body

sides and back of the unit. Fasten the rear of the units

together, with the stacking bracket, using (6) 1/4-20

machine screws, lock washers and nuts, (provided).

C. Install the interconnecting ue parts, carefully following

the instructions contained in the stacking kit. Pay

particular attention to the type of ovens you are stacking

and be sure to follow the corresponding instructions.

D. Check leveling of unit four (4) ways (using a common

carpenter’s level on the rack inside the oven).

E. Maintain clearance from combustibles.

Part # 1955204 Rev 1 (01/08/09)Page 6

Page 7

INSTALLATION Continued

Electrical Connections

Before attempting the electrical connection, the rating

plate should be checked to ensure that the unit’s electrical

characteristics and the supply electrical characteristics agree.

Installation of the wiring must be made in accordance with

U.L. 197 Commercial Electric cooking Appliance Standards,

Local and/or National electrical Code, ANSI/NFPA 70-1990.

1. Switch panel size

2. Overload protection

3. Wire type

4. Wire size

5. Temperature limitations of the wires

6. Method of connection (Cable, Conduit, etc)

The service line will enter through the rear of the unit and is

to be connected to the terminal block (see diagram left). The

terminal block is accessed by removing the lower front cover.

Removal of the body side is not necessary.

Input voltage and phasing must match the units voltage

and phasing. Wiring diagram is attached to the main back of

each oven. Visually check all electrical connections. Energize

electric service to units. The range is wired standard for three

phase connections. If it is necessary to change to single

phase, please refer to wiring diagram attached to the rear of

the oven. Service and unit voltage must agree.

Power Failure

In the event of a power failure, no attempt should be made

to operate this oven.

Part # 1955204 Rev 1 (01/08/09) Page 7

Page 8

OPERATING INSTRUCTIONS

Summit 20 Solid State Control with

Electromechanical Timer

In O Mode

When the oven is o, there are no lights or indicators.

Start Up

Press the Cook/O/Cool Down rocker switch to the “Cook”

position. The green lamp will light indicating the oven is

powered in cook mode.

The oven will begin to heat to the temperature set on the

thermostat dial. The amber lamp will light indicating the heat

is active. As the heat cycles on and o to maintain the set

temperature this light will go on and o accordingly.

The door must be closed for the oven to operate in cook

mode. Opening the door will cause the heat to stop and the

motor and fan will shut o. This is a safety feature.

Fan Speed

The fan speed can be either high (1725 RPM) or low (1150

RPM). The fan speed is controlled by the left rocker switch

marked high and low.

Lights

The oven lights are activated by pressing the light switch

on the control panel. This is a momentary switch and the

lights will only stay lit as long as this button held in the on

position. Lights will work whenever there is electrical power

connected to the oven.

Cool Down

Pressing the Cook/O/Cool down rocker switch to the Cool

down position activates the fan and motor to cool the oven

cavity. The door must be open slightly for the fan and motor

to start. The heat is not active in this mode.

Optimal cool down will be achieved with the door open

slightly. Opening the door too far will shut the fan and motor

o. This is a patented safety feature.

Pressing the button to the OFF position cancels the cool

down and turns the oven o.

Temperature

The temperature range is from 150° to 500°F (66°ºC to 250ºC)

is controlled by rotating the temperature dial and aligning

the indicator to the desired temperature.

Part # 1955204 Rev 1 (01/08/09)Page 8

Page 9

OPERATING INSTRUCTIONS Continued

Timer

The timer is set by rotating the dial clockwise aligning the

indicator to the desired time cycle. The timer will count down

from 2 minutes to 60 minutes. At the end of the timing cycle

the buzzer will sound. The buzzer is turned o by rotating the

dial counter-clockwise to the o position as shown on the

control panel.

NOTE: The timer does not control heating.

Summit 45 Electronic Control With Cook-NHold And Summit 45+ Electronic Control With

Cook-N-Hold & Core Probe

In O Mode

When the controller is o, the display will show “OFF”.

Pressing the ON/OFF key will activate the controller into

Start Up Mode.

On Start Up

In Start Up mode, the controller will heat to the last set

temperature, time and fan speed. The factory defaults are

350°F (177°C), 30 minutes and low fan speed. The display will

indicate “LO” when the oven is below the set temperature.

When the oven cavity reaches the set temperature and is

ready for operation the display will indicate “LOAD”.

NOTE: If the oven temperature goes above the requested

temperature the display will indicate “HI”. If the oven

temperature goes above 575°(302°C) the display will indicate

“HELP” and an audible signal will sound. This is a safety

feature.

If the door is opened during a Cooking mode, the fan and

heat will stop, and the display will indicate “DOOR” until the

door is closed. This is a patented safety feature.

Pressing the ACTUAL TEMP key will display the actual oven

temperature in 5° increments.

Controller Keys

Pressing the ON/OFF key will activate the oven.

Pressing the LIGHT key will turn the lights on for 30 seconds.

The lights will work if the controller is in the o mode. When

the door is opened, the light will come on and stay on for 30

seconds.

Pressing the FAN HIGH key will activate the lower fan speed

and light its LED.

Part # 1955204 Rev 1 (01/08/09) Page 9

Page 10

OPERATING INSTRUCTIONS Continued

Pressing the FAN LOW will activate the higher fan speed and

light its LED.

Pressing the FAN PULSE key the fan will be active the lower

fan speed and light its LED. The fan will be activated for 30

seconds then o for 30 seconds, and continues this cycle.

Pressing the SETBACK key will cool the oven cavity to

a preprogrammed temperature, see: Setting “Set-Back”

Feature. The oven will automatically go into Setback mode

after the pre-programmed non-usage time. The display will

indicate “SETB”. This is an energy-saving feature.

Pressing the COOL DOWN key will deactivate the heat, turn

the fan on high and light its LED. This display will indicate

“OPEN DOOR” if the door is closed, prompting the user

to open the door slightly. With the door open slightly the

display will indicate “COOL”. The Cool down will operate

when the door is closed or opened slightly. Optimal cool-

down will be achieved with the door open slightly. When

the door opens wider, the Cool Down mode will deactivate

and the display will indicate “DOOR”. This is a patented safety

feature. Pressing the COOL DOWN key again will turn the LED

o and stop this mode. Pressing the ON/OFF key will also

cancel Cool down. Cool Down is not active during a cook.

When the ON/OFF switch is pressed to turn the oven o and

the oven is above 200°F (93°C), the oven will go into an AUTO

COOL DOWN mode. In Auto cool Down, the oven will run the

fan on high until the oven cavity drops below 150°F (66°C).

During this time the display will indicate “AUTO”. When the

oven temperature drops below 150°F (66°C) the oven turns

o. This feature protects the oven motor from premature

failure. Optimal cool-down will be achieved with door open

slightly.

Fahrenheit/Celsius

Factory default is Fahrenheit (F). To change to Celsius (C),

press and hold in the “Phantom Key” located to the right of

“Cook/Hold” key. “F” appears in the display. Continue to hold

until “C” is displayed and then release the “Phantom key”

Operating the Controls

Setting the cook temperature and time are done in the same

manner. Pressing the SET key will light the TEMP LED. The

operator then sets the temperature by rotating the dial on

the controller until the desired temperature is shown on the

display. Pressing the SET key a second time lights the TIME

LED and allows the operator to select the desired cook time

as shown on the display. Pressing the Set key a third time

ends the programming.

Part # 1955204 Rev 1 (01/08/09)Page 10

Page 11

OPERATING INSTRUCTIONS Continued

Pressing the START/CANCEL key will start the timing cycle.

The display will count down from the set time in minutes and

seconds (solid colon) or hours and minutes (blinking colon)

then minutes and seconds. When the cycle is completed,

pressing this key will also cancel the “DONE” prompt. To

cancel a timing cycle in progress, press and hold the START/

CANCEL.

Cook-N-Hold Operation

Pressing the COOK/HOLD (45 and 45+ Controllers Only) key

activates the Cook-N-Hold mode and lights is LED. To verify

the proper hold temperature has been selected, press the

SET key twice. The display will show the hold temperature.

At the end of the cook cycle, an audible alarm will sound, the

display will ash “DONE” and change to count “UP” the time

the oven is on hold. The oven will switch to the programmed

hold temperature.

Setting the cook temperature, hold temperature and time

are done in the same manner. Pressing the SET key will

light the TEMP LED. The operator then sets the temperature

by rotating the dial on the controller until the desired

temperature is shown on the display. Pressing the SET key a

second time will light the HOLD LED and allows the operator

to select the desired hold temperature as shown on the

display. Pressing the SET key a third time lights the TIME

LED and allows the operator to select the desired cook time

as shown on the display. Pressing the SET key a fourth time

ends the programming.

Pressing the START/CANCEL key will start the timing

cycle. When the cycle is completed, pressing the key will

also cancel the “DONE” prompt. To cancel a timing cycle

in progress press and hold the START/CANCEL key for 3

seconds.

Core Probe Operation

The Core Probe option (45+ Controller Only) is only active

when the core probe is plugged into its connector. To set the

core temperature, rst plug the core probe into its connector.

The display will indicate “100” and the CORE TEMP LED will

be on.

The operator then sets the temperature by rotating the dial

on the controller until the desired temperature is shown on

the display. Pressing the SET key stores the core temperature

and starts the cooking process.

To set the oven temperature, press the SET key again. The

TEMP LED will light and the oven temperature can be

set by rotating the dial on the controller until the desired

temperature is displayed. Pressing the Set key again will

light the HOLD LED allowing the operator to set the hold

temperature in the same manner.

NOTE: If the hold temperature is not set, the default

hold temperature is 150°F (66°C) or the last programmed

temperature. (Hold temperature range is 140°F (60°C) to

210°F (99°C).

When the core temperature is reached the display will sound

and ash “DONE” for 3 seconds. Automatically, the display

will switch to count “UP” the time the oven is on hold. To

end this cycle, the core probe must be removed from the

connector.

Setting Setback Feature

To set or change the setback settings, press and hold the

SETBACK key for two seconds. The TEMP LED will light and a

temperature will be displayed. Set the temperature using the

dial, then press the SET key. The TEMP LED will go out and

the TIME LED will light (“Time” is factory set at 0). Set the time

using the dial, then press the SET key. Press the SET key one

more time to exit programming.

Note: To disable the setback function, set the temperature to

250º F (121ºC) and the time to zero.

Part # 1955204 Rev 1 (01/08/09) Page 11

Page 12

PERFORMANCE RECOMMENDATIONS

1. Preheat oven thoroughly (approx. 20 minutes) before use.

2. As a general rule, temperature should be reduced 25°

to 50° from that used in a standard/conventional oven.

Cooking time may also be shorter, so we suggest closely

checking the rst batch of each product prepared.

3. Use the chart of suggested times and temperatures as

a guide. These will vary depending upon such factors

as size of load, temperature, and mixture of product

(particularly moisture) and density of product.

4. Keep a record of the times, temperature, and load sizes

you establish for various products. Once you have

determined these, they will be similar for succeeding

loads.

5. When practical, start cooking the lowest temperature

product rst and gradually work up to higher

temperatures.

6. If you nd that your previous temperature setting is more

than 10° higher than needed for succeeding loads, press

COOL DOWN to reach the desired temperature before

setting a new cooking temperature.

10. When baking, weigh or measure the product in each pan

to assure even cooking.

11. When cooking ve pans, use rack positions 1, 4, 6, 8, and

10 and, starting from the top.

12. Do not overload the oven. Five pans are suggested for

most items, i.e., cakes, cookies, rolls, etc. However, the

maximum (10 pans) may be used for sh sticks, chicken

nuggets and hamburgers. Cooking times will have to be

adjusted.

13. Mun pans should be placed in the oven back to front

or with the short side of the pans facing the front. This

results in the most evenly baked product.

14. When re-thermalizing frozen casseroles, preheat the oven

100° over the suggested temperature. Return to cooking

temperature when the oven is loaded. This will help

compensate for the introduction of a large frozen mass

into the cavity.

15. Use pan extenders or two inch deep 18” x 26” pans for

batter type products which weigh more than eight

pounds, i.e., Pineapple Upside down Cake.

7. When loading oven, work as quickly as possible to

prevent loss of heat.

8. Oven will continue to heat even though the timer goes

o. Product should be removed from the oven as soon as

possible to avoid over cooking.

9. Center pans on racks and load each shelf evenly to allow

for proper air circulation within the cavity.

16. Never place anything directly on the bottom of the oven

cavity. This obstructs the airow and will cause uneven

results.

NOTE: Moisture will escape around the doors when baking

products with heavy moisture content, such as chicken,

potatoes, etc. This is normal.

Part # 1955204 Rev 1 (01/08/09)Page 12

Page 13

PROBLEM/SOLUTIONS

Problem Solution

Cakes are dark on the sides and not done in the center Lower oven temperature

Cakes edges are too brown Reduce number of pans or lower oven temperature

Cakes have light outer color Raise temperature

Cake settles slightly in the center Bake longer or raise oven temperature slightly.

Do not open doors too often or for long periods

Cake ripples Overloading pans or batter is too thin

Cakes are too coarse Lower oven Temperature

Pies have uneven color Reduce number of pies per rack

or eliminate use of bake pans

Cupcakes crack on top Lower oven temperature

Meats are browned and not done in center Lower temperature and roast longer.

Meats are well done and browned Reduce time. Limit amount of moisture

Meats develop hard crust Reduce temperature or place pan of water in oven.

Rolls have uneven color Reduce number or size of pans.

Part # 1955204 Rev 1 (01/08/09) Page 13

Page 14

COOKING GUIDE

The following suggested times and temperatures are provided as a starting guide. Elevation, atmospheric conditions, recipe,

cooking pans, and oven loading may aect your actual results.

PRODUCT TEMPERATURE (°F) TIME

Cakes

White Sheet Cakes – 5 lbs 300° 20 min

White Sheet Cakes – 6 lbs 300° 22 min

Yellow Sheet Cake – 5 lbs 325° 15 min

Chocolate Layer Cake – 21 oz 300° 22 min

Angel Food Cake 375° 22 min

Brownies 350° 15 min

Breads

Soda Biscuits 400° 6 min

Yeast Rolls 325° 24 min

Sweet Bread 325° 24 min

Corn Bread 350° 22 min

Gingerbread 300° 24 min

Apple Turnovers 350° 25 min

Cream Pus 300° 25 min

Sugar Cookies 325° 12 min

Chocolate Chip cookies 375° 8 min

Apple Pie (Fresh) 375° 25 min

Blueberry Pie (Fresh) 350° 30 min

Blueberry Pie (Frozen) 300° 50 min

Pumpkin Pie (Frozen 300° 50 min

Frozen Pizza 300° 6 min

Macaroni & Cheese 350° 15 min

Fish Sticks 350° 16 min

Stued Peppers 350° 45 min

Baked Potatoes 350° 60 min

Meats

Chick Parts 350° 45 min

Hamburger Patties-10/lb frozen 350° 8 min

Hamburger Patties - 10/lb fresh 350° 5 min

Hamburger Patties - 4/lb frozen 350° 12 min

Hamburger Patties – 4/lb fresh 350° 8 min

Meatloaf – 4lb 325° 45 min

Bacon 350° 10 min

Roast Beef 20lb 325° 3 hr 15 min

Prime Rib 10lb 300° 1 hr 45 min

Stued Port chops 350° 45 min

Lamb chops 375° 40 min

Boneless Veal Roast 300° 3 Hr

Part # 1955204 Rev 1 (01/08/09)Page 14

Page 15

COOK AND HOLD

Please refer to the operating instructions to program the 450 and 455 control units for Cook and Hold feature. The times and

temperatures listed below are to be used as a starting guide. Your actual results may vary greatly depending on your elevation,

atmospheric conditions, and other items being cooked at the same time.

TIME IN HOURS

Weight in lbs

8 2.5 3.5 1.5 2 1.25 1.5

9 2.75 3.75 1.75 2.25 1.25 1.75

10 3 4.25 2 2.5 1.5 1.75

11 3.25 4.5 2 2.75 1.5 1.75

12 3.5 5 2.25 3 1.5 2

13 3.75 5 2.5 3.25 1.5 2.25

14 4 5.75 2.5 3.5 1.75 2.5

15 4.25 6 2.75 3.5 2 2.5

16 4.5 6.25 2.75 3.75 2 2.75

17 4.75 6.5 3 4 2.25 2.75

18 4.75 6.75 3.25 4.25 2.25 3

19 5 7.25 3.25 4.25 2.25 3

20 5.25 7.5 3.5 4.5 2.5 3.25

21 5.5 7.75 3.5 4.75 2.75 3.5

22 5.75 7.75 3.5 4.75 2.75 3.5

23 6 8.25 3.75 5 2.75 3.75

24 6 8.75 3.75 5 2.75 3.75

25 6.25 9 4.25 5.5 3 4

26 6.5 9.25 4.25 5.5 3.25 4.25

27 6.75 9.5 4.25 5.75 3.25 4.25

28 7 9.75 4.5 6 3.25 4.25

29 7.25 10 4.75 6.25 3.5 4.5

30 7.25 10.25 4.75 6.25 3.5 4.5

Temperature: 200°F Temperature: 250°F Temperature: 300°F

Rare Medium Rare Medium Rare Medium

Part # 1955204 Rev 1 (01/08/09) Page 15

Page 16

CLEANING AND MAINTENANCE

Note: Disconnect line cord from power supply before

cleaning or servicing.

Break-In Period

When oven is new, operate it for one hour at 375°F (191°C)

before you begin your normal cooking operation. After

cooling, wipe the interior, including the racks, with a clean

damp cloth.

Exterior Cleaning

Establish a regular schedule. Any spills should be wiped o

immediately.

1. The oven should always be allowed to cool suciently

before any cleaning is attempted.

2. Wipe exposed, cleanable surface when cool with a mild

detergent and hot water. Stubborn residue spots may be

removed with a lightweight non-metallic scouring pad.

Dry thoroughly with a clean cloth.

3. Stubborn stains may be removed by using a non-metallic

abrasive pad, rubbing in the direction of the metal’s grain.

If necessary, for particularly heavy deposits, you may mix

a thin paste of water and scouring powder, and apply

it with a sponge. Be careful to apply light pressure and

remember to rub only in the direction of the grain in the

metal.

4. Clean with soap and water using a non-metallic scouring

pad, if necessary. If dirt and grease have accumulated, a

mild ammonia solution or commercial oven cleaner such

as Easy-O or Dow may be used.

5. To reinstall, reverse procedure. Place the bottom of the

rack guide against the cavity wall. Keeping the top pulled

away from the wall lift up. Push the top of the guide

against the wall and push down locking it into place.

Fan Area Maintenance

If aluminum foil is routinely used to wrap food or cooking

vessels during oven operation, the following preventive

maintenance must be performed:

1. Turn power switch to “O” position.

2. Remove oven racks and rack guides.

3. Remove air bae and clean any stains or deposits.

4. Check blower wheel and air bae for particles of

aluminum foil or food deposits. Clean ns of blower

wheel. (Caution: edges of blower wheel ns may be

sharp).

5. Reinstall the air bae, rack guides and oven racks.

This simple practice, if performed on a regular basis will keep

your U.S. Range oven operating at peak performance.

4. The control panel surface is easily cleaned with hot water,

soap and a soft cloth. Do not use hard abrasives, solvent

type materials or metallic scouring pads since these will

scratch or cloud the surface.

5. Never spray the perforated areas or control panel with

steam or water, as this will allow moisture into the control

cavity, which could damage electrical components.

Interior Cleaning

Establish a regular cleaning schedule or wipe o, on the

same day when spill overs occur.

1. Cool down oven.

2. Remove oven racks.

3. Lift rack guides on either side of oven o of holders. Racks

and guides may be run through dishwasher while oven

cavity is being cleaned.

Motor Care

The motor on your convection oven is maintenance free

since it is constructed with self-lubricating sealed ball

bearings. It is designed to provide durable service when

treated with ordinary care. We have a few suggestions

to follow on the care of your motor. When the motor is

operating, it cools itself internally by air entering at the rear

of the motor case, provided proper clearance has been

allowed.

Since the blower wheel is in the oven cavity it is at the same

temperature as the oven. If the motor is stopped while the

oven is hot, the heat from the blower wheel is conducted

down the shaft and into the armature of the motor. This

action could shorten the life of the motor.

Part # 1955204 Rev 1 (01/08/09)Page 16

Page 17

CLEANING AND MAINTENANCE Continued

We recommend, at the end of the bake or roasting period,

when the oven will be idle for any period of time, or before

shutting down completely, that the doors be left open

slightly. On the 45 series controllers press the COOL DOWN

key on the control panel. The fan will continue to run until

the oven cools down to 150°F (66°C).

At the end of the day, press the ON/OFF key, for the 45 series

controllers to activate the Auto Cool Down feature. The fan

will run on high until the oven cavity drops below 150°F

(66°C). When the oven temperature drops below 150°F (66°C)

the oven turns o. This feature protects the oven motor

from pre-mature failure. On the 20 series controllers, push

the rocker switch to COOL position. Once cool set the rocker

switch to OFF.

NOTE: Optional cool-down will be achieved with the door

open slightly.

Part # 1955204 Rev 1 (01/08/09) Page 17

Page 18

Part # 1955204 Rev 1 (01/08/09)Page 18

Page 19

Part # 1955204 Rev 1 (01/08/09) Page 19

Page 20

Loading...

Loading...