U.S. Products TORRENT User Manual

®

TORRENT

HARD SURFACE CLEANER

120V

INFORMATION

&

OPERATING

INSTRUCTIONS

CAUTION: DO NOT OPERATE MACHINE UNTIL YOU HAVE READ

ALL SECTIONS OF THIS INSTRUCTION MANUAL

IMPROPER USE OF THE MACHINE WILL VOID THE WARRANTY

1. DANGER: High pressure may cause sever injury. Always wear safety glasses.

NEVER direct the spray towards yourself, other people, or pets.

2. Never allow the spray to remain fixed in one spot.

3. Before each use, remove the spray tool from the hose, and check to make sure the

spray nozzle is securely tightened in the tool. A loose nozzle could fly off during use.

4. If a leak occurs at the hose, IMMEDIATELY turn the machine off. Replace the hose before

restarting.

5. Always use a defoamer to prevent vacuum motor damage when foaming occurs.

6. Keep the machine from rain in snow, extremes in temperatures, and store it in a heated

location. Use the machine indoors. Do not use outdoors.

7. NEVER adjust the pump above 1200 psi.

56041838

5-2010

IMPORTANT SAFETY INSTRUCTIONS

This machine is only suitable for commercial use, for example in hotels, schools,

hospitals, factories, shops, and offices other than normal residential housekeeping

purposes.

When using any electrical appliance, basic precautions should always be followed,

including the following:

NOTE: Read all instructions before using this machine.

WARNING!

To reduce the risk of fire, electric shock, or injury:

• Never adjust the pump pressure above 1200 psi.

• Do not leave the machine unattended when it is plugged in. Unplug the unit from the outlet

when not in use and before servicing.

• To avoid electric shock, do not expose to rain or snow. Store, and use, indoors.

• Do not allow to be used as a toy. Close attention is necessary when used near children.

• Use only as described in this manual. Use only the manufacturer’s recommended

attachments.

• Do not use with damaged cord or plug. If the machine is not working as it should, has been

dropped, damaged, left outdoors or dropped into water, return it to a service center.

• Do not pull by the cord, use the cord as a handle, close a door on the cord, or pull the cord

around sharp edges or corners. Do not run the machine over the cord. Keep the cord away

from heated surfaces. To unplug, grasp the plug, not the cord.

• Do not handle the plug, the cord or the machine with wet hands.

• Extension cords must be 12/3 and no longer than 50 feet. Replace the cord or unplug

immediately if the ground prong becomes damaged.

• Do not put any object into openings. Do not use with any opening blocked; keep free of

dust, lint, hair, and anything that may reduce air flow.

• Keep loose clothing, hair, fingers, and all parts of body away from openings and moving

parts.

• Do not pick up anything that is burning or smoking, such as cigarettes, matches, or hot

ashes, or any health endangering dusts. Do not use to pick up flammable or combustible

liquids such as gasoline or use in areas where they may be present.

• Turn off all controls before unplugging.

• Connect to a properly grounded outlet only.

• Liquid ejected at the spray nozzle could be dangerous as a result of its temperature,

pressure, and/or chemical content.

INSPECTION:

Carefully unpack and inspect your TORRENT for shipping damage. Each machine is tested and inspected

before shipping. Any shipping damage is the responsibility of the carrier. You should notify the carrier

immediately if you notice damage to the box or to the machine or parts.

CLEANING SOLUTIONS:

Select a proper pre-spray for the surface to be cleaned, and apply the pre-spray. Use a neutral pH rinse

or detergent (5 to 10 pH) in the Torrent to prevent premature wear of the pump, seals, and other

components. Damage caused by the use of improper or strong chemicals is not covered by warranty.

Powders are not recommended.

MAINTENANCE:

For optimum performance, flush the machine with clear water at the end of each working day. Once a

month, minimum, run a flushing compound through the machine to break up any mineral or chemical

build-up that may have formed.

Your Torrent is supplied with an HT Technology Triplex Plunger Pump, specifically designed to handle

rigorous duty cycles and high temperatures. Seal life is expected to be 3000 hours.

This pump has an oil-bath crankcase, and a sight gauge is provided so you can view the oil level through

a small opening in the front of the base compartment, directly below the ammeter gauge. The proper fill

level is shown by a red dot. Oil changes are recommended every 300 hours, and on new machines an

initial oil change is recommended at fifty hours. Use SAE-15W-40 oil. See PUMP MAINTAINENCE for

more information. Note that the hoses above the fill port are on quick disconnects to simplify service.

Vacuum motors typically require brush replacement between 500 - 1000 hours.

Clean the body with an all purpose detergent, and protect it with an automobile interior polish. Lubricate

the wheels, castors, and quick disconnects with an all-purpose silicone spray.

Record the serial number and model of your new extractor here:

(and be sure to register your purchase to active your warranty -- go to www.usproducts.com)

Serial Number: __________________ Model: TORRENT-120

Purchase Date:

Write the name and phone number of your distributor:

____________________________________________________________________

____________________________________________________________________

_____________

KEEP THESE INSTRUCTIONS

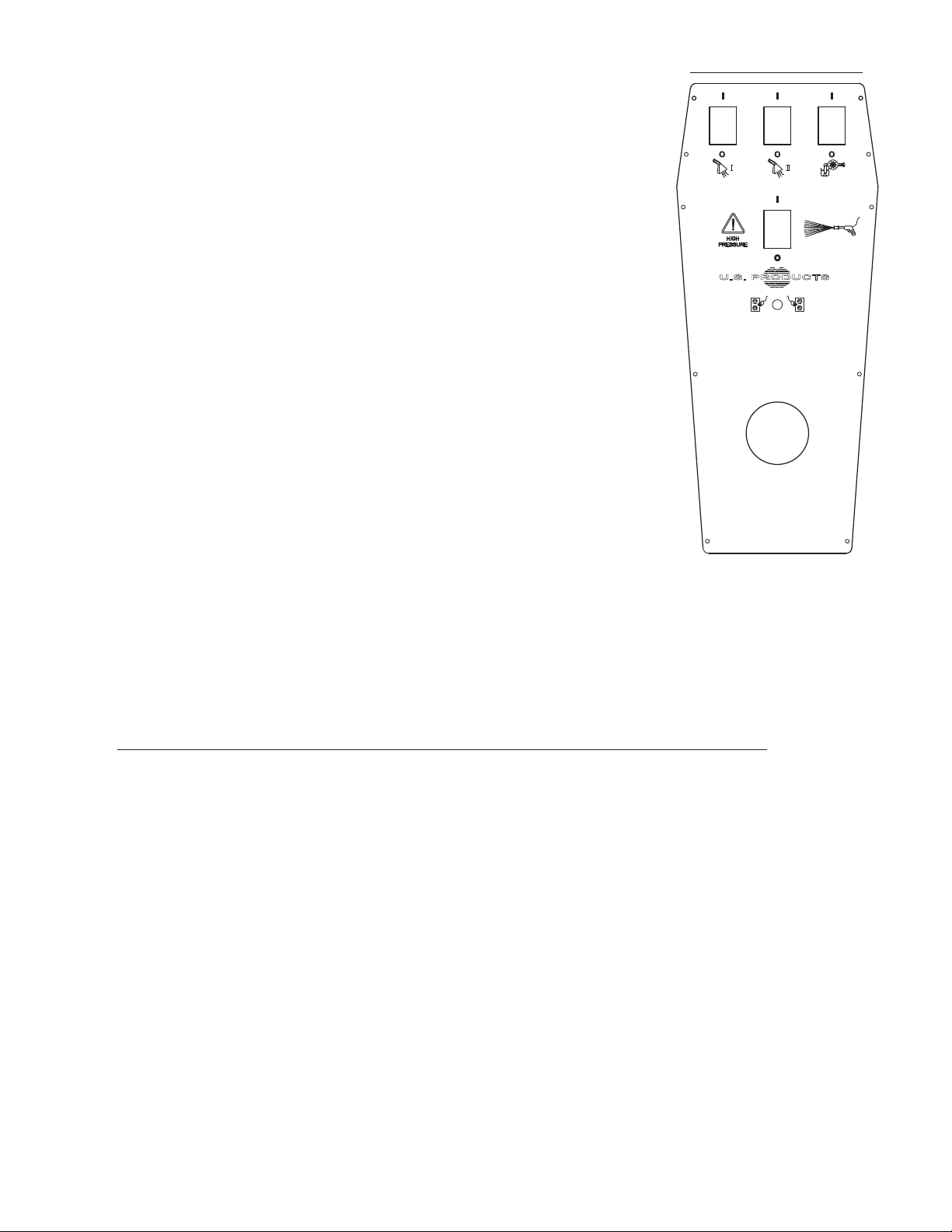

SWITCH PLATE CONTROLS: (refer to Figure 1)

U.S. PRODUCTS

O

O

HIGH

PRESSURE

O

I

I

I

O

I

Vacuum I Switch (1): Turns on/off vacuum motor I.

Vacuum II Switch (2): Turns on/off vacuum motor II.

Dump Pump Switch (3): Turns on/off dump pump. Float switch on

recovery tank automatically turns the pump on when the

solution level in the tank reaches a pre-set level AND the switch is on the ON

position.

High Pressure Pump Switch (4): Turns on/off the high

pressure (400-1200 psi) pump.

Dual Cord Sensor Light (5): The green light will turn on only when the

two power cords are plugged into separate circuits.

Hour Meter (6): Keeps track of the overall time the pump has been in use.

1

6

FIGURE 1

2 3

4

5

FRONT PANEL: (refer to Figure 2)

Pressure Gauge: Measures outlet pressure of high pressure pump in pounds per square inch (psi).

Ammeter: Allows precise adjustment of the pump outlet pressure without overloading the pump mo-

tor. Proper adjustment for maximum pressure is at the break line between green and yellow.

NOTE: Since voltage can vary from one power outlet to another, setting the pressure adjustment based

on amp draw will extend the life of the motor by keeping the current within the correct range.

Pressure Adjustment Knob – Adjusts outlet pressure between 400 – 1200 psi. Note: you must

trigger the tool and spray to see adjustment of pressure. Clockwise increases and counterclockwise

decreases pressure. Let the pump run for about one minute, then adjust the pump using the ammeter

for maximum pressure (set at the break line between green and yellow). For lower pressure, down to

400 psi, simply turn the knob counterclockwise - while spraying - and watch the pressure gauge.

High Pressure Quick Disconnect – Attachment for high pressure solution line.

Auto-Dump Hose Fitting – Male garden hose fitting to attach dump hose.

Direct Feed-Hose Fitting – Female garden hose fitting to attach the direct water feed-hose.

The feed hose has a chemical siphon system and backflow preventer at the faucet end of hose.

Oil Level View Port - Allows viewing of the pump oil level sight-gauge.

4

Loading...

Loading...