U.S. Products PB111-120, PB111-120-DZ, PB111-120-S, PB111-120-B, PB111-120-SP Operating Instructions Manual

...

THE ULTIMATE: PB111

https://harrissupplyind.com - To Order Parts Call 608-268-8080

EXTRACTOR

INFORMATION AND

OPERATING

INSTRUCTIONS

MODELS: PB111-120, PB111-120-DZ, PB111-120-S,

PB111-120-B, PB111-120-SP, PB111-120-SS,

PB111-240

CAUTION: DO NOT OPERATE MACHINE UNTIL YOU HAVE READ

ALL SECTIONS OF THIS INSTRUCTION MANUAL

IMPROPER USE OF THE MACHINE WILL VOID THE WARRANTY

1. Never use the Booster Heat when solvent is in the machine.

2. Never attempt to heat solvent above 130 °F.

3. Always use a nonfl ammable solvent with a fl ash point of 140 °F or higher.

DO NOT SMOKE WHEN USING HYDROCARBON-BASED SOLVENTS.

Even solvents with a fl ash point above 140 °F can be ignited, especially as an aerosol from the wand.

4. The recovery bucket should be emptied each time the holding tank is fi lled.

5. Always make sure the fl oat travels freely up and down the rod after emptying the recovery bucket.

6. Always vacuum out the stainless steel tank and solution lines when switching from a solvent to a

water based detergent, and vice versa (see Operating Instructions).

7. Always use a drop cloth under the machine during operation.

8. Vacuum any unused solution out of the solution tank and empty the recovery bucket after each job.

9. Keep machine from rain and snow, extremes in temperatures, and store in a heated location.

Use the machine indoors. Do not use outdoors.

10. Do not run the pump dry.

11. Never operate a machine that is leaking or in need of a repair.

12. Always use a defoamer. The vacuum shut-off will not activate properly if foam is in the recovery

bucket. Water damage to the vacuum motor or other components will void the warranty.

If you have any questions before you operate the machine, call your supplier for instruction.

12/10 revised 5/14 FROM NO. 56041875 REV B

INSTRUCTIONS FOR USEA - ENGLISH

https://harrissupplyind.com - To Order Parts Call 608-268-8080

revised 6/12

INTRODUCTION

This manual will help you get the most from your equipment. Read it thoroughly before operating the machine.

This product is intended for commercial use only.

PARTS AND SERVICE

Repairs, when required, should be performed by your Authorized Service Center, who employs factory trained service personnel, and maintains an

inventory of original replacement parts and accessories.

Call for repair parts or service. Please specify the Model and Serial Number when discussing your machine.

MODIFICATIONS

Modifi cations and additions to the cleaning machine which affect capacity and safe operation shall not be performed by the customer or user

without prior written approval from the manufacturer. Unapproved modifi cations will void the machine warranty and make the customer liable for

any resulting accidents.

NAMEPLATE

The Model and Serial Number of your machine are shown on the Nameplate. This information is needed when ordering repair parts for the

machine. Use the space below to note the Model and Serial Number of your machine for future reference.

Model _________________________________________

Serial Number ___________________________________

UNPACKING THE MACHINE

When the machine is delivered, carefully inspect the shipping carton and the machine for damage. If damage is evident, save the shipping carton

so that it can be inspected.

CLEANING SOLUTIONS:

The PB111 is capable of either wet or dry cleaning. Only liquid cleaners are recommended (no powders). Solvents with a fl ash point of 140° F or

higher are required for safety. Solvents are normally used full strength. Water based cleaners are normally diluted. Follow label directions. The

stainless steel holding tank can be fi lled with up to 3 gal. of cleaning solution.

WARNING!

The Products sold with this Manual contain or may contain chemicals that are known to certain governments (such as the State of California, as

identifi ed in its Proposition 65 Regulatory Warning Law) to cause cancer, birth defects or other reproductive harm. In certain locations (including

the State of California) purchasers of these Products that place them in service at an employment job site or a publicly accessible space are

required by regulation to make certain notices, warnings or disclosures regarding the chemicals that are or may be contained in the Products at

or about such work sites. It is the purchaser’s responsibility to know the content of, and to comply with, any laws and regulations relating to the

use of these Products in such environments. The Manufacturer disclaims any responsibility to advise purchasers of any specifi c requirements that

may be applicable to the use of the Products in such environments.

A - 2 PB111 - 56041875 12/10

revised 6/12

https://harrissupplyind.com - To Order Parts Call 608-268-8080

ENGLISH - A INSTRUCTIONS FOR USE

IMPORTANT SAFETY INSTRUCTIONS

This machine is only suitable for commercial use, for example in hotels, schools, hospitals, factories, shops and offi ces other than

normal residential housekeeping purposes.

When using any electrical appliance, basic precautions should always be followed, including the following:

NOTE: Read all instructions before using this machine.

WARNING!

To reduce the risk of fi re, electric shock, or injury:

• Do not leave the machine unattended when it is plugged in. Unplug the unit from the outlet when not in use and before

servicing.

• To avoid electric shock, do not expose to rain or snow. Store, and use, indoors.

• Do not allow to be used as a toy. Close attention is necessary when used near children.

• Use only as described in this manual. Use only the manufacturer’s recommended attachments.

• Never add water over 130º F/54º C to the solution tank.

• Do not use with damaged cord or plug. If the machine is not working as it should, has been dropped, damaged, left outdoors or

dropped into water, return it to a service center.

• Do not pull by the cord, use the cord as a handle, close a door on the cord, or pull the cord around sharp edges or corners. Do

not run the machine over the cord. Keep the cord away from heated surfaces. To unplug, grasp the plug, not the cord.

• Do not handle the plug, the cord or the machine with wet hands.

• Extension cords must be 12/3 and no longer than 50 feet. Replace the cord or unplug immediately if the ground prong becomes

damaged.

• Do not put any object into openings. Do not use with any opening blocked; keep free of dust, lint, hair, and anything that may

reduce air fl ow.

• Keep loose clothing, hair, fi ngers, and all parts of body away from openings and moving parts.

• Do not pick up anything that is burning or smoking, such as cigarettes, matches, or hot ashes, or any health endangering dusts.

Do not use to pick up fl ammable or combustible liquids such as gasoline or use in areas where they may be present.

• Turn off all controls before unplugging.

• Use extra care when cleaning on stairs.

• Connect to a properly grounded outlet only.

• Liquid ejected at the spray nozzle could be dangerous as a result of its temperature, pressure,or chemical content.

• Use a respirator and gloves when using dry cleaning solvents. In addition, a fan or blower is helpful to blow fumes away from

the operator.

• Always work in a well ventilated area.

• Always work with the exhaust hose attached to the machine when using solvents.

12/10 A - 3 56041875 - PB111

SAVE THESE INSTRUCTIONS

INSTRUCTIONS FOR USEA - ENGLISH

https://harrissupplyind.com - To Order Parts Call 608-268-8080

revised 5/14

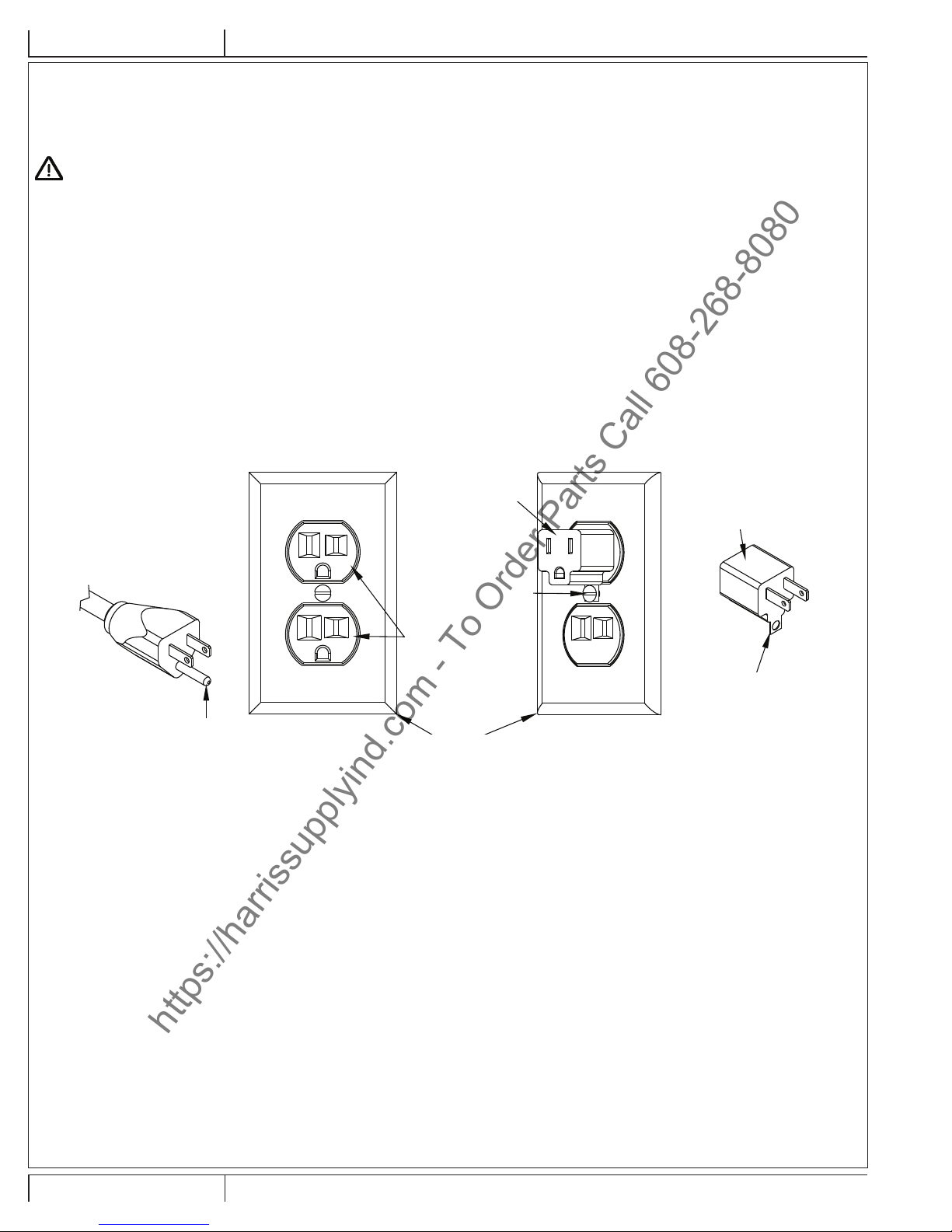

120VAC GROUNDING INSTRUCTIONS

This appliance must be grounded. If it should electrically malfunction, grounding provides a path of least resistance for electric current to reduce

the risk of electric shock. This appliance is equipped with a cord having an equipment-grounding conductor and grounding plug. The plug must be

plugged into an appropriate outlet that is properly installed and grounded in accordance with all local codes and ordinances.

DANGER!

Improper connection of the equipment-grounding conductor can result in a risk of electric shock. Check with a qualifi ed electrician or

service person if you are in doubt as to whether the outlet is properly grounded. Do not modify the plug provided with the appliance.

If it will not fi t the outlet, have a proper outlet installed by a qualifi ed electrician.

This appliance is for use on a nominal 120-volt circuit, and has a grounding plug that looks like the plug illustrated in Figure 1 below. A temporary

adapter illustrated in Figures 2 and 3 may be used to connect this plug to a 2-pole receptacle as shown in Figure 2 if a properly grounded outlet is

not available. The temporary adapter should be used only until a properly grounded outlet (Figure 1) can be installed by a qualifi ed electrician. The

green-colored rigid ear, tab, or the like extending from the adapter must be connected to a permanent ground such as a properly grounded outlet

box cover. Whenever the adapter is used, it must be held in place by a metal screw. Grounding adapters are not approved for use in Canada.

Replace the plug if the grounding pin is damaged or broken.

The Green (or Green/Yellow) wire in the cord is the grounding wire. When replacing a plug, this wire must be attached to the grounding pin only.

Extension cords connected to this machine should be 12 gauge, three-wire cords with three-prong plugs and outlets. DO NOT use extension

cords more than 50 feet (15 m) long.

PLEASE NOTE: FOR NORTH AMERICA ONLY

Adapter

Grounding Pin

FIGURE 1

Metal Screw

Grounded Outlet

Grounded Outlet Box

FIGURE 2

Adapter

Tab for Grounding Screw

FIGURE 3

A - 4 PB111 - 56041875 12/10

revised 6/12

https://harrissupplyind.com - To Order Parts Call 608-268-8080

ENGLISH - A INSTRUCTIONS FOR USE

SET-UP:

1 Make sure the recovery bucket is in place under the dome and in the correct position. The dome must be fl at or it won’t seal properly.

2 Fill the stainless steel holding tank with cleaning solution, to the desired level. Solution must be at least 3” above the fi lter in the bottom of

the tank. NOTE: Attach the exhaust hose when dry cleaning.

3 Position the cleaning tool over the holding tank, and depress the trigger. Turn the pump on (center switch). Allow the solution to spray for

several seconds, to fi ll the lines.

4 SOLVENT HEATING: turn on the Heater switch only. Make sure the Booster Heat switch is turned completely off. Wait two minutes for the

heater to reach operating temperature. Spray over the holding tank again, for about 15 seconds, to preheat the solution line and the tool.

NOTE: the heat will shut off completely if the Booster Heat is turned on with solvent in the tank. Go to Step 5.

WATER HEATING: turn on the Heater switch, and position the Booster switch to the desired temperature. Wait 2 minutes for the heater to

reach operating temperature. Spray over the holding tank for 15 seconds to preheat the solution line and the tool. Wait 30 seconds, then

spray again for 15 seconds. Go to Step 5.

5 Turn on the Vacuum switch (fi rst switch). All rocker switches should be turned on now. You are now ready to begin cleaning.

6 When the recovery bucket is full, the vacuum will automatically shut off. Turn the vacuum switch off. Remove the dome and lift the bucket

out. Empty the bucket, and wipe off any spillage from the outside of the bucket. Reinstall the recovery bucket and the dome.

7 Make sure the fl oat in the bucket travels freely up and down the rod each time you empty the recovery bucket.

TO SWITCH CHEMICAL BASE

8 When switching from a solvent-based product to a water-based detergent, or vice versa, use the following procedure: turn off all the

switches, except the vacuum switch. Leave the vacuum hose in the dome, and disconnect the hoses from the tool. Place the open end of

the vacuum hose into the solution tank, and vacuum out any remaining solution. Place the hose over the fi lter in the tank for 10 seconds.

9 Connect the end of the solution line to the black suction plug. Take the vacuum hose out of the dome, and place the plug in its place. Let the

vacuum run for 20 - 30 seconds to pull all the solution out of the lines and the heater. NOTE: DO NOT LET THE PUMP RUN DRY.

MAINTENANCE:

For optimum performance, fl ush the machine with clear water at the end of each working day. Once a month, minimum, run a fl ushing compound

through the machine to break up any mineral or chemical build-up that may have formed. Clean the fl oat rod each time the recovery bucket is

emptied. Inspect the fi lters regularly and clean as needed. The vacuum fi lter is located under the recovery bucket. The solution fi lter is located at

the bottom of the holding tank. The quick disconnects and castors can be lubricated with a penetrating spray lubricant. Fine steel wool will keep

the brass quick disconnects shinning. An auto interior spray cleaner/protectant will work well to keep the body clean and bright.

12/10 A - 5 56041875 - PB111

INSTRUCTIONS FOR USEA - ENGLISH

https://harrissupplyind.com - To Order Parts Call 608-268-8080

revised 6/12

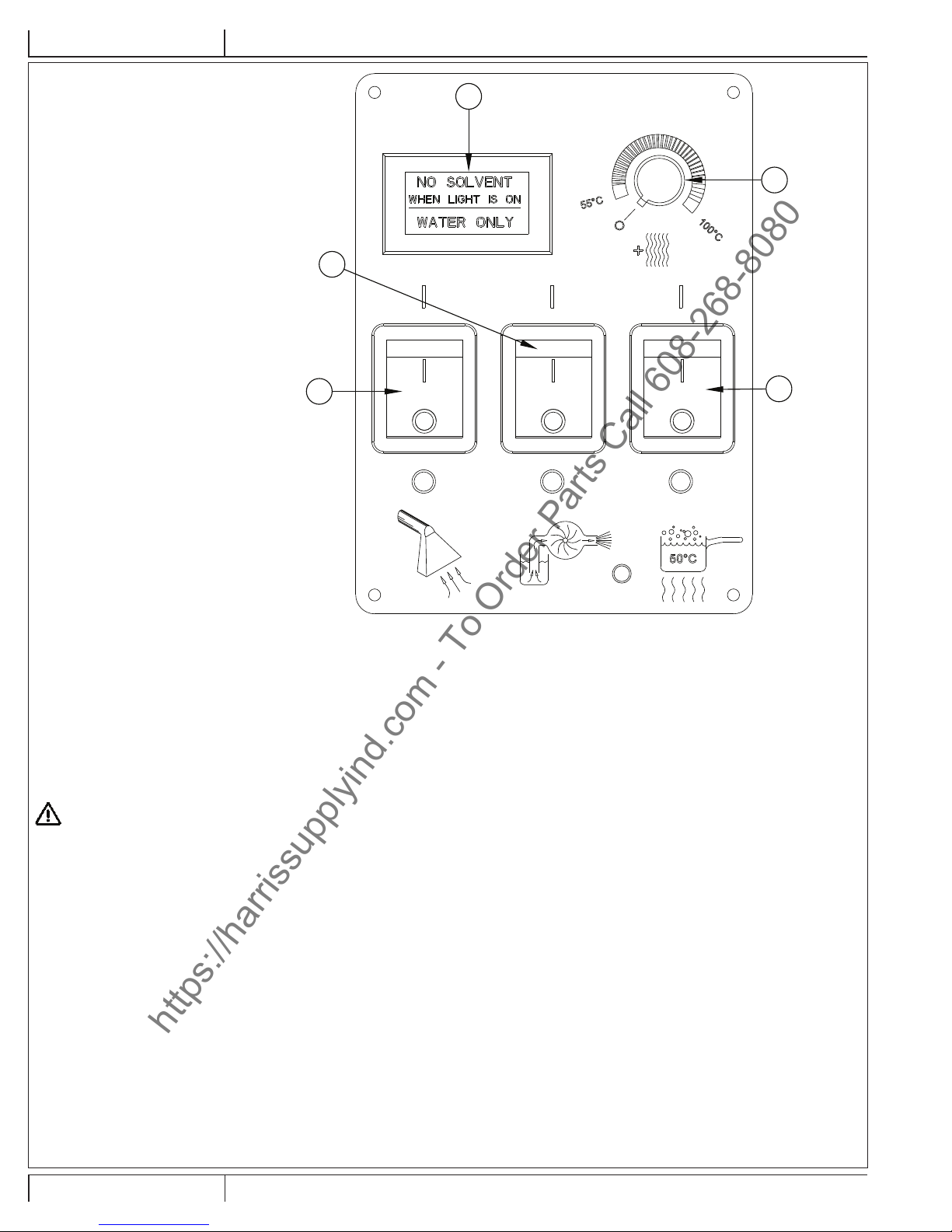

B

E

C

A

A VACUUM

B WARNING INDICATOR

C PUMP

D HEAT

E BOOSTER HEAT

SOLVENT HEATING

Turn on the Heater Switch (D). The Booster Heat switch (E) must be all the way off (turned counterclockwise until it ‘clicks’ off) or the machine will

not heat at all.

WATER HEATING

Turn on the Heater Switch (D). Turn on the Booster Heat Switch (E) to the desired temperature, 130° - 212°F (55° - 100°C)

NOTE: Booster Heat will not work unless the Heat switch is on.

WATER ONLY, NO SOLVENT (E)

This indicator light (B) illuminates when the Booster Heat switch (E) is turned on. It is a reminder that the Booster Heat will only work with waterbased solutions.

D

CAUTION

USE A RAG TO DISCONNECT BRASS FITTINGS AFTER USING THE BOOSTER HEAT. THE FITTINGS CAN GET VERY HOT AND MAY

CAUSE MINOR BURNS.

AUTO VAC SHUT-OFF

When the recovery bucket is full, the vacuum motor will automatically shut off. The fl oat in the bucket may not be raised by foam. Defoamer must

always be used to avoid water damage to the vacuum motor.

SOLVENT SENSING SYSTEM

This unique, patented system determines whether there is solvent or water-based solution in the tank. If solvent is used, the sensor will

automatically prevent heating above 140 °F. To prevent accidental over-heating of solvent, the use of the Booster heat switch - with solvent in the

tank - will cause the entire heat system to shut off.

A - 6 PB111 - 56041875 12/10

Loading...

Loading...