U.S. Products KING COBRA 1200 PRO, King Cobra 1200 KC-1200, King Cobra 1200 KC-1200-TFGREEN, King Cobra 1200 Information And Operating Instructions

King Cobra® 1200 Pro

INFORMATION AND

OPERATING

INSTRUCTIONS

MODELS: KC-1200-500, 56380570, KC-1200-500-DZ

KC-1200-500-B, KC-1200-500-S

CAUTION: DO NOT OPERATE MACHINE UNTIL YOU HAVE READ

ALL SECTIONS OF THIS INSTRUCTION MANUAL

PRECAUCIÓN: NO UTILICE LA MÁQUINA HASTA HABER LEÍDO

TODAS LAS SECCIONES DE ESTE MANUAL DE INSTRUCCIONES

ATTENTION : N’UTILISEZ PAS LA MACHINE AVANT D’AVOIR LU

TOUTES LES SECTIONS DU PRÉSENT MANUEL

IMPROPER USE OF THE MACHINE WILL VOID THE WARRANTY

EL USO INCORRECTO DE LA MÁQUINA ANULARÁ LA GARANTÍA

UNE UTILISATION INCORRECTE DE LA MACHINE ANNULERA LA GARANTIE

3/10 revised 11/12 FORM NO. 56041959

INSTRUCTIONS FOR USEA - ENGLISH

TABLE OF CONTENTS

Page

Introduction ......................................................................................... A-3

Parts and Service ................................................................................. A-3

Nameplate ............................................................................................ A-3

Uncrating the Machine .......................................................................... A-3

Important Safety Instructions ................................................................ A-4

Grounding Instructions .........................................................................A-5

Know Your Machine...................................................................A-6 – A-7

Control Panel ........................................................................................ A-7

Set-Up and Operation ............................................................A-10 – A-11

1200PSI High Pressure Washer ...................................................A-8 - A-9

500PSI and Heat ...................................................................... A-10 - A-11

Auto-Fill .............................................................................................. A-12

Auto-Dump ......................................................................................... A-12

After Use

After Using the Machine ..................................................................... A-13

Maintenance

Maintenance Schedule ....................................................................... A-13

Power Cord Maintenance ................................................................... A-13

Troubleshooting .................................................................................. A-14

Technical Specifi cations ..................................................................... A-14

SECTION II – Parts List ........................................................... D-1 - D-11

Base Assy ....................................................................................D-2 - D-3

Holding Tank Assy ....................................................................... D-4 - D-5

Vacuum Tank Assy ......................................................................D-6 - D-7

Plumbing System .........................................................................D-8 - D-9

Water Flow Diagram ................................................................ D-10 - D-11

A-2 KING COBRA® 1200 PRO - 56041959 3/10

ENGLISH - AINSTRUCTIONS FOR USE

INTRODUCTION

This manual will help you get the most from your extractor. Read it thoroughly before operating the machine.

Note: Bold numbers in parentheses indicate an item illustrated on page A-6 unless otherwise noted.

This product is intended for commercial use only.

PARTS AND SERVICE

Repairs, when required, should be performed by your Authorized Service Center, who employs factory trained service personnel, and maintains an inventory of

original replacement parts and accessories.

Call for repair parts or service. Please specify the Model and Serial Number when discussing your machine.

MODIFICATIONS

Modifi cations and additions to the cleaning machine which affect capacity and safe operation shall not be performed by the customer or user without prior written

approval from the manufacturer. Unapproved modifi cations will void the machine warranty and make the customer liable for any resulting accidents.

NAMEPLATE

The Model and Serial Number of your machine are shown on the Nameplate. This information is needed when ordering repair parts for the machine. Use the

space below to note the Model and Serial Number of your machine for future reference.

Model ______________________________________________

Serial Number ________________________________________

UNPACKING THE MACHINE

When the machine is delivered, carefully inspect the shipping carton and the machine for damage. If damage is evident, save the shipping carton so that it can be

inspected.

WARNING!

The Products sold with this Manual contain or may contain chemicals that are known to certain governments (such as the State of California, as identifi ed in

its Proposition 65 Regulatory Warning Law) to cause cancer, birth defects or other reproductive harm. In certain locations (including the State of California)

purchasers of these Products that place them in service at an employment job site or a publicly accessible space are required by regulation to make certain

notices, warnings or disclosures regarding the chemicals that are or may be contained in the Products at or about such work sites. It is the purchaser’s

responsibility to know the content of, and to comply with, any laws and regulations relating to the use of these Products in such environments. The Manufacturer

disclaims any responsibility to advise purchasers of any specifi c requirements that may be applicable to the use of the Products in such environments.

3/10 A-3 56041959 - KING COBRA® 1200 PRO

INSTRUCTIONS FOR USEA - ENGLISH

IMPORTANT SAFETY INSTRUCTIONS:

This machine is only suitable for commercial use, for example in hotels, schools, hospitals, factories, shops and offi ces other than normal

residential housekeeping purposes.

When using any electrical appliance, basic precautions should always be followed, including the following:

NOTE: Read all instructions before using this machine.

WARNING!

To reduce the risk of fi re, electric shock, or injury:

•

Before each use, remove the spray tool from the hose, and check to make sure the spray nozzles are securely tightened

to the spray tool. A loose nozzle could fl y off during use.

• Never use solvents.

• Do not leave the machine unattended when it is plugged in. Unplug the unit from the outlet when not in use, and before

servicing.

• To avoid electric shock, do not expose to rain or snow. Store, and use, indoors.

• Do not allow the machine to be used as a toy. Close attention is necessary when used near children.

• Use only as described in this manual. Use only the manufacturer’s recommended attachments.

• Never add water over 130 °F/54 °C to the Holding Tank.

• If the machine is not working as it should, has been dropped, damaged, left outdoors, or dropped into water, return it to a service

center.

• Do not pull by the cord, use the cord as a handle, close a door on the cord, or pull the cord around sharp edges or corners. Do

not run the machine over the cord. Keep the cord away from heated surfaces. To unplug, grasp the plug, not the cord.

• Do not handle the plug, the cord, or the machine with wet hands.

• Extension cords must be 12/3 and no longer than 50 feet.

• Do not use with a damaged cord or cord end. If the cord or plug becomes damaged have it repaired immediately by an

authorized service center.

• Do not put any object into openings. Do not use with any opening blocked; keep free of dust, lint, hair, and anything that may

reduce air fl ow.

• Keep loose clothing, hair, fi ngers, and all parts of body away from openings and moving parts.

• Do not pick up anything that is burning or smoking, such as cigarettes, matches, or hot ashes, or any health endangering dusts.

Do not use the machine to pick up fl ammable or combustible liquids such as gasoline or use it in areas where they may be

present.

• Turn off all controls before unplugging.

• Use extra care when cleaning on stairs.

• Connect to a properly grounded outlet only.

• Liquid ejected at the spray nozzle could be dangerous as a result of its temperature, pressure, or chemical content. Use caution.

• Always read chemical MSDS sheets before use.

SAVE THESE INSTRUCTIONS

A-4 KING COBRA® 1200 PRO - 56041959 3/10

revised 5/12

ENGLISH - AINSTRUCTIONS FOR USE

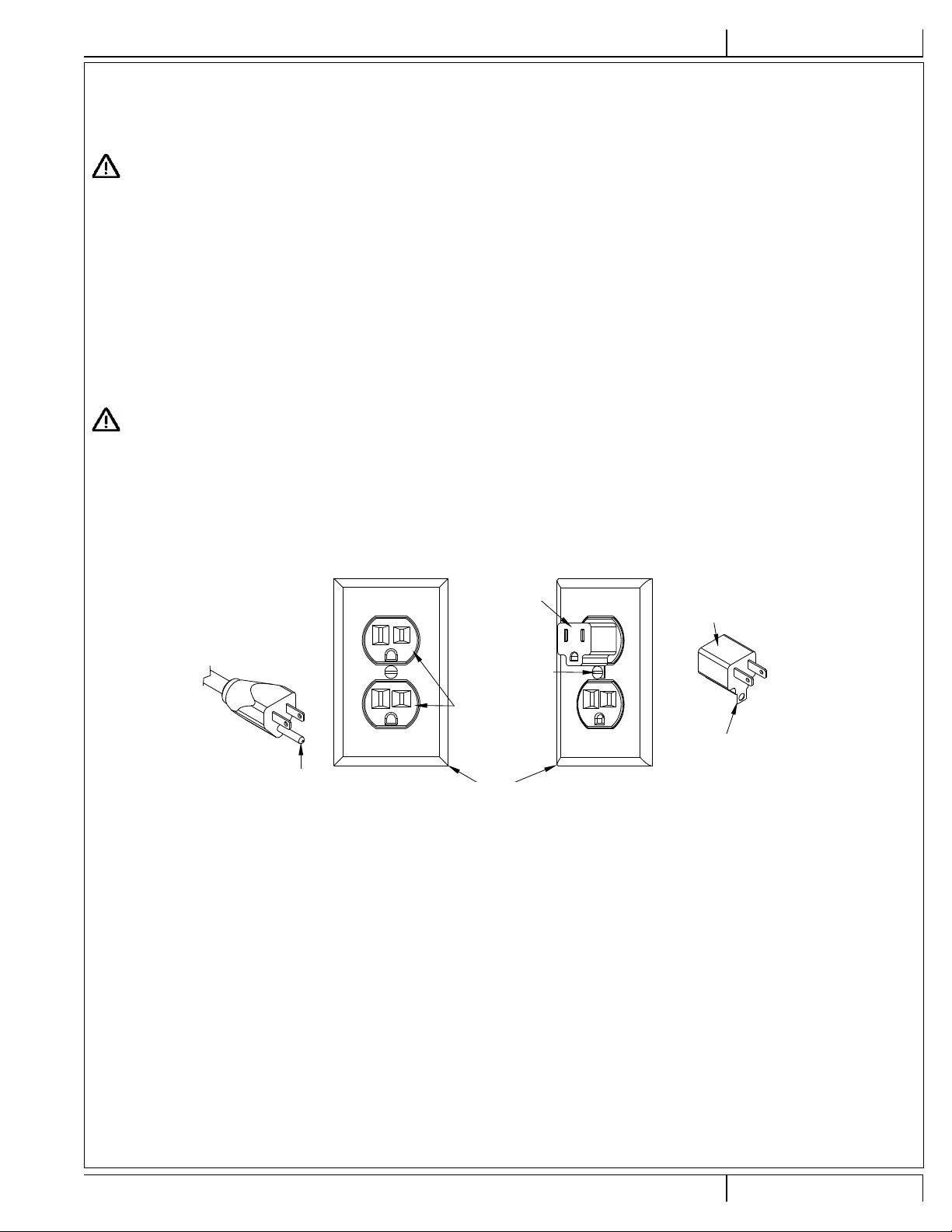

120VAC GROUNDING INSTRUCTIONS

This appliance must be grounded. If it should electrically malfunction, grounding provides a path of least resistance for electric current to reduce the risk of electric

shock. This appliance is equipped with a cord having an equipment-grounding conductor and grounding plug. The plug must be plugged into an appropriate outlet

that is properly installed and grounded in accordance with all local codes and ordinances.

DANGER!

Improper connection of the equipment-grounding conductor can result in a risk of electric shock. Check with a qualifi ed

electrician or service person if you are in doubt as to whether the outlet is properly grounded. Do not modify the plug

provided with the appliance. If it will not fi t the outlet, have a proper outlet installed by a qualifi ed electrician.

This appliance is for use on a nominal 120-volt circuit, and has a grounding plug that looks like the plug illustrated in Figure 1 below. A temporary adapter

illustrated in Figures 2 and 3 may be used to connect this plug to a 2-pole receptacle as shown in Figure 2 if a properly grounded outlet is not available. The

temporary adapter should be used only until a properly grounded outlet (Figure 1) can be installed by a qualifi ed electrician. The green-colored rigid ear, tab, or

the like extending from the adapter must be connected to a permanent ground such as a properly grounded outlet box cover. Whenever the adapter is used, it

must be held in place by a metal screw. Grounding adapters are not approved for use in Canada.

Replace the plug if the grounding pin is damaged or broken.

The Green (or Green/Yellow) wire in the cord is the grounding wire. When replacing a plug, this wire must be attached to the grounding pin only.

Extension cords connected to this machine should be 12 gauge, three-wire cords with three-prong plugs and outlets. DO NOT use extension cords more than 50

feet (15 m) long.

WARNING!

• If an extension cord is used, the plug and socket must be of watertight construction.

• Inadequate extension cords can be dangerous.

PLEASE NOTE: FOR NORTH AMERICA ONLY

Grounding Pin

FIGURE 1

Adapter

Metal Screw

Grounded Outlet

Grounded Outlet Box

FIGURE 2

Adapter

Tab for Grounding Screw

FIGURE 3

3/10 A-5 56041959 - KING COBRA® 1200 PRO

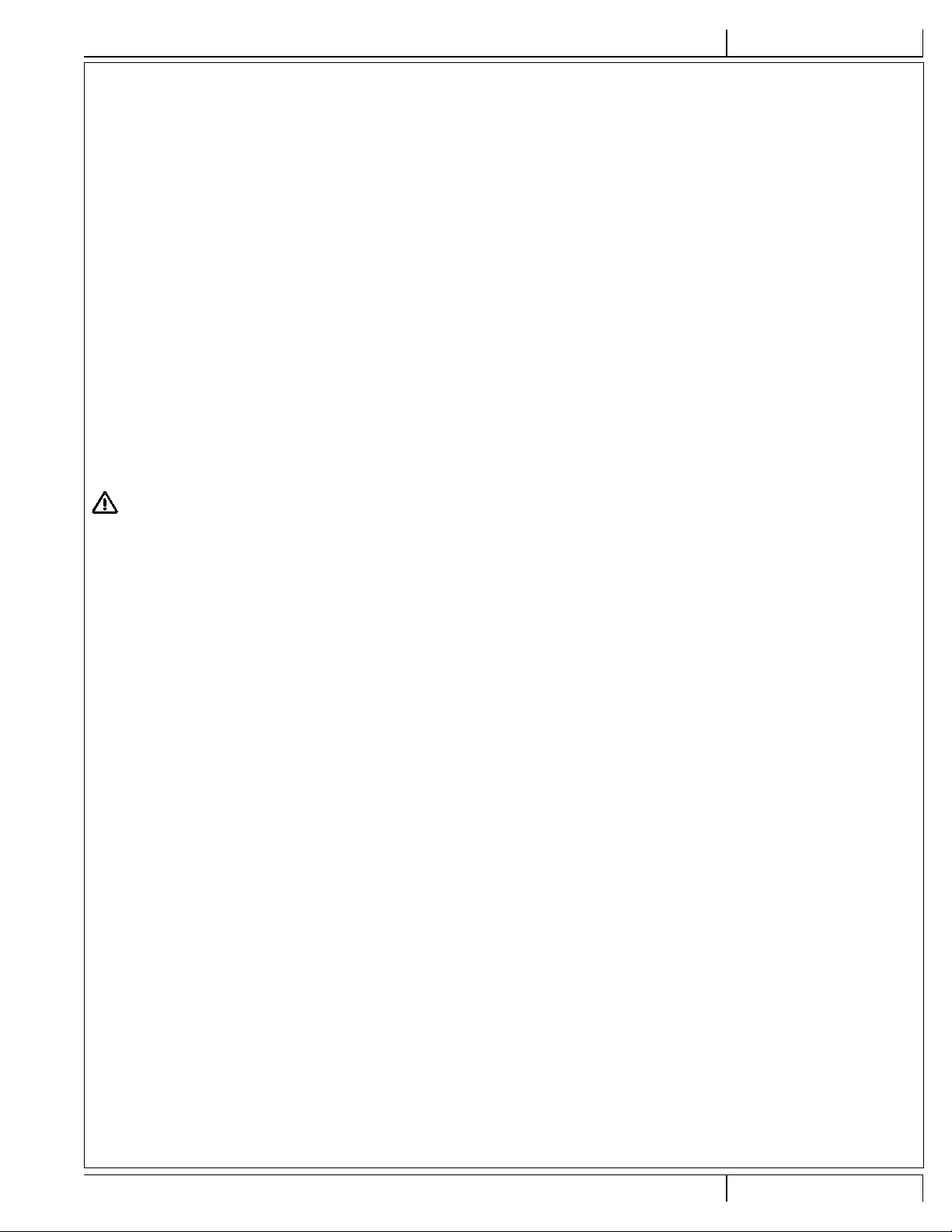

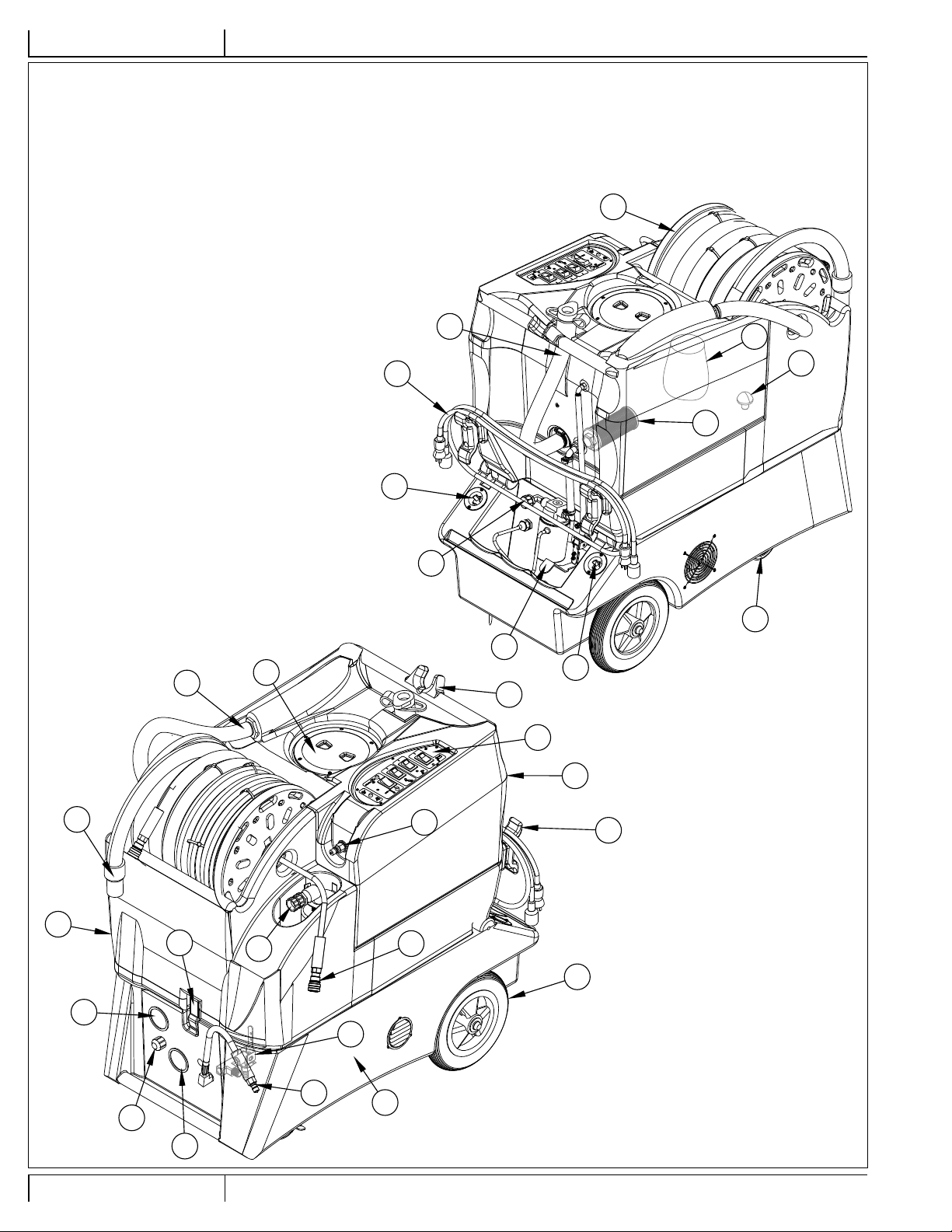

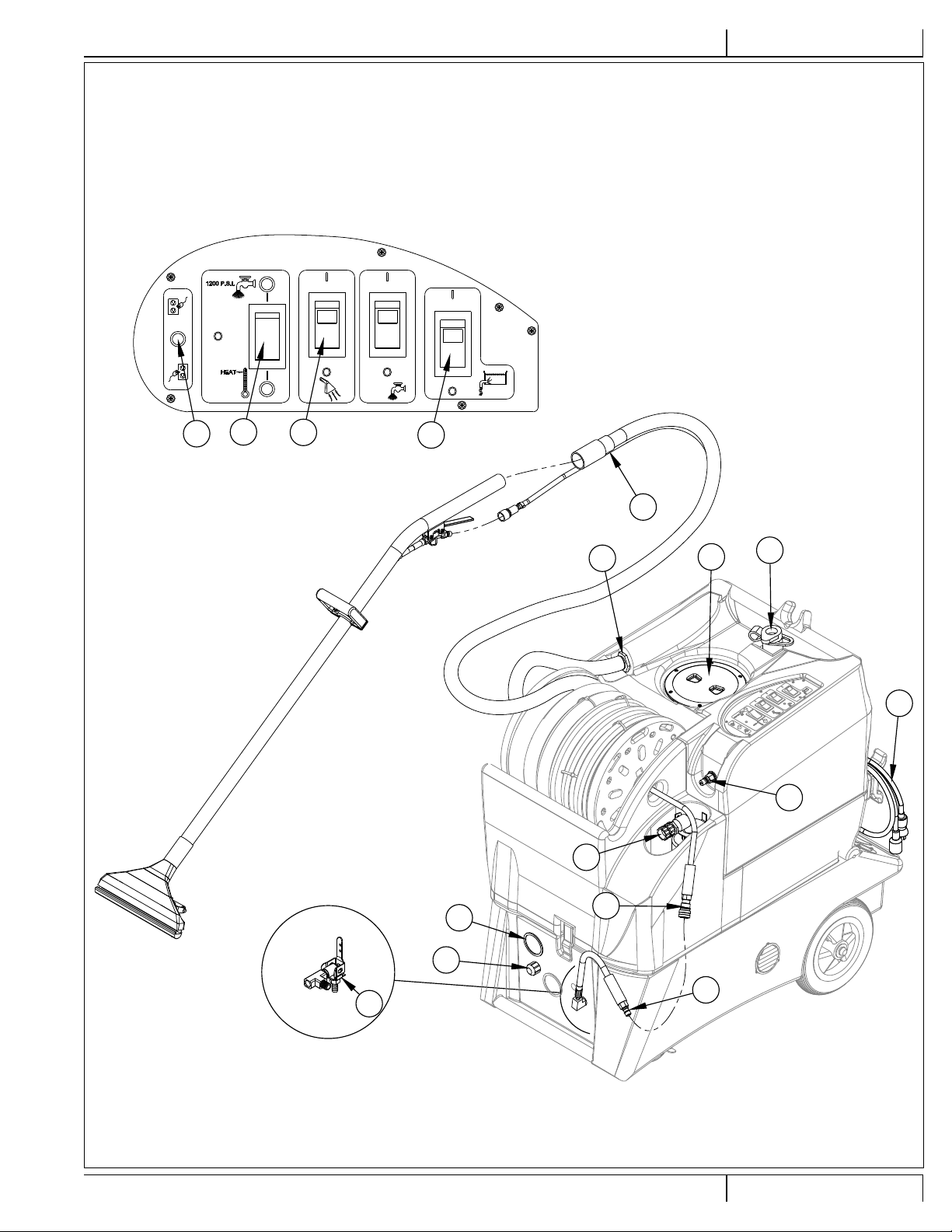

KNOW YOUR MACHINE

1 Vacuum Hose Connection

2 Recovery Tank Lid

3 Wand Holder

4 Control Panel

5 Recovery Tank

6 1200PSI Quick Connect

7 Auto-Fill Hose Connector

8 Rear Wheel

9 Base Compartment

10 500PSI Quick Connect

11 1200PSI Gauge

12 500PSI Gauge

13 500PSI Pressure Adjust Knob

14 Holding Tank

15 Tank Latch

16 Vacuum Hose Reel

17 Recovery Tank Drain Hose

18 Dump Hose Connection

19 Power Cord Receptacle

20 Power Prime Pedal

21 Front Castor with Brake

22 Power Cords

23 Pressure Relief Valve

24 Solution Hose

25 Dump Pump Inlet Filter

26 Pump Inlet Filter

27 Pre-Filter Bag

28 Vacuum Hose

29 Cord Hooks

INSTRUCTIONS FOR USEA - ENGLISH

16

17

22

27

26

25

19

18

14

28

12

15

21

20

1

2

3

19

4

5

6

7

24

29

8

23

10

9

13

11

A-6 KING COBRA® 1200 PRO - 56041959 3/10

ENGLISH - AINSTRUCTIONS FOR USE

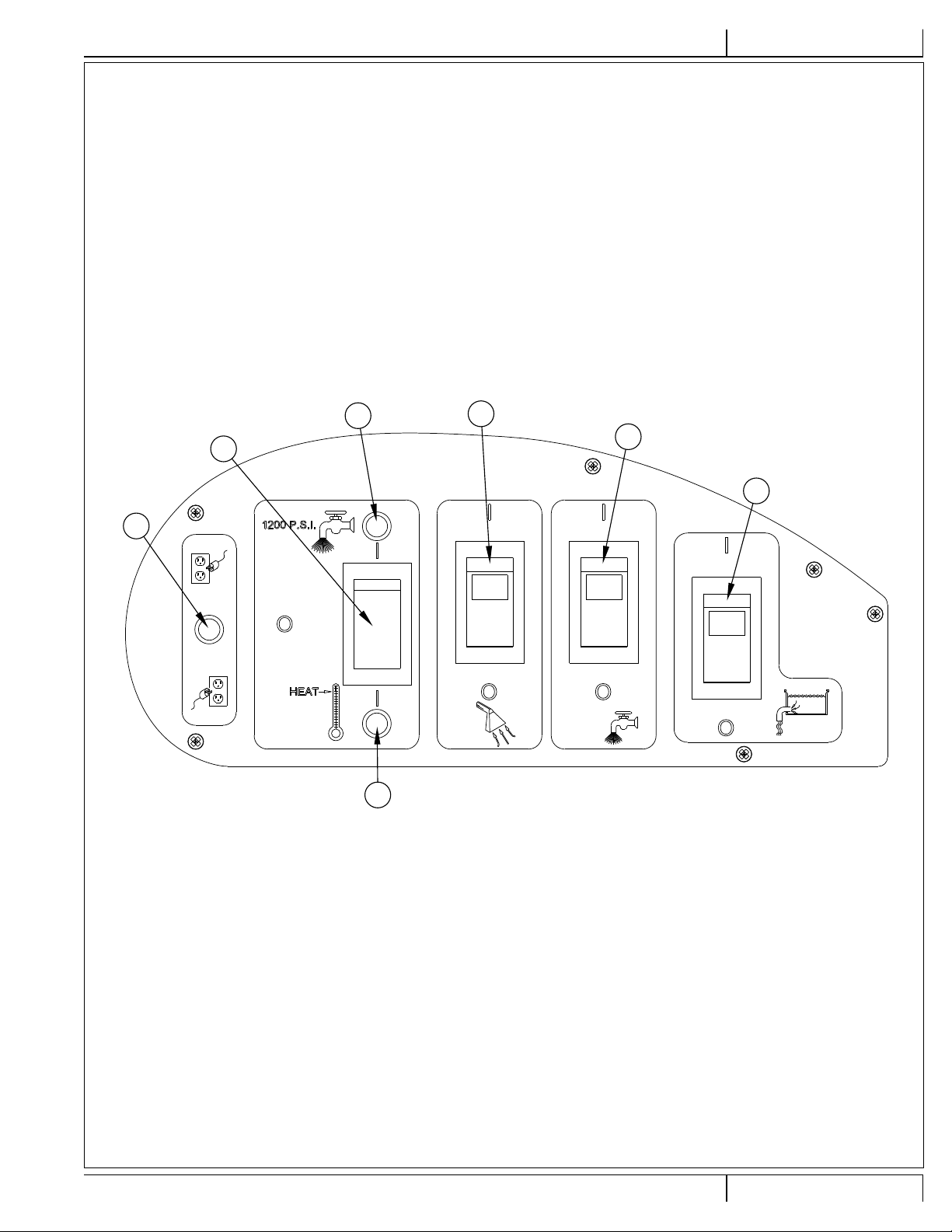

CONTROL PANEL

A Separate Circuit Locator Light: This green light will turn on when the two power cords are plugged into separate circuits. Try different outlets with

one cord until you can get a green light, otherwise a circuit breaker in the wall may trip.

B High Pressure/Heat Switch: This selector switch determines whether you will use the 1200 psi pump or the heater. You can select either, but not

both at the same time. The heater will only work with the 500 psi pump. The center position is OFF, and neither the 1200 psi pump nor the heater is

turned on. CAUTION: do not operate the 1200 psi pump and the 500 psi pump at the same time.

C 1200PSI Indicator Light: This light will turn on when the switch is set to the 1200 PSI pump.

D Vacuum Switch: This switch turns on the vacuum.

E 500PSI Pump Switch: This switch turns on the 500PSI solution pump. CAUTION: do not run both solution pumps at the same time.

F Dump Pump Switch: This last switch turns on the automatic pump-out pump. Use this when you want the machine to automatically pump out the

recovered solution. CAUTION: do not turn on this pump until you have connected the pump-out hose.

G Heat Indicator Light: This light will turn on when you have selected heat instead of the 1200 psi pump.

C

B

D

E

F

A

G

3/10 A-7 56041959 - KING COBRA® 1200 PRO

INSTRUCTIONS FOR USEA - ENGLISH

SET-UP AND OPERATION

1200PSI HIGH PRESSURE WASHER

CAUTION!

Use care when handling hazardous chemicals.

Never leave the machine running when you are not actively using it.

Always use a defoamer when foaming occurs to prevent vacuum motor damage.

DANGER!

Do NOT use solvents, or any chemicals that may be fl ammable, explosive or combustible.

CLEANING SOLUTIONS:

Select a proper pre-spray for the surface to be cleaned, and apply the pre-spray. Use a neutral pH rinse or detergent (6 to 10 pH) in the King Cobra to prevent

premature wear of the pumps, seals, and other components. Damage caused by the use of improper or strong chemicals is not covered by warranty. Powdered

chemicals are not recommended.

1 Before each use, inspect the machine, hoses, and cleaning tools for cleanliness and completeness. Make sure the hoses are in good condition and the

spray nozzle(s) is tight. Be sure the Pre-Filter Bag (27) and the Dump Pump Inlet Filter (25) are installed and are clean.

2 When not using the auto-dump feature, make sure the brass cap is screwed tightly on the Dump Hose Connection (18) on the dump pump on the rear of the

machine. If you choose to use the auto-dump, connect the dump hose to the Dump Hose Connection (18) on the back of the dump pump, and place the

open end of the hose in a drain. Make sure the Recovery Tank Drain Hose (17) is closed, and the Recovery Tank Lid (2) is closed tight.

REFER TO THE AUTO-FILL AND AUTO-DUMP INSTRUCTIONS ON THE FOLLOWING PAGES.

3 If you choose to use the auto-fi ll feature, connect the fi ll hose to the Auto-Fill Hose Connector (7). Turn on the water source, and allow the tank to fi ll with

water. When using the auto-fi ll system, the auto-fi ll fl oat will automatically turn on and turn off as the tank empties and then fi lls. NOTE: If you are not going

to use the auto-fi ll system, just fi ll the tank with water and cleaning chemical. Follow chemical directions regarding dilution and mixing. Do not use harsh

chemicals; they may damage seals in pumps and valves, and cause the pump to wear prematurely.

NOTE: using warm water in the tank may improve the effi ciency of the heat exchanger when cleaning with heat, but never use water with a temperature

exceeding 130 °F / 54 °C.

REFER TO THE AUTO-FILL AND AUTO-DUMP INSTRUCTIONS ON THE FOLLOWING PAGES.

4 Pre-spray the area to be cleaned, with a pump-up sprayer, while the tank is fi lling. Follow chemical directions.

5 Plug in the two power cords (22). Do not connect both cords to the same outlet. The green, ‘separate circuit’ locator light (A) on the switch plate should light

up. If the locator light does not come on, check the circuit breaker box in the wall, and/or try different outlets until it does turn on. Although all systems in

the machine may work correctly if you are not on two circuits, a circuit breaker in a wall panel may trip. If you make sure the green light is turned on, you will

prevent tripped circuit breakers. Turn on the 1200 PSI pump by placing the HIGH PRESSURE/HEAT Switch (B) in the UP position, to select the 1200 PSI

Pump.

NOTE: This switch is off when it is set to the middle position and neither the 1200PSI pump nor the heater are selected. The heater and the 1200PSI pump

cannot operate at the same time.

6 Prime the 1200 psi pump using the ‘power prime’ system. Turn on both the pump (B) and the vacuum (D), cover the Vacuum Hose Connection (1) on the

top of the machine with your hand, then depress the Power Prime Pedal (20). This will pull trapped air through the pump and into the recovery tank, priming

the pump. You should notice a change in the ‘tone’ of the pump (smoother, with less rattle), and the water being pulled into the recovery tank will change

from a white, sputtering fl ow to a clear, solid stream. NOTE: Priming requires a full Holding Tank (14), and it may take between 20 to 90 seconds. Once the

pump has primed, release the Power Prime Pedal (20), and turn both the pump (B) and the vacuum (D) off. Momentarily depress the Power Prime Pedal

(20) again after the pump has stopped running to release any built-up back pressure.

7 Your machine has two solution outputs. The solution output for the 1200 psi pump is a quick disconnect (6) located just above the fi ll hole on the Holding

Tank, on the front face of the machine (the 500 psi outlet is a quick disconnect (10) on the end of a short length of hose, on the front of the base section of

the machine). Attach the Solution Hose (24) from the reel to the 1200PSI Quick Connect (6). Attach the Vacuum Hose (28) on the reel to the Vacuum Hose

Connection (1). Pull the hoses out from the reel. Attach the other ends of the hoses to the cleaning tool.

8 Turn on the vacuum (D) and turn on the dump pump (F). Begin cleaning.

NOTE: The dump pump will automatically turn on and turn off as the tank fi lls and then empties (refer to drawings on following pages).

9 When fi nished with the job, turn off the water source (if using Autofi ll).

ELECTRIC CIRCUIT LOCATOR: This system will inform the operator when the two cords are plugged into separate circuits by turning on the green, circuit

locator light (A). This helps to prevent tripping circuit breakers.

NOTE: If the green circuit locator light (A) does not illuminate when the cords are plugged in, then both cords are on the same circuit. Try other outlets with one

of the cords until you get the locator light to come on.

A-8 KING COBRA® 1200 PRO - 56041959 3/10

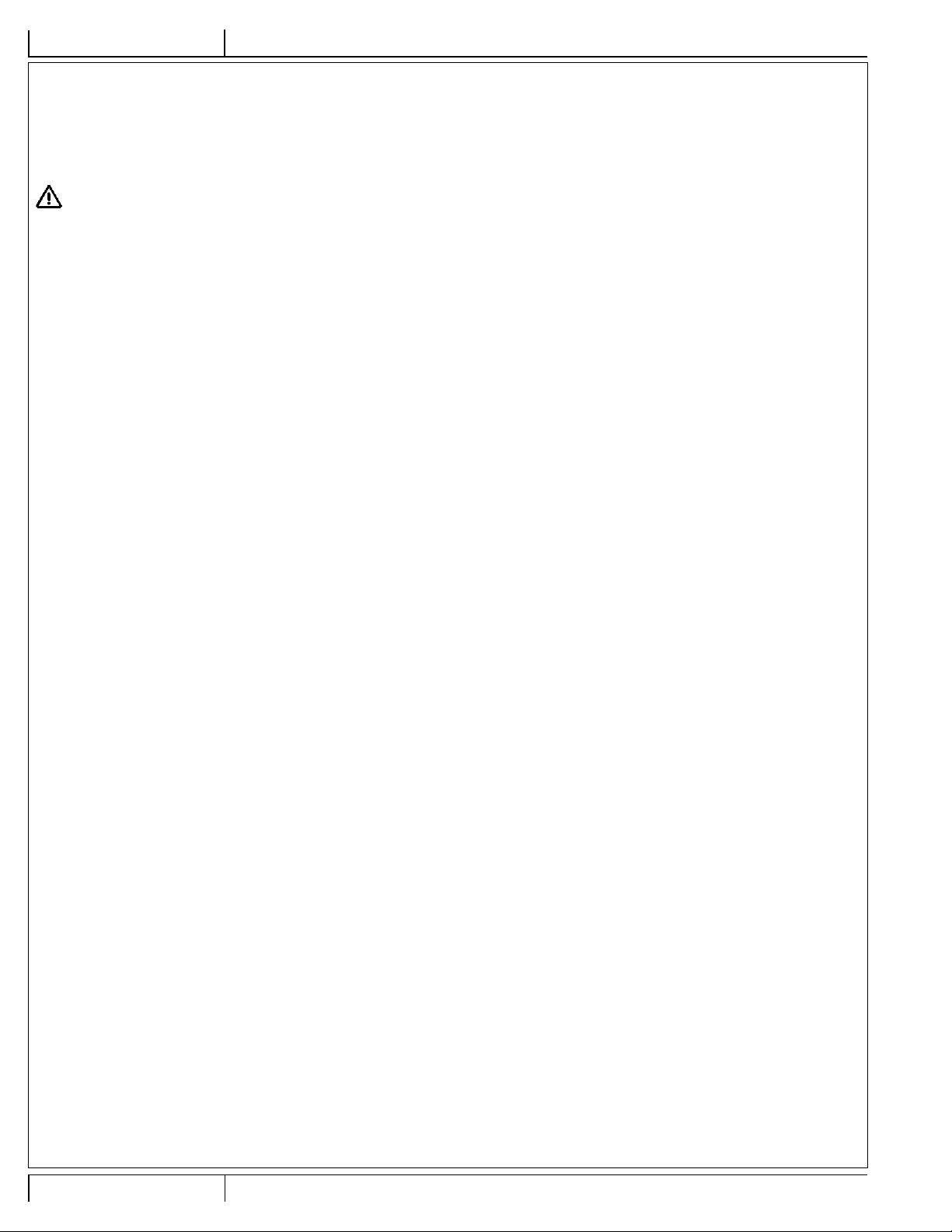

SET-UP AND OPERATION

1200PSI HIGH PRESSURE WASHER

ENGLISH - AINSTRUCTIONS FOR USE

B

A

D

1

F

28

17

2

22

6

7

24

10

3/10 A-9 56041959 - KING COBRA® 1200 PRO

INSTRUCTIONS FOR USEA - ENGLISH

SET-UP AND OPERATION

500PSI AND HEAT

CAUTION!

Use care when handling hazardous chemicals.

Never leave the machine running when you are not actively using it.

Always use a defoamer when foaming occurs to prevent vacuum motor damage.

DANGER!

Do NOT use solvents, or any chemicals that may be fl ammable, explosive or combustible.

CLEANING SOLUTIONS:

Select a proper pre-spray for the surface to be cleaned, and apply the pre-spray. Use a neutral pH rinse or detergent (6 to 10 pH) in the King Cobra to prevent

premature wear of the pumps, seals, and other components. Damage caused by the use of improper or strong chemicals is not covered by warranty. Powdered

chemicals are not recommended.

1 Before each use, inspect the machine, hoses, and cleaning tools for cleanliness and completeness. Make sure the hoses are in good condition and

the spray nozzle(s) is tight. Be sure the Pre-Filter Bag (27) and the Dump Pump Inlet Filter (25) are installed and are clean.

2 When not using the auto-dump feature, just make sure the brass cap is screwed tightly on the Dump Hose Connection (18) on the dump pump on

the rear of the machine. If you choose to use the auto-dump, connect the dump hose to the Dump Hose Connection (18) on the back of the dump

pump, and place the open end of the hose in a drain. Make sure the Recovery Tank Drain Hose (17) is closed, and the Recovery Tank Lid (2) is

closed tight.

REFER TO THE AUTO-FILL AND AUTO-DUMP INSTRUCTIONS ON THE FOLLOWING PAGES.

3 If you choose to use the auto-fi ll feature, connect the fi ll hose to the Auto-Fill Hose Connector (7). Turn on the water source, and allow the tank to fi ll

with water. When using the auto-fi ll system, the auto-fi ll fl oat will automatically turn on and turn off as the tank empties and then fi lls. NOTE: If you

are not going to use the auto-fi ll system, just fi ll the tank with water and cleaning chemical. Follow chemical directions regarding dilution and mixing.

Do not use harsh chemicals; they may damage seals in pumps and valves, and cause the pump to wear prematurely.

NOTE: Using warm water in the tank may improve the effi ciency of the heat exchanger when cleaning with heat, but never use water with a

temperature exceeding 130 °F / 54 °C.

4 Pre-spray the area to be cleaned, with a pump-up sprayer, while the tank is fi lling. Follow chemical directions.

5 Plug in the two power cords (22). Do not connect both cords to the same outlet. The green, ‘separate circuit’ locator light (A) on the switch plate

should light up. If the locator light does not come on, check the circuit breaker box in the wall, and/or try different outlets until it does turn on.

Although all systems in the machine may work correctly if you are not on two circuits, a circuit breaker in a wall panel may trip. If you make sure the

green light is turned on, you will prevent tripped circuit breakers. Select ‘HEAT” by placing the HIGH PRESSURE/HEAT Switch (B) in the DOWN

position.

NOTE: This switch is off when it is set to the middle position and neither the 1200 PSI pump nor the heater are selected. When set to the bottom

position, the heat is selected; the red light will come on and stay on. The heater and the 1200PSI pump cannot operate at the same time.

6 Press the lever on the Pressure Relief Valve (23) to make sure there is no back pressure in the system.

7 Connect the priming/siphon hose to the 500PSI Quick Connect (10) and turn on the pump (E) and place the open end over the Holding Tank (14).

The air should prime out of the pump within 20 - 60 seconds. Watch the water fl ow into the tank. When the water is clear (no air in it) and is fl owing

strongly, turn the pump off and remove the priming hose. NEVER remove the priming hose while the pump is still running.

8 Connect the Solution Hose (24) from the reel to the 500PSI Quick Connect (10) and connect the Vacuum Hose (28) from the reel to the Vacuum

Hose Connection (1). Connect both hoses to the cleaning tool.

9 Turn ON the 500PSI pump (E)

watching the 500PSI Gauge (12). NOTE: The gauge will only read pressure while you are spraying.

10 Spray for a few seconds to fi ll the lines with solution. Wait two minutes to allow the heater to reach temperature.

11 Turn on the vacuum (D) and turn on the dump pump (F). Begin cleaning. NOTE: The dump pump will automatically turn on and turn off as the tank

fi lls and then empties (refer to drawings on following pages). It may take several cycles to heat the lines and the cleaning tool.

12 If you are not using the auto-fi ll and auto-dump features, turn off both the pump (E) and vacuum (D) when the Holding Tank gets low, fi ll the Holding

Tank, and empty and clean the recovery tank.

13 When fi nished with the job, turn off the water source (if using Autofi ll).

ELECTRIC CIRCUIT LOCATOR: This system will inform the operator when the two cords are plugged into separate circuits by turning on the green,

circuit locator light (A). This helps to prevent tripping circuit breakers.

NOTE: If the green circuit locator light (A) does not illuminate when the cords are plugged in, then both cords are on the same circuit. Try other outlets

with one of the cords until you get the locator light to come on.

. Set the pump to the desired pressure by adjusting the 500PSI Pressure Adjust Knob (13) while you are spraying and

A-10 KING COBRA® 1200 PRO - 56041959 3/10

SET-UP AND OPERATION

500PSI AND HEAT

ENGLISH - AINSTRUCTIONS FOR USE

A

B

D

F

28

1

7

2

17

22

6

12

13

23

3/10 A-11 56041959 - KING COBRA® 1200 PRO

24

10

INSTRUCTIONS FOR USEA - ENGLISH

AUTO-FILL

OPERATION:

• Attach a 3/4” garden hose to the Auto-Fill Hose Connector (7), and connect the other end of the hose to your water source.

• Make sure the fl oat that hangs from the auto fi ll valve into the tank is free of obstruction and can move freely.

• Turn on the water supply. NOTE: Do not turn the water pressure on high; just turn the water on.

• The auto-fi ll fl oat will automatically shut-off the fl ow of incoming water when the tank is nearly full, and it will allow the valve to open again once the

water level has dropped to a predetermined level.

AUTO-DUMP

OPERATION:

Before each use: Always use a clean pre-fi lter bag when operating the machine. If necessary, unscrew the stainless steel fi lter at the bottom of the

recovery tank and clean it. Also make sure the ball fl oat in the recovery tank is clean.

• Attach a 3/4” garden hose to the Dump Hose Connection (18) on the dump pump on the back of the base of the machine.

• Run the other end of the hose into a drain.

• Turn ON the dump pump switch (F).

• NOTE: The dump pump is ‘self-priming.’ You should see water start to fl ow within 30 seconds of the pump turning on. If water does not begin to

fl ow, check the fi lter to see if it is plugged with debris.

After each job: Run clear water though the dump pump to wash out any chemical residue. Remove and clean both the Pre-Filter Bag (27) and the

Pump Inlet Filter (26). Reinstall the fi lter once it is clean. Clean and empty the recovery tank.

DANGER!

Do NOT use solvents, or any chemicals that may be fl ammable, explosive or combustible.

CAUTION!

Always use a defoamer in the recovery tank to prevent water or foam from entering the vacuum motor.

DANGER!

Always unplug the King Cobra from the electrical outlet(s) before cleaning or maintaining. Certain internal components are

electrically live, even with switches in their OFF position.

A-12 KING COBRA® 1200 PRO - 56041959 3/10

ENGLISH - AINSTRUCTIONS FOR USE

AFTER USING THE MACHINE

1 To empty the Holding Tank, vacuum out all unused solution into the recovery tank using the vacuum hose. Rinse the tank with clean water.

2 Turn all the Power Switches (B, D, E & F) to OFF (O). Unplug the Power Cords (22). Coil the cords around the Cord Hooks (29) on the rear of the

machine.

3 To empty the recovery tank, loosen the Velcro strap retaining the Recovery Tank Drain Hose (17). Direct the hose to a designated waste water

“DISPOSAL SITE” and remove the plug (hold the end of the hose above the water level in the tank to avoid sudden, uncontrolled fl ow of waste

water). Rinse the tank with clean water. Inspect the drain hose; replace if kinked or damaged.

4 Disconnect the solution and vacuum hoses from the machine, at the Solution Hose Quick Connect (6 or 10) and Vacuum Hose Connection (1)

respectively. Flush the vacuum hose with warm water to wash any debris out of the vacuum hose and cleaning tool. Inspect them for damage. Set

the wand on the Wand Retainer Bracket (3).

5 Wipe the machine with a damp cloth. Do not use abrasive chemicals or solvents.

6 Perform any required maintenance before storage.

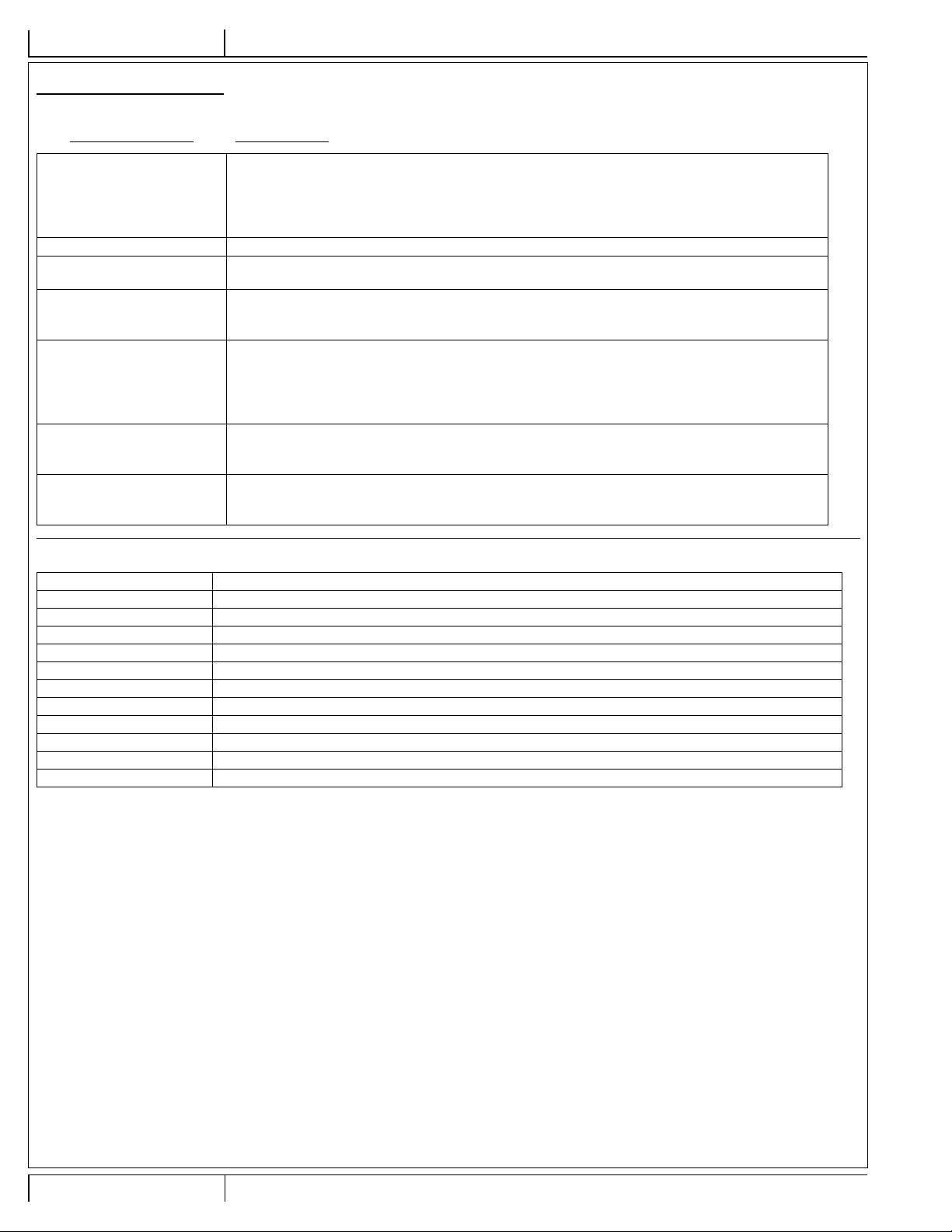

MAINTENANCE SCHEDULE

MAINTENANCE ITEM Daily Weekly Yearly

Check / Clean Tanks & Hoses •

Check / Clean Recovery Tank Shut-Off Float •

Clean Extraction Wand/Tool •

Inspect & Clean Solution Filters •

Check Carbon Brushes •

IMPORTANT!

Motor damage resulting from failure to service the carbon brushes is not covered under warranty. See the Limited

Warranty Statement.

7 Store the machine indoors in a clean, dry place with the recovery tank lid open. Keep from freezing.

POWER CORD MAINTENANCE

Once a week (or more often if necessary), check the power cords for cracked or damaged insulation, exposed wires in the cord or plug, and damaged or

missing ground pin. Repair or replace damaged cord or plug immediately.

MAINTENANCE:

For optimum performance, fl ush the machine with clear water at the end of each working day. Once a month, minimum, run a fl ushing compound through

the machine to break up any mineral or chemical build-up that may have formed. The vacuum motor, pump motors, and the pumps do not require any

scheduled maintenance; however, the motors may require replacement brushes after 1000 - 1500 hours, and the high pressure pumps and unloader

valves may require rebuild kits after 500 -1000 hours (refer to machine part list for numbers). Clean the body with an all purpose detergent, and protect it

with an automobile interior polish. Lubricate the wheels, castors, and quick disconnects with an all purpose silicone spray.

3/10 A-13 56041959 - KING COBRA® 1200 PRO

INSTRUCTIONS FOR USEA - ENGLISH

TROUBLESHOOTING:

IF THIS OCCURS CHECK THIS

Holding Tank is empty, or fi lter is plugged.

Clogged spray tip(s).

NO SPRAY

LOW PUMP PRESSURE

PUMP DOES NOT RUN

LOW SUCTION

NO SUCTION

LOW HEAT

NO HEAT

Pump not running or not primed.

Valve on wand not operating.

Solution hose not completely connected to hose or to machine.

Check to see that the pressure relief valve is fully closed.

This pump motor runs on AC voltage, so it should start running as soon as you turn on the switch. If the pump

motor does not start running, check the wiring to the switch and to the motor. Check the switch to see if it is “open”.

Debris is plugging cleaning tool or vacuum hose.

Drain hose cap is not completely closed.

Recovery tank lid is not seated or gasket is damaged.

Ball in the fl oat is blocking air fl ow. Turn off the vacuum so the ball will drop down, or the recovery tank is full and

needs to be emptied.

No power to motor(s).

Test the switches.

Test the vacuum motors.

Spraying too long. Try spraying for 12-15 seconds, or about three strokes.

Heat exchanger needs to be fl ushed.

Wrong tool being used. Too much water passing through. Longer hose or larger diameter hose, than standard.

Heat is not turned on. The green circuit indicator light must be on.

No power in the wall outlet - check to see if the breaker has tripped.

Call your distributor for additional help.

TECHNICAL SPECIFICATIONS

Rotomolded Body: Lifetime Warranty

Vacuum: 7.2” 3-stage, 140” of water lift

VAC Shutoff: Ball Float

Pump: Positive displacement, fully adjustable 0-500 psi & Positive displacement, 1200 psi, 2.2 gpm

Heat: 2000 Watts, up to 212 °F

Capacity: 16 gallon Holding Tank; 14 gallon recovery tank

Cords: Two, detachable 12/3, hospital grade plugs

Size: 39” H X 21” W X 36” L

Auto dump: 5 gpm

Wheels: 10”, locking, non-marking

Hoses: 25 ft hoses on a reel (patent pending)

Plus: Auto-fi ll and a Power Prime system for the 1200 psi pump

A-14 KING COBRA® 1200 PRO - 56041959 3/10

INSTRUCCIONES DE USOB - ESPAÑOL

ÍNDICE

Página

Introducción ........................................................................................ B-3

Componentes y servicio ....................................................................... B-3

Placa de identifi cación .......................................................................... B-3

Desembalaje de la máquina ................................................................. B-3

Instrucciones importantes de seguridad ............................................... B-4

Instrucciones de conexión a tierra ........................................................ B-5

Conozca su máquina .................................................................B-6 – B-7

Panel de control .................................................................................... B-7

Confi guración y operación ...................................................B-10 – B-11

Limpiadora a alta presión de 1200PSI ........................................ B-8 - B-9

500PSI y calor ..........................................................................B-10 - B-11

Llenado automático ............................................................................ B-12

Vaciado automático ............................................................................ B-12

Después de la utilización

Después de la utilización de la máquina ............................................ B-13

Mantenimiento

Programa de mantenimiento .............................................................. B-13

Mantenimiento del cable de alimentación ..........................................B-13

Resolución de problemas ................................................................... B-14

Especifi caciones técnicas ................................................................... B-14

SECCIÓN II – Lista de piezas .................................................. D-1 - D-11

Conjunto de base ........................................................................D-2 - D-3

Conjunto del depósito de retención .............................................D-4 - D-5

Conjunto del depósito de aspiración ...........................................D-6 - D-7

Sistema de conducciones ............................................................D-8 - D-9

Diagrama del fl ujo de agua ...................................................... D-10 - D-11

B-2 KING COBRA® 1200 PRO - 56041959 3/10

ESPAÑOL - BINSTRUCCIONES DE USO

INTRODUCCIÓN

Este manual lo ayudará a obtener el máximo rendimiento de su extractor. Léalo con atención antes de utilizar la máquina.

Nota: Los números que aparecen en negrita entre paréntesis indican elementos ilustrados en la página B-6, a menos que se indique lo contrario.

Este producto está destinado exclusivamente al uso comercial.

COMPONENTES Y SERVICIO

Las reparaciones, cuando sean necesarias, deben ser realizadas por su Centro Autorizado de Servicio, que utiliza personal de servicio formado en fábrica y lleva

un inventario de las piezas de repuesto y accesorios originales.

Llame para lo referente a piezas de repuesto y servicio. Por favor, especifi que el modelo y el número de serie cuando hable de su máquina.

MODIFICACIONES

El cliente o usuario no deberá realizar modifi caciones o agregados a la máquina limpiadora que afecten la capacidad y la operación segura sin la autorización

previa por escrito del fabricante. Las modifi caciones sin autorización anularán la garantía de la máquina, y el cliente será responsable de cualquier accidente que

resulte.

PLACA DE IDENTIFICACIÓN

El modelo y número de serie de la máquina se indican en la placa de identifi cación. Esta información es necesaria a la hora de solicitar repuestos para la

máquina. Utilice el siguiente espacio para anotar el modelo y el número de serie de su máquina para futuras consultas.

Modelo _____________________________________________

Número de serie ______________________________________

DESEMBALAJE DE LA MÁQUINA

Cuando reciba la máquina, examine con atención el cartón de embalaje y la máquina, con el fi n de comprobar si existe algún daño. Si observa algún daño,

guarde la caja de embalaje para que se pueda inspeccionar.

¡ADVERTENCIA!

Los Productos a la venta con este Manual contienen, o pueden contener, productos químicos reconocidos por algunos gobiernos (como el Estado de California,

según lo indica en su Proposición 65, Ley de Advertencia Regulatoria) como causantes de cáncer, defectos de nacimiento u otros daños reproductivos. En

algunas jurisdicciones (incluido el Estado de California), los compradores de estos Productos que los coloquen en servicio en un emplazamiento laboral o en

un espacio de acceso público tienen la obligación regulatoria de realizar determinados avisos, advertencias o divulgaciones respecto de los productos químicos

contenidos o posiblemente contenidos en los Productos utilizados en tal lugar. Es la responsabilidad del comprador conocer y cumplir con todas las leyes y

reglamentaciones relacionadas con el uso de estos Productos en tales entornos. El Fabricante niega toda responsabilidad de informar a los compradores sobre

requisitos específi cos que pueden regir el uso de los Productos en tales entornos.

3/10 B-3 56041959 - KING COBRA® 1200 PRO

Loading...

Loading...