U.S. Products COBRA-H2 Operator's Manual

®

COBRA

-H2-CSA

OPERATOR’S MANUAL

DO NOT OPERATE THE MACHINE UNTIL YOU HAVE READ THIS SECTION.

IMPROPER USE WILL VOID THE WARRANTY.

• Always use a defoamer when foaming occurs to prevent vacuum motor damage.

• Never use water above 130° F (54°C).

• Do not use outdoors or where temperature is below freezing. Protect your machine

from any extremes in temperatures.

• Do not let the pump run dry. Turn the pump off and refill the tank when cleaning solution

gets low.

• Flush the machine with an acid de-scaler regularly (monthly or more often) to prevent

a build-up of minerals or chemicals in the pump and heat systems. Follow the flush

with a clear water rinse to remove any particles and to rinse the acid from the machine.

• Use approved chemicals only. All chemicals should be mixed thoroughly. Liquid

chemicals are recommended to prevent powder buildups. A pH between 6 and 9 is

recommended. The use of high alkaline detergents or strong acids will accelerate the

wear of the pump and seals, and will void the warranty.

• All extension cords must have a rating of at least 12/3 (#12 cord). Extension cords

should be no longer than 50 feet. Replace the plug immediately if the ground prong

becomes damaged or is broken off.

56041886

03/02/2010

INTRODUCTION

This manual will help you get the most from your COBRA-H2 Extractor. Read these instructions thoroughly

before operating the machine. This product is intended for commercial use only.

UNCRATING

When the machine is delivered, carefully inspect the shipping carton and the machine for damage. If damage

is evident, save the shipping carton so that it can be inspected. Contact the shipping company immediately

for instructions on how to file a freight damage claim.

SERIAL NUMBER PLATE

The Serial Number of your machine is shown on the plate that is mounted on the floor of the base

compartment. This serial number and model are needed when ordering replacement parts for the machine.

Use the space below to note the Model and Serial Number of your machine for future reference.

MODEL : COBRA-H2-CSA SERIAL NUMBER : _____________________________________

Be sure to register your warranty. Go to www.usproducts.com.

PARTS AND SERVICE

Call the distributor from whom you purchased your machine when you need parts or service. Please

specify the Model and Serial Number when discussing your machine.

IMPORTANT SAFETY INSTRUCTIONS

This machine is only suitable for commercial use, for example in hotels, schools, hospitals, factories, shops

and offices other than normal residential housekeeping purposes.

When using any electrical appliance, basic precautions should always be followed, including the following:

NOTE: Read all instructions before using this machine.

WARNING!

To reduce the risk of fire, electric shock, or injury:

• Do not leave the maching unattended when it is plugged in. Unplug the unit from the outlet when not in use

and before servicing.

• To avoid electric shock, do not expose to rain or snow. Store, and use, indoors.

• Do not allow to be used as a toy. Close attention is necessary when used near children.

• Use only as described in this manual. Use only the manufacturer’s recommended attachments.

• Do not use with damaged cord or plug. If the machine is not working as it should, has been dropped,

damaged, left outdoors or dropped into water, return it to a service center.

• Do not pull by the cord, use the cord as a handle, close a door on the cord, or pull the cord around sharp

edges or corners. Do not run the machine over the cord. Keep the cord away from heated surfaces.

• Do not unplug by pulling on the cord. To unplug, grasp the plug, not the cord.

• Do not handle the plug, the cord or the machine with wet hands.

• Do not put any object into openings. Do not use with any opening blocked; keep free of dust, lint, hair, and

anything that may reduce air flow.

• Keep loose clothing, hair, fingers, and all parts of body away from openings and moving parts.

• Do not pick up anything that is burning or smoking, such as cigarettes, matches, or hot ashes, or any

health endangering dusts.

• Turn off all controls before unplugging.

• Use extra care when cleaning on stairs.

• Do not use to pick up flammable or combustible liquids such as gasoline or use in areas where they may

be present.

• Connect to a properly grounded outlet only. See Grounding Instructions.

• Liquid ejected at the spray nozzle could be dangerous as a result of its temperature, pressure or chemical

content.

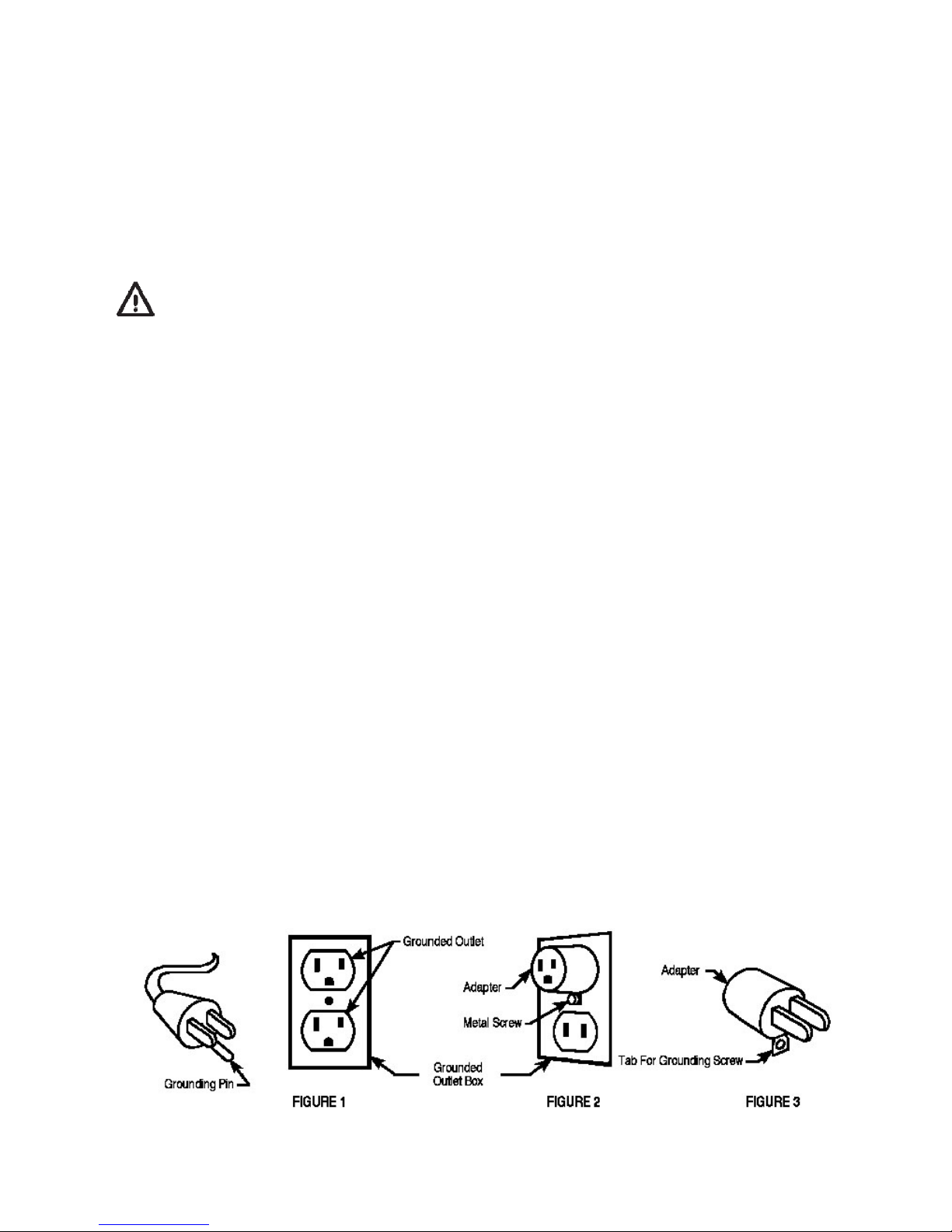

120VAC GROUNDING INSTRUCTIONS

This machine must be grounded. If it should electrically malfunction, grounding provides a path of least

resistance for electric current to reduce the risk of electric shock. This appliance is equipped with a cord

having an equipment-grounding conductor and grounding plug. The plug must be plugged into an appropriate

outlet that is properly installed and grounded in accordance with all local codes and ordinances.

DANGER!

Improper connection of the equipment-grounding conductor can result in a risk of electric shock. Check with a

qualified electrician or service person if you are in doubt as to whether the outlet is properly grounded. Do not modify

the plug provided with the appliance. If it will not fit the outlet, have a proper outlet installed by a qualified electrician.

This appliance is for use on a nominal 120-volt circuit, and has a grounding plug that looks like the plug illustrated

in Figure 1 below. A temporary adapter illustrated in Figures 2 and 3 may be used to connect this plug to a 2-pole

receptacle as shown in Figure 2 if a properly grounded outlet is not available. The temporary adapter should be used

only until a properly grounded outlet (Figure 1) can be installed by a qualified electrician. The green-colored rigid ear,

tab, or the like extending from the adapter must be connected to a permanent ground such as a properly grounded

outlet box cover. Whenever the adapter is used, it must be held in place by a metal screw. Grounding adapters are

not approved for use in Canada.

Replace the plug if the grounding pin is damaged or broken.

The Green (or Green/Yellow) wire in the cord is the grounding wire. When replacing a plug, this wire must be

attached to the grounding pin only.

Extension cords connected to this machine should be 12 gauge, three-wire cords with three-prong plugs and

outlets. DO NOT use extension cords more than 50 feet (15 m) long.

PLEASE NOTE: FOR NORTH AMERICA ONLY

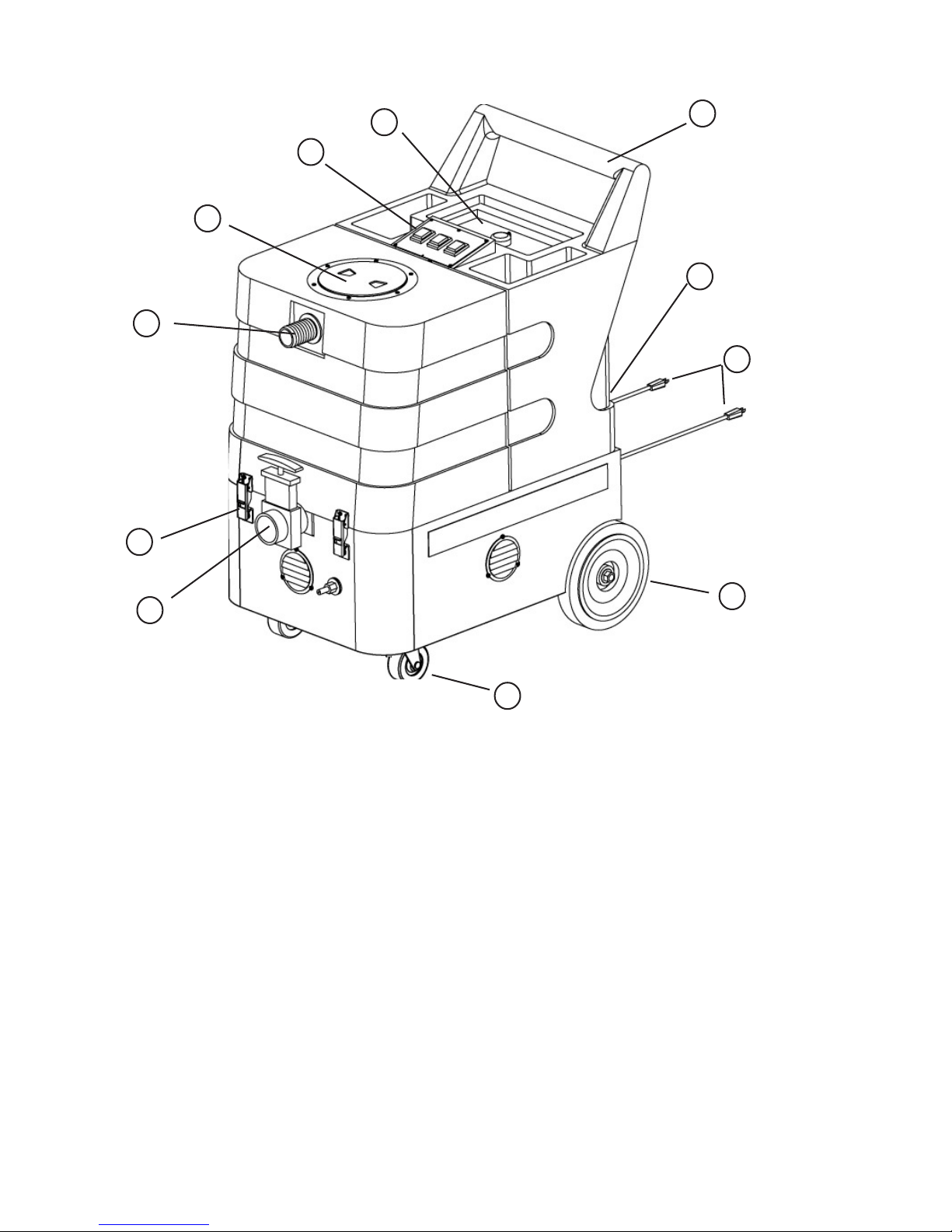

BECOME FAMILAR WITH YOUR NEW EXTRACTOR

2

1

3

4

11

5

10

6

7

9

8

MACHINE DESCRIPTIONS

Operator Handle (1) - Operator holds this to move the machine from one location to another.

Solution Tank Lid (2) - Fill Solution Tank here with warm water and chemicals.

Switch Plate (3) - This is where the switches are located that operate the pump, vacuum and heater.

Recovery Tank Lid (4) - The Recovery Tank can be flushed out by running clean water into this opening

with the Drain Gate (7) open. The vacuum float Shut-OFF can also be accessed through this opening for

maintenance.

Vacuum Inlet (5) - This is where the vacuum hose attaches to the machine.

Latch (6) - Open the latches to access the base compartment, which contains the motors and heater.

Drain Gate (7) - Open this gate to drain the recovered solution out of the machine. Be sure to keep this

gate clean.

Castor (8) - The castor swivels for easy maneuvering in tight spots.

Wheel (9) - Large, non-marking wheels for ease of transport.

Power Cords (10) - Two, 25 foot cords, rated 12 gauge, 3 wire. Do not use if either cord is damaged.

The cord with the red “H” at the retainer is the cord that operates the heat. The other cord powers the

vacuum, pump, and cooling fan.

Circuit Breaker (11) - The circuit breaker is resettable.

OPERATION

1 Inspect the machine, hoses, and cleaning tools for cleanliness and completeness.

2 Fill the Solution Tank with warm water. Using warm water may be a benefit in cleaning

effectiveness, but do not use hot water (above 130° F+/ 54°C) in the tank. Add liquid cleaning

solution with a pH value of between 6 and 9. High pH detergents and/or acid rinses will

accelerate the wear of the seals and will void the warranty.

3 Plug in the power cords. Do not connect both cords to the same outlet. If you are certain the

cords are on separate circuits, turn the Heat switch on. CAUTION: using the Heat switch

when the cords are on the same circuit may cause the circuit breaker in the wall panel to trip.

NOTE: the cord with the red label “H” at the cord retainer supplies power to the heater.

The other cord powers the vacuum, pump, and cooling fan.

4 Attach the spray hose to the solution quick disconnect on the front of the machine and attach

the vacuum hose to the hose barb on the recovery tank. Attach the other ends of the hoses to

the cleaning tool.

5 Allow the heat exchanger two minutes to reach operating temperature.

6 Turn the pump on. Turn the vacuum on. NOTE: the pump has a built in pressure switch; the

pump runs only when you are spraying.

7 Begin cleaning using the correct hoses and tool.

8 Use defoamer in the recovery tank any time foaming occurs.

9 Monitor the water level in the solution tank. Do not let the pump run dry.

10 When the solution tank gets low, turn off the pump, fill the solution tank, empty and clean the

recovery tank.

11 When finished with the job, remove any unused solution from the solution tank, and run a few

gallons of clean water through the system to rinse out any detergent.

BALL FLOAT VACUUM SHUT-OFF

Prior to using the machine, always check that the float filter is clean and the ball can travel freely.

When the recovery tank is full, the ball float will rise and will shut off the vacuum flow to prevent any

more water from entering the tank. Turn off the vacuum, and empty the recovery tank.

NOTE: if foam is present or if the ball float is prevented from rising, the float will not be able to stop

the air flow, and the tank may over fill.

CAUTION!

To avoid vacuum motor damage, always make sure the float filter is clean and the ball can travel

freely prior to using the machine. And always use a defoamer when foaming occurs.

Loading...

Loading...