U.S. Products TORRENT, 56380561 Information And Operating Instructions

TORRENT

HARD SURFACE CLEANER

INFORMATION AND

OPERATING

INSTRUCTIONS

INFORMACIÓN E

INSTRUCCIONES DE USO

INFORMATION ET

DIRECTIVES

D’UTILISATION

®

MODELS: TORRENT, 56380561

A-English

B-Español

C-Français

CAUTION: DO NOT OPERATE MACHINE UNTIL YOU HAVE READ

ALL SECTIONS OF THIS INSTRUCTION MANUAL

IMPROPER USE OF THE MACHINE WILL VOID THE WARRANTY

1. DANGER: High pressure may cause sever injury. Always wear safety glasses.

NEVER direct the spray towards yourself, other people, or pets.

2. Never allow the spray to remain fi xed in one spot.

3. Before each use, remove the spray tool from the hose, and check to make sure the

spray nozzle is securely tightened in the tool. A loose nozzle could fl y off during use.

4. If a leak occurs at the hose, IMMEDIATELY turn the machine off. Replace the hose

before restarting.

5. Always use a defoamer to prevent vacuum motor damage when foaming occurs.

6. Keep the machine from rain in snow, extremes in temperatures, and store it in a

heated location. Use the machine indoors. Do not use outdoors.

7. NEVER adjust the pump above 1200 psi.

revised 11/13 FORM NO. 56041839

INSTRUCTIONS FOR USEA - ENGLISH

revised 1/12

IMPORTANT SAFETY INSTRUCTIONS

This machine is only suitable for commercial use, for example in hotels, schools, hospitals, factories, shops, and offi ces other than

normal residential housekeeping purposes.

When using any electrical appliance, basic precautions should always be followed, including the following:

NOTE: Read all instructions before using this machine.

WARNING!

To reduce the risk of fi re, electric shock, or injury:

Never adjust the pump pressure above 1200 psi.•

Do not leave the machine unattended when it is plugged in. Unplug the unit from the outlet when not in use and before •

servicing.

To avoid electric shock, do not expose to rain or snow. Store, and use, indoors.•

Do not allow to be used as a toy. Close attention is necessary when used near children.•

Use only as described in this manual. Use only the manufacturer’s recommended attachments.•

Do not use with damaged cord or plug. If the machine is not working as it should, has been dropped, damaged, left outdoors •

or dropped into water, return it to a service center.

Do not pull by the cord, use the cord as a handle, close a door on the cord, or pull the cord around sharp edges or corners. •

Do not run the machine over the cord. Keep the cord away from heated surfaces. To unplug, grasp the plug, not the cord.

Do not handle the plug, the cord or the machine with wet hands.•

Extension cords must be 12/3 and no longer than 50 feet. Replace the cord or unplug immediately if the ground prong •

becomes damaged.

Do not put any object into openings. Do not use with any opening blocked; keep free of dust, lint, hair, and anything that •

may reduce air fl ow.

Keep loose clothing, hair, fi ngers, and all parts of body away from openings and moving parts.•

Do not pick up anything that is burning or smoking, such as cigarettes, matches, or hot ashes, or any health endangering •

dusts. Do not use to pick up fl ammable or combustible liquids such as gasoline or use in areas where they may be present.

Turn off all controls before unplugging.•

Connect to a properly grounded outlet only.•

Liquid ejected at the spray nozzle could be dangerous as a result of its temperature, pressure, and/or chemical content.•

•

KEEP THESE INSTRUCTIONS

WARNING!

The Products sold with this Manual contain or may contain chemicals that are known to certain governments (such as the State of California, as

identifi ed in its Proposition 65 Regulatory Warning Law) to cause cancer, birth defects or other reproductive harm. In certain locations (including

the State of California) purchasers of these Products that place them in service at an employment job site or a publicly accessible space are

required by regulation to make certain notices, warnings or disclosures regarding the chemicals that are or may be contained in the Products at or

about such work sites. It is the purchaser’s responsibility to know the content of, and to comply with, any laws and regulations relating to the use

of these Products in such environments. The Manufacturer disclaims any responsibility to advise purchasers of any specifi c requirements that may

be applicable to the use of the Products in such environments.

A - 2 TORRENT - 56041839 1/12

revised 1/12

ENGLISH - AINSTRUCTIONS FOR USE

INSPECTION:

Carefully unpack and inspect your TORRENT for shipping damage. Each machine is tested and inspected before shipping. Any shipping damage

is the responsibility of the carrier. You should notify the carrier immediately if you notice damage to the box or to the machine or parts.

CLEANING SOLUTIONS:

Select a proper pre-spray for the surface to be cleaned, and apply the pre-spray. Use a neutral pH rinse or detergent (5 to 10 pH) in the Torrent to

prevent premature wear of the pump, seals, and other components. Damage caused by the use of improper or strong chemicals is not covered by

warranty. Powders are not recommended.

MAINTENANCE:

For optimum performance, fl ush the machine with clear water at the end of each working day. Once a month, minimum, run a fl ushing compound

through the machine to break up any mineral or chemical build-up that may have formed.

Your Torrent is supplied with an HT Technology Triplex Plunger Pump, specifi cally designed to handle rigorous duty cycles and high temperatures.

Seal life is expected to be 3000 hours.

This pump has an oil-bath crankcase, and a sight gauge is provided so you can view the oil level through a small opening in the front of the base

compartment, directly below the ammeter gauge. The proper fi ll level is shown by a red dot. Oil changes are recommended every 300 hours, and

on new machines an initial oil change is recommended at fi fty hours. Use SAE-15W-40 oil. See PUMP MAINTAINENCE for more information.

Note that the hoses above the fi ll port are on quick disconnects to simplify service.

Vacuum motors typically require brush replacement between 500 - 1000 hours.

Clean the body with an all purpose detergent, and protect it with an automobile interior polish. Lubricate the wheels, castors, and quick

disconnects with an all-purpose silicone spray.

Record the serial number and model of your new extractor here:

(and be sure to register your purchase to active your warranty -- go to www.usproducts.com)

Serial Number: __________________ Model: TORRENT, 56380561

Purchase Date:_____________

Write the name and phone number of your distributor:

____________________________________________________________________

____________________________________________________________________

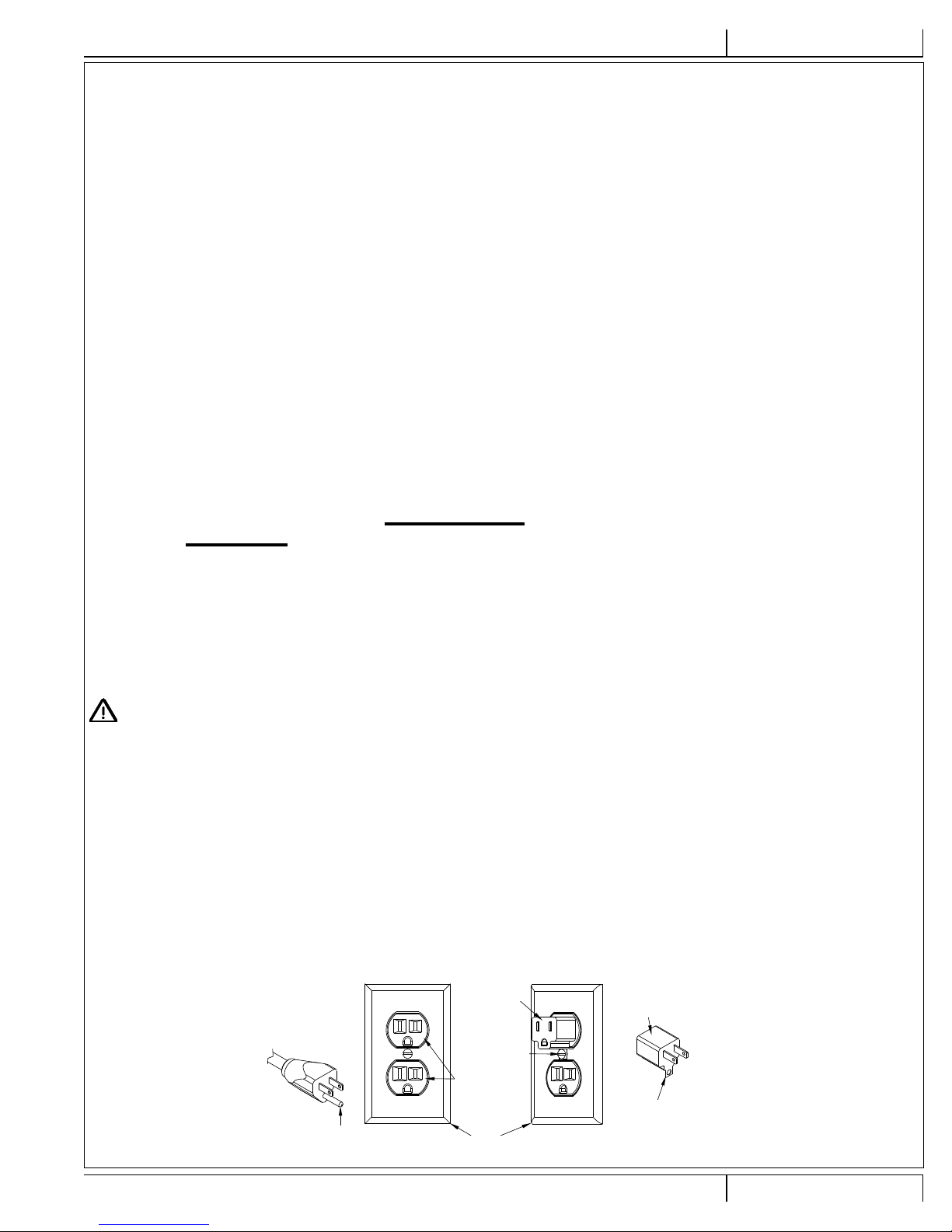

120VAC GROUNDING INSTRUCTIONS

This appliance must be grounded. If it should electrically malfunction, grounding provides a path of least resistance for electric current to reduce

the risk of electric shock. This appliance is equipped with a cord having an equipment-grounding conductor and grounding plug. The plug must be

plugged into an appropriate outlet that is properly installed and grounded in accordance with all local codes and ordinances.

DANGER!

Improper connection of the equipment-grounding conductor can result in a risk of electric shock. Check with a qualifi ed electrician or

service person if you are in doubt as to whether the outlet is properly grounded. Do not modify the plug provided with the appliance. If

it will not fi t the outlet, have a proper outlet installed by a qualifi ed electrician.

This appliance is for use on a nominal 120-volt circuit, and has a grounding plug that looks like the plug illustrated in Figure 1 below. A temporary

adapter illustrated in Figures 2 and 3 may be used to connect this plug to a 2-pole receptacle as shown in Figure 2 if a properly grounded outlet is

not available. The temporary adapter should be used only until a properly grounded outlet (Figure 1) can be installed by a qualifi ed electrician. The

green-colored rigid ear, tab, or the like extending from the adapter must be connected to a permanent ground such as a properly grounded outlet

box cover. Whenever the adapter is used, it must be held in place by a metal screw. Grounding adapters are not approved for use in Canada.

Replace the plug if the grounding pin is damaged or broken.

The Green (or Green/Yellow) wire in the cord is the grounding wire. When replacing a plug, this wire must be attached to the grounding pin only.

Extension cords connected to this machine should be 12 gauge, three-wire cords with three-prong plugs and outlets. DO NOT use extension cords

more than 50 feet (15 m) long.

PLEASE NOTE: FOR NORTH AMERICA ONLY

Adapter

Adapter

Metal Screw

Grounded Outlet

Tab for Grounding Screw

Grounding Pin

FIGURE 1

Grounded Outlet Box

FIGURE 2

FIGURE 3

1/12 A - 3 56041839 - TORRENT

INSTRUCTIONS FOR USEA - ENGLISH

revised 1/12

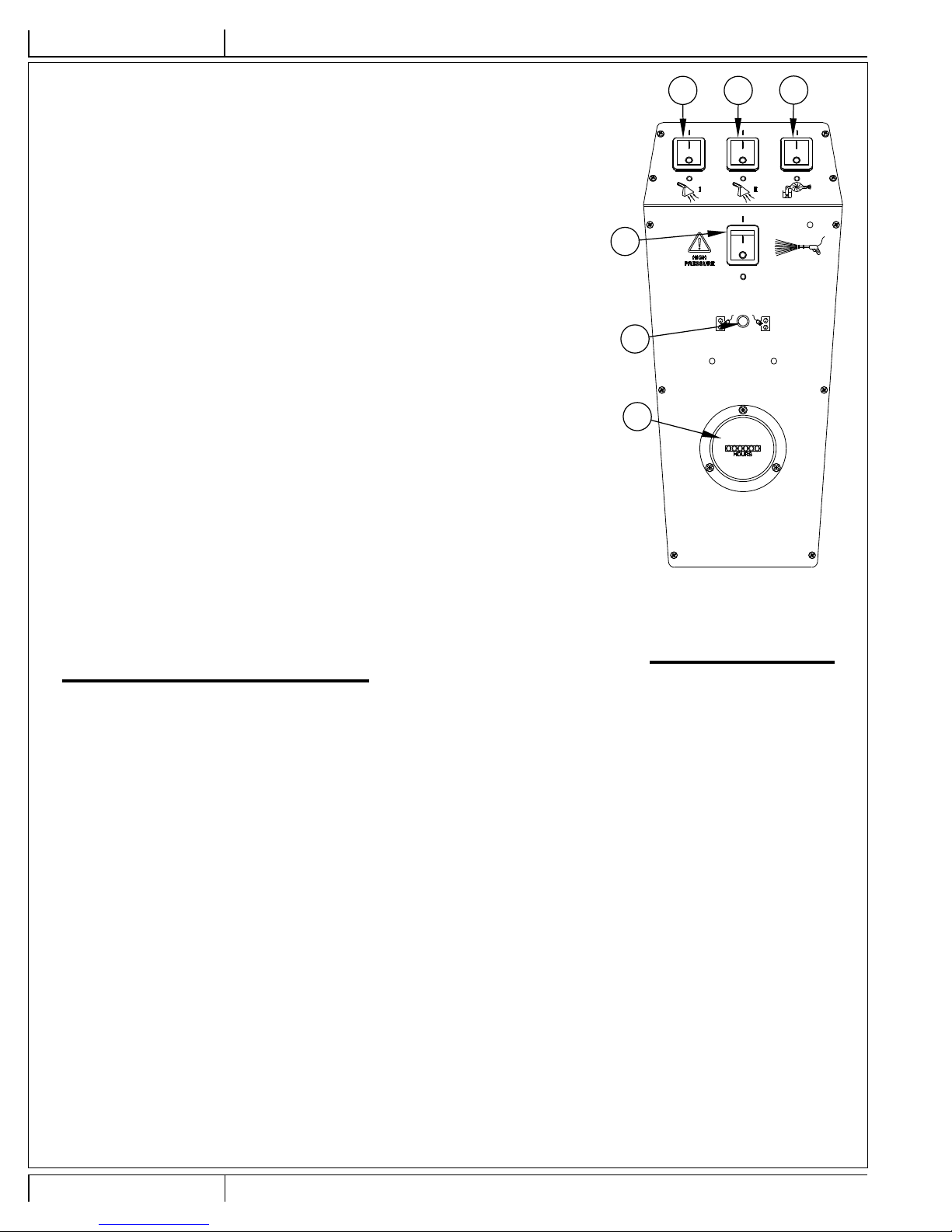

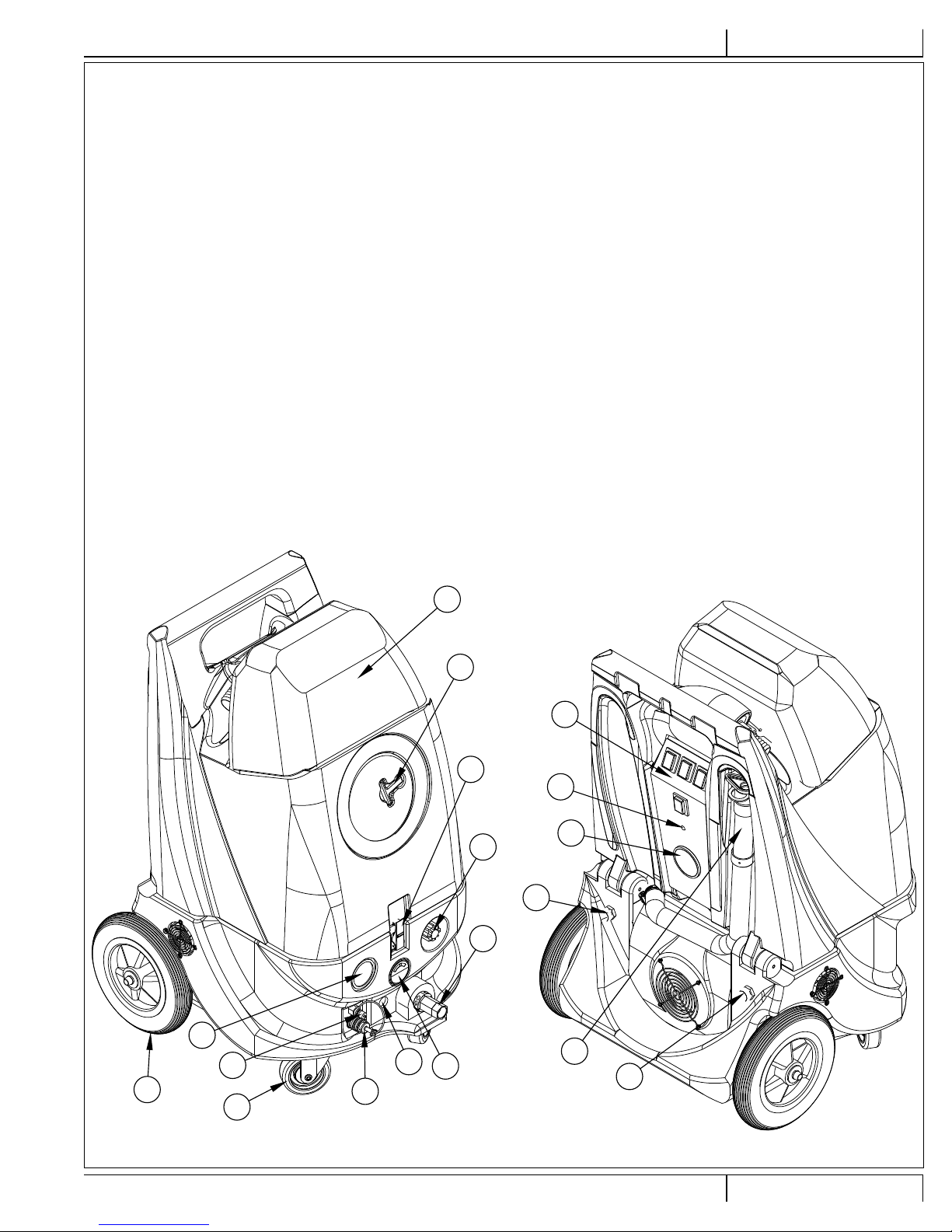

SWITCH PLATE CONTROLS: (REFER TO FIGURE 1)

1 Vacuum I Switch: Turns on/off vacuum motor I.

2 Vacuum II Switch: Turns on/off vacuum motor II.

3 Dump Pump Switch: Turns on/off dump pump. Float switch on recovery tank automatically turns

the pump on when the solution level in the tank reaches a pre-set level AND the switch is on the

ON position.

4 High Pressure Pump Switch: Turns on/off the high pressure (400-1200 psi) pump.

5 Dual Cord Sensor Light: The green light will turn on only when the two power cords are plugged

into separate circuits.

6 Hour Meter: Keeps track of the overall time the pump has been in use.

1 2

3

4

5

6

FIGURE 1

FRONT PANEL: (REFER TO FIGURE 2)

7 Pressure Gauge: Measures outlet pressure of high pressure pump in pounds per square inch (psi).

8 Ammeter: Allows precise adjustment of the pump outlet pressure without overloading the pump motor. Proper adjustment for maximum

pressure is at the break line between green and yellow.

NOTE: Since voltage can vary from one power outlet to another, setting the pressure adjustment based on amp draw will extend the life of

the motor by keeping the current within the correct range.

9 Pressure Adjustment Knob – Adjusts outlet pressure between 400 – 1200 psi. Note: you must trigger the tool and spray to see adjustment

of pressure. Clockwise increases and counterclockwise decreases pressure. Let the pump run for about one minute, then adjust the pump

using the ammeter for maximum pressure (set at the break line between green and yellow). For lower pressure, down to 400 psi, simply turn

the knob counterclockwise - while spraying - and watch the pressure gauge.

10 High Pressure Quick Disconnect – Attachment for high pressure solution line.

11 Auto-Dump Hose Fitting – Male garden hose fi tting to attach dump hose.

12 Direct Feed-Hose Fitting – Female garden hose fi tting to attach the direct water feed-hose. The feed hose has a chemical siphon system

and backfl ow preventer at the faucet end of hose.

13 Oil Level View Port - Allows viewing of the pump oil level sight-gauge.

14 Vacuum Motor Cover

15 Recovery Tank Lid

16 Latch

17 Castor

18 Wheel

19 Switch Plate

20 Dual Cord Sensor Light

21 Hour Meter

22 Power Cord

A - 4 TORRENT - 56041839 1/12

revised 1/12

ENGLISH - AINSTRUCTIONS FOR USE

RECOVERY TANK: (REFER TO FIGURE 2)

Pre-Filter: 800 micron polyester mesh bag with quick-change cord lock. This fi lter hangs inside the tank from the recovery hose inlet

piping. Check the pre-fi lter before operation and clean as required.

Stainless Steel Filter: 50-mesh fi lter screws into base of recovery tank. Inspect daily and clean as needed.

Float Valve: Located on the back wall in recovery tank, it automatically controls dump pump when switch is in ON position. Before

each use, inspect the fl oat to ensure it is in the proper

position and clear of debris that would interfere with free operation.

23 Recovery Tank Dump Hose: Located on the rear of the recovery tank. Use this hose to manually drain the remaining recovered solution

from the tank and during tank cleaning.

FIGURE 2

14

15

19

16

20

21

9

22

12

7

10

18

17

1/12 A - 5 56041839 - TORRENT

11

13

8

22

23

INSTRUCTIONS FOR USEA - ENGLISH

revised 1/12

OPERATION

1. Before each use, inspect the machine, hoses, and cleaning tools for cleanliness and completeness. Make sure hoses are in good condition and

the spray nozzle(s) is tight.

2. Connect direct water feed hose (supplied with chemical feed and back fl ow preventer) to the water supply and to the machine. NOTE: see instruc-

tions on the following page for auto-fi ll and chemical injection.

3. Install the dump hose onto the brass hose fi tting on the front of the machine, and place the open end of the hose in a drain. Add defoamer to the

recovery tank. Foaming can be persistent with hand fl oor cleaning; consider using defoamer (a dry fl ake works very well) applied directly to fl oor

surface after the pre-spray and before the high pressure rinse. Make sure the recovery tank drain hose is closed and the lid is tight on the recovery

tank.

4. Connect the solution hose to the 1200 PSI Quick Disconnect on the front of the machine, and attach the tool to be used to the other end of the

hose. NOTE: Always attach the solution hose before you turn the pump on.

5. Attach one end of the vacuum hose to the hose barb on the front of the recovery tank and the other end of the hose to the cleaning tool.

6. Turn on the water supply. NOTE: see instructions on the following page for auto-fi ll & chemical injection.

7. Plug in the left power cord (as viewed from behind the machine). Plug the other cord into another outlet. Do not connect both cords to the same

outlet. The green, smart circuit locator light on the switch plate should light up. If the green locator light does not come on, check the circuit

breaker box in the wall, and/or try different outlets until it does turn on. Although all systems in the machine may work correctly if you are not on

two circuits, a circuit breaker in a wall panel may trip; if you make sure the green light is turned on, you will prevent tripped circuit breakers.

8. Pre-spray the area to be cleaned with a pump-up sprayer, or use a mop.

9. Point the tool in the proper direction. Turn on the high pressure pump.

CAUTION!

Make sure the solution line and tool are attached before turning the pump on. Extreme pressure will build up, and if the solution line and tool are not attached before starting the pump, you will have to open the machine and manually release the pressure by turning the bleeder value (mounted on the pump assembly) counter-clockwise.

10. Adjust the pump outlet pressure by turning the pressure adjustment cap. 400 -- 1200 psi.

NOTE: do not adjust the pump above 1200 psi.

11. Turn on the vacuum and the dump pump. Begin cleaning NOTE: the dump pump will automatically turn on and off as the tank fi lls and empties.

12. When the job is fi nished, turn off the pumps and vacuums.

13. Run a few gallons of clean water through the system. Completely drain the recovery tank by placing the dump hose over a drain, or a bucket, and

removing the cap. Disconnect the hoses from the cleaning tool.

14. Unplug the power cords.

15. Clean the machine and the tool.

DANGER!

Do NOT use any chemicals that may be fl ammable, explosive, or combustible.

CAUTION!

Use care when handling hazardous chemicals.

Never leave the pump running when you are not actively using it.

SMART CIRCUIT LOCATOR

The green light will show the operator when the two cords are plugged into separate circuits. This helps to prevent tripping circuit breakers.

NOTE: when one cord is plugged in, the green light will be on dimly.

NOTE: if the green, circuit locator light does not illuminate when both cords are plugged in, then both cords are on the same circuit. Try other outlets

with one of the cords until you get the locator light to come on.

A - 6 TORRENT - 56041839 1/12

revised 1/12

ENGLISH - AINSTRUCTIONS FOR USE

AUTO-FILL:

Without Chemical Injection:

Simply connect one end of the water supply hose to a convenient water supply, and connect the other end to the water inlet fi tting on the machine.

NOTE: hot water cleans better than cold water. When all set-up and ready to begin cleaning, turn on the water supply.

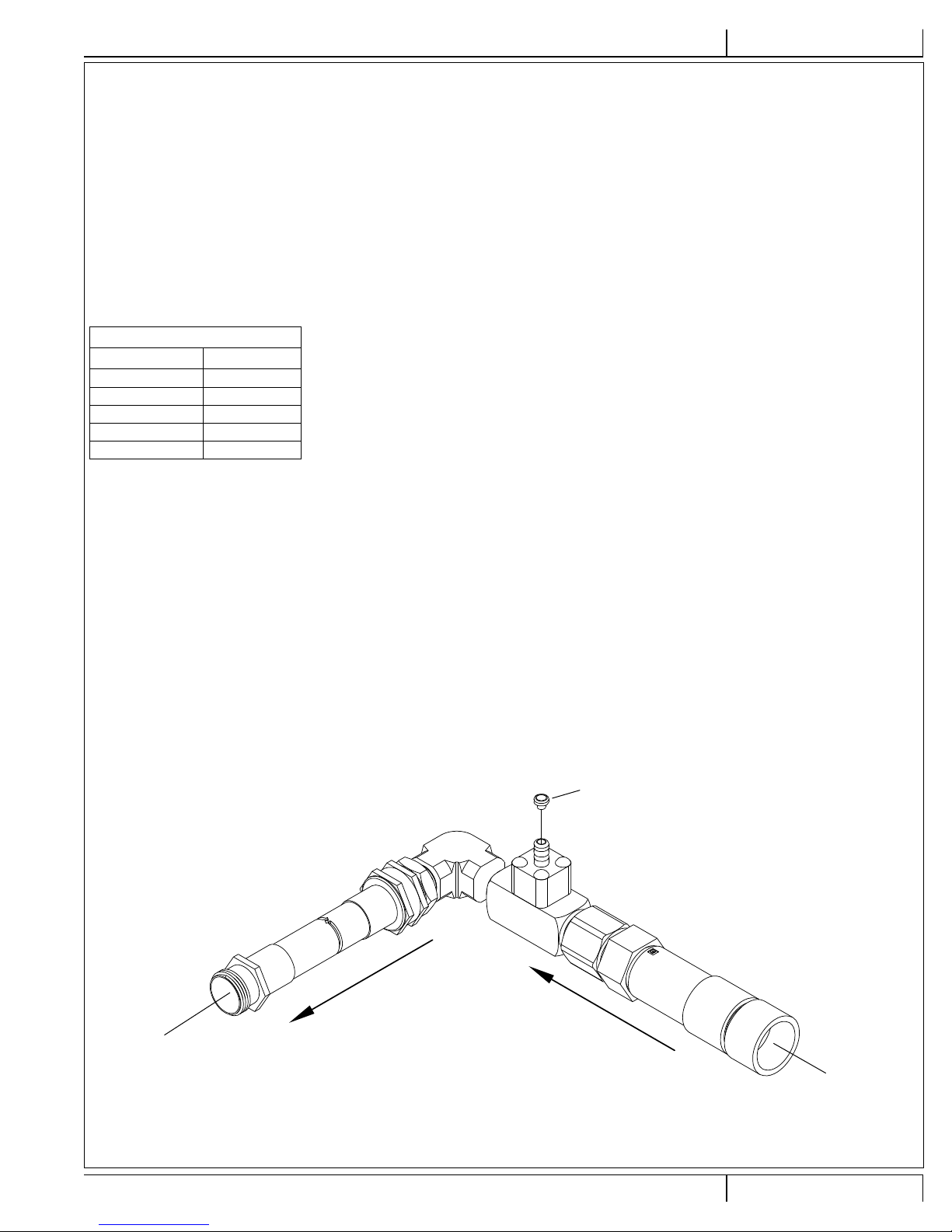

With Chemical Injection:

Chemical Supply:

Place the container of concentrated chemical cleaner -- use a product with a pH between 6 and 10 to avoid premature pump wear, which would

void the warranty -- in a sink or near the water supply. Insert the end of the clear tubing with the foot valve attached into the chemical container.

NOTE: the ceramic weight at the foot valve will keep the valve at the bottom of the container.

Connect the chemical injector to the threads on a water supply (utility sink, garden hose). Bring the clear tubing from the chemical container to the

metering tip.

METERING TIP FLOW RATES

COLOR OZ/GAL

TAN 0.45

ORANGE 0.636

TURQUOISE 1.1

PINK 1.38

GRAY 4.36

The metering tip is replaceable. Change the metering tip to adjust the amount of chemical used per job. Refer to the fl ow rate chart

above and included with your metering tips.

To change the metering tip, carefully unscrew the tip that is installed and replace it with the tip of your choice. Put the tip you

removed in a safe and clean location.

NOTE: the Torquiose tip is installed at the factory.

The solution hose to the

machine attaches here

CHEMICAL INJECTOR & WATER CONNECTION ASSEMBLY

Metering Tip

CHEMICAL INJECTOR

Direction of fl ow

Connects to the

water source

1/12 A - 7 56041839 - TORRENT

INSTRUCTIONS FOR USEA - ENGLISH

revised 1/12

PUMP MAINTENANCE:

Oil Change:

The fi rst oil change is required after the fi rst 50 hours of use. Impurities will get into the oil during the break-in phase, and it is

necessary to change the oil to remove the contamination that can lead to premature pump wear. After this initial oil change, we

recommend changing the oil in the pump every three months or 300 hours of use.

NOTE: in locations with high humidity and/or wide, daily temperature ranges, it is possible for some condensation to appear inside the

pump crankcase. Condensation is evident if the oil looks white and/or milky. While a small amount of condensation in the crankcase

is not a problem, a large amount of water in the oil (20% or more of the liquid is water) requires oil changes more frequently.

NOTE: the pump in your Torrent is in the front of the base compartment. The drain plug is located on the left side of the pump, near

the bottom. The dip stick (and oil fi ll port) is on the top of the pump. The front of the pump contains an Oil Level Indicator that can be

seen through a hole in the front of the base compartment. The indicator is a clear view window with a yellow plate showing. A red dot

in the center of the yellow plate indicates the oil fi ll mark. The oil level should be at or just slightly above the red dot.

NOTE: It is a good idea to run the pump for a few minutes before changing the oil, but be sure to unplug the machine before you

begin the process of changing the oil.

Use 11.8 ounces of SAE 15W-40 oil in your pump. Follow the steps below to correctly change the oil in your Torrent pump.

1. Unplug the machine. Put the machine on a plastic sheet to protect the fl ooring surface from oil.

2. Open the latch and raise the tank. Prop the tank open so your hands are free to work on the pump. Move the two hydraulic

hoses that pass over the pump out of the way by disconnecting them at the quick disconnects at unloader valve assembly.

3. Place a two-cup or larger container under the hole in the base, at the front of the machine, to catch the oil as it drains from the

pump.

4. Loosen the dip stick.

5. Loosen and remove the plug in the bottom of the left side of the pump. Let the oil drain out until the pump is empty.

6. Remove the dip stick. NOTE: take care not to let oil drip onto the pump or other components.

7. Pour a few ounces of fresh oil into the pump, at the dip stick hole, and let it drain through to fl ush out any impurities. Be careful

not to spill any oil on the pump or elsewhere.

8. Replace the pump drain plug. Tighten.

9. Carefully pour about 11 ounces of fresh oil into the pump. Give it a little time to settle.

10. While watching the oil level at the Oil Indicator window (on the front of the pump head), carefully pour a little more oil into the

pump until the level reaches the red dot in the window.

11. Once the oil has reached the correct level, install the dip stick.

12. Clean up any/all oil that may have spilled or dripped inside the base of the machine.

13. Let the tank down. Move the machine away from the oil in the container on the fl oor.

14. Clean up any oil that has spilled. Pick up the container of drained oil, the plastic sheet, the oil container(s) and dispose of all of it

according to environmental regulations.

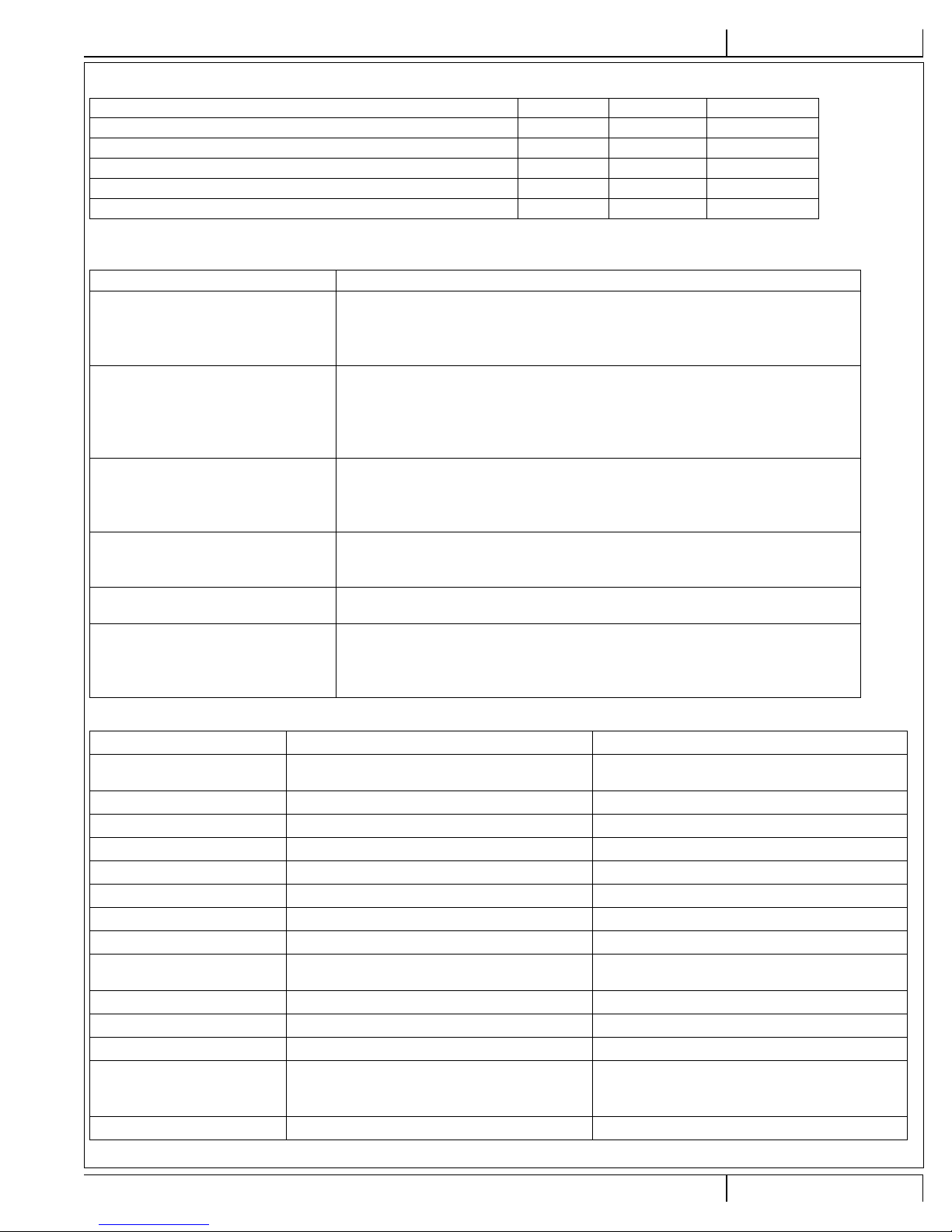

TORRENT PUMP MAINTENANCE SCHEDULE

It is critical that you maintain your pump properly in order to get the performance and longevity that it can provide.Change the oil in your pump after

the fi rst 50 hours of operation, then follow this maintenance schedule.

TASK DAILY WEEKLY AS NEEDED

Inspect and clean pump inlet fi lters X

Check oil for correct level and consistency X

Check pump for oil and water leaks X

Check fi ttings for proper tightness X

Change Oil every 300 hours (after the fi rst one at 50 hours) X

Packing Change X

Valve Change X

NOTE: if the oil shows signs of contamination (milky or discolored) change it immediately, and replace the packings. Keep a record of each task

performed and the date completed.

A - 8 TORRENT - 56041839 1/12

revised 1/12

MAINTENANCE SCHEDULE

TASK DAILY WEEKLY YEARLY

Flush tank out with clean water X

Flush dump pump out with clean water X

Check/Clean Electronic Float X

Check/Clean Ball Floats at Vacuum Inlets in Recovery Tank X

*Check Carbon Brushes X

*Have a US Products service technician check the vacuum motor brushes once a year or after 300 operating hours.

GENERAL TROUBLESHOOTING

IF THIS CHECK THIS

Pump or Vac Does Not Turn On Check the circuit breakers in the wall. If both cords were on one circuit the breaker may

have tripped.

The switches should light up when turned ON. Check the switch to make sure it is

working.

Dump Pump Not Discharging Check the circuit breakers in the wall. If both cords were on one circuit the breaker may

have tripped.

The switches should light up when turned ON. Check the switch to make sure it is

working.

Check electronic fl oat to make sure it is not obstructed and moving freely.

Pump Pressure is Low Check the spray tip(s) for proper size or excessive wear.

The pressure relief valve may be stuck open, or the seat may be worn.

Check the inlet fi lters for dirt or debris.

The pump inlet or outlet valves may be dirty or damaged.

Vacuum Suction is Low Make sure the tank lid is closed tightly, the drain hose is closed tightly, and the recovery

hose is tight at the vac inlet hose barb and at the tool.

Check the hose for cracks.

Water Leaking from Pump Worn packing in pump.

ENGLISH - AINSTRUCTIONS FOR USE

Oil Leaking from Pump Worn piston seals.

Misaligned oil seal O-Ring.

Bad bearing.

Damaged crankcase.

TECHNICAL SPECIFICATIONS (as installed and tested on the unit)

MODEL TORRENT 56380561

POWER CORD:

POWER CONSUMPTION: 15 Amps, each cord 15 Amps, each cord

RECOVERY CAPACITY: 9 gallon 9 gallon

VACUUM INTAKE HOSE: 1.5” inch X 25 ft 1.5” inch X 25 ft

VACUUM MOTOR(s): Two, 3-stage Two, 3-stage

WATER LIFT/CFM: 100 inches / 170 cfm 100 inches / 170 cfm

AIR WATTS: 520 AW in operational range 520 AW in operational range

OVERFLOW PROTECTION: Electronic fl oat; auto off/on Electronic fl oat; auto off/on

HIGH PRESSURE PUMP

DISCHARGE PUMPS: One diaphragm bilge pumps One diaphragm bilge pumps

DISCHARGE HOSE: One 3/4 inch X 50 ft One 3/4 inch X 50 ft

DISCHARGE RATE: 5.2 GPM 5.2 GPM

FILTER SYSTEM:

WEIGHT 145 LBS 145 LBS

Two, 25 ft, 12 gauge, 3-wire with hospital grade

plug

Triplex Plunger Pump, Adjustable 1200-400 psi

working pressure,

One 80 micron mesh strainer at water inlet on

recovery tank; One 60 mesh S/S fi lters in the

recovery tank

Two, 25 ft, 12 gauge, 3-wire with hospital grade plug

Triplex Plunger Pump, Adjustable 1200-400 psi

working pressure,

One 80 micron mesh strainer at water inlet on

recovery tank; One 60 mesh S/S fi lters in the

recovery tank

1/12 A - 9 56041839 - TORRENT

INSTRUCCIONES DE USOB - ESPAÑOL

revised 1/12

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

Esta máquina es apta únicamente para su uso comercial; por ejemplo, en hoteles, colegios, hospitales, fábricas, tiendas y ofi cinas, y

no para limpieza doméstica habitual.

Cuando utilice un aparato eléctrico, se deben respetar las precauciones básicas, incluidas las siguientes:

NOTA: lea todas y cada una de las instrucciones antes de utilizar la máquina.

¡ADVERTENCIA!

Para reducir el riesgo de incendios, descargas eléctricas o lesiones:

Nunca ajuste la presión de la bomba por encima de 1200 psi.•

No abandone la máquina mientras esté enchufada. Cuando no la esté utilizando o antes de realizar el servicio, •

desenchúfela.

Para evitar descargas eléctricas, no la deje expuesta a la lluvia ni a la nieve. Guárdela y úsela en lugares cubiertos.•

No permita que se utilice como juguete. Es necesario prestar mucha atención si se la usa cerca de niños.•

Utilice sólo de la manera descrita en este manual. Utilice únicamente los accesorios recomendados por el fabricante.•

No utilice si observa daños en el cable o el enchufe. Si la máquina no funciona correctamente, se ha caído, ha sufrido •

daños, se ha dejado a la intemperie o ha caído al agua, acuda a un centro de servicio.

No tire del cable ni lo utilice a modo de asa, evite que el cable quede atrapado al cerrar una puerta y no tire de él contra •

bordes afi lados ni esquinas. No haga pasar la máquina por encima del cable. Mantenga el cable alejado de superfi cies

calientes. Para desenchufar, agarre el enchufe y no el cable.

No manipule el enchufe, el cable ni la máquina con las manos húmedas.•

Los alargadores deben ser de 12/3 y su longitud no debe superar los 15,24 m. Sustituya el cable o desenchufe •

inmediatamente si la clavija de tierra está dañada.

No coloque ningún objeto en las aberturas. No utilice la máquina si las aberturas están obstruidas; manténgalas libres de •

polvo, hilos, pelo o cualquier otra sustancia que pueda reducir el caudal de aire.

Mantenga el cabello, las ropas sueltas, los dedos y todas las partes del cuerpo lejos de las aberturas y de las partes en •

movimiento.

No recoja ningún material en combustión o que eche humo, como cigarrillos o cerillas, o cualquier tipo de polvo que •

representara una amenaza para la salud. No utilice para recoger líquidos infl amables o combustibles, como gasolina, ni en

lugares en los que pueda haber dichos líquidos.

Apague todos los controles antes de desenchufar.•

Enchufe sólo a una toma de corriente debidamente conectada a tierra.•

El líquido eyectado por la boquilla de pulverización podría ser peligroso debido a su temperatura, presión y/o contenido •

químico.

•

GUARDE ESTAS INSTRUCCIONES

¡ADVERTENCIA!

Los Productos a la venta con este Manual contienen, o pueden contener, productos químicos reconocidos por algunos gobiernos (como el

Estado de California, según lo indica en su Proposición 65, Ley de Advertencia Regulatoria) como causantes de cáncer, defectos de nacimiento

u otros daños reproductivos. En algunas jurisdicciones (incluido el Estado de California), los compradores de estos Productos que los coloquen

en servicio en un emplazamiento laboral o en un espacio de acceso público tienen la obligación regulatoria de realizar determinados avisos,

advertencias o divulgaciones respecto de los productos químicos contenidos o posiblemente contenidos en los Productos utilizados en tal lugar.

Es la responsabilidad del comprador conocer y cumplir con todas las leyes y reglamentaciones relacionadas con el uso de estos Productos en

tales entornos. El Fabricante niega toda responsabilidad de informar a los compradores sobre requisitos específi cos que pueden regir el uso de

los Productos en tales entornos.

B - 10 TORRENT - 56041839 1/12

Loading...

Loading...