Usp connectors USP SIP User Manual

USP SIP Connection Manual

P

www.

Structural

Insulated Panels

(SIP)

UUSSP

connectors.com

Lumberton • Largo • North W

©

Copyright 2005 United Steel Products Company

ilkesboro • Montgomery • Houston • Rancho Cucamonga • Livermore • Long Beach • Thornhill, Ontario

USP903-051

CCoommppaannyy IInnffoorrmmaattiioon

2

n

C

ompany History

USP Structural Connectors®(United Steel Products

ompany) has been designing, manufacturing, and

C

marketing construction hardware for over 50 years. The

company’s experience in marketing, engineering, and

service has allowed USP to be a leader in developing new

connectors for a changing construction industry.

Burnsville, MN Corporate Office

14305 Southcross Drive

Suite 200

Burnsville, MN 55306

Phone: 1-952-898-8772

Phone: 1-800-328-5934

Fax: 1-507-364-8762

Livermore, Western Region

2150 Kitty Hawk Road

Livermore, CA 94551-9522

Phone: 1-800-227-0470

ISO 9001:2000

Registered

Phone: 1-925-449-4100

Fax: 1-925-373-9213

Largo, Eastern Region

11910 62nd Street North

Largo, FL 33773-3705

Phone: 1-800-328-5934

Fax: 1-727-535-8199

Thornhill, Canadian Office

221 Racco Parkway

Thornhill, ON L4J 8X9

Phone: 1-800-387-3589

Fax: 1-905-669-1563

UUSSPPSSttrruuccttuurraall CCoonnnneeccttoorrss®

in Montgomery, Livermore, Largo,

and North Wilkesboro achieved

registration of its quality

system in accordance with

the requirements of

ISO 9001:2000

®

U

SP Operations Include

• Nine strategically placed manufacturing and warehousing

ocations.

l

• In-house quality control and testing with independent,

third-party plant inspection, and test witnessing.

• On staff licensed professional engineers.

• Our National Factory Technical Sales Force is ready

to help with application questions.

• Ongoing regional and national code evaluations as

products are developed.

Product Questions & Answers

The Customer Service/ Technical Assistance staff is

ready to answer your questions and help solve your

connector related problems. Our staff can assist you in

developing economical solutions to your structural

connection problems.

When calling for Technical Assistance, please have the

following information ready:

• Which USP product are you using?

• What is connector application?

• What is the header material and application?

• What is the load requirement?

Table of Contents

Company Information . . . . . . . . . . . . . . . . . . . . . . . . .2

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

Anchor Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foundation

Anchors

. . . . . . . . . . . . . . . . . . . . . . . . . .

Holdowns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9, 11

ARRANTY

W

United Steel Products Company warrants its products to be free from defects in material

and workmanship. Said products are further warranted as to adequacy of design, provided

products are used in strict accordance with United Steel Product Company’

design limits and are installed in a workmanlike manner

the event products are cut, notched, welded, drilled or in any way altered). No warranty

applies if deterioration occurs due to environmental conditions. United Steel Products

Company’s obligations under this warranty shall be limited to the replacement or repair of

those products demonstrated to be defective. Such remedy shall constitute Customer’s

sole and exclusive remedy and Customer hereby agrees that no other remedy (including,

. (Said warranties do not apply in

Customer Service / Technical Assistance

4-5

7, 9

s current published

Burnsville, MN Corporate Office

Foundation Straps . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Floor Ties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Joist Hangers . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ridge Ties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Specification T

8

iedowns

T

but not limited to claims for INCIDENT

OR ANY CAUSE, LOSS, ACTION, CLAIM OR DAMAGE, INCLUDING LOSS OF TIME,

WHATSOEVER, OR INJURY TO PERSON OR PROPERTY OR ANY OTHER CONSEQUENTIAL

DAMAGE OR INCIDENTAL OR ECONOMIC LOSS) shall be available to Customer

said claims be asserted on the basis of warranty, negligence, strict liability or otherwise.

ARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR

W

IMPLIED, INCLUDING ANY WARRANTIES OF MERCHANTABILITY AND FITNESS FOR

A PARTICULAR PURPOSE, ALL SUCH OTHER WARRANTIES BEING HEREBY

EXPRESSLY EXCLUDED.

ools

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AL, CONSEQUENTIAL

OR SPECIAL

1-800-328-5934

12-13

DAMAGES,

whether

THIS

15

15

GGeenneerraall IInnffoorrmmaattiioon

G-185 Galvanization

TRIPLE ZINC

n

Please Note

• USP Structural Connectors®reserves the right to change

specifications, designs, and models without notice and

liability for such changes. This catalog may not be

eproduced in whole or in part without the prior written

r

approval of USP Structural Connectors®.

• This SIP Connection publication was designed as a

general reference for the USP Product Line. See USP’s

Full Line Catalog for complete product information.

• To achieve the allowable loads presented in this

catalog, all specified fasteners must be used and

proper installation procedures observed. Verify that the

dimensions of supporting members are sufficient to

receive specified fasteners. Any product modifications

void the warranty unless

USP Structural Connectors®is obtained.

• Nails specified as 8d, 10d, 16d, and 20d are common

wire nails.

• See USP’s

code information.

• This publication shows common SIP connections.

Please refer to SIP manufacturers literature for complete

SIP connection information.

• Allowable loads shown in this publication are based on

connections to wood members. Fasteners connecting

only to the panel skin have not been considered.

Full Line Catalog for testing, material, and

prior written permission of

NDS® Standards

The load resistance values presented in this catalog

reflect the calculation criteria set forth in the 1991 revised

and 1997 National

Construction (NDS®) published by the

and Paper Association. The values shown in this catalog

supercede those previously printed.

Design Specification for Wood

American Forest

Douglas Fir-Larch or Hem Fir Equivalent Capacity

Unless otherwise noted, the published design loads in

this catalog apply to Spruce-Pine-Fir lumber

catalog, no provisions are made to increase these loads

when using Douglas Fir-Larch, Southern Pine, or Hem Fir

lumber. Contact USP Technical Assistance for additional

information regarding load capacities for species other

than Spruce-Pine-Fir.

esting

T

On all structurally-rated products, USP performs full-scale

testing in accordance with ASTM D 1761, the standard

recognized by all domestic code agencies. All final testing

is conducted by a third-party testing laboratory.

. In this

Material

USP Structural Connectors®are manufactured from prime

quality steel which meets ASTM A 653 requirements

3

for galvanized steel, and ASTM A 1011, or ASTM A 36 for

hot-rolled steel.

Finish

All galvanized products have a zinc coating as

specified in ASTM A 653. Hot-dip galvanized parts are

galvanized after fabrication per ASTM A 123.

Non-galvanized steel products are prime coated for

corrosion protection.

Corrosion Resistant Finishes

USP Structural Connectors®offers three options for

improved corrosion resistance of their connectors.

Triple Zinc (TZ) – galvanizing provides a prefabrication

coating of 1.85 (G-185) ounces of zinc per square

foot of surface area measured in accordance with

ASTM A 653.

Required Fastener: Hot-dip galvanized fasteners

Hot-Dip Galvanized (HDG) – coating provides an

after fabrication hot-dipped zinc coating. The coating

thickness is dependent on the connector material,

but generally ranges from 1.1 to 2.3 ounces of zinc

per square foot of surface. Hot-dip products meet

requirements set forth in ASTM A 153.

Required Fastener: Hot-dip galvanized fasteners

Stainless Steel (SS) – is the best option for corrosion

protection. Quality stainless steel (316SS grade steel)

is used to fabricate connectors. Although costs are

higher, some applications may need the virtual

corrosion proof quality of stainless steel.

Required Fastener: Stainless Steel fasteners

Connector Use with Preservative T

For minimum corrosion protection, USP Structural

Connectors®recommends consumers use Triple

G-185 or HDG connectors in all outdoor applications and

with treated lumber. In general, connectors, including

anchors and fasteners, installed in corrosive environments

exposed to corrosive materials, or chemicals, can be

damaged, possibly resulting in the reduction of load

values.

in potentially corrosive environments.

For more information on industry changes to pressure

treated wood and associated use of connectors

and fasteners refer to USP’s Corrosion Protection News,

USP953, or visit our website at www

Standard G90 connectors should not be installed

.USPconnectors.com.

reated Wood

Zinc

or

www.USPconnectors.com

e-mail: info@USPconnectors.com

© Copyright 2005 United Steel Products Company

USP903-051

4

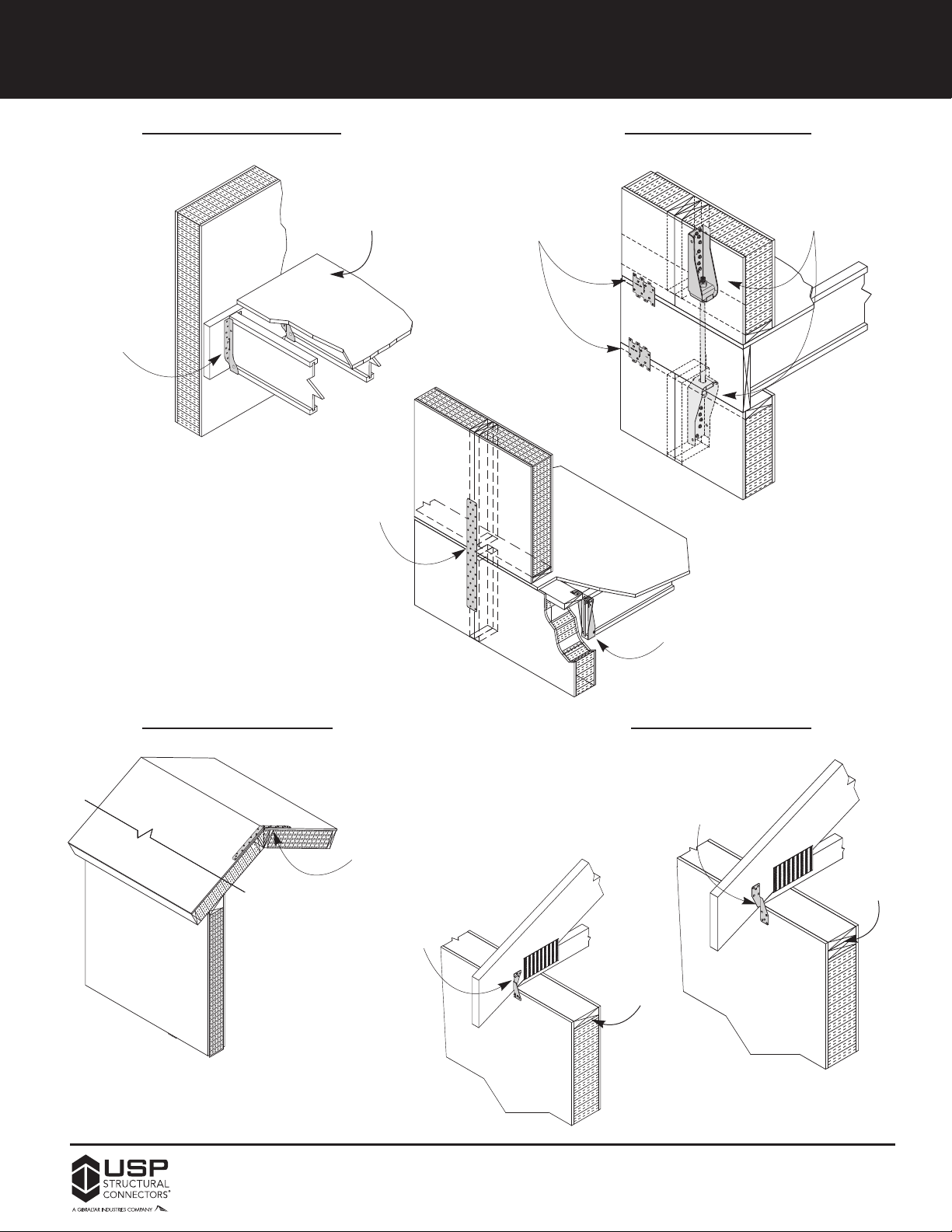

IInnddeex

x

STAD8

Page 10

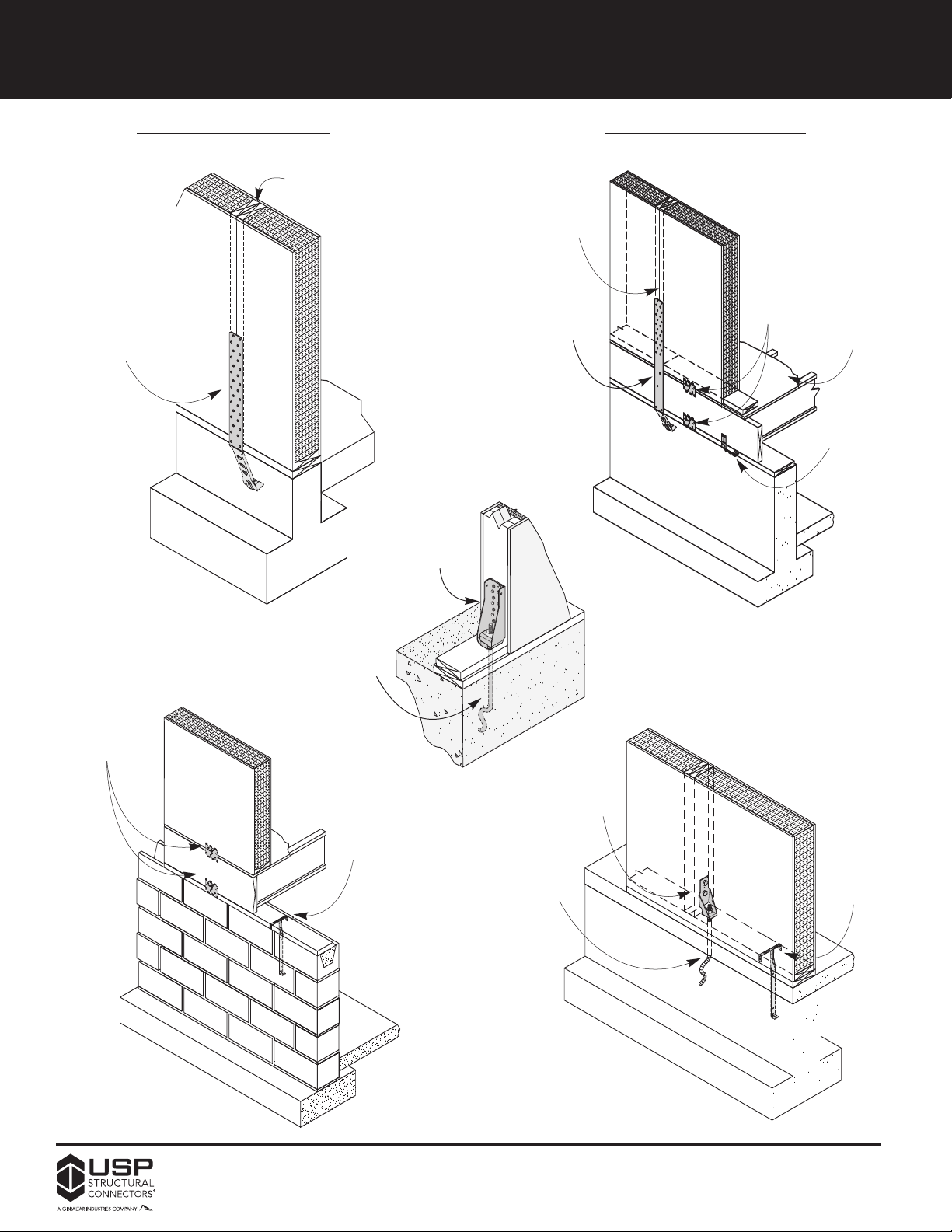

Shear Wall

end post

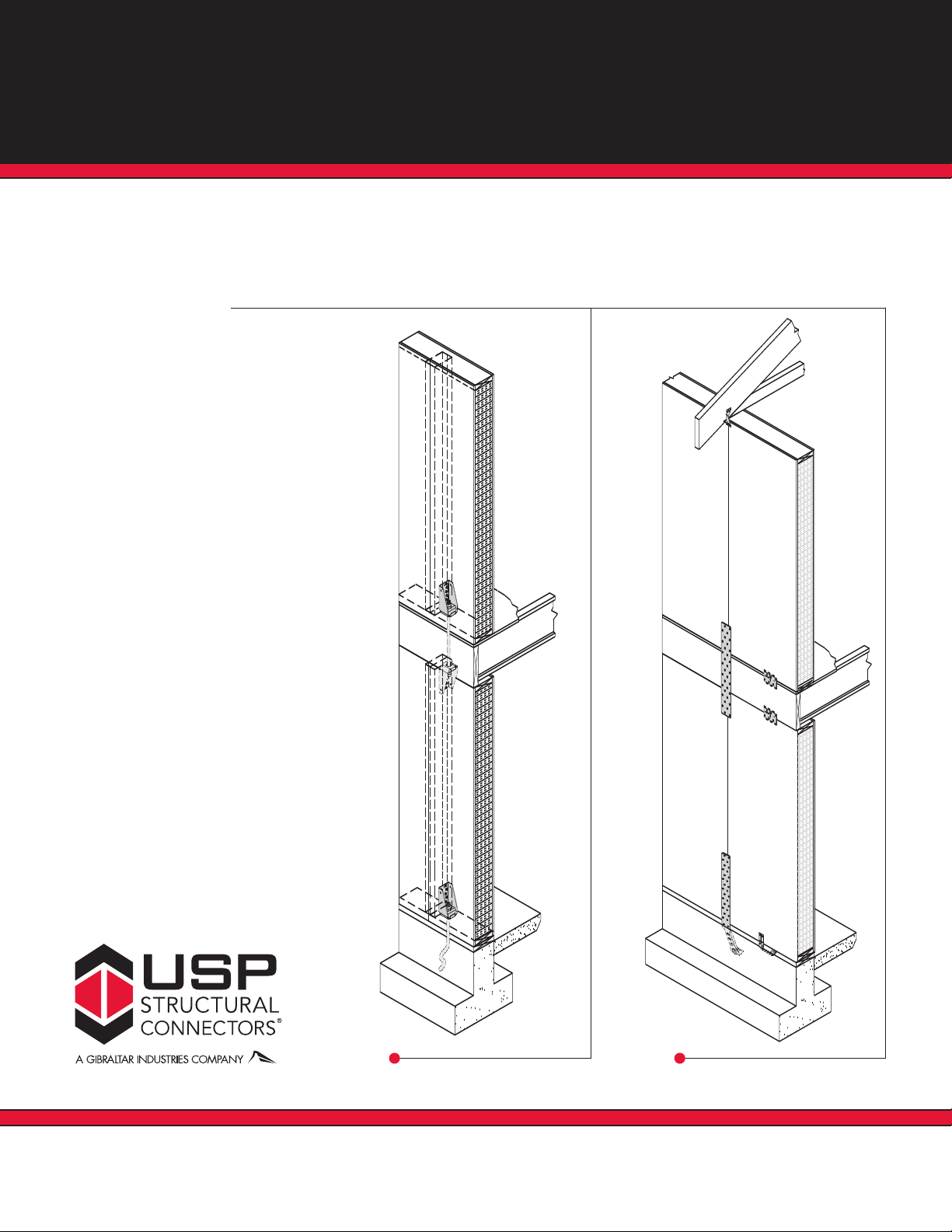

SIP Foundation Connections

Tension compression

post at end of

shear wall

STAD8RJ

Page 10

MP4F

Page 8

Floor

FA3

Page 8

MP4F

Page 8

STB series

Anchor Bolt

Page 9

ST2-TZ

Page 8

PHD

Page 9

STB series

Anchor Bolt

Page 9

TDX

Page 9

ST2-TZ

Page 8

Customer Service / Technical Assistance

Burnsville, MN Corporate Office

1-800-328-5934

IInnddeex

THF

Page 13

x

SIP Multi-Story Connections

Floor

MSTC

Page 11

P4F

M

Page 8

HD

P

Pages 11

5

SIP Rafter & Truss Connections

A

LST

Page 14

RT3

15

Page

2x top plate

THO

Pages 12 & 13

RT7A

15

Page

Double top

plate

www.USPconnectors.com

e-mail: info@USPconnectors.com

© Copyright 2005 United Steel Products Company

USP903-051

Loading...

Loading...