Usp connectors EWP User Manual

EWP Product Guide 2005

P

www.

UUSSP

connectors.com

THF17925

Lumberton • Largo • North W

©

Copyright 2005 United Steel Products Company

LSSH23

ilkesboro • Montgomery • Houston • Rancho Cucamonga • Livermore • Long Beach • Thornhill, Ontario

THO171

18

USP952-051

2

USP Index

IInnddeexxees

s

BPHB

eam & Purlin Hangers . . . . . . . . . . . 22-23, 27-40, 55, 57

CBE Column Bases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48-49

CBS Column Bases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

CBSQ Column Bases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

EPCM End Post Caps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

EWP Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-13

HD Face Mount Hangers . . . . . . . . . . . . . . . 14-15, 17-19, 55-56

H

LBHBeam Hangers . . . . . . . . . . . . . . . . . 26, 31-40, 55, 57-58

HTW Twist Straps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

HUS Face Mount Hangers . . . . . . . . . . . . . . . . . . . . . . 14-15, 17

KCB Column Bases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48-49

KCBQ Column Bases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

KCCC

olumn Caps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52-53

KCCQ Column Caps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

KECC End Column Caps . . . . . . . . . . . . . . . . . . . . . . . . . . 52-53

KECCQ End Column Caps . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

KLCC Lally Column Caps . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

KSTI Strap Ties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46-47

LBH Beam Hangers . . . . . . . . . . . . . . . . . . 26, 31-40. 55, 57-58

LSSH Slope/Skew Hangers . . . . . . . . . . . . . . . . . . . . . . . . 42, 56

LSTA Strap Ties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46-47

LSTI Strap Ties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46-47

MPH Masonry Hangers . . . . . . . . . . . . . 24-25, 27-40, 55, 57-58

MSH Strap Hangers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

MSTA Strap Ties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46-47

MSTC Strap Ties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46-47

Reference Number Index

M

TW Twist Straps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

NA Nails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

NFM Masonry Hangers. . . . . . . . . . . . . . . . . . . . . . 41, 55, 58-59

PAI Purlin Anchors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

PCM Post Caps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

PH Top Flange Hangers. . . . . . . . . . 24-25, 27-28, 33, 55, 57-58

PHI I-Joist Top Flange Hangers . . . . . . . 24-25, 27-35, 55, 57-58

PHMT

op Flange Hangers . . . . . . . . . . . 24-25, 27-40, 55, 57-58

PHX Top Flange Hangers . . . . . . . . . . . 24-25, 27-40, 55, 57-58

PHXU Top Flange Hangers . . . . . . . . . . 24-25, 27-40, 55, 57-58

RT Hurricane/Seismic Anchors . . . . . . . . . . . . . . . . . . . . . . . . 45

SKH Skewed 45˚ Hangers . . . . . . . . . . . . . . . . . . . . . . 20-21, 55

S

KHHSkewed 45˚ Hangers . . . . . . . . . . . . . . . . . . . . . 20-21, 55

Specialty Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55-58

Specification Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

TFI Top Mount Hangers . . . . . . . . . . . . . . . . 22-23, 29-31, 34-35

TFL Top Mount Hangers . . . . . . . . . . . . . . . . . . . . . 22-23, 29-30

THD Face Mount Hangers. . . . . . . . . . . . . . . . . . . . 16-19, 55-56

THDH Face Mount Hangers . . . . . . . . . . . . . . . . . . 16-19, 55-56

THF Face Mount Hangers . . . . . . . . . . . . . . 14-15, 17-19, 55-56

THO Top Mount Hangers. . . . . . . . . . . . . . . . . . . . . 22-23, 27-40

TMP Rafter-to-Plate Connectors . . . . . . . . . . . . . . . . . . . . . . . 43

TMPH Rafter-to-Plate Connectors . . . . . . . . . . . . . . . . . . . . . . 43

WS Wood Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

WS Wood Screw Applications. . . . . . . . . . . . . . . . . . . . . . . 10-11

About the Reference Numbers

Reference numbers shown throughout the

charts in this catalog are part numbers which

may be more familiar to customers in various

regions of the United States. These are

included for the convenience of our new

customers who have recently switched from a

competitor’s product line to USP.

The reference numbers in this catalog are

for general application comparison only and

should not be used as a substitution tool.

The user is responsible to compare specific

load values, fastener schedules, material

specifications, and other factors to

determine suitability of use for any

particular product.

B Hanger . . . . . . . . . . . . . . . . . . . . .27-34

CB Column Base . . . . . . . . . . . . . . . . . .49

CBQ Column Base . . . . . . . . . . . . . . . . 49

CBS Column Base . . . . . . . . . . . . . . . . 50

CBSQ Column Base . . . . . . . . . . . . . . . 50

CC Column Cap . . . . . . . . . . . . . . . . . .52

CCQ Column Cap

WARRANTY

United Steel Products Company warrants its products to be free from defects in material

and workmanship. Said products are further warranted as to adequacy of design, provided

products are used in strict accordance with United Steel Product Company’

design limits and are installed in a workmanlike manner

the event products are cut, notched, welded, drilled or in any way altered). No warranty

applies if deterioration occurs due to environmental conditions. United Steel Products

Company’s obligations under this warranty shall be limited to the replacement or repair of

those products demonstrated to be defective. Such remedy shall constitute Customer

sole and exclusive remedy and Customer hereby agrees that no other remedy (including,

. . . . . . . . . . . . . . . . .54

ECC Column Cap . . . . . . . . . . . . . . . . .52

ECCQ Column Cap . . . . . . . . . . . . . . . 54

EPC Post Cap . . . . . . . . . . . . . . . . . . . .51

GLTV Hanger . . . . . . . . . . . . . . . . . 31-40

H Hurricane Ties . . . . . . . . . . . . . . . . . .45

HB Hanger . . . . . . . . . . . . . . . . . . . .35-36

HGLTVHanger

HGUS Hanger . . . . . . . . . . . . . . . . .18-19

HHUS Hanger . . . . . . . . . . . . . . . . . .18-19

HSUR/HSUL Hanger . . . . . . . . . . . . . . 21

HTS Twist Strap . . . . . . . . . . . . . . . . . . .47

HU Hanger . . . . . . . . . . . . . . . . . . . .17-19

HUS Hanger . . . . . . . . . . . . . . . . . . . . .17

HW Hanger . . . . . . . . . . . . . . . . . . . .29-40

HWU Hanger . . . . . . . . . . . . . . . . . .31-40

ITT Hanger . . . . . . . . . . . . . . . . . . . 27-34

IUS Hanger . . . . . . . . . . . . . . . . . . . . . .17

IUT Hanger . . . . . . . . . . . . . . . . . . .17-18

LBV Hanger

LCB Column Base

LCC Lally Column Cap . . . . . . . . . . . . .54

LSSU Hanger . . . . . . . . . . . . . . . . . . . . 42

. (Said warranties do not apply in

s current published

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

but not limited to claims for INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES,

OR ANY CAUSE, LOSS, ACTION, CLAIM OR DAMAGE, INCLUDING LOSS OF TIME,

WHATSOEVER, OR INJURY TO PERSON OR PROPERTY OR ANY OTHER CONSEQUENTIAL

DAMAGE OR INCIDENTAL OR ECONOMIC LOSS) shall be available to Customer

said claims be asserted on the basis of warranty, negligence, strict liability or otherwise.

WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING ANY WARRANTIES OF MERCHANTABILITY AND FITNESS FOR

A PARTICULAR PURPOSE, ALL SUCH OTHER WARRANTIES BEING HEREBY

s

’

EXPRESSLY EXCLUDED.

31-40

32-37

49

LSTA Strap Tie . . . . . . . . . . . . . . . . . . .46

LSTI Strap Tie . . . . . . . . . . . . . . . . . . . .46

MBHA Masonry Hanger . . . . . . . . . . . 41

MIT Hanger . . . . . . . . . . . . . . . . . . . .29-36

MIU Hanger . . . . . . . . . . . . . . . . . . . 17-19

MSTA Strap Tie . . . . . . . . . . . . . . . . . . 46

. . . . . . . . . . . . . . . . . . 46

MSTC Strap

Tie

MSTI Strap Tie . . . . . . . . . . . . . . . . . . . .46

MTS Twist Strap . . . . . . . . . . . . . . . . . . 47

Nails . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

PAI Purlin Anchor . . . . . . . . . . . . . . . . . 48

PC Post Cap . . . . . . . . . . . . . . . . . . . . .51

SDS Screw . . . . . . . . . . . . . . . . . . . 10-11

SUR/SUL Hanger . . . . . . . . . . . . . . . . . 21

THA Hanger . . . . . . . . . . . . . . . . . . . . 44

THAC Hanger . . . . . . . . . . . . . . . . . . . . 44

THAI Hanger . . . . . . . . . . . . . . . . . . . . 44

W Hanger . . . . . . . . . . . . . . . . . . . . 27-34

WM Hanger

WP Hanger

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

27-34

27-34

WPU Hanger . . . . . . . . . . . . . . . . . . 27-34

whether

THIS

Customer Service / Technical Assistance

Burnsville, MN Corporate Of

1-800-328-5934

fice

HHiissttoorryy && PPrroodduucctt IInnffoorrmmaattiioon

n

3

ompany History

C

USPS

Company) has been designing, manufacturing, and

marketing construction hardware for over 50 years.

T

engineering, and superior customer service has

allowed USP to be the leader in developing new

structural connectors for a changing construction

industry.

tructural Connectors

he company’s experience in marketing,

®

United Steel Products

(

Burnsville, MN Corporate Office

14305 Southcross Drive

Suite 200

Burnsville, MN 55306

Phone: 1-952-898-8772

Phone: 1-800-328-5934

Fax: 1-507-364-8762

Livermore, Western Region

2150 Kitty Hawk Road

Livermore, CA 94551-9522

Phone: 1-800-227-0470

Phone: 1-925-449-4100

Fax: 1-925-373-9213

Largo, Eastern Region

11910 62nd Street North

Largo, FL 33773-3705

Phone: 1-800-328-5934

Fax: 1-727-535-8199

roduct Questions & Answers

P

The Customer Service/ Technical Assistance staff is

ready to answer your questions and help solve your

connector related problems. Our staff can assist you

in developing economical solutions for your structural

connection problems.

When calling for Technical Assistance, please have

the following information ready:

• Which USP product are you using?

• What is the width and height of both the supported

and supporting members?

• What is the header material and application?

What is the load requirement?

•

Thornhill, Canadian Office

221 Racco Parkway

Thornhill, ON L4J 8X9

Phone: 1-800-387-3589

Fax: 1-905-669-1563

USP Operations Include:

• Nine strategically placed manufacturing and

warehousing locations.

• In-house quality control and testing with independent,

third-party plant inspection, and test witnessing.

• On staff licensed professional engineers.

• Our National Factory Technical Sales Force is

ready to help with application questions.

• Ongoing regional and national code evaluations as

products are developed.

ISO 9001:2000 Registered

UUSSPP SSttrruuccttuurraall CCoonnnneeccttoorrss®

in Montgomery, Livermore, Largo,

and North Wilkesboro achieved

registration of its quality

system in accordance with

the requirements of

ISO 9001:2000

®

USP952-051

4

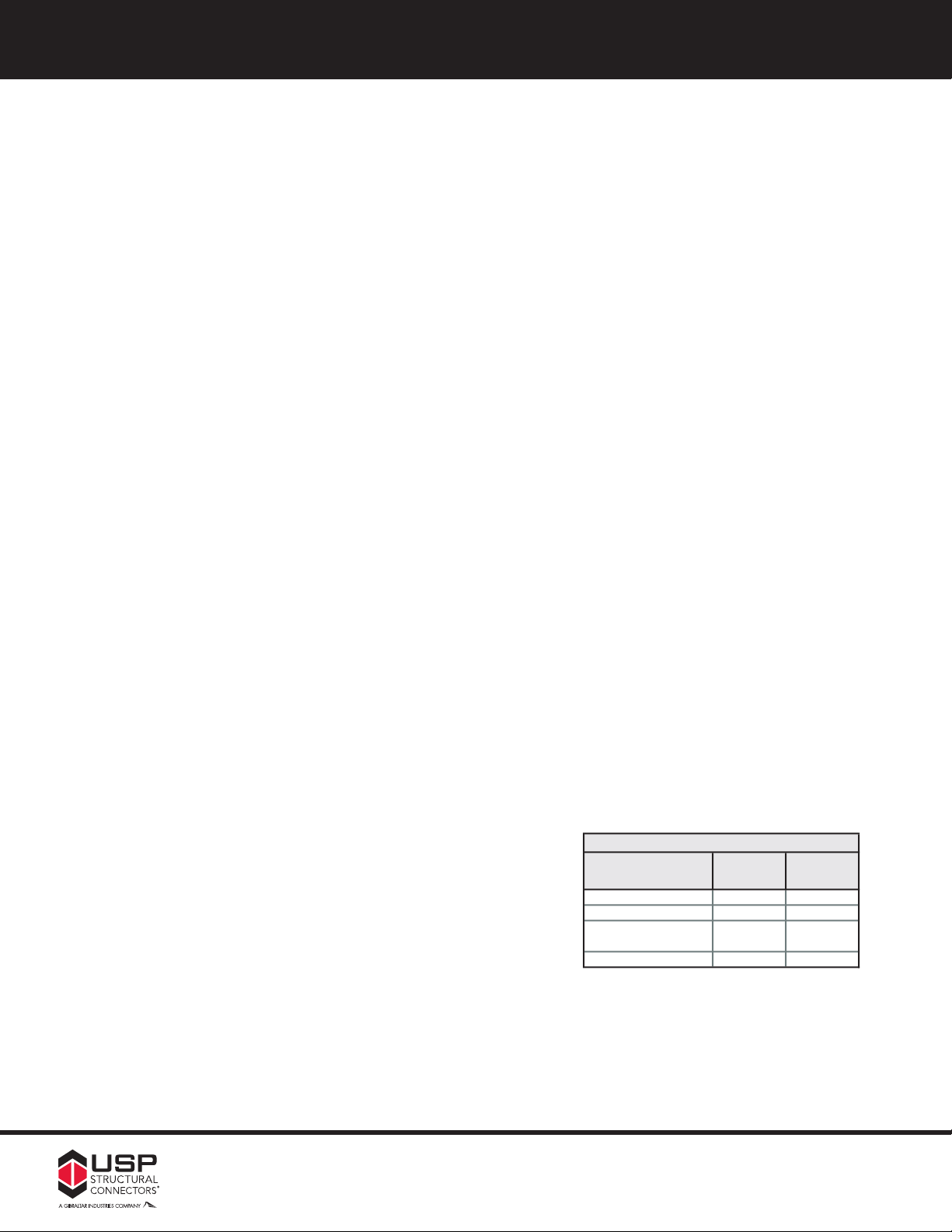

Douglas Fir-Larch (DF-L) 0.50 1.00

Southern Pine (SP) 0.55 1.00

Spruce-Pine-Fir (S-P-F) 0.42 0.86

1) Allowable loads must be adjusted according to the

applicable wood species.

2) When using structural composite lumber, verify wood species

and use above listed adjustment factors.

Douglas Fir (S)

Hem Fir (N)

0.46

0.88

Allowable Load Adjustment Factor

Wood

Species

Specific

Gravity

Adjustment

Factor

PPrroodduucctt IInnffoorrmmaattiioon

n

Please Note

1) USP Structural Connectors®reserves the right to

change specifications, designs, and models without

otice and liability for such changes. This catalog may not

n

e reproduced in whole or in part without the prior written

b

approval of

2) This catalog reflects design changes and design

USP Structural Connectors®.

load

adjustments to some USP products. The information

presented in this publication supercedes all information

published in previous documents, and is valid until

December 31, 2005.

3) This Full Line Catalog was designed as a general

reference for the USP Product Line. Various

specialized publications have been developed for design

professionals, truss manufacturers, contractors, retail

dealers, and building material wholesalers. Product load

values may vary from one publication to

another due to recent product testing, changes in

regulatory criteria, or code evaluation updates. The most

current product information is available on USP’s website.

4) To achieve the allowable loads presented in this

catalog, all specified fasteners must be used and

proper installation procedures observed. Verify that the

dimensions of supporting members are sufficient to

receive specified fasteners. Any product modifications

void the warranty unless

prior written permission of

USP Structural Connectors®is obtained.

5) Some connector models are listed more than once to

indicate installation and/or fastener options.

6)

Nails specified as 8d, 10d and 16d are common

wire

nails.

7) Bolts specified conform to

ASTM A 307 or better.

8) Products are sized for standard lumber, glulam, or

engineered wood products. For applications involving

unusual supporting conditions, excessive shrinkage, or

hostile environments, contact USP Structural Connectors®.

NDS®

Standards

Unless otherwise noted, the load resistance values

presented in this catalog reflect the calculation criteria set

forth in the 1997 or 2001 National Design Specification for

ood Construction (NDS

W

®

) published by the

American

Forest and Paper Association. Load values presented in

this catalog may not match those presented in previous

publications. The values shown in this catalog supercede

those previously printed.

Testing

On all structurally-rated products, USP performs

full-scale testing in accordance with ICC-ES, AC13, or

ASTM D 1761, the standard recognized by all

omestic code agencies. All final testing is conducted by

d

a third-party testing laboratory.

Material

USP Structural Connectors®are manufactured

from prime quality steel which meets ASTM A 653

requirements for galvanized steel, and ASTM A 1011, or

ASTM A 36 for hot-rolled steel.

Finish

All galvanized products have a zinc coating as

specified in ASTM A 653. Hot-dip galvanized parts are

galvanized after fabrication per ASTM A 123.

Non-galvanized steel products are prime coated.

All standard galvanized products manufactured after

January 1, 2005 will be made from G90 material.

Product Design Loads

The design loads listed are the lowest results obtained by

one of the following methods:

1) The lowest ultimate tested load divided by three.

2) Lowest load producing

3) Calculations based on 1997 or 2001 NDS®and current codes.

1

˝ deflection.

/

8

Duration of load adjustments for mechanical fastenings

are as follows:

Floor / Design Load . . . . . 100% no increase.

Roof Snow . . . . . . . . . . . . 115% of design load for 2-month duration of load.

Roof Non-Snow

Uplift. . . . . . . . . . . . . . . . . 133% or 160% of design load for wind/seismic

. . . . . . . .

125% of design load for 7-day duration of load.

loading based on local code requirements.

Spruce-Pine-Fir or Hem Fir Equivalent Capacity

Unless otherwise noted, the published design loads in this

catalog apply to Douglas Fir-Larch or Southern

Pine lumber. When Spruce-Pine-Fir or Hem Fir lumber

is use with

face mount

hangers or

straps, the

nail shear

capacity

maybe

adjusted

according to

the chart to

the right.

Customer Service / Technical Assistance

Burnsville, MN Corporate Of

1-800-328-5934

fice

PPrroodduucctt IInnffoorrmmaattiioon

No

1

1605.3.1.1, 1605.3.2

1) Increase is permitted with multiple transient loads(North American Specification

for the Design of Cold-Formed Steel Structural Members, 2001 Edition, NASPEC)

Steel Stress Increase Allowed

Basic Load

Combinations

Alternate Load

Combinations

n

Allowable Stress Increase Design Values

There have been recent changes in the model building

codes which affect the published design loads in this

catalog, as well as other USP catalogs. Historically,

ome design codes permitted the use of a one-third-

s

stress increase on steel allowable stress design values

hen resisting load combinations including wind and

w

seismic loads. Many states have recently adopted

model building codes which in some cases do not allow

you to take this stress increase. The table below shows

which building codes do and do not allow a

one-third-stress increase on steel.

Code Code Section

ASCE 7-98 No -- -- 2.4.3

ASCE 7-02 No -- -- 2.4.1

2000 IBC No Yes 1605.3.1, 1605.3.2

2003 IBC No

1997 UBC No Yes 1612.3.1, 1612.3.2

The code, however, does allow for a load duration

factor, which increases the allowable wood stress. This

is referenced in the National Design Specification

for Wood Construction which is referenced by

NDS®)

(

the model building codes. Load duration factors of

.15, 1.25, 1.33, and 1.6 are utilized for construction,

1

snow, wind, and seismic loads. For this reason the

tables in the catalog contain columns with allowable

loads listed for the different load duration factors. It is

important to note that the load duration factor is not

related to or affected by the recent changes in the steel

allowable stress increase.

As stated previously, removing the increases on

allowable steel stresses has affected the capacity of

some of our products. These products include many of

our strap ties and strap-type anchors. For these

products where a decrease in the allowable steel

stress controls the published value, the capacity of the

product, the published value reflects this. No

additional reduction is necessary. In addition, to match

the lower capacity of the connector, the minimum

number of nails required has been reduced in many

cases.

5

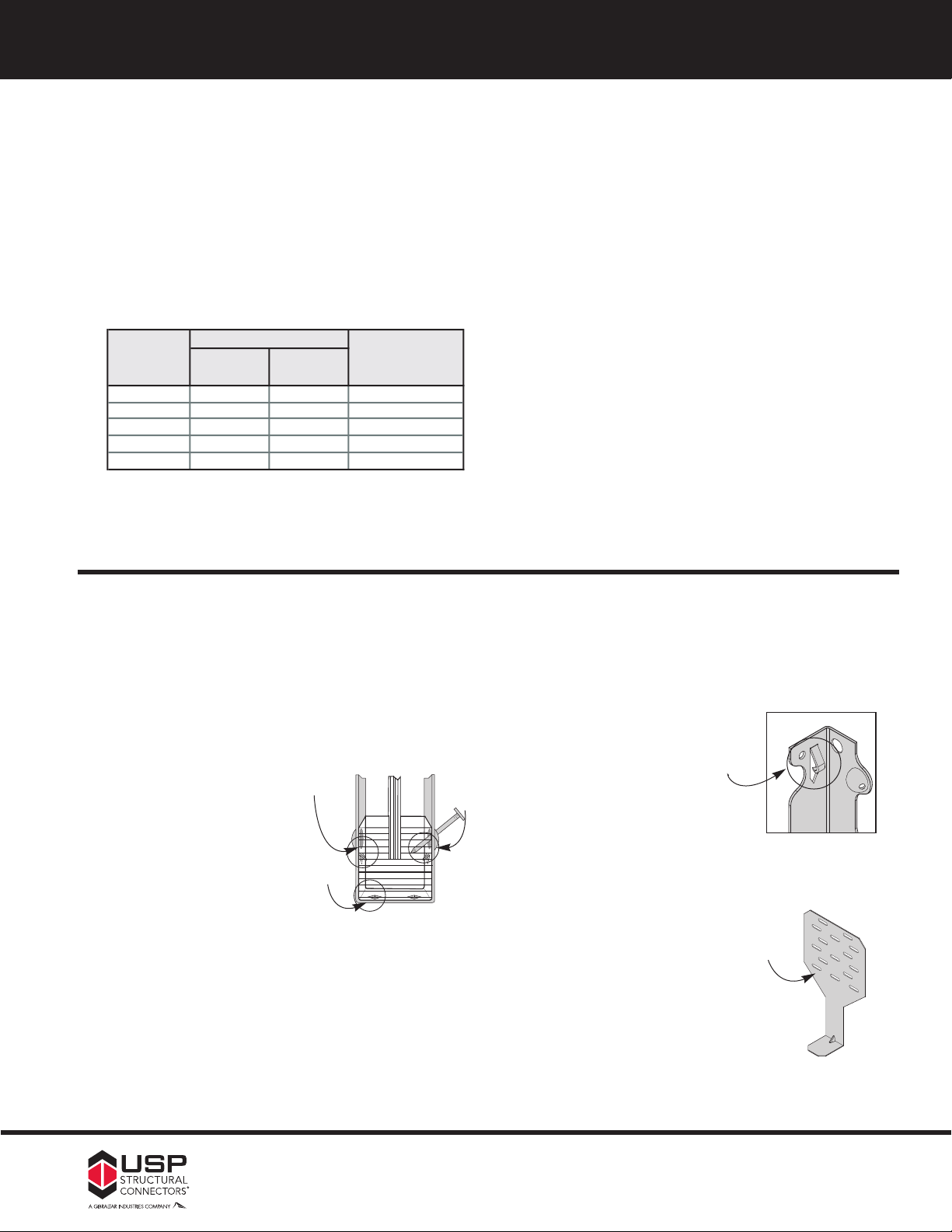

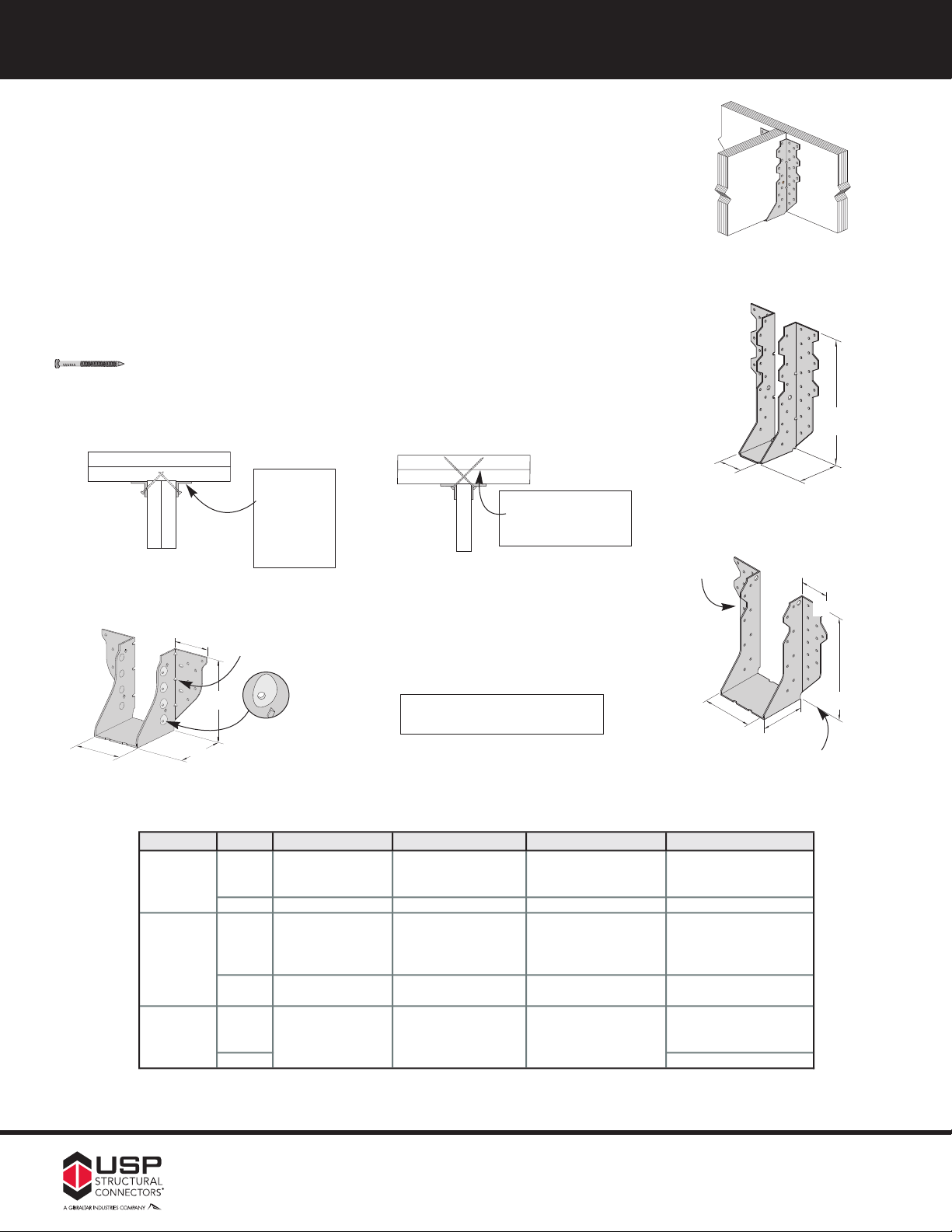

Special Fastening Features

Seat Cleat™ Prongs – U.S. Patent #5,564,248

USP’s TFL, THO and THF I-Joist hangers feature the

patented Seat Cleat™ prong. The Seat Cleat™ allows

framers to “pop” I-Joists into hanger seats for a positive

bearing lock. This prevents spring back during nailing,

reduces post installation I-Joist movment, and eliminates

connector related floor system noise (if hangers are

installed according to

s specifications).

USP’

Simple, quick, and

Slant Nailing

via Dimple

Nail Holes

Seat

Cleat™

Prongs

easy-to-use, the Seat

Cleat™ eliminates the

need to bend tabs and

drive nails from an

awkward angle into the

Diamond

Holes

I-Joist bottom flange.

Slant Nailing via Dimple Nail Holes – U.S. Patent #5,217,317

USP’s Dimple Nail Holes are used to indicate the need

for slant nailing. Unlike tabs, the dimple retains its

shape better under misguided hammer strokes and cannot

be bent or broken. The Dimple Nail Hole also allows for

correct 45° angle placement in I-Joist hangers.

Diamond Holes

Diamond Holes are used to indicate either an optional

fastening pattern or for optional, temporary nailing to

aid installation.

Speed Prongs

Speed prongs help framers

by temporarily holding

connectors in place for

easier nail

Unless

stated otherwise,

fastening.

Speed

Prongs

speed prongs should not

be

considered an alternative

to nail fastening.

Slot Holes

Slot Holes are used to give

installers easier access to tight

fastening locations or to

provide floating action

Slot

Holes

between members. Fasteners

installed in slotted holes resist

shear only in one direction

while allowing limited drift in

the other direction.

www.USPconnectors.com

e-mail: info@USPconnectors.com

© Copyright 2005 United Steel Products Company

USP952-051

6

Product Information

Code Evaluations

ost USP structural products listed in this catalog

M

ave been evaluated or are in the submittal stage for

h

evaluation from one or more of the following code authorities.

With the consolidation of former services (ICBO ES, NES,

SBCCI PST & ESI, and BOCAI evaluation services) into ICC

valuation Service, Inc. (ICC ES), the following evaluation

E

reports now have the status of ICC-ES “Legacy Reports”.

The ICC-ES Web Site provides additional information, and

may be accessed at http://www.icc-es.org.

ICC-ES - ICC Evaluation Service, Inc. ESR-1178

NES - National Evaluation Service

NER-478, 505, 510, 530, 532, 564, 568, 608

ICBO - International Conference of Building Officials.

ICBO ES ER-2039, 2725, 3613, 4846, 5125, 5321,

5356, 5531, 5634, 5830

BOCA - Bldg. Officials and Code Admin. International, Inc.

SBCCI - Southern Bldg. Code Congress International, Inc.

State of Florida product Approvals - FL565, FL567,

METRO - Dade County, Florida

NER-478, 505, 510, 530, 532, 564, 568, 608

SBCCI PST & ESI 2031C, NER-478, 505, 510,

530, 532, 564, 568, 608

FL568, FL569, FL570, FL571, FL572, FL573, FL574,

FL575, FL576, FL577, FL578, FL815, FL816, FL817,

FL818, FL819, FL820, FL821, FL822, FL859, FL1247,

FL1777, FL2033, FL2620, FL2621, FL3017, FL3923

01-0327.04, 01-0417.11, 01-0724.06, 01-0912.05,

02-0102.04, 02-0102.05, 02-0102.06, 02-0128.05,

03-0206.03, 03-0219.02, 03-0508.04, 03-0508.05,

03-0611.05, 04-0427.02, 04-0427.03, 04-0427.04,

05-0204.01

DSA - Division of State Architect, California. DSA PA-076

LA CITY - City of Los Angeles, California

RR23888, 25104, 25029, 25113, 25283, 25303, 25325,

25327, 25332, 25337, 25357, 25433, 25434

ther code agencies may require specific reductions and

O

limitations and may have different load values than those

presented in this catalog. USP recommends consulting

specific code evaluation or product acceptance reports that

govern in the applicable area. Any questions about current

code listings should be directed to the Technical Assistance

staff. USP continuously updates code reports to reflect new

standards and requirements. Visit USP’s Web Site,

www.USPconnectors.com/codereports.htm, or specific

code agencies web sites for current listings. Code evaluation

reports referenced in this catalog may not apply to all stock

numbers or product series listed.

Code Watch

“Code Watch” items are included to highlight some sections

of the model building codes that discuss the use of products

contained in this catalog. The user is strongly encouraged to

consult with a qualified design professional to review the

exact requirements of the relevant code references. Please

note that not all code sections relating to the use of products

contained in this catalog are included. In addition, some

states and local municipalities have developed amendments

to the referenced code section. Shown references are for the

2003 International Residential Code (IRC), 2003 International

Building Code (IBC), and 1997 Uniform Building Code (UBC).

Corrosion Resistant Finishes

USP Structural Connectors™ offers three options for improved corrosion resistance:

Triple Zinc (TZ) – galvanizing provides a prefabrication coating of 1.85 (G-185) ounces of zinc per

square foot of surface area measured in accordance with ASTM A 653.

Required Fastener: Hot-dip galvanized fasteners

Hot-Dip Galvanized (HDG) – coating provides an after-fabrication hot-dipped zinc coating. The

coating thickness is dependent on the connector material, but generally ranges from 1.1 to 2.3

ounces of zinc per square foot of surface. Hot-dip products meet requirements set forth in

ASTM A 153.

Required Fastener: Hot-dip galvanized fasteners

Stainless Steel (SS) – is the best option for corrosion protection. Quality stainless steel (316SS

grade steel) is used to fabricate connectors. Although costs are higher, some applications

may need the virtual corrosion proof quality of stainless steel.

Required Fastener: Stainless Steel fasteners

Customer Service / Technical Assistance

Burnsville, MN Corporate Of

1-800-328-5934

fice

PPrroodduucctt IInnffoorrmmaattiioon

www.uspconnectors.com

PCS.

Para

Madera Tratada

n

Connector Use with Preservative Treated Wood

Recently the wood preservative manufacturers have

egun using Alkaline Copper Quat (ACQ) and Copper

b

Azole (CA-B) as replacement chemicals for CCA in

ome applications. The results of our corrosion testing

s

have shown that ACQ and CA-B preservative

reatments tend to corrode steel at a greater rate than

t

the CCA.

fasteners, installed in corrosive environments

to corrosive materials, or chemicals, can be

possibly resulting in the reduction of load values.

In general, connectors, including

anchors and

or exposed

damaged,

USP

recommends the use of stainless steel connectors for

maximum corrosion protection. However, as an

economical alternative, Triple Zinc G-185 connectors

may be used to provide a minimum level of corrosion

protection with the new wood preservatives. Standard

G90 connectors should not be installed in potentially

corrosive environments.

Corrosion is a multifaceted phenomenon dependent on

many variables. Most of these variables are

related to the environment the steel is placed in. These

variables include, but are not limited to,

exposure to ocean air or salt spray, chemicals used in

fire retardant and preservative treated wood, acid rain,

agricultural chemicals and fertilizers, animal wastes,

swimming pool chemicals, and even common outdoor

exposure with alternately wet and dry conditions. Of

course, there are many more possible corrosive

environments not mentioned here.

Galvanizing the steel, or coating it with a sacrificial

layer of zinc, is the most widely used protective system

in our lumber connector industry. Galvanized coatings

have a proven commercial history under a wide range

of environmental conditions.

• Ask for and follow recommendations of the

reservativewood treater for use of connectors and

p

fasteners in contact with their brand of treated wood

roduct.

p

• Connectors and their fasteners should always be of

ike materials.

l

• USP’s Zinc dichromate

WS Wood Screws are

not recommended for use with preservative or

fire-retardant treated wood.

• For any questions contact USP Technical Assistance

or visit our web site at

www.USPconnectors.com.

• USP clearly differentiates our Triple Zinc products

from standard G90 products. USP’s

TZ product

identification is embossed on all Triple Zinc products.

Following are examples of our Triple Zinc carton labels,

bin cards for retail displays, and individual product

labels.

Product Label

7

riple

T

Zinc G-185 contains roughly three times the

amount of zinc as G60 galvanizing. This provides

additional protection against corrosion attributed to the

new wood preservatives. Unfortunately, we are unable to

predict the service life of particular connectors in

selected environments. We can, however, provide

a relative level of protection information regarding

corrosion resistance. From this we can provide

guidance for the selection of corrosion protection based

on the anticipated environmental conditions.

Here are some Guidelines to follow:

• Potential for corrosion should be a part of the connector

selection criteria.

• USP

recommends the use of stainless steel

connectors for maximum corrosion protection.

However, as a minimum, Triple Zinc G-185 connectors

may be used as an economic alternative for corrosive

protection with the new wood preservatives.

www.USPconnectors.com

e-mail: info@USPconnectors.com

© Copyright 2005 United Steel Products Company

Bin Card

Carton Label

USP952-051

8

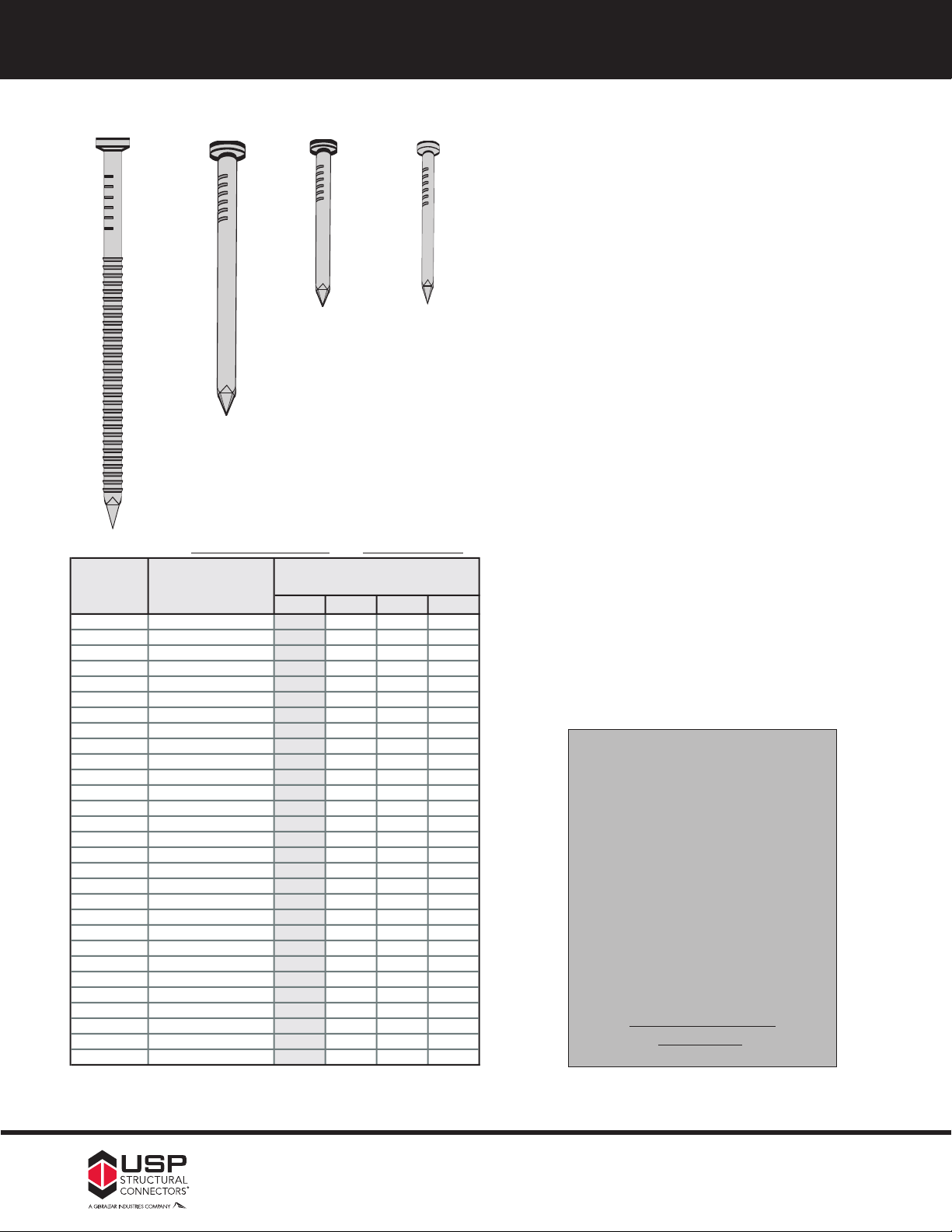

6d 11-1/2 ga. .113 1.13 0.68

8d 10-1/4 ga. .131 1.31 0.79

10d/16d Sinker 9 ga. .148 1.48 0.89

12d 9 ga. .148 1.48 0.89

16d 8 ga. .162 1.62 0.97

20d 6 ga. .192 1.92 1.15

1) Less than the specified nail penetration shall be

multiplied by the applicable adjustment factor.

2) For penetration less than this distance, the nail has no value.

Minimum

Penetration for

Reduced Load

2

(inches)

Minimum

Penetration

for Full Load

(inches)

Nail

Penny

Wire

Gauge

Shank

Diameter

(inches)

Ref. No. Description

Finish

4

Length 3 7 10 12 14 16 18 20 22

NA11 N8 8d x 1-1/2 HDG 0.131 1-1/2 48 152 -- -- -- -- -- -- -- -- -- -- 96 95 94 94

NA11SS SSN8 8d x 1-1/2 SS 0.131 1-1/2 48 143 -- -- -- -- -- -- -- -- -- -- 96 95 94 94

NA9D N10 10d x 1-1/2 HDG 0.148 1-1/2 54 100 -- -- -- -- 126 118 114 112 112 112 111

NA16D N16 16d x 2-1/2 HDG 0.162 2-1/2 99 66 192 177 158 147 140 138 136 136 -- --

NA16D-RS -- -- 16d Ring Shank Bright 0.148 3-1/2 140 47 181 164 147 -- -- -- -- -- -- -- -- -- -- -- --

8d Common -- -- 8d Common Bright 0.131 2-1/2 80 126 -- -- -- -- -- -- -- -- 98 96 95 94 94

10d Common -- -- 10d Common Bright 0.148 3 108 70 -- -- 154 136 125 118 115 114 113 112

16d Sinker -- -- 16d Sinker Bright 0.148 3-1/4 117 60 160 154 136 125 118 115 114 113 -- --

16d Common -- -- 16d Common Bright 0.162 3-1/2 138 48 192 177 158 147 140 138 136 136 -- --

1) Loads are calculated according to specifications of Part II of the National Design Specifications for Wood Construction (NDS®), 2001 Edition.

2) Loads apply to Douglas Fir-Larch (G=0.50) and Southern Pine (G=0.55). For Spruce-Pine-Fir (G=0.42) multiply above values by 0.86, for other wood types

refer to NDS® or consult USP.

3) Value assumes full penetration of at least 10 nail diameters.

4) HDG = Hot-Dip Galvanized; SS = Stainless Steel; Bright = No Finish.

5) For steel with Fu=45,000 psi, and gage minimum bare metal thickness.

Allowable Shear per Nail (Lbs.)

1,2,3,5

Steel Gauge

Nails

Per Lb.

USP

Stock No.

Nail

Diameter

Withdrawal

Load

NNaaiillss –– NNAA sseerriiees

roper fasteners are a critical component in a sound wood frame structure. To ensure

P

s

successful installations of its connectors, USP offers a full range of structurally-rated nails. All

alvanized nails supplied by USP are Hot-dipped for greater corrosion resistance. Stainless

g

steel nails are available on a stock basis size of 8d x 1

1

˝ (see product chart). Any USP

/2

connector requiring a NA16D-RS, nail ships with the nails attached to the connector in

convenient poly bags.

inish:See chart

F

Installation:

• Allowable shear values assume nail embedment into the wood of the entire nail or 10 nail

diameters (whichever is less). Otherwise, the nail must be embedded at least 6 nail

diameters, with the load reduced using the equation below:

Reduced Load = Published Load x Actual Penetration

Nail Diameter x 10

• Load reductions may occur if nails are used other than those specified. See the chart Optional

Nails for Face Mount Hangers and Straight Straps on page 9 for load reduction factors

regarding nail substitutions.

Nail Specification Table

Minimum Fastener Penetration T

able

Reduced Fastener Penetration

Example:

HD210 – listed load is 1680 lbs. @

100% for 16d common nails.

Reduced HD210 capacity if using

2x DF-L or SP header:

1680 lbs. x 1.5 = 1555 lbs. @ 100%

1.62

Customer Service / Technical Assistance

Burnsville, MN Corporate Of

1-800-328-5934

fice

continued on next page

NNaaiillss –– NNAA sseerriieess

DF-L SP S-P-F LVL

16d common 8d common 0.70 0.75 0.60 0.70

16d common 10d Box 0.67 0.72 0.58 0.67

16d common 10d common 0.83 0.91 0.72 0.83

16d common 12d common 0.83 0.91 0.72 0.83

16d common 10d x 1-1/2 0.81 0.88 0.70 0.81

16d common 10d Sinker 0.59 0.64 0.51 0.59

16d common 16d Box 0.74 0.80 0.64 0.74

16d common 16d Sinker 0.83 0.91 0.72 0.83

16d common 16d x 2-1/2 1.00 1.00 0.86 1.00

16d common No. 8 x 1-1/2 Wood Screw 0.60 0.66 0.52 0.60

10d common 8d Box 0.63 0.68 0.54 0.63

10d common 10d Sinker 0.70 0.77 0.61 0.70

10d common 8d common 0.83 0.90 0.72 0.83

10d common 10d Box 0.80 0.87 0.70 0.80

10d common 8d x 1-1/4 0.64 0.69 0.55 0.64

10d common No. 8 x 1-1/2 Wood Screw 0.72 0.79 0.63 0.72

10d common 10d x 1-1/2 0.97 1.00 0.84 0.97

10d common 16d Sinker 1.00 1.00 0.86 1.00

10d common No. 8 x 1-1/2 Wood Screw 0.72 0.79 0.63 0.72

12d common 10d x 1-1/2 0.97 1.00 0.84 0.97

12d common 16d Sinker 1.00 1.00 0.86 1.00

12d common No. 8 x 1-1/2 Wood Screw 0.72 0.79 0.63 0.72

8d common 8d Box 0.75 0.81 0.65 0.75

8d common 8d x 1-1/4 0.76 0.83 0.66 0.76

8d common No. 8 x 1-1/2 Wood Screw 0.86 0.95 0.75 0.86

8d x 1-1/2 8d x 1-1/4 0.76 0.83 0.66 0.76

8d x 1-1/2 No. 8 x 1-1/2 Wood Screw 0.86 0.95 0.75 0.86

10d x 1-1/2 8d x 1-1/2 0.86 0.93 0.74 0.86

10d x 1-1/2 No. 8 x 1-1/2 Wood Screw 0.74 0.81 0.64 0.74

1) No. 8 x 1-1/2 Wood Screw has a shank diameter of 0.164˝ and shall conform to

ANSI/ASME Standard B18.6.1-1981.

Allowable Load

Adjustment Factor

Catalog

Nail

Replacement

Fastener1

N

NA16D-RS

.148 x 3 1/2˝ .162 x 2 1/2˝

A16D

NA9D

.148 x 1

continued

NA11

1

/2˝

.131 x 1

9

1

/2˝

Optional Nails for Face Mount Hangers and Straight Straps

e-mail: info@USPconnectors.com

load table

How to Use:

The base value is the catalog listed nail in Douglas

Fir-Larch and the adjustment factor is the multiplier for

the applicable replacement nail and wood combination.

• Adjustment factors may vary with some custom

hangers or steel thicker than 10 gauge. Contact USP for

exceptions.

• Roofing nails shall not be substituted for any nail size

or type.

Optional Nails Example:

JL210 – listed load is 1595 lbs.

@

If substituting:

8d common nails with DF-L, or

LVL:

1595 lbs. x .83 = 1325 lbs.

8d common nails with SP:

1595 lbs. x .90 = 1435 lbs.

8d common nails with S-P-F:

1595 lbs. x .72 = 1150 lbs.

www.USPconnectors.com

© Copyright 2005 United Steel Products Company

100% for 10d common nails.

No further reductions

are required.

USP952-051

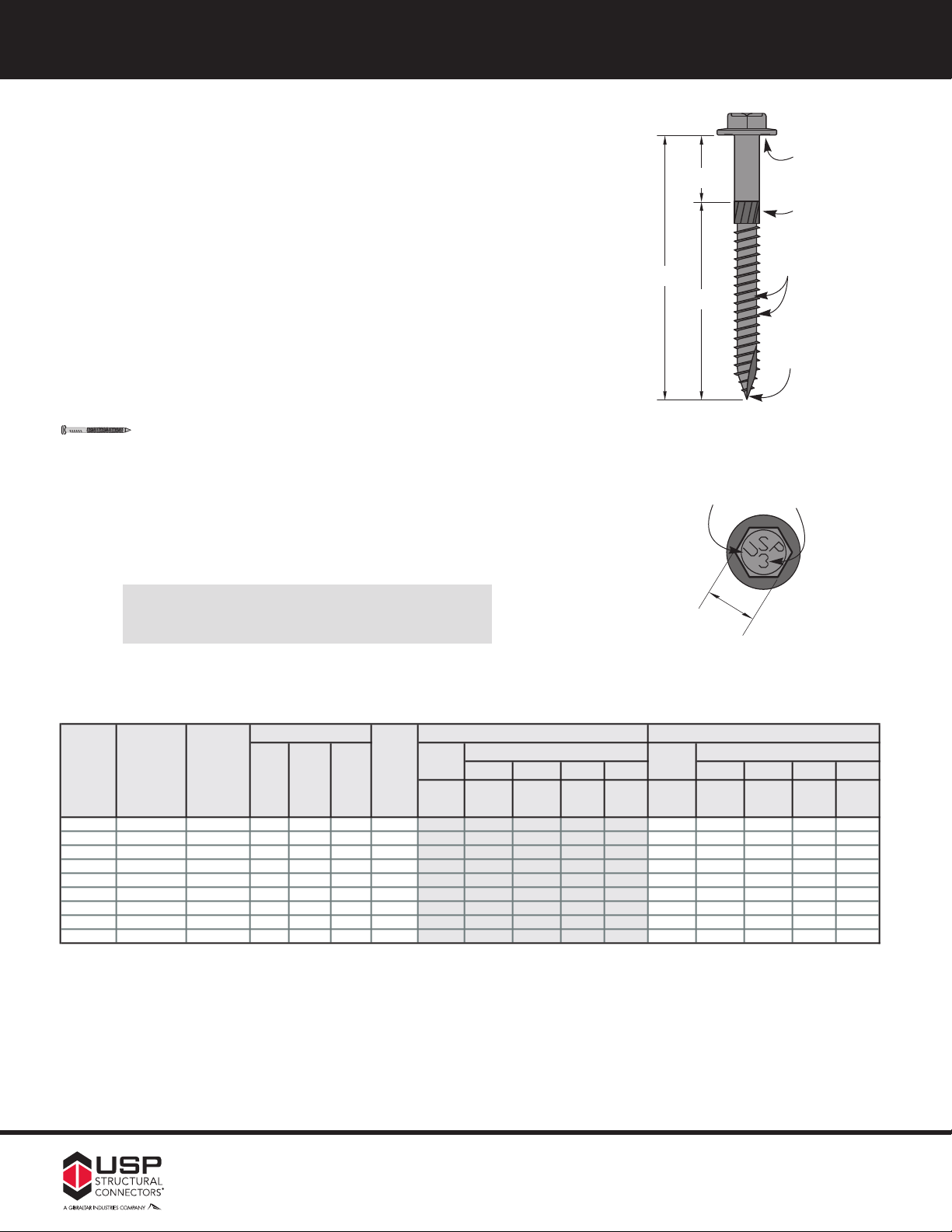

10

12 Gauge 10 Gauge 7 Gauge 3 Gauge 12 Gauge 10 Gauge 7 Gauge 3 Gauge

Ref. No. Description L SH T

Finish

1,5

WS15 SDS1/4x1 1/2 1/4˝ x 1-1/2˝ 1-1/2˝ 1/4˝ 1-1/4˝ Zinc -- -- 251 248 244 243 -- -- 217 214 211 211

WS17 SDS1/4x1 3/4 1/4˝ x 1-3/4˝ 1-3/4˝ 3/8˝ 1-3/8˝ Zinc -- -- 296 293 290 292 -- -- 255 253 251 253

WS2 SDS1/4x2 1/4˝ x 2˝ 2˝ 1/4˝ 1-3/4˝ Zinc -- -- 304 306 313 327 -- -- 262 264 271 284

WS25 SDS1/4x2 1/2 1/4˝ x 2-1/2˝ 2-1/2˝ 1/4˝ 2-1/4˝ Zinc 177 304 306 313 327 137 262 264 271 284

WS3 SDS1/4x3 1/4˝ x 3˝ 3˝ 3/4˝ 2-1/4˝ Zinc 229 304 306 313 327 177 262 264 271 284

WS35 SDS1/4x3 1/2 1/4˝ x 3-1/2˝ 3-1/2˝ 3/4˝ 2-3/4˝ Zinc 229 304 306 313 327 177 262 264 271 284

WS4 -- -- 1/4˝ x 4˝ 4˝ 1˝ 3˝ Zinc 229 304 306 313 327 177 262 264 271 284

WS45 SDS1/4x4 1/2 1/4˝ x 4-1/2˝ 4-1/2˝ 1-1/4˝ 3-1/4˝ Zinc 272 304 306 313 327 216 262 264 271 284

WS6 SDS1/4x6 1/4˝ x 6˝ 6˝ 1-3/4˝ 4-1/4˝ Zinc 272 304 306 313 327 216 262 264 271 284

1) Zinc = Yellow zinc dichromate.

2) Allowable loads are based on the 1997 NDS®. Light Gauge or 3 Gauge loads given assume use with metal side plates, Fes = 45 ksi.

3) Wood-to-wood loads are based on 1-1/2˝ thick wood side members.

4) Loads are for 100% duration of load factors, and may be increased for other duration factors in accordance with the NDS.

DF-L / SP

2,4

Steel to Wood

Steel to Wood

Shear

(100)

Shear

(100)

Wood

to Wood

Shear

(100)

Shear

(100)

Dimensions

USP

Stock No.

Shear

(100)

Shear

(100)

Shear

(100)

Wood

to Wood

(DF-L

to DF-L)

(S-P-F

to S-P-F)

Shear

(100)

S-P-F

2,4

WWoooodd SSccrreewwss –– WWSS sseerriiees

s

The WS Wood Screw is a self-drilling screw used for numerous framing

pplications. This screw features a reverse locking serration on the

a

ottom of the screw head to prevent over tightening against a steel

b

plate which could cause the screw head to shear off. The USP head

stamp identifies screws for easy inspection.

Screw shear capacities are based on a diameter of 0.242˝ when the

shear plane is on the screw shank (SH) and 0.185˝ when the shear

plane is on the knurl or threads (T). USP

WS Wood Screws have a

bending yield strength of 217,000 psi. For conditions not charted here,

screw loads may be calculated as shown in the current NDS® and

increased for duration of load.

Serrations

SH

Beveled reamer on

2-1/2˝ or longer

Wood Screws

L

T

Cut threads

Materials: 1/4˝ diameter Grade 5 steel

Finish: Yellow zinc dichromate

Codes: ICBO 5634, L.A.City RR 25433

Installation:

• Screws are self-drilling.

3

• Install using a low speed clutch drill with

˝ hex head driver. The

8

/

washer head should be flat to the surface and the serrations will

oppose turning and release the clutch. Do not over-tighten the screws.

For Attaching Multi-Ply LVL or PSL members,

see page

11

Self-drilling point

USP name Screw length

3/8˝

Customer Service / Technical Assistance

Burnsville, MN Corporate Of

1-800-328-5934

fice

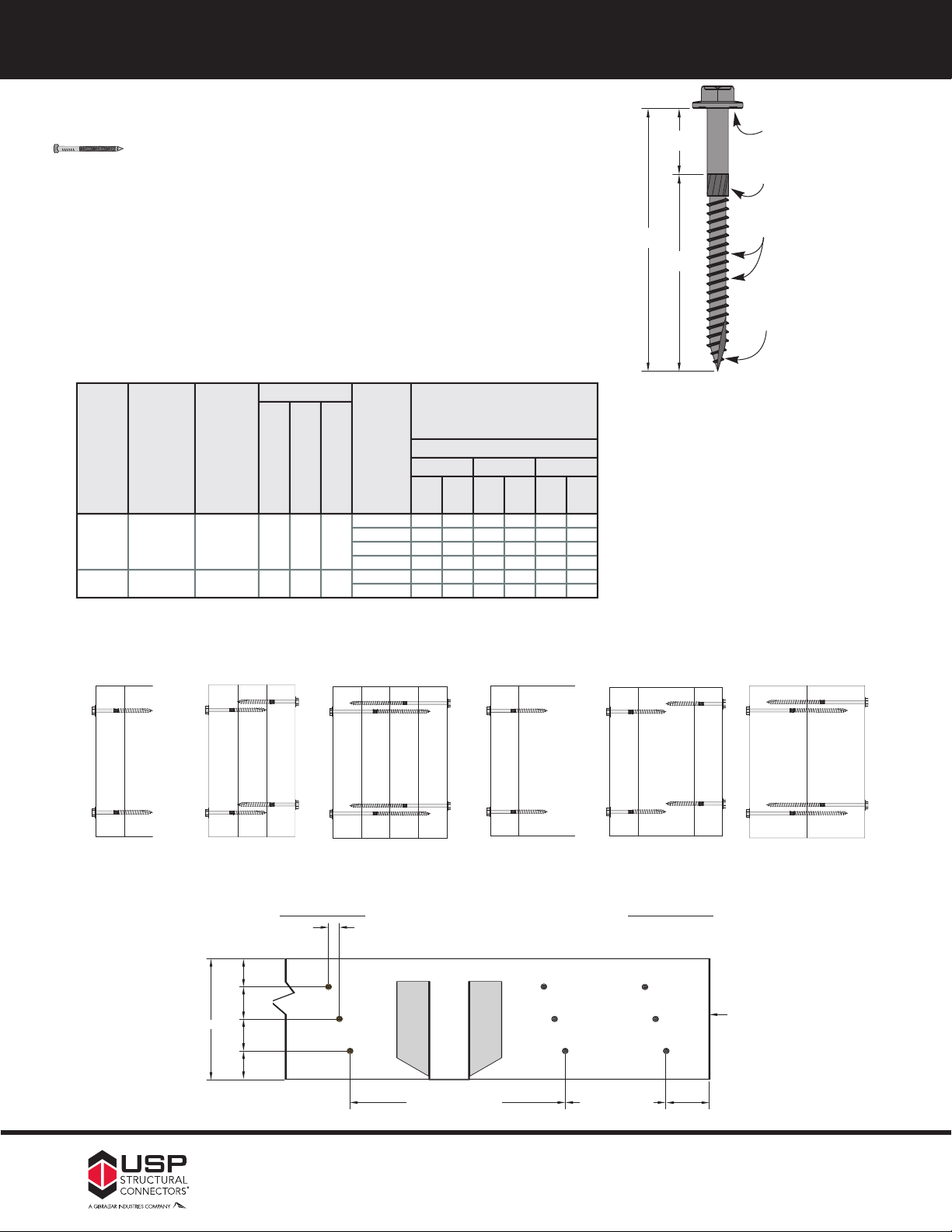

WWoooodd SSccrreeww AApppplliiccaattiioonnss –– WWSS sseerriiees

1) Allowable Uniform Loads are based on the 1997 NDS®.

2) Based on Zscrew = 250 lbs. in Douglas Fir-Larch (G=0.50)

with a side member thickness of not less than 1-3/4˝.

3) Load values depicted assume all uniform load is applied

to the most narrow outside ply only.

4) Load values neglect any contribution of screws installed

Ref. No. Description L SH T to opposite side, even if they extend significantly into the

1 1

00015006651000500750 loaded ply.

2 750 1125 500 750 375 565 5) Loads are for normal (100%) duration of load, and may

4 750 1125 500 750 375 565 be increased in accordance with the code.

5 665 1000 445 665 335 500 6) Uniform loads in table represent the capacity of the

3 665 1000 445 665 335 500 fasteners. The capacity of the LVL or PSL beam may be

6 1000 1500 665 1000 500 750 less and should be checked by a qualified designer or

7) A qualified designer shall ensure the adequacy of a 7˝

wide beam to resist the applied load on one edge;

otherwise, the loads shall be uniformly distributed across

the width or applied equally on both sides.

1-3/4˝

4-1/4˝

WS35

WS6

SDS1/4x6

1/4˝ x 6˝

6˝

SDS1/4x3 1/2

1/4˝ x 3-1/2˝

2-1/2˝

24˝ O.C.

Maximum Allowable Uniform Loads

t

hat can be applied to either outside

m

ember (Lbs. Per Lineal Ft.)

1,2,4,5,6,7

3-1/2˝

1˝

D

imensions

3

Rows

USP

Stock No.

2

Rows3Rows2Rows

M

ultiple

M

embers

Installation

F

igure

3

12˝ O.C.

18˝ O.C.

Wood Screw Spacing

2

Rows3Rows

1) Allowable Uniform Loads are based on the 1997 NDS®.

2) Based on Zscrew = 250 lbs. in Douglas Fir-Larch (G=0.50)

with a side member thickness of not less than 1-3/4˝.

3) Load values depicted assume all uniform load is applied

to the most narrow outside ply only.

4) Load values neglect any contribution of screws installed

to opposite side, even if they extend significantly into the

loaded ply.

5) Loads are for normal (100%) duration of load, and may

be increased in accordance with the code.

6) Uniform loads in table represent the capacity of the

fasteners. The capacity of the LVL or PSL beam may be

less and should be checked by a qualified designer or

with the manufacturer's literature.

7) A qualified designer shall ensure the adequacy of a 7˝

wide beam to resist the applied load on one edge;

otherwise, the loads shall be uniformly distributed across

the width or applied equally on both sides.

Joining 2, 3, or 4 Ply LVL or PSL Member

nstallation Notes:

I

• For 2 ply members, wood screws shall be installed with the screw heads in the

loaded ply.

• For 3 or 4 ply members, wood screws shall be installed in both outer plys.

Designer shall specify all wood screws locations.

•

• Increase edge and end distances if wood splitting occurs.

• Stagger all screws installed into the opposite face.

• A minimum of 2 rows of screws shall be used for all members with H = 5

and larger.

1

/

s

SH

Serrations

11

Beveled reamer

L

Cut threads

T

˝

2

Self-drilling point

Figure 1 Figure 2 Figure 3

WS35 installed

3

in (2) 1

/4˝ Ply

WS35 installed

3

in (3) 1

/4˝ Ply

WS6 installed

in (4) 1

3

/4˝ Ply

Figure 4

WS35 installed

3

in (1) 1

(1) 3

/4˝,

1

/2˝ Ply

Figure 5

WS35 installed

3

in (2) 1

(1) 3

1

/2˝ Ply

/4˝,

Recommended Row Guidelines

1˝ min. Recommended (T

Other Stagger patterns as appr

1

1

/

2˝

min.

1

2

/

2˝

min.

H

1

2

/

2˝

min.

1

1

/

2˝

min.

yp)

Spacing

4˝ min. – 24˝ max.

ed by Engineer ar

ov

e acceptable

Spacing

4˝ min. – 24˝ max.

End of member

4˝ min.

Figure 6

WS6 installed

3

in (2) 1

/4˝ Ply

www.USPconnectors.com

e-mail: info@USPconnectors.com

© Copyright 2005 United Steel Products Company

USP952-051

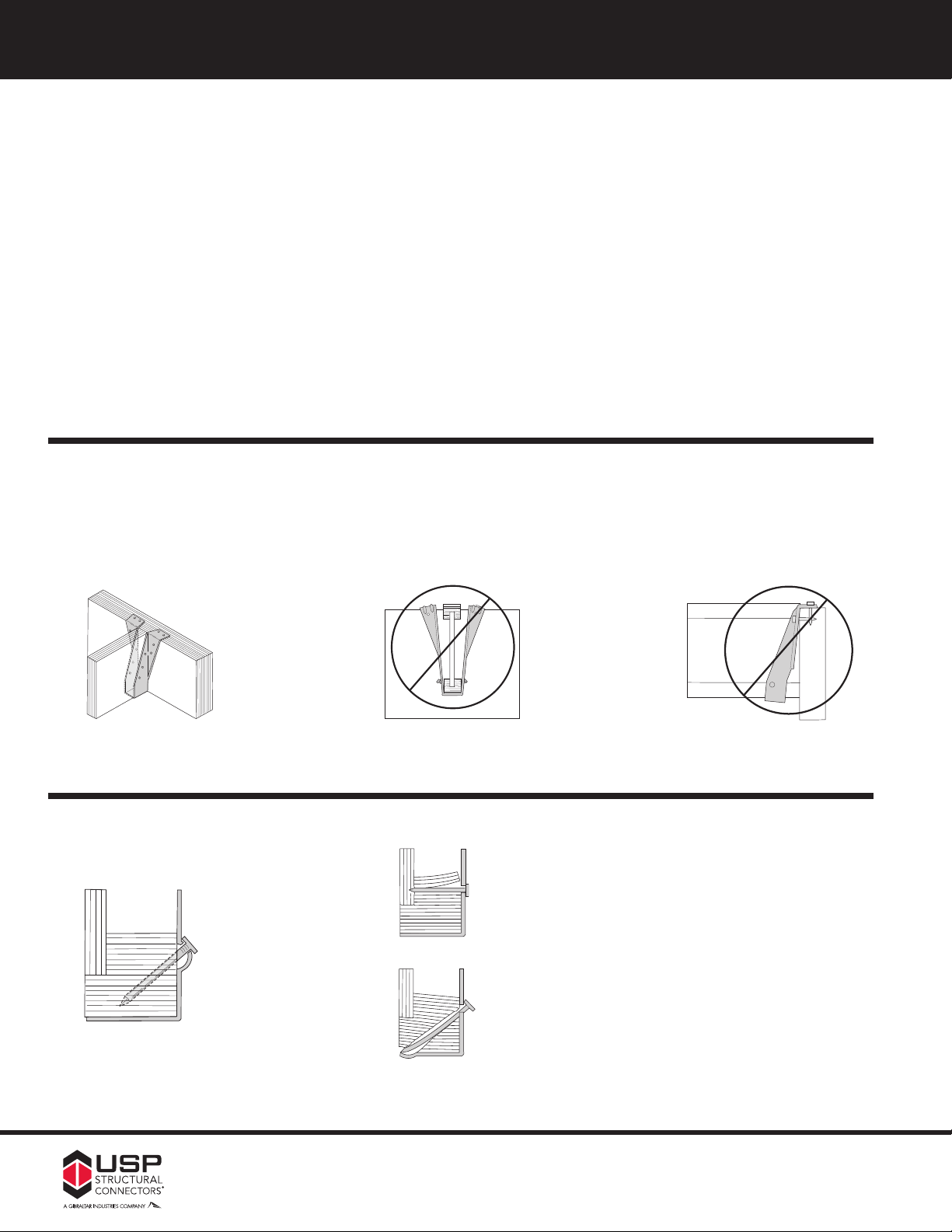

WWoooodd II--JJooiisstt IInnssttaallllaattiioonn ttoo WWooood

12

d

Sloped I-Joists

Use sloped seat hangers and beveled web stiffeners

whenever the slope exceeds the following:

earing lengths of 2

b

of 3

1

2

˝

a

/

2

1

˝.

/

2

etween

b

excess

nd 3

1

or less;

˝

/

2

1

˝

/

2

;

and

3

12 for bearing lengths

:

/

8

1

12 for bearing lengths in

:

/

4

1

:12 for seat

/

2

Multiple I-Joist Plys

Fasten together multiple plys of wood I-Joists, in

accordance with the manufacturer’s installation guidelines,

such that the joists act as a single unit.

I-Joist Rotation

It may be necessary to install straps, blocking, or

sheathing to restrain torsional rotation of a supporting

wood I-Joist when using top mount I-Joist hangers.

Fasteners

I-Joists may split if larger diameter nails or longer nails

installed. Do not install nails larger than 16d common

ails (0.162˝ diameter) into the web stiffeners in the wood

n

-Joist.

I

acker Blocks

B

Pattern the nails used to install backer blocks or web

stiffeners in wood I-Joists to avoid splitting the block. The

nail pattern should be sufficiently spaced to avoid the

same grain line, particularly with solid sawn backer blocks.

Backer blocks must be installed on wood I-Joist acting as

the header, or supporting member. Install in accordance

with the I-Joist manufacturer’s installation guidelines. The

nails used to install hangers mounted to an I-Joist header

must penetrate through the web and into the backer block

on the opposite side.

Install only the specified nails. The flanges of wood

Top Flange Hangers

The thickness of the hanger metal and nail heads on top mount hangers must be evaluated for the effect on

subsequent sheathing. Ensure that the top mount hanger is installed so the flanges of the hanger are not

over-spread which tends to elevate the supported I-Joist causing uneven floor surfaces and squeaking. Similarly, ensure

that the hanger is installed plumb such that the face flanges of the hanger are mounted firmly against the

wide-face surface of the header.

are

wire

Flush framing

Correct Slant Nail Installation

Always secure

wood I-Joist using

10d x 1

nail driven at a

45° angle

and firmly seated

Hanger over-spread

Hanger not plumb

Common Nailing Errors

Wrong Angle

When a nail is driven into the bottom flange of the

wood I-Joist parallel to the glue lines, separation of

1

˝

⁄ 2

veneers can occur which substantially reduces the

design loads of the connection.

Nail Too Long

When using nails longer than USP’s recommended

nails, bottom flange splitting may occur. Also, this can

raise the wood I-Joist off the seat, resulting in uneven

surfaces and squeaky floors along with reduced

allowable loads.

Customer Service / Technical Assistance

Burnsville, MN Corporate Of

1-800-328-5934

fice

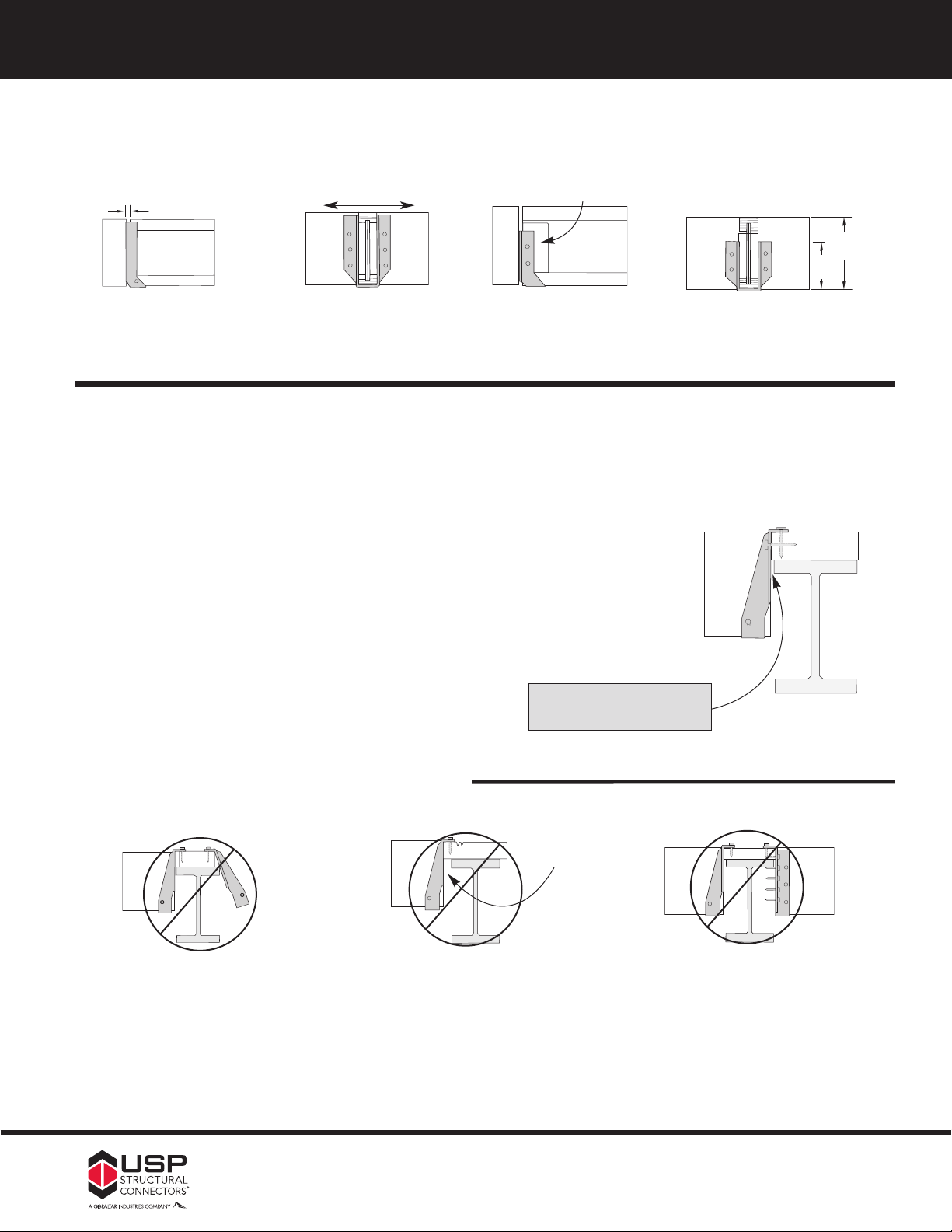

SSuuppppoorrtt HHeeiigghhtt && LLaatteerraall SSttaabbiilliitty

y

13

Hangers for joists without web stiffeners must

support the I-Joist’s top flange and provide lateral

resistance with no more than

1/8˝ maximum gap

1

˝ horizontal deflection.

⁄

8

Resist lateral movement

Hangers for joists with web stiffeners must support a

minimum of 60% of joist depth.

Web stiffener

(Top flange support requirements can be verified in this sections charts under the Web Stiffener Reqd. column.)

Nailer Installations

Correct Hanger Attachment to Nailer

A nailer or sill plate is considered to be any wood member attached to a steel

beam, concrete block wall, concrete stem wall, or other structure unsuitable for

nailing, which is used as a nailing surface for top mount hangers to hold beams

or joists.

Nailer Sized Correctly

Top flange of hanger is fully supported and recommended nails have full

1

/

penetration into nailer, resulting in a carried member hanging safely at the

proper height.

Max.

4˝

60%

M

oist

J

depth

in.

The nailer must be sized to fit the support width as shown and be of sufficient

thickness to satisfy recommended top flange nailing requirements. A design

professional must specify nailer attachment to steel beams.

Avoid direct contact between

hangers and steel beams, which

may cause squeaks.

Wrong Nailer Size Causes Component Failure

1

⁄4˝ Max.

ide

oo W

Too Narrow

op flange not fully supported

T

can cause nail breakout. Or, by

fully supporting top flange,

hanger is tilted back, causing

lifting of carried member which

results in uneven surfaces and

squeaky floors.

Loading can cause cross

grain breaking of nailer.

The recommended nailer

overhang is

per side.

T

1

˝ maximum

⁄

4

Too Thin

op flange nailing cannot fully

T

penetrate nailer, causing reduced

allowable loads. Never use

hangers which require multiple

face nails since the allowable

loads are dependent on all nail

holes being used.

www.USPconnectors.com

e-mail: info@USPconnectors.com

© Copyright 2005 United Steel Products Company

USP952-051

14

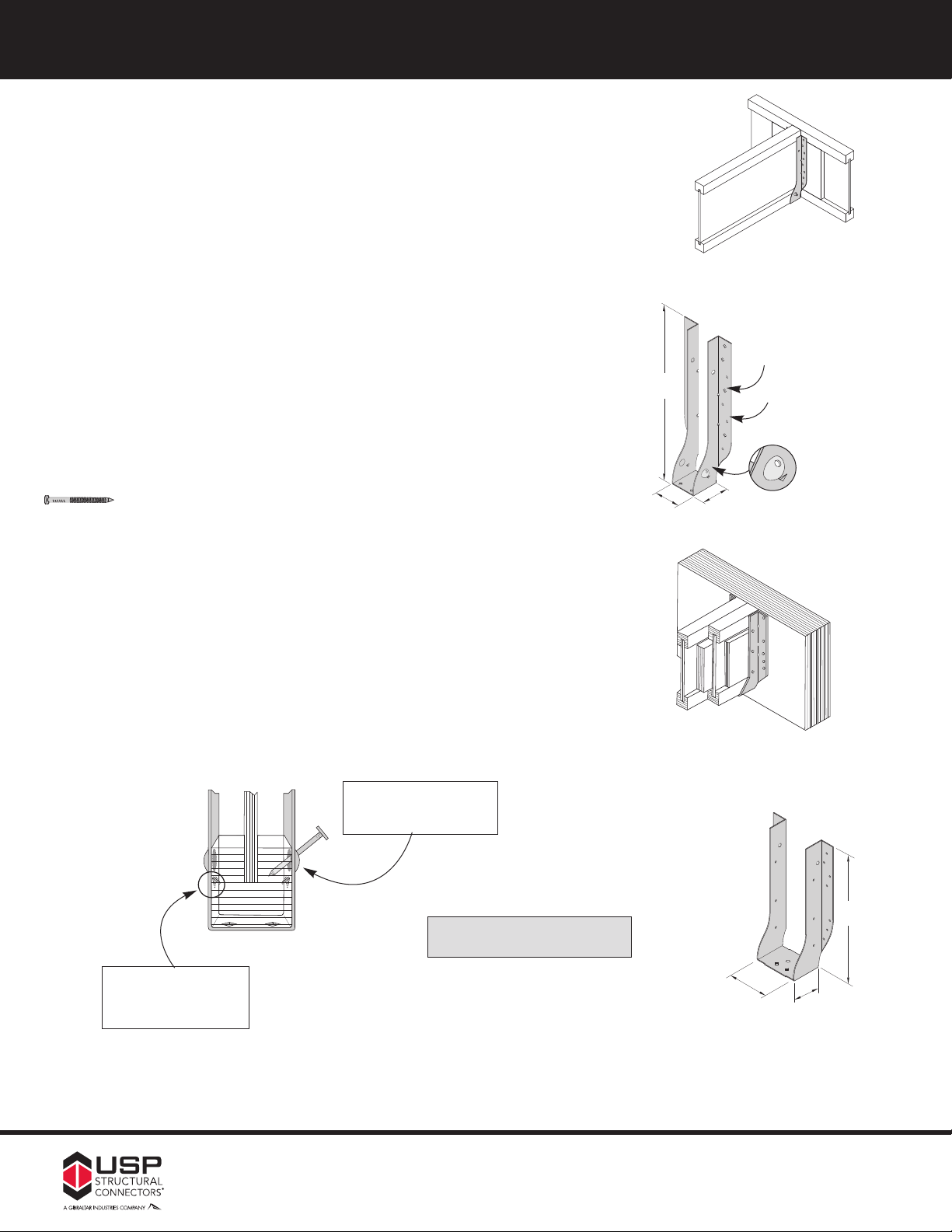

FFaaccee MMoouunntt HHaannggeerrss –– HHDD,, HHUUSS,, && TTHHFF sseerriiees

THF – Designed to provide lateral support for the top chords of I-Joists in

depths up to 16˝. Eliminates the need for web stiffeners in most applications

(see Web Stiffener Reqd. column in EWP Face Mount Hanger chart for

specific applications). Raised Dimple nailing guides help assure correct 45°

nailing into the I-Joist bottom flange.

HD – Designed to support LVL, LSL, and PSL beams and headers in

medium load conditions.

HUS – Designed for medium load conditions. Extended 3˝ deep seat

provides extra truss bearing.

Materials: See EWP Face Mount Hangers charts, pages 17-19.

Finish: G90 galvanizing

Options: See Specialty Options chart on page 15.

Codes: SBCCI, BOCA – NER 478, NER 608, & NER 510,

ICBO 2039, L.A. City RR 25283 &

RR 23888, FL815, FL818, FL821,

DSA PA-076

Patents: #5,217,317 – THF & HUS

#5,564,248 – THF (all models except doubles)

s

Typical THF I-Joist to

I-Joist installation

Additional diamond

nail holes for

H

maximum nailing

Standar

nail holes for

minimum nailing

d round

Installation:

• Use all specified fasteners.

• THF – Install 10d x 1

1

˝ nails into joist through raised dimple at 45° angle.

2

/

• THF Min – Fill all round nail holes.

• THF Max – Fill all round and diamond holes.

• HD – Drive bend line nails into header at 45° to achieve listed loads.

• HUS – Joist nails must be driven at a 30° to 45° angle through the joist into

the header to achieve listed loads.

atented Raised Dimple nail

P

holes allow 45

oist bottom flange

I-J

nailing into

°

.

Some model designs may

vary from illustration shown

W

2˝

THF single

Typical

THF double I-Joist

to LVL installation

Patented dimple

allows 45° nailing

H

atented Seat Cleat™

P

helps lock I-J

for positiv

oist into place

e seating and

nailing ease

W

.

D

THF double

continued on next page

Customer Service / Technical Assistance

Burnsville, MN Corporate Of

1-800-328-5934

fice

FFaaccee MMoouunntt HHaannggeerrss ––

Option USP Series

Skewed

1,3

Sloped Seat

2,3

Sloped / Skewed

1,2,3

Inverted Flange

HUS -- -- -- -- -- --

1) Skewed hangers with skews greater than 15° may have all joist nailing on outside flange.

2) Sloped or sloped / skewed hangers with slopes greater than 15° may have additional joist nails.

3) All sloped, skewed, or combinations require bevel cut on joist in all applications.

4) Modifications to THF hangers do not feature seat cleats.

Not available in

widths less than 2-1/4˝

100% of table load.

65% of table load when

nailing into the support

members end grain.

See Sloped Seat and Skewed

THF

Not available in

widths less than 2-1/4˝

HD

1˚ to 45˚

100% of table load.

65% of table load when

nailing into the support

members end grain.

Allowable

Loads

100% of table load.

75% of uplift load on

skews greater than 15˚.

THF

100% of table load.

75% of uplift load on

skews greater than 15˚.

100% of table load

80% of table load.

75% of uplift load on

skews greater than 15˚.

See Sloped Seat and Skewed

See Sloped Seat and Skewed

Example:

HD410-SK45RSL30D

100% of table load

100% of table load.

65% of table load when

nailing into the support

members end grain.

Add IF,

to product number.

Example: HD410IF

80% of table load.

75% of uplift load on

skews greater than 15˚.

-- --

Range

HUS

Not available in

widths less than 2-1/4˝

-- --

-- --

-- --

1˚ to 45˚

1˚ to 67-1/2˚

when width is 1-3/4˝ or less.

1˚ to 50˚ on all others.

1˚ to 67-1/2˚

when width is 1-3/4˝ or less.

1˚ to 50˚ on all others.

HD

Ordering

HUS

-- --

-- --

Add SK,

angle required,

and right (R) or left (L),

to product number.

Example:

HD410-SK45R

Add SL,

slope required,

and up (U) or down (D),

to product number.

Example:

HD410-SL30D

HD

THF

Drive bend line nails

into header at 45° to

achieve listed loads.

HHDD,, HHUUSS,, && TTHHFF sseerriiees

s

c

ontinued

15

Typical HD

bend line nail installation

Typical HUS

installation

Some model designs may

vary from illustration shown

Drive joist nails into

header at 30° to 45° to

achieve listed loads.

Typical HUS

Patented dimple allows

30° to 45° nailing

2˝

W

D

HUS

H

double shear installation

Specialty Options Chart – refer to Specialty Options pages 55 to 58 for additional details.

Typical HD

installation

Bend line

nailing

H

W

D

HD

e-mail: info@USPconnectors.com

www.USPconnectors.com

© Copyright 2005 United Steel Products Company

USP952-051

16

Skewed

1,3

Sloped Seat

2,3

Sloped / Skewed

1,2,3

Inverted Flange

1) Skewed hangers with skews greater than 15° may have all joist nailing on outside flange. All skewed THDH hangers have nails on one side only.

2) Sloped or sloped / skewed hangers with slopes greater than 15° may have additional joist nails.

3) All sloped, skewed, or combinations require bevel cut on joist in all applications.

THD

Add SK, angle required,

and right (R) or left (L),

to product number.

Example: THDH410-SK45R

Add SL, slope required,

and up (U) or down (D),

to product number.

Example: THDH410-SL30D

1˚ to 45˚

65% of table load

THD

THD

THDH

Not available in widths

less than 3˝. Widths greater

can have one flange inverted.

See Sloped Seat and Skewed

See Sloped Seat and Skewed

Example:

THDH410-SK45RSL30D

Range

Allowable

Loads

85% of table load.

50% of table uplift load.

1˚ to 45˚

Ordering

100% of table load.

65% of table load when

nailing into the support

members end grain.

85% of table load

Add 1IF, one flange,

right (R) and left (L),

Example: THD4101IFR

65% of table load

N/A

52% of table load

52% of table load.

50% of table uplift load.

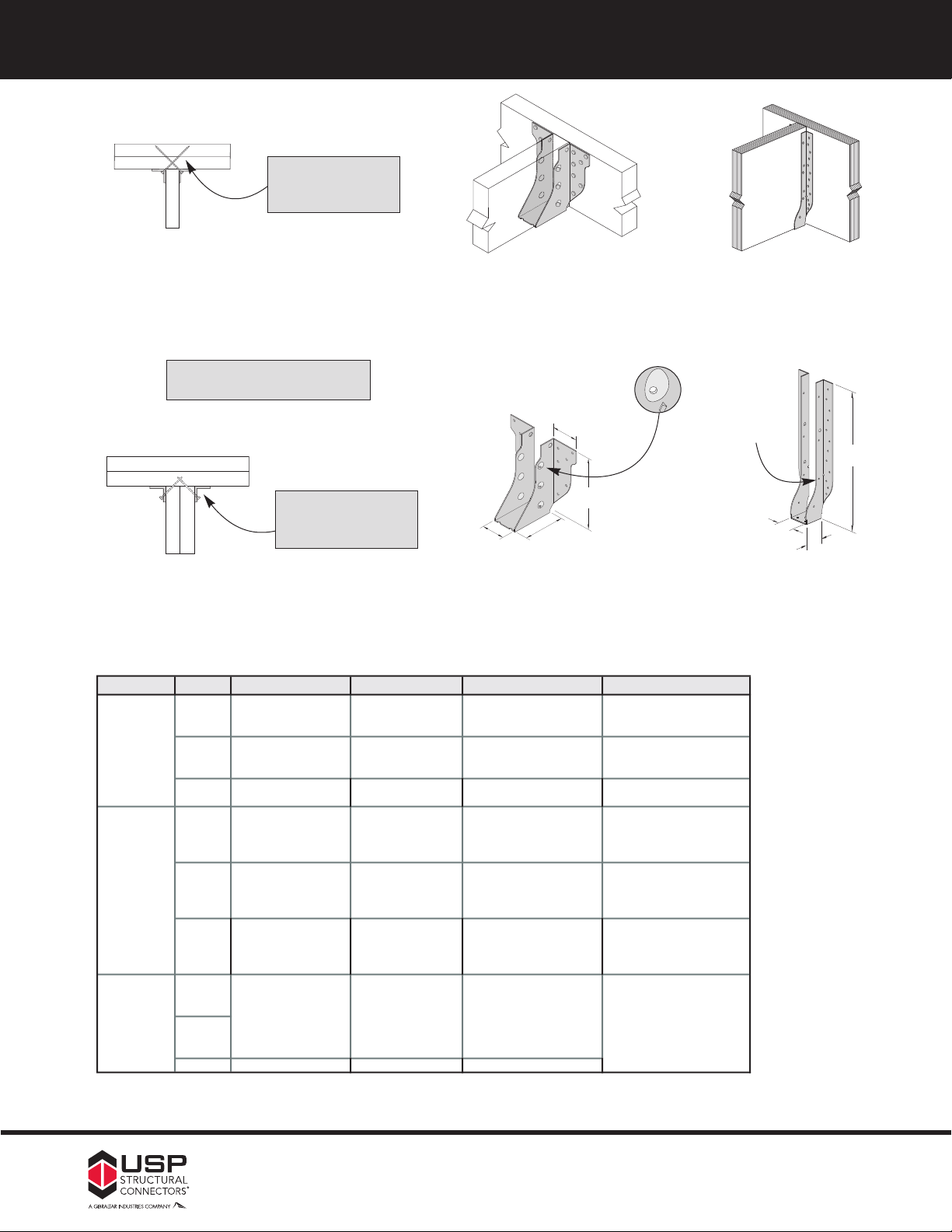

FFaaccee MMoouunntt HHaannggeerrss ––

TTHHDD && TTHHDDHH sseerriieess

THD – Medium-duty hanger for LVL, LSL, and PSL beams.

THDH – Heavy-duty hanger for LVL, LSL, and PSL beams.

Materials: See EWP Face Mount Hangers charts, pages 17-19.

Finish: G90 galvanizing

Options: Rough/ Full sizes available for THD series. THD hangers

with widths greater than 3˝ can have one flange inverted

with no load reduction. Specify left (L) or right (R) flange.

See Specialty Options chart.

Codes: SBCCI, BOCA – NER 478 & NER 608,

ICBO 2039, L.A. City RR 25283,

DSA PA-076, FL815, FL821

Patents: #5,217,317 – THDH

Installation:

• Use all specified fasteners.

• THDH – Drive joist nails into header at 30° to 45° to achieve listed loads.

Typical THD179

installation

H

Typical THDH

double shear installation

21/2˝

H

W

D

THDH26-2

Specialty Options Chart – refer to Specialty Options pages 55 to 58 for additional details.

Option USP Series

THDH 1˚ to 45˚ 1˚ to 45˚ See Sloped Seat and Skewed N/A

Drive joist

nails into

header at

30° to 45°

to achieve

listed loads.

Bend line nailing

Patented dimple

allows 30° to 45°

nailing

Drive bend line nails

into header at 45° to

achieve listed loads.

Typical THDH

bend line nail installation

Some model designs may

vary from illustration shown

Left flange

W

THD single

THD single

W

D

D

3˝

H

Right flange

THD double or larger

THDH N/A

Customer Service / Technical Assistance

Burnsville, MN Corporate Of

1-800-328-5934

fice

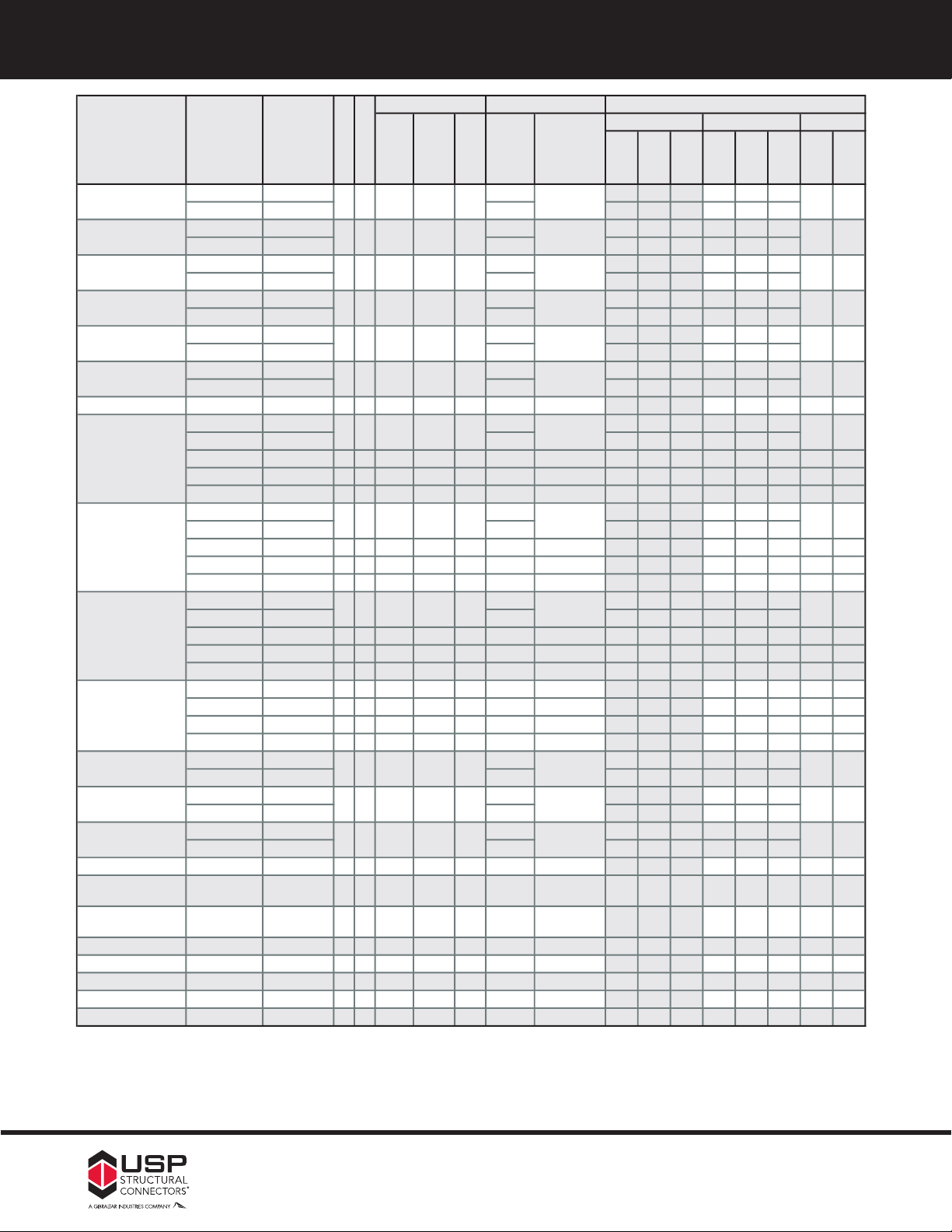

EEWWPP FFaaccee MMoouunntt HHaannggeerrss CChhaarrttss

D

imensions

D

F-L / SP Header

S

-P-F Header

Joist Size Ref. No. W H D

Header

3

Joist

1

100% 115% 125% 100% 115% 125% 133% 160%

THF15925 Min IUS1.56/9.5 (8) 10d 910 1050 1140 785 900 980

THF15925 Max IUT29

(

12) 10d

1

37015751710117513501470

THF15112 Min IUS1.56/11.88

(

8) 10d

9101

0501140785900980

THF15112 Max IUT211

(

16) 10d

1

82521002155157018051960

THF15140 Min

-

- --

(

12) 10d

1

37015751710117513501470

THF15140 Max IUT214 (20) 10d 2100 2135 2155 1960 2135 2155

THF16925 Min -- -- (8) 10d 910 1050 1140 785 900 980

THF16925 Max IUT1.68/9 (12) 10d 1370 1575 1710 1175 1350 1470

THF16112 Min -- -- (8) 10d 910 1050 1140 785 900 980

THF16112 Max IUT1.68/11

(

16) 10d

1

82521002280157018051960

THF16140 Min

-

- --

(

12) 10d

1

37015751710117513501470

THF16140 Max IUT1.68/14

(

20) 10d

2

25522902310196022552310

1-3/4 x 7-1/4 HD1770 HU7 x 14 1-13/16 7-1/8 2 (14) 16d (4) 10d x 1-1/2 1960 2255 2335 1695 1950 2120 610 730

THF17925 Min IUS1.81/9.5 (8) 10d 910 1050 1140 785 900 980

THF17925 Max IUT9 (12) 10d 1370 1575 1710 1175 1350 1470

HD17925 HU9 x 14

1-13/16 9-1/8

2 (18) 16d (6) 10d x 1-1/2 2520 2775 2775 2180 2505 2725 910 1065

THD179 -- -- x 14 1-7/8 8-7/8 3 (38) 16d (20) 10d x 1-1/2 5320 5800 5800 4210 4510 4705 3040 3095

HUS179 HUS1.81/10 x 16 1-13/16 9-1/8 3 (30) 16d (10) 16d 4925 5130 5270 4570 4910 5030 3205 3205

THF17112 Min IUS1.81/11.88 (8) 10d 910 1050 1140 785 900 980

THF17112 Max IUT11 (16) 10d 1825 2100 2280 1570 1805 1960

HD17112

HU11

x 1

4

1-13/16 11-3/8

2 (

22) 16d(6) 10d x 1-1/22870297530452660297530459101065

THD179

-- --

x 141

-7/88-7/8

3 (

38) 16d(20) 10d x 1-1/253205800580042104510470530403095

HUS179 HUS1.81/10 x 16 1-13/16 9-1/8 3 (30) 16d (10) 16d 4925 5130 5270 4570 4910 5030 3205 3205

THF17140 Min IUS1.81/14 (12) 10d 1370 1575 1710 1175 1350 1470

THF17140 Max IUT14 (20) 10d 2280 2445 2470 1960 2255 2450

HD1714 HU14 x 14

1-13/16 13-5/16

2 (26) 16d (8) 10d x 1-1/2 3100 3235 3330 3100 3235 3330 1065 1065

THD179 -- -- x 14 1-7/8 8-7/8 3 (38) 16d (20) 10d x 1-1/2 5320 5800 5800 4210 4510 4705 3040 3095

HUS179 HUS1.81/10 x 16 1-13/16 9-1/8 3 (30) 16d (10) 16d 4925 5130 5270 4570 4910 5030 3205 3205

THF17157 MIU1.81/16 -- 18 1-13/16 15-3/4 3-1/2 (24) 10d (2) 10d x 1-1/2 2735 3145 3310 2350 2705 2940 280 280

HD1714 HU14 x 14

1-13/16 13-5/16

2 (26) 16d (8) 10d x 1-1/2 3100 3235 3330 3100 3235 3330 1065 1065

THD179 -- -- x 14 1-7/8 8-7/8 3 (38) 16d (20) 10d x 1-1/2 5320 5800 5800 4210 4510 4705 3040 3095

HUS179 HUS1.81/10 x 16 1-13/16 9-1/8 3 (30) 16d (10) 16d 4925 5130 5270 4570 4910 5030 3205 3205

THF20925 Min IUS2.06/9.5 (8) 10d 910 1050 1140 785 900 980

THF20925 Max IUT2.06/9 (12) 10d 1370 1575 1710 1175 1350 1470

THF20112 Min IUS2.06/11.88 (8) 10d 910 1050 1140 785 900 980

THF20112 Max IUT2.06/11 (16) 10d 1825 2100 2280 1570 1805 1960

THF20140 Min IUS2.06/14 (12) 10d 1370 1575 1710 1175 1350 1470

THF20140 Max IUT2.06/14 (20) 10d 2280 2470 2470 1960 2255 2450

2 - 2-1/8 x 16 THF20157 IUT2.06/16 -- 18 2-1/8 15-3/4 3-3/8 (24) 10d (2) 10d x 1-1/2 2735 3145 3310 2350 2705 2940 280 280

2-1/4 - 2-5/16

x 9-1/4 - 9-1/2

THF23925 IUT3510 -- 18 2-5/16 9-3/16 2-1/2 (12) 10d (2) 10d x 1-1/2 1370 1575 1710 1175 1350 1470 175 175

2-1/4 - 2-5/16

x 11-1/4 - 11-7/8

THF23118 IUT3512 -- 18 2-5/16 11-3/16 2-1/2 (14) 10d (2) 10d x 1-1/2 1595 1835 1995 1370 1580 1715 300 360

2-1/4 - 2-5/16 x 14 THF23140 IUT3514 -- 16 2-5/16 13-1/2 2-1/2 (18) 10d (2) 10d x 1-1/2 2090 2400 2610 1800 2070 2250 300 360

2-1/4 - 2-5/16 x 16 THF23160 MIU2.37/16 -- 16 2-5/16 15-9/16 2-1/2 (22) 10d (2) 10d x 1-1/2 2550 2935 3035 2200 2530 2750 300 360

2-1/4 - 2-5/16 x 18 - 28 THF23180 MIU2.37/18 x 16 2-5/16 17-1/8 2-1/2 (24) 10d (8) 10d x 1-1/2 2785 3200 3480 2400 2760 3000 1205 1295

2-1/2 x 9-1/4 - 9-1/2 THF25925 IUT310 -- 18 2-1/2 9-1/8 2-1/2 (12) 10d (2) 10d x 1-1/2 1370 1575 1710 1175 1350 1470 175 175

2-1/2 x 11-1/4 - 11-7/8 THF25112 IUT312 -- 18 2-1/2 11-1/8 2-1/2 (14) 10d (2) 10d x 1-1/2 1595 1835 1995 1370 1580 1715 300 360

1) 10d x 1-1/2 nails are 9 gauge (0.148˝ diameter) by 1-1/2˝ long.

2) Uplift loads have been increased 33-1/3% or 60% for wind or seismic loads; no further increase shall be permitted.

3) Minimum nail penetration shall be 1-1/2˝ for 10d nails and 1-5/8˝ for 16d nails.

Load tables address hanger/header/fastener limitations only. Joist limitations must be determined for each installation.

(2) 10d x 1-1/2

280

280

280

280

(2) 10d x 1-1/2

280

280

(2) 10d x 1-1/2

(

2) 10d x 1-1/2

280280280

280

(2) 10d x 1-1/2

280

280

(

2) 10d x 1-1/2

(2) 10d x 1-1/2

2802

80

2802

80

280

280

280

280

280

2802

80

--182-1/8

13-1/4

18

2-1/8

10-7/8

A

llowable Loads (Lbs.)

2

(2) 10d x 1-1/2

(2) 10d x 1-1/2

(

2) 10d x 1-1/2

(

2) 10d x 1-1/2

(2) 10d x 1-1/2

--182-1/8

8-7/8

--1

8

1-3/4

10-15/16

--181-3/4

13-3/8

8-15/16

2

U

plift

2

13-1/2

2

1

1

2

1

3-7/16

2

280

--1

8

1-3/4

--

18

1

-5/8 1-5/8 x 14

--

18

1

-5/8 1-5/8 x 11-1/4 - 12

1-5/8 x 9-1/4 - 9-1/2

--1

8

1-1/2 x 9 -1/4 - 9-1/2

1-5/8

1-1/2 x 14

--1

8

1-1/2

1-1/2 x 11-1/4 - 11-7/8

--

18

1

-1/2

1-3/4 x 11-1/4 - 11-7/8

1-3/4 x 14

2 - 2-1/8

x 9-1/4 - 9-1/2

1-3/4 x 9-1/4 - 9-1/2

1-3/4 x 16

2 - 2-1/8

x 11-1/4 - 11-7/8

2 - 2-1/8 x 14

--

2

USP

Stock No.

9

9

-1/1611-1/16

18

1

-1/2

--

F

astener Schedule

22222

2

Steel Gauge

Web Stiffener Reqd.

17

www.USPconnectors.com

e-mail: info@USPconnectors.com

© Copyright 2005 United Steel Products Company

continued on next page

USP952-051

18

Dimensions

DF-L / SP Header S-P-F Header

J

oist Size

R

ef. No.

W

H

D

H

eader

3

J

oist

1

1

00%115%125%100%115%125%133%160%

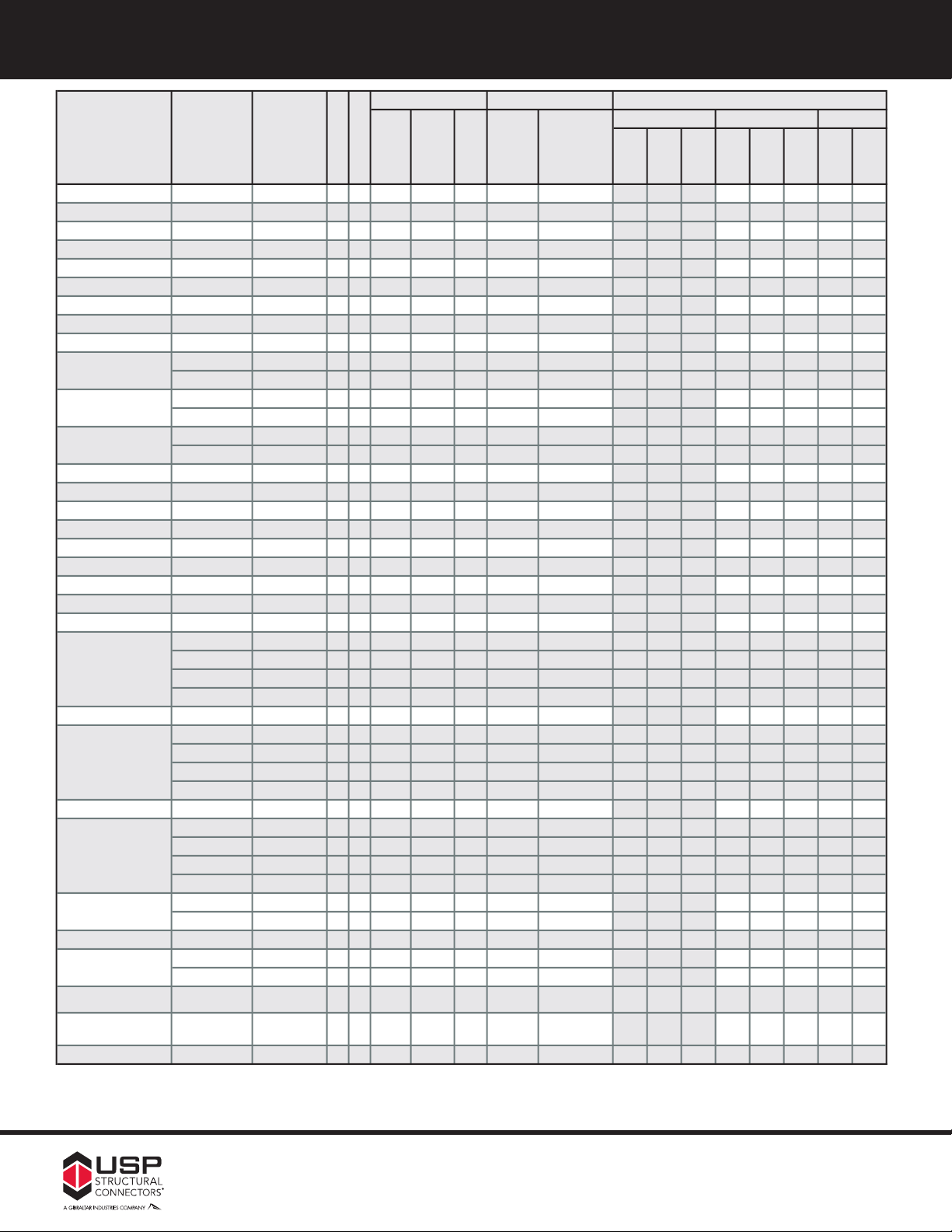

2-1/2 x 13

THF25130

-- --

--162

-1/212-1/42-1/2(18) 10d(2) 10d x 1-1/2209022802280180020702250300360

2-1/2 x 14

THF25140

IUT314

--162

-1/213-7/162-1/2(18) 10d(2) 10d x 1-1/2209024002610180020702250300360

2-1/2 x 16 THF25160 MIU316 -- 16 2-1/2 15-1/2 2-1/2 (22) 10d (2) 10d x 1-1/2 2550 2935 3035 2200 2530 2750 300 360

2-1/2 x 18 - 24 THF25160 MIU316 x 16 2-1/2 15-1/2 2-1/2 (22) 10d (2) 10d x 1-1/2 2550 2935 3035 2200 2530 2750 300 360

2-5/8 x 9-1/4 - 9-1/2 THF26925 IUT2.68/10 -- 18 2-5/8 9-1/16 2-1/2 (12) 10d (2) 10d x 1-1/2 1370 1575 1710 1175 1350 1470 175 175

2-5/8 x 11-1/4 - 11-7/8 THF26112 IUT2.68/12 -- 18 2-5/8 11-1/16 2-1/2 (14) 10d (2) 10d x 1-1/2 1595 1835 1995 1370 1580 1715 300 360

2-5/8 x 14

THF26140

IUT2.68/14

--162

-5/813-3/82-1/2(18) 10d(2) 10d x 1-1/2209024002610180020702250300360

2-5/8 x 16

THF26160

MIU2.68/16--162-5/815-7/162-1/2(22) 10d(2) 10d x 1-1/2255029353035220025302750300360

2-5/8 x 18 - 24

THF26160

MIU2.68/16

x 162

-5/815-7/162-1/2(22) 10d(2) 10d x 1-1/2255029353035220025302750300360

HD27925

HU2.75/10

x 142

-3/48-5/8

2 (

18) 16d(6) 10d x 1-1/22520277527752180250527259101065

THDH27925 HGUS2.75/10 x 12 2-3/4 9-1/8 4 (46) 16d (12) 16d 8170 8260 8260 7250 8260 8260 3490 3490

HD27112 HU2.75/12 x 14 2-3/4 10-7/8 2 (22) 16d (6) 10d x 1-1/2 3080 3540 3610 2660 3060 3330 910 1065

THDH27112 HGUS2.75/12 x 12 2-3/4 10-7/8 4 (56) 16d (14) 16d 8785 9090 9300 8505 8770 8950 4935 5925

HD2714

HU2.75/14

x 142

-3/412-7/8

2 (

26) 16d(8) 10d x 1-1/236103610361031453610361010651065

THDH2714

HGUS2.75/14

x 122

-3/412-1/4

4 (

66) 16d

(

16) 16d

9

0759430966587559060926556456770

3 x 9-1/4 - 14

THF15925-2 MIU29-2

x 163

-1/89-3/162-1/2(12) 10d

(

6) 10d

1

390160017401200138015009301115

3 x 11-1/4 - 14

THF15112-2 MIU211-2

x 163

-1/810-13/162-1/2(14) 10d

(

6) 10d

1

625187020301400161017509301115

3 x 14 THF15140-2 -- -- x 12 3-1/8 12-3/4 2-1/2 (18) 10d (6) 10d 2250 2590 2815 1960 2255 2455 1000 1200

3-1/8 x 9-1/4 - 14 THDH3210 HGUS3.25/10 x 12 3-1/4 9-3/8 4 (46) 16d (12) 16d 8170 8260 8260 7250 8260 8260 3490 3490

3-1/8 x 11-1/4 - 14 THDH3212 HGUS3.25/12 x 12 3-1/4 10-5/8 4 (56) 16d (14) 16d 9870 10180 10385 8755 9855 10035 4935 5925

3-1/4 x 9-1/4 - 14 THF16925-2 HU3.31/9 x 16 3-3/8 9-1/16 2-1/2 (12) 10d (6) 10d 1390 1600 1740 1200 1380 1500 930 1115

3-1/4 x 11-1/4 - 14 THF16112-2 HU3.31/11 x 16 3-3/8 10-3/4 2-1/2 (14) 10d (6) 10d 1625 1870 2030 1400 1610 1750 930 1115

3-1/4 x 14 THF16140-2 HU3.31/14 x 12 3-3/8 12-5/8 2-1/2 (18) 10d (6) 10d 2250 2590 2815 1960 2255 2455 1000 1200

3-1/2 x 9-1/4 - 9-1/2 THF35925 IUT410 -- 18 3-1/2 8-5/8 2-1/2 (12) 10d (2) 10d x 1-1/2 1370 1575 1710 1175 1350 1470 245 245

THF17925-2 -- -- x 16 3-9/16 8-15/16 2-1/2 (12) 10d (6) 10d 1390 1600 1740 1200 1380 1500 930 1115

HD410 HU410 x 14 3-9/16 8-13/16 2-1/2 (18) 16d (10) 10d 2520 2900 3150 2180 2505 2725 1575 1890

THD410 HHUS410 x 14 3-5/8 9 3 (38) 16d (20) 10d 5320 6120 6650 4600 5290 5750 3145 3775

THDH410 HGUS410 x 12 3-5/8 9-1/16 4 (46) 16d (12) 16d 8170 9010 9010 7040 7705 7855 3970 3970

3-1/2 x 11-1/4 - 12 THF35112 IUT412 -- 18 3-1/2 10-5/8 2-1/2 (16) 10d (2) 10d x 1-1/2 1825 2100 2280 1570 1805 1960 245 245

THF17112-2 -- -- x 16 3-5/8 10-9/16 2-1/2 (14) 10d (6) 10d 1625 1870 2030 1400 1610 1750 930 1115

HD412 HU412 x 14 3-9/16 10-13/16 2-1/2 (22) 16d (10) 10d 3080 3540 3850 2660 3060 3330 1575 1890

THD412 -- -- x 14 3-5/8 11 3 (48) 16d (20) 10d 6650 6650 6650 5810 6435 6640 3145 3775

THDH412 HGUS412 x 12 3-5/8 11-1/16 4 (56) 16d (14) 16d 9845 9845 9845 7730 7995 8175 4935 5225

3-1/2 x 14 THF35140 IUT414 -- 16 3-1/2 12-15/16 2-1/2 (20) 10d (2) 10d x 1-1/2 2320 2670 2900 2000 2300 2500 245 245

THF17140-2 -- -- x 12 3-5/8 12-1/2 2-1/2 (20) 10d (6) 10d 2500 2875 3125 2180 2505 2725 1000 1200

HD414 HU414 x 14 3-9/16 12-13/16 2-1/2 (24) 16d (10) 10d 3360 3865 4200 2905 3340 3630 1575 1890

THD414 -- -- x 14 3-5/8 12-7/8 3 (58) 16d (20) 10d 7335 7335 7335 7335 7335 7335 3335 4000

THDH414 HGUS414 x 12 3-5/8 13-1/16 4 (66) 16d (16) 16d 9845 9845 9845 7980 8285 8490 5645 6115

THF17157-2 -- -- x 12 3-5/8 15-3/4 2-1/2 (22) 10d (6) 10d 2750 3165 3440 2400 2760 3000 1000 1200

HD416 HU416 x 14 3-9/16 14-13/16 2-1/2 (26) 16d (12) 10d 3640 4185 4550 3145 3620 3935 1890 2265

3-1/2 x 16 THF35157 IUT416 -- 16 3-1/2 15 2-1/2 (22) 10d (2) 10d x 1-1/2 2550 2935 3190 2200 2530 2750 245 245

THF35165 IUT418 x 16 3-1/2 16-9/16 2-1/2 (24) 10d (8) 10d x 1-1/2 2785 3200 3480 2400 2760 3000 1235 1295

HD418 -- -- x 14 3-9/16 16-1/2 2-1/2 (28) 16d (8) 10d 3920 4510 4570 3390 3895 4255 1260 1425

4 - 4-3/16 x 9-1/4 - 9-1/2 THF20925-2

HU4.12/9,

HU4.28/9

-- 16 4-3/16 8-11/16 2-1/2 (12) 10d (6) 10d 1390 1600 1740 1200 1380 1500 930 1115

4 - 4-3/16

x 11-1/4 - 11-7/8

THF20112-2

HU4.12/11,

HU4.28/11

-- 16 4-3/16 11 2-1/2 (16) 10d (6) 10d 1855 2135 2320 1600 1840 2000 930 1115

4 - 4-3/16 x 14 THF20140-2 -- -- -- 16 4-3/16 13-5/8 2-1/2 (20) 10d (6) 10d 2320 2670 2900 2000 2300 2500 930 1115

2-11/16 x 9-1/4 - 14

3-1/2 x 14 - 20

3-1/2 x 11-1/4 - 16

2-11/16 x 14 - 16

3-1/2 x 9-1/4 - 14

Allowable Loads (Lbs.)

Uplift

2

2-11/16 x 11-1/4 - 16

U

SP

S

tock No.

3-1/2 x 18 - 26

3-1/2 x 16 - 22

Fastener Schedule

EEWWPP FFaaccee MMoouunntt HHaannggeerrss CChhaarrttss

Web Stiffener Reqd.

Steel Gauge

continued

continued on next page

Customer Service / Technical Assistance

Burnsville, MN Corporate Of

1-800-328-5934

fice

Loading...

Loading...