US Modular MA User Manual

MODULAR

INSTALLATION MANUAL

ISO 9001

Certified Quality

Management System

NON-VARIABLE SPEED AIR HANDLERS

MODELS: MA

LIST OF SECTIONS

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

UNIT INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

ELECTRIC HEATER INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . .5

LOW VOLTAGE CONTROL CONNECTIONS . . . . . . . . . . . . . . . . . .6

REQUIRED CONTROL

LIST OF FIGURES

Typical Installation with MC Multi-Position Coils . . . . . . . . . . . . . . . . .3

Coil and Air Handler Attachment Details . . . . . . . . . . . . . . . . . . . . . . .3

Gasket Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Dimensions & Duct Connection Dimensions . . . . . . . . . . . . . . . . . . . .4

Typical Horizontal Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Line Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

LIST OF TABLES

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Low Voltage Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Low Fan Control Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Blower Delays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Heat Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Physical and Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Electrical Data - Cooling Only (60 Hz) - 208/230 . . . . . . . . . . . . . . . . .9

Electrical Data - Cooling Only (60 Hz) - 460 . . . . . . . . . . . . . . . . . . . .9

Conversion Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Electrical Data - 1 Ø - 208/230-1-60 . . . . . . . . . . . . . . . . . . . . . . . . . 10

Electrical Data - (For Multi-Source Power Supply) -

Copper Wire 1 Ø - 208/230-1-60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

SET-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

LINE POWER CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

BLOWER SPEED CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 8

UNIT DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

460V - Line Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Blower Speed Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

460V - Blower Speed Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cooling Models with Electric Heat Wiring . . . . . . . . . . . . . . . . . . . . . 15

Single-Stage Cooling Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Electrical Data - (For Single Source Power Supply) -

Copper Wire 1 Ø - 208/230-1-60 . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Electrical Data - 3 Ø - 208/230-3-60 . . . . . . . . . . . . . . . . . . . . . . . . . 11

Electrical Data - (For Multi-Source Power Supply) -

Copper Wire 3 Ø - 208/230-3-60 . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Electrical Data - (For Single Source Power Supply) -

Copper Wire 3 Ø - 208/230-3-60 . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Electrical Data - 460-3-60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Electrical Data - (For Single Source Power Supply) -

Copper Wire 3 Ø - 460-3-60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Air Flow Data - 60 Hz Models (230 & 460 Volt) . . . . . . . . . . . . . . . . 13

Air Flow Data - 60 Hz Models (208 Volt) . . . . . . . . . . . . . . . . . . . . . 14

SECTION I: GENERAL

This modular air handler provides the flexibility for installation in any

upflow, downflow, or horizontal application. These versatile models may

be used for cooling or heat pump operation with or without electric heat.

A BRAND LABEL (available from Distribution) may be applied to the

center of the blower access panel.

The unit can be positioned for bottom return air in the upflow position,

top return air in the downflow position, and right or left return in the horizontal position.

Top and side power wiring and control wiring, accessible screw terminals for control wiring and easy to install electric heaters all combine to

make the installation easy, and minimize installation cost.

SECTION II: SAFETY

This is a safety alert symbol. When you see this symbol on

labels or in manuals, be alert to the potential for personal

injury.

Understand and pay particular attention to the signal words DANGER,

WARNING, or CAUTION.

DANGER indicates an imminently hazardous situation, which, if not

avoided, will result in death or serious injury

WARNING indicates a potentially hazardous situation, which, if not

avoided, could result in death or serious injury

.

.

CAUTION indicates a potentially hazardous situation, which, if not

avoided may result in minor or moderate injury.

alert against unsafe practices and hazards involving only property damage.

Improper installation may create a condition where the operation of

the product could cause personal injury or property damage.

Improper installation, adjustment, alteration, service or maintenance can cause injury or property damage. Refer to this manual

for assistance or for additional information, consult a qualified contractor, installer or service agency.

This product must be installed in strict compliance with the installation instructions and any applicable local, state, and national codes

including, but not limited to building, electrical, and mechanical

codes.

FIRE OR ELECTRICAL HAZARD

Failure to follow the safety warnings exactly could result in serious

injury, death or property damage.

A fire or electrical hazard may result causing property damage, per-

sonal injury or loss of life.

It is also used to

819288-UIM-A-0212

819288-UIM-A-0212

NOTICE

1. Install this air handler only in a location and position as specified in

SECTION III of these instructions.

2. Always install the air handler to operate within the air handler’s

intended maximum outlet air temperature. Only connect the air

handler to a duct system which has an external static pressure

within the allowable range, as specified on the air handler rating

plate.

3. When an air handler is installed so that supply ducts carry air circulated by the air handler to areas outside the space containing

the air handler, the return air shall also be handled by duct(s)

sealed to the air handler casing and terminating outside the space

containing the air handler.

4. The air handler is not to be used for temporary heating of buildings

or structures under construction.

5. The size of the unit should be based on an acceptable heat loss or

gain calculation for the structure. ACCA, Manual J or other

approved methods may be used.

SAFETY REQUIREMENTS

1. This air handler should be installed in accordance with all national

and local building/safety codes and requirements, local plumbing

or wastewater codes, and other applicable codes.

2. Refer to the unit rating plate for the air handler model number, and

then see the dimensions page of this instruction for supply air plenum dimensions in Figure 3. The plenum must be installed according to the instructions.

3. Provide clearances from combustible materials as listed under

Clearances to Combustibles.

4. Provide clearances for servicing ensuring that service access is

allowed for electric heaters and blower.

5. Failure to carefully read and follow all instructions in this manual

can result in air handler malfunction, death, personal injury and/or

property damage.

6. Check the rating plate and power supply to be sure that the electrical characteristics match.

7. Air handler shall be installed so the electrical components are protected from water.

8. Installing and servicing heating/cooling equipment can be hazardous due to the electrical components. Only trained and qualified

personnel should install, repair, or service heating/cooling equipment. Untrained service personnel can perform basic maintenance

functions such as cleaning and replacing the air filters. When

working on heating/cooling equipment, observe precautions in the

manuals and on the labels attached to the unit and other safety

precautions that may apply.

9. These instructions cover minimum requirements and conform to

existing national standards and safety codes. In some instances

these instructions exceed certain local codes and ordinances,

especially those who have not kept up with changing residential

and non-HUD modular home construction practices. These

instructions are required as a minimum for a safe installation.

INSPECTION

As soon as a unit is received, it should be inspected for possible damage during transit. If damage is evident, the extent of the damage

should be noted on the carrier’s freight bill. A separate request for

inspection by the carrier’s agent should be made in writing. Also, before

installation the unit should be checked for screws or bolts, which may

have loosened in transit. There are no shipping or spacer brackets

which need to be removed.

Also check to be sure all accessories such as heater kits, suspension

kits, and coils are available. Installation of these accessories or field

conversion of the unit should be accomplished before setting the unit in

place or connecting any wiring, electric heat, ducts or piping.

LIMITATIONS

These units must be wired and installed in accordance with all national

and local safety codes.

Voltage limits are as follows:

1

Air Handler Voltage Voltage code

208/230-1-60 21 187-253

460-3-60 41 432-504

1. Rated in accordance with ARI Standard 110, utilization range “A”.

Airflow must be within the minimum and maximum limits approved for

electric heat, evaporator coils and outdoor units.

Entering Air Temperature Limits

Wet Bulb Temp.°F Dry Bulb Temp. °F

Min. Max. Min. Max.

57 72 65 95

Normal Operating

Voltage Range

SECTION III: UNIT INSTALLATION

CLEARANCES

Clearances must be taken into consideration, and provided for as follows:

1. Refrigerant piping and connections - minimum 12” recommended.

2. Maintenance and servicing access - minimum 36” from front of unit

recommended for blower motor / coil replacement.

3. Condensate drain lines routed to clear filter and panel access.

4. Filter removal - minimum 36” recommended.

5. A combustible floor base accessory is available for downflow

applications of this unit, if required by local code.

LOCATION

Location is usually predetermined. Check with owner’s or dealer’s

installation plans. If location has not been decided, consider the following in choosing a suitable location:

1. Select a location with adequate structural support, space for service access, clearance for air return and supply duct connections.

2. Use hanging brackets to wall mount unit as shown.

3. Normal operating sound levels may be objectionable if the air handler is placed directly over some rooms such as bedrooms, study,

etc.

4. Select a location that will permit installation of condensate line to

an open drain or outdoors allowing condensate to drain away from

structure.

5. When an evaporator coil is installed in an attic or above a finished

ceiling, an auxiliary drain pan should be provided under the air

handler as is specified by most local building codes.

6. Proper electrical supply must be available.

In severe high humidity, high temperature indoor unit environments,

seal completely with adequate fiberglass insulation using vapor barrier on the outside.

2 Unitary Products Group

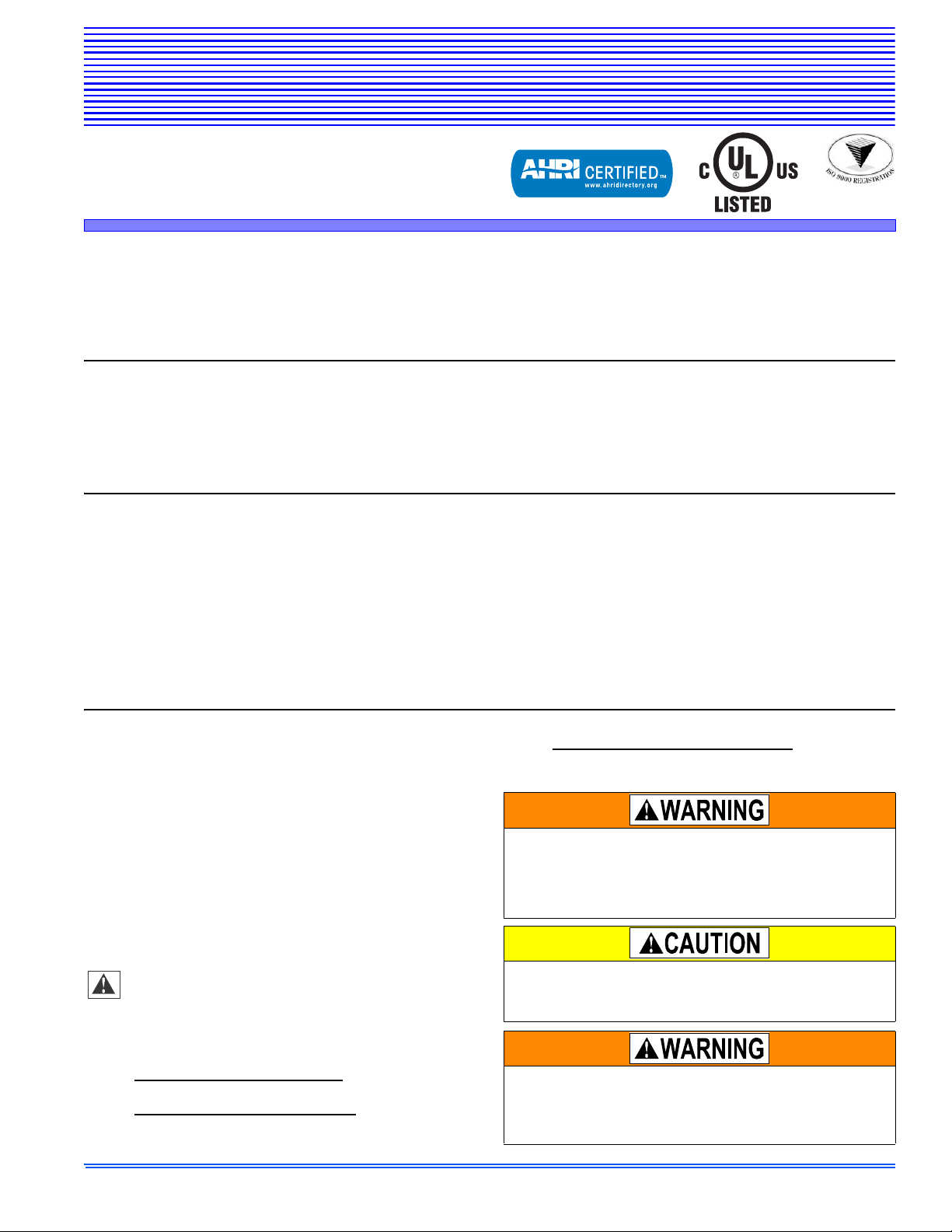

FIGURE 1: Typical Installation with MC Multi-Position Coils

UPFLOW

DOWNFLOW

HORIZONTAL RIGHT

HORIZONTAL LEFT

TIE PLATE

COIL

AIR HANDLER

COIL

TOP PLATE

AIR HANDLER

DOWNFLOW

APPLICATION

UPFLOW & HORIZONTAL

APPLICATIONS

819288-UIM-A-0212

DOWNFLOW AND HORIZONTAL CONVERSION

These air handler units are supplied ready to be installed in a upflow,

downflow and left or right hand horizontal position.

If the unit is to be installed with an evaporator coil, refer to Figure 1 for

unit positioning information.

FIGURE 2: Coil and Air Handler Attachment Details

AIR HANDLER AND COIL UPFLOW AND

HORIZONTAL

1. Apply neoprene gasket to top of coil casing.

2. Position blower casing over coil opening.

3. Attach tie plate to casings of air handler and coil using screws.

4. Remove blower access panel and coil filter door.

5. Disconnect wiring to blower motor. *Note location of wires as these

will be reconnected in a later step.

6. Remove blower motor and housing.

7. Fasten duct flanges of coil to duct flanges of air handler with

screws. See Figure 1.

8. Secure base of air handler to top of coil using screws.

9. Locate 2” wide foam gasket.

10. On the interior of the air handler/coil attachment point, apply foam

gasket over duct flanges on the sides and back.

11. Reinstall blower motor and housing by reversing the process in

Steps 3 and 4.

12. Complete electrical and blower speed connections as outlined in

other sections of this document.

13. Reposition and replace blower access panel.

AIR HANDLER AND COIL DOWNFLOW

1. Position blower casing over duct connection and secure such that

the supply air end of the blower is down.

2. Apply neoprene gasket to return-air side of air handler.

3. Place coil casing over blower return opening.

4. Attach tie plate to casings of air handler and coil using screws.

5. Remove blower access panel and coil filter door.

6. Disconnect wiring to blower motor.

*Note location of wires as these will be reconnected in a later step.

7. Remove blower motor and housing.

8. Fasten duct flanges of coil to base of air handler with screws. See

Figure 1.

9. Secure base of air handler to base of coil using screws.

10. Locate 2” wide foam gasket.

11. On the interior of the air handler/coil attachment point, apply foam

gasket over duct flanges on the sides and back.

12. Reinstall blower motor and housing by reversing the process in

Steps 3 and 4.

13. Complete electrical and blower speed connections as outlined in

other sections of this document.

14. Reposition and replace blower access panel.

Unitary Products Group 3

819288-UIM-A-0212

J

10-3/8”

E

CIRCUIT BREAKER

PANEL

BOTTOM INLET

DIMENSIONS

B

A

K

TOP OUTLET

DIMENSIONS

D

22”

20-1/2”

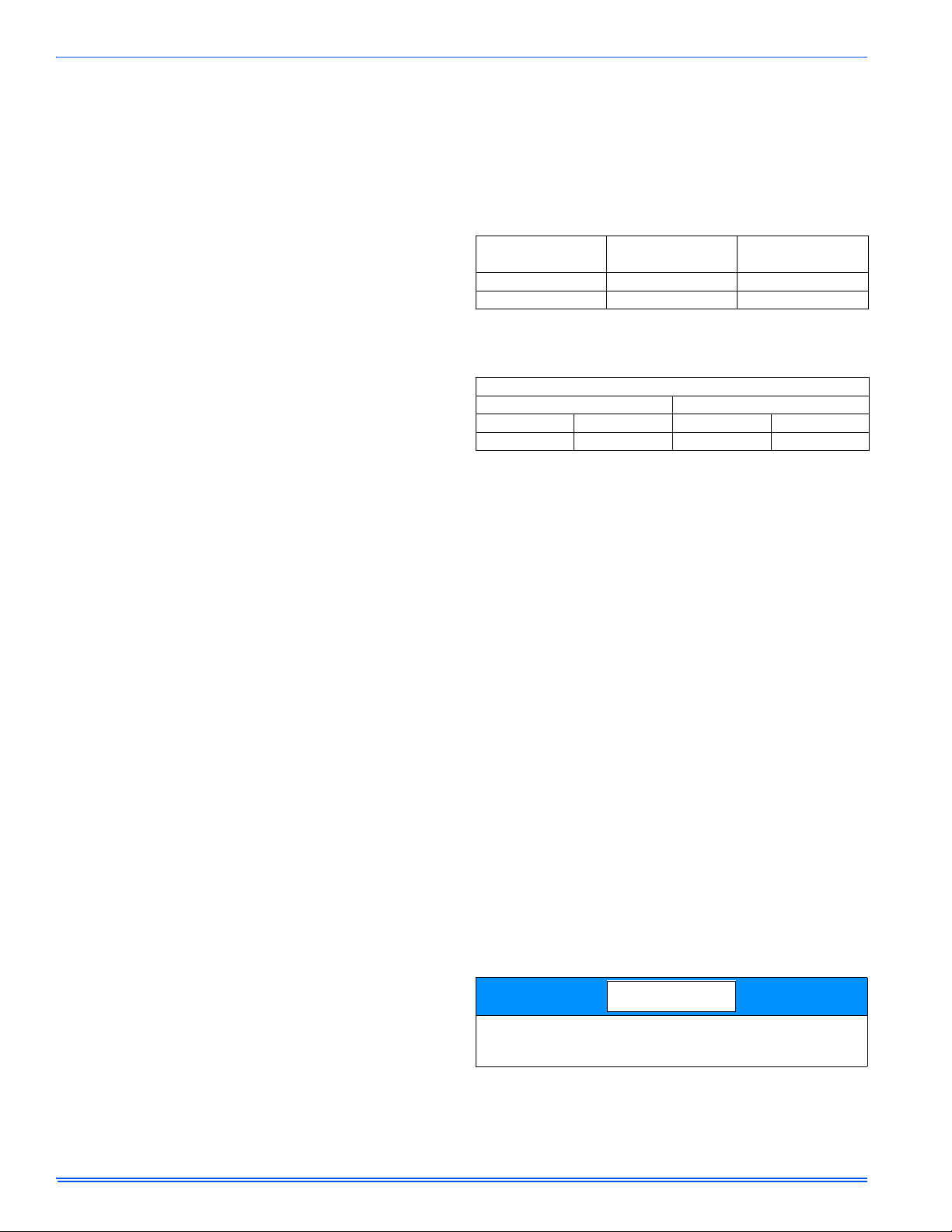

FIGURE 3: Gasket Location

FIGURE 4: Dimensions & Duct Connection Dimensions

TABLE 1:

Dimensions

MA

MODELS

Dimensions

Wiring Knockouts

1

ABDEJK

Height Width Power Control

08B

12B 17-1/2 16-1/2 14-19/32

14D 24-1/2 23-1/2 21-19/32

25

16C 21 20 18-3/32

17-1/2 16-1/2 14-19/32

7/8” (1/2”)

1 3/8” (1”)

1 23/32” (1 1/4”)

7/8” (1/2”)

20D 24-1/2 23-1/2 21-19/32

1. Actual size (Conduit size).

DUCT CONNECTORS

Use 1/2" screws to connect ductwork to bottom of unit. Longer

screws will pierce the drain pan and cause leakage. If pilot holes

are drilled, drill only though field duct and unit bottom flange.

Air supply and return may be handled in one of several ways best

suited to the installation. See Figure 3 for dimensions for duct inlet and

outlet connections.

The vast majority of problems encountered with combination heating

and cooling systems can be linked to improperly designed or installed

duct systems. It is therefore highly important to the success of an installation that the duct system be properly designed and installed.

4 Unitary Products Group

Use flexible duct collars to minimize the transmission of vibration/noise

into the conditioned space. If electric heat is used, non-flammable

material must be used.

Where return air duct is short, or where sound may be a problem,

sound absorbing glass fiber should be used inside the duct. Insulation

of duct work is a must where it runs through an unheated space during

the heating season or through an uncooled space during the cooling

season. The use of a vapor barrier is recommended to prevent absorption of moisture from the surrounding air into the insulation.

The supply air duct should be properly sized by use of a transition to

match unit opening. All ducts should be suspended using flexible hangers and never fastened directly to the structure. This unit is not

designed for non-ducted (freeblow) applications. Size outlet plenum or

transition to discharge opening sizes shown in Figure 3.

819288-UIM-A-0212

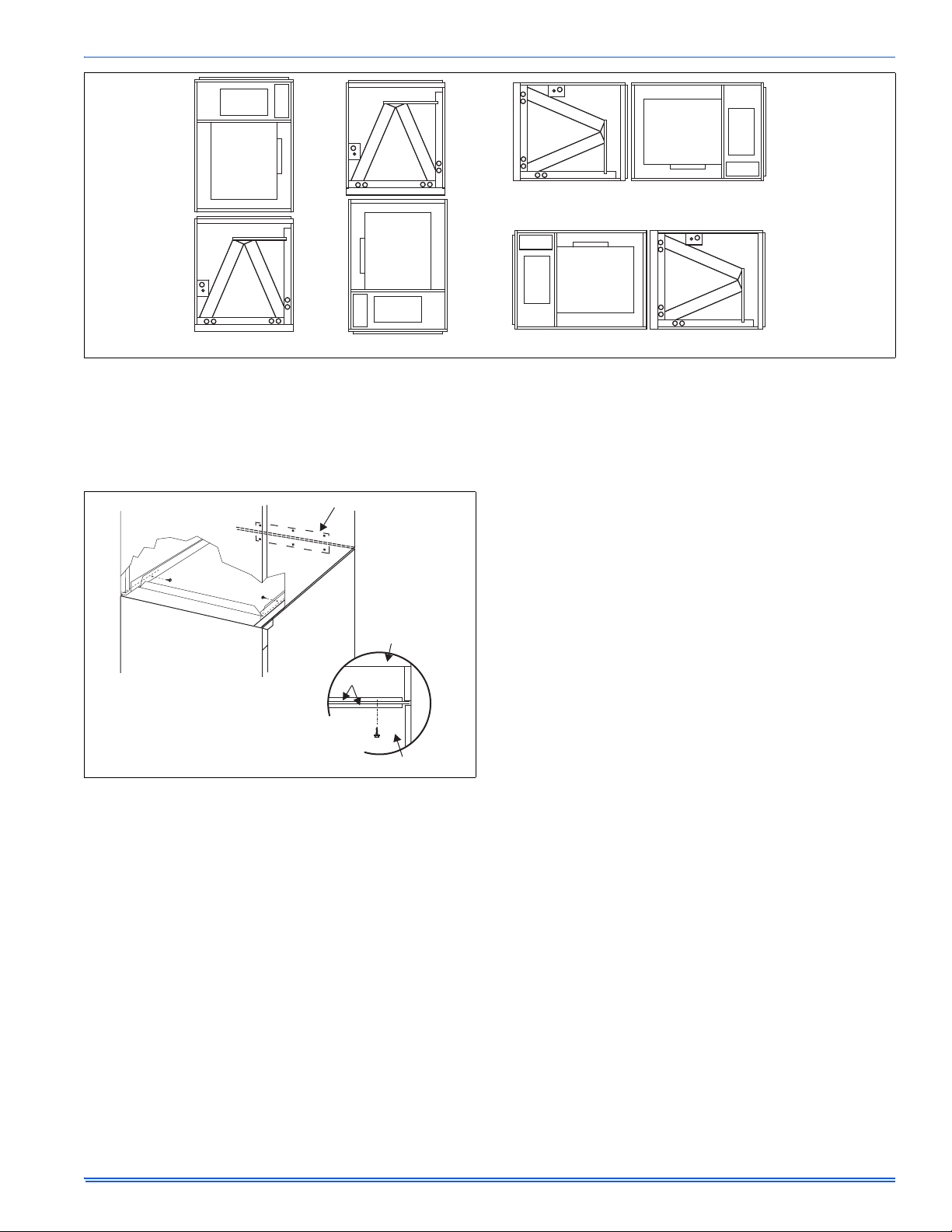

WW

XX

SUSPENSION SUPPORT LOCATIONS FOR HORIZONTAL APPLICATIONS

2

1-1/2

MIN. 1-1/2” x 1-1/2” Angle

Recommended length

26” minimum

with 2” clearance on

both sides of Air Handler

MIN. 3/8”

THREADED ROD

YY

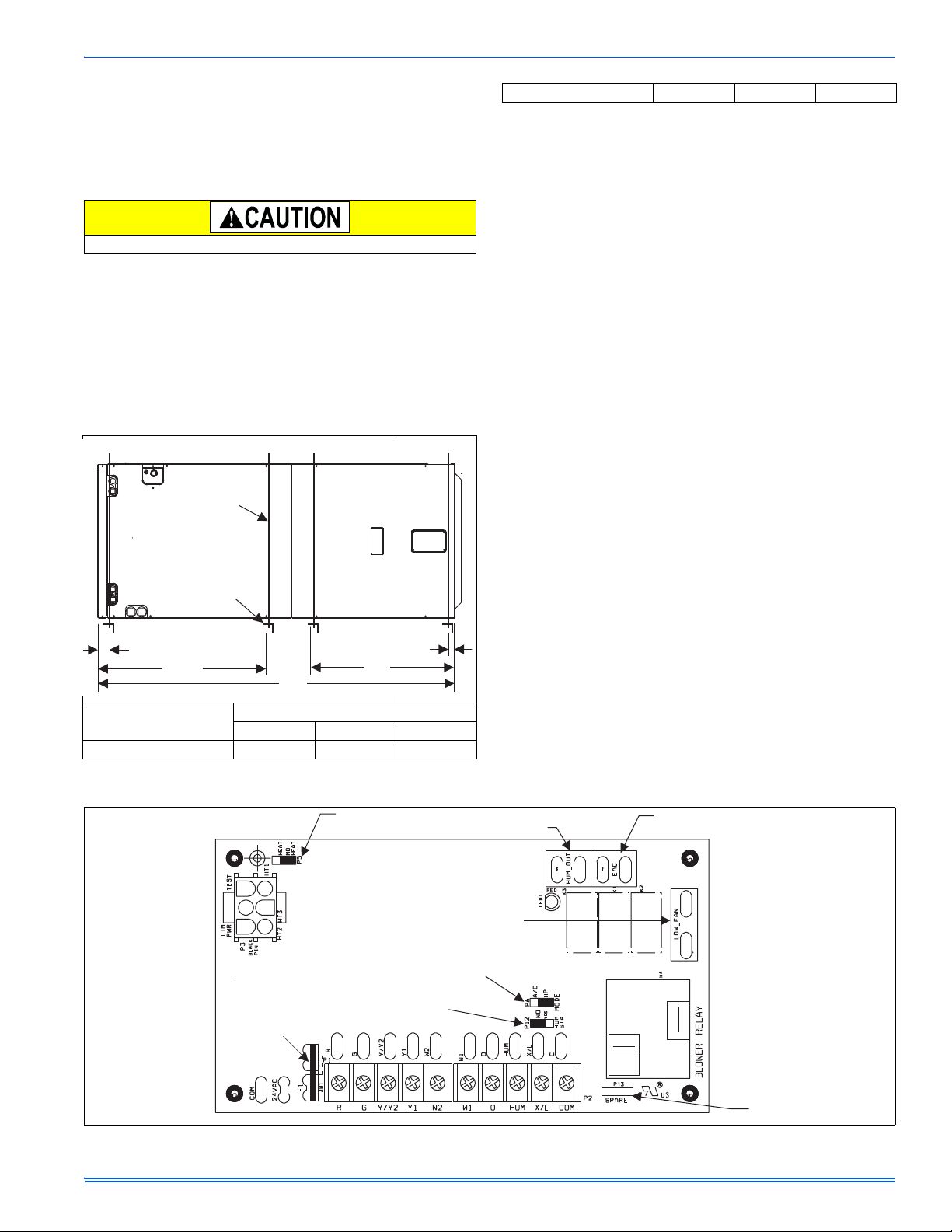

HEAT ENABLE

JUMPER

HUM OUT

RELAY OUTPUT

EAC RELAY

OUTPUT

LOW FAN

RELAY OUTPUT

SPARE

JUMPER

HUM STAT JUMPER

MODE JUMPER

FUSE

Duct work should be fabricated and installed in accordance with local

and/or national codes. This includes the standards of the National Fire

Protection Association for Installation of Air-Conditioning and Ventilating Systems, NFPA No. 90B.

AIR FILTERS

Air filters and filter racks must be field supplied.

.

Equipment should never be operated without filters.

SUSPENSION KITS

A suspension kit is available. Models 1BH0601 (unit size 018-060) is

designed specifically for the units contained in this instruction (upflow

application only). For installation of these accessory kits, see the

instructions packed with the kit.

HORIZONTAL SUSPENSION

For suspension of these units in horizontal applications, it is recommended to use angle steel support brackets with threaded rods, supporting the units from the bottom, at the locations shown in Figure 4.

3-1/2 - 5 Ton 24” 53” - 58” 22”

FIGURE 5: Typical Horizontal Installation

SECTION IV: ELECTRIC HEATER

INSTALLATION

If the air handler requires electric heat, install the electric heat kit

according to the installation instructions included with the kit. After

installing the kit, mark the air handler nameplate to designate the heater

kit that was installed. If no heater is installed, mark the name plate

appropriately to indicate that no heat kit is installed.

The HEAT ENABLE jumper (See Figure 5) must be moved to the HEA T

position to enable operation of the heater.

Use only 4HK heater kits, as listed on Air Handler name plate and in

these Instructions. Use data from Tables 11 through 18 for information

on required minimum motor speed tap to be used for heating operation,

maximum over-current protection device required and minimum electrical supply wiring size required for listed combination of Air Handler and

Heater Kit.

For Upflow, Downflow and Horizontal right hand applications the kits

can be installed without modification.

Field modification is required for Horizontal left-hand airflow application

only. Follow instructions with heater for modification.

Units

(Nominal Tons)

WW XX YY

Dimension

1-1/2 - 3 Ton 16” 48” 22”

FIGURE 5: Typical Horizontal Installation

FIGURE 6: Control Board

Unitary Products Group 5

Loading...

Loading...