USHA PBH56-04, PBH56-06, PBH56-08, PBH56-10, PBH56-12 Datasheet

...

Features

• Heat transfer through ceramic isolated

Cu base

• Isolation between contacts &

mounting base is 2.5KV(rms)

• Weight 120 gm (Approx)

dv/dt ≥ 200 V/µs typ. (Higher upto 1000 V/µs available on request)

Symbol Conditions Units

I

F(AV)

Sin 180 ; Tcase = 85 ˚C 55 A

I

(RMS)

Absolute maximum 110 A

I

TSM

Tvj = 25 ˚C; Half Sine; 10 ms; 0 V

RRM

1500 A

Tvj = 125 ˚C; Half Sine; 10 ms; 0 V

RRM

1250 A

I2t Tvj = 25 ˚C; Half Sine; 10 ms 11000 A2s

Tvj = 125 ˚C; Half Sine; 10 ms 8000 A2s

di/dt Tvj = 125 ˚C 100 A/µs

tq Tvj = 125 ˚C; di/dt=10A/µs; di/dt=50V/µs reapplied typ. 80µs

I

H

Tvj = 25 ˚C (typ. 150/Max.250)mA

I

L

Tvj = 25 ˚C; R

H

33Ω (typ. 300/Max.600)mA

V

T

Tvj = 25 ˚C ; IT = 200 A 1.65V max

V

O

Tvj = 125 ˚C .9V

R

0

Tvj = 125 ˚C 3.5 mΩ

I

DRM

/I

RRM

Tvj = 125 ˚C 15 mA max

V

GT

Tvj = 25 ˚C ; D.C. value 3 V

I

GT

Tvj = 25 ˚C ; D.C. value 150 mA

V

GD

Tvj = 125 ˚C ; D.C. value 0.25 V

I

GD

Tvj = 125 ˚C ; D.C. value 5 mA

R

th(j-c)

cont. 0.57/0.29 ˚C/W

Sin. 180 per thyristor/ per module 0.6/0.3 ˚C/W

rec. 120 .64/0.32 ˚C/W

R

th(c-h)

0.20/0.10 ˚C/W

T

vj

-40.....+ 125 ˚C

T

stg

-40.....+ 125 ˚C

V

ISOL

A.C. 50 Hz: r.m.s.; 1min 3 KV

Moulded Module Assembly

PBT 56 / PBH 56

Technical Data

Typical applications : DC Motor control, Temperature control, Professional light dimming.

Type No. V

RRM

V

RSM

(Volts) (Volts)

PBT 56/04 PBH 56/04 400 500

PBT 56/06 PBH 56/06 600 700

PBT 56/08 PBH 56/08 800 900

PBT 56/10 PBH 56/10 1000 1100

PBT 56/12 PBH 56/12 1200 1300

PBT 56/14 PBH 56/14 1400 1500

PBT 56/16 PBH 56/16 1600 1700

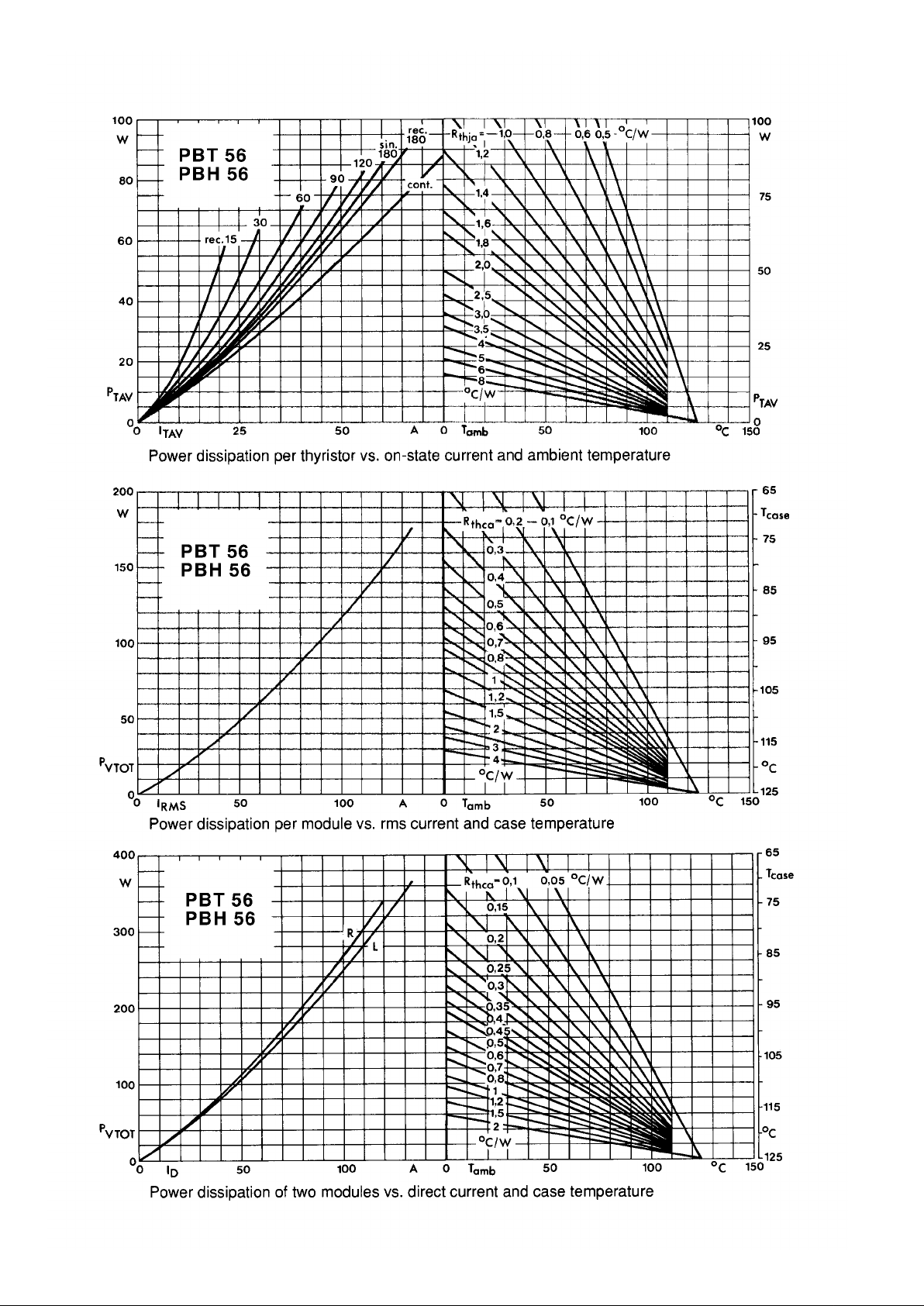

Loading...

Loading...