Page 1

Product Data

PROCESS GAUGES

XR-Series All-welded Process Gauge

and Diaphragm Seal

1PG -

DESCRIPTION

The XR-Series all welded system provides users with a

leak-proof, tamper-resistant gauge and seal solution that

combines the proven durability and performance of our

4-1/2” Model 1981 SOLFRUNT® Process Gauge with

our high quality M&G brand Diaphragm Seals.

l Best solution for operator safety

l Leak-proof – all joints are welded

l Seamless bourdon tube gauge standard

l Compact size

l Tamper resistant – can’t remove gauge

l 4:1 safety ratio

AMETEK USG’s XR models are now available in two

versions. Our new Finned Top version has been upgraded to include cooling fins on the body of the seal to improve its cooling features and an optional flushing port.

The first generation is still available for customers preferring that design, or applications requiring exotic metals,

such as MONEL 400, HASTELLOY, or Tantalum.

The XR-Series offers customers a leak-proof, tamperproof, lower cost alternative to an individual gauge and

diaphragm seal. The XR-Series increases worker safety

by reducing potential leaks in your process by welding the gauge to the seal and including our Model 1981

process gauge with a seamless bourdon tube. Many

companies specify seamless tubing throughout their

plants for their process lines, yet they use gauges that

have welded tubing. The Model 1981 gauges starts with

seamless tubing for our bourdon tubes, which provide a

seamless solution throughout your process.

The XR-81 is compliant to NACE MR-01-03 and MR0175 requirements. The designed operating pressure is

3000 psi at 100°F and has a maximum static pressure

rating of 5000 psi. The standard XR diaphragm seal has

a 4:1 safety ratio and is available in 316l SST, Hastelloy

C, MONEL bodies and 316L SST, HASTELLOY, MONEL

and Tantalum diaphragms. Please reference the following pages for specifics.

APPLICATIONS

l Refineries

l Petrochemical manufacturing

l Oilfield equipment

l Chemical manufacturing

SPECIFICATIONS

GAUGE: Model 1981 with 316L SST socket and 316L SST

seamless Bourdon tube, or Model 1986 with MONEL socket

and MONEL seamless Bourdon tube

RANGES: From 0 to 15 psi to 0 to 3000 psi

PROCESS CONNECTION: 1/2 NPT male connection standard,

other connections available upon request

SEAL WETTED PARTS: 316L stainless steel, MONEL,

HASTELLOY C bodies; 316L stainless steel, MONEL,

HASTELLOY C and Tantalum diaphragms; other wetted

materials may be available upon request

SEAL FILL FLUID: DC 200 silicone standard; other fills available

upon request

OPTIONS: Orifice restrictors on gauge; flush port on seal, StaKool™ cooling element, shatter-resistant window on gauge,

and capillaries

XR-81 SOLFRUNT® Process Gauge

with Welded M&G Finned Top Diaphragm Seal

On-line order fax: +1 215-323-9450 or e-mail: usg.sales@ametek.com

Sales/Technical Support: +1 215-293-4100 | 205 Keith Valley Road | Horsham PA 19044 U.S.A.

© 2012, by AMETEK, Inc. All rights reserved. Printed in the U.S.A. PDF1112STA (160174)

Specifications are subject to change without notice. Visit our Web site for the most up-to-date information.

www.ametekusg.com

Page 2

Product Data

PROCESS GAUGES

XR-Series All-welded Process Gauge

and Diaphragm Seal

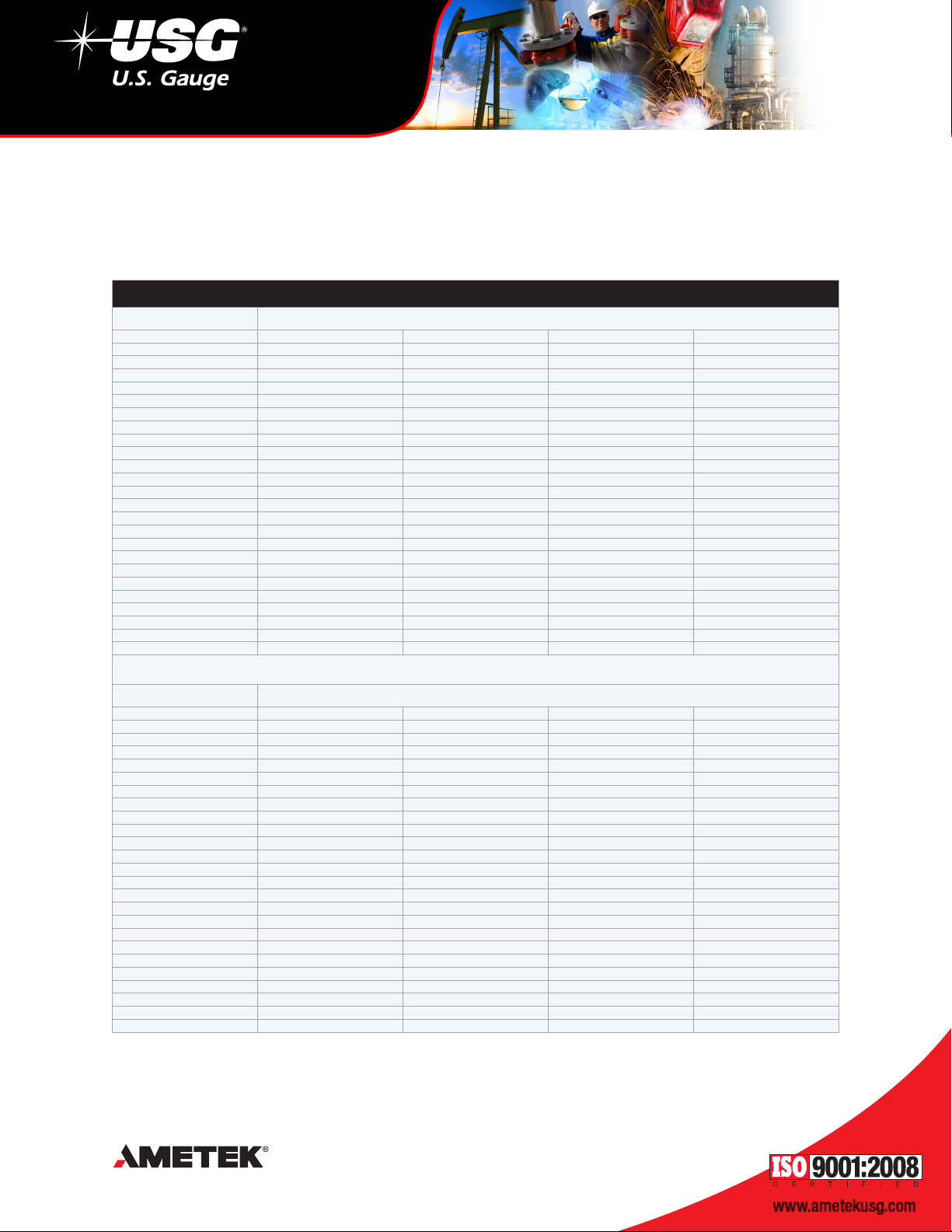

Model XR-81 SOLFRUNT® 4-1/2” Spec No. Selection Chart

Model: XR-81 New Design with Finned Top All-Welded Seals

Connection Size: 1/2" M NPT 1/2" M NPT 1/2" M NPT 1/2" M NPT

Dial Scale2: PSI PSI PSI PSI

Case Type: Dry E-Z Fill E-Z Fill E-Z Fill

Gauge Model: 1981 1981 1981 1981

Seal Upper Material: 316L SST 316L SST 316L SST 316L SST

Diaphragm Material: 316L SST 316L SST 316L SST 316L SST

Seal Lower Material: 316L SST 316L SST 316L SST 316L SST

System Fill Type3: DC 200 DC 200 DC 200 DC 200

Gauge Case Fill Fluid: N/A Dry Glycerin DC 200

Pressure Range: Spec No. Spec No. Spec No. Spec No.

0 - 15 PSI XR1015P27LLRL-- XRL015P27LLRL-- XRL015P27LLRLK- XRL015P27LLRLL0 - 30 PSI XR1030P27LLRL-- XRL030P27LLRL-- XRL030P27LLRLK- XRL030P27LLRLL0 - 60 PSI XR1060P27LLRL-- XRL060P27LLRL-- XRL060P27LLRLK- XRL060P27LLRLL0 - 100 PSI XR1100P27LLRL-- XRL100P27LLRL-- XRL100P27LLRLK- XRL100P27LLRLL0 - 160PSI XR1160P27LLRL-- XRL160P27LLRL-- XRL160P27LLRLK- XRL160P27LLRLL0 - 200 PSI XR1200P27LLRL-- XRL200P27LLRL-- XRL200P27LLRLK- XRL200P27LLRLL0 - 300 PSI XR1300P27LLRL-- XRL300P27LLRL-- XRL300P27LLRLK- XRL300P27LLRLL0 - 400 PSI XR1400P27LLRL-- XRL400P27LLRL-- XRL400P27LLRLK- XRL400P27LLRLL0 - 600 PSI XR1600P27LLRL-- XRL600P27LLRL-- XRL600P27LLRLK- XRL600P27LLRLL0 - 800 PSI XR1800P27LLRL-- XRL800P27LLRL-- XRL800P27LLRLK- XRL800P27LLRLL0 - 1000 PSI XR110CP27LLRL-- XRL10CP27LLRL-- XRL10CP27LLRLK- XRL10CP27LLRLL0 - 1500 PSI XR115CP27LLRL-- XRL15CP27LLRL-- XRL15CP27LLRLK- XRL15CP27LLRLL0 - 2000 PSI XR120CP27LLRL-- XRL20CP27LLRL-- XRL20CP27LLRLK- XRL20CP27LLRLL0 - 2300 PSI XR123CP27LLRL-- XRL23CP27LLRL-- XRL23CP27LLRLK- XRL23CP27LLRLL0 - 3000 PSI XR130CP27LLRL-- XRL30CP27LLRL-- XRL30CP27LLRLK- XRL30CP27LLRLL-

For Flushing Connection the 9th Character is changed to a 9, please see below.

Model: XR-81 New Design with Fin Topped All-Welded Seals and Flushing Connection

Connection Size: 1/2" M NPT 1/2" M NPT 1/2" M NPT 1/2" M NPT

Dial Scale2: PSI PSI PSI PSI

Case Type: Dry EZ-Fill E-Z Fill E-Z Fill

Gauge Model: 1981 1981 1981 1981

Seal Upper Material: 316L SST 316L SST 316L SST 316L SST

Diaphragm Material: 316L SST 316L SST 316L SST 316L SST

Seal Lower Material: 316L SST 316L SST 316L SST 316L SST

System Fill Type3: DC 200 DC 200 DC 200 DC 200

Gauge Case Fill Fluid: N/A Dry Glycerin DC 200

Pressure Range: Spec No. Spec No. Spec No. Spec No.

0 - 15 PSI XR1015P29LLRL-- XRL015P29LLRL-- XRL015P29LLRLK- XRL015P29LLRLL0 - 30 PSI XR1030P29LLRL-- XRL030P29LLRL-- XRL030P29LLRLK- XRL030P29LLRLL0 - 60 PSI XR1060P29LLRL-- XRL060P29LLRL-- XRL060P29LLRLK- XRL060P29LLRLL0 - 100 PSI XR1100P29LLRL-- XRL100P29LLRL-- XRL100P29LLRLK- XRL100P29LLRLL0 - 160 PSI XR1160P29LLRL-- XRL160P29LLRL-- XRL160P29LLRLK- XRL160P29LLRLL0 - 200 PSI XR1200P29LLRL-- XRL200P29LLRL-- XRL200P29LLRLK- XRL200P29LLRLL0 - 300 PSI XR1300P29LLRL-- XRL300P29LLRL-- XRL300P29LLRLK- XRL300P29LLRLL0 - 400 PSI XR1400P29LLRL-- XRL400P29LLRL-- XRL400P29LLRLK- XRL400P29LLRLL0 - 600 PSI XR1600P29LLRL-- XRL600P29LLRL-- XRL600P29LLRLK- XRL600P29LLRLL0 - 800 PSI XR1800P29LLRL-- XRL800P29LLRL-- XRL800P29LLRLK- XRL800P29LLRLL0 - 1000 PSI XR110CP29LLRL-- XRL10CP29LLRL-- XRL10CP29LLRLK- XRL10CP29LLRLL0 - 1500 PSI XR115CP29LLRL-- XRL15CP29LLRL-- XRL15CP29LLRLK- XRL15CP29LLRLL0 - 2000 PSI XR120CP29LLRL-- XRL20CP29LLRL-- XRL20CP29LLRLK- XRL20CP29LLRLL0 - 2300 PSI XR123CP29LLRL-- XRL23CP29LLRL-- XRL23CP29LLRLK- XRL23CP29LLRLL0 - 3000 PSI XR130CP29LLRL-- XRL30CP29LLRL-- XRL30CP29LLRLK- XRL30CP29LLRLL-

2

Contact USG Sales for dual scale dials and single scale metric dials.

3

For factory case liquid filling, substitute LG for Glycerin and LS for Silicone for LX suffix. Contact USG Sales for other case or system fill options.

Diaphragm seal filled with silicon standard. Other fill fluids, such as Halocarbon also available. Please contact Customer Service for more information.

2PG -

On-line order fax: +1 215-323-9450 or e-mail: usg.sales@ametek.com

Sales/Technical Support: +1 215-293-4100 | 205 Keith Valley Road | Horsham PA 19044 U.S.A.

© 2012, by AMETEK, Inc. All rights reserved. Printed in the U.S.A. PDF1112STA (160174)

Specifications are subject to change without notice. Visit our Web site for the most up-to-date information.

www.ametekusg.com

Page 3

Product Data

PROCESS GAUGES

XR-Series All-welded Process Gauge

and Diaphragm Seal

Model XR-86 SOLFRUNT® 4-1/2” Spec No. Selection Chart

Model: XR-86 1st Generation All-Welded Seals

Connection Size: 1/2” M NPT 1/2” M NPT

Dial Scale2: PSI PSI

Case Type: E-Z Fill E-Z Fill

Gauge Model: 1986 1986

Seal Upper Material: 316L SST 316L SST

Diaphragm Material: MONEL MONEL

Seal Lower Material: MONEL MONEL

System Fill Type2: DC 200 DC 200

Case Fill Fluid Type3: Dry See Note 3 Below

Pressure Range: Spec No. Spec No.

0 - 15 PSI 170066KSL 170066KSLX

0 - 30 PSI 170067KSL 170067KSLX

0 - 60 PSI 170068KSL 170068KSLX

0 - 100 PSI 170069KSL 170069KSLX

0 - 160 PSI 170070KSL 170070KSLX

0 - 200 PSI 170071KSL 170071KSLX

0 - 300 PSI 170072KSL 170072KSLX

0 - 400 PSI 170073KSL 170073KSLX

0 - 600 PSI 170074KSL 170074KSLX

0 - 1000 PSI 170075KSL 170075KSLX

0 - 1500 PSI 170540KSL 170540KSLX

2

Contact USG Sales for dual scale dials and single scale metric dials.

3

For factory case liquid filling, substitute LG for Glycerin and LS for Silicone for LX suffix. Contact USG Sales

for other case or system fill options.

Diaphragm seal filled with silicon standard. Other fill fluids, such as Halocarbon also available. Please contact

Customer Service for more information.

XR-86 SOLFRUNT®

All Monel Process Gauge

with Welded M&G

1st Generation Monel

Diaphragm Seal

3PG -

Other XR-Series Products Include:

XR-656 Open Front 4” All SST Process

Gauge and XR Diaphragm Seal, and

XR-659 Solid Front 4” All SST Process

Gauge and XR Diaphragm Seal.

Additional options include a shatterresistant window on gauge, restrictor on

gauge socket, flush port on seal, StaKool™ cooling element and capillaries.

XR-659

XR-656

On-line order fax: +1 215-323-9450 or e-mail: usg.sales@ametek.com

Sales/Technical Support: +1 215-293-4100 | 205 Keith Valley Road | Horsham PA 19044 U.S.A.

© 2012, by AMETEK, Inc. All rights reserved. Printed in the U.S.A. PDF1112STA (160174)

Specifications are subject to change without notice. Visit our Web site for the most up-to-date information.

XR-656

with 1” NPT Process

Connection for Ethanol

Applications

www.ametekusg.com

Page 4

Product Data

PROCESS GAUGES

XR-Series All-welded Process Gauge

and Diaphragm Seal

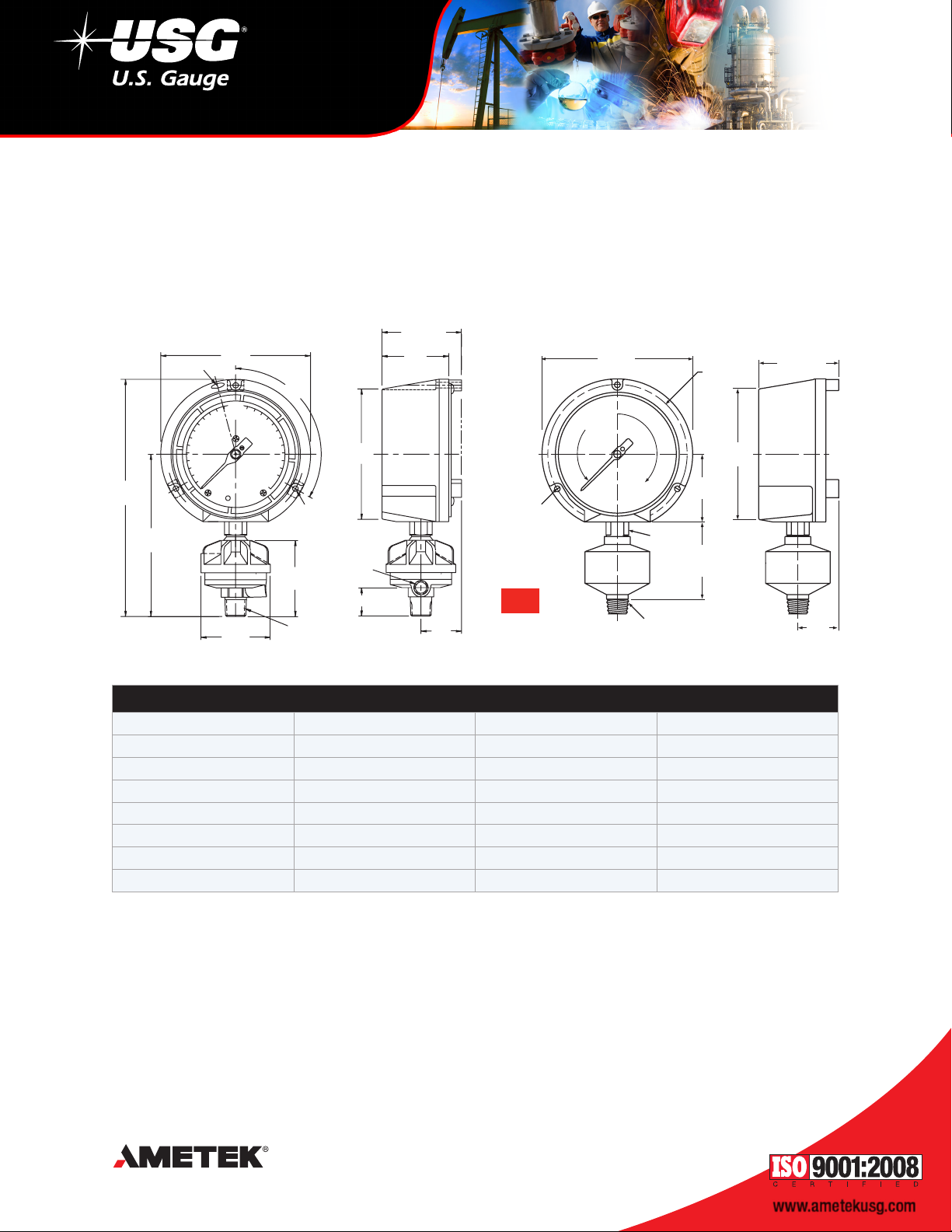

Finned Top Design (316L SST Only) First Generation (Monel, Hastelloy with Monel,

Hastelloy or Tantalum Diaphragm)

5.84

3 HOLES

EQUALLY

SPACED

INCHES

(MM)

Ø 0.22

(5.59)

270°

ARC

(148.3)

0.88

(22.2)

SQUARE

1/2 - 14 ANPT

THREAD

2.62

(66.5)

3.00

(76.1)

Ø5.38

(Ø136.5)

B.C.

5.06

(128.6)

9.31 ± .12

(236.47 ± 3.05)

6.38

(162.05)

FILL PLUG

OPTIONAL

Ø 4.20

(106.568)

WINDOW

OPENING

5.84

(148.3)

270°

ARC

Ø2.71

(Ø68.83)

120º

TYP.

Ø 0.219

(5.56)

3 HOLES EQUALLY

SPACED ON 5.37 B.C.

(136.4)

FLUSH PORT

2.96

(75.18)

1/2 - NPT

PROCESS

CONNECTION

(128.6)

1/4 - NPT

(OPTIONAL)

5.06

3.13

(79.5) MAX.

2.60

(66.04)

1.58

(40.1)

3.13

(79.5) MAX.

(40.1)

4PG -

1.58

XR-Series Canadian Registration (CRN)

Province Number Province Number

Alberta 0F8241.52ADD1 Nunavet 0F8241.5NADD1

British Columbia 0F8241.51ADD1 Ontario 0F8241.5ADD1

Manitoba 0F8241.56ADD1 Prince Edward Island 0F8241.59ADD1

New Brunswick 0F8241.57ADD1 Quebec 0F8241.56ADD1

Newfoundland/Labrador 0F8241.50ADD1 Saskatchewan 0F8241.56ADD1

Northeast Territories 0F8241.5TADD1 Yukon 0F8241.5YADD1

Nova Scotia 0F8241.58ADD1

On-line order fax: +1 215-323-9450 or e-mail: usg.sales@ametek.com

Sales/Technical Support: +1 215-293-4100 | 205 Keith Valley Road | Horsham PA 19044 U.S.A.

© 2012, by AMETEK, Inc. All rights reserved. Printed in the U.S.A. PDF1112STA (160174)

Specifications are subject to change without notice. Visit our Web site for the most up-to-date information.

www.ametekusg.com

Loading...

Loading...