Page 1

Installation

valley

vault

flush cut end

valley

vault

ID stamp

24"

23

3

/4"

72"

23"

vault

valley

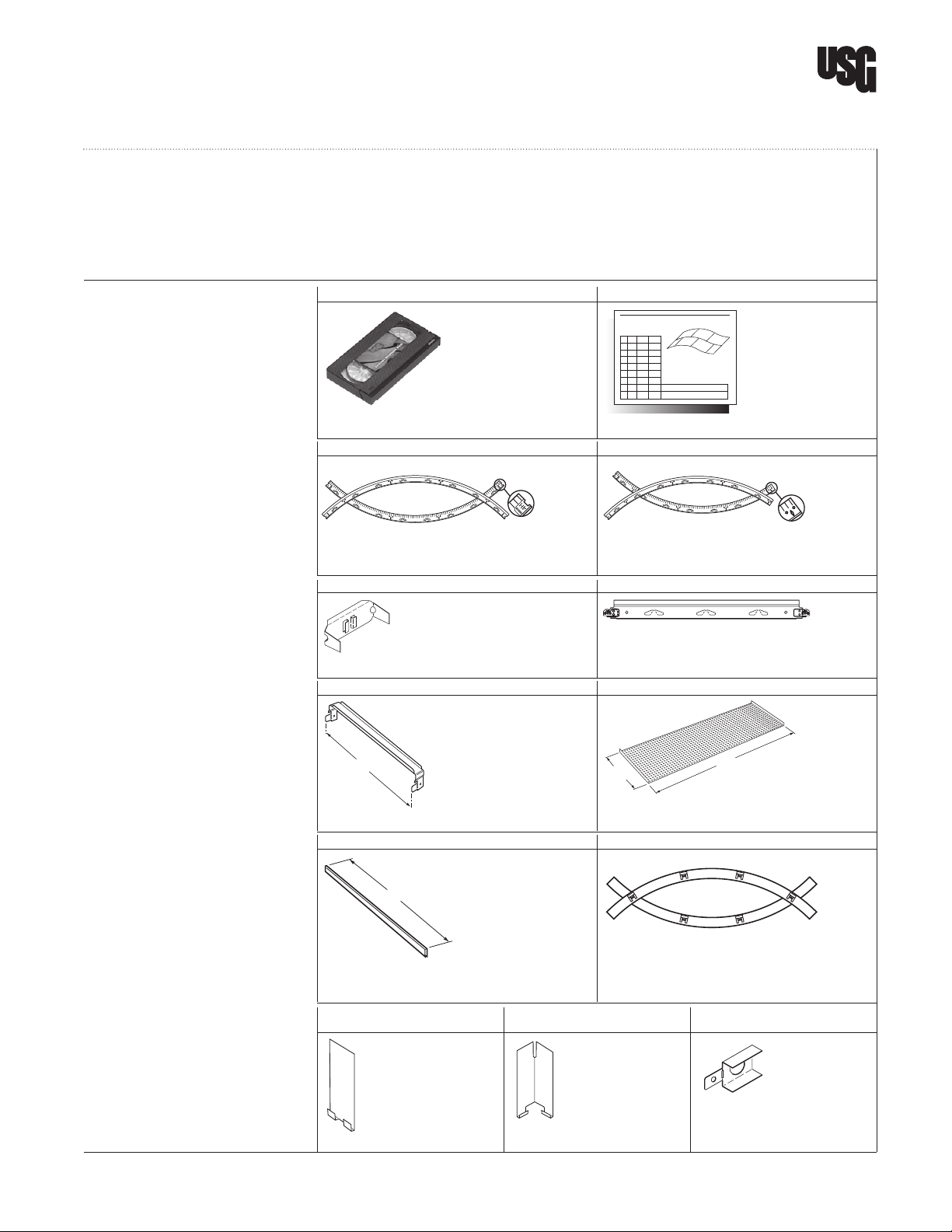

PART LIST

A

A

B

B

C

C

D

D

E

E

F

F

Instructions

One-Directional

™

Curvatura

3-D System

Page 1 of 12

Before beginning installation of the Cu r v a t u r a One-Directional Ceiling System, check the enclosed bill of materials

to ensure that all parts and components are present and undamaged. Read all installation instructions first

and familiarize yourself with the system’s parts and components. This is extremely important because parts will

become permanently damaged if they are installed incorrectly! To help with identification, all parts are poly-bagged

and labeled. Parts and components may include some or all of the following:

Parts and May include some or Installation videotape Bill of Materials (BOM)

Components

Flush-Cut Main Tees for Termination Vault, Valley, and/or Straight Main Tee Segments

Main Tee Splices Termination Cross Tees

all of the following:

Stabilizer Bars 28 x 68 C

C

Edge Trim Fascia Splices Edge Trim Corner Clips C

(if specified on BOM) (if specified on BOM) (if specified on BOM)

u r v at u r a Panel Joint Splices Edge Trim (if specified on BOM)

u r v at u r a One-Directional Panels

u r v at u r a Wall Attachment Clip

Page 2

One-Directional Cu r v a t u r a

Installation Instructions

Page 2 of 12

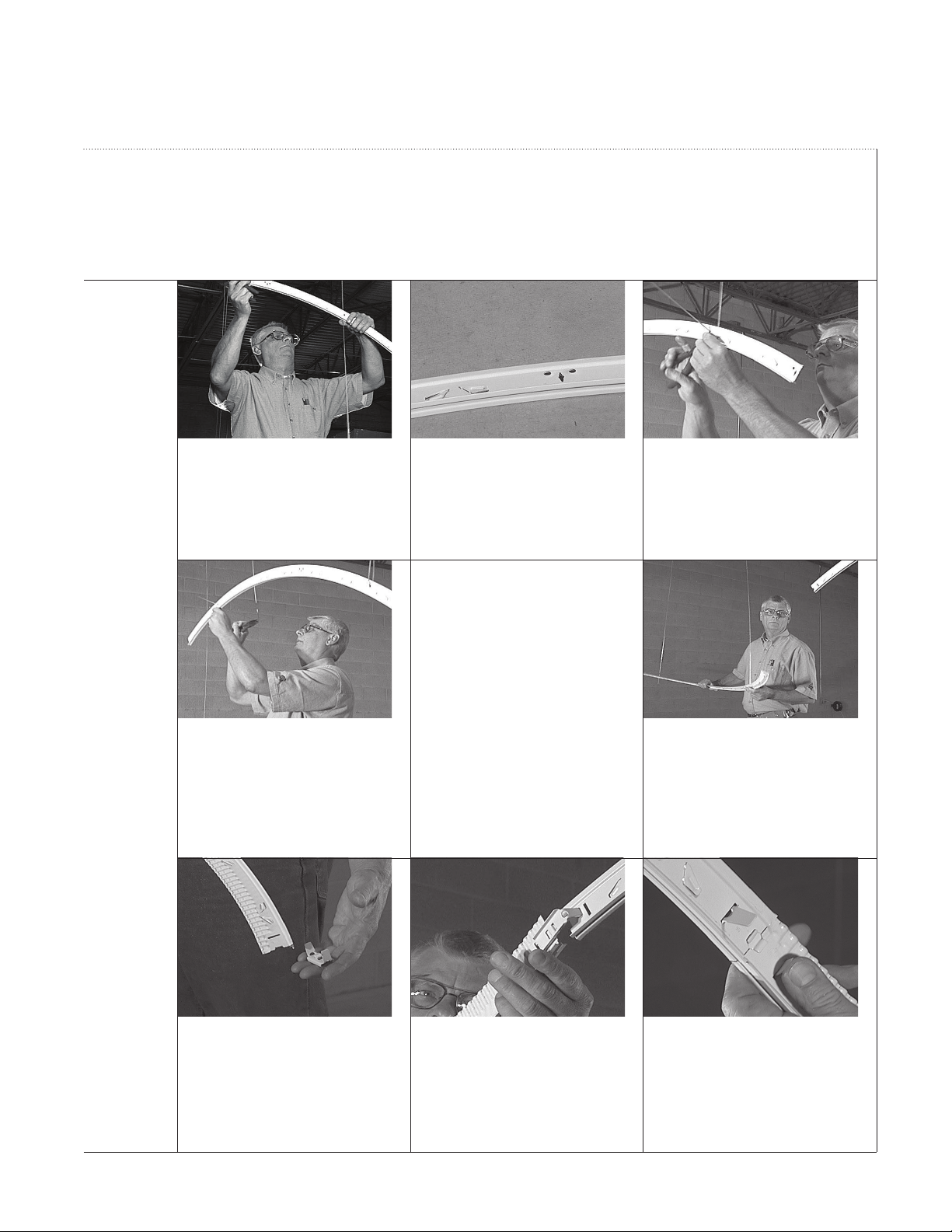

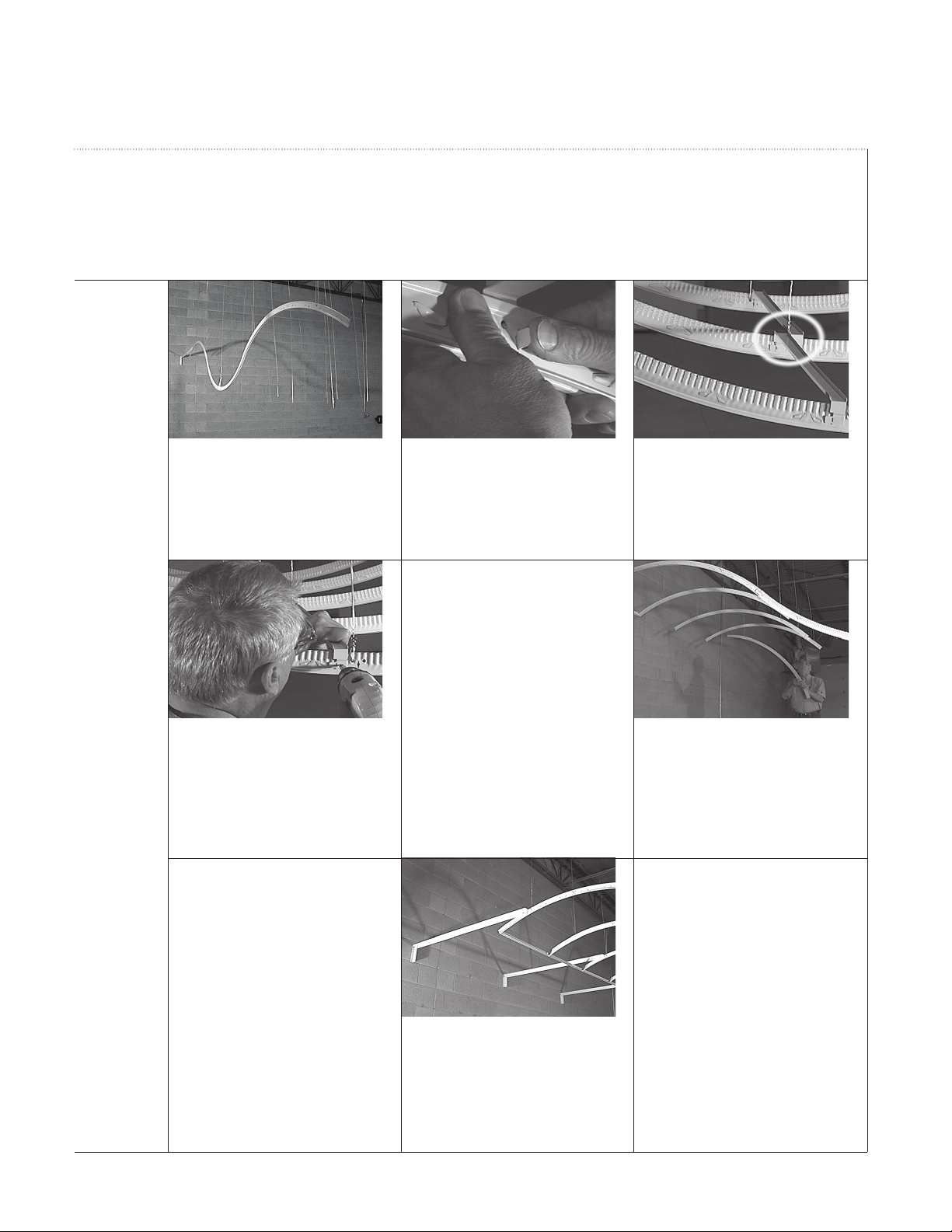

Step 1: Install First Row

of Main Tees

Step 1:

Install First Row

of Main Tees

1. 1. 1.

A. B. C.

Lay the main tees out on the ground as

they will be arranged in the installation.

1. 1. 1.

D. E. F.

Each hanger wire should fall in line with

a pre-punched hanger hole. Because

the tees are curved, the space between

hanger wires will vary along the main tee.

Establish where each hanger wire will

be attached.

Main tees may require field punched

hanger holes several inches from their

termination to allow adequate support

and leveling capabilities

Once you have established where each

hanger wire should go, pre-hang the first

row of hanger wire.

Find a corner starting point based on

locations specified on your architect’s

plans or by scaling from a working

drawing.

1. 1. 1.

G. H. I.

It’s best to start at a point near a wall

or column that can be used for reference

and support.

Refer to the bill of material and ribbon

drawing and locate the appropriate

flush-cut main tee to start the first row

of main tees.

For your reference, part ID codes are

listed on the ribbon drawing and stamped

on the ends of each main tee.

Page 3

One-Directional Cu r v a t u r a

Installation Instructions

Page 3 of 12

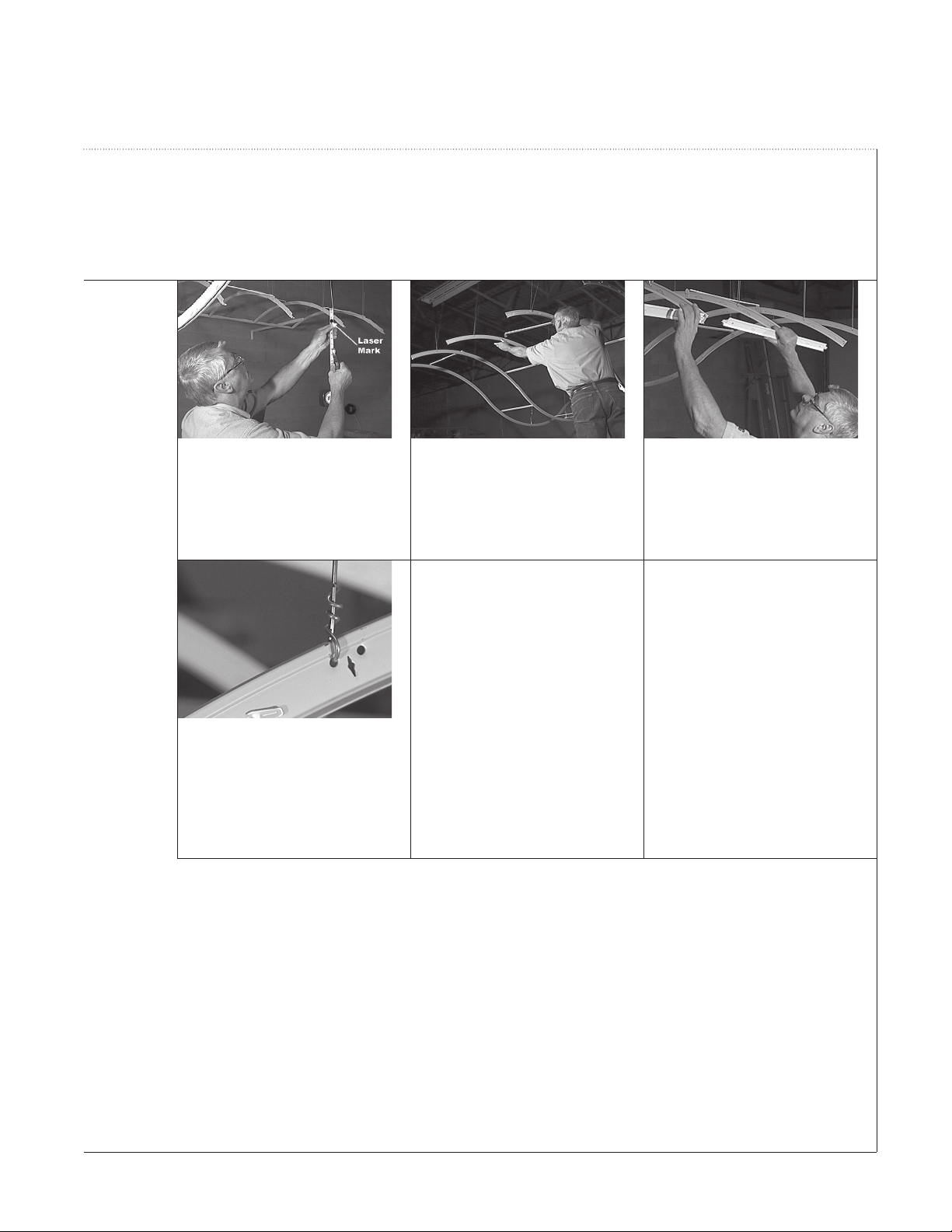

Step 1: Install First Row

of Main Tees

Step 1:

Install First Row

of Main Tees

(continued)

J. K. L.

Install the flush-cut end of the main tee.

M. N.

Tie hanger wires through every other set

of punched holes along the main tee—

roughly, about 4 feet apart.

Each main tee has sets of punched holes

spaced about 2 feet apart.

Remember…

Extra hanger holes are provided to help

work around obstructions. Also, keep

in mind that the space between any two

hanger wires must not exceed 4 feet.

Hang the flush-cut end of the main tee from

the ceiling at the elevation and location

specified on your architect’s plans or by

scaling from a working drawing.

Install the next main tee segment.

Refer to the ribbon drawing to select

the correct segment.

O. P. Q.

Connect this tee to the first tee by

using a main tee splice.

Insert the clip. Then, bend the tabs inward.

Page 4

One-Directional Cu r v a t u r a

Installation Instructions

Page 4 of 12

Step 1: Install First Row

of Main Tees

Step 1:

Install First Row

of Main Tees

(continued)

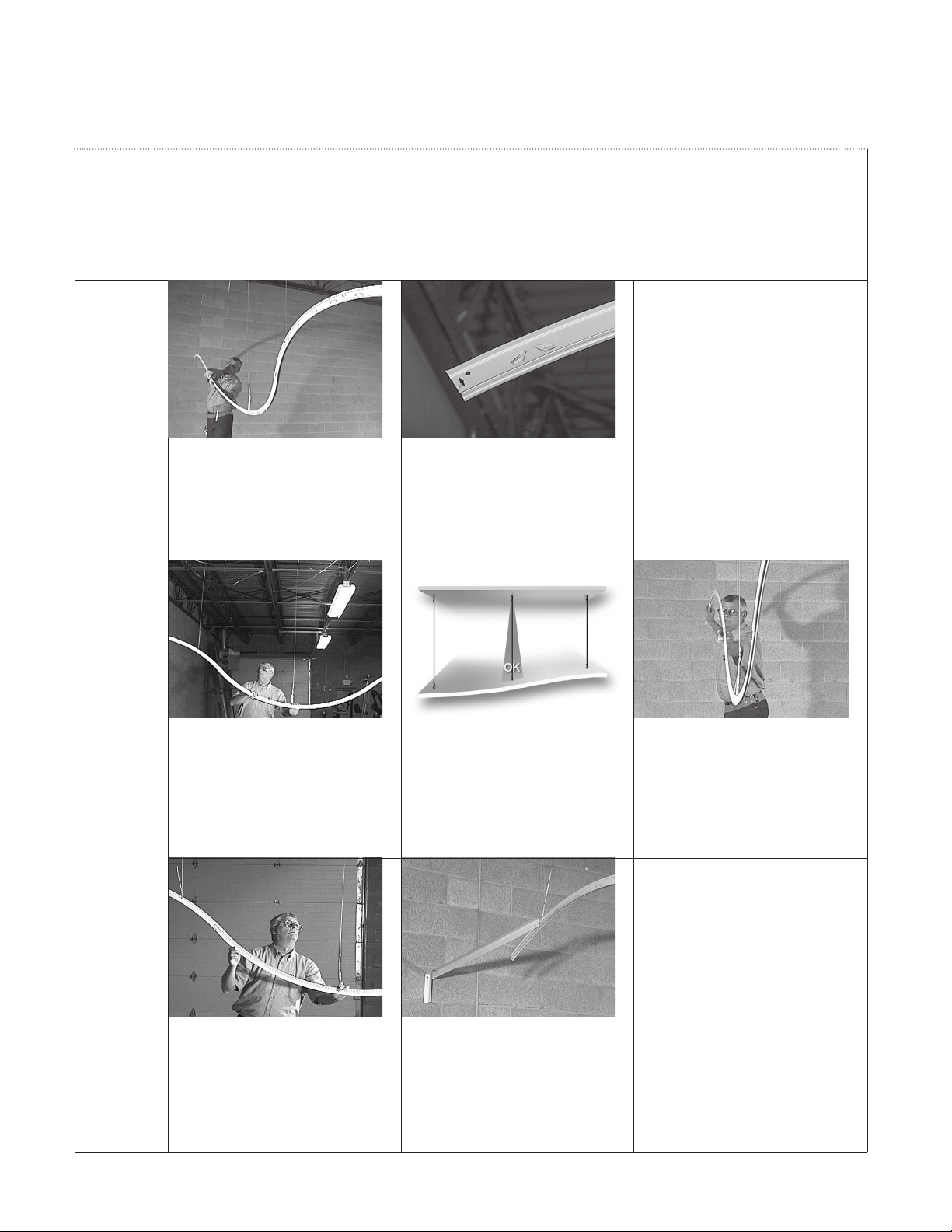

R.

Install main tees and hanger wires

one segment at a time until the entire

row is complete.

S.

Be sure to use the appropriate flush-cut

main tee at the end of the row as specified

on the ribbon drawing.

Remember…

The integrity and accuracy of the first

row of main tees will ultimately determine

the quality of the completed installation

so be sure to check the integrity of the

completed row.

Tip: Extra care at this point will prevent

alignment problems throughout the rest

of the installation.

T. U. V.

Examine the completed row from the side

to ensure that the hanger wires are plumb.

Wires should hang straight and plumb

within 1 in 6, about 10 degrees. If hangers

need to be relocated, move them now.

Examine the completed row end-on. It

should be straight with no waves. If you

need to install additional hanger wires,

install them now.

W. X.

Examine the row of main tees from the

side again. The curve of one tee should

flow smoothly into the curve of the next.

If the curves are not flowing smoothly,

adjust the hanger elevations either up or

down at the joints.

It’s important that the first row of main

tees remains stable during the entire

installation process. So, as a final step

in this first part of the installation, install

temporary bracing to the ceiling or

walls, if necessary, to ensure that the

row remains straight and rigid.

Tip: If necessary, you can punch or drill

extra hanger holes into the main tee to

ensure plumb wires.

Important…

You will be using this first row of main tees

as a template for hanging subsequent

rows, so take extra care to ensure proper

wire spacing before moving on.

Page 5

Stabilizer Bars Installed

Two Feet On Center

2 feet

Multi-ribbon Installation

2 feet

4 feet

One-Directional Cu r v a t u r a

Installation Instructions

Page 5 of 12

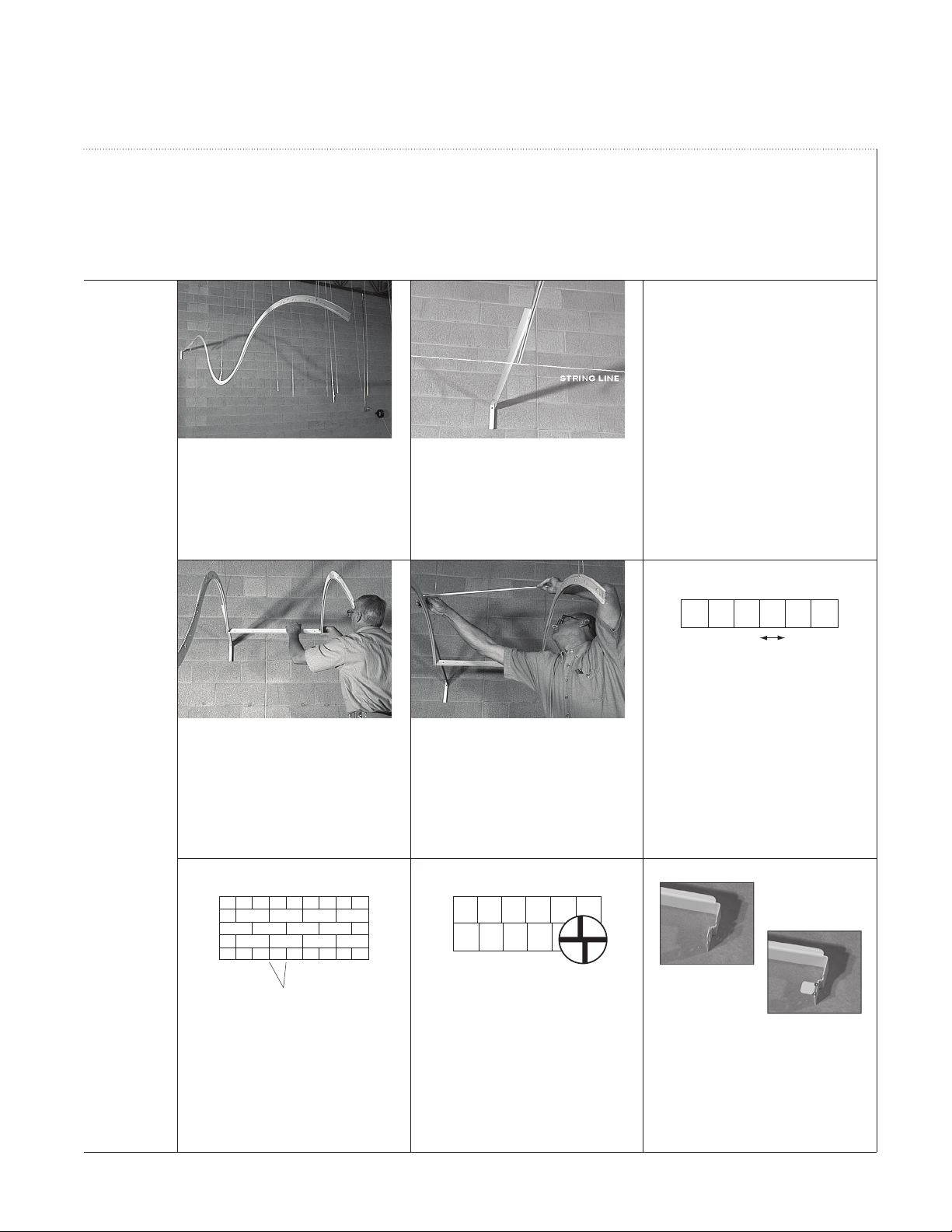

Step 2: Install a Row

of Flush-Cut Main Tees

Step 2:

Install a Row

of Flush-Cut

Main Tees

A. B. 1.

Using the first row of hanger wires as

a template, install additional rows of

hanger wires as needed, two-feet apart.

Using the first row of main tees as

a template, use string lines or a laser

to hang all the flush-cut main tees

at one end.

C. D. E.

As each flush-cut main tee is hung,

connect it to the previous row using

a termination cross tee.

Next, install the stabilizer bars. For a single ribbon installation, stabilizer

bars should be installed 2 feet on center

using all available cross tee holes.

Remember…

Feed hanger wires into the same hanger

holes as were used in the previous main

tee. This will prevent interference with the

stabilizer bars later during the installation.

Single-ribbon installation

F. G. H.

For a multi-ribbon installation, stabilizer bars

should be installed 2 feet on center along

the perimeter modules and staggered on

the inside rows.

Multi-ribbon installation Dual-ribbon installation

In a dual-ribbon installation, stabilizer bars

are installed in the cross tee slots on one

row and offset two feet on center on the

other row.

To install each stabilizer bar, bend the

stabilizer tabs in the same direction as

the offset…

…and insert the tab through the cross

Page 6

One-Directional Cu r v a t u r a

Installation Instructions

Page 6 of 12

Step 2: Install a Row

of Flush Cut Main Tees

Step 2:

Install a Row

of Flush-Cut

Main Tees

(continued)

I(a). I(b). J.

tee slot from the appropriate side. Without bending the tabs, position each

stabilizer bar slightly to the right or left

of the previous stabilizer bar…

…and attach each bar using a self

K. L.

tapping screw at the pilot hole provided. Continue to install the flush-cut main

Tip: You can install additional stabilizer

bars in any row where extra support may

be needed.

tees until all of the tees are installed

at one end.

Important…

Be careful to ensure that the row of

termination cross tees remains straight

and square throughout this phase of

the installation.

Extra care at this point will prevent

alignment issues later during installation.

M.

Install temporary bracing to the ceiling

or nearby walls as necessary to assure

that the row of termination cross tees

remains straight, square, and rigid.

1.

Page 7

One-Directional Cu r v a t u r a

Installation Instructions

Page 7 of 12

Step 3: Install

Remaining Grid

Step 3:

Install

Remaining

Grid

A. B. C.

Using the first row of main tees as

a template, use string lines or a laser

to install the remaining main tees.

Install the stabilizer bars according to

your specific installation as reviewed

previously.

Install termination cross tees at the

opposite ends of each row as indicated

on the ribbon drawing.

E. 1. 1.

Tightly wrap the ends of each hanger

wire to prevent them from being seen

from the side after the entire installation

is complete.

1. 1. 1.

Page 8

One-Directional Cu r v a t u r a

Installation Instructions

Page 8 of 12

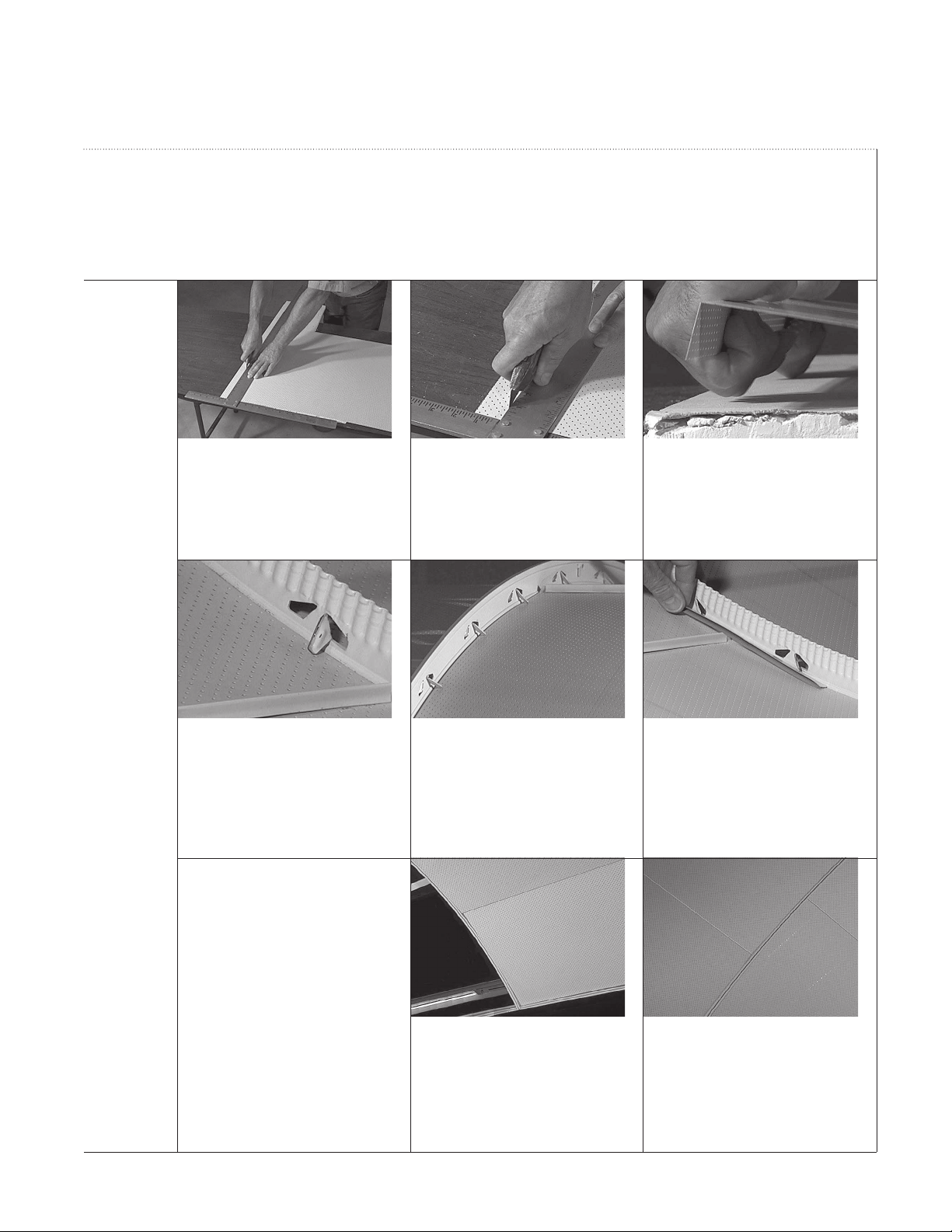

Step 4: Install Panels

Step 4:

Install Panels

A. B. C.

Note that some panels may be directional.

These panels will be marked on the back

and should be installed appropriately.

Insert a Cu r v a t u r a one-directional panel

into the first row by sliding it under the

stabilizer bars…

…and pulling or threading it all the way until

it butts up against the termination

cross tee.

D. E. F.

If you’re using a full panel, cut off the

upturned flange on the one end. This

will make clearance for the hold-down

tabs on the termination cross tee.

Use a screwdriver blade to bend in the

hold-down tab on the termination cross

tee and lock the panel into place.

Do not bend the hold-down tabs on the

main tees at this time.

Slide the next panel into the row…

G. H. I.

…and press a panel joint splice onto

the joint.

Repeat the process until reaching the

end of the row.

Finish the row by cutting a panel to fit

into the last opening.

Page 9

One-Directional Cu r v a t u r a

Installation Instructions

Page 9 of 12

Step 4: Install Panels

Step 4:

Install Panels

(continued)

J. K. L.

Most aluminum panels can be cut using

a straight edge and a sharp drywall knife.

Make a deep score with the drywall

knife…

…and bend the panel back and forth

to break it along the score.

M. N. O.

After the entire row of panels has been

installed, bend the main tee hold-down

tabs to lock the panels against the

main tee.

Bend as many hold-down tabs as necessary to eliminate all gaps between the

panels and main tees. Be careful not to

overbend the tabs as this could damage

the panel.

If a particular joint does not lie flat against

the main tee, cut a short piece of panel

splice about 4 to 5 inches long from the

extra splices provided. Slide one end

under a nearby hold-down tab and wedge

the other end over the top of the splice.

Remember…

1. P. Q.

Once the hold-down tabs are bent, the

panel positions and grid will be locked—

be sure to inspect the installation to

ensure that the grid is square and the

panels are flat before locking.

Start the next row of panels with a cut

panel…

…so that the panel joints are staggered

from one row to the next. Repeat

this process for every other row. Panel

remnants can also be used for this.

Page 10

One-Directional Cu r v a t u r a

Installation Instructions

Page 10 of 12

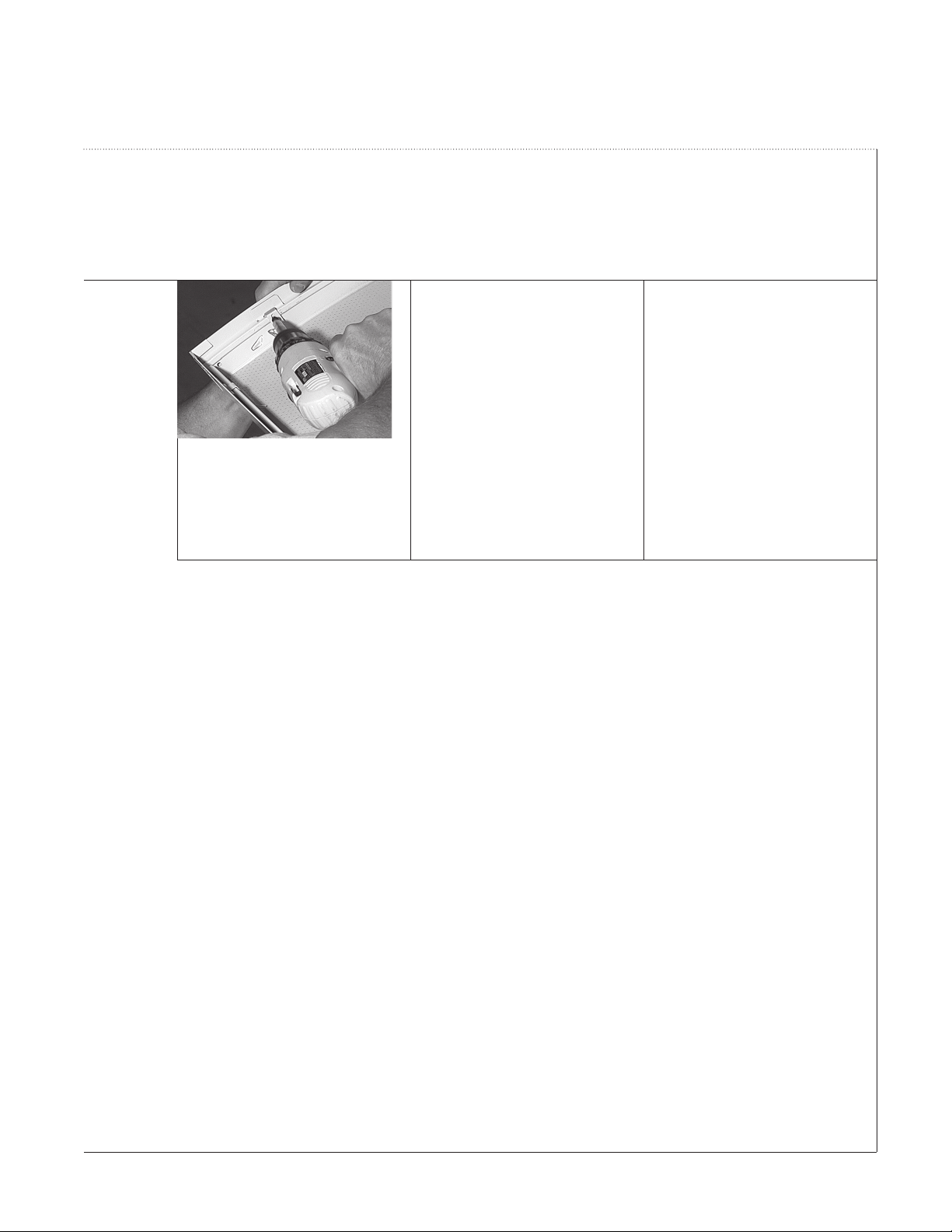

Step 5: Install Edge Trim

Step 5:

Install Edge

Trim

A. B.

Remove any visible temporary bracing that

may have been installed.

Follow the ribbon diagram to locate

the proper positions for each edge trim

segment.

Remember…

For ease of installation, edge trim segments

are 1/8 shorter than main tee segments.

Fascia splices and corner clips are provided

to cover the gaps.

C. D. E.

Start the installation with an appropriate

flush-cut edge trim segment…

…and apply fascia splices and corner

clips along the perimeter.

Hook them over the bottom edge of the

trim and bend the tabs over the top as

shown here.

F. G. H.

Remember, it’s easiest to install fascia

splices progressively.

Squeeze the bottom to get a snug fit

around the trim as shown here.

Then, bend the top of the splice as

shown here.

Page 11

One-Directional Cu r v a t u r a

Installation Instructions

Page 11 of 12

Step 5: Install Edge Trim

Step 5:

Install Edge

Trim

(continued)

I.

Finally, screw attach each edge trim

segment by applying number-six by

three-eighths self-tapping screws in

at least two integral attachment clips

at either end.

Page 12

Technical Service

800 USG.4YOU

Web Site

www.usg.com

Samples/Literature

888 874.2450

Samples/Literature E-mail

samplit@usg.com

Samples/Literature/Fax

888 874.2348

Customer Service

800 950.3839

Note

All products described here

may not be available in all

geographic markets and are

subject to change without

notice. Consult your local

sales office or representative

for information.

Trademarks

The following are trademarks of

USG Interiors, Inc. or a related

company: C

Notice

We shall not be liable for

incidental or consequential

damages, directly or indirectly

sustained, nor for any loss

caused by application of these

goods not in accordance with

current printed instruction or

for other than intended use.

Our liability is expressly limited

to replacement of defective

goods. Any claim shall be

deemed waived unless made

in writing to us within thirty

(30) days from the date it was

or reasonably should have

been discovered.

u r v a t u r a , USG.

Safety First!

Follow good safety practices.

Read material safety data

sheets and related literature on

products before specification

and/or installation.

Manufactured by

USG Interiors, Inc.

550 West Adams Street

Chicago, IL 60661

IC402/rev. 12-03

© 2003, USG Interiors, Inc.

Printed in U.S.A.

Loading...

Loading...