Page 1

DIAMOND and IMPERIAL

Brand Finish Plasters both offer a variety of advantages when used alone or in tandem in

various wall systems. D

IAMOND Brand Finish Plaster is very workable and easy to apply. I

MPERIAL Brand Finish

Plaster provides a higher-strength and more impact-resistant finish, which is why it is often recommended as the

outer coat on a two-coat system. Whether you use D

IAMOND Brand, I

MPERIAL Brand, or a two-coat system combining

the two, you’re sure to be pleased with the variety of textures you can achieve and the refined, finished look of a

well-executed plaster interior.

Preparation Protect the product from moisture during storage and on the job. In cold weather, heat the interior of the building

to a minimum of 55 °F (13 °C) for an adequate period before the application of plaster,while basecoat and finish

are being applied, and until the finish is dry. Keep air circulation at a minimum level during application and until

proper set has been achieved.

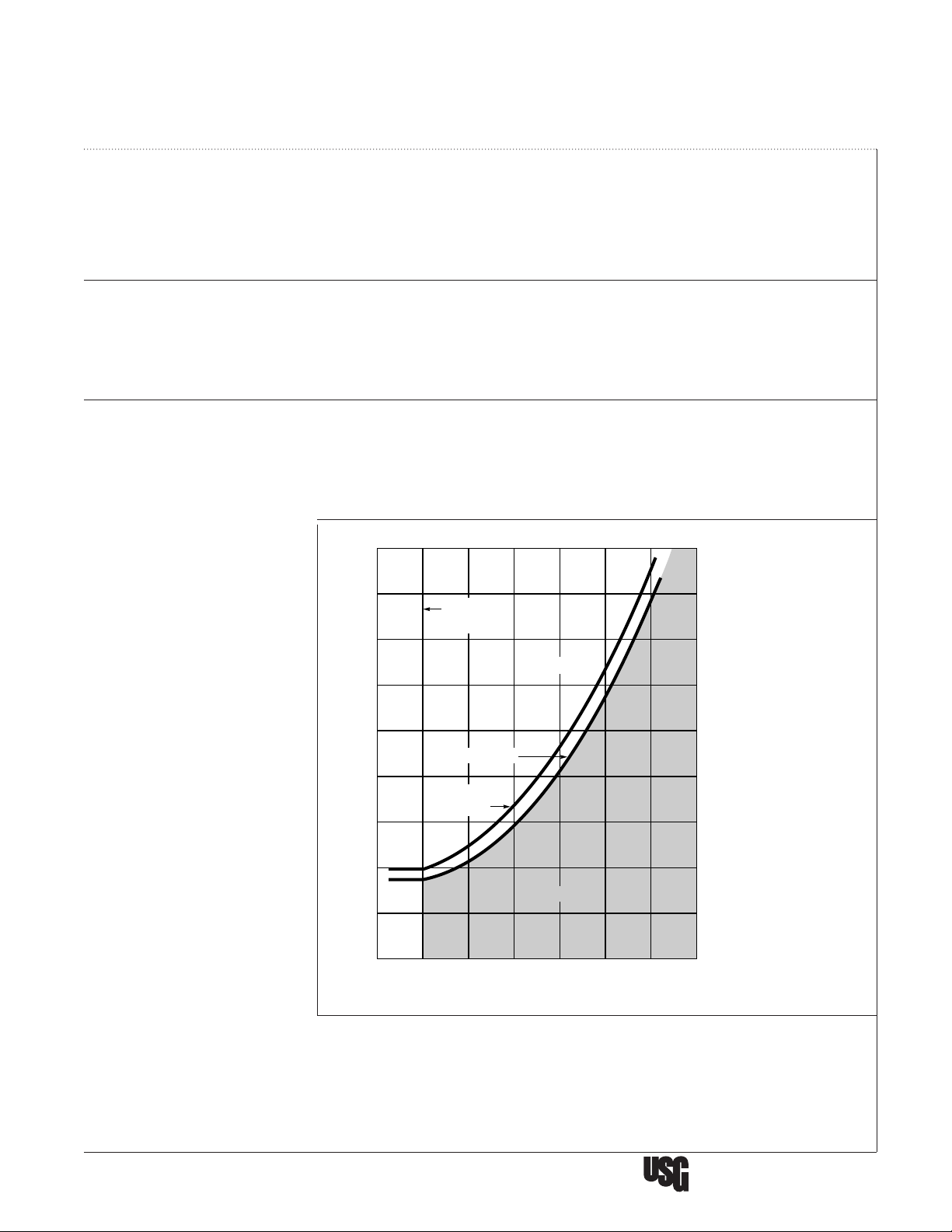

If possible, maintain building temperature-humidity combination in the “normal drying”area of the following graph.

When abnormally dry conditions exist, you can increase humidity by wetting down the floor periodically. During

these periods, make every effort to reduce air movement by closing windows and deflecting heater blower and

duct output away from the surfaces being plastered.

Protect all finish materials and finish surfaces from contact with Finish Plaster.These include glass, ceramic

materials, metal and wood.Apply wood, plastic or other exposed trim after finish application.

DIAMOND®and I

MPERIAL

®

Brand

Finish Plasters

Application Tips

90%

80%

70%

60%

50%

40%

30%

20%

10%

40 50 60 70 80 90 100 110°F

4101621 27323843°C

Plaster Drying Conditions

Maximum Temperature

Minimum Relative Humidity

minimum temp.

for plastering

normal drying

no air movement

detectable air

movement

rapid drying

Page 1 of 6

Page 2

Tools

Joint Preparation

– Joint Tape

– Spring Driven Hand Stapler,3/8 Staples (if tape is not self-adhesive)

– Steel Finishing Knife

–Trowel

Mixing – Heavy Duty Drill with no-load rating of 900 to 1,000 rpm. Drills with sufficient power include Black & Decker

Model #1322; and Milwaukee Models #1250-1, #1630-1, #1670-1 and #1675-1.

–Cage-Type Mixing Paddle

– Metal Mixing Barrel (16-gal., 1-bag size; 30 gal., 3-bag size; 15-gal.smooth-sided, 1-bag size)

– Buckets/Containers for Water

Plastering –Trowels, Rods, Darbys

–Drop Cloths

– Ladders/Scaffolding

–Trowels

Joint To ensure a smooth,seamless surface, the joints between wall panels must be properly treated to conceal and

Treatment reinforce them before plaster is applied.

For Normal Align IMPERIAL

®

Brand Type P (pressure sensitive) Tape over the joint and press it into place over the entire length

Drying Conditions

of the joint. Eliminate wrinkles and assure maximum adhesive bond by pressing the entire length of tape with a

steel finishing knife or trowel. Press the tape into corners with a corner tool. Do not overlap.

Alternatively,you can attach I

MPERIAL

®

Brand Type S Tape with spring-driven hand stapler using 3/8 staples.Use

two staples at each end of the tape; staple the remainder at staggered 24 intervals. At wall-ceiling angles,staple

every 18 to 24 along the ceiling edge only. For wall-to-wall interior angles,staple every 18 to 24 on one edge

only,working from top to bottom. Position the tape to bridge the joint at all interior corners without overlapping. For

fire-rated assemblies, staple either Type P or Type S Tape 8 o.c.

Embed the tape and fill beads with a coat of D

IAMOND or IMPERIAL Brand Interior Finish Plaster and allow to set—but

not dry—prior to finish application. Slightly underfill in the bead by screeding along the bead with edge of trowel

after setting the bead. (Best results are obtained by planning the job to permit continuous application of plaster

from angle to angle.)

For Rapid When building temperature-humidity conditions fall in the “rapid drying” area of the graph,or IMPERIAL Brand

Drying Conditions

Gypsum Base is being applied over steel studs, or in certain applications to framing spaced 24 o.c., use

S

HEETROCK

®

Brand Joint Tape embedded with SHEETROCK®Brand DURABOND™Setting-Type Joint Compound or

S

HEETROCK

®

Brand EASY SAND™Lightweight Setting-Type Joint Compound.

Butter the joints with compound using a trowel or steel finishing knife to force compound into the joints. Center

S

HEETROCK Brand Joint Tape and press it into the fresh compound with a trowel held at a 45° angle. Draw the

trowel along the joint with sufficient pressure to remove excess compound, ensuring the tape is wetted and

covered with a thin skim coat of the excess compound to edge wrinkling or curling. Wipe clean.Allow the joint

treatment to set; then apply a separate coat of joint compound to completely cover the tape, using a 10 or 12

knife or trowel, feathering it 2 to 3 beyond the edges of the tape.Allow it to set and dry before plastering.

Joint areas prepared in this manner should be surface dampened with a light application of water by brush, felt

or sprayer just prior to the plaster application to ensure proper absorption. Failure to do this can cause excessive

initial absorption, while completely wet joints will not allow required absorption.

Page 2 of 6

Page 3

Mixing Mix plaster with a cage-type paddle driven by a heavy-duty drill capable of producing 900-1000 rpm under no

load. The correct approximate water-plaster ratio for I

MPERIAL

Brand Finish (hand application) is 11 to 13 qt./80 lb.

bag (10.5-12.0 L/36.3 kg. bag).Water usage for D

IAMOND Brand Finish Plaster is approximately 12 to 15 qt. per

50-lb. bag.

Place the water in a 12- to 15-gal. smooth-sided container. Start the mixer, slowly add plaster and mix at least 2

minutes to disperse lumps completely.Do not mix more than 5 minutes. Overmixing shortens working time. Do not

mix more than can be applied in 30 minutes. Do not retemper.

For sand float finish with I

MPERIAL Brand Finish Plaster,add up to 20 lb. (9 kg) of clean silica sand per 80-lb. bag to

achieve the desired texture. Using more than 20 lb. of sand per bag will diminish the plaster’s strength to less than

the optimum 3,000 psi. For an eye-catching texture, apply plaster in the normal manner but omit final troweling.

After surface has become firm, float to desired texture using a sponge, piece of carpet or other float.Use water

sparingly.

Note: If you add aggregate to D

IAMOND Brand Interior Finish Plaster,you must add a suitable retarder to allow time

for proper application before the plaster sets. Add 1/4 to 1/2 teaspoon of USG™ Retarder for Lime Containing

Plasters per bag of aggregated D

IAMOND Brand Interior Finish Plaster to the mixing water to allow sufficient working

time. You can also use Cream of Tartar as an alternative retarder.

Plastering I

MPERIAL and D

IAMOND Brand Finish Plasters provide a wide range of finish options with distinct application systems:

1. One Coat, basecoat plaster is not used

2. Two Coat, finish coat over a base coat

3. Two Coat: D

IAMOND Brand basecoat and IMPERIAL Brand finish coat over DUROCK Brand Cement Board or FIBEROCK

Brand Abuse-Resistant Panels treated with a bonding agent

4. Two Coat: I

MPERIAL Brand Finish Plaster—finish coat over sanded STRUCTO-BASE High-Strength Basecoat Plaster

One Coat System Scratch-in a tight, thin coat of Finish Plaster over the entire area, immediately doubling back with plaster from

same batch to full thickness of 1/16 to 3/32. Fill all voids and imperfections. Final-trowel after surface has

become firm, holding the trowel flat and using water sparingly. Do not over-trowel.

For texture finished surfaces, with or without the addition of job-added sand, omit final troweling.The surface is

textured naturally as the material firms and water is removed into the base.

You will obtain the best results by planning plastering to permit continuous application from angle to angle.Where

joining is unavoidable, use the trowel to terminate unset plaster in sharp clean edge—do not feather out. Bring

adjacent plaster up to terminated edge and leave level. Do not overlap. During finish troweling,use excess material

to fill and bridge joining.

Two Coat System IMPERIAL

Brand Basecoat Plaster or DIAMOND Brand Veneer Basecoat applied to IMPERIAL Brand Gypsum Base, or

concrete block or monolithic concrete treated with USG Plaster Bonder.Leave the surface of the base coat rough

and open for the proper bond of finish coat. Allow the basecoat to set to provide proper suction for the finish coat.

Apply a finish coat of I

MPERIAL Brand Finish as indicated above.

Veneer Plaster Over Veneer Plasters provide increased resistance to abrasion, indentation and penetration when used over FIBEROCK

®

FIBEROCK®Brand Abuse-

Brand Abuse-Resistant Panels in commercial and institutional applications such as schools and retail locations.

Resistant Panels

In this two-coat veneer plaster system, DIAMOND Brand Veneer Basecoat Plaster and then IMPERIAL Brand Finish

Plaster are applied over F

IBEROCK Brand Abuse-Resistant Panels attached to framing.

Page 3 of 6

Page 4

Treat joints of the fiber board panels using S

HEETROCK Brand Joint Tape and a S

HEETROCK Brand Setting-Type Joint

Compound (D

URABOND or EASY SAND). Provide an additional coat of setting-type compound to fully conceal the tape.

Allow to completely dry.When the joints are completely dry,treat the entire wall surface with USG Plaster Bonder

according to the application directions. Then apply D

IAMOND Brand Veneer Basecoat Plaster 1/16 to 3/32 thick

using scratch and double-back technique. This is accomplished by applying a tight,thin coat over the entire area,

and immediately doubling back with plaster from the same batch to achieve full thickness. When basecoat plaster

is firm, broom the surface to leave it rough and open for finish.With basecoat set and partially dry,apply I

MPERIAL

Brand Finish Plaster,using a scratch and double-back technique. Complete finishing when material is firm.Leave

finished surface smooth and dense for decorating.

Note that this two-coat technique also works for application over 5/8 F

IBEROCK Brand Abuse Resistant Panels,

5/8 I

MPERIAL Brand Gypsum Base, FIRECODE Core, or 1/2 IMPERIAL Brand Gypsum Base, FIRECODE C Core, in any fire-

rated design, as long as 20-gauge steel framing is used and the proper joint treatment procedure is followed.

Veneer Plaster Prior to application of Finish Plaster, the D

UROCK Brand Cement Board must be treated with USG Plaster Bonder

Over D

UROCK

®

Brand

and the joints treated with S

HEETROCK

®

Brand Joint Tape and S

HEETROCK

®

Brand Setting-Type Joint Compound

Cement Board

(DURABOND or EASY SAND). Then apply DIAMOND Brand Veneer Basecoat Plaster as a basecoat. With the basecoat

set and partially dry, apply I

MPERIAL Brand finish plaster using a scratch and double-back technique. Complete the

finishing when the material is firm. Leave the finished surface smooth and dense for decorating. Note that only

two-coat veneer plaster system may be used over D

UROCK Brand Cement Board.

Veneer Plaster over sanded S

TRUCTO-BASE High-Strength Basecoat Plaster—You can achieve extraordinary levels

of indentation and impact resistance, as well as superior abrasion resistance with I

MPERIAL Brand Finish Plaster

used as the finish coat in this system. Apply a base coat of D

IAMOND Brand Finish Plaster.Allow the base coat to set

and leave it rough to provide proper suction for the finish coat. Apply a finish coat of IMPERIAL Brand Finish Plaster as

indicated above.

Finish Plaster When applying finish plaster to IMPERIAL Brand Gypsum Base, the paper on the gypsum base should be blue.

to Degraded

Sometimes plastering on a jobsite can’t be done until long after the gypsum base has been installed and there

IMPERIAL Brand

has been lengthy exposure to ultraviolet radiation from sunlight. When gypsum base has become degraded due

Gypsum Base

to exposure to sunlight, the face paper turns from blue or grayish blue to gray or tan.When the face paper color

becomes gray to tan, it must be treated with USG

™

Accelerator—Alum Catalyst.

For Alum Catalyst treatment, dissolve three lbs.of alum in one gallon of water. Pour the alum slowly into water and

mix thoroughly.Allow the solution to stand until any undissolved materials have settled; then strain the solution into

a tank-type sprayer (such as a lawn and garden sprayer). One gallon of solution should treat 750 sq. ft.of gypsum

base. Begin applying finish plaster before the alum solution is completely dry.

Note: Alum treatment reduces the

setting time of Diamond Brand Interior Finish Plaster.

Note: If USG Accelerator—Alum Catalyst is not available, an

alternative solution is to apply USG

™

Plaster Bonder over the faded Imperial Brand Gypsum Base. Note: Using USG

Plaster Bonder to correct degraded gypsum base will require you to use a two-coat veneer plaster system, since

the bonder application will eliminate base suction needed for proper one-coat veneer application.

Page 4 of 6

Page 5

Finish Plaster as a Apply D

IAMOND or IMPERIAL Brand Interior Finish Plaster only to interior,structurally sound, clean, smooth monolithic

Base Or Finish Coat Over

surfaces that have been treated with a high-quality bonding agent, such as USG™Plaster Bonder.Grind ridges and

Monolithic Concrete

high points flush, and brush the concrete surface clean of loose particles. Slight irregularities (less than 1/8) will

not interfere with smooth application. Treat voids and depressions with bonding agent and fill them with I

MPERIAL

Brand Basecoat Plaster, D

IAMOND Brand Veneer Basecoat Plaster, or with D

IAMOND Brand Interior Finish Plaster job-

aggregated with one-half to one full part sharp, clean, fine silica sand. After application, leave these areas rough

and open, and allow them to set.The pre-fill should not be more than 1/4 thick. If pre-filled areas are allowed to

dry overnight, recoat these areas with USG Plaster Bonder prior to application of the plaster product. If pre-filled

areas are still “green’’ (set, but not dry), there is no need to recoat the surface with the bonding agent.

Job-aggregate the finish coat of finish plaster with one-half to one full part sharp, clean, fine silica sand.Although

this material may be applied unaggregated, the sand promotes good mechanical bond between the finish coat

and the bonder/concrete substrate. The sand-aggregated finish also builds up material over slight irregularities,

producing an acceptable monolithic finished surface without detracting from smooth finishing. In addition, the

aggregated finish provides options for sand float or other sand textured surfaces. Note: Delay smooth troweling

or texturing until finish plaster surface has become firm and stiff enough for texturing.

D

IAMOND Brand Finish

When applying finish to I

MPERIAL Brand Gypsum Base, first apply a fill coat of job-sanded DIAMOND Brand Interior

Plaster to Radiant Heat

Finish Plaster (1/2 to 1 parts by weight sand per bag) parallel to the direction of the cable and of sufficient thick

Ceilings, Gypsum Base

ness to completely cover the cable. Do not use the cable as a screed. Level the fill coat with a trowel,rod or darby

Radiant Heat Ceiling

to fill any low spots or to remove any high ridges, etc.“Tooth” fill coat to provide a key for the finish coat by the use

of a serrated darby or by lightly brooming prior to set. The average thickness of the fill coat should be 3/16.

Do not apply finish coat until after the fill coat has developed sufficient suction. In good drying weather this takes

about two hours after the fill coat has set; in damp and/or cold weather the time interval might extend overnight.

Thus proper heat and ventilation should be provided. Apply job-sanded D

IAMOND Brand Interior Finish Plaster

(1/4 to 1 parts by weight sand) to a finish thickness between 1/16 minimum and 3/32 maximum. Scratch in a

tight, thin coat over the entire area, immediately doubling back to the full thickness.Fill all imperfections.

Scratch and double back with the same mix of D

IAMOND Brand Interior Finish Plaster.When the surface has become

firm, hold the trowel flat and final trowel using water sparingly. Best results are obtained by continuous application

of an entire ceiling. The total thickness of fill and finish coats should be 1/4.Always work to a wet edge to avoid

dry joinings.

Radiant Heat Ceilings Use USG

™

Plaster Bonder on concrete in accordance with the manufacturer’s directions,prior to the application

Over Monolithic Concrete

of DIAMOND Brand Interior Finish Plaster.The concrete surface must be clean, free of dirt, dust, grease,wax, oil or

other unsound conditions and level.

Coat all metal components in the concrete surface to prevent rusting in the plaster.Remove form ridges. Locate

uneven ceiling areas that may require filling prior to installation of electric cable and plastering. Treat these areas

with USG Plaster Bonder. Then apply D

IAMOND Brand Interior Finish Plaster (fill-coat mix) as a leveling coat and

allow it to set.

Caution: Temperature of concrete ceiling with bonding agent and cable must be above 32 °F

before plastering is started. Air temperature must be above 55 °F.

Apply job-sanded D

IAMOND Brand Interior Finish Plaster to a thickness of 3/8 in two coats to provide a level sur-

face. First apply a fill coat of finish (sanded 1/2 to 1 parts by weight sand per bag of product) parallel to the direction of the cable averaging 5/16 thick and of sufficient thickness to cover the cable and anchor device. Do not use

cables as a screed. Level the fill coat with a trowel, rod or darby to fill any low spots or to remove any high ridges,

etc. The surface should be made rough to provide mechanical key or “tooth” for the finish coat by the use of serrated darby or by lightly brooming prior to set.

Page 5 of 6

Page 6

SAFETY FIRST!

Follow good safety practices.

Read material safety data

sheets and related literature on

products before specification

and/or installation.

Do not apply the finish coat until after the fill coat has developed sufficient suction. In good drying weather this

takes about two hours after the fill coat has set; in damp and/or cold weather the time interval might extend

overnight. Thus proper heat and ventilation should be provided.Apply a finish coat of job-sanded D

IAMOND Brand

Interior Finish Plaster to provide a total thickness of 3/8.

Apply job-sanded D

IAMOND Brand Interior Finish Plaster (no less than 1/4 to 1 parts by weight sand per bag of prod-

uct) to a finish thickness between 1/16 minimum and 3/32 maximum. Scratch in a tight thin coat over the entire

area, immediately doubling back to the full thickness. Fill all voids and imperfections.Scratch and double back with

the same mix of D

IAMOND Brand Interior Finish Plaster.When the surface has become firm, hold the trowel flat and

final trowel using water sparingly.Do not over-trowel. Best results are obtained by continuous application over the

entire ceiling. Always work to a wet edge to avoid dry joinings.

Cleanup Clean mixing containers and tools with water immediately after use. Tightly close partially used containers. When

machines are shut down, they should be hosed off and thoroughly cleaned—made ready for a fresh start. Remove

all scaffolding, empty containers and excess materials from the job site. Sweep the floors and be sure to leave the

building and site in good condition for decoration and finishing.

Trademarks

The following trademarks used

herein are owned by United

States Gypsum or a related

company: D

IAMOND,DURABOND,

E

ASY SAND,FIBEROCK,IMPERIAL,

S

HEETROCK and USG.

Note

Products described here

may not be available in all geographic markets. Consult your

U.S. Gypsum Company sales

office or representative for

information.

Notice

We shall not be liable for incidental or consequential damages, directly or indirectly sustained, nor for any loss caused

by application of these goods

not in accordance with current

printed instructions or for other

than their intended use. Our liability is expressly limited to

replacement of defective goods.

Any claim shall be deemed

waived unless made in writing

to us within thirty (30) days from

the date it was or reasonably

should have been discovered.

Manufactured by

United States Gypsum Company

125 South Franklin Street

Chicago, IL 60606

800 USG.4YOU (874-4968)

www.usg.com

P838/2-04

©2004, United States Gypsum Company

Printed in U.S.A.

Page 6 of 6

Loading...

Loading...