Page 1

®

Fiberock

Underlayment and

Tile Backerboard

Installation

Guide

Interior Floors, Walls and

Countertops.

Page 2

Fiberock® Underlayment and

Tile Backerboard

Fiberock® underlayment and tile backerboard are

all purpose substrates engineered to meet floor

underlayment and wall tile-backing needs

throughout a home. Under resilient flooring,

Fiberock underlayment provides a hard surface

that’s smooth and flat with no bumps or ridges to

show through or affect finished floor covering.

Behind and under tile or natural stone, Fiberock

tile backerboard provides the resistance to water

and mold that is required in bathrooms, kitchens

and entryways. With Fiberock panels, you can rely

on a single family of products to back all types of

tile and resilient flooring in the home.

Integral Water Resistance

This remarkable family of

products is completely different

from other substrates.

Manufactured with a unique,

proprietary technology,

panels feature a durable, waterresistant composition that

eliminates the swelling and

warping often experienced

with fiber cement, plywood,

oriented strand board (OSB),

lauan and other wood-based

underlayments.

Easy to Install

Fiberock panels score easily

and snap with minimal effort.

In fact, the International Certified

Floorcovering Installer Association

awarded

Fiberock underlayment

the “Installer Friendly Seal.”

Fiberock

Proven Performance

Fiberock panels are warranted

for 20 years. They have been

tested by the Tile Council of

North America (TCNA), using the

Robinson Floor Method, and are

approved for residential and light

commercial use (as defined by

TCNA).

Environmentally Friendly

Fiberock panels are made from

95 percent recycled material.

In recognition of the

environmentally sound alternative

these panels provide, United

States Gypsum Company earned

the Green Cross certificate from

Scientific Certification Systems,

a leading testing company that

evaluates environmental claims.

2

Page 3

Introduction

Installing Fiberock panels is quick

and easy. Just follow the simple

installation steps in this booklet

to create a perfect base for tile or

floor coverings.

Note: Do not use Fiberock panels

over concrete subfloors or over

cushion-backed vinyl.

Tools

Common tools like those shown

below are typically all that are

needed to install

Fiberock panels,

though additional, specialized

tools may be required with some

finish materials, such as tile and

natural stone.

Materials

Fiberock Panels

– Sizes and Packaging

Size

(thick x width x length) Units (pcs.)

1/4" x 4' x 4' 60

1/4" x 3' x 5' 60

3/8"

x 4' x 4' 60

3/8"

x 4' x 8' 40

3/8"

x 3' x 5' 60

1/2" x 3' x 5' 50

1/2" x 4' x 8' 30

5/8"

x 3' x 5' 40

5/8" x 4' x 8' 24

– Joint Reinforcement

Behind ceramic tile, use

Durock™ tile backer tape and

latex-based Type I mastic or

latex-modified thin-set mortar.

For sections that will be

painted, use paper tape and

setting-type joint compound.

–

Fasteners

Wall Application: For steel

stud applications (20 ga. or

equivalent), use 1-1/4" or

1-5/8"

Durock™ screws for

steel framing (or equivalent).

For wood stud applications,

use 1/4", 1-5/8" or 2-1/4"

Durock screws for wood

framing (or equivalent) or

1-1/2" hot-dipped galvanized

ring shank roofing nails.

Floor Application: Use 1-1/4"

Durock™ tile backer screws for

wood framing (or equivalent)

or 1-1/2" hot-dipped

galvanized ring shank roofing

nails. For resilient flooring, use

minimum 1/4" crown chisel

point staples, hot-dipped

galvanized ring shank nails or

corrosion-resistant screws.

Fastener length should

be approximately equal

to combined thickness of

underlayment and subfloor.

Fasteners should not

penetrate through subfloor.

–

Floor and Wall Framing

Floor Tile Applications:

Maximum joist spacing

24" o.c. The subfloor system

should be designed with a

minimum deflection limit

of L/360 for the span. Some

finish materials may require a

more rigid subassembly

(such as large format tile

and natural stone products

L/720). In these cases, follow

the manufacturer’s minimum

requirements. The subfloor

should be APA Span-Rated

Plywood or OSB with an

Exposure 1 classification

or better with tongue and

groove or back blocked at

the unsupported edges.

3

Page 4

Handling

Wall Applications: Maximum

stud spacing: 16" o.c.

Framing shall be designed

(based on stud properties

alone) not to exceed L/360

deflection for tile, L/240 for

surfaces that will be painted.

Maximum fastener spacing:

8" o.c. for wood and steel

framing; 6" o.c. for ceiling

applications.

–

Patching Compound

Use a high-quality patching

compound such as D

urock

Floor Patch or equivalent

approved by the resilient-

flooring manufacturer.

–

Adhesive/Mortar

Meeting ANSI A136.1: Type I

ceramic tile adhesive.

Meeting ANSI A118.1: dry-set

mortar.

Meeting ANSI A118.4: latex

portland cement mortar.

–

Grout meeting ANSI A118.7.

–

Ceramic tile meeting ANSI

A137.1.

–

Waterproof Membrane

If waterproofing is desired,

use

Durock™ tile membrane

installed with

Durock™ tile

membrane adhesive. See USG

literature piece CB492 for

Durock tile membrane product

information.

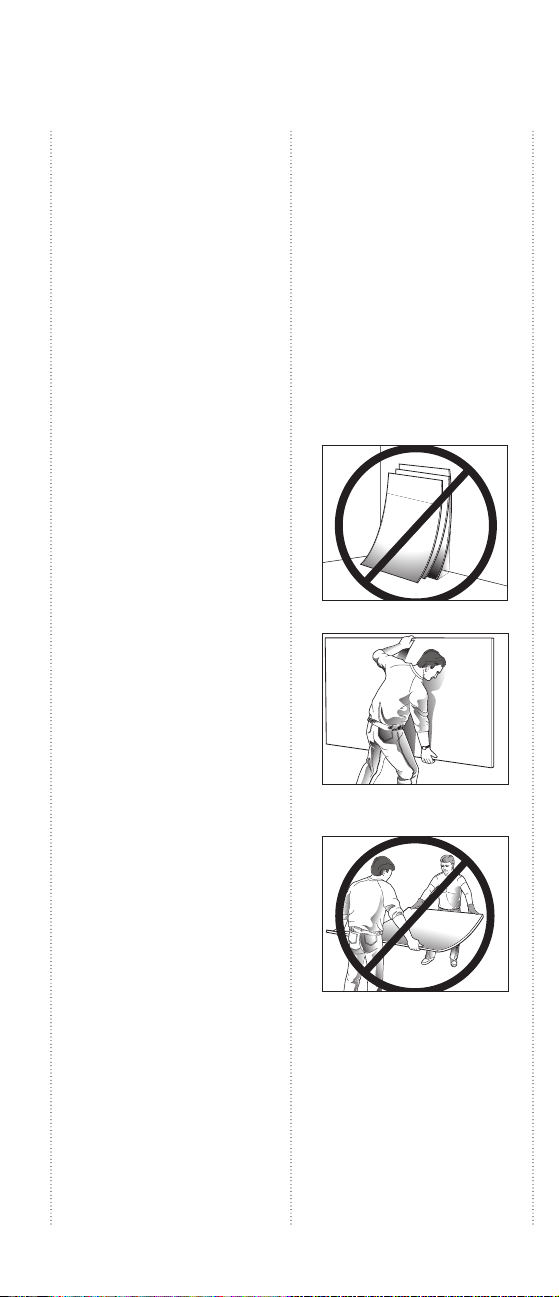

– Protect panels from the

elements with adequate

covering during delivery and

storage.

– Store panels flat on an even,

dry surface. Allow panels to

acclimate to temperature and

humidity at job site prior to

installation.

– Handle panels in an upright

position to prevent breakage.

Incorrect

Correct

Incorrect

4

Page 5

Preparation

sand uneven

joints

fill and

sand gaps

flush with or slightly

below surface

Crawl-Space Requirements

Crawl-space requirements may

vary based on geographic location.

Consult local building codes for

more specific information regarding

vapor barriers and their uses.

Subfloor Requirements

The subfloor system should

be designed for a deflection

limit of L/360 for the span. The

subfloor should be APA SpanRated Plywood or OSB with

an Exposure 1 classification

or better with tongue and

groove or back-blocked at the

unsupported edges.

Resilient Flooring

Joist Minimum

Spacing Subfloor

Thickness

16", 19.2" 23/32"

and 24" o.c.

Ceramic Tile

Joist Minimum

Spacing Subfloor

Thickness

16" o.c. 19/32"

19.2" o.c. 23/32"

24" o.c. 23/32"

Wood Subfloor

Ensure that subfloor and

structure are within tolerances

specified by floor covering

manufacturer. Inspect subfloor

for even, flat surface before

installing underlayment.

Uneven end edge joints and

variations in subfloor panel

thickness may telegraph

through underlayment in vinyl

applications. Sand uneven

joints, if necessary.

Ensure that subfloor is

flat between framing elements.

If subfloor panels appear to

buckle, correct by adding

blocking or cleats under floor.

Fasten cleats to subfloor to

flatten panels. Repair voids, large

gaps and penetrations through

subfloor using a manufacturerapproved floor leveler prior to

installing

Over Existing Vinyl Floor

Fiberock underlayment.

CAUTION: Do not install Fiberock

underlayment over heavily

cushioned, thick foam-backed

floor coverings.

– Ensure that existing floor is

level and meets appropriate

design requirements.

– Repair any missing or broken

vinyl tiles, curling seams,

severe gouges, or protrusions

by filling with floor leveler.

Clean subfloor and leave free

of dust, dirt and debris. Ensure

that subfloor is completely dry

(no more than 12% moisture

in subfloor prior to installation).

Verify that fasteners are flush

with, or slightly below, subfloor

surface.

If floor will be finished with

ceramic tile, make sure that the

existing vinyl covering is fully

adhered and bonded to the floor.

5

Page 6

Cutting and

16" 16"

1/4" gap

cut

edge

factory edges

underlayment

subfloor

Laying Out Panels

Cutting Panels

Maintain temperature and

humidity in space approximate to

that of normal occupancy prior to,

during and after installation.

Install underlayment, with

fastener marks up. Panels may

be cut by scoring and snapping

with a utility knife and straight

edge, or by sawing, working from

the face side. With score-andsnap method, score panel twice

and snap away from cut face,

then snap panel in reverse

direction to break the back.

Where necessary, use a rasp or

surform to smooth the cut edges.

Cutouts

For difficult cuts, combine the

score-and-snap method with use

of a handsaw or low-RPM power

saw. Cut holes for plumbing

with a hole saw, keyhole saw or

variable-speed jigsaw. A power

saw should be used only if

equipped with a dust-collection

device. Always wear an OSHAapproved dust mask when

cutting

Fiberock panels with a

power saw.

For more cutting techniques,

consult your USG

Fiberock

representative.

Panel Layout

Lay cut edges against the wall—

only factory edges should be

joined. Begin laying panels

at one corner. Maintain 1/4"

space between panels and

perimeter walls. Stagger joints

a minimum of 16" so that four

panel corners never meet, and

offset end and edge joints of

panels a minimum of 12"–16"

from subfloor panel joints. Butt

panel edges and ends lightly

together. A maximum 1/32"

gap is allowed.

Preparation for resilient

flooring: Consider critical lighting

when determining panel layout.

Run continuous panel joints in

the direction of the dominant

source of natural light, when

possible.

Prior to installation of final

floor covering, avoid heavy traffic

and moving heavy items across

panels. If necessary, items

such as refrigerators or other

appliances with wheels (or on

wheeled dollies) may be rolled

over underlayment surface; using

strips of hard wood or scrap

underlayment to bear the wheel

traffic is recommended. Allow

a minimum of 24 hours after

floor covering installation before

placing heavy appliances or

furniture on floor.

6

Page 7

Floor Application

Ceramic Tile

Underlayment or Tile Backerboard

Panel Application

Apply Type 1 organic adhesive

with 5/32" v-notched trowel,

latex-fortified mortar with

1/4" square-notched trowel.

Comb out adhesive or mortar in

straight, parallel rows (as shown

below) and immediately cover

with panel. Adhere panels to

subfloor, one panel at a time.

Fastening

Fasten to subfloor with 1-1/4"

D

urock tile backer screws for

wood framing (or equivalent) or

1-1/2" hot-dipped galvanized

ring shank roofing nails spaced

8" o.c. in both directions with

perimeter fasteners at least 3/8"

and less than 5/8" from ends and

edges. Drive nails and screws so

that bottoms of heads are flush

with panel surface to ensure firm

panel contact with subfloor. Do

not overdrive fasteners.

Finishing Joints

Fill joints with latex-fortified

mortar or Type 1 organic

adhesive and immediately

embed D

urock tilebacker tape

or equivalent alkali-resistant,

fiberglass mesh joint tape.

Ceramic Tile Installation

Sweep all debris from

underlayment, and vacuum

carefully to eliminate dust

and dirt.

To set tile, apply latex-fortified

mortar or Type 1 organic

adhesive with a notched trowel.

Key in mortar or adhesive with flat

side of trowel to prime F

iberock

surface, then comb out adhesive

or mortar in straight parallel rows.

When combing out adhesive or

mortar, hold trowel at an angle to

maintain uniform thickness.

7

Page 8

Floor Application

Working a small area at a

time, set tile with a slight

twisting motion and press into

place. Avoid adhesive buildup

on tile edge and in grout space.

Keep tiles aligned so joints are

straight and uniform. Use tile

spacers if desired.

Note: Refer to ANSI A108.4

or A108.5 for complete tile

installation instructions. Refer

to setting material manufacturer

for specific information related

to trowel type and size, proper

tile type and size, mixing

instructions, and set and cure

times.

Resilient Flooring

Underlayment

Selecting Fasteners

Fasten Fiberock underlayment to

subfloor with 1/4" crown chisel

point staples. Do not use screws

or nails.

Fastener length should be

approximately equal to combined

thickness of underlayment and

subfloor. Do not allow fasteners

to penetrate through subfloor.

Fastening Panels

Lay panels flat and press tightly

onto subfloor while fastening.

Begin fastening where three

panels intersect. Affix staples

along joints in a zipper

pattern at 1" o.c., 1/4" from

panel edge. Install staples at 4"

o.c. in the field of panels.

1/4”

Consult your USG

Fiberock

representative for additional

fastening techniques.

When using pneumatic tools,

apply sufficient pressure on gun

to prevent the tool from bouncing.

Set pneumatic tool pressure to

drive fasteners flush or slightly

below underlayment surface.

To prevent fastener heads from

telegraphing through resilient floor

covering, do not countersink more

than 1/16" below surface.

Fasten one panel at a time.

Begin at one end and fan out

across the floor.

Installing Fiberock Panels over

Existing Vinyl Floor Coverings

Do not install underlayment over

heavily cushioned, thick foambacked vinyl. Ensure that existing

floor is level, is fully adhered and

well bonded, and meets

appropriate design requirements.

Repair missing or broken tiles,

curling seams, severe gouges,

protrusions of surface and any

other damage with a high-quality

floor leveler. Follow floorcovering manufacturer's

recommendations for

installations over existing floors.

8

Page 9

Correcting Joint Imperfections

Use Durock patching compound

or equivalent sparingly to fill wide

joints, repair any surface voids

and correct joint lippage (panel

edge sitting above or below

the floor plane). Carefully fill

joints wider than 1/32" and any

surface imperfections with only

enough material to infill void – do

not feather. Correct joint lippage

by applying patching compound

to low side only and feathering

to level. Allow compound to dry

completely (90 min. minimum),

then lightly sand or scrape, taking

care not to scuff panel surface;

use a flat blade to scrape away

any excess material.

Remove all debris from panel

surfaces; vacuum carefully to

eliminate excess dust and dirt.

Applying Floor Covering

Refer to floor-covering

manufacturer's

recommendations for proper

procedures. For proper trowel

selection, refer to adhesive

manufacturer's recommendation

for nonporous substrates. Follow

floor-covering and/or adhesive

manufacturer's guidelines for

setting times before allowing

traffic on the finished floor. Follow

floor-covering manufacturer's

recommendations for preventive

maintenance, cautions and

procedures.

Perimeter-Bonded, Felt-Backed

Resilient Floor Covering

Joint patching is not required

with this type of floor covering

in new construction unless

joint spaces or lippage exceed

1/32". Carefully fill joints wider

than 1/32" with only enough

material to infill void – do not

feather. Correct joint lippage by

applying patching compound

to low side only and feathering

to level. Allow compound to dry

completely (90 min. minimum),

then lightly sand or scrape,

taking care not to scuff panel

surface. Remove dust, dirt

and debris from underlayment

surface before application of

floor covering.

Wood Flooring

Underlayment

Mechanically Fastened

Wood Flooring

Fasteners must be long enough

to penetrate through

underlayment and into subfloor.

To determine proper fastener

length, add thickness of

underlayment to length of

fastener recommended by the

flooring manufacturer. Follow

recommendations on pages

6 and 8 for underlayment

installation.

9

Fiberock

Page 10

Wall and Ceiling

Application

Glued-Down Wood Flooring

Installation of engineered or

solid hardwood glued-down

flooring must strictly follow

manufacturer's instructions.

Follow recommendations above

for underlayment installation.

Ceramic Tile

Tile Backerboard

Framing Requirements

Steel or wood wall framing

shall be structurally sound and

in compliance with local building

code requirements. Damaged

and excessively bowed studs

shall be replaced before installation

of tile backerboard panels.

Space wood or steel framing

24" o.c., maximum. Framing

shall be designed to meet L/360

deflection for tile and L/240

deflection for flexible finishes

such as paint.

Fastening

Space fasteners 8" o.c. for walls,

6" o.c. for ceilings. Fit ends and

edges of panels closely, but not

forced together.

– Wood framing: 1-1/2"

hot-dipped galvanized ring

shank roofing nails or

1-1/4" D

wood framing or

equivalent.

– Steel framing: 1-1/4"

– Joining: Fill joints with

urock screws for

D

urock screws for steel

framing or equivalent.

latex-fortified mortar or

Type 1 organic adhesive

and immediately embed

D

urock tape or equivalent

alkali-resistant, fiberglass

mesh joint tape.

Shim

Place a 1/4" spacer strip or shim

around lip of bathtub or shower

pan to hold bottom edge of panel

off the fixture.

Joint Finishing

In areas that will be tiled, finish

joints with D

urock tile backer

tape and latex-fortified mortar

or Type I mastic. In areas that

will be painted: For taping, use

S

with S

heetrock

heetrock

®

brand joint tape

®

DurabonD®

setting-type joint compound.

For finishing, use

all purpose joint compound.

Do not use P

all purpose or M

compounds on F

Planning Your Tile Installation

sheetrock®

®

lus 3

lightweight

iDweight

iberock panels.

™

joint

Where tile will not cover entire

wall surface, such as above

the tub and shower surrounds,

determine where you want the

tile to end and draw a level line at

this height. Be sure to allow for

height of tile cap, if applicable.

10

Page 11

Countertop Application

Determine whether floor is level

by measuring distance

to desired tile height on both

sides of area to be tiled. If there

is a difference (i.e., the floor

is lower on one side), lay one

vertical row of tile from desired

tile height to low point of floor.

Affix tiles with tile-setting

materials. Use this first row as

a guide to keep tiles and grout

lines level and even throughout

installation.

If new flooring will be installed,

allow for thickness of new

flooring where the wall meets

the floor.

Installing Ceramic Tile

Always follow current ANSI

specifications and TCNA

guidelines for installing tile.

Apply tile-setting material to

tile backerboard with notched

trowel; key in mortar or adhesive

with smooth side of trowel to

prime F

iberock surface first,

then comb out mortar or

adhesive in straight parallel

rows, hold trowel at min. 45º

angle to maintain uniform

thickness.

Working a small area at a time,

set tile with a slight twisting

motion and press into place. Keep

tiles aligned so joints are straight

and uniform. Use tile spacers if

desired. If excess adhesive

squeezes from under tile, remove

before it dries.

Cover plywood base with D

tile membrane, 15 lb. felt or 4 mil

polyethylene and attach with 1/4"

galvanized staple.

Position

Fit ends and edges of panels closely,

but not forced together. Stagger

panel joints from plywood base

joints.

Fasten

Space fasteners 8" o.c. around the

perimeter and in the field of the

board.

Joining

Fill joints with latex-fortified mortar

or Type 1 organic adhesive and

immediately embed alkali-resistant,

fiberglass mesh joint tape.

Finish

Install tile.

Note:

Because cement board fasteners may

protrude through the plywood base when

1/4" cement board is used, 1/2" or 5/8"

cement board is preferred in this

application.

11

urock

Page 12

Trademarks

The following trademarks used herein

are owned by United States Gypsum

Company or a related company:

DurabonD, Durock, Fiberock,

MiDweight, Plus 3, sheetrock,

USG, USG in stylized letters.

Note

Products described here may not be

available in all geographic markets.

Consult your United States Gypsum

Company sales office or representative

for information.

Notice

We shall not be liable for incidental

and consequential damages, directly

or indirectly sustained, nor for any

loss caused by application of these

goods not in accordance with current

printed instructions or for other

than the intended use. Our liability

is expressly limited to replacement

of defective goods. Any claim shall be

deemed waived unless made in writing

to us within thirty (30) days from date

it was or reasonably should have been

discovered.

Product Information

See usg.com for the most

up-to-date product information.

Safety First!

Follow good safety and industrial hygiene

practices during handling and installation

of all products and systems. Take

necessary precautions and wear the

appropriate personal protective equipment

as needed. Read material safety data

sheets and related literature on products

before specification and/or installation.

For warranty or product information

and literature:

800 USG.4YOU (874-4968)

usg.com

Manufactured by

United States Gypsum Company

550 West Adams Street

Chicago, IL 60661

F119/rev. 1-12

© 2012 United States Gypsum Company

Printed in U.S.A.

Loading...

Loading...