Page 1

Installation

w

1

s

Guide

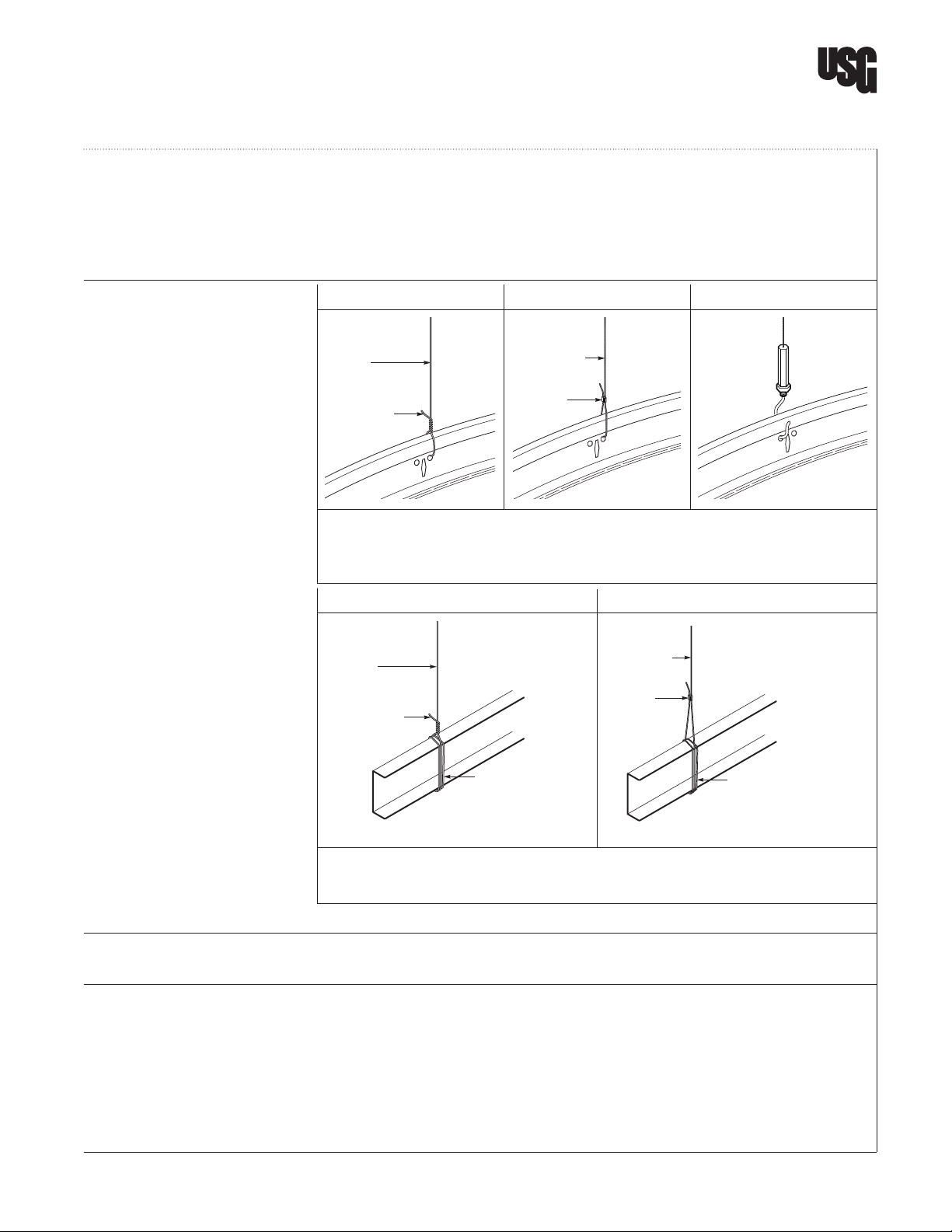

Exposed Hanger

Solutions

Page 1 of 4

For Decorative Ceiling Elements

Hanger

with Twisted-Tie Connection with Loop and Crimp-End Connection with Turnbuckle

Options

Steel wire mesh, or

with Wire Crimp

18-Gauge Stainless Steel Wire 1/32 Stainless Steel Rope Wire 1/32 Stainless Steel Rope Wire

1

18 ga. stainless

steel wire

wrap wire six

times within

1

/2"

/32" stainless

steel cable

wire crimp

Applications: Suitable for use with C2 paired Compässo™ channels, and Curvatura™ and topo™ systems.

Curvatura systems must use infill panels made of solid or perforated aluminum, Diamondflex, Brass or Stainless

transluCents™ Lexan™ or FRP.

18-Gauge Stainless Steel Wire 1/32 Stainless Steel Rope Wire

18 ga. stainless

steel wire

wrap wire six

times within

1

/2"

three loops

around channel

/32" stainless

teel rope wire

ire crimp

Applications: Suitable for use with libretto™ gridless metal ceiling system.

three loops

around channel

ASTM – 18-gauge stainless steel meets ASTM Designation A580: Standard Specification for Stainless Steel Wire.

Designations – 1/32 rope wire meets ASTM Designation A492: Standard Specification for Stainless Steel Rope Wire.

Features and – Provides an attractive alternative to standard 12-gauge wires

Benefits – Less visible for more finished, discreet appearance

– Installs quickly and easily

– Meets or exceeds manufacturer’s recommendations; see load matrix on next page

Page 2

Page 2 of 4

Connection Spacing and

Termination Method

4 3 2

Brass and Stainless Steel wire mesh 0.6 7.5 10 15

Trim (lbs./lin. ft.) 4 3 2

C

Notes:

– Quality of wire connection can very widely depending on field conditions, equipment and user experience.

– 30 lbs. per 18-gauge wire and 1/32 stainless steel rope wire is the maximum recommended load including

any additional or live load during installation.

– Suitability of decorative ceiling hanger devices must be determined by user. These are not to be used where

Installation

Curvatura System Aluminum (solid and perforated) 0.5 7.5 10 15

Libretto Gridless Metal Solid and perforated 0.6 7.5 10 —

Ceiling System

topo System topo infill 0.5 7.5 10 15

2

Paired Compässo Channels 8 3.5 7.5 10 15

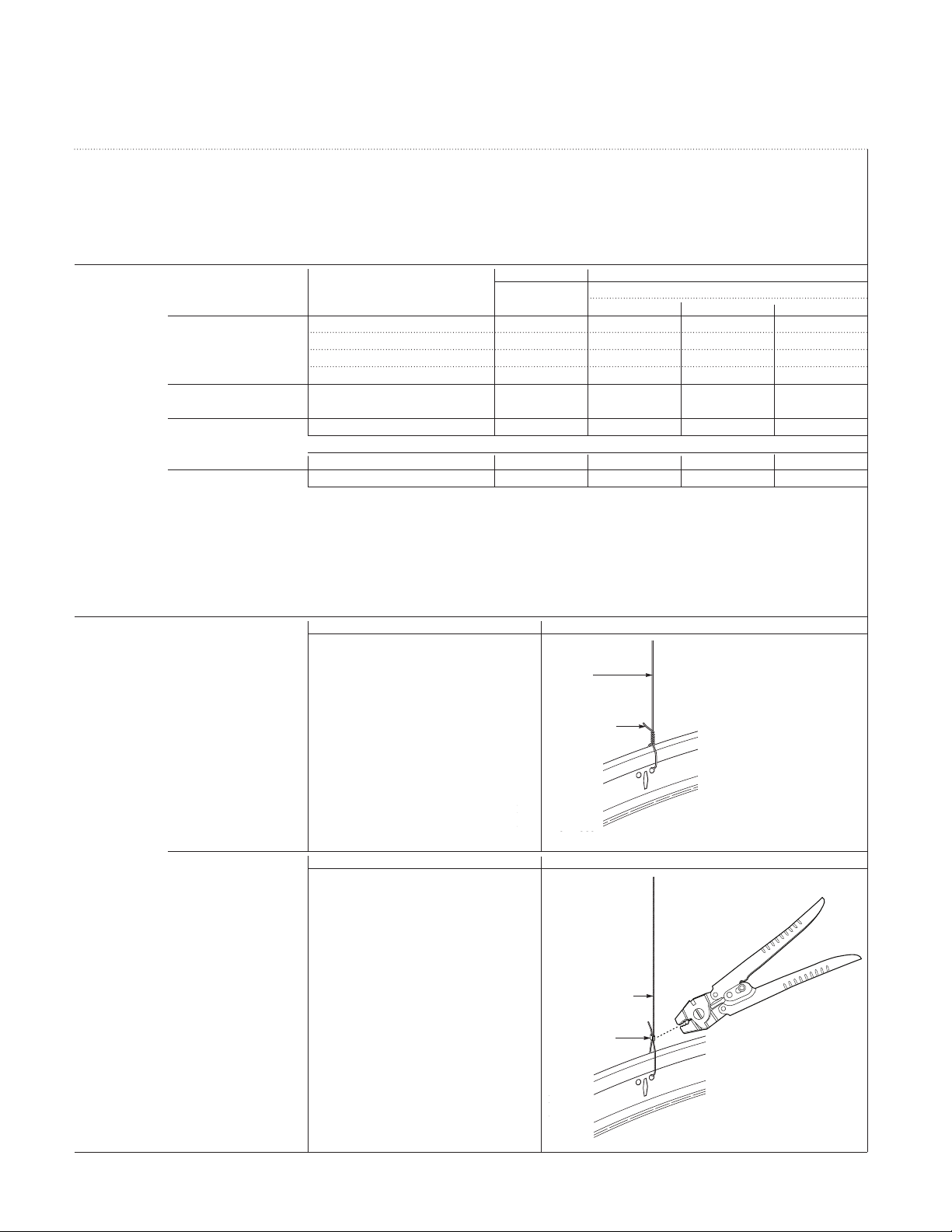

18-Gauge Stainless Steel Twisted-Tie Connection Detail

Infill Panel Options System Weight Maximum Uniform Load On Carriers (lbs./lin. ft.)

(lbs./sq. ft.) Hanger Spacing (along main tee or carrier)

DiamonDflex 0.6 7.5 10 15

transluCents (Lexan or FRP) 0.6 7.5 10 15

Installer must determine safe connection spacing and means for loads to be encountered.

hangers must conform to ASTM C636, “Standard Practice for Installation of Metal Ceiling Suspension System

for Acoustical Tile and Lay-In Panels.”

Six complete twists inside 1/2, first loop

to third loop.

18 ga. stainless

steel wire

wrap wire six

times within

1

/2"

1/32 Stainless Steel Loop and Crimp-End Connection Detail

Rope Wire

Feed rope wire down through one side of

oval crimp (USG Part No. 205241), through

hanger hole on tee or bracket and back up

through other side of oval crimp. Using crimper

(USG Part No. 202880), fully compress oval

two times, one above the other, using smallest

notch of tool. Crimp cannot be undone, so be

sure tee or bracket is in correct location before

pinching oval closed.

1

/2" stainless

steel rope wire

wire crimp

Page 3

Page 3 of 4

Technical Service 800 USG.4YOU

Web Site usg.com

Samples/Literature 888 874.2450

Samples/Literature Fax 888 874.2348

Customer Service 800 950.3839

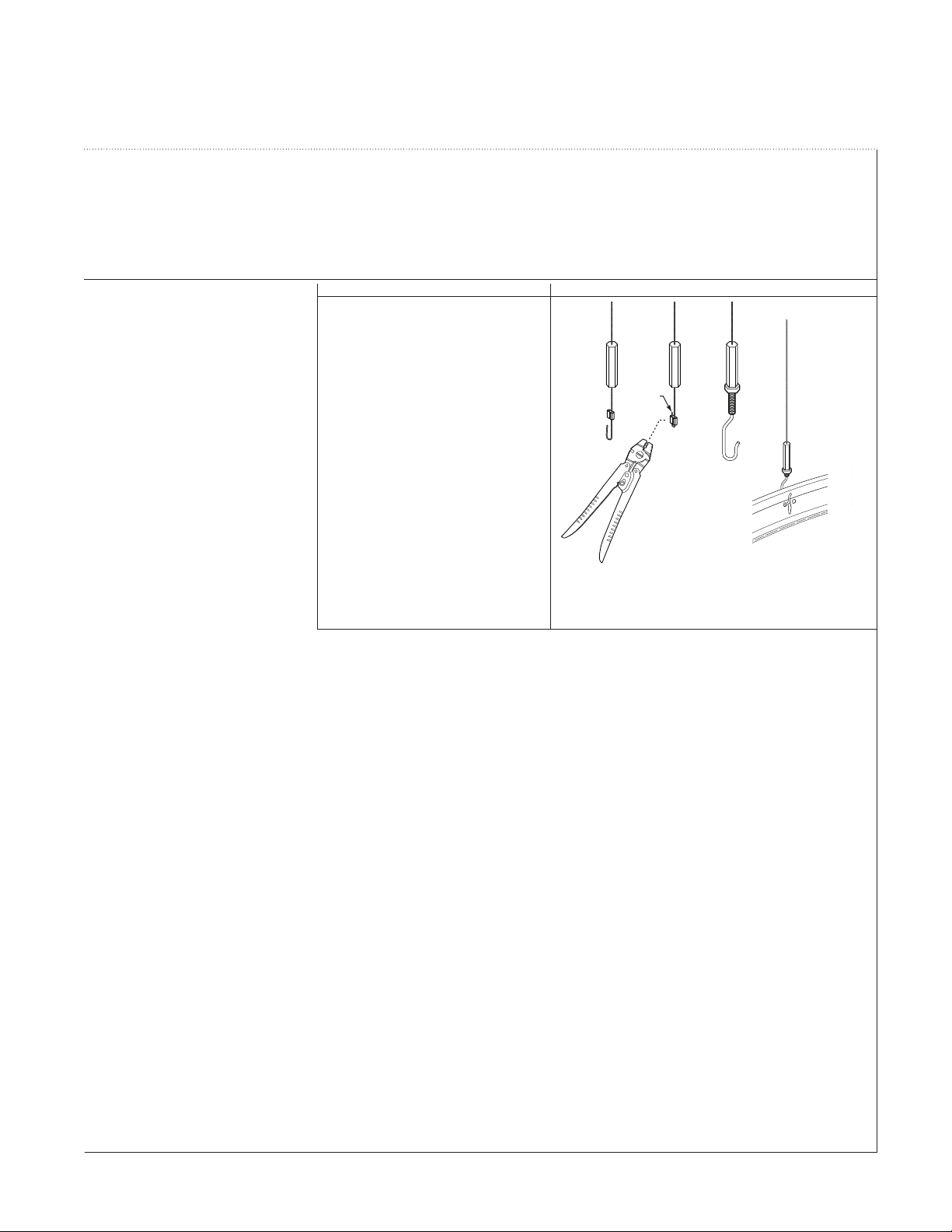

Turnbuckle Connection Detail

Feed rope wire down through turnbuckle

sleeve and into one barrel of oval crimp (USG

Part No. 205241); bend rope wire end to

form a hook. Pull bent rope wire back up,

feeding short side of hook into second barrel

of oval crimp; trim any excess rope wire.

Using crimper (USG Part No. 202880),

fully compress oval two times, one above the

other, using smallest notch of tool. Draw rope

wire back through turnbuckle sleeve, pulling

compressed crimp all the way in.

Screw nut about halfway onto threaded turn-

buckle shaft and hook turnbuckle into hanger

hole on tee or bracket. Screw sleeve onto

threaded turnbuckle shaft and adjust as

necessary (turnbuckle provides approximately

3/8 vertical adjustment).

trim end

Page 4

Product Information

See usg.com for the most

up-to-date product information.

Note

All products described here

may not be available in all

geographic markets and are

subject to change without

notice. Consult your local

sales office or representative

for information.

Manufactured by

USG Interiors, Inc.

550 West Adams Street

Chicago, IL 60661

Trademarks

The following are trademarks of

USG Interiors, Inc. or a related

Compässo, Curvatura,

company:

ibretto, topo, transluCents,

l

USG. Lexan is a trademark of

General Electric Company.

Notice

We shall not be liable for

incidental or consequential

damages, directly or indirectly

sustained, nor for any loss

caused by application of these

goods not in accordance with

current printed instruction or

for other than intended use.

Our liability is expressly limited

to replacement of defective

goods. Any claim shall be

deemed waived unless made

in writing to us within thirty

(30) days from date it was or

reasonably should have been

discovered.

Safety First!

Follow good safety/industrial

hygiene practices during

installation. Wear appropriate

personal protective equipment.

Read MSDS and literature

before specification and

installation.

IC453/rev. 4-13

© 2013 USG Interiors, Inc.

Printed in U.S.A.

Loading...

Loading...