Page 1

Durock™

Tile Membrane

System

installation

guide

Durock™ Tile Membrane

Membrane for ceramic

Durock™ Tile Membrane Adhesive

floor tile installation

Page 2

An easy-to-install tile backer on a roll

with superior tile bond.

Durock™ brand tile membrane is a thin,

water-proof, vapor-permeable membrane

used under tile in residential and lightcommercial floor, wall and countertop

applications. Easy to install, with outstanding

tile bond, this membrane provides a highperformance crack-isolation solution when

used with Durock™ tile membrane adhesive.

Back side (light)Cementitious side (dark)

2

Page 3

Products

ToolsStart with Quality

Durock™ Tile Membrane

Ideal for floor, wall and countertop

applications.

Durock™

Membrane Adhesive

A superior adhesive with proprietary acrylic polymer and an

additive for mold and mildew

resistance, used with

tile membrane to provide crack

isolation.

Durock tile membrane may also

be installed with the following

products, which do not provide

crack isolation: Type 1 organic

adhesive and latex-modified

thin-set mortar.

Durock

In general, common tools like

scissors, a straightedge, and a

notched trowel or 3/89-nap paint

roller (for applying

membrane adhesive) are used for

tile membrane installation. Other

tools you may need for installation

include: tape measure, utility knife,

caulk and caulking gun.

Durock tile

3

Page 4

Preparation Installation of

Tile Membrane

1. Ensure that substrate is clean,

even, flat, designed to support

ceramic tile, and properly

installed according to manufacturers’ specifications.

2. Substrate must be free

of sealers, waxes, bond

breakers, dust and dirt.

3. If

Durock tile membrane is

installed directly over a woodbased subfloor, ensure that

all fasteners are seated correctly and there are no uneven

joints. Sand or fill if necessary.

1. Precut the full width of mem-

brane to provide a tight fit to

the perimeter of the room.

2. Spread adhesive over an area

the full width of the sheet and

as far as can be comfortably

reached.

– For

Durock tile membrane

adhesive, use a 3/89-nap

paint roller or a 1/169 U-notch

trowel.

– For Type 1 organic adhesive,

use a 1/169 U-notch trowel.

– For latex-modified thin-set

mortar, use a 1/89 U-notch

trowel. Roll or trowel adhesive

in parallel rows across the

width or length to avoid trapping air under the membrane.

For installations over non-

porous surfaces, such as

vinyl, laminate and existing

tile—allow adhesive to air-dry,

becoming translucent and

developing tack, before

installing D

urock tile

membrane. Time will vary

depending on temperature,

humidity and substrate type;

however, a minimum of 15

minutes should be allowed.

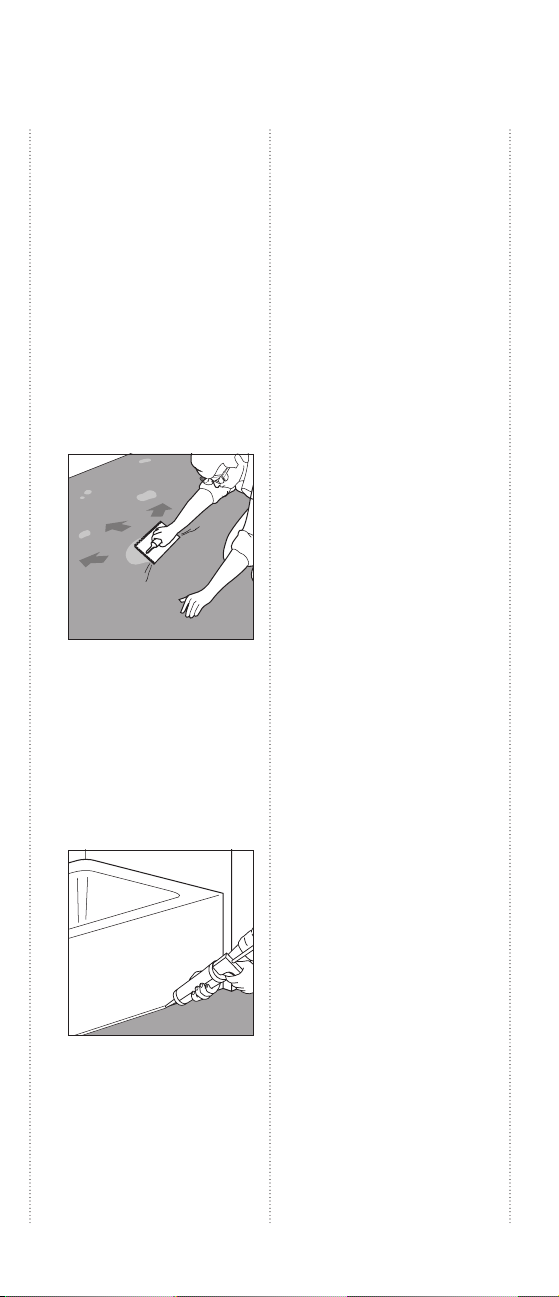

3. Install membrane with

cementitious side out. Embed

into adhesive, using the flat

edge of the trowel or with a

non-segmented hand roller.

Start in the center of the

4

Page 5

sheet and work out towards

the edges, removing all air

bubbles. Overlap each row

29, making sure that a

sufficient amount of

adhesive is applied to the

joint area.

For wall applications, begin

from the lowest point and work

toward the highest point of

coverage so that all horizontal

membrane seams are lapped

in a shingle-like manner.

4. Areas unable to receive verti-

cal flashing, such as pipe penetrations and bathroom tubs,

should be sealed using a good

quality silicone sealant. Run a

continuous bead and tool the

material to provide continuity

to the membrane.

6. Install tiles on cementitious

(dark) side of membrane with

ANSI A118.4 latex-modified

Portland cement mortar or ANSI

A136.1 Type 1 organic adhesive. Determine correct

trowel size based on tile material and size to achieve at least

95% coverage of the average

tile contact area.

7. After tile installation, do not

walk on floor for at least 48

hours unless walking boards

or plywood sheets are used, as

per current TCNA Handbook for

Ceramic Tile Installation.

8. Select, prepare and install ANSI

A118.7 latex-modified or ANSI

A118.8 modified epoxy emulsion grout per grout manufacturer recommendations.

5. Allow membrane adhesive to

cure sufficiently (minimum

2 hours for

Durock tile membrane adhesive, minimum

4 hours for Type 1 organic

adhesive or 8 hours for latexmodified thin-set mortar).

5

Page 6

Installation of

Flashing

If flashing is required:

1. Cut 39-49 strip from end of

Durock tile membrane roll.

Pre-crease the material in

half lengthwise, with half to

be adhered to the floor and

half to the vertical surface.

Install all corner pieces first,

then fill in between corners

around the perimeter as

necessary.

2. Apply Durock tile membrane

adhesive with a 3/89-nap paint

roller or a 1/169 U-notch

trowel; apply Type 1 organic

adhesive or latex-modified

thin-set mortar with a 1/169

U-notch trowel.

Use the trowel’s smooth edge

to fully embed the material.

4. For inside corners, provide a

relief cut, but place adhesive

where the membrane folds

over itself to ensure a waterdurable connection. Overlap

butt joints by 1-1/29 and

use the mastic to ensure a

water-durable connection.

Apply adhesive to the vertical

and horizontal legs of the butt

joint. Work the material carefully into position and smooth

out, using the flat edge of

the trowel.

3. Install membrane with the

cementitious side out. For

outside corners, make a relief

cut and press into adhesive.

5. Allow membrane to cure

adequately before setting tile.

6

Page 7

Product Information

See usg.com for the most

up-to-date product information.

Trademarks

The following trademark used

herein is owned by United

States Gypsum Company:

Durock, uSG, uSG in stylized letters.

Notice

We shall not be liable for

incidental and consequential

damages, directly or indirectly

sustained, nor for any loss

caused by application of these

goods not in accordance with

current printed instructions

or for other than the intended

use. Our liability is expressly

limited to replacement of

defective goods. Any claim

shall be deemed waived unless

made in writing to us within

thirty (30) days from date it

was or reasonably should have

been discovered.

Safety First!

Follow good safety and industrial hygiene practices during

handling and installation of all

products and systems. Take

necessary precautions and

wear the appropriate personal

protective equipment as

needed. Read material safety

data sheets and related literature on products before specification and/or installation.

For warranty or product

information and literature:

800 USG.4YOU (874.4968)

usg.com

durocktilemembrane.com

United States

Gypsum Company

550 West Adams Street

Chicago, IL 60661

CB493/rev. 10-11

© 2011, United States Gypsum Company

Printed in U.S.A.

Loading...

Loading...