Page 1

Durock™ Shower System

Strength Beneath the Surface™

Sistema de Ducha Durock™ / Système de Douche Durock

Shower Assembly with Prefabricated Durock™ Shower System

Conjunto de ducha con Sistema de Ducha Durock™ Prefabricado

Ensemble de douche avec Système de Douche Préfabriqué D

™

urock

™

Installation Guide

Guía de instalación / Guide d’installation

Page 2

Pipe Seal

Sello de tubería

Joint de tu yau

Table of Contents

Approved Substrate

Substrato aprobado

Fond recommandé

Strong, Thin Waterproof Membrane

Membrana impermeable delgada y fuerte

Membrane d’étanchéité fine et résistante

Introduction ............................................. 2

Durock Shower System Kits ............................ 2

Special Features

Shower Walls

Pipe Seal

................................................. 3

Mixing Valve Seal

Shower Floor

Shower Floor and Drain Assembly

Grate Assembly

......................................... 2

......................................... 2–3

....................................... 3

.......................................... 3–4

................. 4–5

.......................................... 5

Tabla de Contenido

Introducción ............................................. 6

Juegos del Sistema de Ducha

Características especiales

Paredes de la ducha

Sello de tubería

.................................. 6—7

.......................................... 7

Sello de válvula de mezcla

Piso de la ducha

...................................... 7–8

Piso de la ducha y conjunto de drenaje

Conjunto de rejilla

...................................... 9

Durock ................. 6

................................ 6

............................. 7

............ 8–9

Optimal 5" High-Density EPS Shower Curb

Ext raordinario borde d e ducha de 5 pulgadas fab ricado de EPS

de alta densidad

Seuil de do uche de hauteur optimal e de 12,5 cm ( 5 po) en PSE

haute densité

High-Density EPS Shower Tray

Base de du cha fabricada de E PS de alta densidad

Receveur d e douche en PSE hau te densité

Innovative, Versatile Drain Assembly

Conjunto d e drenaje versátil e inn ovador

Ensemble de drainage novateur et polyvalent

Designer and Pro Series Drain Grates

Rejillas de drenaje serie profesional o de diseñador

Grilles de d rainage des séries Pr o ou Design

Mixing Valve Seal

Sello de vál vula de mezcla

Joint de robinet mélangeur

Table des matières

Introduction ............................................ 10

Kits de Système de Douche

Caractéristiques particulières

Parois de douche

Joint de tuyau

................................... 10–11

........................................... 11

Joint de robinet mélangeur

Sol de la douche

..................................... 11–12

Sol de la douche et ensemble de drainage

Ensemble de grille

Produ cts from the co ver:

Duro ck™ Curb

Duro ck™ Waterproofing Membrane

Duro ck™ Waterproofing Band

Duro ck™ Preformed Corners

Duro ck™ Pre-Sloped Tray

Duro ck™ Drain Body

Duro ck™ Grate Assembly

Produ ctos de la cubie rta:

Borde Dur ock™

Membrana Impermeable

Banda Impermeable

Duro ck

..................................... 13

Duro ck™

™

Durock .................. 10

......................... 10

............................. 11

....... 12–13

Duro ck

™

™

™

™

Duro ck™

™

™

™

™

™

Esquinas Preformadas Duro ck

Base en Pendiente Preformada Durock

Cuerpo del Drenaje Duroc k

Conjunto de Rejilla Durock

Produits en couverture :

Seuil Duroc k™

Membrane d’Étanchéité

Bande d’Étanchéité

Angles Préformés Duroc k

Receveur avec Pente Préformée Du rock

Corps de D rain Durock

Ensemble de G rille Durock

For more detailed instructions visit durockshowersystem.com

Para obtener instrucciones detalladas adicionales, visite durockshowersystem.com

Pour plus de détails concernant les instructions, visiter le site durockshowersystem.com

1

Page 3

Discover the new, innovative and waterproof

urock

D

™

Shower System for tiled showers.

The Durock Shower System continues the tradition of quality, performance and reliability, which has

defined D

urock products for 30 years. The Durock Shower System makes waterproofing shower installations

easier and faster by featuring: a pre-sloped EPS shower tray that installs more quickly than conventional

mud-bed showers; a thin, durable and waterproof membrane; and an easy-to-position drain assembly

that accepts all D

Durock Shower System Kits

32" x 60" offset drain

(81.2 cm x 152.4 cm)

32" x 60" center drain

(81.2 cm x 152.4 cm)

48" x 48" center drain

(122 cm x 122 cm)

Special Features

Durock waterproofing

membrane—a pliable, durable,

sheet-applied waterproofing

membrane and vapor retarder

with a uniform thickness of .012"

(.3 mm) that makes installation

easy without excessive buildup.

urock Shower System

The D

makes waterproof shower

installation easier and faster

by featuring: a prefabricated

pre-sloped shower tray that

installs more quickly than

conventional mud-bed showers;

a thin, durable, waterproof

membrane; an easy-to-position

drain assembly that accepts all

urock Shower System 4" or 5"

D

(10 cm or 12.5 cm) grate options

(grates sold separately).

The pre-sloped shower tray

is ideal for new construction

and repair or remodel projects.

urock Shower System 4" or 5" (10 cm or 12.5 cm) grate options (grates sold separately).

The tray dramatically reduces

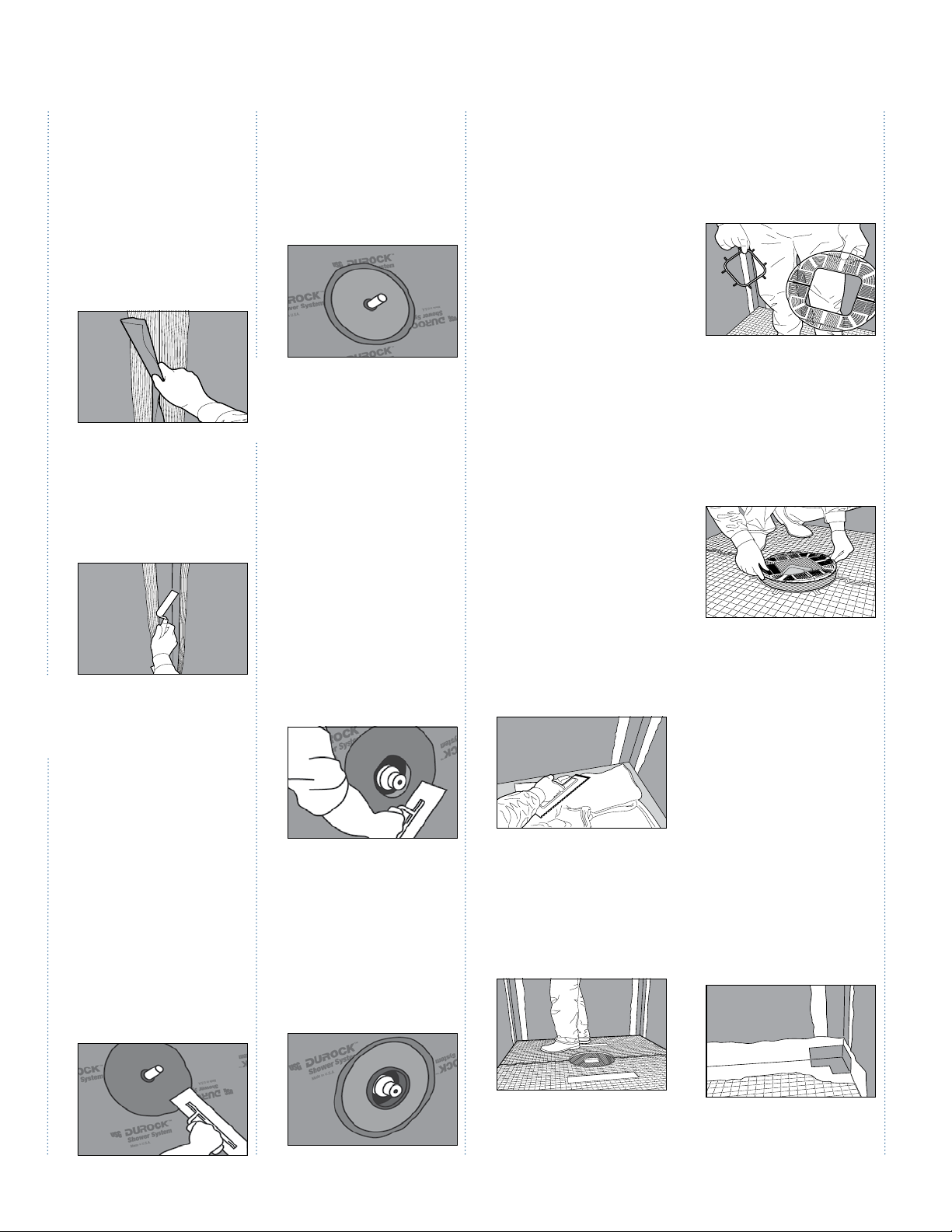

Shower Wa l ls

installation time compared to

conventional mud-bed showers

and its gradual pre-slope allows

for easy installation of tile.

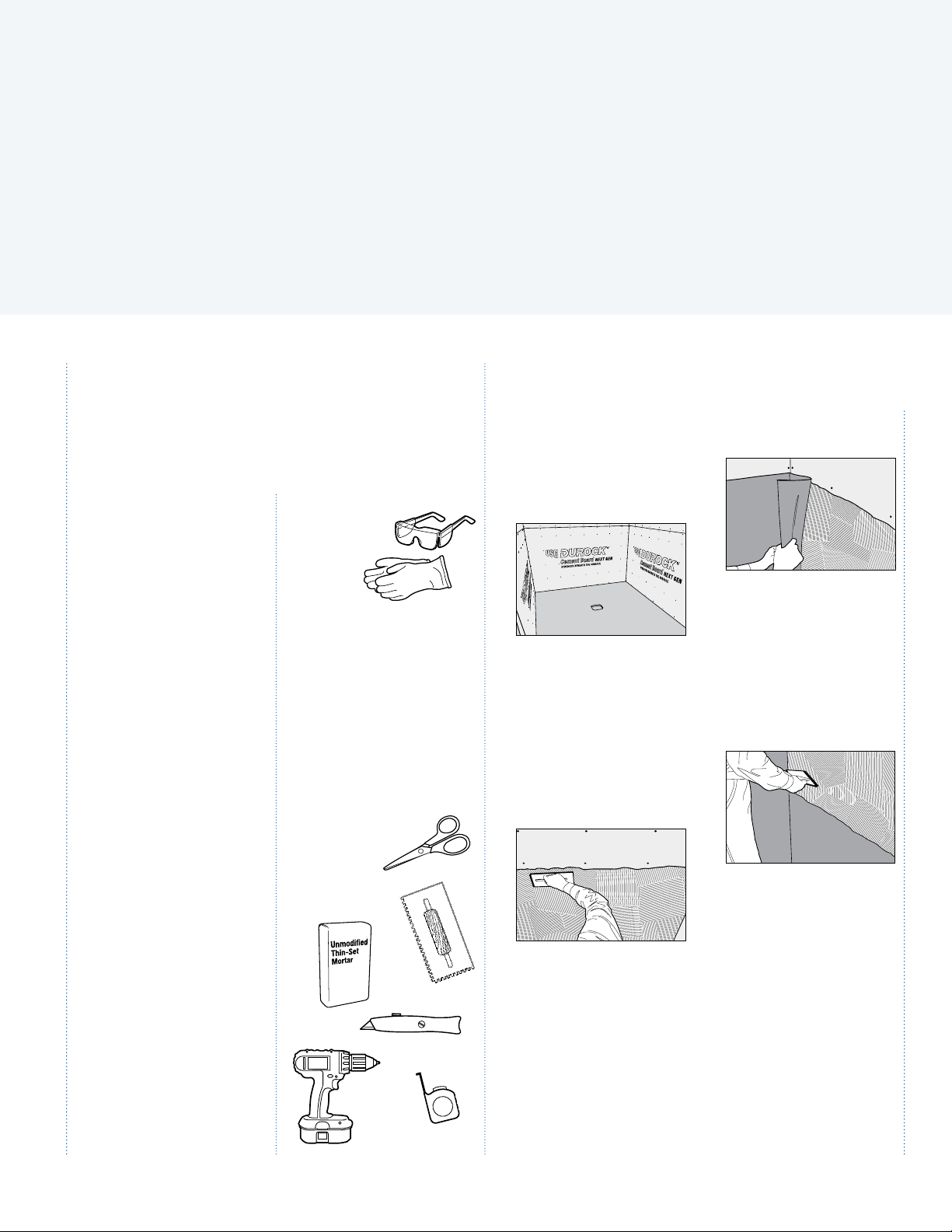

Tools and Materials

1. Use only code-approved

wall substrate suitable for

wet areas, such as

Cement Board, or F

Durock®

iberock

Tile Backerboard.

pockets and to ensure

proper adhesion.

®

Safety Glasses

Gloves

Scissors

Trowels

- 3/16" x 3/16" (5 mm x 5 mm)

Tip: Start from the center of the

wall and work toward the edges.

v-notched trowel or 1/8" x 1/8"

(3 mm x 3 mm) square or

u-notched trowel

- 1/4" x 3/8" (6 mm x 10 mm)

square or u-notched trowel

- finishing trowel

- margin trowel

Unmodified thin-set mortar

meeting ANSI 118.1 (minimum

50 lb., 26 kg)

2. Apply unmodified thin-set

mortar to wall substrate

using a 3/16" x 3/16"

(5 mm x 5 mm) v-notched

trowel or 1/8" x 1/8"

(3 mm x 3 mm) square or

u-notched trowel.

4. Overlap all adjoining

sections of the

Durock

Shower System

Waterproofing Membrane a

minimum of 2" (5 cm).

Utility Knife

Tape Measure

Drill

Tip: The mortar should be loose but

still hold ridges from your trowel.

3. Embed Durock™ Shower

System Waterproofing

Note: Shingle-lapping of

membrane is not required,

provided that a minimum 2"

(5 cm) overlap is maintained at

all joints. Alternatively, adjoining

sections of D

Waterproofing Membrane can be

abutted and then seamed with

5" (13 cm) wide D

System Waterproofing Band.

urock Shower System

urock

™

Shower

Membrane into the mortar

using a finishing trowel,

drywall taping knife, or

similar tool to remove air

2

Page 4

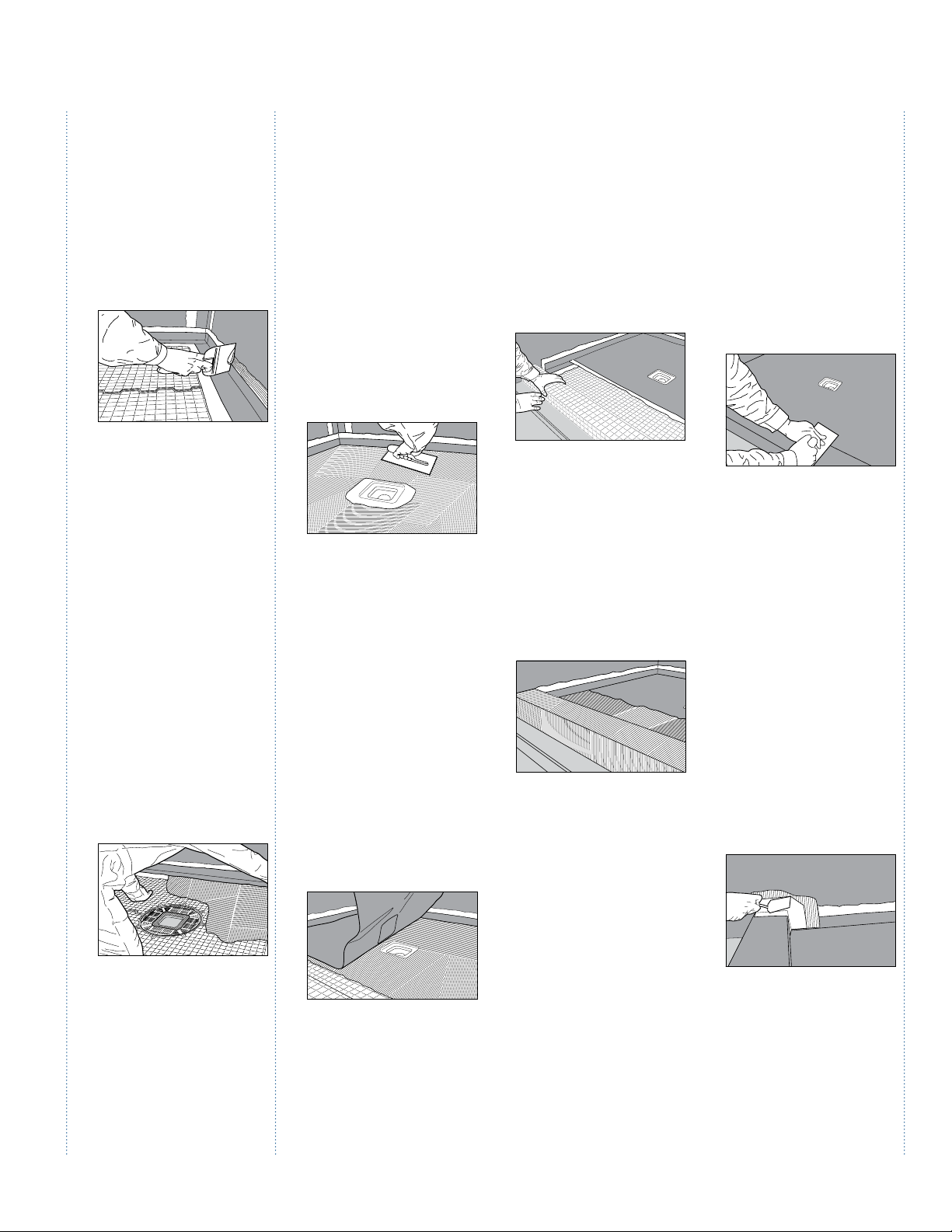

Shower Wa l ls

cont.

Pipe Seal cont. Shower Floor

5. Install Durock™ Shower

System Waterproofing Band

at all vertical inside wall

corners using unmodified

thin-set mortar and a

3/16" x 3/16" (5 mm x 5 mm)

v-notched trowel or 1/8" x

1/8" (3 mm x 3 mm) square

or u-notched trowel.

Tip: To center waterproofing

band at inside wall corners,

crease waterproofing band by

folding in half lengthwise. Embed

waterproofing band in thin-set

mortar using a drywall taping knife

or margin trowel.

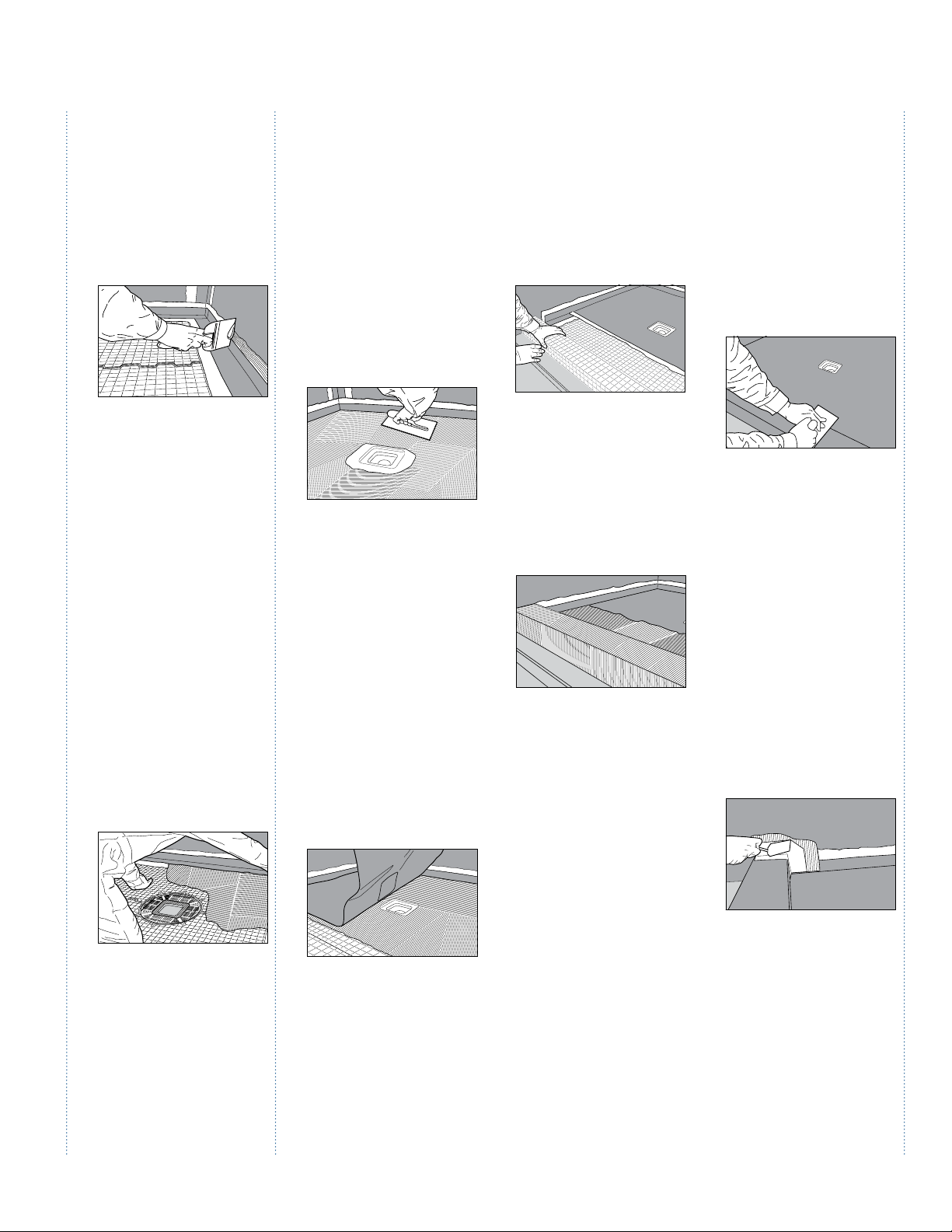

Pipe Seal

Durock™ Pipe Seals are designed

to seal pipe penetrations in waterproof wall assemblies; e.g., pipe

penetrations at shower heads,

tub spouts, body sprays, etc.

1. Apply unmodified thin-set

mortar to the substrate

using a 3/16" x 3/16"

(5 mm x 5 mm) v-notched

trowel or 1/8" x 1/8"

(3 mm x 3 mm) square or

u-notched trowel.

2. Place seal over pipe and

embed into the mortar using

a finishing trowel, drywall

taping knife, or similar tool

to remove air pockets and to

ensure proper adhesion.

Mix i n g Va lve S e a l

Durock™ Mixing Valve Seals

are designed to seal mixing

valve openings in waterproof

wall assemblies in tub surrounds

and showers.

1. Apply unmodified thin-set

mortar to the substrate

using a 3/16" x 3/16"

(5 mm x 5 mm) v-notched

trowel or 1/8" x 1/8"

(3 mm x 3 mm) square or

u-notched trowel.

2. Place seal into mixing valve

opening and embed into the

mortar using a finishing trowel,

drywall taping knife, or

similar tool to remove air

pockets and to ensure proper

adhesion.

1. Place shower tray disk on

subfloor at desired drain

location. Using the removable

subfloor cutout template on

the shower tray disk, trace

the hole location on the

subfloor before cutting.

Note: Alignment of drain grate

to tile layout must be established

before cutting the hole in the

subfloor.

Tip: Dry-lay the pre-sloped

shower tray, then align the shower

tray disk with the clock marks on

the tray to the desired position

before marking and cutting the

hole in the subfloor.

2. Apply unmodified thin-set

mortar to the subfloor

using a 1/4" x 3/8"

(6 mm x 10 mm) square

or u-notched trowel. Floor

must be level prior to

installation of shower tray.

If necessary, apply

Durock™

Self Leveling Underlayment

prior to installation.

3. Firmly embed

Durock™

Shower System Pre-Sloped

Shower Tray into the mortar.

Check underside of tray to

ensure full mortar coverage.

4. Remove integrated cutout

template—used for drain

hole cutout in subfloor—

from shower tray disk prior

to installation.

5. Install shower tray disk by

fully embedding in the thinset mortar and positioning to

match drain hole orientation

using the clock marks on the

shower tray.

6. Apply unmodified thin-set

mortar to pre-sloped shower

tray and wall junction using

a 3/16" x 3/16" (5 mm x 5 mm)

v-notched trowel or 1/8" x 1/8"

(3 mm x 3 mm) square or

u-notched trowel. Embed

Durock™ Shower System

Preformed Inside Corners

into the mortar, using a

drywall knife or margin

trowel to remove air pockets

and ensure proper adhesion

to shower tray and wall

junction.

For more detailed instructions visit durockshowersystem.com

3

Page 5

Shower Floor

cont.

Shower Floor

Drain Assembly (See Drain A ssembly and Grate Assembly on page 5)

7. Install

Durock Shower

System Waterproofing Band

at all floor/wall junctions

using unmodified thin-set

mortar and a 3/16" x 3/16"

(5 mm x 5 mm) v-notched

trowel or 1/8" x 1/8"

(3 mm x 3 mm) square or

u-notched trowel.

Tip: To center waterproofing

band at floor/wall junctions,

crease waterproofing band by

folding in half lengthwise. Embed

waterproofing band in thin-set

mortar using a drywall taping knife

or margin trowel.

8. Apply unmodified thin-set

mortar to the surface of the

pre-sloped shower tray, and

tray disk—make sure to fill

the shower tray disk—and

apply the mortar to the bottom

of the drain bonding flange.

Apply the mortar with a

3/16" x 3/16" (5 mm x 5 mm)

v-notched trowel or

1/8" x 1/8" (3 mm x 3 mm)

square or u-notched trowel.

9. Next, install the Durock™

Drain Assembly into the

pre-sloped shower tray disk,

pressing firmly to ensure

proper alignment and full

support of the bonding

flange. Once in place apply

unmodified thin-set mortar

to the top of the bonding

flange. Do not fill the recessed

areas of the bonding flange

with thin-set mortar until the

grate assembly is ready to be

installed.

Note: If there is no access to

the waste line from below, the

Durock Drain Assembly must be

connected to the waste line at the

same time it is pressed into the

mortar.

10. Embed Dur oc k Shower

System Waterproofing

Membrane into the thin-set

mortar using a finishing

trowel, drywall taping knife,

or similar tool to remove air

pockets and ensure proper

adhesion to the pre-sloped

shower tray and drain

assembly bonding flange.

11. Apply unmodified thin-set

mortar to the subfloor and

edge of the pre-sloped

shower tray, curb(s), and

adjacent walls—using a

1/4" x 3/8" (6 m m x 10 mm)

square or u-notched

trowel—and firmly press

shower curb(s) into the

mor tar.

12. Apply unmodified thin-set

mortar to the pre-sloped

shower tray and curb(s)

using a 3/16" x 3/16"

(5 mm x 5 mm) v-notched

trowel or 1/8" x 1/8"

(3 mm x 3 mm) square or

u-notched trowel.

13. Apply

Durock Shower

System Waterproofing

Membrane to remaining

pre-sloped tray section,

overlapping seams a

minimum of 2", and wrap

over and around curb(s). Use

a finishing trowel, drywall

taping knife, or similar tool

to remove air pockets and

ensure proper adhesion.

14. Install

Durock™ Shower

System Preformed Inside

and Outside Corners to seal

curb/wall junctions using

unmodified thin-set mortar

and a 3/16" x 3/16"

(5 mm x 5 mm) v-notched

trowel or 1/8" x 1/8"

(3 mm x 3 mm) square or

u-notched trowel. Embed

preformed corners in the

thin-set mortar using a

drywall taping knife or

margin trowel to ensure

proper adhesion to shower

curb(s) and wall.

Tip: Before applying mortar to

shower tray and shower tray

disk, establish the location of the

hole in the shower membrane

that corresponds to the recessed

area at the top of the drain body

by first dry-fitting the drain body

and membrane. Cut the opening

in the shower membrane using

the provided membrane cut-out

template.

4

Page 6

Shower Floor

Drain Assembly cont.

Grate Assembly

15. The Durock Shower System

waterproofing application is

now complete. Before

water testing and setting

tile, allow a minimum of

24 hours to ensure both

proper curing of thin-set

mortar and waterproof

performance at all seams

and connections.

16. Insert a water test plug

and fill the shower with

approximately 3" of water.

After 24 hours check for

leakage and remove the

plug. This confirms the

waterproofing is sound.

17. You are now ready to apply

thin-set mortar to the shower

walls and floor and set tile.

1. The

Durock™ Shower System

Grate Assembly is installed at

the same time as the floor tile.

Tip: Remove the construction plug

from the grate tray by pushing up

from the inside, then apply a light

coating of petroleum jelly to the

plug’s edges to keep grout from

bonding to the plug’s perimeter

(this is especially important when

using urethane or epoxy grout

which bonds more aggressively).

2. Install the construction

plug into the grate tray,

and snap the assembly into

the grate tray riser. Apply

thin-set mortar to both the

underside of the grate tray

and to the recessed area of

the drain assembly’s bonding

flange. Place the assembly

into the horizontal adjustment

ring, then place the grate

assembly into the recessed

area of the drain body.

Tip: During the grouting process,

expose the top surface of the

construction plug up to its outer

edges while keeping the grout joints

immediately surrounding the plug

as full as possible.

3. After grouting the shower

floor, wait at least 24

hours before removing

the construction plug. To

remove the construction

plug after grouting, press

down firmly a few times

on the center of the plug

to create a separation line

between the perimeter and

the surrounding grout joints.

Insert a thin screw (drywall

screw or similar) into one

of the four start holes in

the construction plug and

thread the screw far enough

in so that the screw grips

the plug firmly, then use the

screw to pull the plug out.

Install the grate.

Note: The construction plug

ensures that the grate tray remains

absolutely square and in perfect

form for subsequent installation

of the grate. Removing the

construction plug prematurely can

cause the grout to crack, creating

an improper fit to the grate.

For tile application, refer

to manufacturer of setting

material for specific

information related to type

of mortar, as well as to size

and type of trowel.

Align the grate assembly with

the layout of the floor tile and

adjust vertically to ensure the

construction plug is even with,

or slightly below, the surface

of the surrounding tile.

For more detailed instructions visit durockshowersystem.com

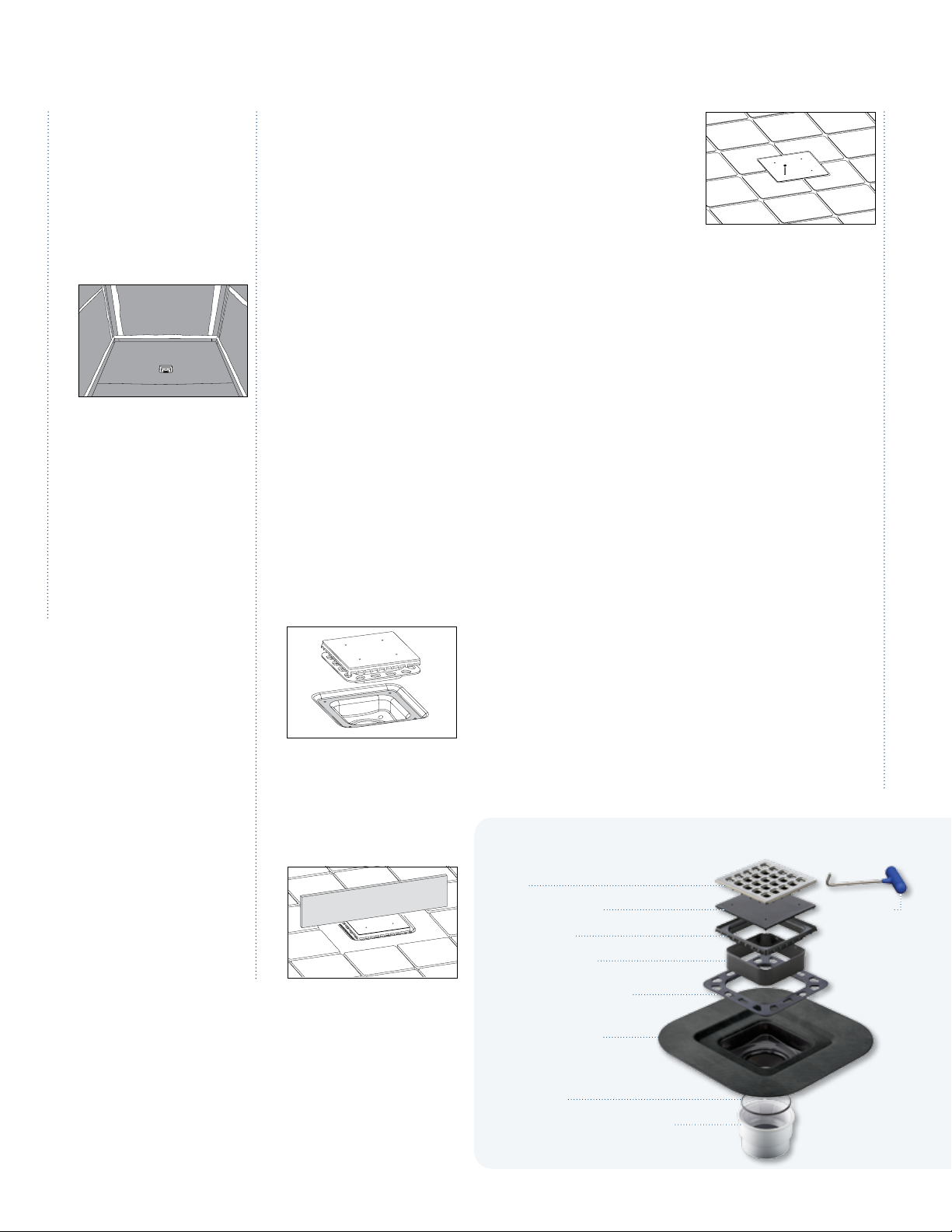

Drain Assembly and Grate Assembly

Grate

Construction Plug

Grate Tray

Grate Tray Riser

Horizontal

Adjustment Ring

Drain Body

with Integrated

Bonding Flange

O-Ring

PVC or ABS Bushing with

2" (5 cm) Coupling Socket

5

Grate Puller

Page 7

Descubra el Sistema de Ducha Durock™ para duchas de azulejos,

nuevo, innovador e impermeable.

El Sistema de Ducha Du rock continúa la tradición de calidad, desempeño y fiabilidad que durante 30 años ha

definido a los productos

al incluir: una base de ducha en pendiente preformada fabricada de EPS que se instala más rápidamente que las

duchas convencionales sobre capa de mortero; una membrana duradera, delgada e impermeable; un conjunto de

drenaje fácil de colocar que se adapta a todas las opciones de rejilla de 4 pulgadas o 5 pulgadas (10 cm o 12.5 cm)

del Sistema de Ducha

Durock. El Sistema de Ducha Durock facilita y agiliza la instalación de duchas impermeables

Durock (las rejillas se venden por separado).

Juegos del Sistema de

Ducha D

urock

Drenaje descentrado de 32 pulgadas x

60 pulgadas (81.2 cm x 152.4 cm)

Drenaje central de 32 pulgadas x 60

pulgadas (81.2 cm x 152.4 cm)

Drenaje central de 48 pulgadas x 48

pulgadas (122 cm x 122 cm)

Características especiales

Membrana impermeable

membrana impermeable aplicada

en láminas, plegable y duradera, y

retardador de vapor con un grosor

uniforme de 0.012 pulgada (0.3 mm) lo

cual facilita la instalación sin generar

una acumulación excesiva.

El Sistema de Ducha

y agiliza la instalación de duchas

impermeables ya que incluye: una base

de ducha en pendiente preformada

prefabricada que se instala más

rápidamente que las duchas

convencionales sobre capa de

mortero; una membrana duradera,

delgada e impermeable; y un conjunto

de drenaje fácil de colocar que se

adapta a todas las opciones de rejilla

de 4 pulgadas o 5 pulgadas (10 cm o

12.5 cm) del Sistema de Ducha

(las rejillas se venden por separado).

La base de ducha en pendiente

preformada es ideal para

construcciones nuevas y para proyectos

de reparación o remodelación.

La base reduce dramáticamente el

tiempo de instalación en comparación

con las duchas convencionales sobre

capa de mortero, y su pendiente

gradual prefabricada facilita la

instalación de los azujelos.

Duro ck—una

Duro ck facilita

Duro ck

Herramientas y Materiales

Gafas de seguridad

Guantes

Tijeras

Llanas

- Llana con ranuras en V de 3/16

pulgada x 3/16 pulgada (5 mm x 5 mm)

o llana cuadrada o con ranuras en U

de 1/8 pulgada x 1/8 pulgada

(3 mm x 3 mm)

- llana cuadrada o con ranuras en U

de 1/4 pulgada x 3/8 pulgada

(6 mm x 10 mm)

- llana de acabado

- llana para esquinas

Mortero de fraguado delgado sin

modificar cumple la norma ANSI 118.1

(mínimo 50 lb., 26 kg)

Cuchillo para uso general

Cinta métrica

Taladro

Paredes de la ducha

1. Utilice únicamente un substrato

de pared que cumpla con los

requisitos de código para uso

en áreas mojadas, tal como el

Tablero de Cemento

Tablero de Respaldo para Losetas

Fibe rock®.

2. Aplique mortero de fraguado

delgado sin modificar al substrato

de pared utilizando una llana con

ranuras en V de 3/16 pulgada x

3/16 pulgada (5 mm x 5 mm) o

llana cuadrada o con ranuras en U

de 1/8 pulgada x 1/8 pulgada

(3 mm x 3 mm).

Consejo práctico: El mortero

debe estar suave pero aún así

debe preservar las ranuras

formadas por la llana.

3. Coloque la Membrana

Impermeable del Sistema de Ducha

Durock™ en el mortero utilizando

una llana de acabado, una

espátula de enmascaramiento

para paredes de yeso, o una

herramienta similar para eliminar

las bolsas de aire y garantizar una

adhesión adecuada.

Duro ck®, o el

Consejo práctico: Comience

desde el centro de la pared y

avance hacia los bordes.

4. Traslape todas las secciones

adyacentes de la Membrana

Impermeable del Sistema de

Ducha

Duro ck 2 pulgadas (5 cm)

como mínimo.

Nota: No es necesario traslapar

la membrana como se hace con

las tejas ya que todas las juntas

se traslapan 2 pulgadas (5 cm)

como mínimo. Alternativamente,

las secciones adyacentes de

la Membrana Impermeable

del Sistema de Ducha

pueden colocarse a tope, y

luego empalmarse con la Banda

Impermeable del Sistema de

Ducha

Duro ck™ de 5 pulgadas

(13 cm).

Duro ck

6

Page 8

Paredes de la ducha

(cont.)

Sello de tubería

(cont.)

Piso de la ducha

5. Instale la Banda Impermeable

del Sistema de Ducha

en todas las esquinas de paredes

interiores verticales utilizando

mortero de fraguado delgado sin

modificar y una llana con ranuras

en V de 3/16 pulgada x 3/16

pulgada (5 mm x 5 mm) o llana

cuadrada o con ranuras en U de

1/8 pulgada x 1/8 pulgada

(3 mm x 3 mm).

Consejo práctico: Para centrar

la banda impermeable en las

esquinas de paredes interiores,

pliegue la banda impermeable

doblándola por la mitad a lo largo.

Coloque la banda impermeable en

el mortero de fraguado delgado

utilizando una espátula de

enmascaramiento para paredes

de yeso o una llana para esquinas.

Duro ck™

Sello de tubería

Los Sellos de Tubería Durock™ han sido

diseñados para sellar penetraciones

de tuberías en conjuntos de pared

impermeables, por ejemplo,

penetraciones de tuberías en

cabezales de ducha, caños de bañeras,

rociadores para el cuerpo, etc.

1. Aplique mortero de fraguado

delgado sin modificar al substrato

utilizando una llana con ranuras

en V de 3/16 pulgada x 3/16

pulgada (5 mm x 5 mm) o llana

cuadrada o con ranuras en U de

1/8 pulgada x 1/8 pulgada

(3 mm x 3 mm).

2. Coloque el sello sobre la tubería y

fíjelo en el mortero utilizando una

llana de acabado, una espátula de

enmascaramiento para paredes

de yeso, o una herramienta similar

para eliminar las bolsas de aire y

garantizar una adhesión adecuada.

Sello de válvula

de mezcla

Los Sellos de Válvula de Mezcla

Duro ck™ están diseñados para sellar

aberturas de válvulas de mezcla en

conjuntos de pared impermeables, en

alrededores de bañeras y en duchas.

1. Aplique mortero de fraguado

delgado sin modificar al substrato

utilizando una llana con ranuras

en V de 3/16 pulgada x 3/16

pulgada (5 mm x 5 mm) o llana

cuadrada o con ranuras en U de

1/8 pulgada x 1/8 pulgada

(3 mm x 3 mm).

2. Coloque el sello sobre la abertura

de la válvula de mezcla y fíjelo en

el mortero utilizando una llana

de acabado, una espátula de

enmascaramiento para paredes

de yeso, o una herramienta

similar para eliminar las bolsas

de aire y garantizar una adhesión

adecuada.

1. Coloque el anillo de la base

de ducha en el substrato en la

ubicación de drenaje deseada.

Utilizando una plantilla de corte

removible para el substrato en el

anillo de la base de ducha, trace

la ubicación del agujero en el

substrato antes de cortar.

Nota: Se debe establecer el

alineamiento de la rejilla de

drenaje con la distribución de

los azulejos antes de cortar el

agujero en el substrato.

Consejo práctico: Ajuste

en seco la base de ducha en

pendiente preformada, luego

alinee el anillo de la base de

ducha con las marcas de reloj en

la base en la posición deseada

antes de marcar y cortar el

agujero en el substrato.

2. Aplique mortero de fraguado

delgado sin modificar al substrato

utilizando una llana cuadrada o

con ranuras en U de 1/4 pulgada

x 3/8 pulgada (6 mm x 10 mm).

El piso debe estar nivelado antes

de instalar la base de ducha. De

ser necesario, aplique Contrapiso

Autonivelante

instalar.

3. Coloque firmemente la Base de

Ducha en Pendiente Preformada

del Sistema de Ducha

el mortero. Revise la parte inferior

de la base para asegurar plena

cobertura del mortero.

Duro ck™ antes de

Duro ck™ en

4. Retire la plantilla de corte

integrada—que se utilizó para

cortar el agujero del drenaje en el

substrato—del anillo de la base

de ducha antes de instalar.

5. Instale el anillo de la base

de ducha colocándolo

completamente en el mortero

de fraguado delgado de manera

que coincida con la orientación

utilizando las marcas de reloj en la

base de ducha.

6. Aplique mortero de fraguado

delgado sin modificar a la base de

ducha en pendiente preformada

y a la unión de la pared utilizando

un llana con ranuras en V de

3/16 pulgada x 3/16 pulgada

(5 mm x 5 mm) o llana cuadrada o

con ranuras en U de 1/8 pulgada

x 1/8 pulgada (3 mm x 3 mm).

Coloque las Esquinas Interiores

Preformadas del Sistema de

Ducha

Duro ck™ en el mortero,

utilizando una espátula para

paredes de yeso o llana para

esquinas para eliminar las bolsas

de aire y garantizar una adhesión

adecuada a la base de ducha y la

unión de la pared.

Para obtener instrucciones detalladas adicionales,

visite durockshowersystem.com

7

Page 9

Piso de la ducha

(cont.)

Piso de la ducha

Conjunto de drenaje (Consulte Conjunto de drenaje y Conjunto de rejilla en la página 9)

7. Instale la Banda Impermeable

del Sistema de Ducha

todas las uniones del piso/pared

utilizando mortero de fraguado

delgado sin modificar y una llana

con ranuras en V de 3/16 pulgada

x 3/16 pulgada (5 mm x 5 mm) o

llana cuadrada o con ranuras en U

de 1/8 pulgada x 1/8 pulgada

(3 mm x 3 mm).

Dur ock™

Consejo práctico: Para centrar la

banda impermeable en las uniones

del piso/pared, pliegue la banda

impermeable doblándola por la mitad

a lo largo. Coloque la banda

impermeable en el mortero de

fraguado delgado utilizando una

espátula de enmascaramiento

para paredes de yeso o una llana

para esquinas.

8. Aplique mortero de fraguado

delgado sin modificar a la superficie

de la base de ducha en pendiente

preformada, y el anillo de la base —

asegúrese de rellenar el anillo de

la base de ducha—y aplique el

mortero en la par te inferior de borde

de adherencia del drenaje. Aplique

mortero utilizando una llana con

ranuras en V de 3/16 pulgada x

3/16 pulgada (5 mm x 5 mm) o llana

cuadrada o con ranuras en U de 1/8

pulgada x 1/8 pulgada

(3 mm x 3 mm).

9. Luego, instale el Conjunto de

Drenaje

Dur ock™ en el anillo de

la base de ducha en pendiente

preformada, presionando

firmemente para garantizar

una alineación adecuada y un

soporte completo al reborde de

adherencia. Una vez instalado,

aplique mortero de fraguado

delgado sin modificar en la parte

superior del reborde de adherencia.

No rellene las áreas en reba jo del

reborde de adherencia con el

mortero de fraguado delgado

hasta que el conjunto de rejilla

esté listo para instalar.

Nota: Si no hay acceso a la línea

de desechos desde la parte

inferior, el Conjunto de Drenaje

Duro ck deberá conectarse a la

línea de desechos a la vez que se

presiona contra el mortero.

10. Coloque la Membrana

Impermeable del Sistema de

Ducha

Du roc k™ en el mortero

de fraguado delgado utilizando

una llana de acabado, una

espátula de enmascaramiento

para paredes de yeso, o una

herramienta similar para eliminar

las bolsas de aire y garantizar una

adhesión adecuada a la base de

ducha en pendiente preformada

y al reborde de adherencia del

conjunto de drenaje.

11. Aplique mortero de fraguado

delgado sin modificar al substrato

y al borde de la base de ducha en

pendiente preformada, al borde(s)

y las paredes adyacentes—

utilizando una llana cuadrada o

con ranuras en U de ¼ pulgada x

3/8 pulgada (6 mm x 10 mm)—y

presione firmemente el borde(s)

de la ducha en el mortero.

12. Aplique mortero de fraguado

delgado sin modificar a la base de

ducha en pendiente preformada y

al borde(s) utilizando un llana con

ranuras en V de 3/16 pulgada x

3/16 pulgada (5 mm x 5 mm) o

llana cuadrada o con ranuras en U

de 1/8 pulgada x 1/8 pulgada

(3 mm x 3 mm).

13. Aplique la Membrana

Impermeable del Sistema de

Ducha

Duro ck al área restante de

la base en pendiente preformada,

traslapando las costuras 2

pulgadas como mínimo, y cubra

sobre y alrededor del borde(s).

Utilice una llana de acabado, una

espátula de enmascaramiento

para paredes de yeso, o una

herramienta similar para eliminar

las bolsas de aire y garantizar una

adhesión adecuada.

14. Instale las Esquinas Interiores

y Exteriores Preformadas del

Sistema de Ducha

sellar las uniones de los bordes/

paredes utilizando mortero de

fraguado delgado sin modificar

y una llana con ranuras en V de

3/16 pulgada x 3/16 pulgada

(5 mm x 5 mm) o llana cuadrada

o con ranuras en U de 1/8

pulgada x 1/8 pulgada (3 mm

x 3 mm). Coloque las esquinas

preformadas en el mortero de

fraguado delgado utilizando una

espátula de enmascaramiento

para paredes de yeso o llana para

esquinas para garantizar una

adhesión adecuada al borde(s) y

la pared de la ducha.

Duro ck™ para

Consejo práctico: Antes de

aplicar mortero a la base de ducha

y al anillo de la base de ducha,

establezca la ubicación del agujero

en la membrana de la ducha que

corresponde al área en rebajo en la

parte superior del cuerpo del drenaje

ajustando primero en seco el cuerpo

del drenaje y la membrana. Corte

la abertura en la membrana de

la ducha utilizando la plantilla de

corte de membrana incluida.

8

Page 10

(Conjunto de drenaje cont.)

Conjunto de rejillaPiso de la ducha

15. La aplicación de impermeabilización

del Sistema de Ducha

ha finalizado. Antes de probar la

impermeabilidad e instalar los

azulejos, deje que transcurra un

mínimo de 24 horas p ara

garantizar el curado adecuado

del mortero de fraguado delgado

y la impermeabilidad de todas las

costuras y conexiones.

16. Inserte un tapón de prueba

del agua y llene la ducha con

aproximadamente 3 pulgadas

de agua. Luego de transcurridas

24 horas, verifique que no

haya fugas y retire el tapón.

Esta prueba confirma que la

impermeabilización es estanca.

17. Ahora está listo para aplicar

mortero de fraguado delgado a

las paredes y el piso de la ducha e

instalar los azulejos.

Dur ock

1. El Conjunto de Rejilla del Sistema de

Ducha

Duro ck™ y las losetas para

pisos se instalan simultáneamente.

Consejo práctico: Retire el

tapón temporal de la bandeja

para rejilla empujándolo desde

la parte interior, y luego aplique

una capa delgada de vaselina

a los bordes del tapón para

evitar que la lechada se adhiera

a los bordes del tapón (esto

es especialmente importante

cuando se utiliza lechada de

uretano o epoxi, cuya adherencia

es más fuerte).

2. Instale el tapón temporal en la

bandeja para rejilla y encaje el

conjunto en la pieza elevadora

de la bandeja para rejilla. Aplique

mortero de fraguado delgado

al lado inferior de la bandeja

para rejilla y al área en rebajo

del reborde de adherencia del

conjunto de drenaje. Coloque el

conjunto en la placa de ajuste

horizontal, y luego coloque el

conjunto de rejilla en el área de

rebajo del cuerpo del drenaje.

Consejo práctico: Durante

la instalación de la lechada,

exponga la superficie superior

del tapón temporal a los bordes

exteriores mientras mantiene las

juntas de lechada que rodean el

tapón lo más llenas posibles.

3. Luego de instalar la lechada en

el piso de la ducha, espere un

mínimo 24 horas antes de retirar

el tapón temporal. Para retirar el

tapón temporal luego de haberse

instalado la lechada, presione

firmemente unas cuantas veces

el centro del tapón temporal para

crear una línea de separación

entre el borde del tapón y las

juntas de la lechada adyacentes.

Inserte un tornillo delgado (tornillo

para pared de yeso o similar) en

uno de los cuatro orificios pilotos

del tapón temporal y enrosque el

tornillo lo suficientemente para

que pueda agarrar bien el tapón, y

luego utilice el tornillo para retirar

el tapón. Instale la rejilla.

Nota: El tapón temporal

garantiza que la bandeja para

rejilla permanezca completa y

perfectamente cuadrada para

la instalación subsiguiente

de la rejilla. Extraer el tapón

temporal antes de tiempo podría

ocasionar el agrietamiento de la

lechada e impedir que se ajuste

correctamente a la rejilla.

Para la aplicación de losetas,

consulte al fabricante del

material de fraguado para

obtener información específica

relacionada al tipo de mortero, así

como el tamaño y tipo de llana.

Alinee el conjunto de rejilla con la

Para obtener instrucciones detalladas adicionales,

visite durockshowersystem.com

distribución de las losetas para

pisos, y ajuste verticalmente para

garantizar que el tapón temporal

esté nivelado o esté levemente

debajo de la superficie de las

losetas adyacentes.

Conjunto de drenaje y Conjunto de rejilla

Rejilla

Tapón temporal

Bandeja para rejilla

Pieza elevadora de la

bandeja para rejilla

Placa de ajuste

horizontal

Cuerpo del drenaje

con reborde de

adherencia integrado

Anillo O

Buje PVC o ABS con manguito de

acoplamiento de 2 pulgadas (5 cm)

9

Extractor de

rejilla

Page 11

Découvrez le dernier Système de Douche Durock™ novateur et

étanche pour douches carrelées.

Le Système de Douche Durock poursuit la tradition de qualité, de performance et de fiabilité qui a distingué les

produits

de douche en procurant : un receveur de douche en PSE avec pente préformée qui s’installe plus rapidement

que des receveurs traditionnels sur lit de mortier, une membrane d’étanchéité fine et durable, et un ensemble de

drainage facile à positionner qui accepte toutes les options de grilles de 10 cm ou de 12,5 cm (4 po ou 5 po) du

Système de Douche

Durock depuis 30 années. Le Système de Douche Durock facilite et accélère l’étanchéité des installations

Durock (grilles vendues séparément).

Kits de Système de Douche Durock

drain décentré de 81,2 cm x 152,4 cm

(32 po x 60 po)

drain centré de 81,2 cm x 152,4 cm

(32 po x 60 po)

drain centré de 122 cm x 122 cm

(48 po x 48 po)

Caractéristiques particulières

La Membrane d’Étanchéité

une membrane d’étanchéité parevapeur, flexible, durable, appliquée à

la feuille, d’une épaisseur uniforme

de 0,3 mm (0,012 po) qui facilite

l’installation sans surépaisseur

excessive.

Le Système de Douche

facilite et accélère l’étanchéité

des installations de douche en

procurant : un receveur de douche

avec pente préformée qui s’installe

plus rapidement que des receveurs

traditionnels sur lit de mortier, une

membrane d’étanchéité fine et

durable, et un ensemble de drainage

facile à positionner qui accepte toutes

les options de grilles de 10 cm ou de

12,5 cm (4 po ou 5 po) du Système

de Douche

séparément).

Le receveur de douche avec

pente préformée est idéal pour les

constructions neuves et les projets de

réparation ou de rénovation.

Le receveur réduit significativement

le temps d’installation comparé

aux douches sur lit de mortier et sa

pente préformée graduelle facilite

l’installation des carreaux.

Duro ck (grilles vendues

Duro ck––

Duro ck

Outils et matériaux

Lunettes de sécurité

Gants

Ciseaux

Truelles

- truelle à encoches en V de 5 mm

x 5 mm (3/16 po x 3/16 po) ou à

encoches carrées ou en U de 3 mm x

3 mm (1/8 po x 1/8 po)

- truelle à encoches carrées ou en U

de 6 mm x 10 mm (1/4 po x 3/8 po)

- truelle de finition

- truelle carrée

Mortier à couche mince non modifié

conforme à ANSI 118.1

(minimum 26 kg, 50 lbs)

Couteau universel

Mètre ruban

Perceuse

Parois de douche

1. Utiliser seulement un fond mural

homologué pour les endroits

humides, tels que le Panneau de

Ciment

Duro ck®, ou le Panneau

Support de Carreaux

2. Appliquer un mortier à couche

mince non modifié sur le fond

mural au moyen d’une truelle à

encoches en V de 5 mm x 5 mm

(3/16 po x 3/16 po) ou à encoches

carrées ou en U de 3 mm x 3 mm

(1/8 po x 1/8 po).

Conseil : Le mortier doit être

fluide mais préserver les rainures

formées par la truelle.

3. Sceller la Membrane d’Étanchéité

du Système de Douche

dans le mortier à l’aide d’une

truelle de finition, un couteau de

rubanage pour cloison sèche, ou

un outil similaire pour enlever les

poches d’air et assurer une forte

adhésion.

Fibe rock®.

Duro ck™

Conseil : Travailler du centre de

la paroi vers les bords.

4. Faire chevaucher toutes les

sections adjacentes de la

Membrane d’Étanchéité du

Système de Douche

5 cm (2 po) au minimum.

Remarque : Un chevauchement

de la membrane à la manière

de tuiles n’est pas nécessaire

tant que tous les joints se

chevauchent sur 5 cm (2 po)

au minimum. Alternativement,

les sections adjacentes de la

Membrane d’Étanchéité du

Système de Douche

peuvent être assemblées en

about, puis raccordées au moyen

de la Bande d’Étanchéité de 13

cm (5 po) du Système de Douche

Duro ck™.

Duro ck sur

Duro ck

10

Page 12

Parois de douche

suite

Joint de tuyau

suite

Sol de la douche

5. Installer une Bande d’Étanchéité

du Système de Douche

dans tous les angles intérieurs

verticaux des parois en utilisant

un mortier à couche mince non

modifié et une truelle à encoches

en V de 5 mm x 5 mm

(3/16 po x 3/16 po) ou à encoches

carrées ou en U de 3 mm x 3 mm

(1/8 po x 1/8 po).

Conseil : Pour centrer la

bande d’étanchéité pour angles

intérieurs des parois, plier la

bande d’étanchéité en deux

sur toute la longueur. Sceller

la bande d’étanchéité dans

le mortier à couche mince au

moyen d’un couteau de rubanage

ou d’une truelle carrée.

Duro ck™

Joint de tuyau

Les Joints de Tuyaux Du rock™ sont

conçus pour sceller les percées de

tuyaux dans les assemblages de

parois étanches, par exemple les

percées de tuyaux des pommes de

douche, des becs de baignoire, des

douchettes, etc.

1. Appliquer un mortier à couche

mince non modifié sur le fond au

moyen d’une truelle à encoches

en V de 5 mm x 5 mm

(3/16 po x 3/16 po) ou à encoches

carrées ou en U de 3 mm x 3 mm

(1/8 po x 1/8 po).

2. Placer le joint sur le tuyau et le

sceller dans le mortier à l’aide

d’une truelle de finition, un

couteau de rubanage pour cloison

sèche, ou d’un outil similaire pour

enlever les poches d’air et assurer

une forte adhésion.

Joint de robinet

mélangeur

Les Joints de Robinet Mélangeur

Duro ck™ sont conçus pour sceller les

passages dans les assemblages de

parois étanches autour des baignoires

et des douches.

1. Appliquer un mortier à couche

mince non modifié sur le fond au

moyen d’une truelle à encoches

en V de 5 mm x 5 mm

(3/16 po x 3/16 po) ou à encoches

carrées ou en U de 3 mm x 3 mm

(1/8 po x 1/8 po).

2. Placer le joint dans le passage du

robinet mélangeur et le sceller

dans le mortier à l’aide d’une

truelle de finition, un couteau de

rubanage pour cloison sèche, ou

d’un outil similaire pour enlever

les poches d’air et assurer une

forte adhésion.

1. Placer l’anneau du receveur de

douche sur le sous-plancher à

l’emplacement voulu pour le drain.

Au moyen du gabarit démontable

de découpe du sous-plancher

placé sur l’anneau du receveur de

douche, tracer l’emplacement du

trou sur le sous-plancher avant de

procéder à la découpe.

Remarque : L’alignement

de la grille de drainage en

considération de la pose du

carrelage doit être établi avant de

découper le trou dans le sousplancher.

Conseil : Poser à sec le receveur

de douche avec pente préformée,

puis aligner l’anneau du receveur

de douche avec les repères

d’orientation sur le receveur à la

position voulue avant de marquer

et de procéder à la découpe du

sous-plancher.

2. Appliquer un mortier à couche

mince non modifié au sousplancher au moyen d’une truelle

à encoches carrées ou en U de 6

mm x 10 mm (1/4 po x 3/8 po).

Le plancher doit être de niveau

avant l’installation du receveur

de douche. En cas de besoin,

appliquer une Sous-couche

Autolissante

l’installation.

3. Sceller fermement le Receveur

avec Pente Préformée du

Système de Douche

le mortier. Vérifier le dessous

du receveur pour garantir

l’application complète du mortier.

Duro ck™ avant

Duro ck™ dans

4. Retirer le gabarit de découpe

intégré––utilisé pour la découpe

du trou de drainage dans le

sous-plancher––de l’anneau

du receveur de douche avant

l’installation.

5. Installer l’anneau du receveur

de douche en le scellant

complètement dans le mortier à

couche mince et le positionnant

de manière à respecter les

repères d’orientation sur le

receveur de douche.

6. Appliquer un mortier à couche

mince non modifié au receveur de

douche avec pente préformée et

aux raccords des parois au moyen

d’une truelle à encoches en V de

5 mm x 5 mm (3/16 po x 3/16 po)

ou à encoches carrées ou en U

de 3 mm x 3 mm (1/8 po x 1/8 po).

Sceller les Angles Intérieurs

Préformés du Système de Douche

Duro ck™ dans le mortier au moyen

d’un couteau de rubanage pour

cloison sèche ou d’une truelle

carrée pour enlever les poches

d’air et assurer une forte adhésion

entre le receveur de douche et le

raccord de paroi.

Pour plus de détails concernant les instructions,

visiter le site durockshowersystem.com

11

Page 13

Sol de la douche

suite

Sol de la douche

Ensemble de drainage (Voir l’Ensemble de drainage et l’Ensemble de grille à la page 13)

7. Installer une Bande d’Étanchéité

de Système de Douche

dans tous les raccords de sol et

de paroi en utilisant un mortier à

couche mince non modifié et une

truelle à encoches en V de

5 mm x 5 mm (3/16 po x 3/16 po)

ou à encoches carrées ou en U de

3 mm x 3 mm (1/8 po x 1/8 po).

Duro ck

Conseil : Pour centrer la bande

d’étanchéité dans les raccords

de sol et de paroi, plier la bande

d’étanchéité en deux sur toute

la longueur. Sceller la bande

d’étanchéité dans le mortier à

couche mince au moyen d’un

couteau de rubanage ou d’une

truelle carrée.

8. Appliquer le mortier à couche

mince non modifié sur la surface

du receveur de douche avec

pente préformée et sur l’anneau

du receveur––s’assurer de

remplir l’anneau du receveur de

douche– – et appliquer le mortier

au bas de la bride de collage du

drain. Appliquer le mortier au

moyen d’une truelle à encoches

en V de 5 mm x 5 mm

(3/16 po x 3/16 po) ou à encoches

carrées ou en U de 3 mm x 3 mm

(1/8 po x 1/8 po).

9. Ensuite, installer l’Ensemble de

Drainage

du receveur de douche avec

pente préformée, en appuyant

fermement pour garantir

l’alignement correct et le support

complet de la bride de collage.

Une fois en place, appliquer du

mortier à couche mince non

modifié sur le dessus de la bride

de collage. Ne pas remplir les

renfoncements de la bride de

collage avec du mortier à couche

mince avant que l’ensemble de

grille soit prêt à être installé.

Remarque : S’il n’y a pas

d’accès à la conduite d’évacuation

depuis le dessous, l’Ensemble

de Drainage

être connecté à la conduite

d’évacuation en même temps qu’il

est enfoncé dans le mortier.

10. Sceller la Membrane d’Étanchéité

du Système de Douche

dans le mortier à l’aide d’une

truelle de finition, un couteau de

rubanage pour cloison sèche, ou

d’un outil similaire pour enlever

les poches d’air et assurer une

forte adhésion entre le receveur

de douche avec pente préformée

et la bride de collage de

l’ensemble de drainage.

Durock™ dans l’anneau

Duro ck doit

Duro ck

11. Appliquer le mortier à couche

mince non modifié au sousplancher et au bord du receveur

de douche avec pente préformée,

au seuil(s), et au parois

adjacentes– –au moyen d’une

truelle à encoches carrées ou en

U de 6 mm x 1 mm (1/4 po x 3/8

po)––et appuyer fermement le(s)

seuil(s) de douche dans le mortier.

12. Appliquer un mortier à couche

mince non modifié au receveur de

douche avec pente préformée et

sur le(s) seuil(s) au moyen d’une

truelle à encoches en V de 5 mm

x 5 mm (3/16 po x 3/16 po) ou à

encoches carrées ou en U de 3

mm x 3 mm (1/8 po x 1/8 po).

13. Appliquer la Membrane

d’Étanchéité de Système de

Douche

Durock à la section

restante du receveur de douche

avec pente préformée, en faisant

chevaucher les joints de 5 cm (2

po) au minimum, et en recouvrant

le(s) seuil(s) ainsi que les abords.

Utiliser une truelle de finition, un

couteau de rubanage pour cloison

sèche ou un outil similaire pour

enlever les poches d’air et assurer

une forte adhésion.

14. Installer des Angles Intérieurs et

Extérieurs Préformés du Système

de Douche

les raccords seuil/parois en

utilisant un mortier à couche

mince non modifié et une truelle

à encoches en V de 5 mm x 5 mm

(3/16 po x 3/16 po) ou à encoches

carrées ou en U de 3 mm x 3

mm (1/8 po x 1/8 po). Sceller les

angles préformés dans le mortier

à couche mince au moyen d’un

couteau de rubanage ou d’une

truelle carrée pour garantir une

adhésion forte entre le(s) seuil(s)

et la paroi.

Durock™ pour sceller

Conseil : Avant d’appliquer le

mortier au receveur de douche et

à l’anneau du receveur de douche,

établir l’emplacement du trou

dans la membrane de la douche

qui correspond au renfoncement

en haut du corps du drain en

montant d’abord à sec le corps du

drain et la membrane. Découper

l’ouverture dans la membrane de

la douche au moyen du gabarit de

découpe de la membrane.

12

Page 14

Suite de l’Ensemble de drainage

Ensemble de grilleSol de la douche

15. L’application de l’étanchéité pour

Système de Douche

maintenant terminée. Avant de

vérifier avec de l’eau et de poser

les carreaux, laisser un minimum

de 24 heures pour garantir

la prise correcte du mortier à

couche mince ainsi que la bonne

étanchéité de tous les joints et

raccords.

16. Insérer un bouchon d’essai et

remplir la douche d’environ 7,5

cm (3 po) d’eau. Après 24 heures,

vérifier l’absence de fuite et

enlever le bouchon. Ceci confirme

que l’étanchéité est bonne.

17. Tout est prêt maintenant pour

l’application du mortier à couche

mince sur les parois et le sol de

la douche et pour la pose les

carreaux.

Duro ck est

1. L’Ensemble de Grille du Système

de Douche

même temps que les carreaux

pour sol.

Conseil : Enlever le bouchon

temporaire du cadre de grille en

le poussant depuis l’intérieur,

puis appliquer une fine couche de

gelée de pétrole sur les bords du

bouchon pour empêcher le coulis

d’adhérer autour du bouchon

(ceci est plus particulièrement

important lors de l’utilisation de

coulis à l’uréthane ou à l’époxy

dont l’adhérence est plus forte).

2. Installer le bouchon temporaire

dans le cadre de grille et emboîter

l’ensemble dans la rehausse

de cadre de grille. Appliquer un

mortier à couche mince sur le

dessous du cadre de grille ainsi

que dans le renfoncement de la

bride de collage de l’ensemble

de drainage. Placer l’ensemble

dans la platine de positionnement

horizontal, puis placer l’ensemble

de la grille dans le renfoncement

du corps du drain.

Duro ck™ est installé en

Conseil : Pendant l’application

du coulis, laisser la surface du

bouchon temporaire exempte

de coulis jusqu’à ses bords

extérieurs tout en s’assurant que

les joints les plus proches du

bouchon sont aussi bien remplis

que possible.

3. Après l’application du coulis sur

le sol de la douche, attendre au

moins 24 heures avant d’enlever

le bouchon temporaire. Pour

enlever le bouchon temporaire

après l’application du coulis,

appuyer fermement à plusieurs

reprises sur le centre du bouchon

temporaire pour créer une ligne

de séparation entre le bord du

bouchon et les joints de coulis

avoisinants.

Insérer une vis effilée (vis à

cloison sèche ou similaire) dans

un des quatre avant-trous du

bouchon temporaire et la visser

suffisamment loin pour disposer

d’une bonne prise, puis utiliser

la vis pour retirer le bouchon.

Installer la grille.

Remarque : Le bouchon

temporaire garantit que le cadre

de grille reste complètement

d’équerre et sans déformation

aucune pour l’installation

ultérieure de la grille. Enlever

le bouchon temporaire

prématurément peut provoquer la

fissuration des joints, et créer un

ajustement incorrect de la grille.

Pour la pose des carreaux, se

reporter aux instructions du

fabricant du produit adhésif

pour les indications spécifiques

correspondantes au type de

mortier, ainsi qu’à la dimension et

au type de truelle.

Aligner l’ensemble de la grille

Pour plus de détails concernant les instructions,

visiter le site durockshowersystem.com

avec le carrelage et l’ajuster

verticalement pour garantir que le

bouchon temporaire affleure ou

soit très légèrement en-dessous

de la surface des carreaux

environnants.

Ensemble de drainage et ensemble de grille

Grille

Bouchon temporaire

Cadre de grille

Rehausse de cadre

de grille

Platine de positionnement

horizontal

Corps de drain avec

bride de collage

intégrée

Joint torique

Manchon PVC ou ABS avec douille

de raccordement de 5 cm (2 po)

13

Extracteur de

grille

Page 15

Notes/Notas/Remarques

14

Page 16

Product Information

Visit durockshowersystem.com to download the

Durock™ Shower System Installation Guide.

complete

Safety First!

Follow good safety and industrial hygiene practices

during handling and installation of all products and

systems. Take necessary precautions and wear

the appropriate personal protective equipment

as needed. Read material safet y data sheets and

related literature on products before specification

and/or installation.

Notice

We shall not be liable for incidental and

consequential damages, directly or indirectly

sustained, nor for any loss caused by application of

these goods not in accordance with current printed

instructions or for other than the intended use.

Our liability is expressly limited to replacement of

defective goods. Any claim shall be deemed waived

unless made in writing to us within thirty (30) days

from date it was or reasonably should have been

discovered.

Trad emar ks

The following are trademarks of United States

Gypsum Company or a related company:

USG, DUROCK, FIBEROCK, STRENGTH BENEATH

THE SURFACE, and the blue, black, and white

design elements.

Información del producto

Visite durockshowersystem.com para descargar la

guía completa de instalación del Sistema de Ducha

Duro ck™.

¡La segu ridad es lo prime ro!

Siga todas las prác ticas de seguridad e higiene

industrial durante el manejo y la instalación de todos

los productos y sistemas. Tome las precauciones

necesarias y lleve puesto el equipo de protección

personal apropiado según sea necesario. Consulte las

hojas de datos de seguridad del material y cualquier

información relacionada sobre los productos antes de

la especificación y/o la instalación.

Aviso

No nos haremos responsables por daños incidentales

o indirectos, sostenidos directa o indirectamente, ni

por cualquier pérdida causada por la aplicación de

estos productos sin seguir las instrucciones impresas

incluidas, o por el uso que no sea el correspondiente

a su diseño. Nuestra responsabilidad se limita

expresamente al reemplazo de productos defectuoso s.

Cualquier reclamación será considerada nula a menos

que se nos haga llegar a nosotros por escrito en un

plazo de treinta (30) días a partir de la fecha en que

se descubrió el problema o en que, razonablemente,

debió haberse descubierto.

Marcas comerciales

Las siguientes son marcas comerciales de United

States Gypsum C ompany o de una compañía

relacionada: USG, DUROCK, FIBEROCK, STRENGTH

BENEATH T HE SURFAC E, y los elementos de diseño

azul, negro y blanco.

Informations sur le produit

Visiter durockshowersystem.com pour télécharger le

guide complet du Système d’I nstallation de Douche

Duro ck™.

La sécurité d’abord!

Appliquer de bonnes méthodes de sécurité et

d’hygiène au t ravail pendant la manipulation et

l’installation de tous les produits et systèmes. Prendre

toutes les précautions néc essaires et au besoin porter

un équipement de protection individuel approprié.

Consulter les fiches signalétiques et les brochures

connexes des produits avant leur spéci fication et/ou

leur installation.

Avis

Nous ne pouvons être tenus responsables pour

des dommages connexes ou consécutifs, encourus

directement ou indirectement, ou pour toute perte

causée par l’application de ces produit s si les

instructions courantes imprimées n’ont pas été

suivies, ou encore si le produit est utilisé pour une fi n

autre que son usage prévu. Notre responsabilité se

limite expressément au remplacement des produits

défectueux. Toute réclamation sera refusée à moins

d’être soumise par écrit dans les trente (3 0) jours

suivant la date du dommage ou à par tir du moment où

il devrait avoir été raisonnablement découvert.

Marques de commerce

Les marques de commerce suivantes sont la propriété

de United States Gypsum C ompany ou d’une

entreprise associée : USG, DUROCK, FIBEROCK,

STRENGT H BENEATH THE S URFACE et les éléments

de design bleu, noir et blanc.

For product information and literature:

durockshowersystem.com

Para solicitar información y literatura de

productos: durockshowersystem.com

Pour obtenir des informations et de

la documentation sur les produits :

durockshowersystem.com

United States Gypsum Company

550 West Adams Street

Chicago, IL 60661

CB598/INST/7-13

© 2013 United States Gypsum Company

Printed in U.S.A.

Impreso en EE.UU.

Imprimé aux É.-U.

Loading...

Loading...