Page 1

Keysight N9342C/43C/44C

Handheld Spectrum Analyzer

99 Washington Street

Melrose, MA 02176

800.517.8431

TestEquipmentDepot.com

Notice: This document contains references to

Agilent. Pl

Measurement business has become

Keysight Technologies.

ease note that Agilent’s Test and

User's Guide

Page 2

Notices

© Keysight Technologies, Inc. 2010-2015

No part of this manual may be reproduced in

any form or by any means (including electronic

storage and retrieval or translation into a

foreign language) without prior agreement and

written consent from Keysight Technologies,

Inc. as governed by United States and

international copyright laws.

Part Number

N9342-90002

Edition

Fifth Edition, February 2015

Printed in China

Keysight Technologies, Inc.

No. 116 Tian Fu 4th Street HiTech Industrial Zone (South)

Chengdu 610041, China

Software Revision

This guide is valid for A.03.40 revisions of the

N9342C/43C/44C firmware or later.

CAUTION

A CAUTION notice denotes a hazard. It

calls attention to an operating procedure,

practice, or the like that, if not correctly

performed or adhered to, could result in

damage to the product or loss of important data. Do not proceed beyond a CAU-

TION notice until the indicated conditions

are fully understood and met.

WARNING

A WARNING notice denotes a hazard. It

calls attention to an operating procedure, practice, or the like that, if not correctly performed or adhered to, could

result in personal injury or death. Do not

proceed beyond a WARNING notice until

the indicated conditions are fully understood and met.

Battery Marking

Keysight Technologies, through Rechargeable

Battery Recycling Corporation (RBRC), offers free

and convenient battery recycling options in the

U.S. and Canada.

Warranty

The material contained in this document is

provided “as is,” and is subject to being

changed, without notice, in future editions.

Further, to the maximum extent permitted by

applicable law, Keysight disclaims all

warranties, either express or implied, with

regard to this manual and any information

contained herein, including but not limited to

the implied warranties of merchantability

and fitness for a particular purpose. Keysight

shall not be liable for errors or for incidental

or consequential damages in connection with

the furnishing, use, or performance of this

document or of any information contained

herein. Should Keysight and the user have a

separate written agreement with warranty

terms covering the material in this document

that conflict with these terms, the warranty

terms in the separate agreement shall

control.

Technology Licenses

The hardware and/or software described in

this document are furnished under a license

and may be used or copied only in accordance

with the terms of such license.

Restricted Rights Legend

If software is for use in the performance of a

U.S. Government prime contract or

subcontract, Software is delivered and

licensed as “Commercial computer software”

as defined in DFAR 252.227-7014 (June 1995),

or as a “commercial item” as defined in FAR

2.101(a) or as “Restricted computer software”

as defined in FAR 52.227-19 (June 1987) or any

equivalent agency regulation or contract

clause. Use, duplication or disclosure of

Software is subject to Keysight Technologies’

standard commercial license terms, and

non-DOD Departments and Agencies of the

U.S. Government will receive no greater than

Restricted Rights as defined in FAR

52.227-19(c)(1-2) (June 1987). U.S.

Government users will receive no greater than

Limited Rights as defined in FAR 52.227-14

(June 1987) or DFAR 252.227-7015 (b)(2)

(November 1995), as applicable in any

technical data.

Page 3

1 Overview

Introduction 2

Front Panel Overview 5

Display Annotations 6

Top Panel Overview 8

Instrument Markings 9

2 Getting Started

Checking Shipment and Order List 12

Power Requirements 13

AC Power Cords 14

Safety Considerations 15

Working with Batteries 18

Powering the Analyzer on for the First Time 20

Preparation for Use 21

Power On and Preset Settings 21

Factory Default Settings 22

Visual and Audio Adjustment 23

General System Settings 23

Timed Power On/Off 24

IP configuration 24

Ext Input 24

Show System 25

Adding an Option 26

Show Error 26

Perform Calibration 26

Data Securities 28

Upgrading Firmware 28

Probe Power Output 29

HSA and BSA PC software 30

Making Basic Measurements 31

Contents

Page 4

3 Functions and Measurements

Measuring Multiple Signals 34

Measuring a Low-Level Signal 39

Improving Frequency Resolution and Accuracy 44

Making Distortion Measurements 45

Making a Stimulus Response Transmission Measurement 51

Measuring Stop Band Attenuation of a Low-pass Filter 53

Making a Reflection Calibration 55

Measuring Return Loss Using the Reflection Calibration Routine 57

Making a Power Measurement with USB Power Sensor 58

Spectrum Monitor 68

Demodulating an FM Signal 70

Modulation Analysis 72

AM/FM Modulation Analysis 72

ASK/FSK Modulation Analysis 75

Channel Scanner 78

Top/Bottom N Channel Scanner 78

List N Channel Scanner 80

Channel Scanner Setup 82

Cable & Antenna Test 83

Preparation 83

Measuring Cable Reflection 84

Measurement Functions 87

File Operation 90

Viewing a file list 90

Saving a file 92

Deleting a file 93

Loading a file 93

Page 5

4Key Reference

Amptd 96

Display 102

BW 103

RBW 103

VBW 103

VBW/RBW 104

Avg Type 104

Sweep 106

Sweep Time 106

Sweep Type 107

Single Sweep 107

Trigger 108

Gated Sweep 109

Sweep Setup 110

Enter 111

ESC/Bksp 111

Frequency 112

Marker 115

Marker 115

Marker Trace 115

Mode 116

Marker To 118

Function 119

Marker Table 119

Read Out 120

Zoom In/Out 120

Delta Ref 121

All Off 121

Logging Start/Stop 121

Peak 122

MEAS 124

OBW 124

ACPR 125

Channel Power 126

Spectrum Emission Mask (SEM) 128

Page 6

MODE 135

Spectrum Analyzer 135

Tracking Generator 135

Power Meter 138

Spectrum Monitor 144

SPAN 148

Span 148

Full 148

Zero 148

Last Span 148

Trace 149

Trace 149

Clear Write 149

Max Hold 149

Minimum Hold 150

View 150

Blank 150

Detector 150

Average 152

Average Dura. 152

Limit 153

Limit Type 153

Limit Line 153

Limits 153

Limits Edit 154

Margin 154

Save Limits 154

Recall Limits 154

5Error Messages

Overview 156

Error Message List 157

6 Troubleshooting

Check the basics 162

Contact Keysight Technologies 164

Page 7

7 Menu Map

Display 167

Sweep 168

FREQ 169

Limit 169

Marker 170

Peak 171

File/Mode - Task Planner 172

Mode - Tracking Generator 173

Mode - Modulation Analysis (AM/FM) 174

Mode - Modulation Analysis (ASK/FSK) 175

Mode - Cable & Antenna Test 176

Mode - Power Meter 177

Meas (1) 178

Meas (2) 179

Span 179

System 180

Trace 181

Page 8

Page 9

Overview

1 Overview

The Keysight N934XC is a series of handheld

spectrum analyzer with a frequency range from

100 kHz to 20.0 GHz.

N9342C: 100 kHz - 7 GHz

N9343C: 1 MHz - 13.6 GHz

N9344C: 1 MHz - 20 GHz

It provides good usability and exceptional

performance for installation and maintenance,

spectrum monitoring, and on- site repair tasks. It

provides several measurement modes for different

applications. Each mode offers a set of automatic

measurements that pre- configure the analyzer

settings for ease of use.

1

Page 10

Overview

Introduction

Introduction

The analyzer provides ultimate measurement

flexibility in a package that is ruggedized for field

environments and convenient for mobile

applications.

Functionality and Feature

The analyzer provides you with a comprehensive

functionality set and measurement convenience,

including:

• Power Measurement

provides power measurement functionality on

(Occupied Bandwidth), channel power, and

OBW

(Adjacent Channel Power Ratio).

ACPR

• Spectrum Emission Mask

Provides a Pass/Fail testing capability with a

mask for out- of- channel emissions measurement.

• Tracking Generator (Option TG7)

Provides an RF source for scalar network

analysis (exclusive for N9342C).

• Spectrum Monitor (Option SIM)

Provides

a signal over time. The analyzer can be used to

monitor the signal capturing performance or

intermittent

• High-sensitivity Measurement (Option PA7, P13, P20)

Includes a pre- amplifier, enabling highly

sensitivity measurements, this can be used to

measure the low- level signals.

• High Accuracy Power Measurement

Supports Keysight U2000 series (option PWM)

and U2020 series (option PWP) power sensors

for high accuracy power measurement as a

power meter.

the capability to analyze the stability of

event over extended periods of time.

2

Page 11

Overview

Introduction

• Baseband Channel (Option BB1)

Provides superior DANL and SSB between 3 kHz

to 12 MHz.

• Cable & Antenna Test (Option CA7; Requires option TG7)

Provides a built- in VSWR bridge. Return loss,

cable loss and distance- to- fault measurement

function are available for the field test.

• Modulation Analysis

Provides AM/FM (option AMA) and ASK/FSK

(Option DMA) modulation analysis function.

• Task Planner (Option TPN)

Provides task planner function to integrate

different measurements for test automation.

• Time-gated Spectrum Analysis (Option TMG)

Measures any one of several signals separated in

time and excludes interfering signals.

• Channel Scanner (Option SCN)

provide the channel scan function in spectrum

monitoring, coverage test, and band clearance.

3

Page 12

Overview

640 480×

Introduction

Optimized Usability

The analyzer provides the enhanced usability as

below:

• The 6.5-inch TFT colorful LCD screen (

enables you to read the scans easily and clearly

both

• The arc-shaped handle and rugged rubber casing

ensure a comfortable and firm hold.

• Socket/Telnet remote control via USB, and LAN

port.

• The PC Software on help kit CD provides further

editing and data analysis functions.

• The 3-hour-time battery provides continuous wo

time during field testing.

• The light sensor adjusts the display brightness

according to the environment to save power.

• Keys are back-lit provides easy access in

low- light conditions.

• Keypad can be locked and unlocked with pass-

word to forbid undesired keypad operation.

• Built-in GPS, with built- in GPS antenna (Optio

GPS) offers the GPS location for the field testing.

• User Data Sanitation (Option SEC) allows user to

erase all customized files and data in anal

for security.

pixels)

indoors and outdoors.

rk

n

yzer

4

Page 13

Front Panel Overview

N9342CN

Handheld Spectr um Anal yzer

100 kHz - 6.0GHz

Preset

System File Limi t Disp

1

ABC

2DEF 3

GHI

4JKL 5MNO 6PQR

7STU 8

VWX9YZ_

F1

F2

F3

F4

F5

F6

F7

Mode Meas Trace Amptd

User

Span

Save

Freq

0

ENTER

Sweep

BW

SHIFT

Peak

Marker

Esc/Bksp

14

1

2

3

5

6

7

8

9

10

11

1213

4

Front Panel Overview

Caption Function

1 Power Switch Toggles the analyzer between on and off

2 Function keys Includes functional hardkeys for measurements.

3 Preset Returns the analyzer to a known state and turns

4 SHIFT Switches alternate upper function of the function

5 Enter Confirms a parameter selection or configuration

6 Peak/Marker Activates the peak search or marker function

7 ESC/Bksp Exits and closes the dialog box or clears the letter

8 Alphanumeric

keys

9 Arrow keys Increases or decreases a parameter step by step

10 Knob Selects the mode or edits a numerical parameter

11 Softkeys Indicates current menu functions on the screen

12 Speaker Actives in demodulation mode

13 Light Sensor Adjusts the screen and hardkey back-light

14 Screen Displays spectrum traces and status information

on/off the power save feature (press for 1 sec.)

keys and Peak/Marker hardkey.

input as a back space key.

includes a positive/negative, a decimal point and

ten alphanumeric keys

according to the environmental light.

Overview

5

Page 14

Overview

1

2

3

4

8

9

10

11

12

13

16

15

19

18

5

20

17

14

6

PA

7

Display Annotations

Display Annotations

Description Associated Function Key

1 Time and date [System] > {Time/Date}

2 Reference level [Amptd]

3 Amplitude scale [Amptd] > [Scale/Div]

4 Average [Trace] > {More} > {Average}

5 Trace and detector [Trace] > {More} > {Detector}

6 Preamplifier and

sweep and trigger mode

7 Sweep status and

trigger type

8 Center frequency or

start frequency

9 Resolution Bandwidth [BW] > {RBW}

10 Display status line Displays status and messages.

6

[Amptd] > {Preamp} and

[Sweep] > {Trigger}

[Sweep] > {Sweep Setup} and

[System] > {Port setting} > {Ext Input}

[Freq]

Page 15

Display Annotations

Overview

11 Video bandwidth and

frequency offset

12 Frequency span or

stop frequency

13 Sweep time [Sweep] > {Sweep Time}

14 Status annunciator Power and USB stick status

15 Softkey menu See key label description in the Key

16 Softkey menu title Refers to the current activated

17 Remote annunciator

and shift annunciator

18 Marker information [Marker]

19 GPS information [System] > {More} > {GPS}

20 Attenuation [Amplitude] > {Attenuation}

[BW] > {VBW} or [Freq] > {Freq

Offset}

[Span] or [Freq] > {Stop Freq}

Reference for more information.

function

Indicates the remote mode and shift

key mode

7

Page 16

Overview

Ext Pow er

Charging

PC

Ext Trig /

RF Out 50

Antenna

GPS

Probe

Power Ext Ref

12-16

VDC

55

W MAX

RF Input 50

50 VDC MAX

30dBm (1W) M AX

50 VDC MAX

REV

PWR

30dBm (1W) MAX

LAN

1

2

10

3

4

5

7

8

12

6

9

11

Top Panel Overview

Top Panel Overview

Items Function

1External DC power

connector

2 LED indicator (Charging) Lights (On) when the battery is charging

3 LED indicator Lights (On) when external DC power is

4 USB interface (Device) Connects to a PC

5 USB interface (Host) Connects to a USB memory stick or disk

6 Headphone Connects to a headphone

7 LAN Interface Connects to a PC for SCPI remote control

8 RF OUT Connector The output for the built-in tracking generator.

9 Probe power connector Provides power for high- impedance AC probes

10 EXT TRIG IN/REF IN

(BNC, Female)

11 GPS antenna connector Connects an GPS Antenna (option GPA) for GPS

12 RF IN Connector (50 Ω) Accepts an external signal input.

Provides input for the DC power source via an

AC-DC adapter, or Automotive type DC adapter.

connected.

Enabled with Option TG7.

or other accessories (+15 V, –12 V, 150 mA

maximum).

Connects to an external TTL signal or a 10 MHz

reference signal. The TTL signal is used to

trigger the analyzer’s internal sweep

application.

8

Page 17

Instrument Markings

ISM1-A

ICES/NMB-001

The CE mark shows that the product complies with all

relevant European Legal Directives.

The CSA mark is a registered trademark of the

Canadian Standards Association.

All Level 1, 2 or 3 electrical equipment offered for sale

in Australia and New Zealand by Responsible Suppliers

must be marked with the Regulatory Compliance Mark.

This symbol is an Industrial Scientific and Medical

Group 1 Class A product (CISPR 11, Clause 4)

The ISM device complies with Canadian

Interference- Causing Equipment Standard- 001.

Cet appareil ISM est conforme à la norme NMB- 001 du

Canada.

The instruction manual symbol: indicates that the user

must refer to specific instructions in the manual.

The standby symbol is used to mark a position of the

instrument power switch.

Indicates the time period during which no hazardous or

toxic substance elements are expected to leak or

deteriorate during normal use. Forty years is the

expected useful life of the product.

Korea Certification indicates this equipment is Class A

suitable for professional use and is for use in

electromagnetic environments outside of the home.

Instrument Markings

Overview

The symbol indicates this product complies with the

WEEE Directive (2002/96/EC) marking requirements and

you must not discard this equipment in domestic

household waste.

9

Page 18

Overview

Instrument Markings

10

Page 19

Getting Started

2 Getting Started

Information on checking the analyzer when

received, preparation for use, basic instrument use,

familiarity with controls, defining preset

conditions, updating firmware, and contacting

Keysight Technologies.

11

Page 20

Getting Started

Checking Shipment and Order List

Checking Shipment and Order List

Check the shipment and order list when you

receive the shipment.

• Inspect the shipping container for damages.

Signs of damage may include a dented or torn

shipping container or cushioning material that

might indicate signs of unusual stress or compacting.

• Carefully remove the contents from the shipping

container, and verify if the standard

and your ordered options are included in the

shipment.

accessories

12

Page 21

Power Requirements

Getting Started

Power Requirements

The AC power supplied must meet the following

requirements

Voltage : 100 to 240 VAC

Frequency: 50/60 Hz

Power: Maximum 80 W

The AC/DC power supply charger adapter supplied

with the analyzer is equipped with a three- wire

power cord, in accordance with international safety

standards. This power cord grounds the analyzer

cabinet when it is connected to an appropriate

power line outlet. The power cord appropriate to

the original shipping location is included with the

analyzer.

Various AC power cables are available from

Keysight that are unique to specific geographic

areas. You can order additional AC power cords

that are appropriate for use in different areas. The

AC Power Cord table provides a lists of the

available AC power cords, the plug configurations,

and identifies the geographic area in which each

cable is typically used.

The detachable power cord is the product

disconnecting device. It disconnects the main AC

circuits from the DC supply. The front- panel

switch is only a standby switch and does not

disconnect the instrument from the AC LINE

power.

:

13

Page 22

Getting Started

250V 10A

125V 10A

230V 15A

250V 16A

AC Power Cords

AC Power Cords

Plug Type Cable Part

Number

8121-1703 BS 1363/A Option 900

8120-0696 AS 3112:2000 Option 901

250V 10A

8120-1692 IEC 83 C4 Option 902

250V 16A

8120-1521 CNS 10917-2

8120-2296 SEV 1011 Option 906

250V 10A

8120-4600 SABS 164-1 Option 917

8120-4754 JIS C8303 Option 918

125V 15A

8120-5181 SI 32 Option 919

a

Plug

Description

A 5-15P

/NEM

For use in

Country & Region

United Kingdom, Hong

ong, Singapore, Malaysia

K

Australia, New Zealand

Continental Europe, Korea,

nesia, Italy, Russia

Indo

Option 903

Unite States, Canada,

iwan , M e x i co

Ta

Switzerland

South Africa, India

Japan

Israel

8120-8377 GB 1002 Option 922

China

250V 10A

a. Plug description describes the p lug only. The part number is for the complete cable assembly.

14

Page 23

Safety Considerations

WARNING

WARNING

WARNING

WARNING

Keysight has designed and tested the N934xC

handheld spectrum analyzer for measurement,

control and laboratory use in accordance with

Safety Requirements IEC 61010- 1. The tester is

supplied in a safe condition. The N934xC is also

designed for use in Installation Category II and

Pollution Degree 2 per IEC 61010- 1.

Read the following safety notices carefully before

you start to use a N934xC handheld spectrum

analyzer to ensure safe operation and to maintain

the product in a safe condition.

Personal injury may result if the analyzer’s cover is

removed. There are no operator-serviceable parts inside.

Always contact Keysight qualified personnel for service.

Disconnect the product from all voltage sources while it

is being opened.

This product is a Safety Class I analyzer. The main plug

should be inserted in a power socket outlet only if provided

with a protective earth contact. Any interruption of the

protective conductor inside or outside of the product is likely

to make the product dangerous. Intentional interruption is

prohibited.

Getting Started

Safety Considerations

Electrical shock may result when cleaning the analyzer

with the power supply connected. Do not attempt to

clean internally.

case only.

Use a dry soft cloth to clean the outside

Always use the three-pin AC power cord supplied with

this product. Failure to ensure adequate earth grounding

by not using this cord may cause personal injury and

product damage.

15

Page 24

Getting Started

WARNING

CAU-CAUTION

CAU-CAUTION

CAU-CAUTION

CAU-CAUTION

Safety Considerations

Danger of explosion if the battery is incorrectly replaced.

Replace only with the same type battery recommended.

Do NOT dispose of batteries in a fire.

Do NOT place batteries in the trash. Batteries must be

recycled or disposed of properly.

Recharge the battery only in the analyzer. If left unused, a

fully charged battery will discharge itself over time.

Temperature extremes will affect the ability of the battery

to charge. Allow the battery to cool down or warm up as

necessary before use or charging.

Storing a battery in extreme hot or cold temperatures will

reduce the capacity and lifetime of a battery. Battery

storage is recommended at a temperature of less than

o

25

C.

Never use a damaged or worn-out adapter or battery.

Charging the batteries internally, even while the analyzer

is powered off, the analyzer may keep warm. To avoid

overheating, always disconnect the analyzer from the AC

adapter before storing the analyzer into the soft carrying

case.

Connect the automotive adapter to the power output

connector for IT equipment, when charging the battery on

your automotive.

16

The VxWorks operating system requires full conformity to

USB 1.1 or USB 2.0 standards from a USB disk. Not all the

USB disk are built that way. If you have problems

connecting a particular USB disk, please reboot the

analyzer before inserting another USB stick.

The analyzer cannot be used in the standard soft carrying

case for more than 1 hours if the ambient temperature is

higher than 35

o

C.

Page 25

Getting Started

Safety Considerations

Environmental Requirements

The N934xC is designed for use under the

following conditions:

• Operating temperature:

o

C to 40oC (using AC- DC adapter)

0

o

C to +50oC (using battery)

–10

• Storage temperature: –40

• Battery temperature: 0

• Humidity: < 95% (40

o

C to 45oC

o

C)

o

C to +70oC

Electrical Requirements

The analyzer allows the use of either a lithium

battery pack (internal), AC- DC adapter shipped

with the analyzer, or optional automotive +12 VDC

adapter for its power supply.

Electrostatic Discharge (ESD) Precautions

This analyzer was constructed in an ESD protected

environment. This is because most of the

semiconductor devices used in this analyzer are

susceptible to damage by static discharge.

Depending on the magnitude of the charge, device

substrates can be punctured or destroyed by

contact or proximity of a static charge. The result

can cause degradation of device performance, early

failure, or immediate destruction.

These charges are generated in numerous ways,

such as simple contact, separation of materials,

and normal motions of persons working with static

sensitive devices.

When handling or servicing equipment containing

static sensitive devices, adequate precautions must

be taken to prevent device damage or destruction.

Only those who are thoroughly familiar with

industry accepted techniques for handling static

sensitive devices should attempt to service circuitry

with these devices.

17

Page 26

Getting Started

Working with Batteries

Working with Batteries

The battery provides you approximately 3 hours of

operating time for your long time measurement in

field test.

Installing a Battery

Step Notes

1 Open the battery cover Use a phillips type screwdriver,

2 Insert the battery Observe correct battery polarity

3 Close the battery cover Push the cover closed, then

loosen the retaining screw, then

pull the battery cover open.

orientation when installing.

re-fasten the cover with the

retaining screw.

Viewing the Battery Status

Determine the battery status using either of the

following methods:

• Check the battery icon in the lower- right corner

of the front- panel screen: it indicates the

approximate level of charge.

• Press [System] > {System Info} > {Show System} >

{Page down} to check the current battery

information.

18

Page 27

Getting Started

CAU-CAUTION

Working with Batteries

Charging a Battery

You may charge the battery both in the tester and

in the external battery charger (option BCG).

Connect the automotive adapter to the IT power outlet of your

automobile (with option 1DC) for battery recharging.

1 Insert the battery in the analyzer.

2 Plug in the AC- DC adapter and switch on the

external power.

3 The charge indicator lights, indicating that the

battery is charging. When the battery is fully

charged, the green charging indicator turns off.

During charging and discharging, the battery

voltage, current, and temperature are monitored. If

any of the monitored conditions exceed their safety

limits, the battery will terminate any further

charging or discharging until the error condition is

corrected.

The charging time for a fully depleted battery, is

approximately four hours.

19

Page 28

Getting Started

CAU-CAUTION

Install battery

Press Power Switch

Powering the Analyzer on for the First Time

Powering the Analyzer on for the First Time

Insert the battery into the analyzer or connect the

analyzer to an external power supply via the

AC- DC adapter, then press the power switch on

the front panel of your N934xC to power on the

analyzer.

Use only the original AC-DC adapter or originally supplied

battery for the power source.

The maximum RF input level of an average continuous

power is 30 dBm (or +

connecting a signal into the analyzer that exceeds the

maximum level.

Allow the analyzer to warm-up for 30 minutes

before making a calibrated measurement. To meet

its specifications, the analyzer must meet operating

temperature conditions.

50 VDC signal input). Avoid

20

Page 29

Preparation for Use

This section provides the basic system

configuration which is frequently used before or

after the measurement operation.

Power On and Preset Settings

Selecting a preset type

Press [SYS] > {PwrOn/Off Preset} > {Preset Type} to

choose the preset types. The analyzer has three

types of preset setting for you to choose from:

DFT Restores the analyzer to its factory- defined

settings. The factory default settings can be

found, “Factory Default Settings” on page 22.

User Restores the analyzer to a user- defined

setting. Refer to the descriptions as below.

Restores the analyzer to the last setting.

Last

Saving a User-defined Preset

If you frequently use system settings that are not

the factory defaults, refer to the following steps to

create a user- defined system settings that can be

easily recalled:

1 Set the analyzer parameters using the knob, the

arrow keys, or the numeric keypad.

2 Press [SYS] > {PwrOn/Off Preset} > {Save User} to

save the current parameters as the user preset

setting.

3 Press [SYS] > {PwrOn/Off Preset} > {Preset Typ e U se r }

to set the preset mode to user defined system

setting.

4 Press [Preset]. The instrument will be set to the

state you previously saved.

Getting Started

Preparation for Use

21

Page 30

Getting Started

Preparation for Use

Factory Default Settings

Parameter Default Setting

Center Frequency Specific to Product

Start Frequency 0.0 Hz

Stop Frequency Specific to Product

Span Specific to Product

Reference Level 0.0 dBm

Attenuation Auto (20 dB)

Scale/DIV 10 dB/DIV

Scale Type Log

RBW Auto (3 MHz)

VBW Auto (3 MHz)

Average Type Log Power

Sweep time Auto

Sweep Mode Normal

Probe Power Off

Trace 1 Clear write

Trace 2 Blan k

Trace 3 Blan k

Trace 4 Blan k

Trace 1 D e t e c tio n Pos Peak

Trace 2 Detection Pos Peak

Trace 3 Detection Pos Peak

Trace 4 Detection Pos Peak

Trace Average All Off

Marker All Off

Mode Spectrum Analyzer

22

Page 31

Getting Started

Preparation for Use

Visual and Audio Adjustment

Display Adjustment

Press [System] > {Brightness} > {Brightness} to toggle

the screen brightness between Auto and Man. When

it is set to Auto, the brightness adjusts according to

the environment automatically with the built-in

light sensor. When it is set to Man, you can set a

fixed brightness value manually.

Setting Button Backlight

Press [System] > {Keypad Setting} > {BackLight} to tog-

gle the backlight button between Auto and Man. You

can select the backlight brightness and the auto- off

idle time in manual mode.

Setting Key Beep

Press [System] > {Key Settings} >{Beeper} to activate

the key beep function as an indicator of key

operation.

General System Settings

Provides the following system setting options:

Time/Date

Press [System] > {Time/Date} to set the date and time

of the analyzer.

The allowed input for the time is HHMMSS format,

and YYYYMMDD format for the date.

Power Saving

Press [System] > {Screen Setting} > {Power Saving} to

select a power saving mode which turns off the

LCD display after a user- defined idle time. Press

any key to re- activate the LCD display after the

LCD display power- saving mode has been triggered.

23

Page 32

Getting Started

Preparation for Use

Timed Power On/Off

Pressing [System] > {Power On/Off Preset} > {Timed Pwr

On} or {Timed Pwr Off} sets the time switch to power

on/off the N934xC in a user- defined time and date.

This function requires the power supply to be

connected or charged battery installed.

Press {Repeat Mode Once/Everyday} to set the N934xC

boot up/off in the pre- saved time everyday. The

pre- saved date is invalid in this mode.

IP configuration

The N934xC supports LAN port connection for

data transfer. Press [System] > {Port Setting} > {IP

Admin} > {IP Address Static} to manually set the IP

address, gateway and subnet mask with the proper

LAN information. Or, just press [System] > {Setting}

> {IP Admin} > {IP Address DCHP} to get the IP address

in LAN dynamically according DCHP.

Press {Apply} to enable all the configurations you

set.

Ext Input

Toggles the channel for external input between Ref

and Tr i g. Ref refers to a 10 MHz reference signal; Tri g

refers to a TTL signal.

24

External Reference (Ref)

Use the external reference function as follows:

1 Input a 10 MHz signal into the EXT TRIG IN/REF IN

connector.

2 Press [System] > {Port Setting} > {Ext Input Ref} to

enable the external reference signal input.

Then, the analyzer will disable the internal

reference and switch to accept the external

reference.

Page 33

Getting Started

NOTE

Preparation for Use

External Trigger (Trig)

When an external TTL signal is used for the

triggering function, the analyzer uses the inner

reference as default.

Use the external trigger function as follows:

1 Press [System] > {Port Setting} > {Ext Input Trig} to

enable the external TTL signal input.

2 Press [SPAN] > {Zero Span} to activate the Tri gg e r

function.

3 Access the associated softkeys to select the

rising edge (Ext Rise) or the falling edge (Ext Fall)

as the trigger threshold.

The trace will halt in external trigger mode until the trigger

threshold is met or the free run function is activated.

Show System

Pressing [System] > {System Info} > {Show system}

displays the following hardware, software, and

battery information of the analyzer:

Machine Model Battery Info

MCU Firmware Version Name

DSP Firmware Version Serial NO.

FPGA Firmware Version Capacity

RF Firmware Version Temperature

RF Module S/N Charge Cycles

KeyBoard Module S/N Voltage

This Run Time Current

Temperature Charge Status

Source Voltage Remain Time

Power Source Host ID

25

Page 34

Getting Started

Preparation for Use

Adding an Option

Pressing [System] > {More} > {Service} > {Add Option}

brings up a dialog box for entering the option

license code. Use the numeric keypad to input the

option license code and then use the [ENTER] key as

a terminator. If the analyzer recognizes the option

license code, a message “Option activated

successfully” will appear in the status line.

Otherwise, a message “Invalid option licence” will

appear in the status line. Press [System] > {System

Info} > {Installed Options} to view the options.

Show Error

Pressing [System] > {System Info} > {Error history}

accesses a list of the 30 most recent error

messages. The most recent error will appear at the

bottom of the list. If the error list is longer than 30

entries, the analyzer reports an error message

[–350, Query overflow]. For more information,

refer to “Error Messages” on page 155.

Perform Calibration

The N934xC provides three manual calibration

function to calibrate the time base and amplitude.

The analyzer should warm up for 30 minutes

before calibration.

26

Time Base Calibration

Perform a time base calibration to guarantee the

frequency accuracy.

When the calibration function is triggered, the

current measurement is interrupted and a gauge

displays on the LCD. A message will display on the

LCD which indicates the calibration is finished,

and the interrupted measurement restarts.

Please refer to the operation procedures below:

1 Input a 10 MHz, 0 dBm signal to EXT TRIG IN.

2 Press [System] > {More} > {Service} > {Calibration} >

{Time Base by Ext} to initiate a calibration.

Page 35

Getting Started

NOTE

Preparation for Use

The analyzer provides the GPS time base

calibration function (Option GPS is required).

Locate the analyzer on an open ground to receive

the GPS signal from satellites. Then press [System]

> {More} > {Service} > {Calibration} > {Time Base by GPS}

to perform a GPS time base calibration.

Time base calibration takes only a short time when the inner

temperature is stable. When the inner temperature is

increasing, calibration takes a long period of time or will fail. If

the input reference signal is abnormal, the calibration cycle

will take a long and unpredictable time to exit, and the LCD

displays an error message.

Amplitude Calibration

The analyzer provides the internal amplitude

calibration function. Please refer to the procedures

below to perform an amplitude calibration:

1 Press [System] > {More} > {Service} > {Calibration} >

{Amplitude calibration} > {Calibration}

2 Connect a 50 MHz CW signal to RF IN connector.

The allowed amplitude range is from –2 dBm to

2 dBm. Then press [Enter] to continue.

3 Input the amplitude number of the 50 MHz

signal in the pop- up window and press [Enter] as

a terminator.

The analyzer will perform a calibration according

to the input amplitude value. Press {Clear data} to

set to the factory- preset status with default

amplitude calibration data. The amplitude

calibration function is only available with the

firmware revision A.02.08 or later.

27

Page 36

Getting Started

CAU-CAUTION

CAU-CAUTION

Preparation for Use

Data Securities

The N934xC offers the optional memory erase

function for data security. Press [System] > {More} >

{Securities} > {Erase Memory} to erase all the user

data in internal memory. Press Enter as a

terminator to start the erase process immediately.

The memory erase process takes 15 minutes

approximately. During the erase process, there must be a

constant power supply to ensure the successful erase. If

the erase process is interrupted, please reboot the

instrument and erase memory again.

Upgrading Firmware

Please follow the steps below to update the

firmware:

1 Download the latest N934xC firmware from

2 Extract files to the root directory of a USB stick.

You will see a folder named “N934xDATA” with

file Bappupgrade.hy.

3 Insert the USB stick into the top panel USB

connector.

4 Press [System] > {More} > {Service} > {Upgrade

Firmware} to activate the updating procedure.

Press Enter to upgrade the firmware. The

analyzer will perform the update automatically.

5 Unplug the USB stick and restart the analyzer

when message “All modules have been upgraded,

please restart” is displayed.

6 Press [System] > {System Info} > {Show System} to

find the updated MCU firmware version.

In updating process, there must be a constant power supply to

for at least 15 minutes. If power fails during the updating

process it can cause damage to the instrument.

28

Page 37

Getting Started

Preparation for Use

Probe Power Output

The Probe Power provides power for

high- impedance AC probes or other accessories

(+15 V, –12V, 150 mA maximum).

The Probe power is set to off as default. Press

[System] > {More} {Port Setting} > {Probe Power On} to

switch on the probe power output.

29

Page 38

Getting Started

HSA and BSA PC software

HSA and BSA PC software

Keysight HSA and BSA PC software is an

easy- to- use, PC- based remote control tool for the

N9342C/43C/44C HSA handheld spectrum analyzer.

It is able to be discretely used as a spectrum

monitor to display and control the trace scans

simultaneously with the analyzer, or a file manager

to send/get files between the analyzer and PC. It

also provides some data analysis function for your

further use.

For the further description of the HSA PC

software, please refer to the online help embedded

in this software.

30

Page 39

Making Basic Measurements

This section provides information on basic analyzer

operations. It assumes that you are familiar with

the front and top panel buttons and keys, and

display annotations of your analyzer. If you are

not, please refer to “Front Panel Overview” on page 5,

“Top Panel Overview” on page 8, and “Instrument

Markings” on page 9.

For more details on making measurements, please

refer to “Functions and Measurements” on page 33”.

Entering Data

When setting measurement parameters, there are

several ways to enter or modify active function

values:

1 Using the Front Panel Knob

Increases or decreases the current value.

2 Using the Arrow Keys

Increases or decreases the current value by the

step unit defined.

Press [Freq] > {CF Step} to set the frequency by an

auto- coupled step (Step = Span/10, when {CF Step}

mode is set to Auto).

3 Using the Numeric Keypad

Enters a specific value. Press a terminator key

(either a specified unit softkey or [ENTER]) to

confirm input.

4 Using the Shift Hardkey

Press the blue shift key first, then press the

function hardkeys to select the upper alternative

function.

5 Using the Enter Key

Terminates an entry or confirms a selection.

Making Basic Measurements

Getting Started

31

Page 40

Getting Started

Making Basic Measurements

Viewing a Signal on the Analyzer

1 Use a signal generator to generate a CW signal

of 1.0 GHz, at a power level of 0.0 dBm.

2 Press [System] > {PwrOn/Off Preset} > {Preset Type}

and select DFT to toggle the preset setting to the

factory- defined status.

3 Press the green [Preset] key to restore the

analyzer to its factory- defined setting.

4 Connect the generator’s RF OUT connector to the

analyzer’s RF IN connector.

5 Press [Freq] > 1 > {GHz} to set the analyzer center

frequency to 1 GHz.

6 Press [Span] > 5 > {MHz} to set the analyzer

frequency span to 5 MHz.

7 Press [Peak] to place a marker (M1) at the high-

est peak (1 GHz) on the display.

The Marker amplitude and frequency values appear

in the function block and in the upper- right corner

of the screen.

Use the front- panel knob, arrow keys, or the

softkeys in the Peak Search menu to move the

marker and show the value of both frequency and

amplitude displayed on the screen.

Figure 2-1 View a signal (1 GHz, 0 dBm)

32

Page 41

Functions and Measurements

3 Functions and Measurements

33

Page 42

Functions and Measurements

Measuring Multiple Signal s

Measuring Multiple Signals

This section provides information on measuring

multiple signals.

Comparing Signals on the Same Screen

The N934xC can easily compare frequency and

amplitude signal differences, for example,

measuring radio or television signal spectra. The

Delta Marker function allows two signals to be

compared when both appear on the screen at the

same time.

In the following example, a 50 MHz signal is used

to measure frequency and amplitude differences

between two signals on the same screen. The Delta

Marker function is demonstrated in this example.

1 Press [Preset] to set the analyzer to the factory

default setting.

2 Input a signal (0 dB, 50 MHz) to the RF IN

connector of the analyzer.

3 Set the analyzer start frequency, stop frequency,

and reference level to view the 50 MHz signal

and its harmonics up to 100 MHz:

• Press [FREQ] > 40 > {MHz}

• Press [FREQ] > 110 > {MHz}

• Press [AMPTD] > 0 > {dBm}

4 Press [PEAK] to place a marker on the highest

peak on the display (50 MHz).

The {Next Left PK} and {Next Right PK} softkeys are

available to move the marker from peak to peak.

5 Press [Marker] > {Delta} to anchor the first marker

(labeled as M1) and activate a delta marker.

The label on the first marker now reads 1R,

indicating that it is the reference point.

34

Page 43

Functions and Measurements

NOTE

Measuring Multiple Signals

6 Move the second marker to another signal peak

using the front panel knob. In this example the

next peak is 100 MHz, a harmonic of the 50 MHz

signal:

Press [Peak] > {Next Right PK} or {Next Left PK}.

To increase the resolution of the marker readings, turn on

the frequency count function. For more information, please

refer to

“Improving Frequency Resolution and

Accuracy” on page 44

.

Figure 3 Del ta pair marker with signals (same screen)

35

Page 44

Functions and Measurements

Frequency

Enter

7

MOD

On/Off

RF

4

102

9

6

3

On/Off

Amplitude FM

Utility

LF Out

Preset

Local

AM I/Q

File

Trigger

PulseM

·

Sweep

8

5

Remote

Standby

On

N9310A RF Signal Generator 9 kHz - 3.0 GHz

REVERSE PWR

4W MAX 30VDC

LF OUT RF OUT 50

FUNCTIONS

Frequency

Enter

7

MOD

On/Off

RF

4

102

9

6

3

On/Off

Amplitude FM

Utility

LF Out

Preset

Local

AM I/Q

File

TriggerPulseM

·

Sweep

8

5

Remote

Standby

On

N9310A RF Signal Generator 9 kHz - 3.0 GHz

REVERSE PWR

4W MAX 30VDC

LF OUT RF OUT 50

FUNCTIONS

Directional

coupler

Signal generator

Signal generator

Measuring Multiple Signal s

Resolving Signals of Equal Amplitude

In this example a decrease in resolution bandwidth

is used in combination with a decrease in video

bandwidth to resolve two signals of equal

amplitude with a frequency separation of 100 kHz.

Notice that the final RBW selected is the same

width as the signal separation, while the VBW is

slightly narrower than the RBW.

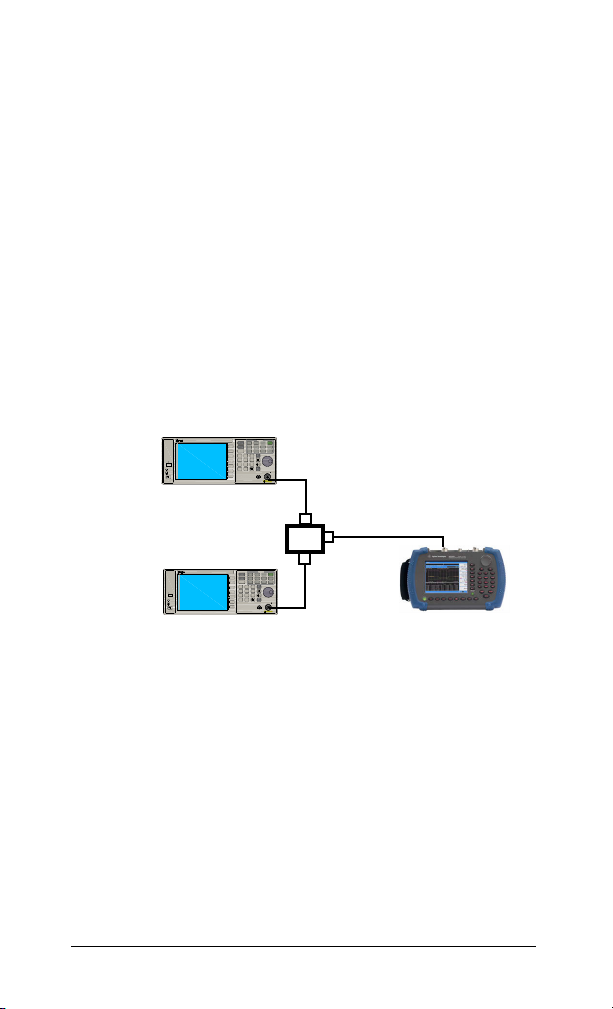

1 Connect two sources to the analyzer input as

shown below.

Figure 4 Setup for obtaining two signals

36

2 Set on

e source to 300 MHz. Set the frequency of

the other source to 300.1 MHz. Set both source

amplitudes to –20 dBm.

3 Setup the analyzer to view the signals:

• Press [PRESET]

• Press [FREQ] > 300.05 > {MHz}

• Press [SPAN] > 2 > {MHz}

• Press [BW] > 30 > {kHz}

Page 45

Functions and Measurements

Measuring Multiple Signals

Use the knob or the arrow keys to further reduce

the resolution bandwidth and better resolve the

signals.

As you decrease the resolution bandwidth, you

improve the resolution of the individual signals and

it also increases the sweep timing. For fastest

measurement times, use the widest possible

resolution bandwidth.

Under factory preset conditions, the resolution

bandwidth is coupled to the span.

Figure 5 Resol ving signals of equal amplitude

37

Page 46

Functions and Measurements

Measuring Multiple Signal s

Resolving Small Signals Hidden by Large

Signals

This example uses narrow resolution bandwidths to

resolve two input signals with a frequency

separation of 50 kHz and an amplitude difference

of 60 dB.

1 Connect two sources to the analyzer input

connector as shown in Figure 4 on page 36.

2 Set one source to 300 MHz at –10 dBm. Set the

other source to 300.05 MHz at –70 dBm.

3 Set the analyzer as follows:

• Press [PRESET]

• Press [FREQ] > 300.05 > {MHz}

• Press [SPAN] > 500 > {kHz}

• Press [BW] > 300 > {Hz}

4 Reduce the resolution bandwidth filter to view

the smaller hidden signal. Place a delta marker

on the smaller signal:

• Press [Peak]

• Press [MARKER] > {Delta}

• Press [Peak] > {Next Right PK} or {Next Left PK}

38

Figure 6 Resol ving a small signal hidden by a larger signal

Page 47

Functions and Measurements

Measuring a Low-Level Signal

Measuring a Low-Level Signal

This section provides information on measuring

low- level signals and distinguishing them from

spectrum noise. There are four techniques used to

measure low- level signals.

Reducing Input Attenuation

The ability to measure a low- level signal is limited

by internally generated noise in the spectrum

analyzer.

The input attenuator affects the level of a signal

passing through the analyzer. If a signal is very

close to the noise floor, reducing input attenuation

will bring the signal out of the noise.

1 Preset the analyzer:

2 Input a signal (1 GHz, –80 dBm) to RF IN.

3 Set the CF, span and reference level:

• Press [FREQ] > 1 > {GHz}

• Press [SPAN] > 5 > {MHz}

• Press [AMPTD] > –40 > {dBm}

4 Move the desired peak (1 GHz) to the center of

the display:

• Press [Peak]

• Press [MARKER] > {Marker To} > {To Center}

Figure 7 A signal closer to the noise level (Atten: 10 dB)

39

Page 48

Functions and Measurements

Measuring a Low-Level Signal

5 Reduce the span to 1 MHz and if necessary

re- center the peak.

• Press [SPAN] > 1 > {MHz}

6 Set the attenuation to 20 dB. Note that increas-

ing the attenuation moves the noise floor closer

to the signal level.

• Press [AMPTD] > {Attenuation} > 20 > {dB}

Figure 8 A signal closer to the noise level (Atten: 20 dB)

40

7 Press [AMPTD] >

attenuation to 0 dB.

Figure 9 A signal closer to the noise level (Atten: 0 dB)

{Attenuation} > 0 > {dB} to set the

Page 49

Functions and Measurements

Measuring a Low-Level Signal

Decreasing the Resolution Bandwidth

Resolution bandwidth settings affect the level of

internal noise without affecting the amplitude level

of continuous wave (CW) signals. Decreasing the

RBW by a decade reduces the noise floor by 10 dB.

1 Refer to “Reducing Input Attenuation” on page 39,

and follow steps 1, 2 and 3.

2 Decrease the resolution bandwidth:

• Press [BW], and toggle RBW setting to Man

(manual), then decrease the resolution

bandwidth using the knob, the arrow keys or

the numeric keypad.

The low level signal appears more clearly because

the noise level is reduced.

Figure 10 Decreasing resolution band width

41

Page 50

Functions and Measurements

Measuring a Low-Level Signal

Using the Average Detector and

Increased Sweep Time

The analyzer’s noise floor response may mask

low- level signals. Selecting the instruments

averaging detector and increasing the sweep time

will smooth the noise and improve the signal’s

visibility. Slower sweep times are necessary to

average noise variations.

1 Refer to “Reducing Input Attenuation” on page 39,

and follow steps 1, 2, and 3.

2 Press [TRACE] > {More} > {Detector} > {Average} to

select the average detector.

3 Press [Sweep] > {Sweep Time} to set the sweep

time to 500 ms.

Note how the noise appears to smooth out. The

analyzer has more time to average the values for

each of the displayed data points.

4 Press [BW] > {Avg Type} to change the average

type.

Figure 11 Using the average detector

42

Page 51

Functions and Measurements

NOTE

Measuring a Low-Level Signal

Tra ce Av era gin g

Averaging is a digital process in which each trace

point is averaged with the previous sweep’s data

average for the same trace point.

Selecting averaging, when the analyzer is auto

coupled, changes the detection mode to sample,

smoothing the displayed noise level.

This is a trace processing function and is not the same as

using the average detector (as described on

1 Refer to the first procedure “Reducing Input

Attenuation” on page 39, and follow steps 1, 2,

and 3.

2 Press [TRACE] > {Average} (On) to turn average on.

3 Press 50 > [ENTER] to set the average number to

50.

As the averaging routine smooths the trace, low

level signals become more visible.

Figure 12 Trace averaging

page 42).

43

Page 52

Functions and Measurements

NOTE

Improving Frequency Resolution and Accuracy

Improving Frequency Resolution and Accuracy

This section provides information on using the

frequency counter to improve frequency resolution

and accuracy.

Marker count properly functions only on CW signals or discrete spectral components. The marker must be > 40 dB

above the displayed noise level.

1 Press [PRESET] (factory preset)

2 Input a signal (1 GHz, –30 dBm) to the ana-

lyzer’s RF IN connector.

3 Set the center frequency to 1 GHz and the span

MHz.

to 5

4 Press [MARKER] > {Function} > {Counter} to turn the

frequency counter on.

5 Move the marker by rotating the knob to a point

half- way down the skirt of the signal response.

6 Press [MARKER] > {Function} > {Normal} to turn off

the marker counter.

Figure 13 Using the frequency counter

44

Page 53

Functions and Measurements

Making Distortion Measurements

Making Distortion Measurements

This section provides information on measuring

and identifying signal distortion.

Identifying Analyzer Generated Distortion

High level input signals may cause analyzer

distortion products that could mask the real

distortion present on the measured signal. Use

trace and the RF attenuator to determine which

signals, if any, may be internally generated

distortion products.

In this example, a signal from a signal generator is

used to determine whether the harmonic distortion

products are generated by the analyzer.

1 Input a signal (200 MHz, –10 dBm) to the

analyzer RF IN connector.

2 Set the analyzer center frequency and span:

• Press [Preset] (factory preset)

• Press [Freq] > 400 > {MHz}

• Press [Span] > 700 > {MHz}

The signal produces harmonic distortion products

200 MHz from the original 200 MHz signal).

(spaced

Figure 14 Harmonic d istortion

45

Page 54

Functions and Measurements

Making Distortion Measurements

3 Change the center frequency to the value of the

second (400 MHz) harmonic:

• Press [Peak]

• Press [Marker] > {Marker To} > {To Center}

4 Change the span to 50 MHz and re- center the

signal:

• Press [Span] > 50 > {MHz}

• Press [Peak]

5 Set the attenuation to 0 dB:

• Press [Amptd] > {Attenuation} > 0 > {dB}

• Press [Marker] > {Marker To} > {To Ref}

6 To determine whether the harmonic distortion

products are generated by the analyzer, first save

the trace data in trace 2 as follows:

• Press [Trace] > {Trace (2)}

• Press [Trace] > {Clear Write}

7 Allow trace 2 to update (minimum two sweeps),

then store the data from trace 2 and place a

delta marker on the harmonic of trace 2:

• Press [Trace] > {View}

• Press [Peak]

• Press [Marker] > {Delta}

The Figure 15 shows the stored data in trace 2 and

the measured data in trace 1. The Marker Delta

indicator reads the difference in amplitude between

the reference and active trace markers.

46

Page 55

Functions and Measurements

Making Distortion Measurements

Figure 15 Identifying Analyzer Distortion (O dB atten)

ess [AMPTD] > {Attenuation} > 10 > {dB} to

8 Pr

increase the RF attenuation to 10 dB.

Figure 16 Identifying Analyzer Distortion (10 dB atten)

The marker readout comes from two sources:

eased input attenuation causes poorer

• Incr

signal- to- noise ratio. This causes the marker

delta value to be positive.

• Reduced contribution of the analyzer circuits

to the harmonic measurement causes the

marker to be negative.

A large marker delta value readout indicates

significant measurement errors. Set the input

attenuator at a level to minimize the absolute value

of marker delta.

47

Page 56

Functions and Measurements

Frequency

Enter

7

MOD

On/Off

RF

4

102

9

6

3

On/Off

Amplitude FM

Utility

LF Out

Preset

Local

AM I/Q

File

TriggerPulseM

·

Sweep

8

5

Remote

Standby

On

N9310A RF Signal Generator 9 kHz - 3.0 GHz

REVERSE PWR

4W MAX 30VDC

LF OUT RF OUT 50

FUNCTIONS

Frequency

Enter

7

MOD

On/Off

RF

4

102

9

6

3

On/Off

Amplitude FM

Utility

LF Out

Preset

Local

AM I / Q

File

TriggerPulseM

·

Sweep

8

5

Remote

Standby

On

N9310A RF Signal Generator 9 kHz - 3.0 GHz

REVERSE PWR

4W MAX 30VDC

LF OUT RF OUT 50

FUNCTIONS

Signal generator

Signal generator

Directional

coupler

Making Distortion Measurements

Third-Order Intermodulation Distortion

Two- tone, third- order intermodulation (TOI)

distortion is a common test in communication

systems. When two signals are present in a

non- linear system, they may interact and create

third- order intermodulation distortion products

that are located close to the original signals.

System components such as amplifiers and mixers

generate these distortion products.

In this example we test a device for third-order

intermodulation using markers. Two sources are

used, one is set to 300 MHz and the other to

301 MHz.

1 Connect the equipment as shown in figure below.

48

This combination of signal generators and

directional coupler (used as a combiner) results in

a two- tone source with very low intermodulation

distortion.

Although the distortion from this setup may be

better than the specified performance of the

analyzer, it is useful for determining the TOI

performance of the source/analyzer combination.

Page 57

Functions and Measurements

NOTE

Making Distortion Measurements

After the performance of the source/analyzer

combination has been verified, the DUT (device

under test, for example, an amplifier) would be

inserted between the directional coupler output

and the analyzer input.

The coupler used should have a high isolation between

the two input ports to limit the sources intermodulation.

2 Set one source (signal generator) to 300 MHz

and the other source to 301 MHz. This will

define the frequency separation at 1 MHz. Set

both sources equal in amplitude, as measured by

the analyzer. In this example, they are both set

to –5 dBm.

3 Set the analyzer center frequency and span:

• Press [PRESET] (Factory preset)

• Press [FREQ] > 300.5 > {MHz}

• Press [SPAN] > 5 > {MHz}

4 Reduce the RBW until the distortion products

are visible:

• Press [BW] > {RBW}, and reduce the RBW using

the knob, the arrow keys or the numeric keypad.

5 Move the signal to the reference level:

• Press [Peak]

• Press [MARKER] > {Marker To} > {To Ref}

6 Reduce the RBW until the distortion products

are visible:

• Press [BW] > {RBW}, and reduce the RBW using

the knob, the arrow keys or the numeric keypad.

7 Activate the second marker and place it on the

peak of the distortion product (beside the test

signal) using the Next Peak:

• Press [MARKER] > {Delta}

• Press [Peak] > {Next Left (Right) PK}

49

Page 58

Functions and Measurements

Making Distortion Measurements

8 Measure the other distortion product:

• Press [MARKER] > {Normal}

• Press [Peak] > {Next Left (Right) Peak}

9 Measure the difference between this test signal

and the second distortion product.

• Press [MARKER] > {Normal}

• Press [Peak] > {Next Left/Right Peak}

Figure 17 TOI test screen

50

Page 59

Making a Stimulus Response Transmission Measurement

N9340A

HANDHELD SPECTRUM ANALYZER

100 kHz - 3.0 GHz

PRESET

ENTER

FREQ SPANAMPTD

BW/

SWP

SYS MO DE MEAS TRACE

ESC/CLR

2DEF 3GHI1ABC

5MNO4JKL

6

PQR

8

VWX7STU9YZ_

0SAVE

LIMIT

MARKER

DUT

CAU-CAUTION

Functions and Measurements

Making a Stimulus Response Transmission

Measurement

The procedure below describes how to use a

built-in tracking generator to measure the rejection

of a low pass filter, a type of transmission

measurement.

1 To measure the rejection of a low pass filter,

connect the equipment as shown below.

A 370 MHz low- pass filter is used as a DUT in

this example.

Figure 18 Transmission Measurement Test Setup

2 Press [Pres

et] to perform a factory preset.

3 Set the start and stop frequencies and resolution

bandwidth:

• Press [FREQ] > {Start Freq} > 100 > {MHz}

• Press [FREQ] > {Stop Freq} > 1 > {GHz}

• Press [BW] > {RBW} > 1 > {MHz}

4 Turn on the tracking generator and if necessary,

set the output power to –10 dBm:

Press [MODE] > {Track Generator} > {Amplitude (On)} >

–10 > {dBm}.

Excessive signal input may damage the DUT. Do not

exceed the maximum power that the device under test can

tolerate.

51

Page 60

Functions and Measurements

Making a Stimulus Response Transmission Measurement

5 Press [Sweep] > {Sweep Time (Auto)} to put the

sweep time into stimulus response auto coupled

mode.

6 Increase the measurement sensitivity and smooth

the noise:

Press [BW] > {RBW} > 30 > {kHz}

Press [BW] > {VBW} > 30 > {kHz}

A decrease in the displayed amplitude is caused

by tracking error.

7 Connect the cable from the tracking generator

output to the analyzer input. Store the frequency

response in trace 4 and normalize:

Press [MEAS] > {Normalize} > {Store Ref} (1 → 4) >

{Normalize (On)}

8 Reconnect the DUT to the analyzer and change

the normalized reference position:

Press [MEAS] > {Normalize} > {Norm Ref Posn} > 8 >

[ENTER]

9 Measure the rejection of the low- pass filter:

Press [Marker] > {Normal} > 370 > MHz, {Delta} > 130

> {MHz}

The marker readout displays the rejection of the

filter at 130 MHz above the cutoff frequency of

the low- pass filter.

52

Figure 19 Measure the Rejection Range

Page 61

Measuring Stop Band Attenuation of a Low-pass Filter

CAU-CAUTION

Functions and Measurements

Measuring Stop Band Attenuation of a

Low-pass Filter

When measuring filter characteristics, it is useful

to look at the stimulus response over a wide

frequency range. Setting the analyzer x- axis

(frequency) to display logarithmically provides this

function. The following example uses the tracking

generator to measure the stop band attenuation of

a 370 MHz low pass filter.

1 Connect the DUT as shown in Figure 18 on

page 51. This example uses a 370 MHz low pass

filter.

2 Press [Preset] to perform a factory preset.

3 Set the start and stop frequencies:

• Press [FREQ] > {Start Freq} > 100 > {MHz}

• Press [FREQ] > {Stop Freq} > 1 > {GHz}

• Press [AMPTD] > {Scale Type} > {Log}

4 Press [BW] > 10 > {kHz} to set the resolution

bandwidth to 10 kHz.

Excessive signal input may damage the DUT. Do not exceed

the maximum power that the device under test can

tolerate.

5 Turn on the tracking generator and if necessary,

set the output power to - 10 dBm:

Press [MODE] > {Track Generator} > {Amplitude (On)} >

–10 > {dBm}.

6 Press [Sweep] > {Sweep Time (Auto)} to put the

sweep time into stimulus response auto coupled

mode. Adjust the reference level if necessary to

place the signal on screen.

7 Connect the cable (but not the DUT) from the

tracking generator output to the analyzer input.

Store the frequency response into trace 4 and

normalize:

Press [MEAS] > {Normalize} > {Store Ref} (1 → 4) >

{Normalize (On)}

53

Page 62

Functions and Measurements

Measuring Stop Band Attenuation of a Low-pass Filter

8 Reconnect the DUT to the analyzer. Note that the

units of the reference level have changed to dB,

indicating that this is now a relative measurement.

9 To change the normalized reference position:

Press [MEAS] > {Normalize} > {Norm Ref Posn} > 8 >

[ENTER]

10Place the reference marker at the specified cut-

off frequency:

Press [MARKER] > {Mode} > {Normal} > 370 > MHz

11 Set the 2nd marker as a delta frequency of

MHz:

37

Press {Delta} > 37 > MHz

12In this example, the attenuation over this

frequency range is 19.16 dB/octave (one octave

above the cutoff frequency).

13Use the front- panel knob to place the marker at

the highest peak in the stop band to determine

the minimum stop band attenuation. In this

example, the peak occurs at 600 MHz. The

attenuation is 51.94 dB.

Figure 20 Minimum Stop Band Attenuation

54

Page 63

Functions and Measurements

N9340A

HANDHELD SPECTRUM ANALYZER

100 kHz - 3.0 GHz

PRESET

ENTER

FREQ SPANAMPTD

BW/

SWP

SYS MODE MEAS TRACE

ESC/CLR

2DEF 3GHI1ABC

5MNO4JKL

6

PQR

8VWX7ST U 9 YZ_

0SAVE

LIMIT

MARKER

Coupled Port

Short

Circuit

DUT

or

NOTE

Making a Reflection Calibration

Making a Reflection Calibration

The following procedure makes a reflection

calibration using a coupler or directional bridge to

measure the return loss of a filter. This example

uses a 370 MHz low- pass filter as the DUT. The

tracking generator (option TG7) is needed for this

measurement. For N9342C handheld spectrum

analyzer with option CA7 or CAU, please refer to

the “Measuring Cable Reflection” on page 84 to make

a reflection measurement.

The calibration standard for reflection calibration

is usually a short circuit connected at the reference

plane (the point at which the DUT is connected). A

short circuit has a reflection coefficient of 1 (0 dB

return loss). It reflects all incident power and

provides a convenient 0 dB reference.

1 Connect the DUT to the directional bridge or

coupler as shown below. Terminate the

unconnected port of the DUT.

Figure 21

Reflection Measurement Short Calibration Test Setup

If possible, use a coupler or bridge with the correct test port

connector types for both calibrating and measuring. For the

best results, use the same adapter for the calibration and the

measurement. Terminate the second port of a two port device.

2 Connect the tracking generator output of the

analyzer to the directional bridge or coupler.

55

Page 64

Functions and Measurements

CAU-CAUTION

NOTE

Making a Reflection Calibration

3 Connect the analyzer input to the coupled port

of the directional bridge or coupler.

4 Press [Preset] to perform a factory preset.

5 Turn on the tracking generator and if necessary,

set the output power to –10 dBm:

Press [MODE] > {Track Generator} > {Amplitude (On)} >

–10 > {dBm}

Excessive signal input may damage the DUT. Do not exceed

the maximum power that the device under test can tolerate.

6 Set the start and stop frequencies and RBW:

• Press [FREQ] > {Start Freq} > 100 > {MHz}

• Press [FREQ] > {Stop Freq} > 1 > {GHz}

• Press [BW] > 1 > MHz

7 Replace the DUT with a short circuit.

8 Press [MEAS] > {Normalize} > {Store Ref (1 → 4)} >

{Normalize (On)} to normalize the trace.

It activates the trace 1 minus trace 4 function

and displays the results in trace 1. The

normalized trace or flat line represents 0 dB

return loss. Normalization occurs in each sweep.

Replace the short (cal device) with the DUT.

Since the reference trace is stored in trace 4, changing trace 4

to Clear Write invalidates the normalization.

Figure 22 Short Circuit Normalized

56

Page 65

Measuring Return Loss Using the Reflection Calibration Routine

Functions and Measurements

Measuring Return Loss Using the Reflection

Calibration Routine

This procedure uses the reflection calibration

routine in the previous procedure “Making a

Reflection Calibration” on page 55, to calculate the

return loss of the 370 MHz low- pass filter.

1 After calibrating the system with the above

procedure, reconnect the filter in place of the

short (cal device) without changing any analyzer

settings.

2 Use the marker to read return loss. Position the

marker with the front-panel knob to read the

return loss at that frequency.

Rotate the knob to find the highest peak and

the readout is the maximum return loss.

Figure 23 Measuring the Return Loss of the Filter

57

Page 66

Functions and Measurements

CAU-CAUTION

Making a Power Measurement with USB Power Sensor

Making a Power Measurement with USB

Power Sensor

Average power measurements provide a key metric

in transmitter performance.

Base station transmit power must be set accurately

to achieve optimal coverage in wireless networks. If

the transmit power is set too high due to

inaccurate power measurements, undesired

interference can occur. If the transmit power is set

too low, coverage gaps or holes may occur. Either

case may affect system capacity and may translate

into decreased revenue for service providers.

Figure 24 Connection with base station

Average power can be measured for the channel of

erest while the base station is active. All other

int

channels should be inactive. Average power is a

broadband measurement. If other signals are

present the analyzer will also measure their power

contributions.

58

The maximum power for the RF IN port and the RF OUT port of

the analyzer is +20 dBm. The maximum power for the Power

Sensor port is +24 dBm. When directly coupled to a base station, the test set can be damaged by excessive power applied

to any of these three ports.

To prevent damage in most situations when directly coupling

an analyzer to a base station, use a high power attenuator

between the analyzer and the BTS.

Page 67

Making a Power Measurement with USB Power Sensor

NOTE

NOTE

Functions and Measurements

The N934xC spectrum analyzer supports the U2000

and U2020 series USB power sensors.

The U2000 Series USB power sensors do not need

manual calibration and zero routines performed.

Calibration and zeroing are performed without

removing the power sensor from the source,

through internal zeroing. With internal zeroing of

U2000 Series USB power sensors, there is no need

to disconnect the sensor or power- off the DUT. The

U2000 Series do not require 50 MHz reference

signal calibration, allowing the factory calibration

to ensure measurement accuracy. For best

accuracy, users are recommended to perform

external zeroing for input signals below - 30 dBm

for best accuracy

If you suspect other signals may be present, it is

recommended that you turn off all the other channels and

.

measure average power only on the signal of interest.

Another option is to measure channel power (which is less

accurate), that filters out all other channels (signals). You can

measure channel power for CDMA using the CDMA Analyzer

or CDMA Over Air tool. For other modulation formats, use

their respective analyzers (that is, GSM, 1xEV-DO, or

W-CDMA) or measure channel power using either the

spectrum analyzer or the Channel Scanner tool.

Connect the power meter as close as possible to the power

amplifier/duplexer output. Do not use a coupled port. Sensors

may not be as accurate at the power levels provided by

coupled ports.

59

Page 68

Functions and Measurements

CAU-CAUTION

Making a Power Measurement with USB Power Sensor

Making an Average Power Measurement

To make an average power measurement, connect

the power sensor and cable, zero and calibrate the

meter, before making a measurement.

Zeroing of the Power Meter will occur

automatically:

• Every time the Power Meter function is used.

• When a 5 degree C. change in instrument

temperature occurs.

• Whenever the power sensor is changed.

• Every 24 hours (min.).

• Before measuring low level signals -for example,

10 dB above the lowest specified power the

power sensor is capable of.

Calibrate the Power Meter every time you cycle the

power on and off.

In most situations, you can press {Zero} to complete

the two steps (zero and cal) together.

To Make a Basic Average Power Measurement

You can follow the steps below to make a basic

average power measurement.

1 Press [Preset] to perform a factory preset.

2 Press [MODE] > {Power Meter} to access the power

meter mode.

3 Zero and calibrate the meter. Press {Zeroing} to

make a zero operation of the power sensor

followed by a calibration operation.