Page 1

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176 - TestEquipmentDepot.com

Keysight N2002A

Noise Source Test Set

User’s Guide

Page 2

Notices

© Keysight Technologies, Inc.

2003-2015

No part of this manual may be

reproduced in any form or by any

means (including electronic storage

and retrieval or translation into a

foreign language) without prior

agreement and written consent from

Keysight Technologies, Inc. as

governed by United States and

international copyright laws.

Trademark Acknowledgments

Manual Part Number

N2002-90003

Edition

Edition 1, March 2015

Printed in USA/Malaysia

Published By:

Keysight Technologies

1400 Fountaingrove Parkway

Santa Rosa, CA 95403

Warranty

THE MATERIAL CONTAINED IN THIS

DOCUMENT IS PROVIDED “AS IS,”

AND IS SUBJECT TO BEING

CHANGED, WITHOUT NOTICE, IN

FUTURE EDITIONS. FURTHER, TO

THE MAXIMUM EXTENT PERMITTED

BY APPLICABLE LAW, KEYSIGHT

DISCLAIMS ALL WARRANTIES,

EITHER EXPRESS OR IMPLIED WITH

REGARD TO THIS MANUAL AND

ANY INFORMATION CONTAINED

HEREIN, INCLUDING BUT NOT

LIMITED TO THE IMPLIED

WARRANTIES OF

MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE.

KEYSIGHT SHALL NOT BE LIABLE

FOR ERRORS OR FOR INCIDENTAL

OR CONSEQUENTIAL DAMAGES IN

CONNECTION WITH THE

FURNISHING, USE, OR

PERFORMANCE OF THIS

DOCUMENT OR ANY INFORMATION

CONTAINED HEREIN. SHOULD

KEYSIGHT AND THE USER HAVE A

SEPARATE WRITTEN AGREEMENT

WITH WARRANTY TERMS

COVERING THE MATERIAL IN THIS

DOCUMENT THAT CONFLICT WITH

THESE TERMS, THE WARRANTY

TERMS IN THE SEPARATE

AGREEMENT WILL CONTROL.

Technology Licenses

The hardware and/or software

described in this document are

furnished under a license and may be

used or copied only in accordance

with the terms of such license.

Restricted Rights Legend

U.S. Government Rights. The

Software is “commercial computer

software,” as defined by Federal

Acquisition Regulation (“FAR”) 2.101.

Pursuant to FAR 12.212 and

27.405-3 and Department of Defense

FAR Supplement (“DFARS”)

227.7202, the U.S. government

acquires commercial computer

software under the same terms by

which the software is customarily

provided to the public. Accordingly,

Keysight provides the Software to

U.S. government customers under its

standard commercial license

a. The license set forth in the EULA

represents the exclusive authority by

which the U.S. government may use,

modify, distribute, or disclose the

Software. The EULA and the license

set forth therein, does not require or

permit, among other things, that

Keysight: (1) Furnish technical

information related to commercial

computer software or commercial

computer software documentation

that is not customarily provided to

the public; or (2) Relinquish to, or

otherwise provide, the government

rights in excess of these rights

customarily provided to the public to

use, modify, reproduce, release,

perform, display, or disclose

commercial computer software or

commercial computer software

documentation. No additional

government requirements beyond

those set forth in the EULA shall

apply, except to the extent that those

terms, rights, or licenses are

explicitly required from all providers

of commercial computer software

pursuant to the FAR and the DFARS

and are set forth specifically in writing

elsewhere in the EULA. Keysight shall

be under no obligation to update,

revise or otherwise modify the

Software. With respect to any

technical data as defined by FAR

2.101, pursuant to FAR 12.211 and

27.404.2 and DFARS 227.7102, the

U.S. government acquires no greater

than Limited Rights as defined in

FAR 27.401 or DFAR 227.7103-5 (c),

as applicable in any technical data..

Safety Notices

CAUTION

A CAUTION notice denotes a

hazard. It calls attention to an

operating procedure, practice, or

the like that, if not correctly

performed or adhered to, could

result in damage to the product

or loss of important data. Do not

proceed beyond a CAUTION

notice until the indicated

conditions are fully understood

and met.

WARNING

A WARNING notice denotes a

hazard. It calls attention to an

operating procedure, practice, or

the like that, if not correctly

performed or adhered to, could

result in personal injury or death.

Do not proceed beyond a

WARNING notice until the

indicated conditions are fully

understood and met.

Page 3

iii

Page 4

General Safety Information

This instrument has been designed and tested in accordance with IEC Publication

61010-1+A1+A2:1992 Safety requirements for Electrical Equipment for Measurement, Control

and Laboratory Use and has been supplied in a safe condition.

The instruction documentation contains information and warnings which must be followed by the user to

ensure safe operation and to maintain the instrument in a safe condition.

WARNING No operator serviceable parts inside, refer servicing to service trained

personnel.

WARNING If this instrument is not used as specified, the protection provided by the equipment could be

impaired. This instrument must be used in a normal condition (in which all means of protection

are intact only).

CAUTION This instrument is designed for use in Installation Category I and Pollution Degree 2

as per IEC 61010 and 60664 respectively.

NOTE This product does not contain an operator replaceable fuse. Disregard the marking

referring to the '~ Line Fuse'. This is not a mains operated unit.

iv

Page 5

Safety Symbols

The following symbols on the instrument and in the manual indicate precautions which must be taken to

maintain safe operation of the instrument.

The Instruction Documentation Symbol. The product is marked with this symbol

when it is necessary for the user to refer to the instructions in the supplied

documentation.

This symbol indicates that a device, or part of a device, may be susceptible to

electrostatic discharges (ESD) which can result in damage to the product.

Observe ESD precautions given on the product, or its user documentation, when

handling equipment bearing this mark.

The CE mark shows that the product complies with all relevant European Legal

Directives

The C-Tick mark is a registered trademark of the Australian Communications

Authority. This signifies compliance with the Australian EMC Framework

Regulations under the terms of the Radiocommunications Act of 1992.

ISM Group 1 Class A

ICES/NMB-003

This is a symbol of an Industrial, Scientific, and Medical Group 1 Class A product.

This ISM device complies with Canadian ICES-003.

Cet appareil ISM est conforme a la norme NMB-003 du Canada

This equipment is Class A suitable for professional use and is for use in

electromagnetic environments outside of the home.

v

Page 6

vi

Page 7

Table of Co n tents

1. Using the N2002A

Introd

uction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Recommended Test Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

N2002A Verification Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Replaceable Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Contacting Keysight Technologies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2. The Noise Source Calibration Process and Recommended Test Equipment

The Calibration Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Calibration Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Test Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Excess Noise Ratio (ENR dB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Loading the Reference Standard’s ENR Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Overview of the ENR Measurement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

The Test Equipment Connection Diagrams for ENR Measurements . . . . . . . . . . . . . . . . 24

ENR Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Reflection Coefficient Magnitude and Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Contents

Reference Standard Noise Source Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Recommended Test Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3. Using the Manual Calibration Procedure

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Before You Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Recording the Test Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Failure During the Test Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

ENR Manual Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

The Equations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

System Uncertainty Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Reflection Coefficient Manual Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Calibrating the 8753. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Measuring the DUT over 1st Frequency Range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Calibrating the 8722. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Measuring the DUT over 1st Frequency Range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Keysight N2002A User’s Guide vii

Page 8

Contents

4. Manually Programming Data into an Keysight Smart Noise Source

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Data Programming Process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Formatting the Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Editing the Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Programming the Data File into the SNS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

5. Using the Keysight N2002A Noise Source Demonstration Software

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Additional Software Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

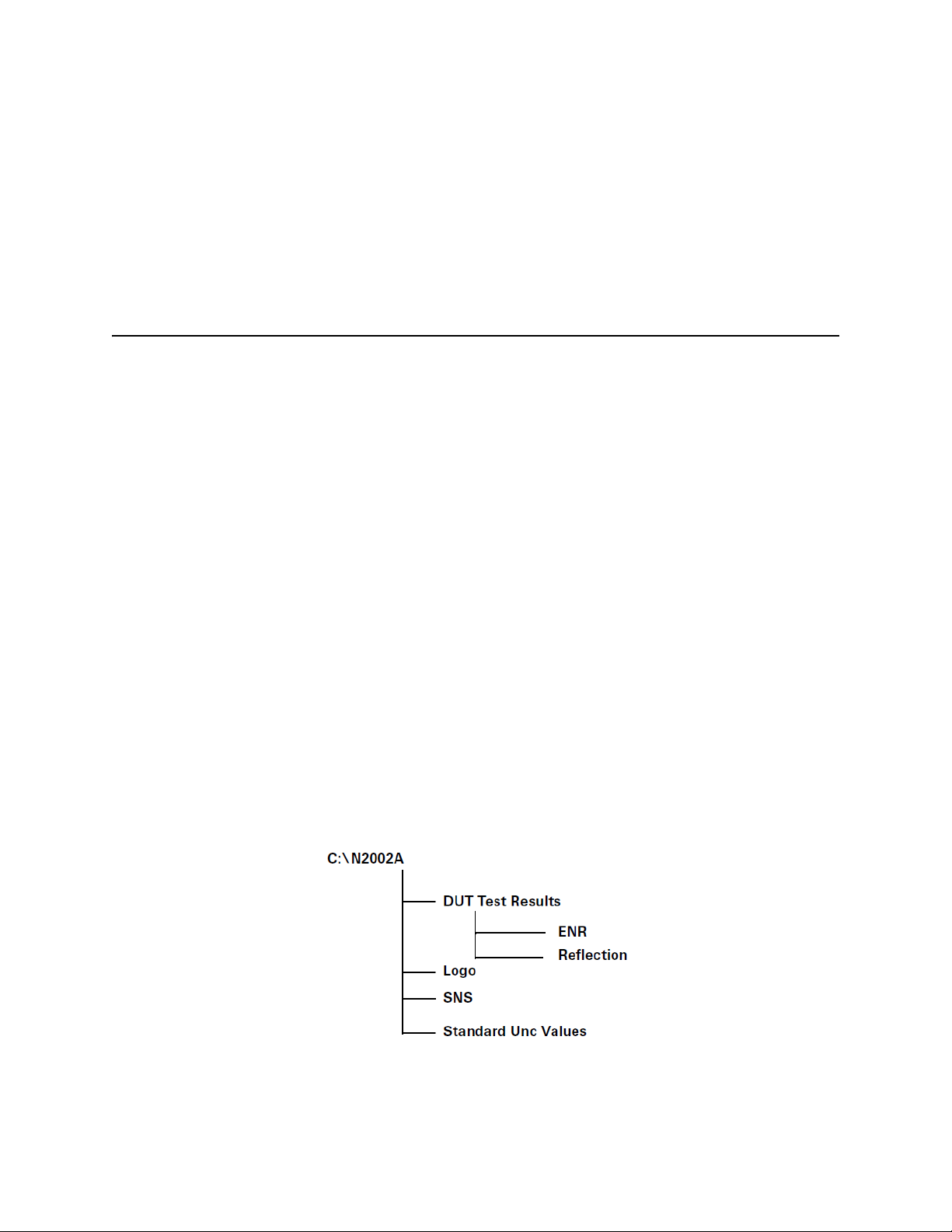

Directory Structure Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Opening the VEE Pro 6.0 (.vee) Software File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

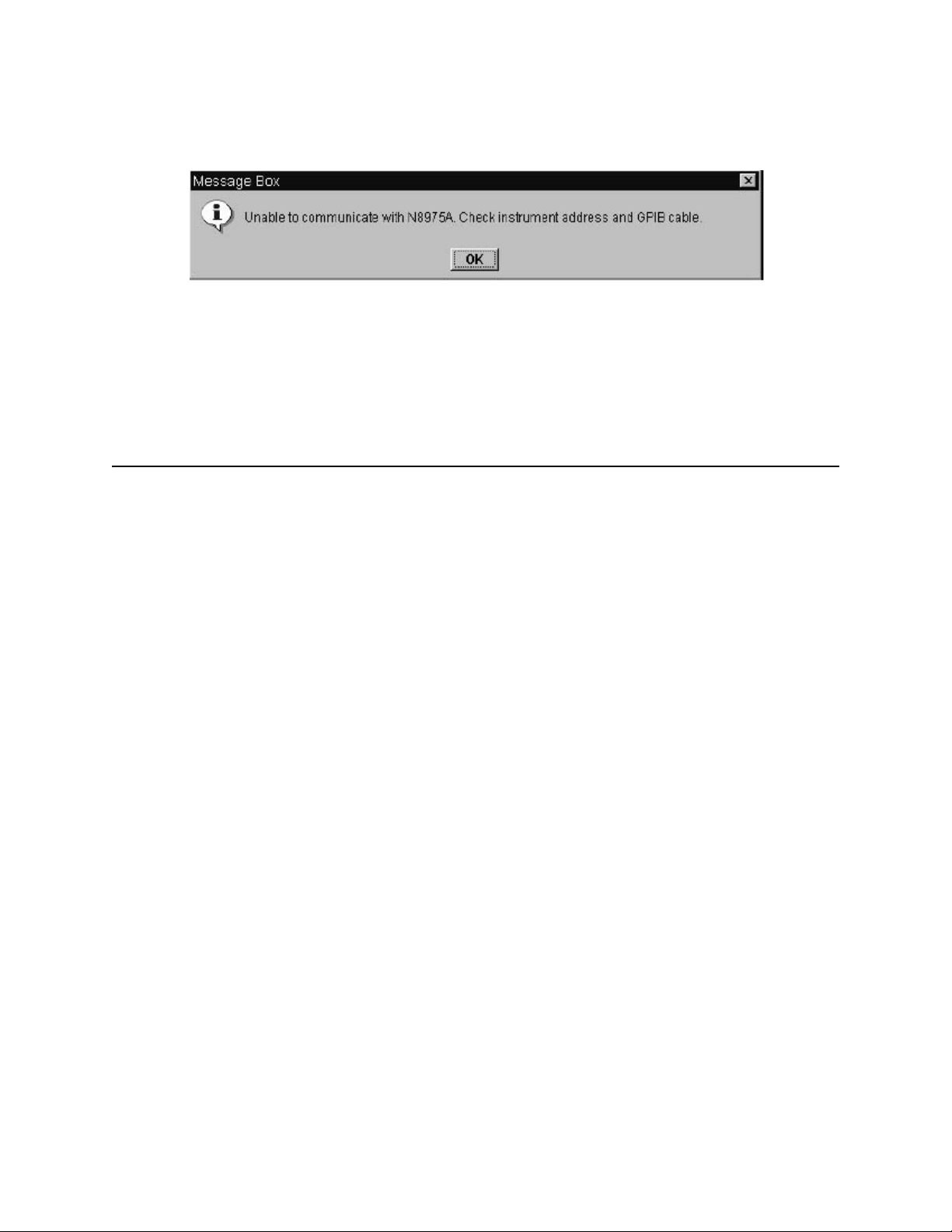

Setting up the Address Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Configuring the VEE Pro 6.0 Run Time File IO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Before running the Keysight N2002A Noise Source Demonstration Software . . . . . . . . .56

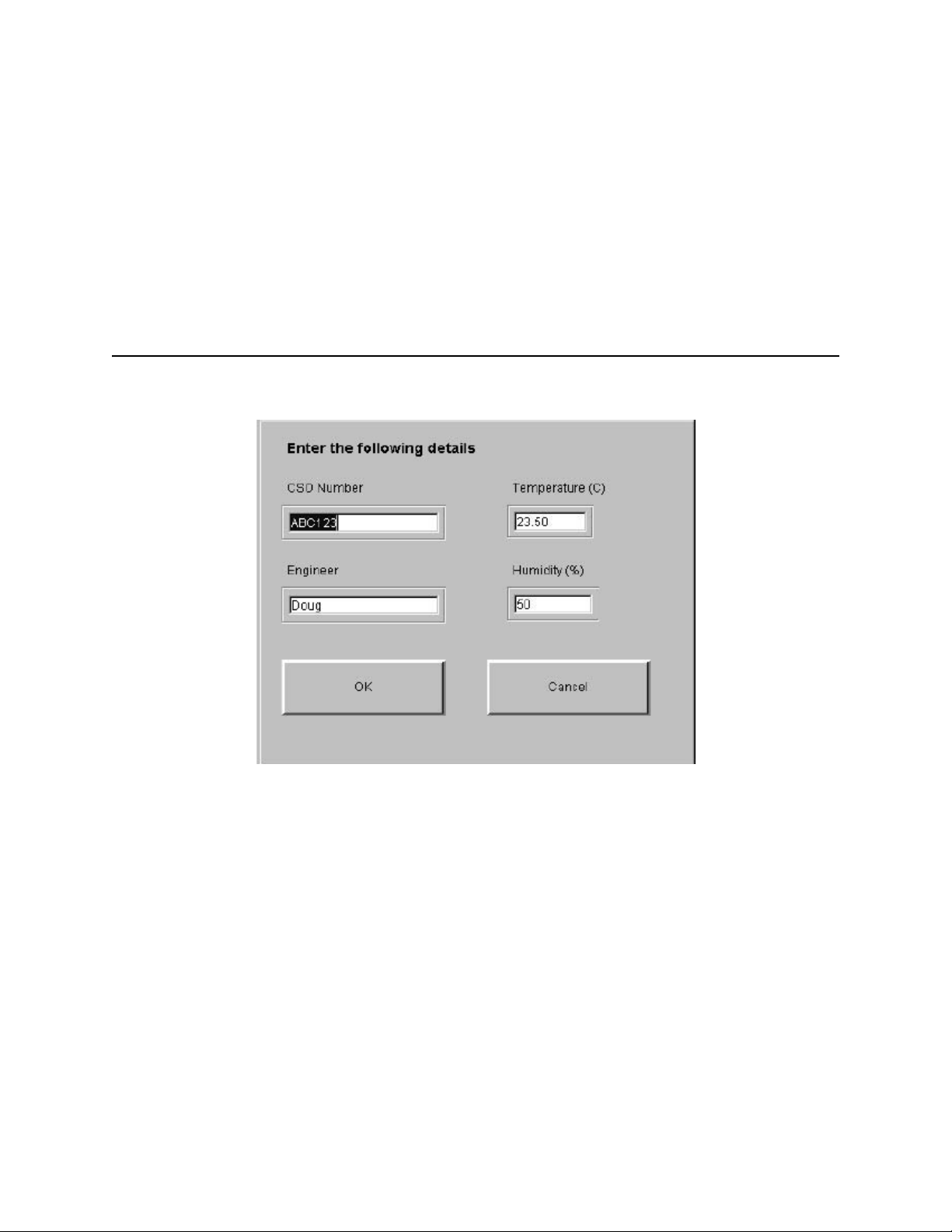

The ENR Measurement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

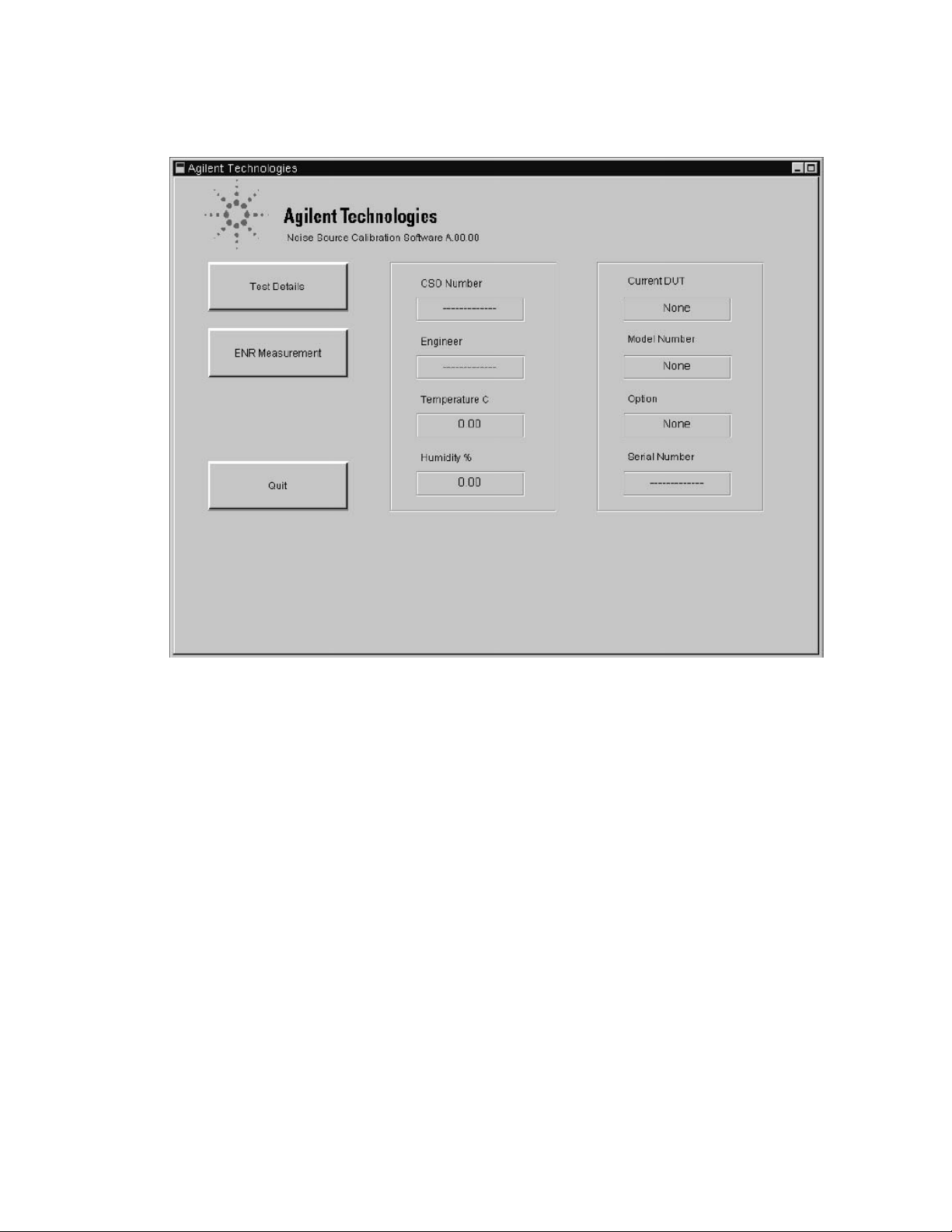

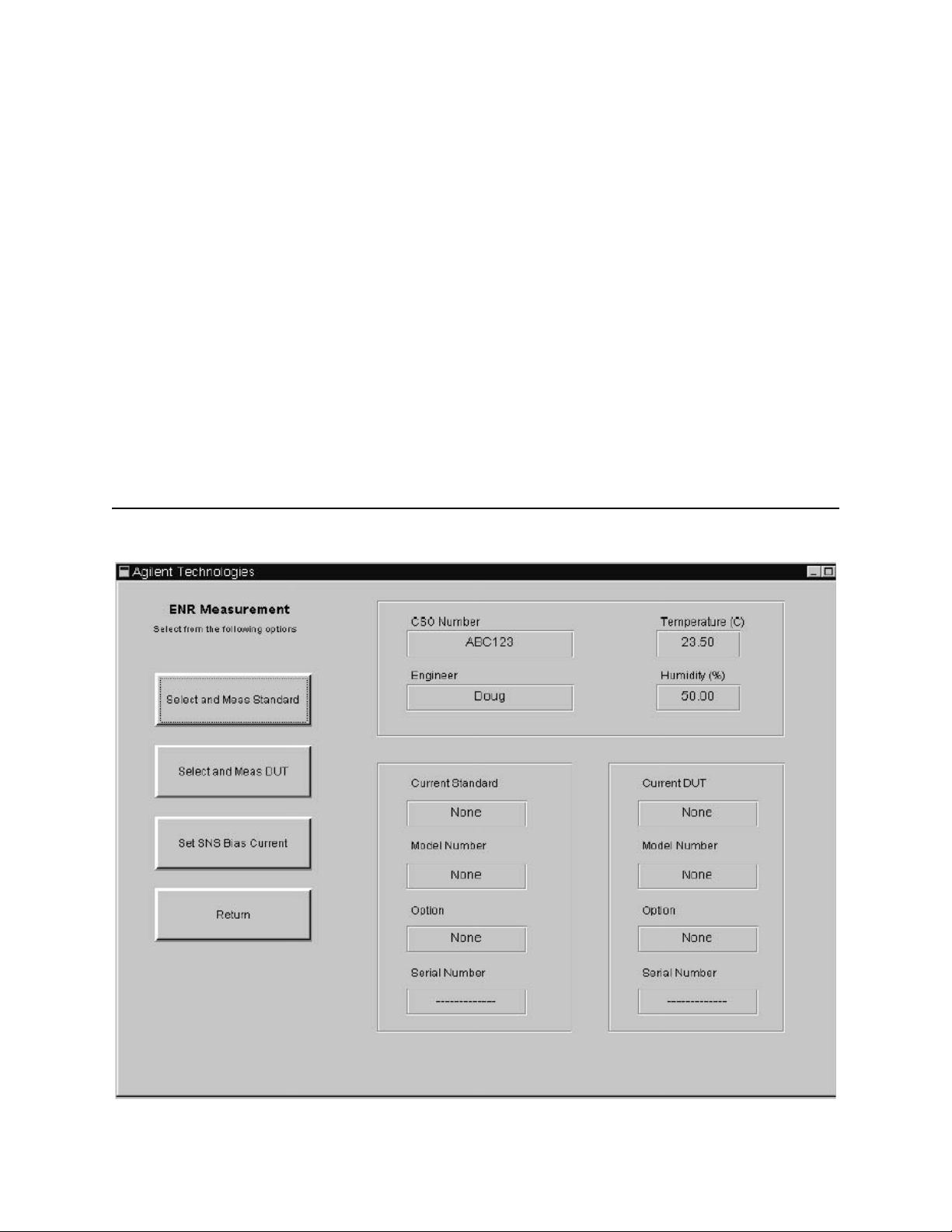

Running the Keysight N2002A Noise Source Demonstration Software. . . . . . . . . . . . . . . . . .60

Test Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

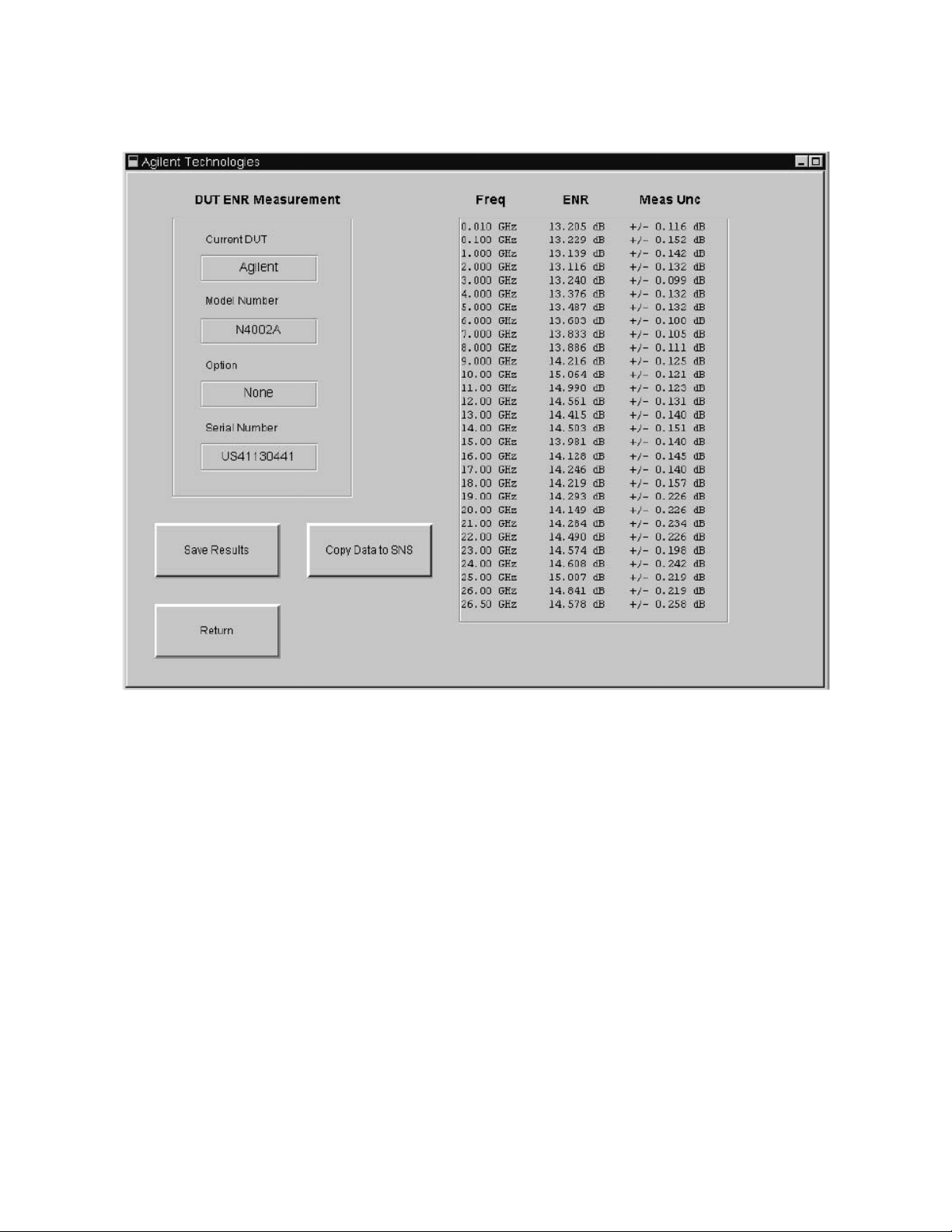

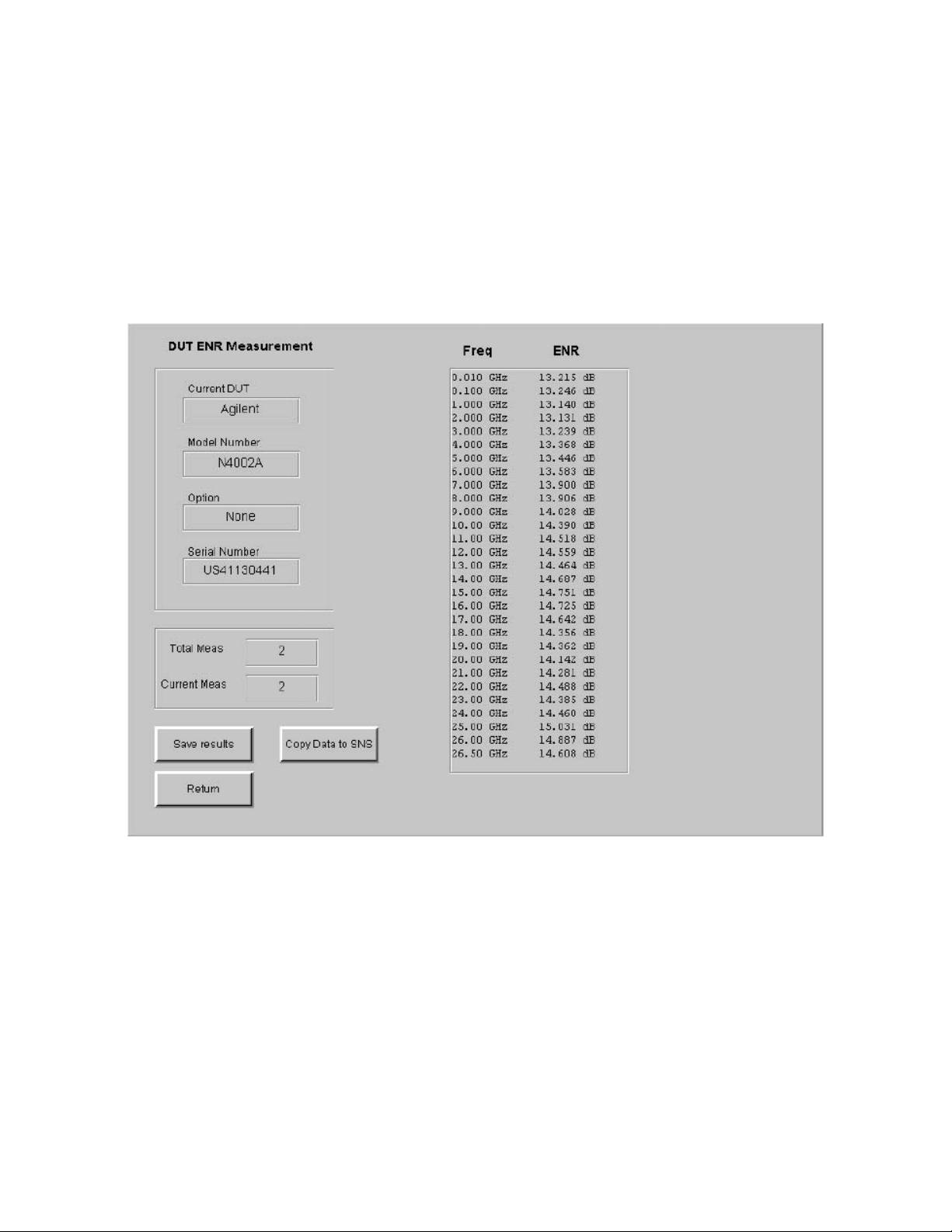

ENR Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

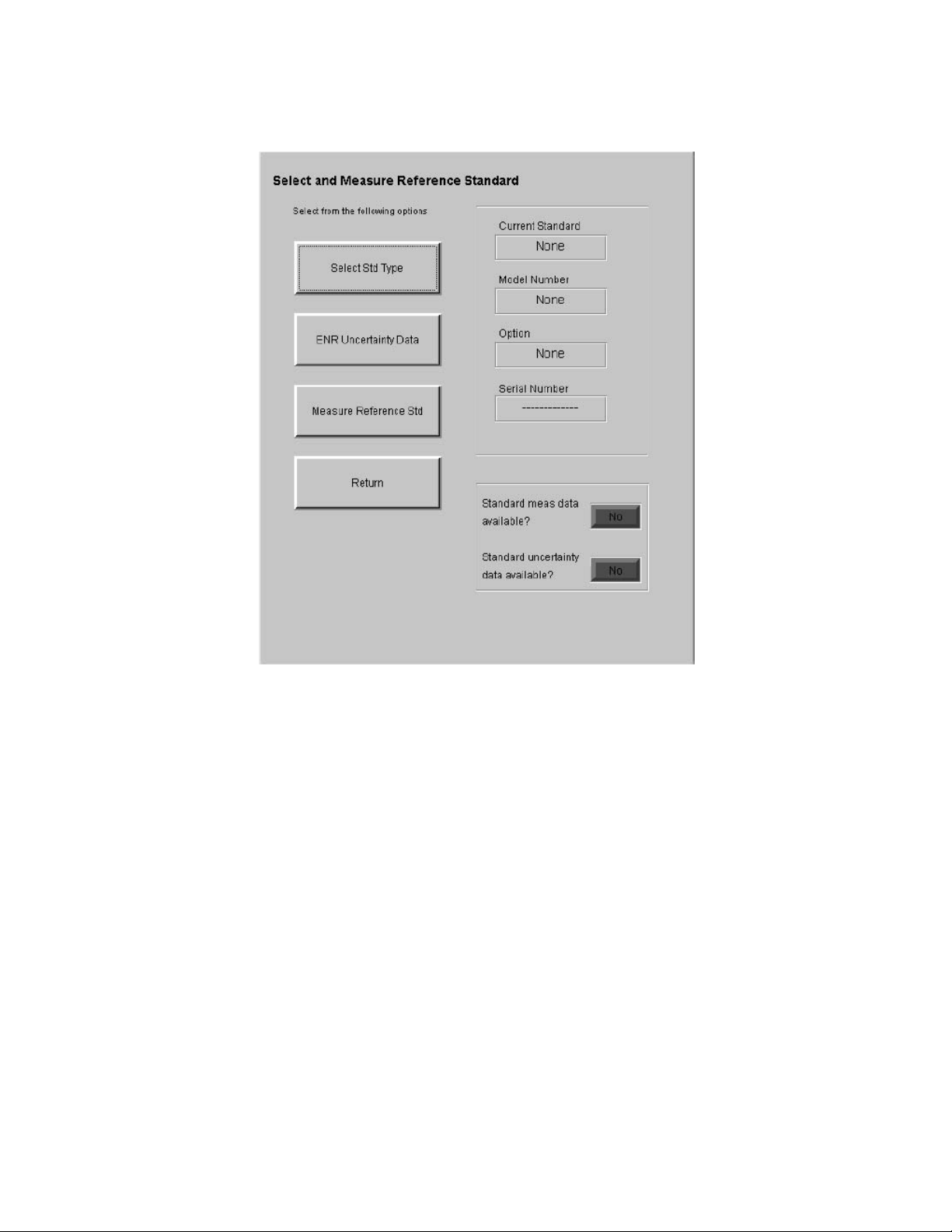

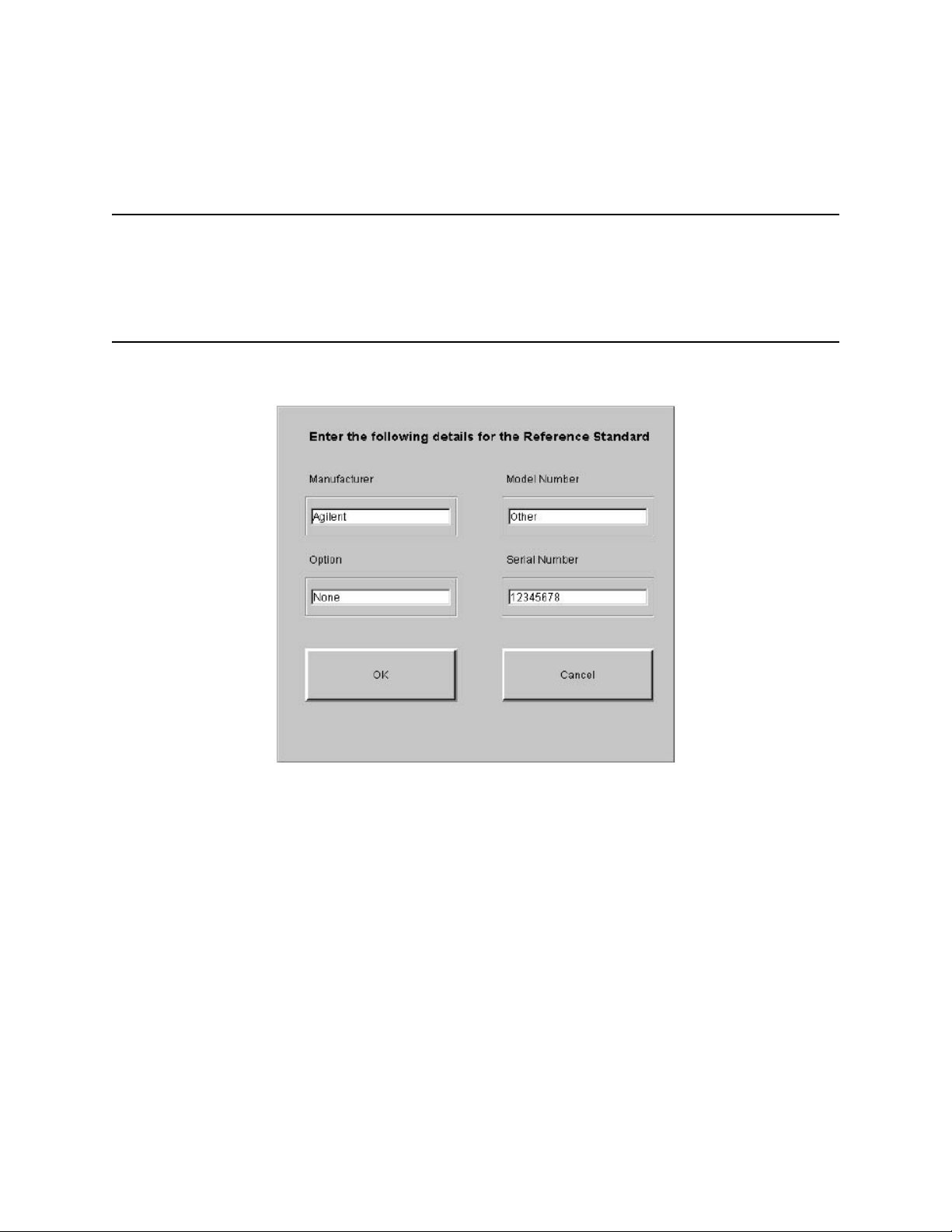

Selecting and Measuring the Reference Standard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Selecting the Reference Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

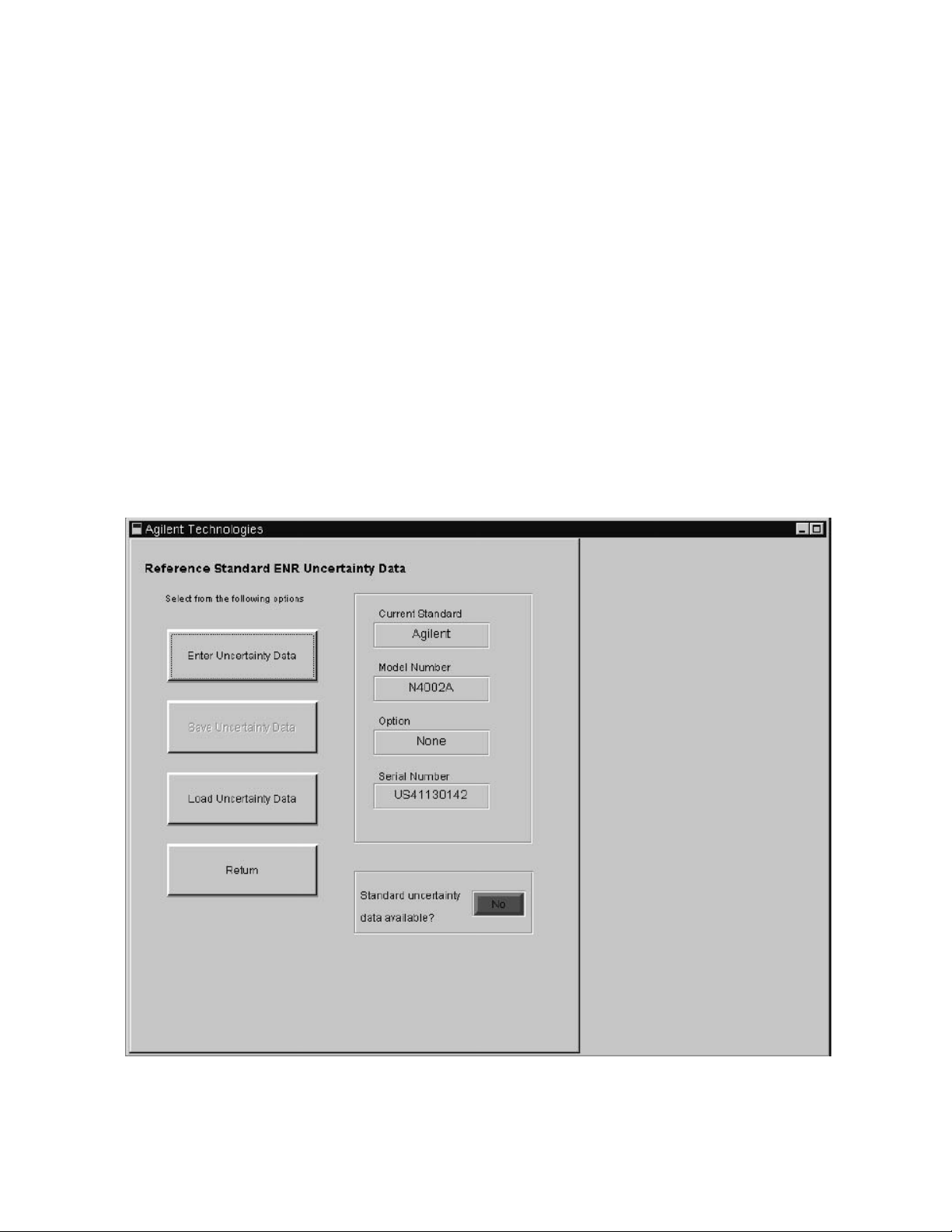

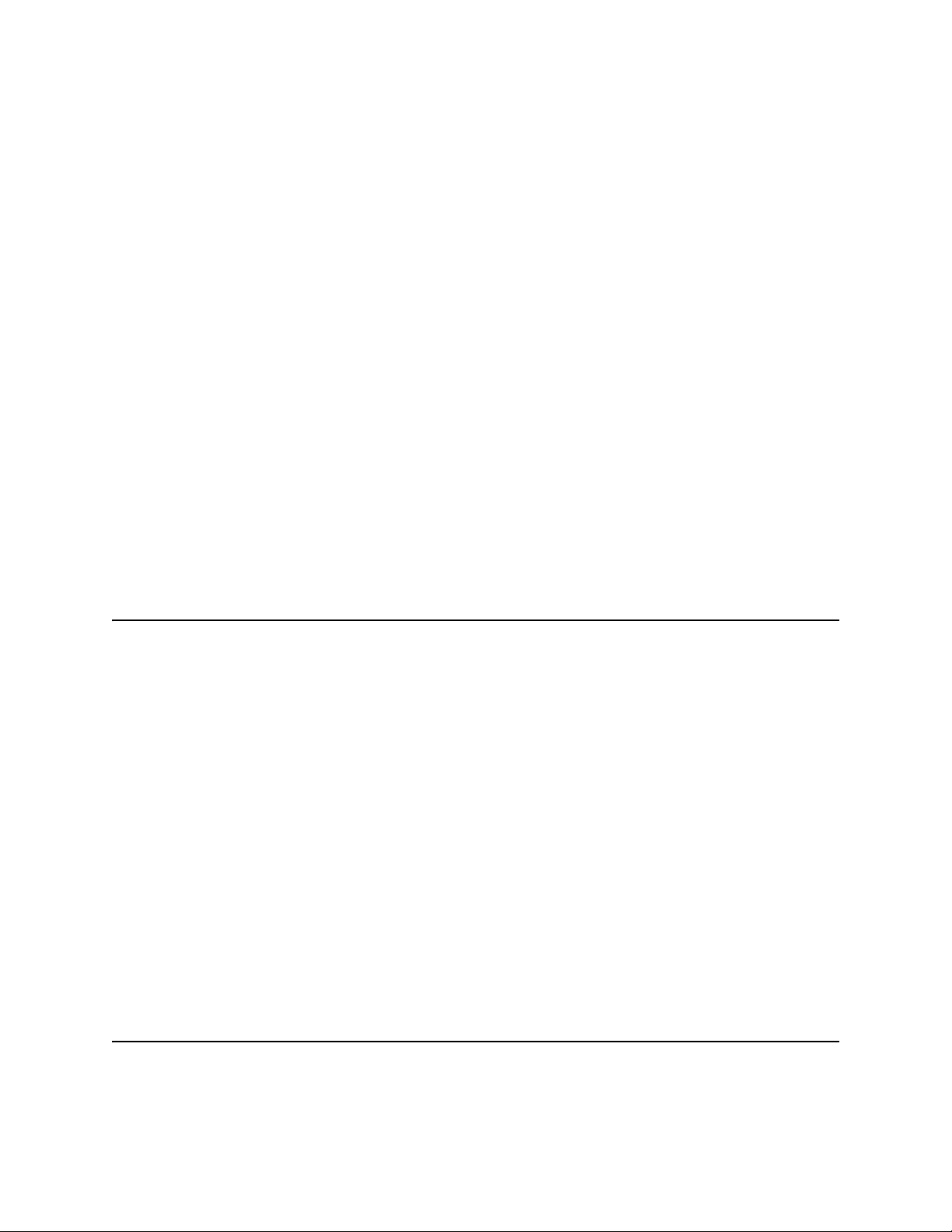

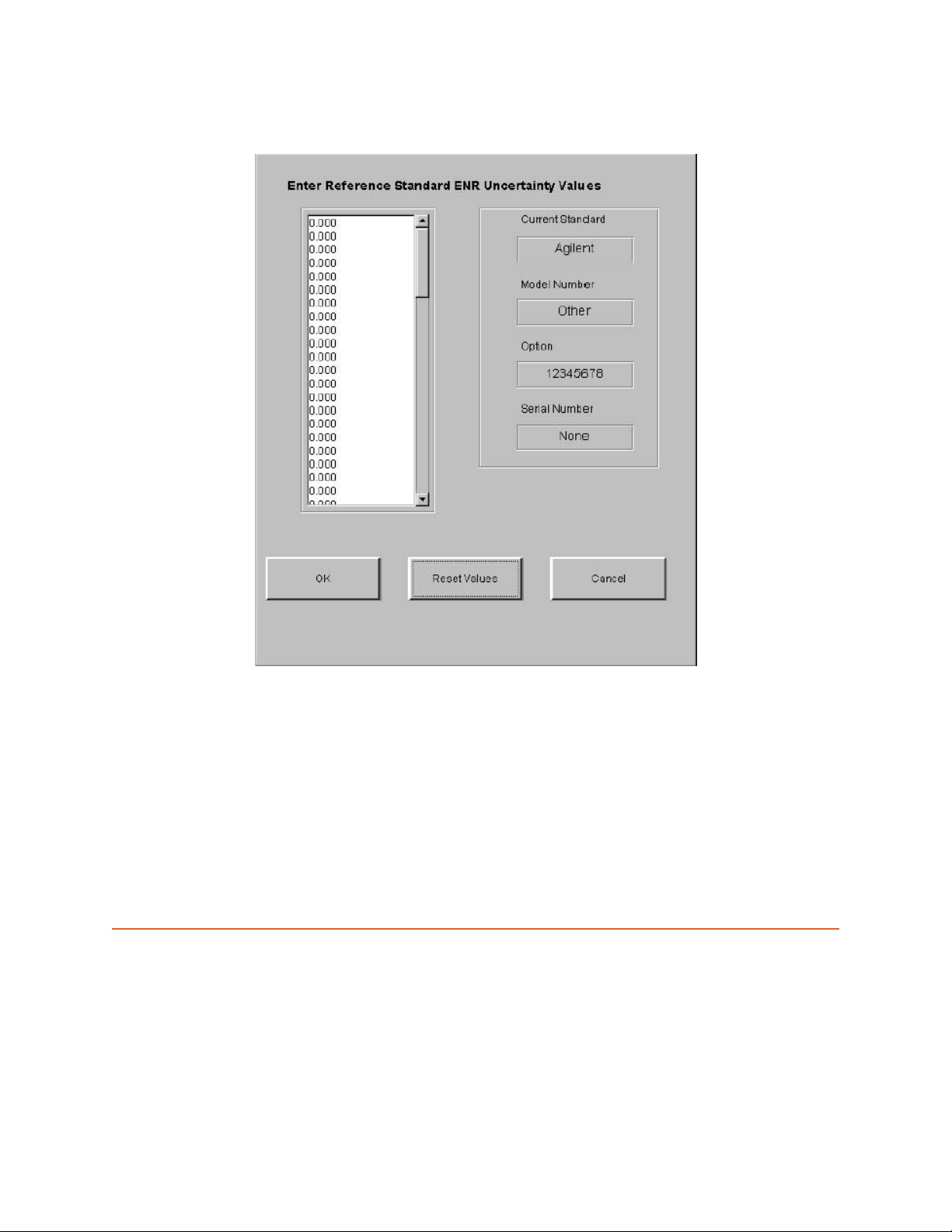

Entering Reference Standard Uncertainty Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Selecting Reference Standard Measurement Uncertainty Data . . . . . . . . . . . . . . . . . . . .69

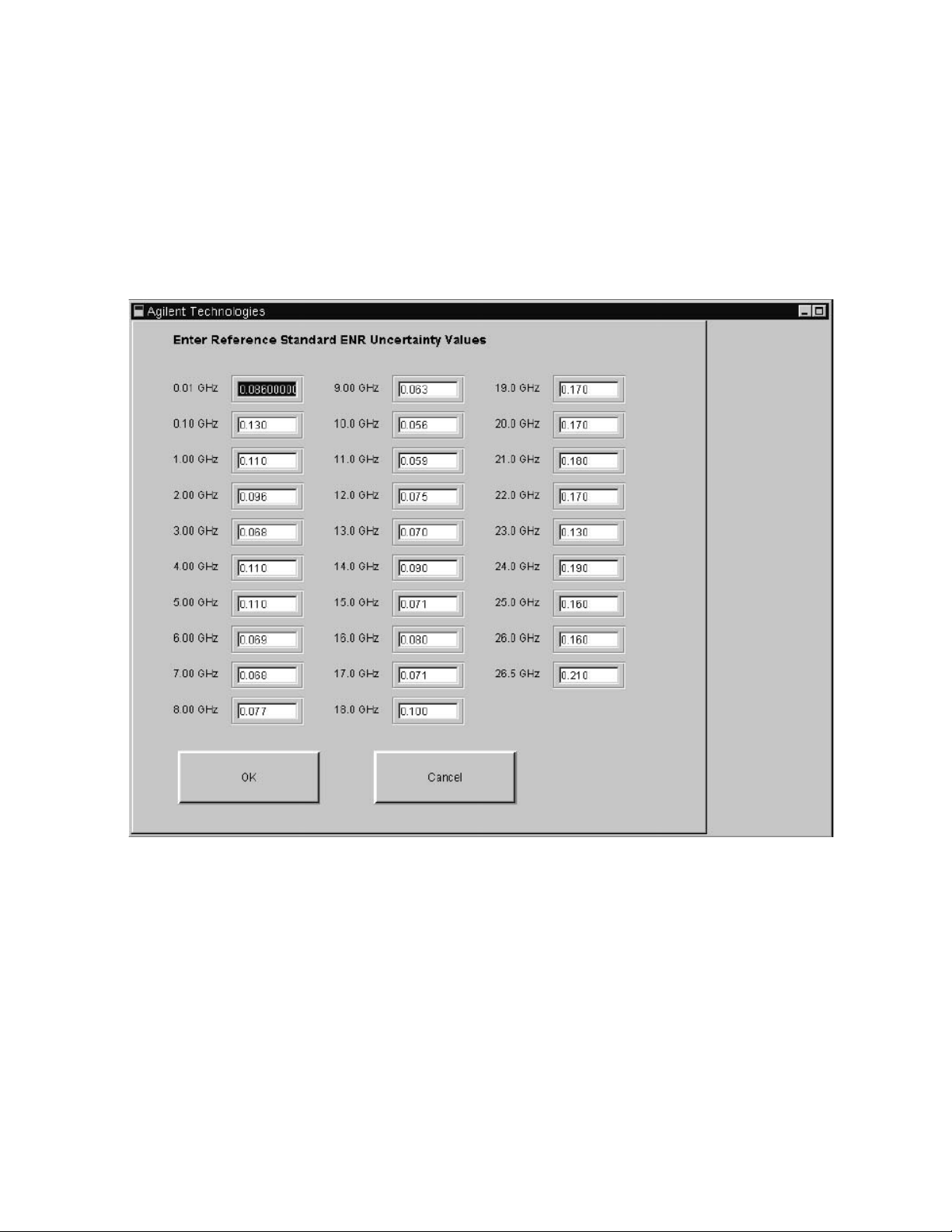

Performing Reference Standard Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

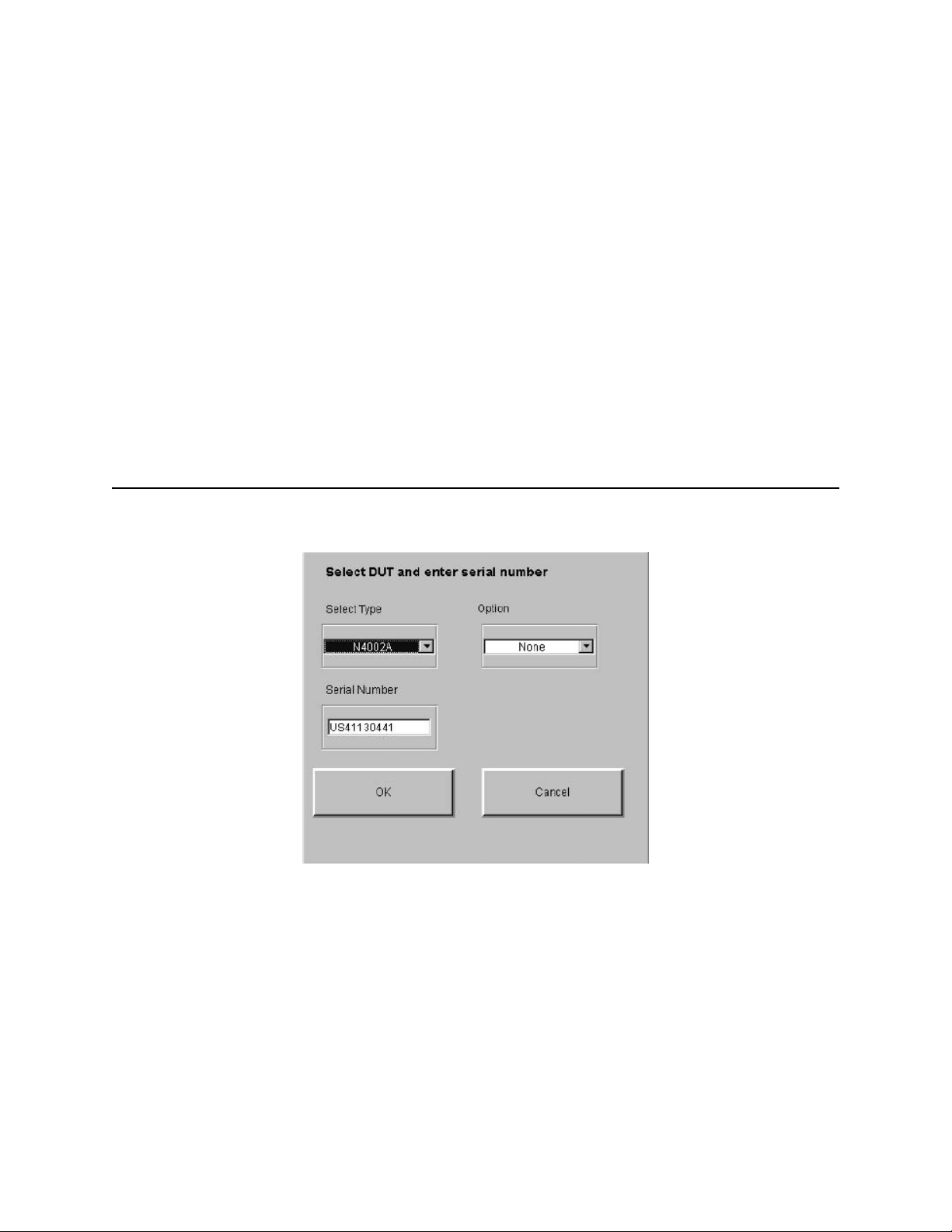

Selecting the DUT to be Measured . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Selecting the DUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Measuring a DUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

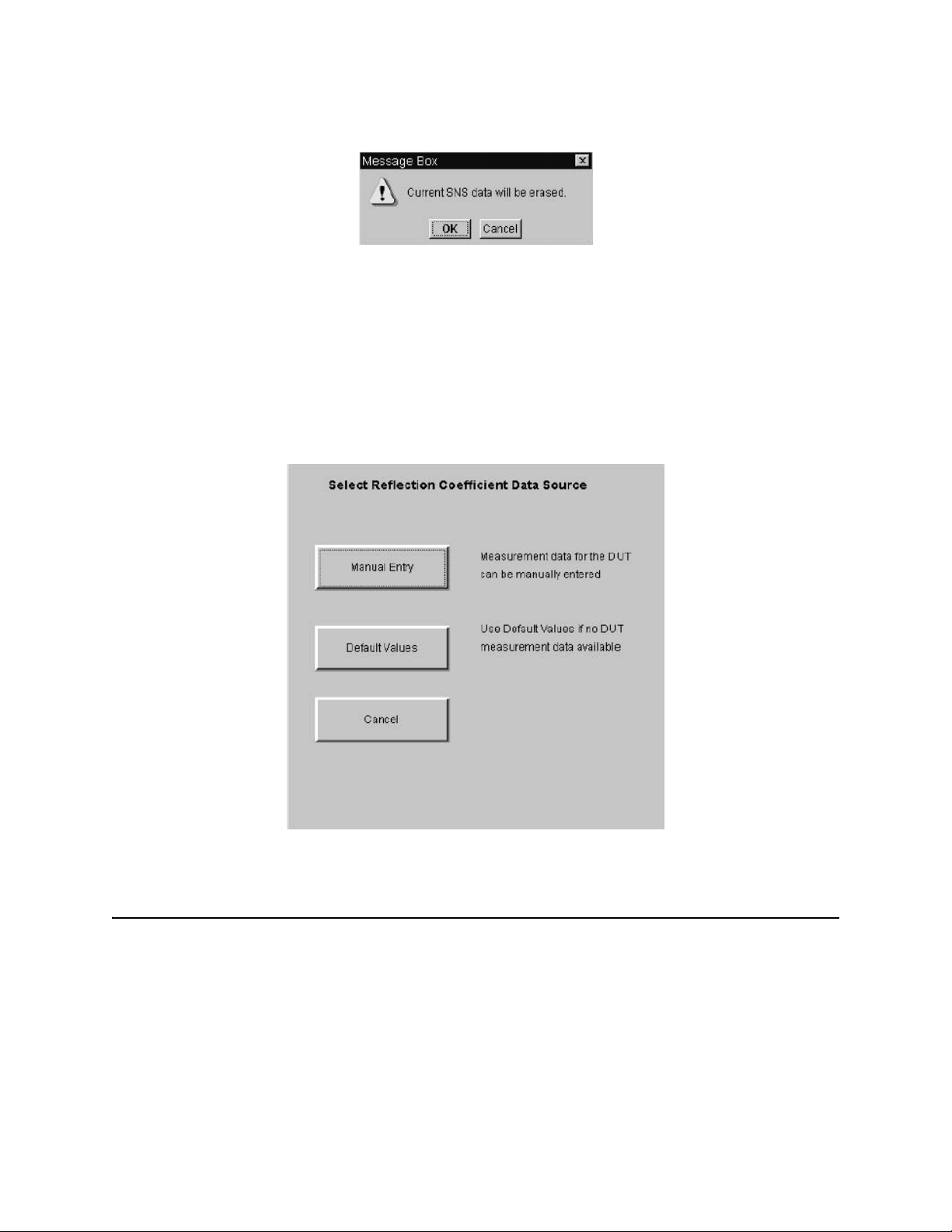

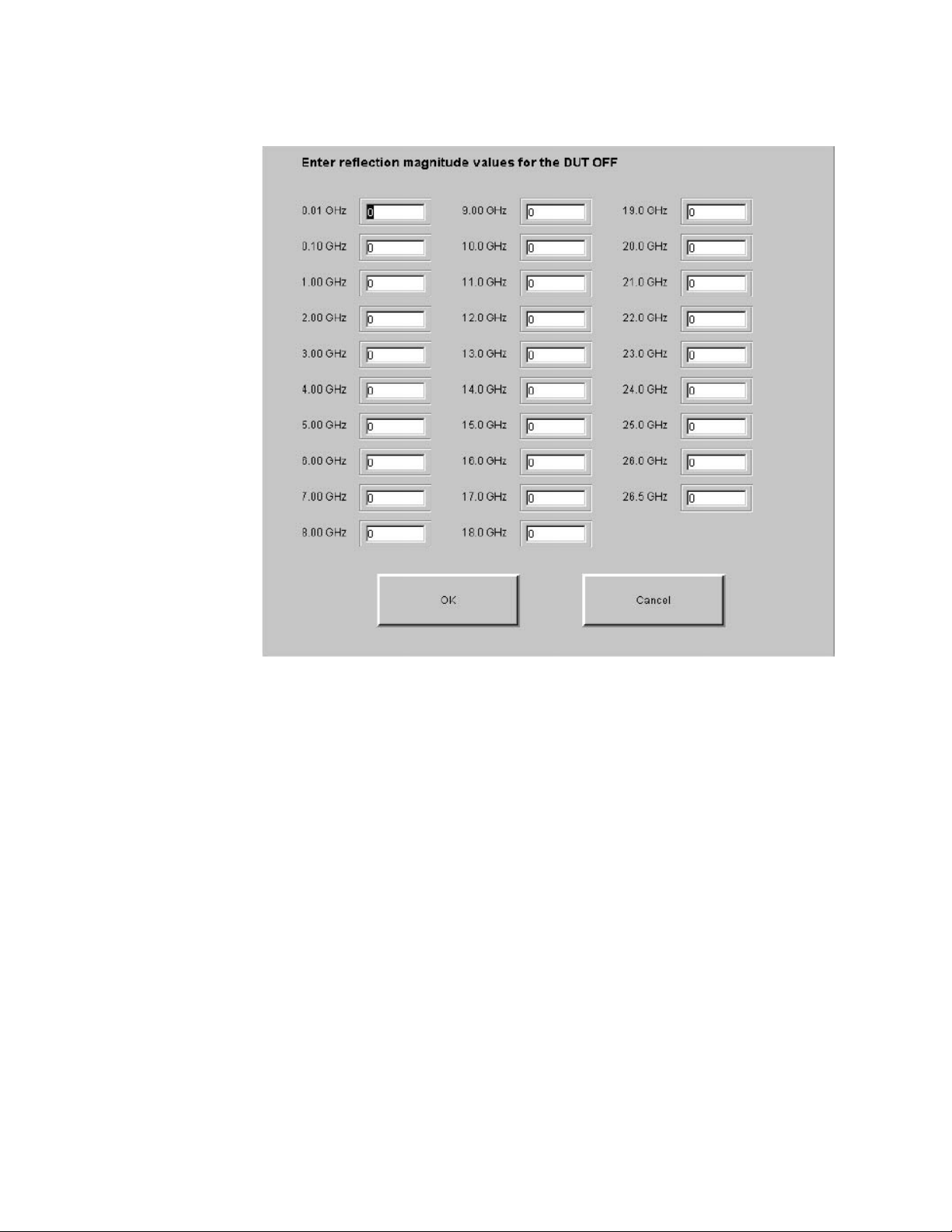

Copying Data to SNS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Making Multi Measurement on a DUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Selecting Other . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Setting SNS Bias Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

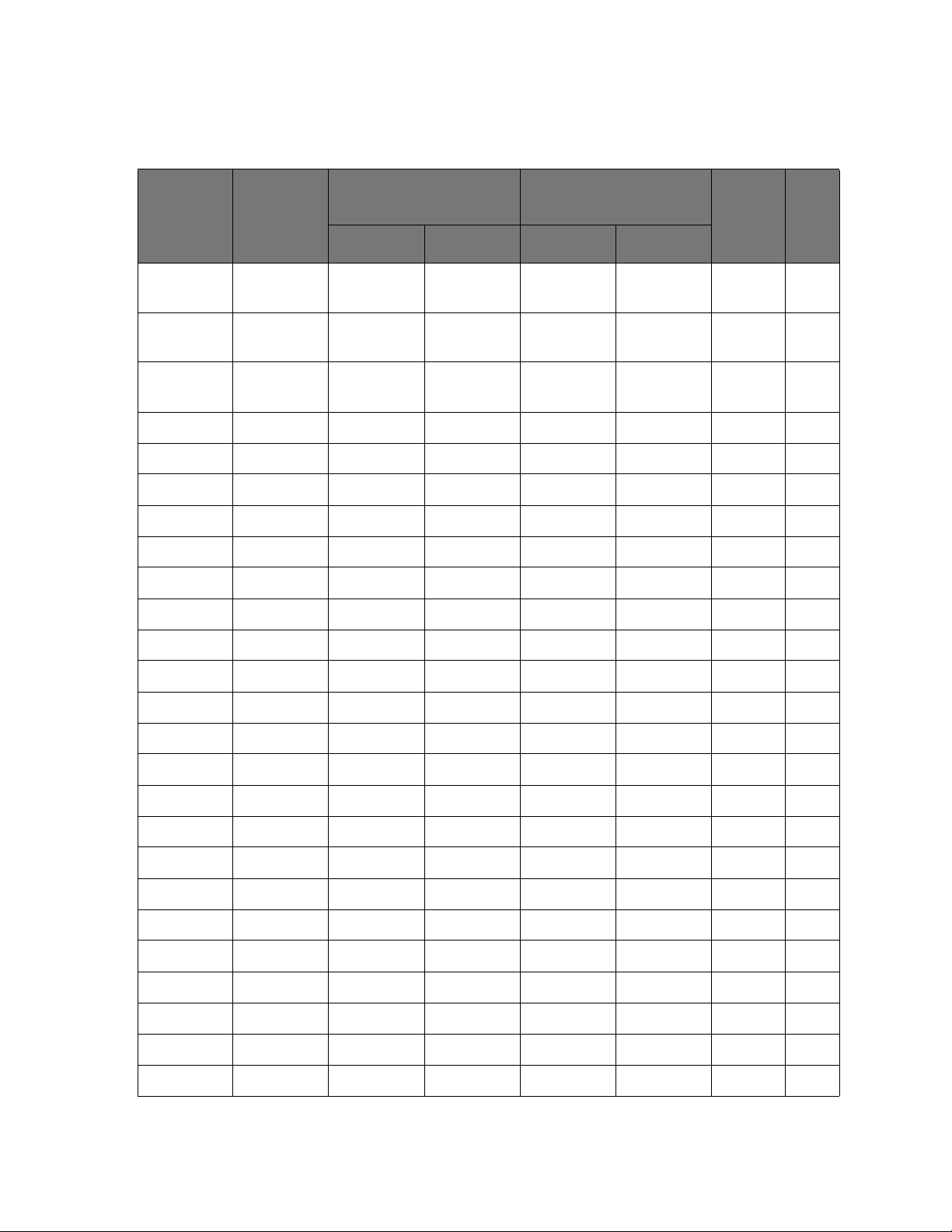

A:.Test Records for the 346A

Reflection Coefficient Magnitude and Phase Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

Excess Noise Ratio (ENR) Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Uncertainty Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

viii Keysight N2002A User’s Guide

Page 9

B:.Test Records for the 346B

Reflection Coefficient Magnitude and Phase Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Excess Noise Ratio (ENR) Test Record. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Uncertainty Test Record. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

C:.Test Records for the 346C

Reflection Coefficient Magnitude and Phase Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Excess Noise Ratio (ENR) Test Record. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Uncertainty Test Record. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

D:.Test Records for the N4000A

Reflection Coefficient Magnitude and Phase Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Excess Noise Ratio (ENR) Test Record. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Uncertainty Test Record. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

E:.Test Records for the N4001A

Contents

Reflection Coefficient Magnitude and Phase Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Excess Noise Ratio (ENR) Test Record. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Uncertainty Test Record. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

F:.Test Records for the N4002A

Reflection Coefficient Magnitude and Phase Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Excess Noise Ratio (ENR) Test Record. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Uncertainty Test Record. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

G:.Caring for Connectors

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Connector Part Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Handling and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Visual Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Obvious Defects and Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Mating Plane Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Precision 7 mm Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Sexed Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Compressed Air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Cleaning Alcohol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Precision 7 mm Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Cleaning Interior Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Drying Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Keysight N2002A User’s Guide ix

Page 10

Contents

Mechanical Inspection: Connector Gages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

Mechanical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

Precision 7mm Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

Sexed Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

50 Ohm Type-N Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

75 Ohm Type-N Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

Using Connector Gages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

Inspecting and Cleaning the Gage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

Zeroing the Gage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

Measuring Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

Making Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

Align Connectors Carefully . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

To Make a Preliminary Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

Final Connection Using a Torque Wrench . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

Disconnection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

Adapters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .128

Principles of Microwave Connector Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .130

x Keysight N2002A User’s Guide

Page 11

Keysight Technologies

Noise Source Test Set

N2002A

1 Using the N2002A

This chapter contains specifications and typicals for the Keysight N2002A noise

source test set. The distinction between specification and typicals is described

as follows.

Specifications describe the performance of parameters covered by the product

warranty. (The temperature range is 0 ⁰C to 55 ⁰C, unless otherwise noted.)

Typical performance describes additional product performance information

that is not covered by the product warranty. It is performance beyond

specification that 80% of the units exhibit with a 95% confidence level over the

temperature range 20 ⁰C to 30 ⁰C. Typical performance does not include

measurement uncertainty.

Introduction

This manual contains operating information for the Keysight N2002A Noise Source

Test Set. It is needed when making Excess Noise Ratio (ENR) tests on a noise

source. The N2002A Noise Source Test Set operates over

10.0 MHz to 26.5 GHz.

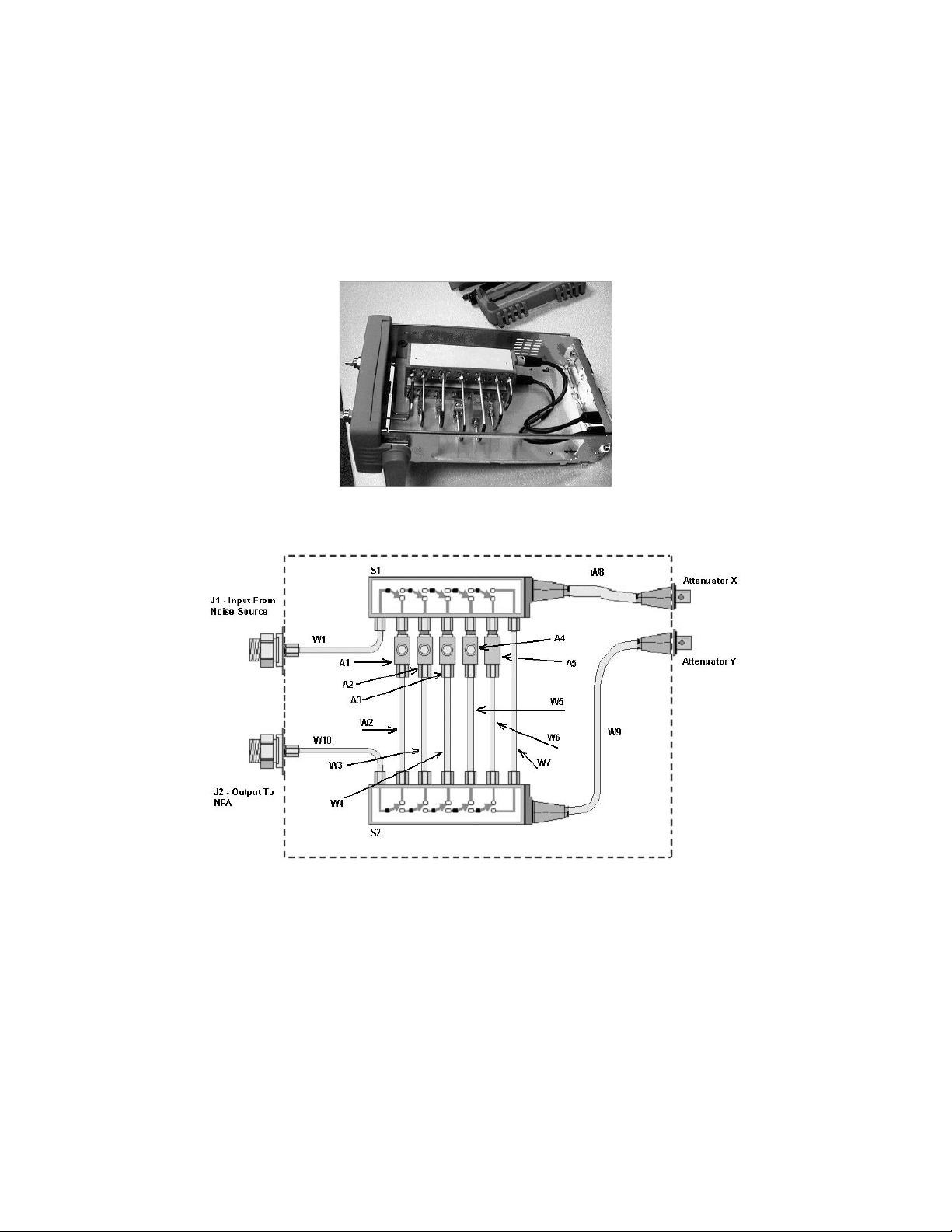

Figure 1-1 The N2002A Noise Source Test Set

The Keysight N2002A Noise Source Test Set is controlled by a 11713A

Attenuator/Switch Driver. The 11713A can be controlled using the supplied

a frequency range of

9

Page 12

Using the N2002A

Introduction

Keysight N2002A Noise Source Demonstration Software or it can be controlled

manually. These control methods are described in separate chapters.

Recommended Test Equipment

Table 2-4 on page 29 and Table 2-5 on page 30 lists the recommended test

equipment for the

coefficient magnitude and phase calibration respectively.

Limited substitution of test equipment is supported when using the Keysight

N2002A Noise Source Demonstration Software.

The noise source calibration process needs adapters and cables. The cables

and adapters are available as an option (Option 001) with the Keysight

N2002A. Keysight Technologies recommends using high quality cables and

precision adapters. You must ensure all cables and adapters are specified for

the frequency range they are operating in. You also need to ensure that they

are in good electrical and mechanical condition.

For assistance in choosing the appropriate cable/adapter, or if you are not sure

about the correct selection of cables and adapters please contact your local

Keysight sales office.

excess noise ratio (ENR) measurement and the reflection

NOTE System performance is only guaranteed if each instrument in the test

system/process is within the manufacturer’s recommended calibration

period.

CAUTION Ensure the correct torque settings are used at all times. Refer to Table G-2 on

page 126.

Before You Start

Switch the test equipment on and let it warm up for at least one hour. Allow

the Noise Sources to stabilize at the ambient room temperature. Do not use a

noise source for one hour prior to performing the tests.

Read the rest of this section before you start any of the tests.

Recording the Test Results

If you are doing the measurements manually, ensure you make a copy of the

Test Record of the model you are measuring. Test Records are provided in the

Appendices for each noise source model.

10 Keysight N2002A User’s Guide

Page 13

Using the N2002A

Introduction

Keysight Technologies recommend that you make a copy of the Test Record,

recording the test results on the copy, and keep the copy for your calibration

test record. This record could prove valuable in tracking gradual changes in

test results over long periods of time.

Failure During the Test Procedures

If the ENR tests fail and you suspect the N2002A or the DUT requires repair.

Please contact your local Keysight Customer Sales and Service Office for

replacement parts or repair service information. Refer to “Service” on page 19

for your local Sales and Service Offices.

Handling Precautions

Proper connector care is essential. See Appendix G:, “Caring for Connectors,”

on page 111 for more information.

CAUTION Do not rotate the Noise Source body when connecting it to the Noise Source

Test Set, or internal damage may result.

CAUTION Do not drop the noise source. Dropping can damage the unit.

Keysight N2002A User’s Guide 11

Page 14

Using the N2002A

Description

Description

Figure 1-2 shows the Noise Source Test Set with the cover removed.

Figure 1-3 shows the internal wiring and the reference designators of the parts

used in the Noise Source Test Set.

Figure 1-2 The Noise Source Test Set with Outer Cover Removed

Figure 1-3 The Noise Source Test Set Schematic Component Layout

12 Keysight N2002A User’s Guide

Page 15

Using the N2002A

Operation

Operation

This section refers to control operation of the Keysight N2002A Noise Source

Test Set. The Noise Source Test Set is controlled by a 11713A

attenuator/switch driver. The 11713A switch controlling settings are shown in

the Table 1-1. For more detailed operating instructions, refer to the Keysight

11713A Attenuator/Switch Driver Operating and Service Manual (Part number

11713-90023).

NOTE Connect the X and Y Drive cables between the rear panels of the Noise

Source Test Set and the 11713A Attenuator/Switch Driver.

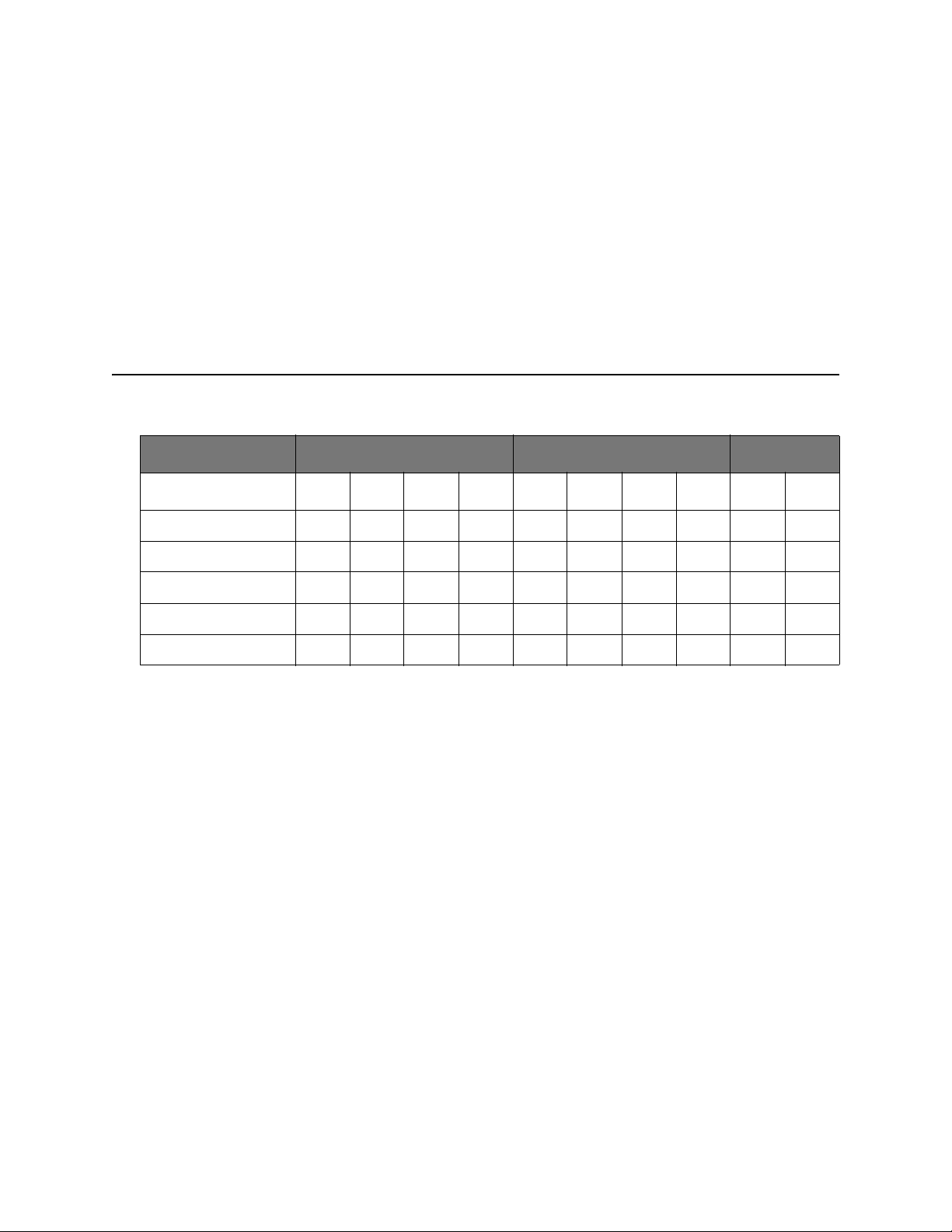

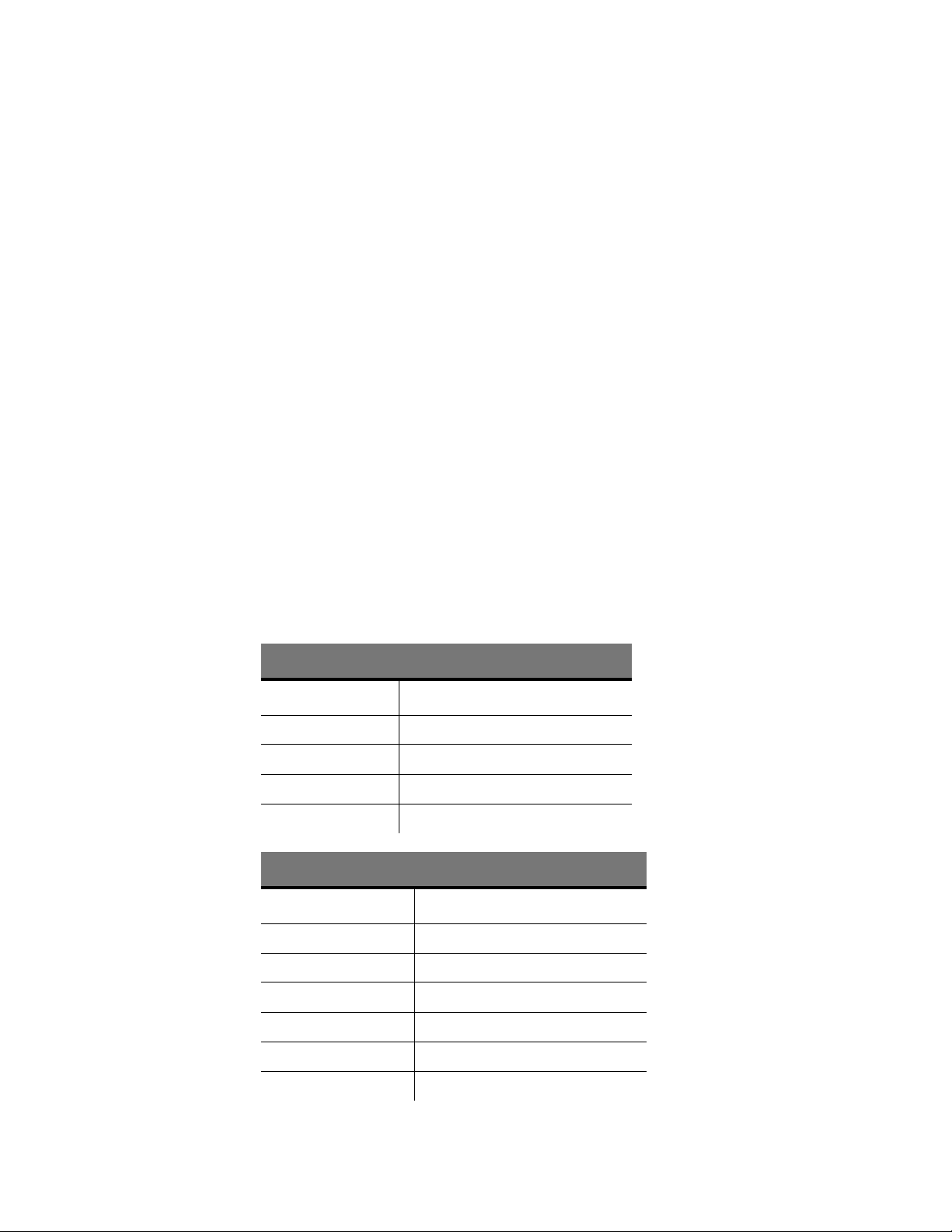

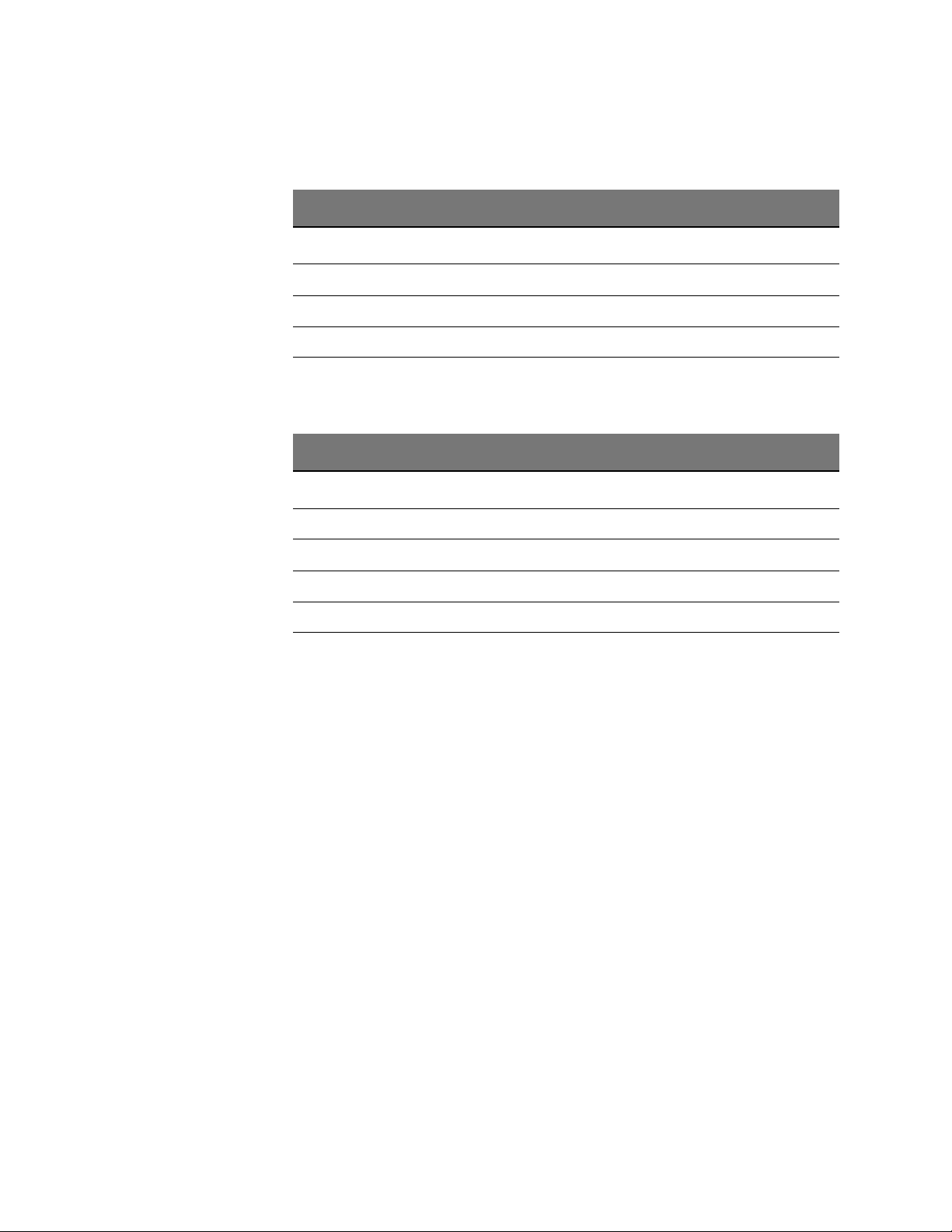

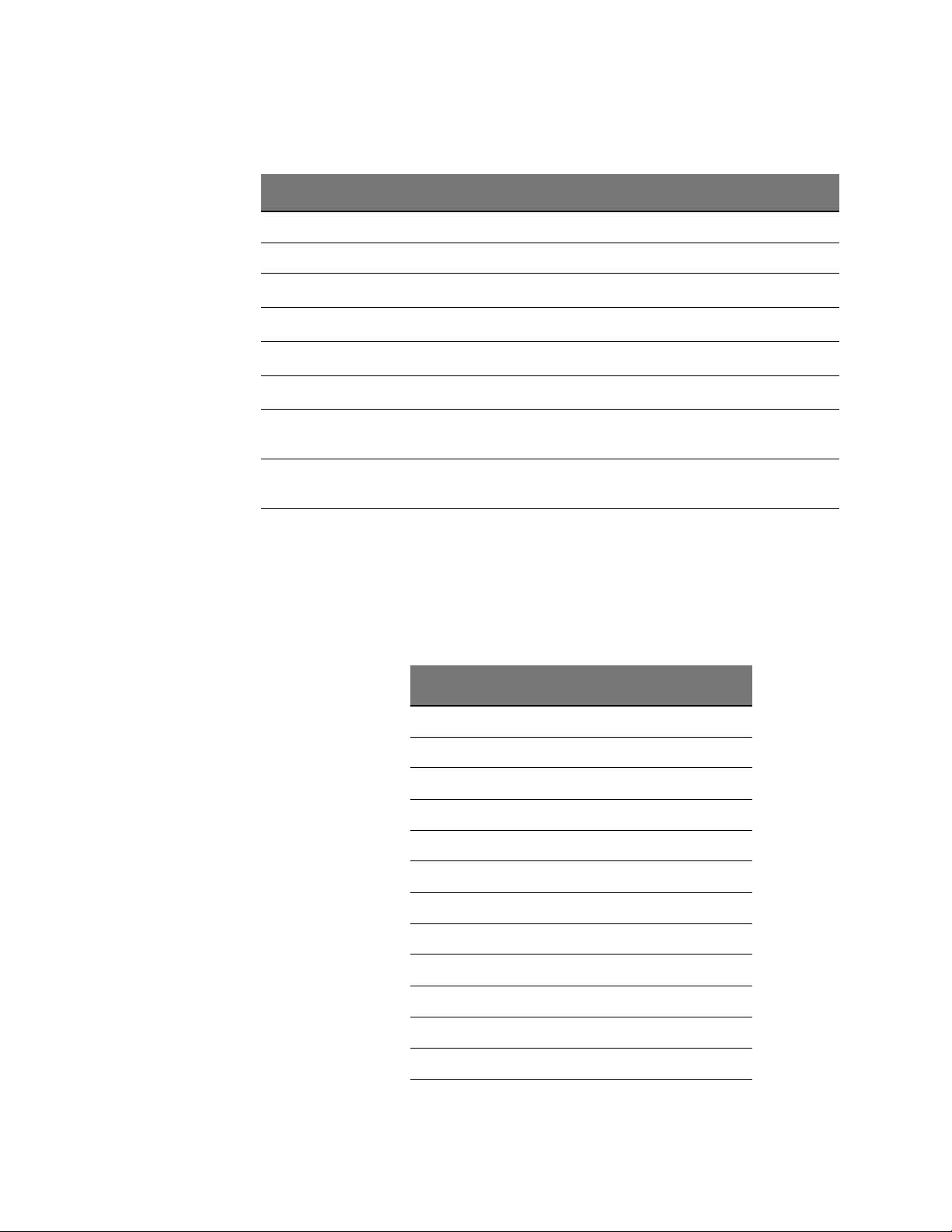

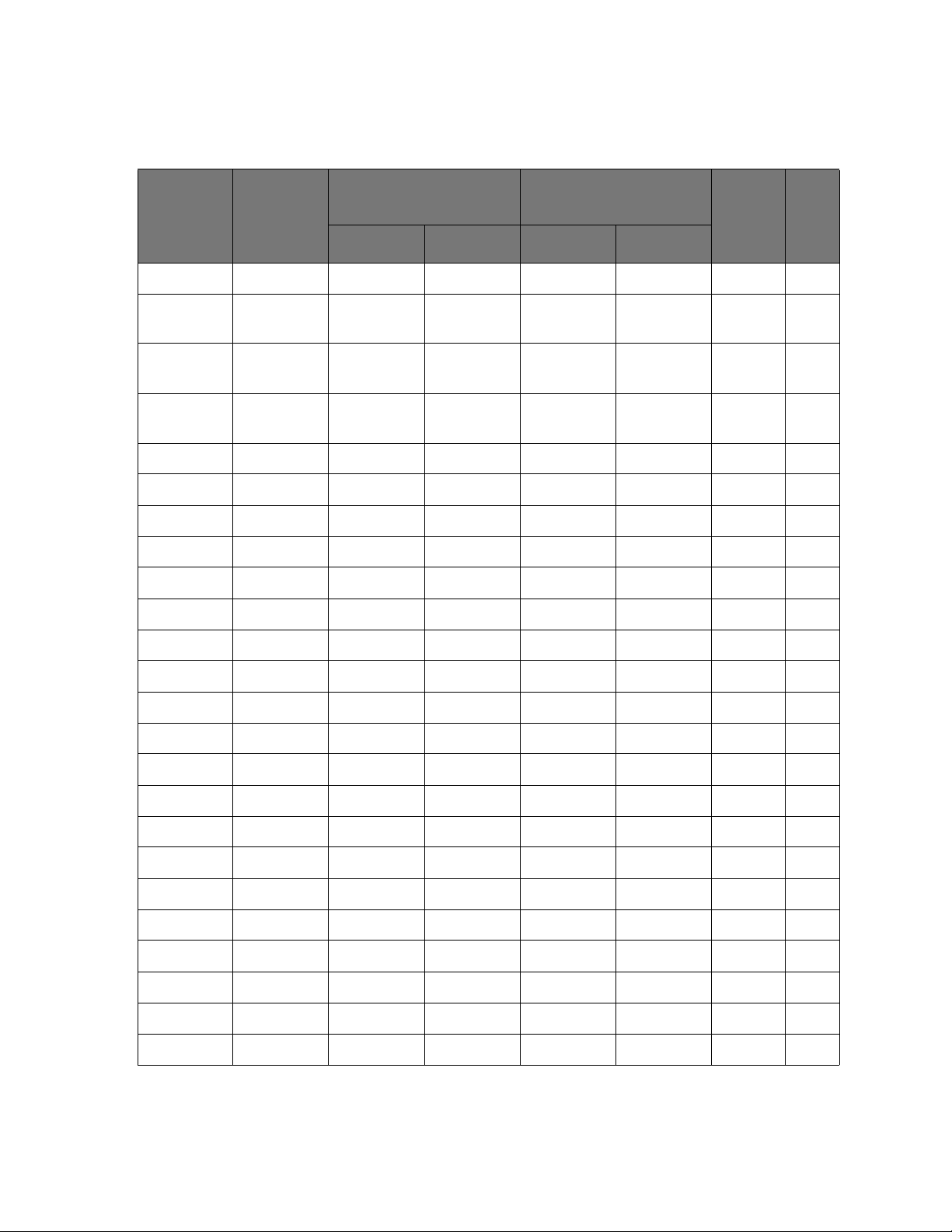

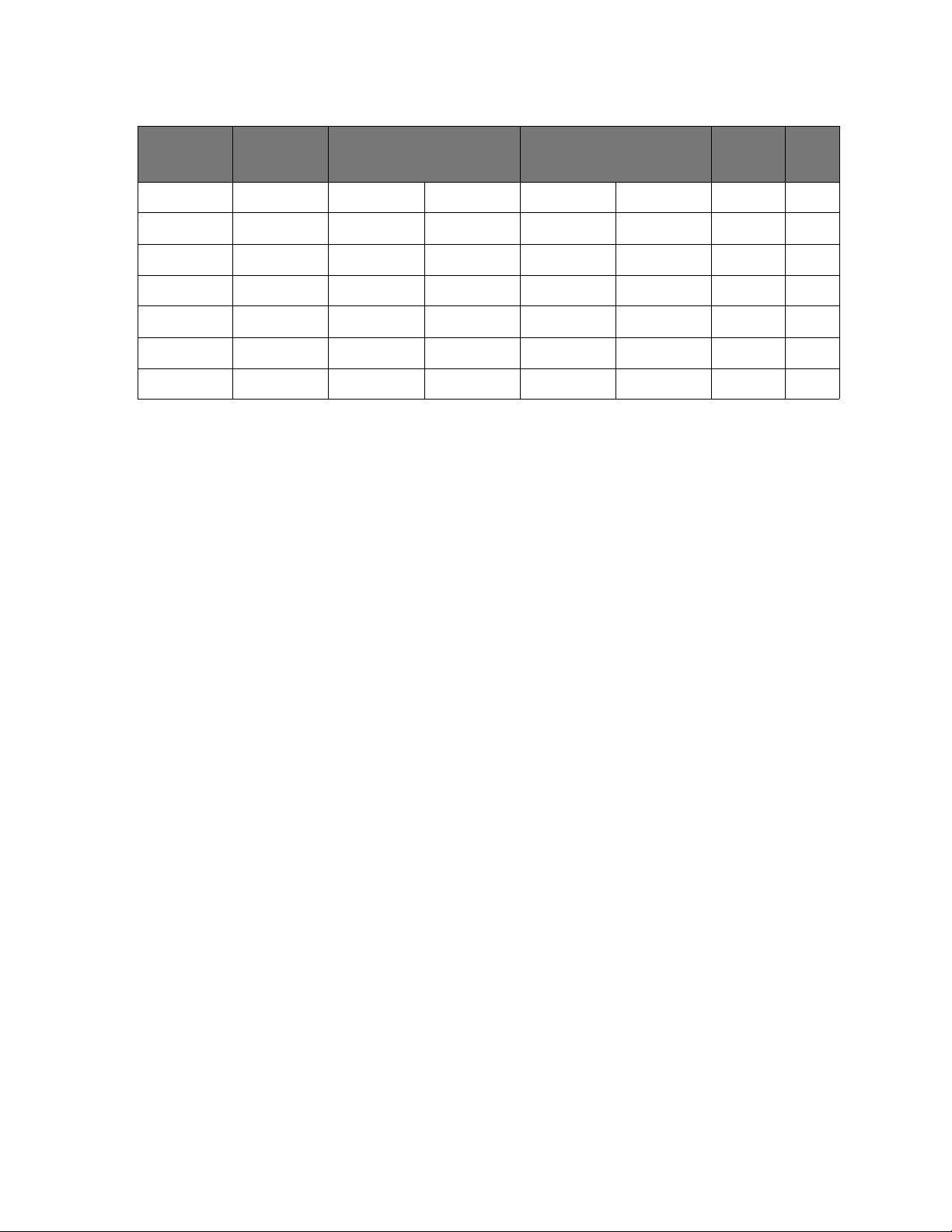

Table 1-1 11713A Attenuator/Switch Driver Settings

Frequency Path (MHz) Attenuator X Attenuator Y Switches

1234567890

10 to <3000 xx

3000 to 6000 x x

<6000 to 12000 x x

>12000 to 18000 x x

>18000 to 26500 x x

Keysight N2002A User’s Guide 13

Page 16

Maintenance

N2002A Verification Test

Using the N2002A

Maintenance

Proper connector care is a vital part of the maintenance which should be

performed by the user. The life of the connector can be greatly extended by

following the general connector care practices outlined in Appendix G:,

“Caring for Connectors,” on page 111.

The verification test procedure involves confirming that the N2002A Noise

Source Test Set’s switch paths are functioning and the VSWR meets its typical

limit. Tab le 1-2 lists the typical VSWR limit and the switch positions on the

11713A.

Equipment Required

— Network analyzer frequency coverage from 10 MHZ to 26.5 GHz.

— Appropriate network analyzer calibration kits.

— Keysight 11713A Attenuator / Switch Driver.

— Viking cables for connection to 11713A.

Connections Required

Connect the Viking control cables from the rear of the 11713A

attenuator/switch driver to the rear of the N2002A Noise Source Test Set.

Connect Atten X on the 11713A to the Attenuator X on the N2002A and Atten

Y on the 11713A to Attenuator Y on the N2002A.

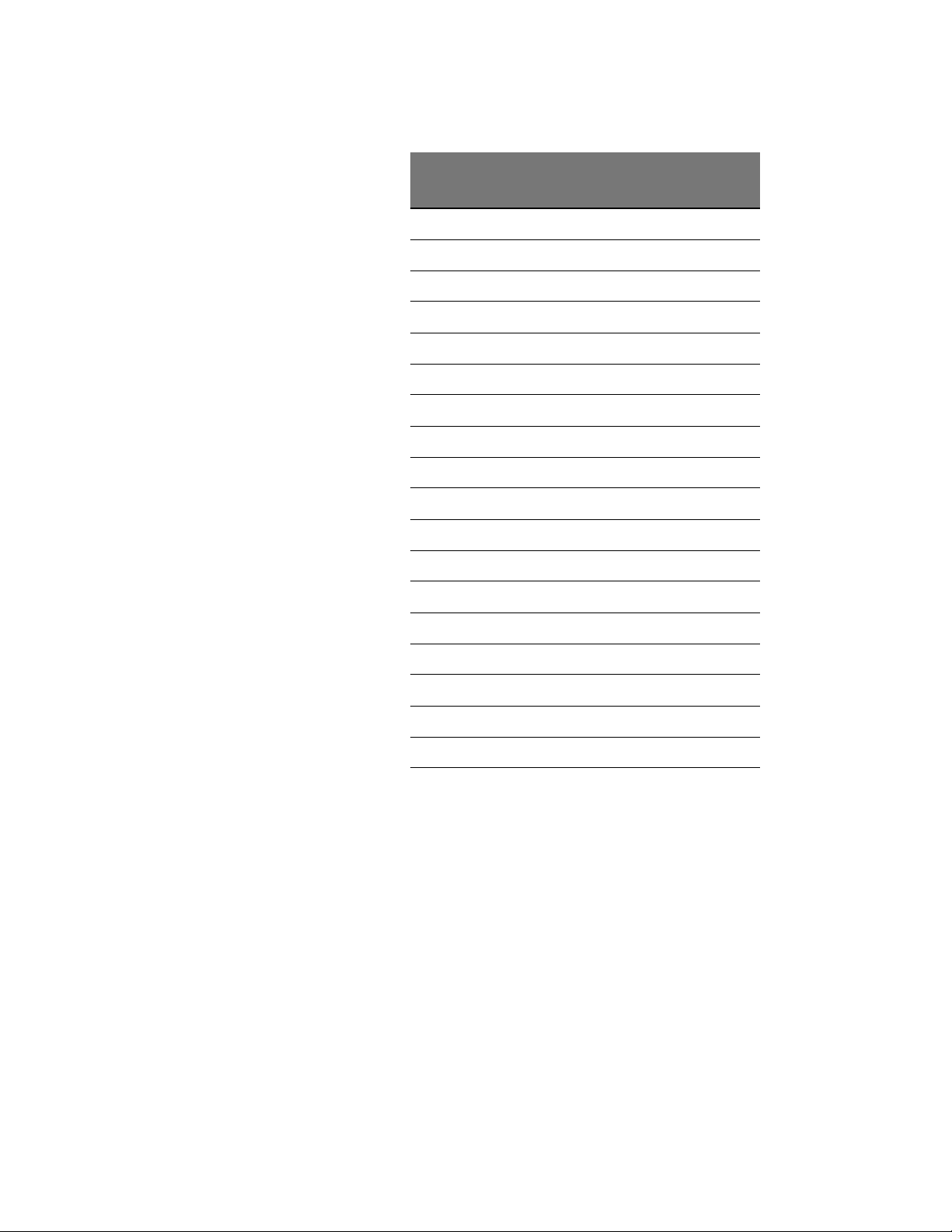

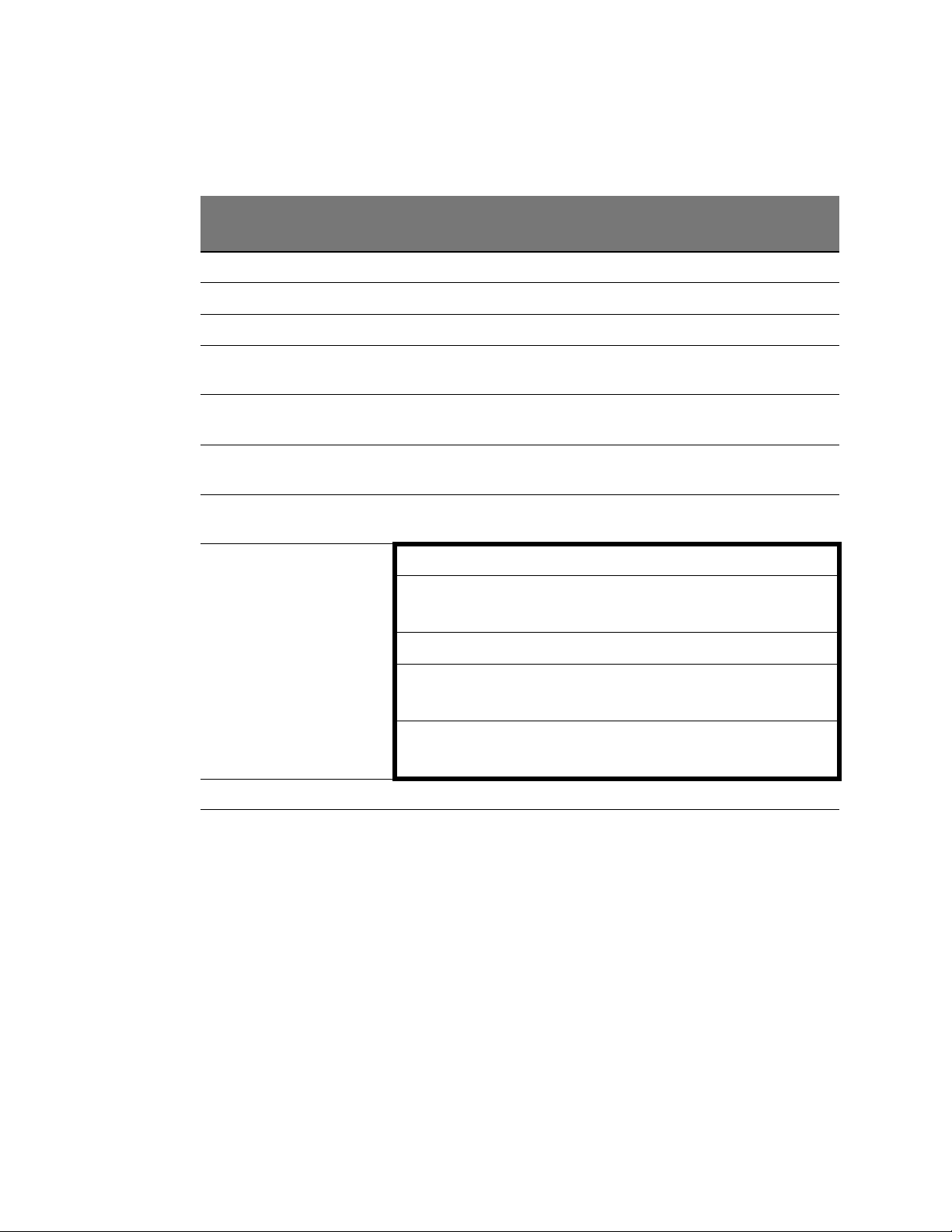

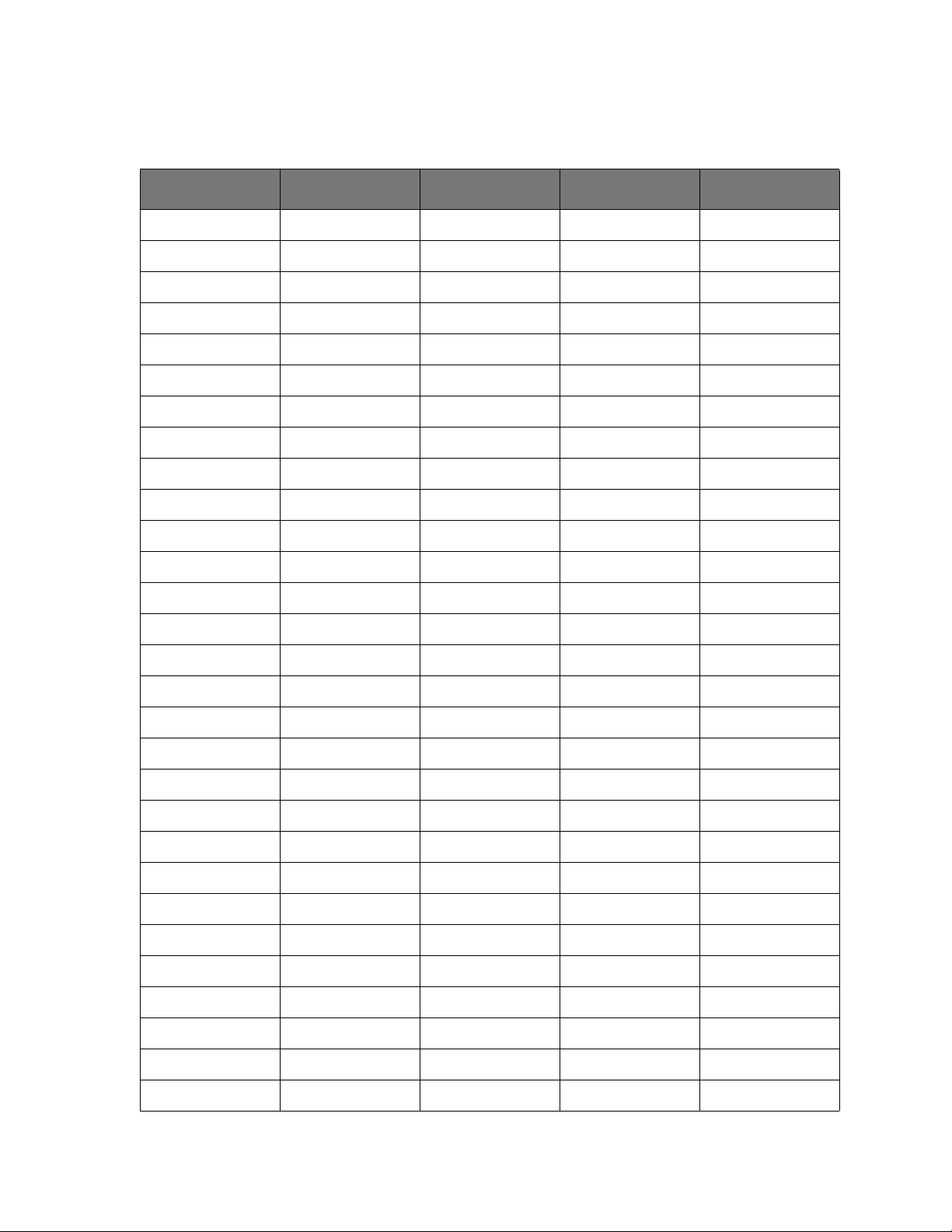

Table 1-2 Typical VSWR

Frequency Typical VSWR

Limit

10 MHz 1:1.05 0 On, 9 On

100 MHz 1:1.05 0 On, 9 On

1 GHz 1:1.05 0 On, 9 On

2 GHz 1:1.05 0 On, 9 On

3 GHz 1:1.05 0 On, 9 On

4 GHz 1:1.1 1 On, 5 On

5 GHz 1:1.1 1 On, 5 On

Switch

Positions

6 GHz 1:1.1 1 On, 5 On

7 GHz 1:1.15 3 On, 7 On

8 GHz 1:1.15 3 On, 7 On

14 Keysight N2002A User’s Guide

Page 17

Using the N2002A

Maintenance

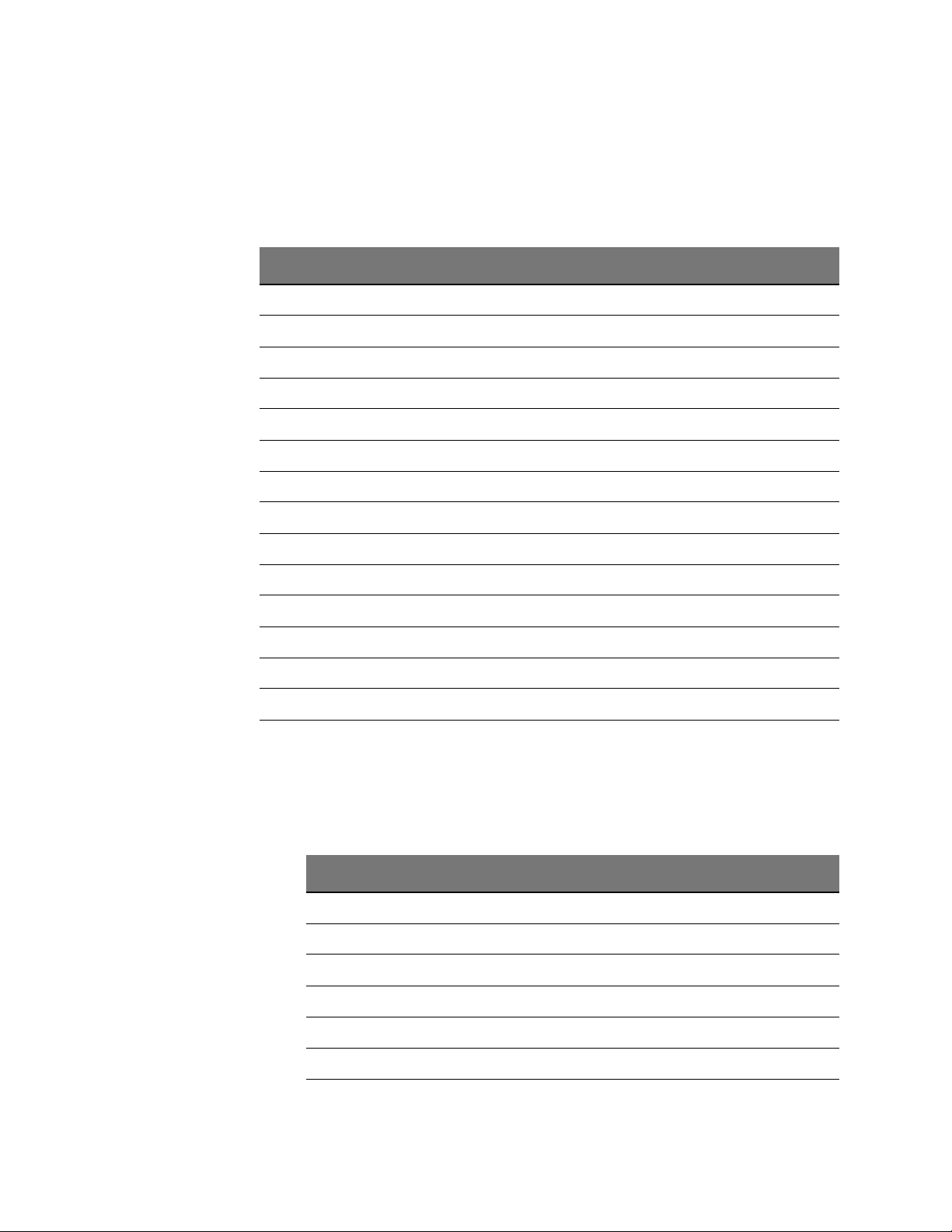

Table 1-2 Typical VSWR

Frequency Typical VSWR

Limit

9 GHz 1:1.15 3 On, 7 On

10 GHz 1:1.15 3 On, 7 On

11 GHz 1:1.15 3 On, 7 On

12 GHz 1:1.15 3 On, 7 On

13 GHz 1:1.15 2 On, 6 On

14 GHz 1:1.15 2 On, 6 On

15 GHz 1:1.15 2 On, 6 On

16 GHz 1:1.15 2 On, 6 On

17 GHz 1:1.15 2 On, 6 On

18 GHz 1:1.15 2 On, 6 On

19 GHz 1:1.18 4 On, 8 On

20 GHz 1:1.18 4 On, 8 On

21 GHz 1:1.18 4 On, 8 On

Switch

Positions

22 GHz 1:1.18 4 On, 8 On

23 GHz 1:1.18 4 On, 8 On

24 GHz 1:1.18 4 On, 8 On

25 GHz 1:1.18 4 On, 8 On

26 GHz 1:1.18 4 On, 8 On

26.5 GHz 1:1.18 4 On, 8 On

Keysight N2002A User’s Guide 15

Page 18

Using the N2002A

General Specifications

General Specifications

NOTE This instrument is designed for indoor use only.

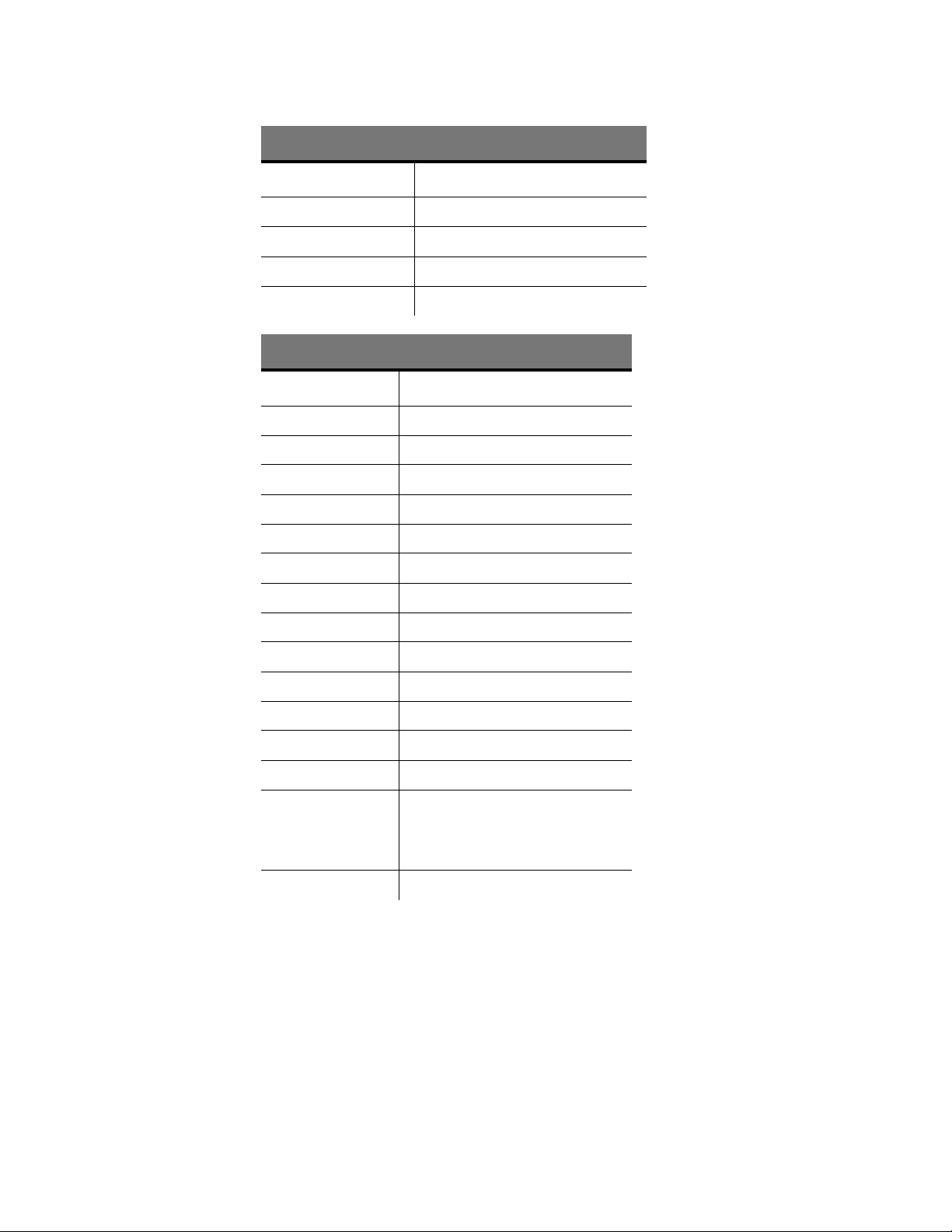

Table 1-3 Physical Dimension Specifications

Height 88.5 mm (3.5 inches)

Width 212.6 mm (8.5 inches)

Depth 348.3 mm (13.7 inches)

Weight 3.36 kg

Temperature Range

Humidity Range

Altitude Range

Operating: 0

Storage: -40

Operating: Up to 95% relative humidity to 40

Operating: To 4,600 meters

⁰C to +55 ⁰C

⁰C to +70 ⁰C

⁰C (non-condensing)

16 Keysight N2002A User’s Guide

Page 19

Using the N2002A

Replaceable Parts

Replaceable Parts

Table 1-4 and Table 1-5 lists the replaceable parts available for the Keysight

N2002A Noise Sources Test Set.

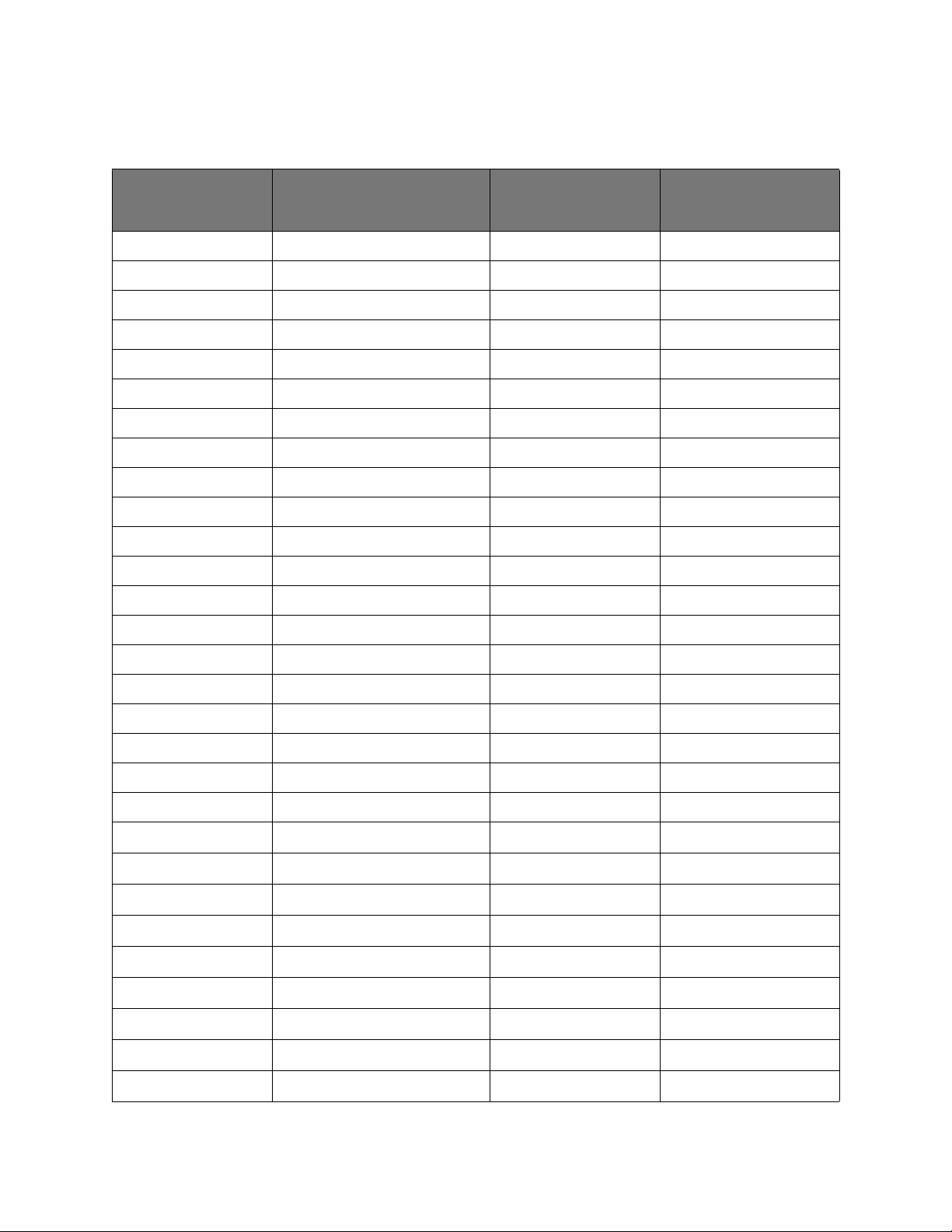

Table 1-4 Replaceable Parts

Reference Quantity Description Part Number

A1 1 18GHz - 26.5GHz Isolator N2002-80001

A2 1 12GHz - 18GHz Isolator N2002-80002

A3 1 6GHz - 12GHz Isolator N2002-80003

A4 1 3GHz - 6GHz Isolator N2002-80004

A5 1 3dB Attenuator 8493C

J1, J2 2 Bulkhead Connector 5062-1247

S1, S2 2 Multi-port Switch 8769K

W1 1 Semi rigid cable N2002-62003

W2, W3 2 Semi rigid cable N2002-62007

W4 1 Semi rigid cable N2002-62006

W5 1 Semi rigid cable N2002-62005

W6 1 Semi rigid cable N2002-62008

W7 1 Semi rigid cable N2002-62002

W8, W9 2 Viking cable N2002-62001

W10 1 Semi rigid cable N2002-62004

To order parts contact your local Keysight Technologies Sales and Service

Office. Refer to “Service” on page 19 for your local Sales and Service Offices

Table 1-5 Replaceable Parts

Description Quantity Part Number

Front Frame 1 N2002-20001

EMI Screen 1 N2002-20002

Front Panel 1 N2002-00003

Chassis 1 N2002-00005

Base Plate 1 N2002-00002

Switch Support 1 N2002-00001

Rear Panel 1 N2002-00004

Keysight N2002A User’s Guide 17

Page 20

Using the N2002A

Replaceable Parts

Table 1-5 Replaceable Parts

Description Quantity Part Number

Rear Bezel 1 E4418-20008

Cover 1 E4418-61027

Front Bumper 1 34401-86011

Rear Bumper 1 34401-86012

Handle 1 34401-45011

18 Keysight N2002A User’s Guide

Page 21

Service

Using the N2002A

Service

Contacting Keysight Technologies

When returning a Noise Source Test Set to Keysight Technologies for repair

send it to your nearest Sales and Service Office. These are listed in Table 1-6.

FAQs, instrument software updates, documentation, and other support

information can be accessed from this site.

To obtain servicing information or to order replacement parts, contact the

nearest Keysight office listed in Table 1-6. In any correspondence or telephone

conversations, refer to the instrument by its model number (N9030A) and full

serial number (ex. MY49250887). With this information, the Keysight

representative can quickly determine whether your unit is still within its

warranty period.

Table 1-6

By internet, phone, or fax, get assistance with all your test and measurement

needs.

Americas

Country Phone Number

Canada (877) 894 4414

Brazil 55 11 3351 7010

Mexico 001 800 254 2440

United States 1 800 829-4444

Asia Pacific

Country Phone Number

Australia 1 800 629 485

China 800 810 0189

Hong Kong 800 938 693

India 1 800 112 929

Japan 0120 (421) 345

Korea 080 769 0800

Keysight N2002A User’s Guide 19

Page 22

Using the N2002A

Service

Asia Pacific

Country Phone Number

Malaysia 1 800 888 848

Singapore 1 800 375 8100

Taiwan 0800 047 866

Other AP Countries (65) 6375 8100

Europe and Middle

Country Phone Number

Austria 0800 001122

Belgium 0800 58580

Finland 0800 523252

France 0805 980333

Germany 0800 6270999

Ireland 1800 832700

Israel 1 809 343051

Italy 800 599100

Luxembourg +32 800 58580

Netherlands 0800 0233200

Russia 8800 5009286

Spain 0800 000154

Sweden 0200 882255

Switzerland 0800 805353

Opt. 1 (DE)

Opt. 2 (FR)

Opt. 3 (IT)

United Kingdom 0800 0260637

20 Keysight N2002A User’s Guide

Page 23

Keysight Technologies

Noise Source Test Set

N2002A

2 The Noise Source Calibration Process and

Recommended Test Equipment

The Calibration Process

The calibration process consists of two performance verification tests:

— Excess Noise Ratio (ENR dB) test.

— Reflection Coefficient Magnitude and Phase tests.

The performance verification test procedures verify the electrical performance

to traceable standards of the following Keysight noise sources in accordance

with their published specification.

— 346A

— 346B

— 346C

— N4000A

— N4001A

— N4002A

NOTE The noise source calibration process also allows you to calibrate both

Keysight Technologies and other manufacturer’s noise sources operating

between 10.0 MHz and 26.5 GHz.

NOTE All tests are performed without access to the interior of the noise source.

21

Page 24

The Noise Source Calibration Process and Recommended Test Equipment

The Calibration Process

NOTE The noise source calibration process also allows you to calibrate additional

measurement frequency points other than the standard card inal points. The

measurement frequency points are determined by the frequency entries in the

ENR table.

The maximum measurement frequency/ENR pairs is 81.

Calibration Cycle

The noise sources require periodic verification of operational performance.

Under normal use and environmental conditions, a noise source is calibrated at

12 month intervals.

22 Keysight N2002A User’s Guide

Page 25

The Noise Source Calibration Process and Recommended Test Equipment

Test Descriptions

Test Descriptions

Excess Noise Ratio (ENR dB)

The Excess Noise Ratio (ENR) test is based on comparing the DUT test results

to a reference standard test resul ts. The reference standard is a calibrated

noise source with known ENR values. Measurements are taken on both the

reference standard and the DUT. The DUT ENR values are derived from these

resul ts.

These results verify that the noise source meets its published specification. The

specifications are provided in Table 2-1 on page 25.

The measurements are generally made at the cardinal frequencies points,

however, the NFA can allow up to 81 frequency/ENR pairs to be stored. The

suppled test records in the appendices only contain the cardinal frequency

points, therefore you need to create test record to increase this quantity.

NOTE The test should be performed within an environmental ambient temperature

of 296 ±1K (23° ±1°C).

Loading the Reference Standard’s ENR Data

Step 1. If you are using an SNS as a Reference Standard, the NFA uploads its ENR

data automatically. The NFA needs enabled to make this happen

automatically.

NOTE Further information on loading SNS ENR data, refer to the NFA User’s Guide.

Step 2. If you are using a 346x as a Reference Standard. you can use one of the

following methods:

—The A: drive.

—The C: drive.

— Create a file from the data supplied with the noise source, for example, the

certificate of calibration or the floppy disc.

— If you only want to calibrate the ENR data on a 346x noise source you can

use the ENR data on the noise source label.

Keysight N2002A User’s Guide 23

Page 26

The Noise Source Calibration Process and Recommended Test Equipment

Test Descriptions

Overview of the ENR Measurement Procedure

The process operates in the following method:

NOTE The ENR values of the reference standard (ENR1) are known.

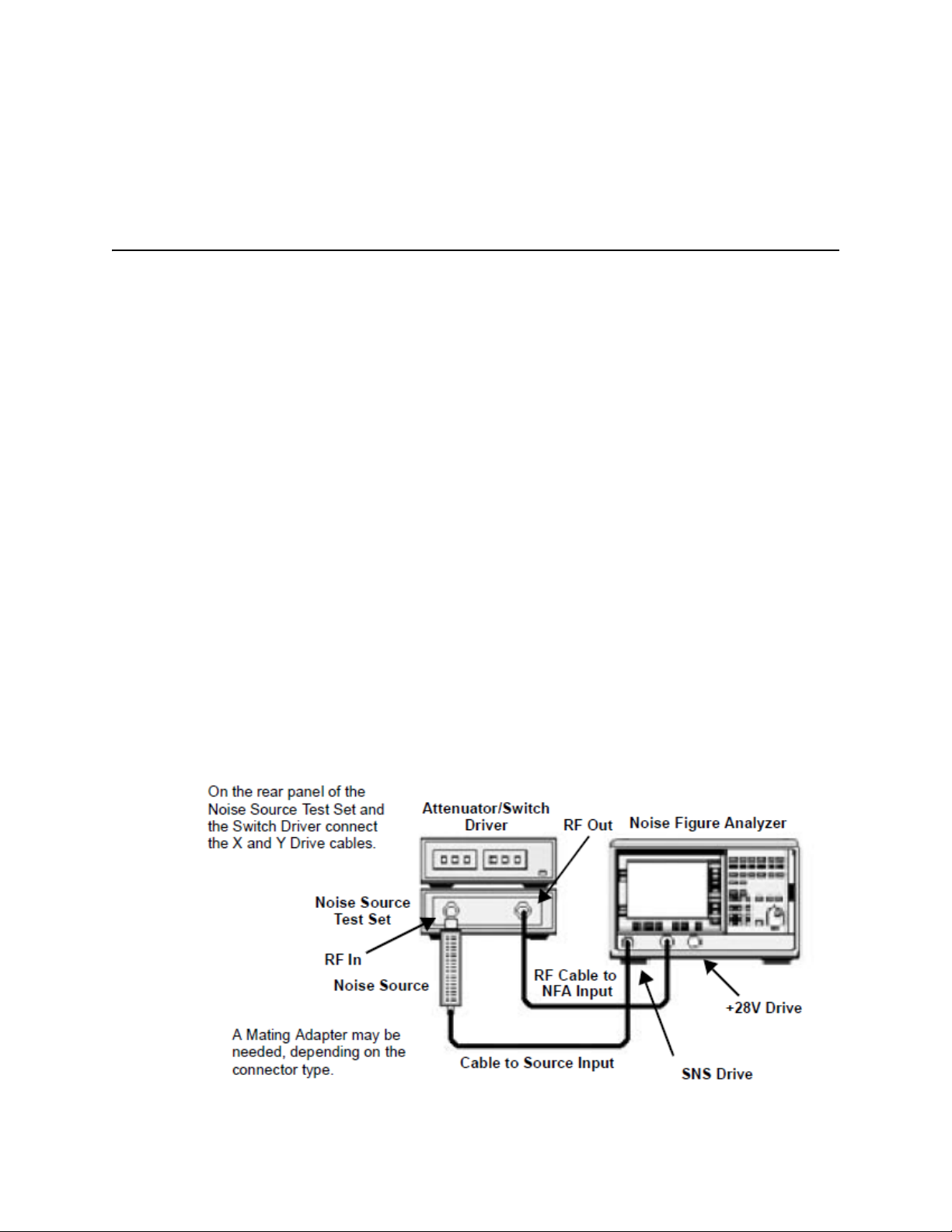

Step 1. Connect the test equipment together as shown in Figure 2-1.

Step 2. Set the test equipment to the measure the first frequency point.

Step 3. Measure a linear Y-Factor on the reference standard.

Step 4. On the Test Record note the result under the (Y

Step 5. Set the test equipment to the measure the next frequency point and repeat

the process until all the measurement points are complete.

Step 6. Remove the reference standard from the N2002A input and connect the DUT.

Step 7. Set the test equipment to the measure the first frequency point.

Step 8. Measure linear Y-Factor on the DUT.

Step 9. On the Test Record note the result under the (Y

Step 10. Repeat this process for the remaining measurement points.

Step 11. Using these measurement results, entering them in the equations, calculate

the ENR and the uncertainty values.

The Test Equipment Connection Diagrams for ENR Measurements

Figure 2-1 ENR Measurements

) column.

1

) column.

2

24 Keysight N2002A User’s Guide

Page 27

The Noise Source Calibration Process and Recommended Test Equipment

Test Descriptions

ENR Specifications

NOTE Specifications are valid at ambient temperature 23⁰ Celsius only (296 K).

Table 2-1 ENR Range for the Noise Sources

Instrument Model ENR Range

N4000A/346A 4.5 - 6.5 dB

N4001A/346B 14 - 16 dB

N4002A/346C 12 - 17 dB

Reflection Coefficient Magnitude and Phase

The Reflection Coefficient test measures the input magnitude and phase of the

noise source under test and verifies that it meets its published specification.

The specifications are provided in Table 2-2 on page 27 and Table 2-3 on

page 27. The tests are measured in the Source ON and OFF states.

The specified frequency ranges are swept for the maximum magnitude and

phase and the resultant maximum value is displayed on the VNA. The test also

measures the magnitude and phase at cardinal (pre-determined) frequency

points. These cardinal frequency points depend on the model and option being

tested.

The test equipment is connected together as shown in Figure 2-2 on page 26.

Overview of the Reflection Coefficient Magnitude and Phase

Measurement Procedure

NOTE The procedure requires network analyzer frequency range coverage from 10.0

MHz to 26.5 GHz. This procedures uses two VNAs, the 8753 is used to cover

the range 10.0 MHz to 3.0 GHz, and the 8722 is used to cover the range 3.0

GHz to 26.5 GHz.

The procedure operates in the following method:

Step 1. Calibrate the 8753 over the specified range, for example, 10.0 MHz to

1.5 GHz.

Step 2. Measure the DUT’s reflection coefficient, in an OFF and ON state, over the

specified range, for example, 10.0 MHz to 1.5 GHz.

Step 3. Note these resultant values on the Test Record.

Keysight N2002A User’s Guide 25

Page 28

The Noise Source Calibration Process and Recommended Test Equipment

Test Descriptions

Step 4. Measure the DUT’s reflection coefficient, in an OFF and ON state, at the

cardinal frequency points in the specified range.

Step 5. Note these resultant values on the Test Record.

Step 6. Repeat the Calibration and Measurement process using the 8753 over the

specified range, for example, 1.5 GHz to 3.0 GHz.

Step 7. Calibrate the 8722 over the specified range, for example, from 3.0 GHz to 7.0

GHz.

Step 8. Measure the DUT’s reflection coefficient, in an OFF and ON state, over the

specified range, for example, 3.0 GHz to 7.0 GHz.

Step 9. Note these resultant value on the Test Record.

Step 10. Measure the DUT’s reflection coefficient, in an OFF and ON state, at the

cardinal frequency points in the specified range.

Step 11. Note these resultant values on the Test Record.

Step 12. Repeat the Calibration and Measurement process using 8722 over the

specified range, for example, 3.0 GHz to 7.0 GHz

The Test Equipment Connection Diagrams for Reflection and Phase

Measurements

Figure 2-2 Reflection and Phase Measurements

26 Keysight N2002A User’s Guide

Page 29

The Noise Source Calibration Process and Recommended Test Equipment

Test Descriptions

Reflection and Phase Specifications

Table 2-2 Reflection Coefficient for 346x Noise Source

Frequency Range Model

346A 346B 346C

10.0 MHz to 30.0 MHz 0.13 0.13 0.11

30.0 MHz to 5.0 GHz 0.07 0.07 0.11

5.0 GHz to 18.0 GHz 0.11 0.11 0.11

18.0 GHz to 26.5 GHz ---------------- ---------------- 0.15

Table 2-3 Reflection Coefficient for the N400xA SNS

Frequency Range Model

N4000A N4001A N4002A

10.0 MHz to 1.5 GHz 0.02 0.07 0.10

1.5 GHz to 3.0 GHz 0.02 0.07 0.10

3.0 GHz to 7.0 GHz 0.06 0.09 0.10

7.0 GHz to 18.0 GHz 0.10 0.11 0.11

18.0 GHz to 26.5 GHz ---------------- ---------------- 0.15

Keysight N2002A User’s Guide 27

Page 30

The Noise Source Calibration Process and Recommended Test Equipment

Reference Standard Noise Source Selection

Reference Standard Noise Source Selection

The reference standard selection defines the measurement frequencies of both

the reference standard and the DUT. Both the reference standard and the DUT

must be measured at the same frequency points.

The accuracy of the DUT’s ENR measurement results is dependent on the

calibration accuracy of the reference standard. Also, a proportion of the DUT’s

measurement uncertainty is based on the reference standard’s measurement

uncertainty. Therefore, to maximize the measurement accuracy and minimize

the measurement uncertainty, a reference standard that has been calibrated by

a national standards laboratory is recommended.

NOTE

NOTE A Reference Standard’s ENR values are valid at calibration temperature only.

A Reference Standard’s uncertainty values are only valid at ambient

temperature 23°C ±1°C (296K).

More than one reference standard may be required for more accurate results.

Keysight Technologies recommend using the same type of reference standard

as the noise source being measured.

The ENR measurement process requires various adapters and cables. For more

accurate results Keysight Technologies recommend using high quality cables

and precision adapters. Care should be taken to ensure all cables and adapters

are specified for the frequency range in which they are used and that they are

in good electrical and mechanical condition.

Keysight Technologies noise sources can be used at non-standard (not

cardinal) frequency points by creating an ENR table containing the wanted

measurement frequency points. However, the ENR values and the ENR

uncertainty values of the reference standard must be manually interpolated

from the supplied data.

28 Keysight N2002A User’s Guide

Page 31

The Noise Source Calibration Process and Recommended Test Equipment

Recommended Test Equipment

Recommended Test Equipment

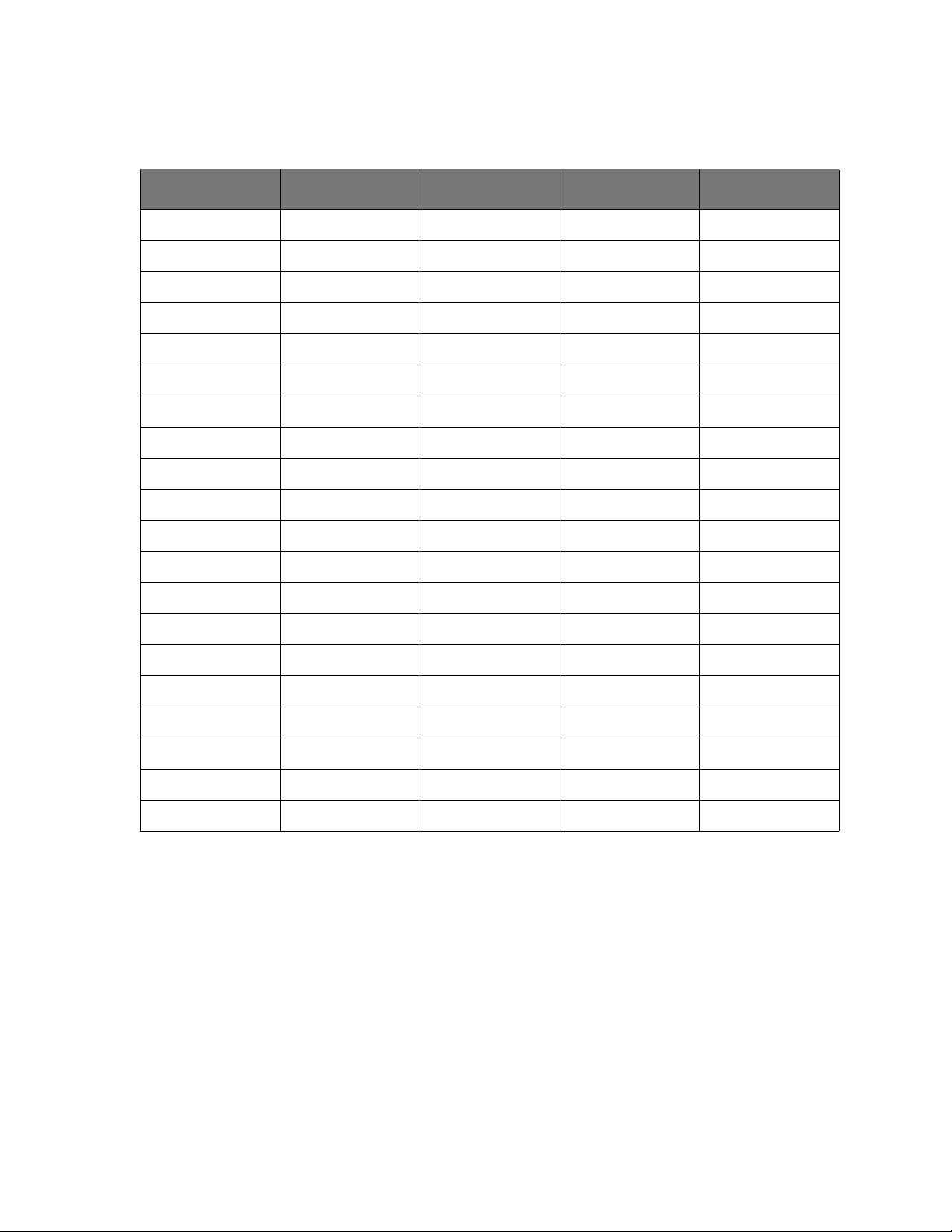

Table 2-4 Recommended Test Equipment for ENR Measurements

Equipment Description Critical Specifications for Equipment

Substitution

Noise Figure Analyzer No substitute available for SNS N8975A

Noise Source Test Set No substitute available N2002A

Attenuator/Switch Driver Compatible with 8768K multi-port switch 11713A

Attenuator/Switch Driver

Interconnect Cables (x2)

Standard Noise Source

(Dependant on DUT)

RF Cable 10MHz to 26.5GHz 3.5mm (M) to 3.5mm (M),

Adapter (NFA and Noise

Source Test Set)

Adapter (Dependant on DUT) DUT Connector Type: Adapter Type:

Compatible with 11713A Viking terminals 11764A

See “Reference Standard Noise Source Selection” on page 28

61 cm (24 in)

3.5mm Precision (F) to 3.5mm (F) 1250-1749

Type N (Male)

3.5mm (F) to Type N (F)

Type N (Female) 3.5mm (F) to Type N (M) 1250-1744

Recommended Model

11500E

1250-1745

APC 7

3.5mm (F) to APC 7

3.5mm (Male)

3.5mm (F) to 3.5mm (F)

BNC Lead Length 122cm (48”), Frequency 10MHz 10503A

SNS Interconnect Cable No substitute available 11730A

1250-1747

1250-1749

Keysight N2002A User’s Guide 29

Page 32

The Noise Source Calibration Process and Recommended Test Equipment

Recommended Test Equipment

Table 2-5 Recommended Test Equipment for ENR Measurements

Equipment Description Critical Specifications for

Equipment Substitution

Noise Figure Analyzer No substitute available for SNS N8975A

Vector Network Analyzer 1 10MHz to 3GHz 8753ES or 8753ET, opt 004

Vector Network Analyzer 2 3GHz to 18GHz or 26.5GHz 8722ES or 8722ET, opt 004

Calibration Kit 1 Connector: Type N

Impedance: 50 Ohm

Bandwid th: 10MHz to 3GHz

Calibration Kit 2 Connector: 3.5mm

Impedance: 50 Ohm

Bandwid th: 10MHz to 3GHz

Calibration Kit 3 Connector: 7 mm

Impedance: 50 Ohm

Bandwid th: 10MHz to 3GHz

Calibration Kit 4 Connector: Type N

Impedance: 50 Ohm

Bandwid th: 10.0 MHz to 18.0 GHz

Calibration Kit 5 Connector: 3.5 mm

Impedance: 50 Ohm

Bandwid th: 10.0 MHz to 18.0 GHz

Recommended Model

85032E

85033D

85031B

85054D

85052D

Calibration Kit 6 Connector: 7 mm

Impedance: 50 Ohm

Bandwid th: 10.0 MHz to 18.0 GHz

BNC Lead Length 122cm (48") 10503A

SNS Interconnect Cable No substitute available 11730A

85050D

30 Keysight N2002A User’s Guide

Page 33

Keysight Technologies

Noise Source Test Set

N2002A

3 Using the Manual Calibration Procedure

Introduction

Before You Start

Switch the test equipment on and let it warm up for at least one hour. Allow

the Noise Sources to stabilize at the ambient room temperature. Do not use a

noise source for one hour prior to performing the tests.

Read the rest of this section before you start any of the tests. Make a copy of

the Test Record of the models you are measuring.

Recording the Test Results

Test Records are provided in the Appendices for each Keysight noise source

model.

Keysight Technologies recommend that you make a copy of the Test Record,

recording the test results on the copy, and keep the copy for your calibration

test record. This record could prove valuable in tracking gradual changes in

test results over long periods of time.

Failure During the Test Procedures

If any of the tests fail and you suspect the unit requires repair. Please contact

your local Keysight Customer Sales and Service Office for replacement parts or

repair service information. Refer to

Service Offices.

“Service” on page 19 for your local Sales and

31

Page 34

Using the Manual Calibration Procedure

ENR Manual Procedure

ENR Manual Procedure

This procedure must be performed using the Test Records.

Before you start, enter the reference standard’s ENR values in the Standard

ENR1 column in the ENR Test Record and the reference standard’s uncertainty

values in the Standard ENR1 Uncertainty column in the Uncertainty Test

Record. These values are needed when calculating the DUT’s values using the

equations.

NOTE Refer to “Reference Standard Noise Source Selection” on page 28 for

information on this selection criteria.

CAUTION Ensure the correct torque settings are used at all times. Refer to Appendix G’s

Table 2 on page 126.

Step 1. Connect the equipment as shown in Figure 2-1. Depending on the reference

standard noise source selected, connect the equipment using either the SNS

interconnect cable or the BNC lead. Ensure the reference standard noise

source RF connector is the same type as the DUT and connect using the

preferred adapters listed in Table 2-4 on page 23.

Step 2. Ensure the Noise Figure Analyzer preset is set to factory settings.

a. Press the System key.

b. Press the More 1 of 3 menu key.

c. Press the Power On/Preset menu key.

d. Set the Power On to Power On (Preset) and Preset to Preset (Factory).

Step 3. Press Preset and wait for the preset routine to finish.

Step 4. Load the reference standard noise source ENR data.

Refer to Chapter 2’s “Loading the Reference Standard’s ENR Data” on

page 23 for information on this.

NOTE Do not calibrate the NFA. Ensure the NFA displays Uncorr.

Step 5. Select the display to meter mode.

a. Press the Format key.

b. Press the Format menu key.

c. Press the Meter menu key.

32 Keysight N2002A User’s Guide

Page 35

Using the Manual Calibration Procedure

ENR Manual Procedure

Step 6. Set the measured result to Y-Factor.

a. Press the Result key.

b. Press the Y-Factor menu key.

Step 7. Set the Y-Factor scale to linear units.

a. Press the Scale key.

b. Set the Units to Units (Linear).

Step 8. Set sweep to single.

a. Press the Sweep key.

b. Set the Sweep to Sweep Mode (Single).

Step 9. Set the frequency mode to fixed.

a. Press the Frequency/Points key.

b. Press the Freq Mode menu key.

c. Press the Fixed menu key.

Step 10. Set the averaging to 128 (or greater).

a. Press the Averaging/Bandwid th key.

b. Set the Averaging to Averaging (On).

c. Set the Average Mode to Average Mode (Sweep).

d. Press the Averages menu key and on the numeric key pad press 1, 2, 8,

followed by the Enter key.

Step 11. Alignment point.

Step 12. Set the frequency to 10.0 MHz.

a. Press the Frequency/Points key.

b. Press the Fixed Freq menu key and on the numeric key pad press 1, 0,

followed by the MHz menu key.

NOTE 10.0 MHz is the first frequency listed in the test record.

Step 13. Set the Attenuator/Switch Driver as follows:

a. Ensure LOCAL LED is on.

b. Set the switch to the required frequency path, for example, switches 9 and

0 are on, when measuring between 10.0 MHz and 3.0 GHz.

Keysight N2002A User’s Guide 33

Page 36

Using the Manual Calibration Procedure

ENR Manual Procedure

NOTE Refer to Table 1-1 on page 13 for Attenuator/Switch Driver settings for other

frequency ranges.

Step 14. On the NFA, press the Restart key, this restarts the NFA’s sweep.

Step 15. When the measurement is finished, in the Test Record, enter the Y-factor

reading next to the frequency point measured in the Standard Y

(Lin)

1

column.

Step 16. Repeat the steps for the remaining frequencies listed in the test record.

NOTE Set the Attenuator/Switch to the appropriate frequency path when changing

between frequency ranges.

Step 17. Connect the DUT as shown in Figure 2-1 on page 24. Depending on the DUT,

either use the SNS interconnect cable or the BNC cable.

Step 18. Set the frequency to 10.0 MHz

a. Press the Frequency/Points key.

b. Press the Fixed Freq menu key and on the numeric key pad press 1, 0,

followed by the MHz menu key.

NOTE 0.0 MHz is the first frequency listed in the test record.

Step 19. Set the Attenuator/Switch Driver as follows:

a. Ensure LOCAL LED is on.

b. Set the switch to the required frequency path, for example, switches 9 and

0 are on, when measuring between 10.0 MHz and 3.0 GHz.

Step 20. On the NFA, press the Restart key, this restarts the NFA’s sweep.

Step 21. When the measurement is finished, in the Test Record enter the Y-factor

reading next to the frequency point measured in the DUT Y

Step 22. Repeat the steps for the remaining frequencies listed in the test record.

(Lin) column.

2

NOTE Set the Attenuator/Switch to the appropriate frequency path when changing

between frequency ranges.

34 Keysight N2002A User’s Guide

Page 37

Using the Manual Calibration Procedure

ENR

2

10

Y21–()T

0

10

ENR

1

10

--------------

Y11–()

----------------------

×

×

T

0

------------------------------------------------------------------

log×=

UcENR

2

UcENR

1

()2UcSys()+

2

=

ENR Manual Procedure

Step 23. Using the Equation 3-1 and the results in the ENR Test Record, calculate the

value of each fixed frequency point for the DUT. Enter the ENR2

ENR

2

calculated values in the DUT ENR

Step 24. Complete the ENR Test Record results for the DUT and ensure the measured

values are within the published specification.

Step 25. Using the Equation 3-2 and the results in the Uncertainty Test Record,

calculate the ENR

DUT. Enter the U

Step 26. Complete the Uncertainty Test Record results for the DUT.

Step 27. If using an SNS series, transfer the data to the SNS using the procedure in the

section “Data Programming Process” on page 48.

The Equations

Equation 3-1 ENR Equation

(dB) column.

2

uncertainty value of each fixed frequency point for the

2

ENR2 calculated value in DUT ENR2 Uncertainty column.

c

The overall expanded uncertainty is calculated using the following equation for

each ENR

Noise Ratio (ENR dB) Test Records.

Equation 3-2 Uncertainty Equation

Keysight N2002A User’s Guide 35

value at each frequency point. See also the Appendixes for Excess

2

Page 38

Using the Manual Calibration Procedure

ENR Manual Procedure

Table 3-1 Terms Used in the Equations

Term Description

TO 290 Kelvin

DUT Device under test

ENR

ENR

Y

1

Y

2

U

C

1

2

ENR

1

Primary Standard Excess Noise Ratio value at each fixed frequency point

DUT calculated Excess Noise Ratio value at each fixed frequency point

Primary Standard measured linear Y-Factor at each fixed frequency point

DUT measured linear Y-Factor at each fixed frequency point

Primary Standard expanded uncertainty for each ENR value at each fixed

frequency point

ENR

U

C

2

DUT calculated expanded uncertainty for each ENR value at each fixed

frequency point

Sys Overall Test system uncertainty at each fixed frequency point

U

C

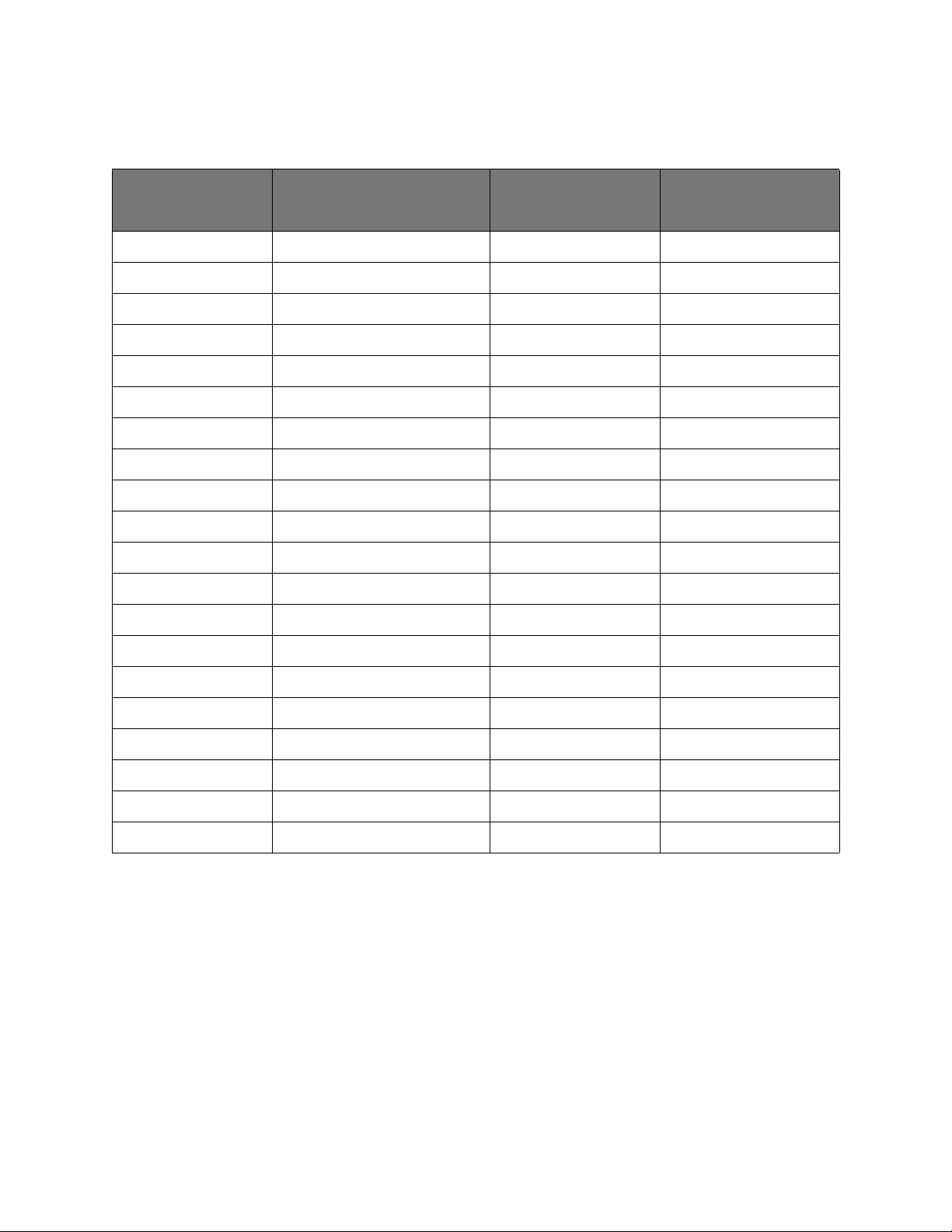

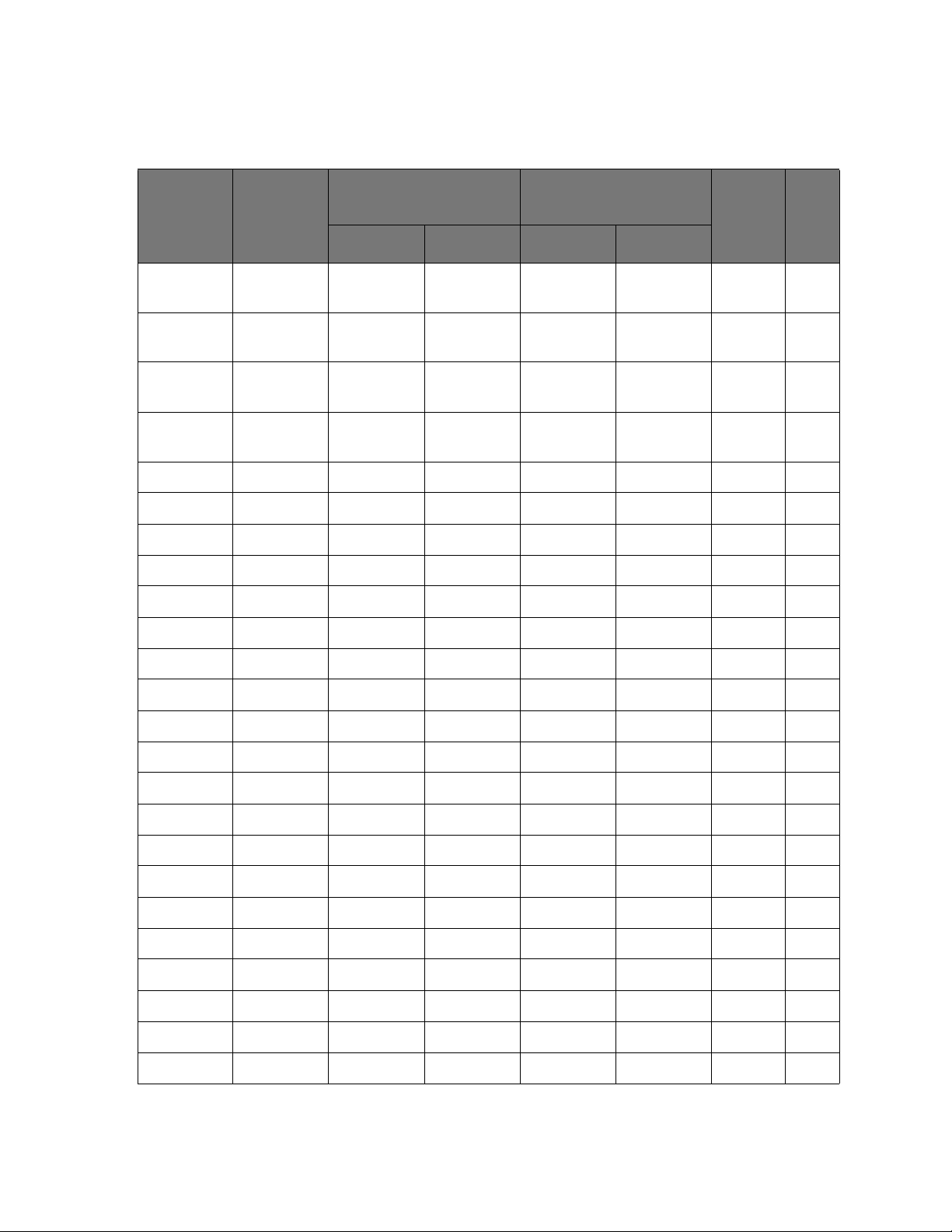

System Uncertainty Values

Table 3-2 is a summary of the uncertainty analysis calculations.

Table 3-2 Uncertainty Analysis Calculation Resul ts

Frequency (GHz) UcSys (± dB)

0.01 0.0785

0.10 0.0785

1.00 0.0905

2.00 0.0905

3.00 0.0726

4.00 0.0726

5.00 0.0726

6.00 0.0726

7.00 0.0800

8.00 0.0800

9.00 0.1076

10.00 0.1076

11.00 0.1076

36 Keysight N2002A User’s Guide

Page 39

Using the Manual Calibration Procedure

ENR Manual Procedure

Table 3-2 Uncertainty Analysis Calculation Resul ts

Frequency (GHz) UcSys (± dB)

12.00 0.1076

13.00 0.1211

14.00 0.1211

15.00 0.1211

16.00 0.1211

17.00 0.1211

18.00 0.1211

19.00 0.1491

20.00 0.1491

21.00 0.1491

22.00 0.1491

23.00 0.1491

24.00 0.1491

25.00 0.1491

26.00 0.1491

26.50 0.1491

Keysight N2002A User’s Guide 37

Page 40

Using the Manual Calibration Procedure

Reflection Coefficient Manual Procedure

Reflection Coefficient Manual Procedure

This test measures the Reflection Coefficient Magnitude and Phase of a noise

source from 10.0 MHz to 26.5 GHz. It may need two Vector Network Analyzers

(VNAs) to achieve the frequency range required.

Some noise sources have a break point which transgress the frequency range

of the Vector Network Analyzers. These have been identified in the Test

Records and you need to calibrate and test in these ranges.

NOTE The procedures refer to the key presses on an 8753ET. Other network

analyzers, for example, the 8753D may have different key labeling. Please

refer to the appropriate user’s guide for the relevant menu maps.

Calibrating the 8753

Use the following procedure to calibrate the 8753.

NOTE Ensure the noise source’s RF connector is the same type as the VNA and

connected using the preferred adapters listed in Table 2-5 on page 30.

NOTE The following example measures an N4000A. This model needs reflection and

phase measured over two frequency ranges, 10.0 MHz to 1.5 GHz and 1.5

GHz to 3.0 GHz. The model you are measuring may need different frequency

ranges measured, hence you need to confirm this by using your model’s

specifications and adjust the procedure accordingly.

Step 1. Factory Preset the Vector Network Analyzer.

a. Press the Preset key.

Step 2. Set the Active Channel to 1.

a. Press the Chan 1 key.

Step 3. Set the measurement mode to S11.

a. Press the Meas key.

b. Press the Reflection menu key.

Step 4. Set the 10.0 MHz start and 1.5 GHz stop frequencies.

a. Press the Start key.

b. Press the 1, 0, M/m keys.

38 Keysight N2002A User’s Guide

Page 41

Using the Manual Calibration Procedure

Reflection Coefficient Manual Procedure

c. Press the Stop key.

d. Press the 1, ., 5 , G/n keys.

Step 5. Set the measurement format to Polar.

a. Press Format key.

b. Press the Polar menu key.

Step 6. Set the number of measurement points to 401 points.

a. Press the Sweep Setup key.

b. Press the NUMBER of POINTS menu key.

c. Press the 4, 0, 1, x1 keys.

Step 7. Set the power level to –30dBm.

a. Press the Power key.

b. Press the -, 3, 0, x1 keys.

Step 8. If required, connect an adapter to connect the noise source under test to port

1 of the VNA.

NOTE The connector type (male/female) applies to the test port or adapter if fitted,

not the DUT’s connector.

Step 9. Select the appropriate calibration kit being used.

a. Press the Cal key

b. Press the CAL KIT menu key.

c. Press the SELECT CAL KIT menu key.

d. Select the calibration kit being used, for example, press the 85032B/E

menu key.

NOTE The calibration kit selection is dependent on the noise source under test.

e. Press the Return menu key.

Step 10. Select a S11 port calibration.

a. Press the Cal key.

b. Press the Calibrate Menu menu key.

c. Press the Reflection 1-Port menu key.

Keysight N2002A User’s Guide 39

Page 42

Using the Manual Calibration Procedure

Reflection Coefficient Manual Procedure

Step 11. Connect the Open to the test port (or, if fitted, the adapter) and perform the

open calibration.

a. Press the Opens menu key.

b. Select either Open (M) or Open (F) menu key.

c. When complete, press the Done Opens menu key.

Step 12. Connect the Short to the test port (or, if fitted, the adapter) and perform the

short calibration.

a. Press the Shorts menu key.

b. Select either Short (M) or Short (F) menu key.

c. When complete, press the Done Shorts menu key.

Step 13. Connect the Load to the test port (or, if fitted, the adapter) and perform the

load calibration.

a. Press the Loads menu key.

b. When complete, press Done 1-port CAL.

Step 14. Save the calibration.

a. Press the Save/Recall menu key.

b. Press the Save State menu key.

c. Note the Register the calibration data is saved in.

Measuring the DUT over 1st Frequency Range

Use the following procedure to measure the DUT.

NOTE The following example measures an N4000A. This model needs reflection and

phase measured over two frequency ranges, 10.0 MHz to 1.5 GHz and 1.5

GHz to 3.0 GHz using the 8753. The model you are measuring may need

different frequency ranges measured, hence you need to confirm this by

using your model’s specifications and adjust the procedure accordingly.

Step 1. Connect the equipment as shown in Figure 2-2 on page 26.

NOTE Ensure the VNA’s RF connector is the same type as the DUT and connected

using the preferred adapters listed in Table 2-5 on page 30.

Step 2. Ensure the VNA display format is set to Polar.

a. Press the Meas key. (This returns the format to Polar.)

40 Keysight N2002A User’s Guide

Page 43

Using the Manual Calibration Procedure

Reflection Coefficient Manual Procedure

Step 3. On the VNA, set the averaging to 16.

a. Press the Avg key.

b. Press the Averaging to Averaging (On).

c. Press the Averaging Factor menu key.

d. Press the 1, 6, x1 keys.

Step 4. Ensure the Noise Figure Analyzer preset is set to factory settings.

a. Press the System key.

b. Press the More 1 of 3 menu key.

c. Press the Power On/Preset menu key.

d. Set the Power On to Power On (Preset) and Preset to Preset (Factory).

Step 5. On the NFA, press Preset and wait for the routine to finish.

Step 6. On the NFA, set the sweep to single and wait for the sweep to finish.

a. Press the Sweep key.

b. Set the Sweep to Sweep Mode (Single).

Step 7. On the NFA, set the noise source to off.

a. Press the Sweep key.

b. Press the Manual Meas menu key.

c. Press the Manual State (On) menu key.

d. Press the Noise Source Off menu key.

Step 8. n the VNA, press the Marker Search key.

Step 9. On the VNA, press the Search: Max menu key.

Step 10. Record the Source OFF maximum displayed reflection magnitude and phase

values on the Test Record.

Step 11. On the NFA, press the Noise Source On menu key.

Step 12. On the VNA, press the Marker Search key.

Step 13. On the VNA, press the Search: Max menu key.

Step 14. Record the Source ON maximum displayed reflection magnitude and phase

values on the Test Record.

Step 15. On the VNA, set the marker to 10.0 MHz.

ess the Marker key.

a. Pr

ess the 1, 0, M/m keys.

b. Pr

Keysight N2002A User’s Guide 41

Page 44

Using the Manual Calibration Procedure

Reflection Coefficient Manual Procedure

Step 16. Record the Source ON maximum displayed reflection magnitude and phase

values on the Test Record to 10.0 MHz.

Step 17. Repeat the steps for the 100.0 MHz and 1.0 GHz cardinal frequency points

listed in the Test Record and note their values on the test record.

Step 18. On the NFA, press the Noise Source Off menu key.

Step 19. Recording the Source OFF maximum displayed reflection magnitude and

phase values on the test record at 1.0 GHz.

Step 20. Repeat the step for the 100.0 MHz and 10.0 MHz cardinal frequency points

listed in the Test Record and note their values on the Test Record.

Step 21. Ensure all the measured values are within the published specification.

NOTE Repeat the calibration and measurement procedure for the other frequency

ranges as applicable.

Calibrating the 8722

Use the following procedure to calibrate the 8722.

NOTE The following example measures an N4000A. This model needs reflection and

phase measured over two frequency ranges, 3.0 GHz to 7.0 GHz and 7.0 MHz

to 18.0 GHz using the 8722. The model you are measuring may need different

frequency ranges measured, hence you need to confirm this by using your

model’s Test Records and adjust the procedure accordingly.

NOTE Ensure the noise source’s RF connector is the same type as the DUT and

connected using the preferred adapters listed in Table 2-5 on page 30.

Step 1. Factory Preset the Vector Network Analyzer.

a. Press the Preset key.

Step 2. Set the Active Channel to 1.

a. Press the Chan 1 key.

Step 3. Set the measurement mode to S11.

a. Press the Meas key.

b. Press the Reflection menu key.

Step 4. Set the 3.0 GHz start and 7.0 GHz stop frequencies.

42 Keysight N2002A User’s Guide

Page 45

Using the Manual Calibration Procedure

Reflection Coefficient Manual Procedure

a. Press the Start key.

b. Press the 3, ., 0, G/n keys.

c. Press the Stop key.

d. Press the 7, ., 0 , G/n keys.

Step 5. Set the measurement format to Polar.

a. Press Format key.

b. Press the Polar menu key.

Step 6. Set the number of measurement points to 401 points.

a. Press the Sweep Setup key.

b. Press the NUMBER of POINTS menu key.

c. Press the 4, 0, 1, x1 keys.

Step 7. Set the power level to –30dBm.

a. Press the Power key.

b. Press the -, 3, 0, x1 keys.

Step 8. If required, connect an adapter to connect the noise source under test to port

1 of the VNA.

NOTE The connector type (male/female) applies to the test port or adapter if fitted,

not the DUT’s connector.

Step 9. Select the appropriate calibration kit being used.

a. Press the Cal key

b. Press the CAL KIT menu key.

c. Press the SELECT CAL KIT menu key.

d. Select the calibration kit being used, for example, press the 85032B/E

menu key.

NOTE The calibration kit selection is dependent on the noise source under test.

e. Press the Return menu key.

Step 10. Select a S11 port calibration.

a. Press the Cal key.

Keysight N2002A User’s Guide 43

Page 46

Using the Manual Calibration Procedure

Reflection Coefficient Manual Procedure

b. Press the Calibrate Menu menu key.

c. Press the Reflection 1-Port menu key.

Step 11. Connect the Open to the test port (or, if fitted, the adapter) and perform the

open calibration.

a. Press the Opens menu key.

b. Select either Open (M) or Open (F) menu key.

c. When complete, press the Done Opens menu key.

Step 12. Connect the Short to the test port (or, if fitted, the adapter) and perform the

short calibration.

a. Press the Shorts menu key.

b. Select either Short (M) or Short (F) menu key.

c. When complete, press the Done Shorts menu key.

Step 13. Connect the Load to the test port (or, if fitted, the adapter) and perform the

load calibration.

a. Press the Loads menu key.

b. When complete, press Done 1-port CAL.

Step 14. Save the calibration.

a. Press the Save/Recall menu key.

b. Press the Save State menu key.

c. Note the Register the calibration data is saved in.‘

Measuring the DUT over 1st Frequency Range

Use the following procedure to measure the DUT.

NOTE The following example measures an N4000A. This model needs reflection and

phase measured over two frequency ranges, 3.0 GHz to 7.0 GHz and 7.0 MHz

to 18.0 GHz using the 8722. The model you are measuring may need different

frequency ranges measured, hence you need to confirm this by using your

model’s Test Records and adjust the procedure accordingly.

NOTE Ensure the noise source’s RF connector is the same type as the DUT and

connected using the preferred adapters listed in Table 2-5 on page 30.

Step 1. Connect the equipment as shown in Figure 2-2 on page 26.

44 Keysight N2002A User’s Guide

Page 47

Using the Manual Calibration Procedure

Reflection Coefficient Manual Procedure

Step 2. Ensure the VNA display format is set to Polar.

a. Press the Meas key. (This returns the format to Polar.)

Step 3. On the VNA, set the averaging to 16.

a. Press the Avg key.

b. Press the Averaging to Averaging (On).

c. Press the Averaging Factor menu key.

d. Press the 1, 6, x1 keys.

Step 4. Ensure the Noise Figure Analyzer preset is set to factory settings.

a. Press the System key.

b. Press the More 1 of 3 menu key.

c. Press the Power On/Preset menu key.

d. Set the Power On to Power On (Preset) and Preset to Preset (Factory).

Step 5. On the NFA, press Preset and wait for the routine to finish.

Step 6. On the NFA, set the sweep to single and wait for the sweep to finish.

a. Press the Sweep key.

b. Set the Sweep to Sweep Mode (Single).

Step 7. On the NFA, set the noise source to off.

a. Press the Sweep key.

b. Press the Manual Meas menu key.

c. Press the Manual State (On) menu key.

d. Press the Noise Source Off menu key.

Step 8. On the VNA, press the Marker Search key.

Step 9. On the VNA, press the Search: Max menu key.

Step 10. Record the Source OFF maximum displayed reflection magnitude and phase

values on the Test Record.

Step 11. On the NFA, press the Noise Source On menu key.

Step 12. On the VNA, press the Marker Search key.

Step 13. On the VNA, press the Search: Max menu key.

Step 14. Recor

d the Sour

ce ON maximum displayed reflection magnitude and phase

values on the Test Record.

Step 15. On the VNA, set the marker to 3.0 GHz.

Keysight N2002A User’s Guide 45

Page 48

Using the Manual Calibration Procedure

Reflection Coefficient Manual Procedure

a. Press the Marker key.

b. Press the 3, ., 0, G/n keys.

Step 16. Record the Source ON maximum displayed reflection magnitude and phase

values on the Test Record at 3.0 GHz.

Step 17. Repeat the steps for the 4.0 GHz, 5.0 GHz, 6.0 GHz, and 7.0 GHz cardinal

frequency points listed in the Test Record and note their values on the Test

Record.

Step 18. On the NFA, press the Noise Source Off menu key.

Step 19. Recording the Source OFF maximum displayed reflection magnitude and

phase values on the test record at 7.0 GHz.

Step 20. Repeat the step 13 for the 4.0 GHz, 5.0 GHz, 6.0 GHz, and 7.0 GHz cardinal

frequency points listed in the Test Record and note their values on the Test

Record.

Step 21. Ensure all the measured values are within the published specification.

NOTE Repeat the calibration and measurement procedure for the other frequency

ranges as applicable.

46 Keysight N2002A User’s Guide

Page 49

Keysight Technologies

Noise Source Test Set

N2002A

4 Manually Programming Data into an Keysight Smart

Noise Source

Introduction

This section describes the procedure used to program data into an Keysight

N400xA Series Smart Noise Sources.

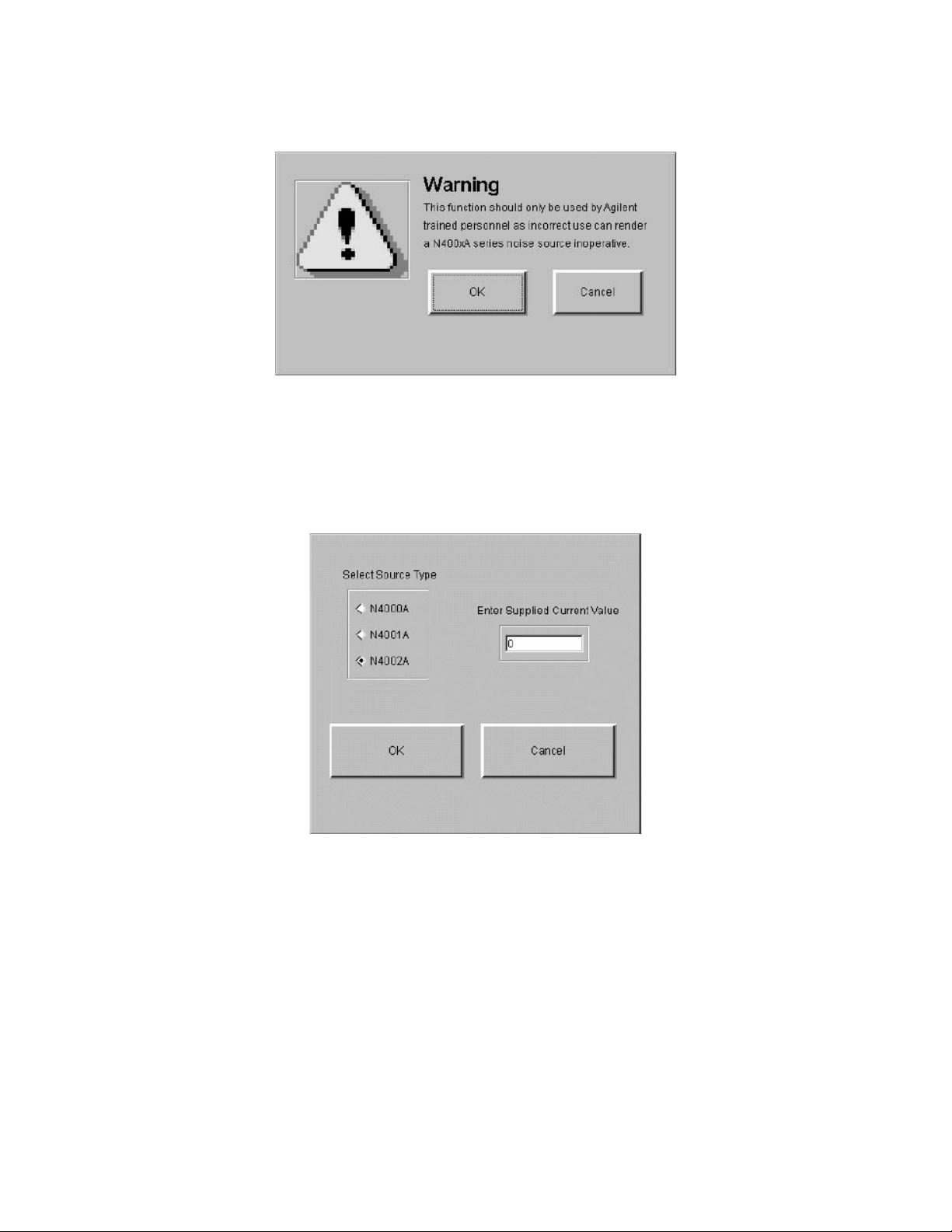

WARNING This procedure is performed at the your own risk. Failure to correctly

follow this procedure may render the noise source inoperative.

Equipment Required

The following equipment is required to program data into an Keysight N400xA

smart noise source series:

— An Keysight NFA Series Noise Figure Analyzer.

— An 11730A Noise Source cable to connect the noise source to the NFA.

— A 3.5 inch formatted floppy disk.

—A personal computer.

47

Page 50

Manually Programming Data into an Keysight Smart Noise Source

Data Programming Process

Data Programming Process

The new calibration data to be programmed into the smart noise source must

be in the correct format. Formatting the data can only be performed on a PC.

When the data is in the correct format it is copied to the NFA, and then

programmed into the smart noise source

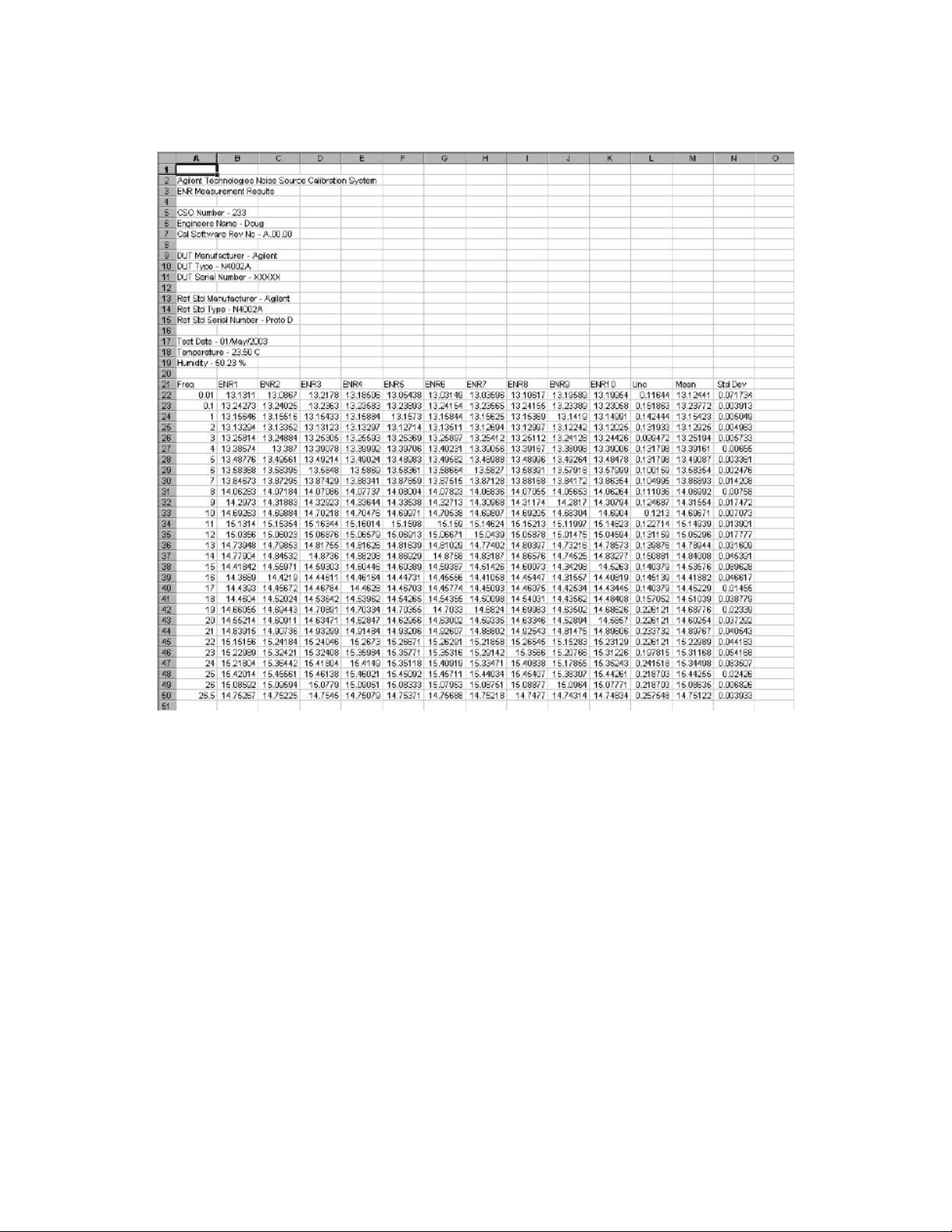

Formatting the Data

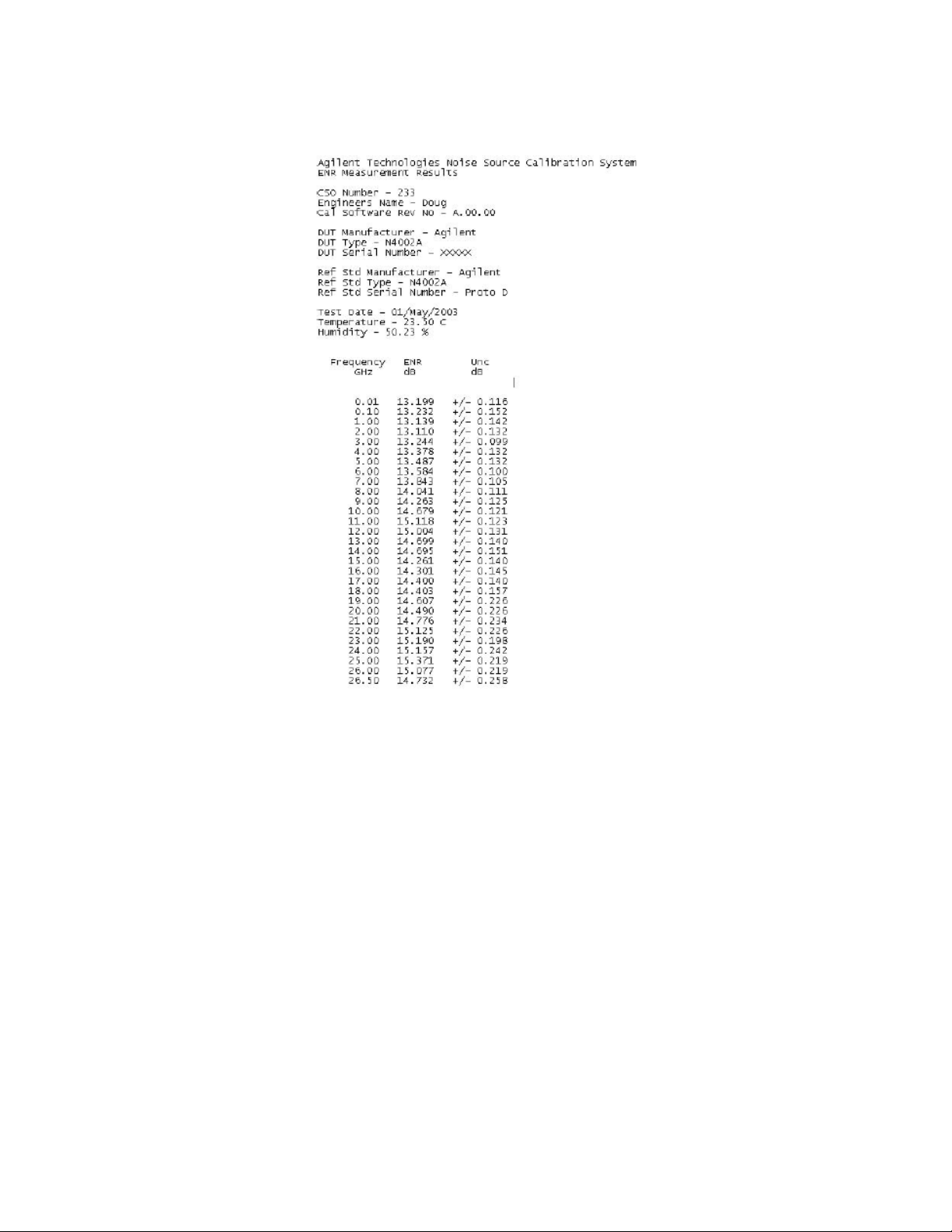

An example data file is shown in page 51 and shows the cardinal frequency

points of an 18.0 GHz SNS. This example file can be used as a template for

formatting the data to be programmed into the smart noise source.

Alternatively, the data currently contained into the SNS can be copied to a PC

and used as a template, using the following procedure.

Step 1. Connect the smart noise source to the NFA.

Step 2. Confirm the Source Preference is set to SNS. To do this follow Step 3 through

to Step 5.

Step 3. Press the ENR key.

Step 4. Press the SNS Setup menu key.

Step 5. Ensure Preference is set to Preference (SNS).

Step 6. Save the data from the smart noise source by pressing File key.

Step 7. Press the Save menu key.

Step 8. Press the ENR menu key.

Step 9. Press the SNS menu key.

Step 10. Using the Alpha Editor, name the file, for example, template.enr.

Step 11. Transfer this template file to your PC from the floppy disk.

Step 12. Save a copy of this file in your PC.

The file can be edited in an ASCII text editor, for example, Notepad.

Editing the Data File

There are only certain fields in the data file which you should edit. The example

data file shown in page 51, shows the following information:

— The NFA model.

— The NFA serial number.

— The NFA firmware revision.

— The date that the data file was created.

— The serial number of the smart noise source.

48 Keysight N2002A User’s Guide

Page 51

Manually Programming Data into an Keysight Smart Noise Source

Data Programming Process

— The model number of the smart noise source.

— The calibration date.

— The temperature the calibration was carried out under.

— The humidity the calibration was carried out under.

The fields that are edited in the data file are:

— [Caldate 20010227] - Calibration Date (yyyymmdd)

— [Temperature 23.000000] - Temperature the calibration was performed at.

— [Humidity 30.000000] - Humidity the calibration was performed at.

NOTE Do not change the value shown in the field marked [Current xxxx], as this

affects the smart noise source’s performance.

The other fields in the data file contain the frequency points, ENR (dB) values,

ENR uncertainties, and Reflection and Phase values. The frequency points can

be added or removed as required. The maximum number of points is 81.

NOTE Each field must have a data entry, for this process to work correctly.

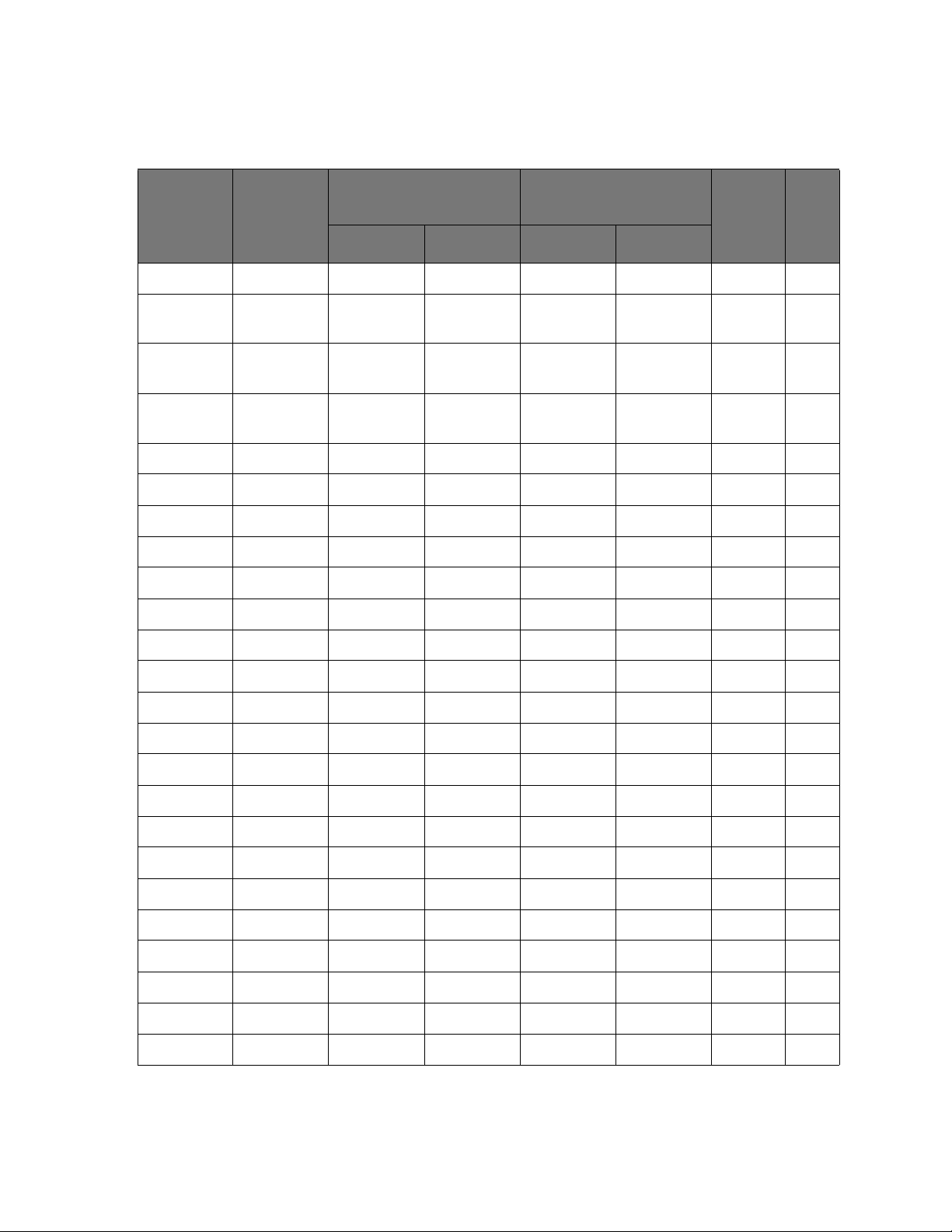

Programming the Data File into the SNS

Program the data file into the SNS use the following procedure.

Step 1. Save the new data file as ‘writesns.enr’ to a floppy disk.

Step 2. Insert the floppy disk in the NFA’s floppy drive.

Step 3. Press the System key.