Page 1

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176 - TestEquipmentDepot.com

Keysight Technologies

E4416A/4417A Power

Meters

Service Guide

Page 2

Notices

CAUTION

WARNING

Copyright Notice

© Keysight Technologies 2001–2016

No part of this manual may be

reproduced in any form or by any

means (including electronic storage

and retrieval or translation into a

foreign language) without prior

agreement and written consent from

Keysight Technologies as governed by

United States and international

copyright laws.

Manual Part Number

E4416-90014

Edition

Edition 14, January 8, 2016

Printed in:

Printed in Malaysia

Published by:

Keysight Technologies

Bayan Lepas Free Industrial Zone,

11900 Penang, Malaysia

Technology Licenses

The hardware and/or software

described in this document are

furnished under a license and may be

used or copied only in accordance with

the terms of such license.

U.S. Government Rights

The Software is “commercial computer

software,” as defined by Federal

Acquisition Regulation (“FAR”) 2.101.

Pursuant to FAR 12.212 and 27.405-3

and Department of Defense FAR

Supplement (“DFARS”) 227.7202, the

U.S. government acquires commercial

computer software under the same

terms by which the software is

customarily provided to the public.

Accordingly, Keysight provides

Software to U.S. government

customers under its standard

commercial license, which is embodied

its End User License Agreement

in

(EULA). The license set forth in the

EULA represents the exclusive

authority by which the U.S.

government may use, modify,

distribute, or disclose the Software.

The EULA and the license set forth

therein, does not require or permit,

among other things, that Keysight: (1)

Furnish technical

information related to commercial

computer software or commercial

computer software documentation that

is not customarily provided to the

public; or (2) Relinquish to, or

otherwise provide, the government

rights in excess of these rights

customarily provided to the public to

use, modify, reproduce, release,

perform, display, or disclose

commercial computer software or

commercial computer software

documentation. No additional

government requirements beyond

those set forth in the EULA shall apply,

except to the extent that those terms,

rights, or licenses are explicitly required

from all providers of commercial

computer software pursuant to the FAR

and the DFARS and are set forth

specifically in writing elsewhere in the

EULA. Keysight shall be under no

obligation to update, revise or

otherwise modify the Software. With

respect to any technical data as

defined by FAR 2.101, pursuant to FAR

12.211 and 27.404.2 and DFARS

227.7102, the U.S. government

acquires no greater than Limited Rights

as defined in FAR 27.401 or DFAR

227.7103-5 (c), as applicable in any

technical data.

the

Warranty

THE MATERIAL CONTAINED IN THIS

DOCUMENT IS PROVIDED “AS IS,” AND

IS SUBJECT TO BEING CHANGED,

WITHOUT NOTICE, IN FUTURE

EDITIONS. FURTHER, TO THE MAXIMUM

EXTENT PERMITTED BY APPLICABLE

LAW, KEYSIGHT DISCLAIMS ALL

WARRANTIES, EITHER EXPRESS OR

IMPLIED, WITH REGARD TO THIS

MANUAL AND ANY INFORMATION

CONTAINED HEREIN, INCLUDING BUT

NOT LIMITED TO THE IMPLIED

WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR

PURPOSE. KEYSIGHT SHALL NOT BE

LIABLE FOR ERRORS OR FOR

INCIDENTAL OR CONSEQUENTIAL

DAMAGES IN CONNECTION WITH THE

FURNISHING, USE, OR PERFORMANCE

OF THIS DOCUMENT OR OF ANY

INFORMATION CONTAINED HEREIN.

SHOULD KEYSIGHT AND THE USER

HAVE A SEPARATE WRITTEN

AGREEMENT WITH WARRANTY TERMS

COVERING THE MATERIAL IN THIS

DOCUMENT THAT CONFLICT WITH

THESE TERMS, THE WARRANTY TERMS

IN THE SEPARATE AGREEMENT SHALL

CONTROL.

Safety Information

A CAUTION notice denotes a hazard. It

calls attention to an operating

procedure, practice, or the like that, if

not correctly performed or adhered to,

could result in damage to the product

or loss of important data. Do not

proceed beyond a CAUTION notice

until the indicated conditions are fully

understood and met.

A WARNING notice denotes a hazard. It

calls attention to an operating

procedure, practice, or the like that, if

not correctly performed or adhered to,

could result in personal injury or death.

Do not proceed beyond a WARNING

notice until the indicated conditions are

fully understood and met.

2 Keysight E4416A/E4417A Power Meters Service Guide

Page 3

Certification

Warranty

Keysight Technologies certifies that this product met its published specifications

at the time of shipment from the factory. Keysight Technologies further certifies

that its calibration measurements are traceable to the United States National

Institute of Standards and Technology, to the extent allowed by the Institute’s

calibration facility, and to the calibration facilities of other International Standards

Organization members.

This Keysight Technologies instrument product is warranted against defects in

material and workmanship for a period of one year from date of shipment. During

the warranty period, Keysight Technologies will at its option, either repair or

replace products which prove to be defective. For warranty service or repair, this

product must be returned to a service facility designated by Keysight

Technologies. Buyer shall prepay shipping charges to Keysight Technologies and

Keysight Technologies shall pay shipping charges, duties, and taxes for products

returned to Keysight Technologies from another country. Keysight Technologies

warrants that its software and firmware designated by Keysight Technologies for

use with an instrument will execute its programming instructions when properly

installed on that instrument. Keysight Technologies does not warrant that the

operation of the instrument, or firmware will be uninterrupted or error free.

Keysight E4416A/E4417A Power Meters Service Guide 3

Page 4

Limitation of Warranty

WARNING

CAUTION

The foregoing warranty shall not apply to defects resulting from improper or

inadequate maintenance by Buyer, Buyer-supplied software or interfacing,

unauthorized modification or misuse, operation outside of the environmental

specifications for the product, or improper site preparation or maintenance. NO

OTHER WARRANTY IS EXPRESSED OR IMPLIED. KEYSIGHT TECHNOLOGIES

SPECIFICALLY DISCLAIMS THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE.

Exclusive Remedies

THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE

REMEDIES. KEYSIGHT TECHNOLOGIES SHALL NOT BE LIABLE FOR ANY DIRECT,

INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, WHETHER

BASED ON CONTRACT, TORT, OR ANY OTHER LEGAL THEORY.

Warnings and Cautions

This guide uses warnings and cautions to denote hazards.

A warning calls attention to a procedure, practice or the like, which, if not

correctly performed or adhered to, could resul t in injury or the loss of life. Do

not proceed beyond a warning until the indicated conditions are fully

understood and met.

A caution calls attention to a procedure, practice or the like which, if not

correctly performed or adhered to, could result in damage to or the

destruction of part or all of the equipment. Do not proceed beyond a caution

until the indicated conditions are fully understood and met.

4 Keysight E4416A/E4417A Power Meters Service Guide

Page 5

Safety Symbols

The following symbol on the instrument and in the documentation indicates

precautions that must be taken to maintain safe operation of the instrument.

Caution, risk of danger.

The Instruction Documentation Symbol. The product is marked with this symbol

when it is necessary for the user to refer to the instructions in the supplied

documentation.

Alternating current (AC).

This symbol indicates the operating switch for ‘Stand-by’ mode. Note, the

instrument is NOT isolated from the mains when the switch is pressed.

To isolate the instrument, the mains coupler (mains input cord) should be removed

from the power supply.

This symbol indicates the operating switch for ‘On’ mode).

External Protective Earth Terminal.

While this is a Class I product, provided with a protective earthing

conductor in a power cord, an external protective earthing terminal has also been

provided. This terminal is for use where the earthing cannot be assured. At least an

18AWG earthing conductor should be used in such an instance, to ground the

instrument to an assured earth terminal.

Keysight E4416A/E4417A Power Meters Service Guide 5

Page 6

Personal Safety Considerations

WARNING

WARNING

CAUTION

This is a Safety Class I product (provided with a protective earthing ground

incorporated in the power cord). The mains plug shall only be inserted in a socket

outlet provided with a protective earth contact. Any interruption of the protective

conductor, inside or outside the instrument, is likely to make the instrument

dangerous. Intentional interruption is prohibited

If this instrument is not used as specified, the protection provided by the

equipment could be impaired. This instrument must be used in a normal

condition (in which all means of protection are intact) only.

No operator serviceable parts inside. Refer servicing to qualified personnel.

To prevent electrical shock, do not remove covers.

For continued protection against fire hazard, replace the line fuse(s) only

with fuses of the same type and rating (for example, normal blow, time delay,

etc.). The use of other fuses or material is prohibited.

General Safety Considerations

Before this instrument is switched on, make sure it has been properly

grounded through the protective conductor of the ac power cable to a

socket outlet provided with protective earth contact.

Any interruption of the protective (grounding) conductor, inside or outside

the instrument, or disconnection of the protective earth terminal can result

in personal injury.

Any adjustments or service procedures that require operation of the

instrument with protective covers removed should be performed only by

trained service personnel.

6 Keysight E4416A/E4417A Power Meters Service Guide

Page 7

Regulatory Markings

The CE mark shows that the product complies with all the relevant European legal

Directives (if accompanied by a year, it signifies when the design was proven.

This ISM device complies with Canadian ICES-001.

Cet appareil ISM est conforme à la norme NMB-001 du Canada.

This is the symbol of an Industrial Scientific and Medical Group 1 Class A product.

The CSA mark is a registered trademark of the Canadian Standards Association.

Keysight E4416A/E4417A Power Meters Service Guide 7

Page 8

IEC 1010-1 Compliance

This instrument has been designed and tested in accordance with IEC Publication

1010-1 +A1:1992 Safety Requirements for Electrical Equipment for Measurement,

Control and Laboratory Use and has been supplied in a safe condition. The

instruction documentation contains information and warnings which must be

followed by the user to ensure safe operation and to maintain the instrument in a

safe condition.

Recommended Calibration Interval

Keysight Technologies recommends a two-year calibration cycle for the E4416A

and E4417A power meter.

8 Keysight E4416A/E4417A Power Meters Service Guide

Page 9

Sales and Service Offices

NOTE

By Internet, phone, or fax, get assistance with all your test and measurement needs.

In any correspondence or telephone conversations, refer to the power sensor by

its model number and full serial number. With this information, the Keysight

Technologies representative can quickly determine whether your unit is still

within its warranty period.

Country Phone Number Fax Number

United States 800 829 4444 800 829 4433

Canada 877 894 4414 800 746 4866

China 800 810 0189 800 820 2816

Europe 31 20 547 2111 -

Japan (81) 426 56 7832 (81) 426 56 7840

Korea (080) 769 0800 (080) 769 0900

Latin America (305) 269 7500 -

Taiwan 0800 047 866 0800 286 331

Other Asia Pacific Countries: (65) 6375 8100 (65) 6755 0042

Keysight E4416A/E4417A Power Meters Service Guide 9

Page 10

Returning Your Power Meter for Service

CAUTION

Use the information in this section if you need to return your power meter to

Keysight Technologies.

Package the Power Meter for Shipment

Use the following steps to package the power meter for shipment to Keysight

Technologies for service:

1. Fill in a blue service tag (available at the end of this guide) and attach it to the

power meter. Please be as specific as possible about the nature of the

problem. Send a copy of any or all of the following information:

– Any error messages that appeared on the power meter display.

– Any information on the performance of the power meter.

Power meter damage can result from using packaging materials other than

those specified. Never use styrene pellets in any shape as packaging

materials. They do not adequately cushion the power meter or prevent it

from shifting in the carton. Styrene pellets cause power meter damage by

generating static electricity and by lodging in the rear panel.

2. Use the original packaging materials or a strong shipping container that is

made of double-walled, corrugated cardboard with 159 kg (350 lb) bursting

strength. The carton must be both large enough and strong enough to

accommodate the power meter and allow at least 3 to 4 inches on all sides of

the power meter for packing material.

10 Keysight E4416A/E4417A Power Meters Service Guide

Page 11

3. Surround the power meter with at least 3 to 4 inches of packing material, or

enough to prevent the power meter from moving in the carton. If packing foam

TM

is not available, the best alternative is SD-240 Air Cap

from Sealed Air

Corporation (Commerce, CA 90001). Air Cap looks like a plastic sheet covered

with 1-1/4 inch air filled bubbles. Use the pink Air Cap to reduce static

electricity. Wrap the power meter several times in the material to both protect

the power meter and prevent it from moving in the carton.

4. Seal the shipping container securely with strong nylon adhesive tape.

5. Mark the shipping container "FRAGILE, HANDLE WITH CARE" to ensure careful

handling.

6. Retain copies of all shipping papers.

Keysight E4416A/E4417A Power Meters Service Guide 11

Page 12

About this Guide

Characteristics and Specifications This chapter lists the power meter's

1

specifications and describes how to interpret these specifications.

Performance Tests This chapter contains procedures which allow you to test the

2

power meter's electrical performance to it's specifications.

Adjustments This chapter contains checks and adjustments that ensure proper

3

performance of the power meter.

Theory of Operation This chapter describes how each of the power meter's

4

individual assemblies operate.

Replaceable Parts This chapter details the power meter's replaceable parts. It also

5

explains how to assemble and disassemble the power meter.

Troubleshooting This chapter contains troubleshooting flow charts designed to

6

isolate faults in the Rmt I/O, GPIB and RS232/422 interface ports.

Keysight 432A Power Meters & 478A Sensors: Additional Information This

A

appendix contains additional information for Keysight 432A power meters and

478A sensors.

Equipment Required For Performance Tests And Adjustments This appendix lists

B

equipment required for performance tests and adjustments.

Measurement Uncertainty Analysis - Power Reference Level Test This appendix

C

contains information on the Measurement Uncertainty Analysis in Power

Reference Level Test

Measuremet Uncertainty Analysis - Instrument Accuracy Test This appendix

D

contains information on the Measurement Uncertainty Analysis in Instrument

Accuracy Test

12 Keysight E4416A/E4417A Power Meters Service Guide

Page 13

Table of Contents

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Limitation of Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Exclusive Remedies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Personal Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

General Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Regulatory Markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

IEC 1010-1 Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Recommended Calibration Interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Sales and Service Offices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Returning Your Power Meter for Service . . . . . . . . . . . . . . . . . . . . . . . .10

Package the Power Meter for Shipment . . . . . . . . . . . . . . . . . . . . . .10

About this Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

1 Characteristics and Specifications

2Performance Tests

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Performance Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Calibration Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Test Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Thermistor Mount Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Zero Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Test Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Keysight E4416A/E4417A Power Meters Service Guide 13

Page 14

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Instrument Accuracy (Normal Path) Test . . . . . . . . . . . . . . . . . . . . . . . 31

Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Test Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Instrument Accuracy (Average Path) Test . . . . . . . . . . . . . . . . . . . . . . . 38

Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Test Procedure 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Test Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Test Procedure 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Test Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Power Reference Level Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Test Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Keysight E-Series Power Sensor Interface Test . . . . . . . . . . . . . . . . . . 52

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Keysight E932x Power Sensor (Average Path) Functional Test . . . . . . 53

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Test Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Time Base Accuracy Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

14 Keysight E4416A/E4417A Power Meters Service Guide

Page 15

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Test Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Output Standing Wave Ratio (SWR) Test . . . . . . . . . . . . . . . . . . . . . . .60

Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Test Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Performance Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

3Adjustments

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Post-Repair Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Power Reference Oscillator Frequency Adjustment . . . . . . . . . . . . . . . 74

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Power Reference Oscillator Level Adjustment . . . . . . . . . . . . . . . . . . . .77

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Measurement Uncertainty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

Display Brightness and Contrast Adjustment . . . . . . . . . . . . . . . . . . . .83

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

4 Theory of Operation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

A1 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

A2 Processor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Keysight E4416A/E4417A Power Meters Service Guide 15

Page 16

A3 Front Panel Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

A4 Comms Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

A5 Daughter Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

A6 Measurement Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Average Path Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Normal Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Ancillary Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Functional Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

5Replaceable Parts

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Assembly Part Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Front Panel Connector Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Firmware Upgrades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Assembly and Disassembly Guidelines . . . . . . . . . . . . . . . . . . . . . . . . 107

Removing the Power Meter Cover . . . . . . . . . . . . . . . . . . . . . . . . . 107

Removing the A1 Power Supply Assembly . . . . . . . . . . . . . . . . . . . 108

Removing the A2 Processor Assembly . . . . . . . . . . . . . . . . . . . . . . 109

Removing the A4 Comms Assembly . . . . . . . . . . . . . . . . . . . . . . . . 111

Removing the A5 Daughter or A6 Measurement Assemblies . . . . 113

Removing the A7 Fan Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Removing the Power Meter RAM Battery (BT1) . . . . . . . . . . . . . . . 115

Removing the A3 Front Panel Assembly . . . . . . . . . . . . . . . . . . . . . 116

Replacing the Front Panel Power Reference Cable Assembly . . . . 120

Replacing the Rear Panel Power Sensor Cable Assemblies

(Options 002 and 003) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Replacing the Rear Panel Power Reference Cable Assembly

(Option 003) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Replacing the Rear Panel Recorder Output(s) Cable Assembly . . 125

Replacing The Chassis Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 126

6 Troubleshooting

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Suggested Diagnostic Equipment . . . . . . . . . . . . . . . . . . . . . . . . . 128

16 Keysight E4416A/E4417A Power Meters Service Guide

Page 17

A Keysight 432A Power Meters & 478A Sensors: Additional Information

Keysight 432A Power Meters: Additional Information . . . . . . . . . . . . . 140

Keysight 478A Sensors: Additional Information . . . . . . . . . . . . . . . . . .141

B Equipment Required For Performance Tests And Adjustments

Summary Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .144

C Measurement Uncertainty Analysis - Power Reference Level Test

Measurement Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .148

Define the Measurand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .148

Define the Measurement Equation . . . . . . . . . . . . . . . . . . . . . . . . .148

Uncertainty Equation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .151

Voltage Measurements Uncertainty . . . . . . . . . . . . . . . . . . . . . . . .151

Mismatch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .153

Calibration factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .154

Sensor Calibration Factor Drift . . . . . . . . . . . . . . . . . . . . . . . . . . . .155

Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Repeatability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .156

Sensitivity Coefficients (Ci) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .158

Combined Standard Uncertainty (uc(y)) . . . . . . . . . . . . . . . . . . . . .160

Expanded Uncertainty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

D Measuremet Uncertainty Analysis - Instrument Accuracy Test

Measurement Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .162

Uncertainties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .163

Define the Measurand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .163

Define the Measurement Equation . . . . . . . . . . . . . . . . . . . . . . . . .163

Sensitivity Coefficients Ci: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .170

Combined Standard Uncertainty uc(y): . . . . . . . . . . . . . . . . . . . . . .170

Expanded Uncertainty kuc(y): . . . . . . . . . . . . . . . . . . . . . . . . . . . . .172

Keysight E4416A/E4417A Power Meters Service Guide 17

Page 18

THIS PAGE HAS BEEN INTENTIONALLY LEFT BLANK.

18 Keysight E4416A/E4417A Power Meters Service Guide

Page 19

List of Figures

Figure 2-1 Zero Test Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Figure 2-2 Instrument Accuracy (Normal Path) Test Setup . . . . .32

Figure 2-3 Test Setup With Attenuator Connected . . . . . . . . . . .35

Figure 2-4 Instrument Accuracy (Average Path) Test Setup . . . .39

Figure 2-5 Instrument Accuracy (Average Path) Test Setup . . . .43

Figure 2-6 Power Reference Level Test Setup . . . . . . . . . . . . . . .49

Figure 2-7 Sensor (Average Path) Functional Test Setup . . . . . . .54

Figure 2-8 Sensor (Average Path) Functional Test Setup With

Figure 2-9 Time Base Accuracy Test Setup . . . . . . . . . . . . . . . . . .58

Figure 2-10 Output Standing Wave Ratio Test Setup . . . . . . . . . . .62

Figure 3-1 Adjustment Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

Figure 3-2 A2L9 Adjustment Location . . . . . . . . . . . . . . . . . . . . . .76

Figure 3-3 Adjustment Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Figure 3-4 A2R90 Adjustment Location . . . . . . . . . . . . . . . . . . . .82

Figure 6-1 Troubleshooting Guide - TTL Output 1 . . . . . . . . . . .130

Figure 6-2 Troubleshooting Guide - TTL Output 1 (continued) .131

Figure 6-3 Troubleshooting Guide - TTL Output 2 . . . . . . . . . . .132

Figure 6-4 Troubleshooting Guide - TTL Output 2 (continued) .133

Figure 6-5 Troubleshooting Guide - TTL Inputs . . . . . . . . . . . . .134

Figure 6-6 Troubleshooting Guide - TTL Inputs (continued) . . .135

Figure 6-7 Troubleshooting Guide - TTL Inputs (continued) . . .136

Figure 6-8 Troubleshooting Guide - RS232/422 Interface . . . . .137

Figure C-1 Measurement Setup . . . . . . . . . . . . . . . . . . . . . . . . . .149

Figure D-1 Measurement Setup . . . . . . . . . . . . . . . . . . . . . . . . . .162

Attenuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Keysight E4416A/E4417A Power Meters Service Guide 19

Page 20

THIS PAGE HAS BEEN INTENTIONALLY LEFT BLANK.

20 Keysight E4416A/E4417A Power Meters Service Guide

Page 21

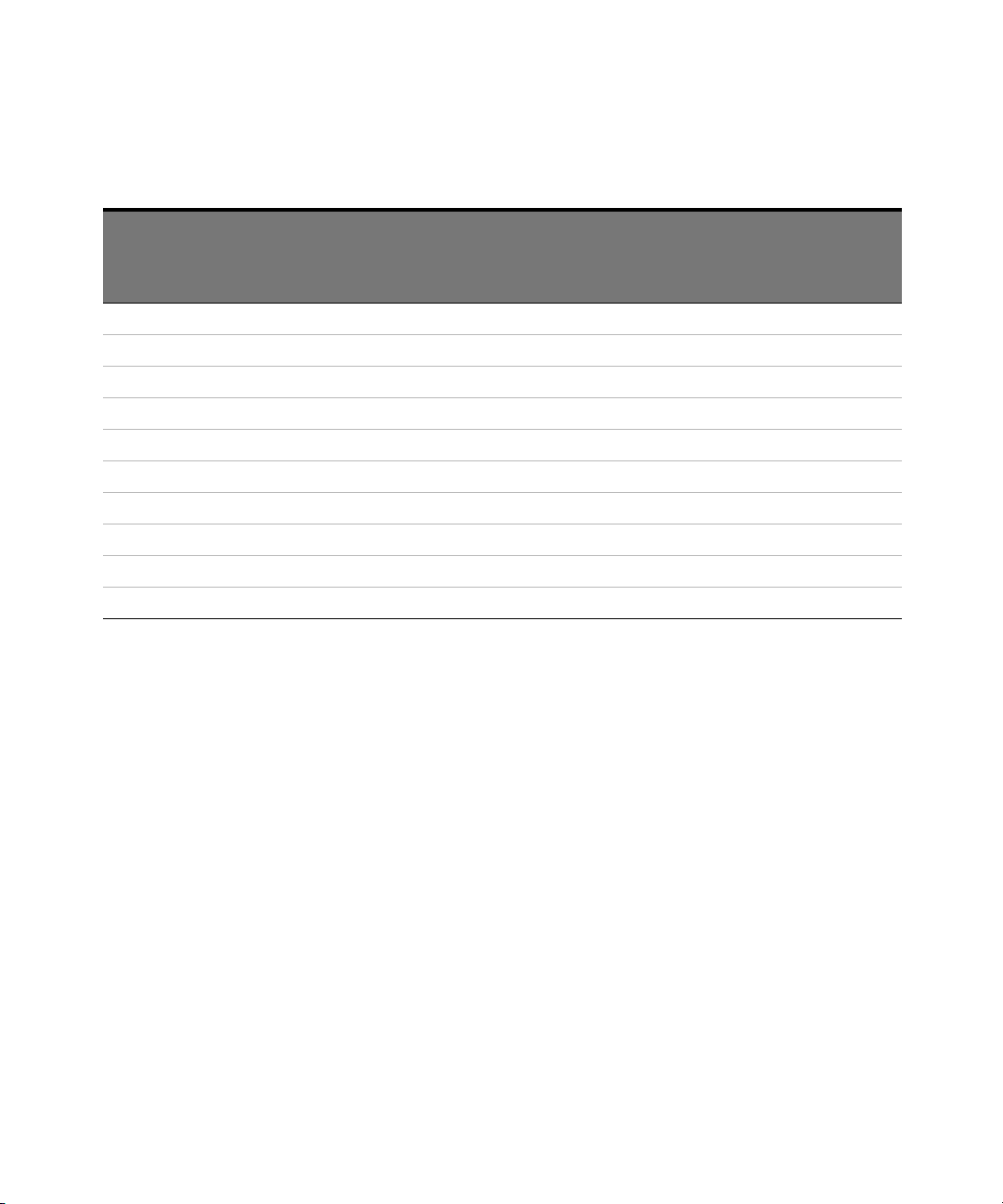

List of Tables

Table 2-1 Zero Test Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Table 2-2 Instrument Accuracy (Normal Path) Test:

Results Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Table 2-3 Instrument Accuracy Results (For Indication Only) . . .41

Table 2-4 Instrument Accuracy Results . . . . . . . . . . . . . . . . . . . .46

Table 2-5 Power Reference Level Test Result . . . . . . . . . . . . . . .51

Table 2-6 Functional Test (Average Path) Results . . . . . . . . . . . . 57

Table 2-7 Power Reference Level Test Result . . . . . . . . . . . . . . .59

Table 2-8 Output SWR Result . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Table 2-9 Performance Test Record . . . . . . . . . . . . . . . . . . . . . . .68

Table 3-1 Post Repair Adjustments, Tests, and Checks . . . . . . .73

Table B-1 Equipment Required For Performance Tests And

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .144

Table C-1 Measurement Repeatability Results . . . . . . . . . . . . .156

Table C-2 Combined Standard Uncertainty . . . . . . . . . . . . . . . .160

Table D-1 Standard Uncertainty Results . . . . . . . . . . . . . . . . . .165

Table D-2 Voltage Correction Multiplier . . . . . . . . . . . . . . . . . . .168

Table D-3 Combined Standard Uncertainty . . . . . . . . . . . . . . . .171

Keysight E4416A/E4417A Power Meters Service Guide 21

Page 22

THIS PAGE HAS BEEN INTENTIONALLY LEFT BLANK.

22 Keysight E4416A/E4417A Power Meters Service Guide

Page 23

E4416A/E4417A Power Meters

Service Guide

1 Characteristics and

Specifications

For the characteristics and specifications of the E4416A/E4417A Power Meters,

refer to the datasheet at

http://literature.cdn.keysight.com/litweb/pdf/5980-1469E.pdf.

23

Page 24

1 Characteristics and Specifications

THIS PAGE HAS BEEN INTENTIONALLY LEFT BLANK.

24 Keysight E4416A/E4417A Power Meters Service Guide

Page 25

E4416A/E4417A Power Meters

Service Guide

2 Performance Tests

Introduction 26

Zero Test 28

Instrument Accuracy (Normal Path) Test 31

Instrument Accuracy (Average Path) Test 38

Power Reference Level Test 47

Keysight E-Series Power Sensor Interface Test 52

Keysight E932x Power Sensor (Average Path) Functional Test 53

Time Base Accuracy Test 58

Output Standing Wave Ratio (SWR) Test 60

Performance Test Record 68

25

Page 26

2 Performance Tests

NOTE

Introduction

The performance tests described in this chapter test the power meter's electrical

performance against the specifications detailed in chapter 1. They are used for

incoming inspection, the calibration cycle (also called periodic maintenance), or

after repairs have been made.

The following conditions must be met for valid performance tests:

– The power meter and test equipment must have a 30 minute warm-up for all

specifications.

– The line voltage for the power meter must be 85 to 264 Vac and the line

frequency must be 50 to 440 Hz.

– The ambient temperature must be 0

The following performance tests are described in this chapter:

– Instrument accuracy (normal path) test.

– Instrument accuracy (average path) test.

– Power reference level test.

– Keysight E-Series power sensor interface test.

ºC to 55 ºC.

– Keysight E932x power sensor (average path) functional test.

– Time base accuracy test.

– Output standing wave ratio (SWR) test.

Equipment Required

Each performance test description details the equipment required by the test. In

addition, Appendix B summarizes the equipment required for all performance

tests and adjustments.

26 Keysight E4416A/E4417A Power Meters Service Guide

Page 27

Performance Test Record

Performance test results can be recorded in Table 2-9, “Performance Test Record”

on page 68. The Performance Test Record table lists the performance test

specifications and the acceptable limits for each specification.

Calibration Cycle

Keysight E4416A and E4417A power meters require performance tests to be run

every two years to verify that they are operating within specified tolerances. Under

conditions of heavy usage or severe operating environments, this calibration cycle

should be performed more frequently.

Test Procedures

It is assumed that the person performing the tests understands how to operate

the specified test equipment. Equipment settings, other than those for the power

meter, are stated in general terms. It is assumed that the person will select the

proper cables, adapters, and probes required for test setups illustrated in this

chapter.

Performance Tests 2

Thermistor Mount Option

The following thermistor mount options are offered:

– 478A Option H75 with VRC at 200 Ω only (reflection and correction data

provided.

– 478A Option H76 with VRC at 200 Ω only (reflection and correction data

provided.

– 478A Option H77 with VRC at 100 and 200 Ω (reflection and correction data at

50 MHz only).

Keysight E4416A/E4417A Power Meters Service Guide 27

Page 28

2 Performance Tests

Zero Test

Specification

Electrical Characteristics Performance Limits

Accuracy: Zero set (Digital settability of zero)

[a] This performance limit is determined by the zero set specification of the power sensor used in the measurement plus the measurement noise.

The range calibrator has a zero set specification of ±0.05 mW. The calibrator measurement noise specification is 110 nW at 16 averages. At

512 averages a noise multiplier of 0.24 is required, giving a measurement noise specification of 0.0264 mW (0.24x512).

±0.0764 mW

Description

After the power meter is initially calibrated and zeroed, the change in the digital

readout is monitored. This test also takes drift and noise into account, since drift,

noise and zero readings cannot be separated.

Equipment

[a]

– Range Calibrator: Keysight 11683A

– Power Sensor Cable: Keysight 11730A

28 Keysight E4416A/E4417A Power Meters Service Guide

Page 29

Test Setup

Keysight 11730A

Power

Meter

CHANNEL A

Power Meter

Range

Calibrator

NOTE

Preset

Local

Confirm

Meas

Display

Units

W

Figure 2-1 Zero Test Setup

Procedure

The following procedure should be performed for the Zero Test.

The procedure details the key presses required on the Keysight

Technologies E4418B. For the Keysight Technologies E4419B, the equivalent key

presses should be performed on both channels.

Performance Tests 2

1 Connect the equipment as shown in Figure 2-1.

2 Switch the power meter on.

3 Press then .

4 Press , , for a reading in watts.

5 Set the range calibrator as follows:

–RANGE: 3μW

– POLARITY: NORMAL

–FUNCTION: STANDBY

–LINE: ON

Keysight E4416A/E4417A Power Meters Service Guide 29

Page 30

2 Performance Tests

NOTE

Channel

Change

Change

Enter

Zero

Cal

Zero

When switching the range calibrator to STANDBY, allow enough time for the

range calibrator to settle to its zero value before attempting to zero the power

meter. This settling would appear on the power meter display as downward drift.

When the drift has reached minimum, (typically less than 60 seconds), the range

calibrator is settled.

6 Set the filter length:

– Press .

– Highlight the Filter parameter using the up/down arrow keys.

– Scroll through the Filter values by pressing . Select a value of

– Highlight the filter length using the forward arrow key. Press . The

– Press .

7 Zero the power meter:

MAN.

Filter Length pop-up window is displayed. Set the filter length to 512.

Press

, . Wait approximately 10 seconds for the wait symbol to

disappear.

8 Wait 30 seconds then verify that the power meter’s reading is within ±0.05 μW.

Record the reading.

Tab le 2-1 Zero Test Results

Min Channel A Actual Results Channel B Actual Results

(E4417A Only)

–76.40 nW _________________ _________________ +76.40 nW

Max

30 Keysight E4416A/E4417A Power Meters Service Guide

Page 31

Instrument Accuracy (Normal Path) Test

σ

nΣ x

2

Σx()

2

–

nn 1–()

--------------------------

=

Accuracy 2.58

σ

=

Specification

Electrical Characteristics Performance Limits (maximum)

Accuracy 0.8% or 0.04 dB

Description

This test verifies the accuracy of the normal path in the power meter by

calculating linear error over 50 samples. The standard deviation is then calculated

using the non-biased or n-1 method:

Equation 2-1: Standard Deviation

Performance Tests 2

Keysight E4416A/E4417A Power Meters Service Guide 31

The test result is obtained by applying a factor of K = 2.58:

Equation 2-2: Accuracy

This accuracy figure represents electrical performance of the normal path with

confidence limits of 99%.

Page 32

2 Performance Tests

Breakout box

Digital Voltmeter

+ input

black

red

Power sensor cable

CHANNEL A

Power meter

Power sensor

Power ref

Power sensor

cable

− input

Equipment

– Power sensor: Keysight E9321A.

–2 × Power sensor cable: Keysight E9288A.

– 30 dB reference attenuator: Keysight 11708A.

– Digital voltmeter (DVM): Keysight 3458A.

– Breakout box kit: Keysight E9288AZ-K01 (comprises a breakout box (coupler)

and a pair of interconnecting red/black leads).

Test Setup

Figure 2-2 Instrument Accuracy (Normal Path) Test Setup

32 Keysight E4416A/E4417A Power Meters Service Guide

Page 33

Procedure

NOTE

Preset

Local

Confirm

Zero

Cal

Zero

Use the following procedure to perform the instrument accuracy (normal path) test:

The procedure details the key presses required on the Keysight E4416A. For the

Keysight E4417A the equivalent key presses should be performed on both

channels.

Connect the equipment as shown in Figure 2-2.

1 Switch the power meter on.

2 Preset the instrument:

3 Press then .

4 Zero the power meter:

Performance Tests 2

Press

disappear.

5 Reset the digital voltmeter:

On the DVM press Shift (the blue key below the DVM display window), to reset

the instrument.

6 Remove any offset errors introduced by the DVM and the breakout box kit with

no power applied:

– On the DVM press Shift, Auto Zero.

– Press

window.

– Press once.

– Press eight times. The words "math null" are shown on the DVM

display window.

– Press Enter to complete the key sequence.

Keysight E4416A/E4417A Power Meters Service Guide 33

, . Wait approximately 25 seconds for the wait symbol to

five times. The word "math" is shown on the DVM display

Page 34

2 Performance Tests

Zero

Cal

Power Ref On

Zero

Cal

Cal

Zero

Cal

Cal

Cal A

System

More

Service

Self Test

More

Fast Path Accuracy

Ref Volts at 0.0 dBm

Enter

NOTE

7 Turn on the power reference:

– Press

8 Connect the E9321A sensor to the power reference.

9 Calibrate the system:

– For the E4416A press

– For the E4417A press ,

10 Provide a point of reference against which the power meter can base its

measurements:

– Setup: press

– Entry: read the value shown on the DVM display. Set the reference voltage

on the pop-up window on the power meter to this value and press .

This value provides a point of reference that allows the power meter and

DVM measurements to be compared at varying power levels.

When operating the power meter in this test mode, the range of power levels

that can be applied is +3 dBm to −30 dBm. Power levels outside this range may

cause inaccurate results to be obtained and in some cases may cause damage

to the E9321A sensor.

,

,

,

, , , ,

,

,

34 Keysight E4416A/E4417A Power Meters Service Guide

Page 35

11 Connect the 30 dB reference attenuator as shown in Figure 2-3:

Digital Voltmeter

+ input

black

red

Breakout box

Power Sensor

Power Meter

CHANNEL A

Power ref

Power sensor cable

Power sensor cable

Attenuator

− input

Measure

NOTE

x

DVMValue PowerMeterValue–()

DVMValue

----------------------------------------------------------- ----------

⎝⎠

⎛⎞

100×=

%

Figure 2-3 Test Setup With Attenuator Connected

12 Take a measurement:

Wait 30 seconds to allow the power level to settle, then press on

the power meter.

Performance Tests 2

13 Record the values displayed on both the power meter and DVM displays. Note

down the values in Table 2-2.

These values tend to drift. They must therefore be recorded simultaneously or

with as small a delay as possible between them.

14 Repeat step 13 a further 49 times to obtain a set of 50 pairs of measured

values.

15 Calculate the measurement error for each pair of measured values using the

following equation:

Keysight E4416A/E4417A Power Meters Service Guide 35

Page 36

2 Performance Tests

Note down each x value in the Error Value (x) column of Table 2-2 .

16 Calculate the linear standard deviation of the data using Equation 2-1:

Standard Deviation, where n = number of samples (50) and x = calculated error

values (listed in the Error Value (x) column of Tab le 2-2)

17 Calculate the result of the linear accuracy test using Equation 2-2: Accuracy.

Enter the result into Ta ble 2- 9, “Performance Test Record” on page 27,

ensuring that the value is within its published specification.

Tab le 2-2 Instrument Accuracy (Normal Path) Test: Results Table

Sample

Number

1 _________ _________ _________ 26 _________ _________ _________

2 _________ _________ _________ 27 _________ _________ _________

3 _________ _________ _________ 28 _________ _________ _________

4 _________ _________ _________ 29 _________ _________ _________

5 _________ _________ _________ 30 _________ _________ _________

6 _________ _________ _________ 31 _________ _________ _________

7 _________ _________ _________ 32 _________ _________ _________

8 _________ _________ _________ 33 _________ _________ _________

9 _________ _________ _________ 34 _________ _________ _________

10 _________ _________ _________ 35 _________ _________ _________

11 _________ _________ _________ 36 _________ _________ _________

12 _________ _________ _________ 37 _________ _________ _________

13 _________ _________ _________ 38 _________ _________ _________

14 _________ _________ _________ 39 _________ _________ _________

15 _________ _________ _________ 40 _________ _________ _________

16 _________ _________ _________ 41 _________ _________ _________

17 _________ _________ _________ 42 _________ _________ _________

18 _________ _________ _________ 43 _________ _________ _________

Power Meter

Value

DVM Value

Error Value

(x)

Sample

Number

Power Meter

Value

DVM Value

Error Value

(x)

36 Keysight E4416A/E4417A Power Meters Service Guide

Page 37

Performance Tests 2

Table 2-2 Instrument Accuracy (Normal Path) Test: Results Table (continued)

Sample

Number

19 _________ _________ _________ 44 _________ _________ _________

20 _________ _________ _________ 45 _________ _________ _________

21 _________ _________ _________ 46 _________ _________ _________

22 _________ _________ _________ 47 _________ _________ _________

23 _________ _________ _________ 48 _________ _________ _________

24 _________ _________ _________ 49 _________ _________ _________

25 _________ _________ _________ 50 _________ _________ _________

Power Meter

Value

DVM Value

Error Value

(x)

Sample

Number

Power Meter

Value

DVM Value

Error Value

(x)

Keysight E4416A/E4417A Power Meters Service Guide 37

Page 38

2 Performance Tests

NOTE

Instrument Accuracy (Average Path) Test

Specification

Electrical Characteristics Performance Limits (maximum)

Accuracy

[a] This performance limit does not include the corresponding sensor power linearity specification.

±0.5% or 0.02 dB

Description

The power meter accuracy is verified for various power inputs. There are two

different methods described in this section that can be used to perform this test.

One of these methods has a higher measurement uncertainty value associated

with it.

Test Procedure 1

[a]

The measurement uncertainty of this test procedure is relatively high at power

levels of 30 μW and below, as it uses a standard 11683A Range Calibrator. As

such, this test procedure should be used for indication only.

Equipment

– Range calibrator: Keysight 11683A.

– Power sensor cable: Keysight E9288A.

38 Keysight E4416A/E4417A Power Meters Service Guide

Page 39

Test Setup

Power Meter

CHANNEL A

Range Calibrator

Power sensor cable

NOTE

Preset

Local

Confirm

Meas

Display

Units

W

Figure 2-4 Instrument Accuracy (Average Path) Test Setup

Procedure

Use the following procedure to perform the instrument accuracy (average path)

test:

Performance Tests 2

The procedure details the key presses required on the Keysight E4416A. For the

Keysight E4417A the equivalent key presses should be performed on both

channels.

1 Connect the equipment as shown in Figure 2-4.

2 Switch the power meter on.

3 Preset the instrument:

Press

4 Set the display units to watts:

Press

Keysight E4416A/E4417A Power Meters Service Guide 39

then .

, , .

Page 40

2 Performance Tests

Meas

Display

Resolution

4

NOTE

Channel

Change

Change

Enter

Zero

Cal

Zero

5 Set the display resolution:

Press

6 Set the range calibrator as follows:

–RANGE: 3 μW

– POLARITY: NORMAL

–FUNCTION: STANDBY

–LINE: ON

When switching the range calibrator to STANDBY, allow enough time for the

range calibrator to settle to its zero value before attempting to zero the power

meter. This settling would appear on the power meter display as downward drift.

When the drift has reached minimum, (typically less than 60 seconds), the range

calibrator is settled.

7 Set the filter length:

– Press .

– Highlight the Filter parameter using the up/down arrow keys.

– Scroll through the Filter values by pressing . Select a value of

MAN.

,then press until is selected.

– Highlight the filter length using the forward arrow key. Press . The

Filter Length pop-up window is displayed. Set the filter length to 512.

– Press .

8 Zero the power meter:

Press

disappear.

9 Set the range calibrator's FUNCTION switch to CALIBRATE.

10 Set the range calibrator's RANGE switch to 1 mW.

40 Keysight E4416A/E4417A Power Meters Service Guide

, . Wait approximately 10 seconds for the wait symbol to

Page 41

11 Calibrate the power meter:

Zero

Cal

Cal

NOTE

Performance Tests 2

Press

,

12 Set the range calibrator's RANGE switch to the positions shown in Ta ble 2- 3.

For each setting, verify that the power meter's reading is within the limits

shown.

Table 2-3 Instrument Accuracy Results (For Indication Only)

Range Calibrator

Setting

3 μW3.100 μW 3.230 μW _________________ _________________

10 μW9.900 μW 10.10 μW _________________ _________________

30 μW 31.40 μW 31.80 μW _________________ _________________

100 μW 99.50 μW 100.5 μW _________________ _________________

300 μW314.40 μW 317.60 μW _________________ _________________

1 mW 0.995 mW 1.005 mW _________________ _________________

3 mW 3.141 mW 3.171 mW _________________ _________________

10 mW 9.984 mW 10.08 mW _________________ _________________

30 mW 31.63 mW 31.94 mW _________________ _________________

100 mW 100.9 mW 101.8 mW _________________ _________________

Min

[a]

Max

[a]

Channel A Actual

Results

Results (E4417A Only)

Channel B Actual

[a] These performance limits are determined by the zero set specification of the power sensor used in the measurement plus the measurement

noise.

The nominal outputs for the 3 μW, 30 μW, 300 μW, 3 mW, 10 mW, 30 mW and

100 mW settings are 3.16 μW, 31.6 μW, 100 μW, 316 μW, 3.156 mW, 10.034

mW, 31.785 mW, and 101.35 mW respectively.

It is not necessary to check instrument accuracy in dBm. The power meter uses

the same internal circuitry to measure power and mathematically converts watts

to dBm.

Keysight E4416A/E4417A Power Meters Service Guide 41

Page 42

2 Performance Tests

NOTE

Test Procedure 2

This test procedure makes use of a 11683A Range Calibrator fitted with Option

H01. The measurement uncertainty of this test procedure is significantly lower

than the previously described method (refer to Appendix D, Measuremet

Uncertainty Analysis - Instrument Accuracy Test for a description of the

measurement uncertainty analysis). As such, this test procedure should be used

to ensure the power meter meets its published specification.

Equipment

– Range Calibrator: Keysight 11683A Option H01

– Power Sensor Cable: Keysight E9288A

– DC Calibrator: Datron 4000A

42 Keysight E4416A/E4417A Power Meters Service Guide

Page 43

Test Setup

Power Meter

Power sensor

Range Calibrator

DC Calibrator

CHANNEL A

cable

NOTE

Figure 2-5 Instrument Accuracy (Average Path) Test Setup

Procedure

Performance Tests 2

The following procedure should be performed for the Instrument Accuracy

Test.The procedure details the key presses required on the Keysight E4416A. For

the Keysight E4417A the equivalent key presses should be performed on both

channels.

1 Connect the equipment as shown in Figure 2-5.

2 Unplug the range calibrator's power cord. Due to a ground loop design

problem with the 11683A Option H01 range calibrator, it does not operate

properly unless ground loops are eliminated. The range calibrator continues to

operate with no power applied, and disconnecting the power cord eliminates

the problem.

Keysight E4416A/E4417A Power Meters Service Guide 43

Page 44

2 Performance Tests

WARNING

Preset

Local

Confirm

Meas

Display

Units

W

Meas

Display

Resolution

4

NOTE

There is a small risk of mild electrical shock from the chassis of the 11683A

Option H01 range calibrator unless the power meter is connected.

3 Figure 2-5 shows the HI/LO outputs of the DC calibrator connected to the DC

reference input of the range calibrator. Ensure that the Guard and LO output of

the DC calibrator are floating, and are not connected to the earth ground.

4 Switch the power meter on.

5 Preset the instrument:

Press

6 Set the display units to watts:

Press

7 Set the display resolution:

Press

8 Set the range calibrator as follows:

– RANGE: 100 mW

– POLARITY: NORMAL

–FUNCTION: STANDBY

– REF SWITCH: EXT

–LINE: OFF

When switching the range calibrator to STANDBY, allow enough time for the

range calibrator to settle to its zero value before attempting to zero the power

meter. This settling would appear on the power meter display as downward drift.

When the drift has reached minimum, (typically less than 60 seconds), the range

calibrator is settled.

then .

, , .

,then press until is selected.

44 Keysight E4416A/E4417A Power Meters Service Guide

Page 45

Performance Tests 2

Channel

Change

Change

Enter

Zero

Cal

Zero

Zero

Cal

Cal

9 Set the DC calibrator as follows:

– SET VALUE: 0 (ZERO)

–FUNCTION: DC

–OUTPUT: OFF

10 Set the filter length:

– Press .

– Highlight the Filter parameter using the up/down arrow keys.

– Scroll through the Filter values by pressing . Select a value of

MAN.

– Highlight the filter length using the forward arrow key. Press . The

Filter Length pop-up window is displayed. Set the filter length to 512.

– Press .

11 Zero the power meter:

Press

, . Wait approximately 10 seconds for the wait symbol to

disappear.

12 Set the DC calibrator output to 144.93 mV, and set the output switch to '+'.

13 Calibrate the power meter:

Press

, .

14 Set the DC calibrator output to the values shown in Ta ble 2-4. For each

setting, set the filter length of the power meter to the carbon-dating value,

and verify that the power meter reading is within the limits shown. Refer to

step 10 for details on how to setup the filter length.

Keysight E4416A/E4417A Power Meters Service Guide 45

Page 46

2 Performance Tests

Tab le 2-4 Instrument Accuracy Results

DC

Calibrator

Setting

458.31 μV 3.1623 μW 256 0.028 μW 3.0977 μW _____ _____ 3.2269 μW 3.1257 3.1989

1.4493 mV 10 μW 256 0.027 μW 9.904 μW _____ _____ 10.096 μW 9.931 10.069

4.5831 mV 31.6228 μW 256 0.027 μW 31.428 μW _____ _____ 31.819 μW 31.455 31.792

14.493 mV 100μW 64 0.073 μW99.49 μW _____ _____ 100.51 μW 99.563 100.437

45.831 mV 316.2278 μW 64 0.104 μW314.72 μW _____ _____ 317.74 μW 314.824 317.636

144.93 mV 1 mW 16 0.2 μW 0.9954 mW _____ _____ 1.0047 mW 995.6 1004.5

459.12 mV 3.1623 mW 16 0.9 μW 3.1477 mW _____ _____ 3.1769 mW 3148.6 3176

1.4588 V 10 mW 16 1.6 μW 9.954 mW _____ _____ 10.046 mW 995.6 10044.4

4.6872 V 31.6228 mW 16 4.8 μW 31.477 mW _____ _____ 31.769 mW 31481.8 31764.2

15.588 V 100 mW 16 18.5 μW 99.54 mW _____ _____ 100.46 mW 99558.5 100441.5

Effective

Power

Applied

Power

Meter

Filter

Setting

Meas Unc Lower Limit Ch A

Result

Ch B

Result

Upper Limit GuardBan

d Lower

Limit (in

μW)

GuardBan

d Upper

Limit (in

μW)

46 Keysight E4416A/E4417A Power Meters Service Guide

Page 47

Performance Tests 2

NOTE

Power Reference Level Test

Electrical Characteristics Performance Limits (maximum) Cond itions

Power reference 1 mW Internal 50 MHz oscillator factory set to

±0.4% traceable to National Physical

Laboratory (NPL), UK.

Power reference accuracy setting ±0.1% Guardbanded Test Line Limits.

Power reference accuracy after

2 years

Description

This test verifies the power level accuracy of the internal 50 MHz oscillator-also

called the power reference oscillator. The power reference oscillator output is

factory adjusted to 1 mW ±0.4%. This accuracy includes a performance limit of

0.1% and a system measurement uncertainty figure of 0.3% (traceable to the

National Physical Laboratory (NPL), UK). Refer to Appendix C for the

measurement uncertainty of the system.

The setting of the oscillator output accuracy is determined from the system

measurement uncertainty plus any chosen test line limit.

For example, if a test line limit of 1 mW ±0.2% was chosen while maintaining a

system measurement uncertainty of ±0.3%, the overall accuracy of the test

setup for the 1 mW power output becomes 0.3% + 0.2%, giving a setting

accuracy of 0.5%.

If an equivalent measurement system is employed for post-factory test (with

ambient temperature of 23 ±3 °C), the power reference oscillator output can again

be set to 1 mW ±0.4%. This setting is sufficient to ensure that the power reference

oscillator meets the accuracy specification of ±0.5% after 2 years. This

specification includes the ±0.4% setting and also takes into account other factors

that will contribute to determining the accuracy after 2 years. The complete

breakdown of the ±0.5% specification is as follows:

±0.9% (0 to 55 ºC) Worst case power meter accuracy, taking

into account the possibility of oscillator

drift and operation at 55 º.

Keysight E4416A/E4417A Power Meters Service Guide 47

Page 48

2 Performance Tests

P

meas

2V

compV1V0

–()V

0

2

V

1

2

–+

4R CalibrationFactor()

--------------------------------------------------------=

– Test line limit: 0.1%.

– System uncertainty: 0.3%.

– 2 year oscillator drift: 0.04%.

– Delta environment: <0.06%.

The same equipment used to measure the accuracy of the power reference

oscillator can also be used to set it to the post-factory accuracy of ±0.4% (for

further information refer to Chapter 3, "Adjustments").

The following procedure ensures maximum accuracy in measuring power

reference oscillator output using Keysight test instruments of known capability.

Signal acquisition criteria may vary if alternative test instruments are used. In

such cases refer to the manufacturer's guidelines for further information.

The test is performed using Equation 2-4:

Equation 2-4: Power Level Provided By The Reference Oscillator

The components of this equation are defined as follows:

is the voltage measured between V

–V

0

after the Keysight 432A has been zeroed.

is the voltage measured between V

–V

1

power is approximately 1 mW.

–V

– R is the resistance of the mount resistor in the Keysight 432A power meter. For

– Calibration Factor is the value of the thermistor mount at 50 MHz.

48 Keysight E4416A/E4417A Power Meters Service Guide

is the voltage between the Keysight 432A V

comp

ground with power applied.

further information refer to Appendix A.

and VRF with no power applied and

comp

and VRF with power applied. This

comp

connector and chassis

comp

Page 49

Equipment

mount

Power Meter

Test Power Meter

V

RF

V

comp

Thermistor

Power ref

Digital Voltmeter

+ input

− input

NOTE

– Test power meter: Keysight 432A.

– Thermistor mount: Keysight 478A Option H75 or H76.

– Digital voltmeter (DVM): Keysight 3458A.

Test Setup

Performance Tests 2

Figure 2-6 Power Reference Level Test Setup

Procedure

Use the following procedure to perform the power reference level test:

The procedure details the key presses required on the Keysight E4416A. For the

Keysight E4417A the equivalent key presses should be performed on both

channels.

1 Set the DVM to measure resistance:

Connect the DVM between the V

432A and pin 1 on the thermistor mount end of the sensor cable. Verify that no

power is applied to the Keysight 432A.

Keysight E4416A/E4417A Power Meters Service Guide 49

connector on the rear panel of the Keysight

RF

Page 50

2 Performance Tests

NOTE

Preset

Local

Confirm

Zero

Cal

Power Ref On

2 Round off the DVM reading to two decimal places and note this value as the

internal bridge resistance (R) of the Keysight 432A (approximately 200 Ω).

– R ____________ Ω

3 Connect the equipment as shown in Figure 2-6, ensuring that the DVM input

leads are isolated from chassis ground.

Ensure that the Keysight 432A and the power meter under test have been

powered on for at least 30 minutes before moving to step 4.

4 Preset the power meter:

Press , then on the power meter.

Set the Keysight 432A RANGE switch to Coarse Zero. Adjust the front panel

Coarse Zero control to obtain a zero meter indication.

5 Zero the Keysight 432A test power meter:

– Fine zero the Keysight 432A on the most sensitive range.

– Set the RANGE switch to 1 mW.

6 Set the DVM to measure microvolts.

7 Connect the positive and negative input leads to the V

and VRF connectors

comp

respectively, on the rear panel of the test power meter.

8 Observe the reading on the DVM. If less than 400 µV, proceed to the next step.

If 400 µV or greater, press and hold the test power meter Fine Zero switch and

adjust the Coarse Zero control so that the DVM indicates 200 µV or less.

Release the Fine Zero switch and proceed to the next step.

9 Round the DVM reading to two decimal places.

Record this reading as V

–V

___________

0

.

0

10 Turn the power reference on:

Press

, .

50 Keysight E4416A/E4417A Power Meters Service Guide

Page 51

11 Round the DVM reading to two decimal places.

Performance Tests 2

Record this reading as V

___________

–V

1

.

1

12 Disconnect the DVM negative input lead from the VRF connector on the

Keysight 432A. Reconnect it to the Keysight 432A chassis ground.

13 Observe the DVM reading. Record the reading as V

–V

___________

comp

14 Calculate the Power Reference Oscillator power using equation 2-4.

15 Verify that P

is within the limits shown in Table 2-5 and record the reading

meas

in the table.

Table 2-5 Power Reference Level Test Result

Min Max Actual Result

0.991 mW 1.009 mW __________________

comp

.

Keysight E4416A/E4417A Power Meters Service Guide 51

Page 52

2 Performance Tests

NOTE

Keysight E-Series Power Sensor Interface Test

Description

Keysight E-Series power sensors have sensor calibration tables stored in

EEPROM. This enables the power meter to download frequency and calibration

factor data automatically. The frequency and calibration factor data have

checksums which are compared to the data downloaded by the power meter. For

the Keysight E4417A dual channel power meter, this test must be performed on

both channels.

This test verifies that the power meter can successfully download this data from

the sensor.

Equipment

– Power sensor cable: Keysight E9288A.

– Power sensor: Keysight E9321A.

Procedure

1 Connect the E9321A power sensor to the power meter's Channel A input. The

following message appears:

– For the Keysight E4416A: Reading Sensor.

– For the Keysight E4417A: Reading Sensor ChA.

When all data has been downloaded this message disappears and a reading is

displayed on the measurement window. If the download fails, a warning

message and error flag are displayed on the front panel. The SCPI error

message -310, System Error is also displayed.

When no power sensor is connected to the Channel A input, the following

message is displayed on the measurement window:

– For the Keysight E4416A: No Sensor.

– For the Keysight E4417A: No Sensor ChA.

2 For the Keysight E4417A repeat step 1 for Channel B.

52 Keysight E4416A/E4417A Power Meters Service Guide

Page 53

Performance Tests 2

NOTE

Keysight E932x Power Sensor (Average Path) Functional Test

Description

This test verifies that the meter/sensor combination can make average path RF

measurements in both upper and lower power ranges.

Keysight E-Series power sensors operate over a wide dynamic range: the value is

sensor dependent and ranges from −70 dBm to +44 dBm. However as there is an

amplifier in these power sensors, the voltages presented to the power sensor

connector are always within the range of voltages available from the Keysight

11683A range calibrator.

Equipment

– Power sensor cable: Keysight E9288A.

– Reference attenuator: Keysight 11708A.

– Power sensor: Keysight E9321A.

Test Setup

Refer to Figure 2-7 and Figure 2-8 below.

Procedure

Use the following procedure to perform the test:

The procedure details the key presses required on the Keysight E4416A. For the

Keysight E4417A the equivalent key presses must be performed on both

channels.

Keysight E4416A/E4417A Power Meters Service Guide 53

Page 54

2 Performance Tests

Power Meter

CHANNEL A

Power Sensor

Power sensor cable

Power ref

Preset

Local

Confirm

Channel

Change

Enter

Done

1 Connect the equipment as shown in Figure 2-7.

Figure 2-7 Sensor (Average Path) Functional Test Setup

2 Preset the instrument:

Press

then .

3 Set the sensor mode to AVG only:

Press .

– Highlight the Sensor Mode parameter using the up/down arrow keys.

– Press .

– A pop-up window is displayed.

– Scroll through the Sensor Mode values using the up/down arrow keys.

Select a value of AVG only.

– Press .

– Press .

54 Keysight E4416A/E4417A Power Meters Service Guide

Page 55

4 Zero the instrument:

Zero

Cal

Zero

Cal

Power Meter

CHANNEL A

Power Sensor

Power sensor cable

30 dB attenuator

Zero

Cal

Power Ref On

Channel

Change

Done

Performance Tests 2

Press

, . Wait approximately 25 seconds for the

wait symbol to disappear.

5 Press to calibrate the power meter.

6 Connect the 30 dB attenuator as shown in Figure 2-8.

Figure 2-8 Sensor (Average Path) Functional Test Setup With Attenuator

7 Turn on the power reference:

Press

,

Keysight E4416A/E4417A Power Meters Service Guide 55

8 Switch to the power sensor's lower range:

– Press .

– Scroll through the Range values by pressing . Select a value of

LOWER.

– A pop-up window is displayed.

– Press .

9 Verify that the display reads −30 dBm ±1 dB. Record the reading in Table 2-6.

Page 56

2 Performance Tests

Channel

Change

Done

Zero

Cal

Power Ref Off

Channel

Change

Done

Zero

Cal

Power Ref On

10 Switch to the power sensor's upper range:

– Press .

– Move to the Range parameter using the up/down arrow keys.

– Scroll through the Range values by pressing . Select a value of

– Press .

11 Verify that the display reads −30 dBm ± 1 dB. Record the reading in Table 2-6 .

12 Turn on the power reference:

UPPER.

Press

,

13 Switch to the power sensor's lower range:

– Press .

– Move to the Range parameter using the up/down arrow keys.

– Scroll through the Range values by pressing . Select a value of

LOWER.

– Press .

14 Disconnect the 30 dB attenuator and reconnect the test setup as shown in

Figure 2-7.

15 Turn on the power reference:

Press

,

16 Verify that an overload error is displayed on the status line at the top of the

power meter's display and that the display reads 999.99 dBm.

56 Keysight E4416A/E4417A Power Meters Service Guide

Page 57

17 Switch to the power sensor's upper range:

Channel

Change

Done

– Press .

– Move to the Range parameter using the up/down arrow keys.

– Scroll through the Range values by pressing . Select a value of

UPPER.

– Press .

18 Verify that the display reads 0 dBm ±1 dB. Record the reading.

Table 2-6 Functional Test (Average Path) Results

Test Channel A Resul ts Channel B Results

Low Range, 30 dB pad _________________ _________________

Upper Range, 30 dB pad _________________ _________________

Low Range, no pad _________________ _________________

High Range, no pad _________________ _________________

Performance Tests 2

(Keysight E4417A Only)

Keysight E4416A/E4417A Power Meters Service Guide 57

Page 58

2 Performance Tests

Power Meter (rear)

Trig out

Frequency Counter

Time Base Accuracy Test

Specification

Electrical Characteristics Performance Limits

Frequency accuracy 10 MHz ±0.01%

Description

This test measures the accuracy of the power meter's time base frequency. Time

base frequency determines the accuracy of the sampling rate when making

measurements. Time base frequency is measured by attaching a frequency

counter to the Trig Out socket on the rear of the power meter then enabling test

mode from the service menu.

Equipment

– Frequency counter: Keysight 53132A.

Test Setup

58 Keysight E4416A/E4417A Power Meters Service Guide

Figure 2-9 Time Base Accuracy Test Setup

Page 59

Procedure

Preset

Local

Confirm

System

More

Service

Self Test

More

Time Base

Enable 10 MHz TB

Use the following procedure to perform the test:

1 Connect the equipment as shown in Figure 2-9.

2 Switch on the power meter.

3 Preset the instrument:

Performance Tests 2

Press

4 Enable time base test mode:

Press

then .

, , , , ,

,

5 Note the reading on the frequency counter and verify that it is within the limits

shown in Table 2-7:

Table 2-7 Power Reference Level Test Result

Min Max Actual Result

9.9990 MHz 10.0010 MHz ________________