Page 1

User’s Guide

Keysight 81150A and

81160A Pulse Function

Arbitrary Noise Generator

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176 - TestEquipmentDepot.com

Page 2

Keysight

Pulse Function Arbitrary

Noise Generator

81150A and 81160A

User’s Guide

Page 3

Notices

CAUTION

WARNING

© Keysight Technologies 2011, 2014

No part of this manual may be reproduced in any

form or by any means (including electronic

storage and retrieval or translation into a foreign

language) without prior agreement and written

consent from Keysight Technologies as governed

by United States and international copyright laws.

Manual Part Number

81160-91020

Edition

Edition 2.0, August 2014

Printed in Germany

Keysight Technologies, Deutschland GmbH

Herrenberger Str. 130

71034 Böblingen, Germany

For Assistance and Support

Warranty

The material contained in this document is

provided “as is,” and is subject to being

changed, without notice, in future editions.

Further, to the maximum extent permitted by

applicable law, Keysight disclaims all

warranties, either express or implied, with

regard to this manual and any information

contained herein, including but not limited to the

implied warranties of merchantability and

fitness for a particular purpose. Keysight shall

not be liable for errors or for incidental or

consequential damages in connection with the

furnishing, use, or performance of this document

or of any information contained herein. Should

Keysight and the user have a separate written

agreement with warranty terms covering the

material in this document that conflict with

these terms, the warranty terms in the separate

agreement shall control.

Technology Licenses

The hardware and/or software described in this

document are furnished under a license and may

be used or copied only in accordance with the

terms of such license.

Restricted Rights Legend

If software is for use in the performance of a U.S.

Government prime contract or subcontract,

Software is delivered and licensed as

“Commercial computer software” as defined in

DFAR 252.227-7014 (June 1995), or as a

“commercial item” as defined in FAR 2.101(a) or

as “Restricted computer software” as defined in

FAR 52.227-19 (June 1987) or any equivalent

agency regulation or contract clause. Use,

duplication or disclosure of Software is subject to

Keysight Technologies’ standard commercial

license terms, and non-DOD Departments and

Agencies of the U.S. Government will receive no

greater than Restricted Rights as defined in FAR

52.227-19(c)(1-2) (June 1987). U.S. Government

users will receive no greater than Limited Rights

as defined in FAR 52.227-14 (June 1987) or DFAR

252.227-7015 (b)(2) (November 1995), as

applicable in any technical data.

Safety Notices

A CAUTION notice denotes a hazard. It

calls attention to an operating

procedure, practice, or the like that, if

not correctly performed or adhered to,

could result in damage to the product

or loss of important data. Do not

proceed beyond a CAUTION notice until

the indicated conditions are fully

understood and met.

A WARNING notice denotes a hazard.

It calls attention to an operating

procedure, practice, or the like that, if

not correctly performed or adhered to,

could result in personal injury or

death. Do not proceed beyond a

WARNING notice until the indicated

conditions are fully understood and

met.

Page 4

The following general safety precautions

must be observed during all phases of

operation of this instrument. Failure to

comply with these precautions or with

specific warnings elsewhere in this manual

violates safety standards of design,

manufacture, and intended use of the

instrument.

Keysight Technologies assumes no liability

for the customer's failure to comply with

these requirements.

Before operation, review the instrument and

manual for safety markings and instructions.

You must follow these to ensure safe

operation and to maintain the instrument in

safe condition.

This product is a Safety Class 1 instrument

(provided with a protective earth terminal).

The protective features of this product may

be impaired if it is used in a manner not

specified in the operation instructions.

All Light Emitting Diodes (LEDs) used in this

product are Class 1 LEDs as per IEC 60825-1.

This instrument is intended for indoor use in

an installation category II, pollution degree 2

environment. It is designed to operate at a

maximum relative humidity of 95% and at

altitudes of up to 2000 meters.

Refer to the specifications tables for the ac

mains voltage requirements and ambient

operating temperature range.

Verify that all safety precautions are taken.

The power cable inlet of the instrument

serves as a device to disconnect from the

mains in case of hazard. The instrument

must be positioned so that the operator can

easily access the power cable inlet. When

the instrument is rack mounted the rack

must be provided with an easily accessible

mains switch.

To minimize shock hazard, the instrument

chassis and cover must be connected to an

electrical protective earth ground. The

instrument must be connected to the ac

power mains through a grounded power

cable, with the ground wire firmly connected

to an electrical ground (safety ground) at the

power outlet. Any interruption of the

protective (grounding) conductor or

disconnection of the protective earth

terminal will cause a potential shock hazard

that could result in personal injury.

Do not operate the instrument in the

presence of flammable gases or fumes.

Operating personnel must not remove

instrument covers. Component replacement

and internal adjustments must be made only

by qualified personnel.

Instruments that appear damaged or

defective should be made inoperative and

secured against unintended operation until

they can be repaired by qualified service

personnel.

4

Page 5

Indicates warning or caution. If you see this

This product complies with the WEEE

Directive (2002/96/EC) marketing

requirements. The affixed label indicates

that you must not discard this

electrical/electronic product in domestic

household waste.

Product category: With reference to the

equipment types in the WEEE Directive

Annexure I, this product is classed as a

“Monitoring and Control instrumentation”

product.

Do not dispose in domestic household

waste.

symbol on a product, you must refer to the

manuals for specific Warning or Caution

information to avoid personal injury or damage to

the product.

Notice for European Community: This product

complies with the relevant European legal

Directives: EMC Directive 89/336/EEC and Low

Voltage Directive 73/23/EEC.

General Recycling Mark for plastic parts used in

the product.

Safety requirements for electrical equipment for

measurement, control, and laboratory use

CAN/CSA C22.2 No. 1010.1 (1993) UL 3101, 3111

(First Editions). This equipment has also been

evaluated to IEC 61010 edition 1 including

amendments 1 and 2.

Conformity Mark of the Australian ACA for EMC

compliance.

Page 6

Appendix

Contents

Contents ................................................................................................................................................................ 6

1 Introduction .......................................................................................................................................... 13

2 Front-Panel Menu Operation ............................................................................................................. 17

2.1 The Front Panel ...................................................................................................................... 19

2.2 Help is Available .................................................................................................................... 24

2.3 The Front-Panel Display at a Glance .................................................................................... 25

2.3.1 Menu Mode ................................................................................................................ 25

2.3.2 Graph Mode................................................................................................................ 26

2.4 The Front-Panel Number Entry ............................................................................................. 27

2.5 The Rear Panel ....................................................................................................................... 28

2.6 Preparing the 81150A / 81160A for Use.............................................................................. 30

2.7 Using the Built-in Help System............................................................................................. 31

2.8 Selecting the Mode of Operation ......................................................................................... 32

2.9 Selecting Trigger Mode and Source ..................................................................................... 33

2.10 Selecting the Waveform ........................................................................................................ 37

2.11 Selecting the Advanced Mode.............................................................................................. 40

2.11.1 Modulation ............................................................................................................... 40

2.11.2 Burst ......................................................................................................................... 41

2.11.3 Sweep ....................................................................................................................... 42

2.12 Setting the Output Frequency ............................................................................................... 43

2.13 Setting the Output Amplitude ............................................................................................... 45

2.13.1 Converting the amplitude from one unit to another ............................................. 47

2.14 Selecting Delay....................................................................................................................... 48

2.15 Selecting DC Volts ................................................................................................................. 50

2.16 Setting a DC Offset Voltage .................................................................................................. 51

2.17 Setting the Duty Cycle of a Square Wave ........................................................................... 53

2.18 Setting the High-Level and Low-Level Values .................................................................... 54

2.19 Configuring a Pulse Waveform ............................................................................................. 55

2.20 Setting up a Pattern ............................................................................................................... 57

6

Page 7

Introduction

2.21 Viewing a Waveform Graph .................................................................................................. 59

2.22 Outputting a Stored Arbitrary Waveform ............................................................................. 60

2.23 Selecting the Output Termination ........................................................................................ 62

2.24 Outputting a Modulated Waveform...................................................................................... 64

2.25 Outputting an FSK Waveform ............................................................................................... 67

2.26 Outputting a PWM Waveform .............................................................................................. 70

2.27 Outputting a Frequency Sweep ............................................................................................ 72

2.28 Outputting a Burst Waveform............................................................................................... 75

2.29 Triggering a Sweep or Burst ................................................................................................. 78

2.30 Storing the Instrument State ................................................................................................ 79

2.31 Configuring the Remote Interface ........................................................................................ 82

2.31.1 GPIB Configuration .................................................................................................. 82

2.31.2 USB Configuration ................................................................................................... 83

2.31.3 LAN Configuration ................................................................................................... 84

2.32 Resetting the 81150A / 81160A ........................................................................................... 89

3 Features and Functions ...................................................................................................................... 90

3.1 Trigger Mode .......................................................................................................................... 92

3.1.1 Arming Source ........................................................................................................... 94

3.1.2 Arming Slope .............................................................................................................. 96

3.1.3 Internal Trigger Period/Frequency ........................................................................... 97

3.2 Output Configuration ............................................................................................................. 99

3.2.1 Output Function ......................................................................................................... 99

3.2.2 Output Frequency .................................................................................................... 101

3.2.3 Output Amplitude .................................................................................................... 104

3.2.4 DC Offset Voltage .................................................................................................... 107

3.2.5 Output Units ............................................................................................................. 109

3.2.6 Load Impedance ....................................................................................................... 110

3.2.7 Output Source Impedance ...................................................................................... 111

3.2.8 Voltage Autoranging................................................................................................ 112

3.2.9 Amplifier Type Selection ......................................................................................... 113

3.2.10 Digital Channel Addition ....................................................................................... 114

3.2.11 Voltage Limits ........................................................................................................ 115

3.2.12 Duty Cycle (Square Waves) .................................................................................. 116

3.2.13 Symmetry (Ramp Waves) ..................................................................................... 118

81150A and 81160A User’s Guide 7

Page 8

Appendix

3.2.14 Output Control ....................................................................................................... 119

3.2.15 Parameter Coupling ............................................................................................... 120

3.2.16 Polarity .................................................................................................................... 124

3.2.17 Strobe Output ......................................................................................................... 125

3.2.18 Trigger Output ........................................................................................................ 126

3.2.19 Sync Output............................................................................................................ 127

3.3 Input Configuration .............................................................................................................. 129

3.3.1 External In Parameters ............................................................................................ 130

3.3.2 Modulation In Parameters ...................................................................................... 134

3.3.3 Reference Clock ....................................................................................................... 139

3.4 Pulse Waveforms ................................................................................................................. 141

3.4.1 Pulse Period ............................................................................................................. 142

3.4.2 Pulse Width .............................................................................................................. 143

3.4.3 Leading Edge/Trailing Edge ................................................................................... 145

3.5 Pattern Capabilities.............................................................................................................. 148

3.5.1 Pattern Mode ........................................................................................................... 149

3.5.2 Pattern Source ......................................................................................................... 150

3.5.3 Configuring the External Pattern Source ............................................................... 152

3.5.4 Selecting a Pattern .................................................................................................. 159

3.5.5 Creating, Editing and Storing a Pattern ................................................................. 161

3.5.6 Bitshape Selection................................................................................................... 168

3.5.7 Creating, Editing and Storing a Bitshape............................................................... 170

3.5.8 Triggered and Gated Patterns................................................................................. 176

3.6 Noise ..................................................................................................................................... 178

3.7 Amplitude Modulation (AM) ............................................................................................... 180

3.7.1 Selecting AM Modulation ....................................................................................... 181

3.7.2 Carrier Waveform Shape ......................................................................................... 182

3.7.3 Carrier Frequency ..................................................................................................... 183

3.7.4 Modulating Waveform Shape ................................................................................. 184

3.7.5 Modulating Waveform Frequency .......................................................................... 185

3.7.6 Modulating Depth .................................................................................................... 186

3.7.7 DSSC (Double Sideband Suppressed Carrier Mode) ............................................ 188

3.7.8 Modulating Source .................................................................................................. 190

3.8 Frequency Modulation (FM) ................................................................................................ 191

3.8.1 Selecting FM Modulation........................................................................................ 192

3.8.2 Carrier Waveform Shape ......................................................................................... 193

8

Page 9

Introduction

3.8.3 Carrier Frequency ..................................................................................................... 194

3.8.4 Modulating Waveform Shape ................................................................................. 195

3.8.5 Modulating Waveform Frequency .......................................................................... 196

3.8.6 Peak Frequency Deviation....................................................................................... 197

3.8.7 Modulating Source .................................................................................................. 198

3.9 Phase Modulation (PM) ...................................................................................................... 199

3.9.1 Selecting PM Modulation ....................................................................................... 200

3.9.2 Carrier Waveform Shape ......................................................................................... 201

3.9.3 Carrier Frequency ..................................................................................................... 202

3.9.4 Modulating Waveform Shape ................................................................................. 203

3.9.5 Modulating Waveform Frequency .......................................................................... 204

3.9.6 Phase Deviation ....................................................................................................... 205

3.9.7 Modulating Source .................................................................................................. 206

3.10 Frequency-Shift Keying (FSK) Modulation ......................................................................... 207

3.10.1 Selecting FSK Modulation .................................................................................... 208

3.10.2 Carrier Waveform Shape ....................................................................................... 209

3.10.3 FSK Carrier Frequency ........................................................................................... 210

3.10.4 FSK “Hop” Frequency............................................................................................ 211

3.10.5 FSK Rate ................................................................................................................. 212

3.10.6 FSK Source ............................................................................................................. 213

3.11 Pulse Width Modulation (PWM) ........................................................................................ 214

3.11.1 Selecting PWM Modulation ................................................................................. 215

3.11.2 Pulse Waveform .................................................................................................... 216

3.11.3 Pulse Period ........................................................................................................... 217

3.11.4 Modulating Waveform Shape............................................................................... 218

3.11.5 Modulating Waveform Frequency ........................................................................ 219

3.11.6 Width Deviation ..................................................................................................... 220

3.11.7 Duty Cycle Deviation ............................................................................................. 221

3.11.8 Modulating Source ................................................................................................ 224

3.12 Frequency Sweep ................................................................................................................. 225

3.12.1 Selecting a Sweep ................................................................................................. 227

3.12.2 Start Frequency and Stop Frequency ................................................................... 228

3.12.3 Center Frequency and Frequency Span ............................................................... 229

3.12.4 Idle Frequency ........................................................................................................ 231

3.12.5 Sweep Type ............................................................................................................ 232

3.12.6 Sweep Time............................................................................................................ 234

3.12.7 Marker Frequency .................................................................................................. 235

81150A and 81160A User’s Guide 9

Page 10

Appendix

3.12.8 Triggered/Gated Sweep........................................................................................ 236

3.13 Burst Mode ........................................................................................................................... 238

3.13.1 Selecting a Burst ................................................................................................... 239

3.13.2 Continuous Burst Mode ........................................................................................ 240

3.13.3 Triggered Burst Mode ........................................................................................... 241

3.13.4 Gated Burst Mode ................................................................................................. 242

3.13.5 Burst Count ............................................................................................................ 243

3.13.6 Burst Phase ............................................................................................................ 244

3.14 Arbitrary Waveforms............................................................................................................ 245

3.14.1 Creating and Storing an Arbitrary Waveform...................................................... 246

3.14.2 Managing Stored Waveforms............................................................................... 253

3.14.3 Additional Information on Arbitrary Waveforms ................................................ 256

3.15 System-Related Operations................................................................................................. 257

3.15.1 Instrument State Storage...................................................................................... 258

3.15.2 Export/Import State .............................................................................................. 261

3.15.3 Error Conditions ..................................................................................................... 263

3.15.4 Beeper Control ....................................................................................................... 265

3.15.5 Display Brightness................................................................................................. 266

3.15.6 Display Control ....................................................................................................... 267

3.15.7 Time ........................................................................................................................ 269

3.15.8 Date......................................................................................................................... 270

3.15.9 Firmware Revision Query ...................................................................................... 271

3.15.10 SCPI Language Version Query............................................................................ 272

10

3.16 Remote Interface Configuration ......................................................................................... 273

3.16.1 GPIB Address ......................................................................................................... 274

3.16.2 DHCP/Auto-IP On/Off (LAN) ............................................................................... 275

3.16.3 IP Address (LAN) ................................................................................................... 276

3.16.4 Subnet Mask (LAN) ............................................................................................... 277

3.16.5 Default Gateway (LAN) ......................................................................................... 278

3.16.6 Host Name ............................................................................................................. 279

3.16.7 Domain Name (LAN) ............................................................................................. 280

3.16.8 DNS Server (LAN).................................................................................................. 281

3.16.9 WINS Server (LAN) ............................................................................................... 282

3.16.10 Current Configuration (LAN)............................................................................... 284

3.17 Software Update .................................................................................................................. 286

3.18 Installing Licenses ............................................................................................................... 288

Page 11

Introduction

3.19 Diagnostics/Calibration Overview...................................................................................... 290

3.20 Security ................................................................................................................................. 293

3.21 Factory Default Settings ...................................................................................................... 294

4 Remote Programming Reference .................................................................................................... 299

4.1 Keysight 81150A / 81160A Remote Control ...................................................................... 299

4.1.1 Programming Recommendations ........................................................................... 300

4.2 81150A / 81160A SCPI Command Summary .................................................................... 302

4.3 Common Command Summary ............................................................................................ 315

4.4 81150A / 81160A SCPI Instrument Command List Format.............................................. 317

4.5 81150A / 81160A SCPI Instrument Elements Name ........................................................ 318

4.5.1 APPLy Commands ................................................................................................... 319

4.5.2 Arbitrary Waveform Commands ............................................................................. 329

4.5.3 Burst Commands ..................................................................................................... 352

4.5.4 Level Commands...................................................................................................... 361

4.5.5 Modulation Commands ........................................................................................... 371

4.5.6 Channel Command .................................................................................................. 414

4.5.7 Output Commands ................................................................................................... 416

4.5.8 Output Function Commands ................................................................................... 431

4.5.9 Reference Clock Commands ................................................................................... 465

4.5.10 Non-Volatile Storage Commands ......................................................................... 468

4.5.11 Status Reporting Commands ................................................................................ 482

4.5.12 Sweep Commands ................................................................................................. 488

4.5.13 System-Related Commands.................................................................................. 499

4.5.14 Display Commands ................................................................................................ 520

4.5.15 Triggering Commands ........................................................................................... 524

4.5.16 Pattern Related Commands .................................................................................. 536

4.6 Common Command List ...................................................................................................... 573

4.7 Status Model ........................................................................................................................ 576

4.7.1 Status register structure ......................................................................................... 578

4.7.2 Status Byte Register................................................................................................ 579

4.7.3 STATus Commands ................................................................................................. 580

4.7.4 STATus Questionable Data Register command subsystem ................................ 580

4.8 Programming Basics ............................................................................................................ 583

4.8.1 Before you begin...................................................................................................... 583

4.8.2 Application Programs .............................................................................................. 587

81150A and 81160A User’s Guide 11

Page 12

Appendix

5 Error Messages.................................................................................................................................. 595

6 Application Programs ....................................................................................................................... 597

7 Tutorial ................................................................................................................................................ 599

7.1 Direct Digital Synthesis ....................................................................................................... 600

7.2 Creating Arbitrary Waveforms ............................................................................................ 604

7.3 Pulse Waveform Generation ............................................................................................... 607

7.4 Pattern Generation............................................................................................................... 609

7.4.1 Multi-Level Pattern Definitions .............................................................................. 610

7.4.2 Pattern Types and Sequencing Capabilities .......................................................... 612

7.4.3 Trigger Modes .......................................................................................................... 613

7.4.4 Defining the Shape of a Bit..................................................................................... 614

7.4.5 External Patterns ..................................................................................................... 618

7.5 Noise Generation ................................................................................................................. 620

7.5.1 Limitations of User-defined Noise Distributions .................................................. 622

7.6 Trigger Modes ...................................................................................................................... 624

7.7 External In to Trigger Out Timing ....................................................................................... 627

7.8 Signal Imperfections ............................................................................................................ 629

7.9 Output Amplitude Control ................................................................................................... 631

7.10 Attributes of AC Signals ...................................................................................................... 634

7.11 Modulation ........................................................................................................................... 637

7.12 Frequency Sweep ................................................................................................................. 644

7.13 Burst ...................................................................................................................................... 647

7.14 Channel Addition.................................................................................................................. 649

7.15 Coupling between Channels ............................................................................................... 651

A Appendix ............................................................................................................................................. 653

A.1 Coupled Parameters when channel coupling is on .......................................................... 653

12

A.2 Pulse Parameter Definitions ............................................................................................... 656

A.3 Keysight 81150A / 81160A in comparison with other Keysight instruments ................ 663

A.3.1 Keysight 81110A/81104A/81101A instrument family......................................... 663

A.3.2 Keysight 33220A ..................................................................................................... 665

A.4 Preparing a USB Flash Drive using Windows Vista® ....................................................... 668

Page 13

Introduction

Keysight

Technologies’

81150A / 81160A

Pulse Function

Arbitrary Noise

Generator

The Keysight Technologies 81150A and 81160A is a Pulse Pattern and

Function Arbitrary Noise Generator with built-in arbitrary waveform and

pulse capabilities

Its combination of bench-top and system features makes this Pulse Function

Arbitrary Noise Generator a versatile solution for your testing requirements

now and in the future.

Features and

Benefits

81150A: 1 Hz-120 MHz pulse generation with variable rise/fall time

81150A: 1 Hz-240 MHz sine waveform outputs

81160A: 1 Hz-330 MHz pulse generation with variable rise/fall time

81160A: 1 Hz-500 MHz sine waveform outputs

Pulse, sine, square, ramp, noise and arbitrary waveforms

FM, AM, PM, FSK, PWM modulation capability

One or two channels

81150A: 14-bit, 2GSa/s, 512 KSa deep arbitrary waveform memory

per channel

81160A: 14-bit, 2.5GSa/s, up to 256 KSa deep arbitrary waveform

memory per channel

USB, GPIB and LAN connectivity.

Glitch free change of timing parameters delay, frequency, transition

time, width, duty cycle

LXI class C compliant

Benchtop Testing

The 81150A / 81160A features a graphic display showing all pulse

parameters at a glance. The cursor keys and the modify knob allow fast and

simple operation.

The user interface is designed to minimize the time invested in getting

familiar with the instrument. After familiarization, the instrument supports

quick setups of signals. This leaves you free to concentrate on the

measurement task and testing of the DUT.

1 Introduction

81150A and 81160A User’s Guide 13

Page 14

Appendix

What’s inside this

Manual

This manual provides detailed information about the following:

Front-Panel Menu Operation

Features and Functions

Remote Programming Reference

Error Messages

Application Programs

Tutorial

Purpose of this

Manual

The purpose of this manual is to enable you to install, initialize, and start the

81150A / 81160A and to understand the front-panel menu features of the

81150A / 81160A.

Who should read

this Manual

This manual is intended for testers and Engineers who will be using the

81150A / 81160A to test other devices.

How this document

is organized

This section provides information on the chapters, and their content.

Topic

What information does it contain?

Introduction

Introduces the 81150A / 81160A, defines the purpose and

intended audience of this manual; explains how information is

organized in this manual.

Front-Panel Menu Operation

Introduces you to the Front-Panel Menu and describes some of

the menu features of the 81150A / 81160A Pulse Pattern and

Function Arbitrary Noise Generator.

Features and Functions

Gives a detailed description of the 81150A / 81160A’s

capabilities and operation. You will find this section useful when

you are operating the 81150A / 81160A from the front panel or

over the remote interface.

Navigating this manual

14

Page 15

Introduction

Topic

What information does it contain?

Remote Programming Reference

Contains reference information to help you program the 81150A

/ 81160A over the remote interface.

Error Messages

Describes the error reporting model that is used by the 81150A /

81160A.

Application Programs

Describes the various types of programming examples available

for the 81150A / 81160A and where to find them.

Tutorial

Gives an overview of the internal operations of the 81150A /

81160A.

Terms and

conventions used in

this manual

The following table lists the terms and conventions used in this manual:

The icon...

Indicates…

A note or important information.

A tip

A caution or warning

Notes within a table

Acronyms used in

this manual

The following table lists the acronyms and abbreviations used in this manual:

Acronym

Explanation

DHCP

Dynamic Host Configuration Protocol

DNS

Domain Name Service

DUT

Device Under Test

Conventions

Acronyms used in this Document

81150A and 81160A User’s Guide 15

Page 16

Appendix

References

The Getting Started Guide along with this manual forms a part of the 81150A

and 81160A product documentation suite.

16

Page 17

Front-Panel Menu Operation

Introduction

This section introduces the front-panel menu and describes the menu

features of the 81150A / 81160A Pulse Pattern and Function Arbitrary Noise

Generator.

2 Front-Panel Menu Operation

81150A and 81160A User’s Guide 17

Page 18

Appendix

What’s inside this

Chapter

The following topics are discussed in this section:

The Front Panel

Help is Available

The Front-Panel Display at a Glance

Menu Mode

Graph Mode

The Front-Panel Number Entry

The Rear Panel

Preparing the 81150A / 81160A for Use

Using the Built-in Help System

Selecting the Mode of Operation

Selecting Trigger Mode

Selecting the Waveform

Selecting the Advanced Mode

Setting the Output Frequency

Setting the Output Amplitude

Selecting Delay

Selecting DC Volts

Setting a DC Offset Voltage

Setting the Duty Cycle of a Square Wave

Setting the High-Level and Low-Level Values

Configuring a Pulse Waveform

Setting up a Pattern

Viewing a Waveform Graph

Outputting a Stored Arbitrary Waveform

Selecting the Output Termination

Outputting a Modulated Waveform

Outputting an FSK Waveform

Outputting a PWM Waveform

Outputting a Frequency Sweep

Outputting a Burst Waveform

Triggering a Sweep or Burst

Storing the Instrument State

Configuring the Remote Interface

Resetting the 81150A / 81160A

18

Page 19

Front-Panel Menu Operation

Introduction

The instrument is mainly operated from the front panel, when used for

benchtop testing.

This section explains the Keys, Functions, Inputs/Outputs and Controls,

seen on the Front Panel of the 81150A / 81160A.

Ch 1

Ch 2

Coupling

Graph

Cancel

7 8 9

4

5 6

1 2 3

0 . +/-

Out 2 Out 2 Out 1 Out 1

Man Cont Pulse Square M od

Store/

Recall

Utility

Help

Sweep

BurstArb

Ramp

Noise

SineTrig

Gat ed

max.±15V

Trigger Out 2 Strobe Out 2External In

Trigger Out 1 Strobe Out 1

81150A

Pulse Function Arbitrary Generator

120 MHz

Local

Power Switch Menu Softkeys Cancel

Graph / Local

Numeric Keypad Inputs / Outputs

USB Host

Channel 1 Selection

Channel Coupling

Channel 2 Selection

Navigation

Keys

Rotary Knob

Cursor Keys

Trigger

Modes

Waveform

Type

Advanced

Modes

Special

Function Keys

Ch 1

Ch 2

Coupli ng

Gr aph

Canc el

L oc a l

m a x . ± 1 0 V

Ex t e r na l I n Sy nc Ou t A Sy nc Ou t B

7

8

9

4 5 6

1 2 3

0 .

+/-

Out2 Out 2 Out1 Out 1

Man Cont Pulse Square Mod

Store/

Recall

Utility

Help

Sweep

BurstArb

Ramp

Noise

SineTrig

Gated

Channel 1 Selection

Channel Coupling

Channel 2 Selection

USB Host

Power Switch

Menu Softkeys Cancel

Graph / Local

Numeric Keypad Inputs / Outputs

Special

Function Keys

Advanced

Modes

Waveform

Type

Trigger

Modes

Rotary Knob

Cursor Keys

Navigation

Keys

2.1 The Front Panel

Front Panel of the 81150A

81150A and 81160A User’s Guide 19

Front Panel of the 81160A

Page 20

Appendix

Power Switch

The front panel switch is used to switch on and off the instrument.

When the front panel switch is off, the instrument is in standby mode. The

instrument is disconnected from the AC line power only by disconnecting

the power cord.

USB

The Front Panel contains a USB host connector. It is intended to connect

USB drives to store instrument states and waveforms on an external

memory.

Menu Softkeys

The five keys below the main display screen are called softkeys (softwarecontrolled keys). The current function of each softkey is indicated in the

corresponding box on the display.

Some softkeys hold additional symbols to indicate that they provide

extended functionality.

Yellow Triangles: These are visible on the five softkeys on the

Front Panel. The yellow triangles indicate that there are more choices

further, and keep pressing to view the available options.

White Rectangles: Indicate that by pressing them, you can

enter into another screen.

The following examples explain the above-mentioned points:

Pressing this softkey will toggle between

Frequency and Period representation.

Pressing this softkey will open the output

configuration screen.

More Key

Pressing the MORE key switches to the next layer of softkeys on the current

screen.

20

Page 21

Front-Panel Menu Operation

Pressing the Cancel key cancels the selection/input and helps you exit out

of a screen. But the functionality of exiting out of a screen is limited to a

few screens, like selecting an Arbitrary waveform.

The 81150A / 81160A consists of two channels and operates in two

different modes of operation:

Coupling off: The two channels operate entirely independent. Frequency

generation for both channels is based on same clock reference.

Coupling on: The frequency, trigger mode, waveform type and advanced

mode are identical for both channels. The delay between the channels is

specified.

A modulation input (for AM, FM, PM, FSK, PWM) for each channel is

provided on the back-panel. In the two channel version each channel can

modulate the other channel.

Refer to the Appendix for a list of all coupled parameters.

Press the Graph key to view a graphical representation of the waveform.

Press it again to exit from that mode.

Not every screen has a graphical representation, e.g. like the Trigger Mode

Screen.

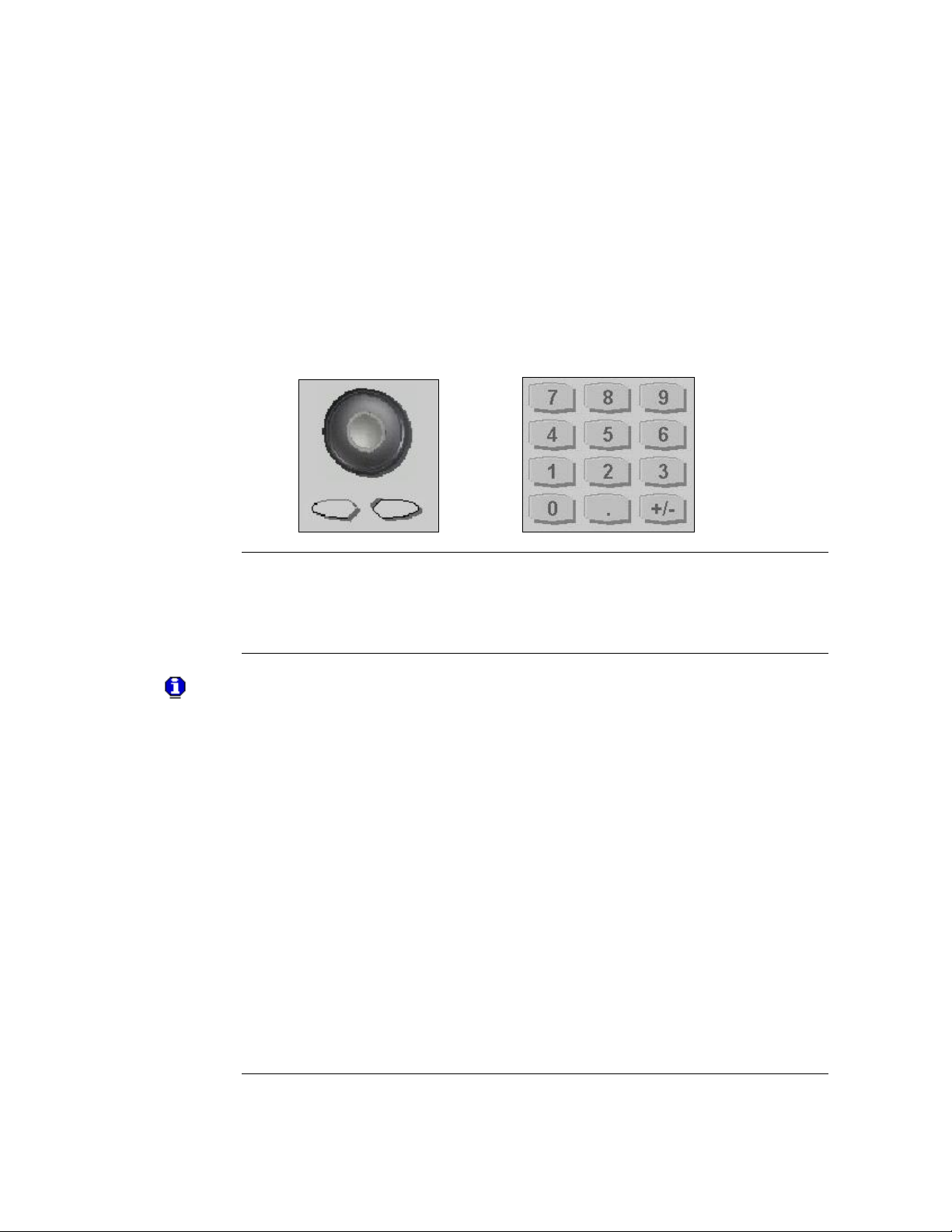

Numeric Keypad,

Cursor Keys,

Rotary Knob

These keys are used to select and modify parameters when operating the

instrument.

Use the numeric keypad to enter numbers and the menu softkeys to select

units.

Use the Rotary knob and cursor keys to modify the displayed number.

81150A and 81160A User’s Guide 21

Page 22

Appendix

Inputs/Outputs

The major inputs and outputs of the instrument are available at the front

panel:

The external input (EXTERNAL IN) can be used to connect an

external arming source (triggered or gated modes).

The trigger signal (TRIGGER OUT) marks the start of the pulse period

or of parts of a pattern (see Mode/Trigger Screen.). You can set the

output levels according to the used technology (TTL and ECL) or

enter test-specific values. Trigger Out is available as a physical BNC

connector at the 81150A. For the 81160A, a ‘Logical Trigger Signal’ is

generated for channel 1 and channel 2 internally and is routed to the

physical BNC connector Sync Out A and/or Sync Out B using a

configurable switch matrix.

The strobe signal (STROBE OUT) marks beginning and end of a burst

in Burst mode. Strobe Out is available as a physical BNC connector

at the 81150A. For the 81160A, a ‘Logical Strobe Signal’ is generated

for channel one and channel 2 internally and is routed to the physical

BNC connector Sync Out A and/or Sync Out B using a configurable

switch matrix.

81160A only: The sync signal (SYNC OUT) outputs the ‘Logical

Trigger Signal’ and/or the ‘Logical Strobe Signal’ at the front panel

BNC connector. The instrument offers full flexibility how ‘Logical

Trigger Signal’ and/or ‘Logical Strobe Signal’ is routed to Sync Out A

and/or Sync Out B.

The OUTPUT connectors provide the signal output (normal and

inverted) and the indicators show the current state of the output (on

or off).

Special Function

Keys

The instrument provides the following special function keys:

Man

Store/Recall

Help

The function of each of these keys is explained below.

In triggered or gated mode, the MAN key can be used to manually arm

and/or trigger the instrument.

22

Page 23

Front-Panel Menu Operation

Trigger Modes

The trigger modes are explained below in subsequent sections:

Continuous

External Triggered

External Gated

Internal Triggered

Manual

See Selecting Trigger Mode section for more details.

Waveform Types

The standard waveforms include: Pulse, Sine, Noise, Square, Ramp and

Arbitrary.

The predefined arbitrary waveforms include: Exponential rise, exponential

fall, sin(x)/x, cardiac, gaussian, haversine, negative ramp, and DC.

Advanced modes of

Operation

There are three advanced modes of operation available:

Modulation: Selects the modulation type from AM, FM, PM, FSK,

PWM.

Sweep: For frequency sweeps.

Burst: Repeats selected waveform n times.

The following sections provide more details on the modulation types.

The Store/Recall key can be used to store to/recall from 1 to 4 individual

settings in the instrument memory. In the internal memory location 0 there

is a default setting stored.

The Utility key enables you to enable/disable DC mode, change the Output

Setup, and also contains information about the I/O Interfaces and the

system settings of the 81150A / 81160A.

The Help key provides access to the instrument’s integrated help or in

warning or error state, access to Warning/Error Report screen.

81150A and 81160A User’s Guide 23

Page 24

Appendix

Introduction

Whenever you are in doubt or the instrument signals warnings or errors,

press the Help key.

Pressing the Help key opens the ‘Main Help Page’.

This main help page is the table of contents of the integrated help system

which lists all the help topics. You can obtain information by selecting the

corresponding link and then by pressing the Follow Link softkey.

Warnings and

Errors

If there are warnings or errors pending (indicated by a flushing W or E on

the screen), pressing the Help key displays a list of the current messages.

Using the Error Queue and Warning softkeys, you can toggle between both

lists. For more information on warnings and errors, see Warnings and Errors.

Exit Help

To exit Help, press the Help key again, or press any other parameter screen

key, e.g. Pulse, Sine, etc.

2.2 Help is Available

24

Page 25

Front-Panel Menu Operation

Introduction

This section explains the Menu and the Graph mode as seen on the Front

Panel of the 81150A / 81160A.

Introduction

This section explains the Menu as seen on the Front Panel of the 81150A /

81160A.

Channel Information

Units

Channel 1 Information

(Channel addition)

Channel 2 Information

(Frequency Coupling)

Softkey Labels

Trigger Information for

Channel 1 and 2

Numeric Readout

2.3 The Front-Panel Display at a Glance

2.3.1 Menu Mode

81150A and 81160A User’s Guide 25

Page 26

Appendix

Introduction

To enter the Graph mode, press the key.

To exit, press the key again.

Not all screens have a graphical representation.

The trigger mode screen will always be in textual mode, even if graph

mode is enabled.

2.3.2 Graph Mode

26

Page 27

Front-Panel Menu Operation

Entering/modifying

numbers

You can enter numbers or modify the displayed number from the front-panel

using one of the following two methods:

Rotary Knob + Arrow Keys

Numeric keypad + softkeys

For selecting units

Use the numeric keypad and menu softkeys to select the units.

The left/right arrows below the Rotary Knob are used to move left

and right to select the digit to be modified on a given screen.

When setting the cursor to the ‘exponent field’ the exponent can be

changed via the Rotary Knob (only if the resulting number does fall

within the allowed range)

The cursor position is remembered when the cursor is placed on the

leftmost digit and the value is decreased from 1 to 0. In this case the

cursor changes it’s color to green for some seconds and the cursor

position will be set back to the previous one when incrementing the

value again. For example, select the frequency to be edited and set

the cursor to the leftmost digit and then decrement the value by

turning the Rotary Knob counter clockwise. The cursor will move one

digit to the right when the digit would go from 1 to 0 and changes it’s

color to green. When incrementing while the cursor is green, it will

jump back to the initial digit when crossing the 0 to 1 border.

The left arrow key can be used to delete the digit left to the input

cursor when entering values with the numeric keypad.

2.4 The Front-Panel Number Entry

81150A and 81160A User’s Guide 27

Page 28

Appendix

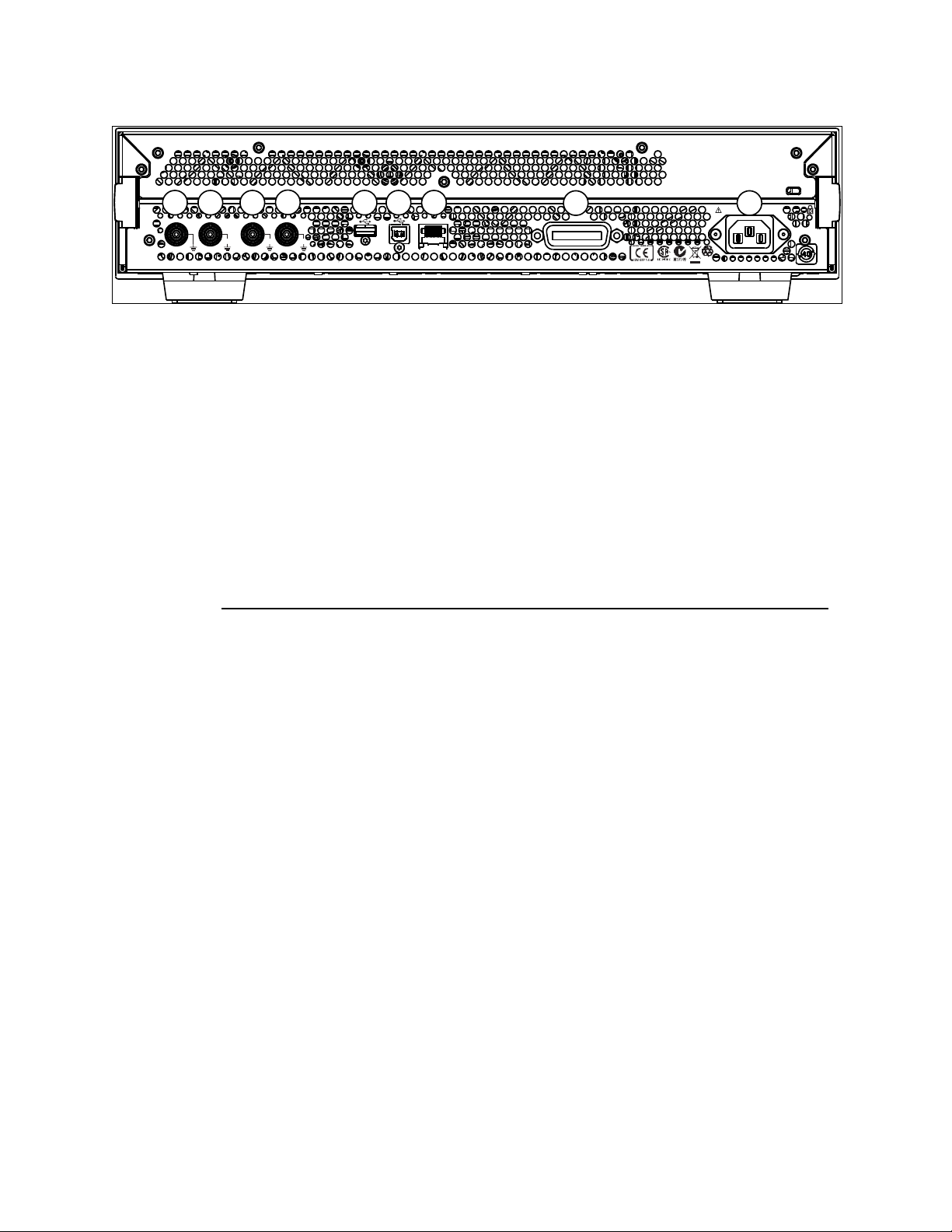

Introduction

The rear panel contains:

GP-IB connector

USB device connector

LAN connector

These three are used for remote control of the instrument.

Channel 1 Modulation In

Channel 2 Modulation In

10 MHz Clock Ref-In

10 MHz Clock Ref-Out

A USB Host Connector is used to connect external USB storage device for

storing instrument settings or software updates.

4 5 6 7 8 921 3

2.5 The Rear Panel

Rear panel of the 81150A

1 USB Interface Connector (Host type for external mass memory)

2 USB Interface Connector (device type for remote programming)

3 LAN Interface Connector

4 Channel 1 External Modulation Input Terminal

5 Channel 2 External Modulation Input Terminal

6 External 10 MHz Reference Input Terminal

7 10 MHz Reference output Terminal

8 GPIB Interface Connector

9 Power

28

Page 29

Front-Panel Menu Operation

G PI B

L AN

M o d u l a t i o n I n 1M o d u l a t i o n I n 21 0 M H z Re f I n1 0 M H z Re f O u t

1V

pp

2 0 0 - 2 4 0VAC 5 0 - 6 0 H z 1 8 0 W m a x .

1 0 0 - 1 2 7VAC 5 0 - 4 0 0 H z 1 8 0 W m a x .

10Vpk10V

pk

42V

pk

m a x . 5 V

r m s

± 1 0 V

m a x .

m a x . 5 V

r m s

5 6 71 2 3

4

8 9

Rear panel of the 81160A

1 10 MHz Reference Output Terminal

2 External 10 MHz Reference Input Terminal

3 Channel 1 External Modulation Input Terminal

4 Channel 2 External Modulation Input Terminal

5 USB Interface Connector (Host type for external mass memory)

6 USB Interface Connector (device type for remote programming)

7 LAN Interface Connector

8 GPIB Interface Connector

9 Power

81150A and 81160A User’s Guide 29

Page 30

Appendix

Check the List of

supplied items

Before preparing the 81150A / 81160A for use, check the list of supplied

items, given below:

One Power Cord

USB Cable

Product CD

This User’s Guide (if ordered in printed version)

Getting Started Guide (if ordered in printed version)

Certificate of Calibration

Keysight Automation Ready CD

Connect the Power

Cord and turn on

the 81150A /

81160A

The instrument runs a short power-on self test, which takes about 45-50

seconds. The 81150A / 81160A powers up in the sine wave function at 1

MHz with an amplitude of 1 Vpp (into a 50 termination) or the power-down

setting. At power-on, the Output connector is disabled. To enable the Output

connector, press the output key.

If the 81150A /

81160A does not

turn on….

Steps:

Verify that the power cord is firmly connected to the power

receptacle on the rear panel (the power-line voltage is automatically

sensed at power-on).

You should also make sure that the 81150A / 81160A is connected to

a power source that is energized.

Then, verify that the 81150A / 81160A is turned on.

If the power-on tests fail, the instrument automatically switches to the

diagnostics screen and displays the power on messages.

2.6 Preparing the 81150A / 81160A for Use

30

Page 31

Front-Panel Menu Operation

Introduction

The built-in help system is designed to provide context-sensitive assistance

on any front-panel key or menu softkey. A list of help topics is also available

to assist you with several front-panel operations.

To view the help

information for a

function key

Steps:

Press and hold down the key. If the message contains more

information than will fit on the display, press the up/down keys or

turn the knob to view the remaining information.

Press the Help key to exit Help.

To view the list of

topics

Steps:

Press the Help key to view the list of available help topics.

To scroll through the list, press the up/down arrow keys or rotate the

knob. Select any topic using the Previous Link and Next Link keys,

and press Follow link to obtain details on the selected topic.

Press the Help key to exit Help.

To view the help

information for

displayed

messages

Whenever a limit is exceeded or any other invalid configuration is found, the

81150A / 81160A will display a message. For example, if you enter a value

that exceeds the frequency limit for the selected function, a message will be

displayed. The built-in help system shows all active messages.

Steps:

Press the Help key. Upon doing this, you will see an error or warning

is active (red or yellow text scrolling on the display and a red E or

orange W indicator blinking in the input line). The instrument will

automatically switch to the error or warning screen.

Press the Help key to exit Help.

2.7 Using the Built-in Help System

81150A and 81160A User’s Guide 31

Page 32

Appendix

Introduction

The Mode of operation consists of the following four components:

Coupling between Ch1 & Ch2

Trigger Mode

Waveform Type

Advanced Modes

These are further explained below:

Coupling between

Ch1 & Ch2

There are two output channels available for the Keysight 81150A / 81160A.

The 2 channel version operates in two different modes of operation:

Coupling off: The two channels operate entirely independent. Frequency

generation for both channels is based on the same clock reference.

Coupling on: The frequency, trigger mode, waveform type and advanced

mode are identical for both channels. The delay between the channels is

specified.

Refer to the Appendix for a list of all coupled parameters.

The Trigger Mode, Waveform Type and the Advanced Modes are explained

in the following sections.

2.8 Selecting the Mode of Operation

32

Page 33

Front-Panel Menu Operation

Introduction

The source of a trigger event can be Internal, External, or Manual. The

default is External.

The following trigger modes are explained below:

Continuous

External Triggered

External Gated

Internal Triggered

Manual

The following table explains the functionality of the 81150A / 81160A.

2.9 Selecting Trigger Mode and Source

81150A and 81160A User’s Guide 33

Page 34

Appendix

Trigger Mode

Continuous

Function

Pulse

Square

Sine

Ramp

Noise

Arb

DC

Arming Source

Not Applicable

Advanced Mode

None

Burst

Sweep

Modulation

Trigger Mode

Triggered

Function

Pulse

Square

Sine

Ramp

Noise

Arb

Arming Source

MAN Key

External-In

Internal

Advanced Mode

None

Burst

Sweep

Trigger Mode

Gated

Function

Pulse

Square

Sine

Ramp

Noise

Arb

Arming Source

MAN Key

External-In

Advanced Mode

None

Burst

Sweep

Continuous

Continuous starts the next waveform cycle immediately after the previous

one has finished.

This is used for a continuous waveform, burst, sweep or modulation. The

external input is not used in continuous mode.

34

Page 35

Front-Panel Menu Operation

External Triggered

Triggered generates exactly one ‘signal’ when the trigger condition is met

In the external trigger mode, the 81150A / 81160A will accept a hardware

trigger applied to the front-panel External In connector. The 81150A /

81160A initiates one sweep or outputs one burst each time External In

receives a pulse with the specified edge.

To select the external source, follow these steps:

Press the key on the front panel.

Press Source softkey to select External In as the source. Upon

pressing the Source softkey while the highlight is on the trigger

source, the instrument allows you to choose one of the available

trigger sources. The value can also be changed by turning the Rotary

Knob.

To specify whether the 81150A / 81160A triggers on the rising or falling

edge, follow these steps:

Press the key on the front panel.

Select the desired edge by pressing the Ext-In Sense softkey.

Change the value either by pressing the softkey or by turning the

knob.

External Gated

Gated starts the generation of ‘signals’ as long as the gate is active.

The active level (high or low) at External In enables waveforms, bursts or

sweeps. The last waveform, burst or sweep is always completed.

Internal Triggered

In internal triggered mode, the instrument triggers a single waveform cycle,

sweep or burst at an adjustable trigger rate.

E.g. generate a pulse every 250ms

This mode is enabled by pressing the key on the front panel and

then setting source to Internal. As soon as Source is set to Internal, the

trigger frequency/period can be adjusted by navigating to Int Freq or Int.

Period (depends on which of the two is currently active). Switching between

Int Freq and Int Period is done by navigating to the internal trigger

frequency/period and then pressing the corresponding softkey.

81150A and 81160A User’s Guide 35

Page 36

Appendix

Manual

In the manual trigger mode, you can manually trigger the 81150A / 81160A

by pressing the front panel key. The 81150A / 81160A initiates one

waveform cycle, sweep or outputs one burst for each time you press or

release the key. The key is illuminated while the 81150A / 81160A is

waiting for a manual trigger.

Front Panel

Operation

To set the Trigger Mode, do the following:

Press the corresponding key on the Front-Panel.

For selecting the arming source, press the Front panel key for the

desired trigger mode, press the Source softkey or navigate to Source

using the navigation keys.

Then change the selection.

36

Page 37

Front-Panel Menu Operation

Introduction

The 81150A / 81160A can output six standard waveforms including:

Pulse

Sine

Square

Ramp

Noise

Arbitrary

You can also select one of the seven built-in arbitrary waveforms or create

your own custom waveforms.

You can internally modulate any of the standard waveforms (except pulse

and noise and DC) and also arbitrary waveforms using AM, FM, PM or FSK.

Pulse Waveform

Characteristics

A pulse is defined by the following parameters:

Amplitude/Offset or High-Level/Low-Level

Period or Frequency (not applicable for triggered pulses)

Width in seconds or Duty Cycle or Trailing delay in seconds

Delay in seconds

Delay as percentage of the period (not applicable for triggered

pulses)

Delay as phase in degree (not applicable for triggered pulses)

Leading edge transition time in seconds

Leading edge transition time in percent of width

Trailing edge transition time in seconds

Trailing edge transition time in percent of width

Polarity

Source Impedance

Load Impedance

2.10 Selecting the Waveform

81150A and 81160A User’s Guide 37

Page 38

Appendix

Pattern

Characteristics

Patterns are defined by the following parameters:

Internal or external pattern source

PRBS patterns and user defined patterns

NRZ formatting and Arbitrary Bit Waveform

Pattern Mode - On/Off

Patterns are also characterized by 2, 3 or 4 different levels per bit

Adjustable loop offset, allowing emulation of initialization preamble

and looped test pattern

External pattern source allows re-timing and re-shaping of externally

provided data stream

Sine Wave

Characteristics

A sine wave is defined by the following parameters:

Amplitude/Offset or High/Low Level

Period or Frequency

Delay in seconds

Delay in percent of period

Delay as phase in degree

Polarity

Source Impedance

Load Impedance

Square Wave

Characteristics

A square wave is defined by the following parameters:

Amplitude/Offset or High-Level/Low-Level

Period or Frequency

Duty Cycle

Delay in seconds

Delay as percentage of the period

Delay as phase in degree

Polarity

Source Impedance

Load Impedance

The instrument will always generate the fastest possible transition times

when generating square waves.

38

Page 39

Front-Panel Menu Operation

Ramp Wave

Characteristics

A ramp is defined by the following parameters:

Amplitude/Offset or High/Low Level

Period or Frequency

Delay in seconds

Delay in percent of period

Delay as phase in degree

Symmetry point in percent of period.

Polarity

Source Impedance

Load Impedance

Noise Wave

Characteristics

Noise is defined by the following parameters:

Amplitude/Offset or High/Low Level

Probability Density Function (PDF)

Source Impedance

Load Impedance

Arbitrary Wave

Characteristics

Arbitrary waveforms are defined by the following parameters:

Amplitude/Offset or High/Low Level

Period or Frequency

Delay in seconds

Delay in percent of period

Delay as phase in degree

Source Impedance

Load Impedance

81150A: Arbitrary waveforms can have up to 512k samples. The local

waveform editor allows to create and edit waveforms with up to 16k

samples.

81160A: Arbitrary waveforms can have up to 256k samples (1 channel) /

128k samples (2 channels). The local waveform editor allows to create and

edit waveforms with up to 16k samples.

81150A and 81160A User’s Guide 39

Page 40

Appendix

Introduction

There are three advanced modes of operation available:

Modulation

Burst

Sweep

These advanced modes are further explained below.

Introduction

The following types of modulation are available:

AM

FM

PM

FSK

PWM

To select

Modulation

Refer to Chapter 3, Features and Functions to understand how to select any

of these modulations.

The 81150A / 81160A will allow only one modulation mode to be

enabled at a time. For example, you cannot enable AM and FM at the

same time. When you enable AM, the previous modulation mode is

turned off.

The 81150A / 81160A will not allow any advanced mode to be

enabled with another advanced mode on the same channel.

2.11 Selecting the Advanced Mode

2.11.1 Modulation

40

Page 41

Front-Panel Menu Operation

Introduction

You can configure the 81150A / 81160A to output a waveform with a

specified number of pulses/waveform cycles, called a burst. You can output

the burst at a rate determined by the internal rate generator or the signal

level on the Front Panel External In connector.

A burst can be initiated either by:

An Internal Immediate event, which triggers a continuous burst.

A trigger source, which triggers a triggered burst.

An active gate, which enables a gated burst.

Select the function

and amplitude for

the burst

For burst waveforms, you can select sine, square, ramp, pulse, or arbitrary

waveforms.

Burst mode cannot be used when using DC or noise.

Select the burst

mode

Press and specify the #Cycles and the Start Phase softkeys

to set the desired values.

The Start Phase defines the phase at which signal generation starts.

The allowed range is -360 to +360. It is only applicable to Sine and

Arb waveforms.

Refer to Outputting a Burst Waveform for details.

2.11.2 Burst

81150A and 81160A User’s Guide 41

Page 42

Appendix

Introduction

In the frequency sweep mode, the 81150A / 81160A “steps” from the start

frequency to the stop frequency at a sweep rate which you specify.

The 81150A / 81160A can produce a frequency sweep for sine, square,

ramp, or arbitrary waveforms (pulse, noise, and dc are not allowed).

To select a Sweep

Press to output a sweep using the present settings for frequency,

output amplitude, and offset. Enable sweep before setting up any of the

other sweep parameters.

The 81150A / 81160A will not allow the sweep mode to be enabled at the

same time when burst or any modulation mode is enabled. When you enable

sweep, the burst or modulation mode is turned off.

2.11.3 Sweep

42

Page 43

Front-Panel Menu Operation

Introduction

At power-on, normally, the instrument outputs the same setting as before

power-down. The default frequency is 1 MHz and the default amplitude is 1

Vpp.

When you change functions, the same frequency is used if the present value

is valid for the new function.

The following steps show you how to change the frequency.

Press the

“Frequency”

softkey

To set the waveform frequency, press the Frequency softkey. Pressing the

frequency softkey when Frequency is already selected, will toggle to Period.

The current selection is highlighted as shown in the image below.

Enter the

magnitude of the

desired frequency

Using the numeric keypad, enter the desired value, say 1.2

2.12 Setting the Output Frequency

81150A and 81160A User’s Guide 43

Page 44

Appendix

Select the desired

units

Select and press the softkey that corresponds to the desired units. Press the

More softkey to view more units available for the current selection. When

you select the units, the 81150A / 81160A outputs a waveform with the

displayed frequency (if the output is enabled).

You can also enter the desired value using the knob and cursor keys.

You can also change the exponent by setting the input cursor to the

exponent field and turning the Rotary Knob. To do this, use the

left/right key to place the cursor on the exponent you wish to

change.

44

Page 45

Front-Panel Menu Operation

Introduction

At power-on, normally, the instrument outputs the same setting as before

power-down.

When you change functions, the same amplitude is used if the present value

is valid for the new function.

The following steps show you how to change the amplitude:

Press the “Ampl”

softkey

To set the amplitude using a high level and low level, press the Ampl

softkey.

This will offer the level representations and units that can be chosen

for the output levels.

Choose the appropriate option from the given choices.

Press More to go to the units screen. Choose from the given units, by

pressing that unit itself.

2.13 Setting the Output Amplitude

81150A and 81160A User’s Guide 45

Page 46

Appendix

Enter the

magnitude of the

desired amplitude

Using the numeric keypad, enter the desired value.

Select the desired

units

Select and press the softkey that corresponds to the desired units. When

you select the units, the 81150A / 81160A outputs a waveform with the

displayed amplitude (if the output is enabled). For this example, press mVrms.

46

Page 47

Front-Panel Menu Operation

Introduction

You can easily convert the displayed amplitude from one unit to another.

For example, the following steps show you how to convert the amplitude

from Vrms to Vpp.

Enter the numeric

entry mode

To switch between different representations, press the amplitude, offset,

high level, low level softkey and then choose the different representation.

You can choose between High/Low, Ampl/Offs.

Select the new

units

Steps:

Press Ampl softkey and then press the MORE softkey.