Page 1

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176 - TestEquipmentDepot.com

ilent 53131A/132A

Ag

225 MHz Universal Counter

Operating Guide

Manual Part Number 53131-90055

Printed in Malaysia

Page 2

Agilent 53131A/132A

225 MHz Universal Counter

Operating Guide

This guide describes how to use the Agilent 53131A/132A 225 MHz Universal

Counter.

Agilent 53131A/132A 225 MHz

Universal Counter

Page 3

Copyri ght Agilent Techno logies

W

C

W

Inc., 1993, 1996, 1998, 1999

All Rights Reserved. Reproduction,

adaptation, or translations without

prior written permission is

prohibited, except as allowed under

the copyright laws.

Printed: October 1999

Printed in Malaysia

Manual part numb er

53131-90055

Certification

and Warranty

Certification

Agilent Technologies certifies that

this product met its published

specification at the time of shipment

from the factory. Agilent

Technologies further certifies that its

calibration measurements are

traceable to the United States

National Institute of Standards and

Technology (formerly National

Bureau of Standards), to the extent

allowed by the Institute’s calibration

facility, and to the calibration

facilities of other International

Standards Organization members.

War ra nty

Agilent warrants Agilent hardware,

accessories and supplies against

defects in materials and

workmanship for a period of one

year from date of shipment. If

Agilent receives notice of such

defects during the warranty period,

Agilent will, at its option, either

repair or replace products which

prove to be defective. Replacement

products may be either new or likenew.

Agilent warrants that Agilent

software will not fail to execute its

programming instructions, for the

period specified above, due to

defects in material and workmanship

when properly installed and used. If

Agilent receives notice of such

defects during the warranty period,

Agilent will replace software media

which does not execute its

programming instructions due to

such defects.

For detailed warranty information,

see back matter.

Safety Considerations

General

This product and related

documentation must be reviewed for

familiarization with this safety

markings and instructions before

operation.

Before Cleaning

Disconnect the product from

operating power before cleaning.

Warning Symbols That M ay Be

Used In This Book

Instruction manual symbol; the

product will be marked with this

symbol when it is necessary for the

user to refer to the instruction

manual.

Indicates hazardous voltages.

Indicates earth (ground) terminal.

or

Indicates terminal is connected to

chassis when such connection is not

apparent.

Indicates Alternating current.

Indicates Direct current.

Safety Considerations (contd)

ARNING

BODILY INJURY OR DEATH

MAY RESULT FROM

FAILURE TO HEED A

WARNING. DO NOT

PROCEED BEYOND A

WARNING UNTIL THE

INDICATED CONDITIONS

ARE FULLY UNDERSTOOD

AND MET.

AUTION

Damage to equipment, or incorrect

measurement data, may result

from failure to heed a caution. Do

not proceed beyond a CAUTION

until the indicated conditions are

fully understood and met.

Safety Earth G round

An uninterruptible safety earth

ground must be maintained from the

mains power source to the product’s

ground circuitry.

ARNING

WHEN MEASURING POWER

LINE SIGNALS, BE

EXTREMELY CAREFUL AND

ALWAYS USE A

STEP-DOWN ISOLATION

TRANSFORMER WHICH

OUTPUT IS COMPATIBLE

WITH THE INPUT

MEASUREMENT

CAPABILITIES OF THIS

PRODUCT. THIS PRODUCT’S

FRONT AND REAR PANELS

ARE TYPCIALLY AT EARTH

GROUND. THUS, NEVER TRY

TO MEASURE AC POWER

LINE SIGNALS WITHOUT AN

ISOLATION TRANSFORMER.

Agilent Technologies, Inc 7.NC.NL.A.11.0 3.97.R 1.P.CW6FC

815 S.W. 14th Street

Loveland, Colorado U.S.A.

Page 4

Warranty (contd)

Agilent does not warrant that the

operation of Agilent products will be

uninterrupted or error free. If Agilent

is unable, within a reasonable time,

to repair or replace any product to a

condition as warranted, customer

will be entitled to a refund of the

purchase price upon prompt retur n of

the product.

Agilent products may contain

remanufactured parts equivalent to

new in performance or may have

been subjected to incidental use.

The warranty period begins on the

date of delivery or on the date of

installation if installed by Agilent. If

customer sched ules or delay s Agilent

installation more than 30 days after

delivery, warranty begins on the 31st

day from delivery.

Warranty does not apply to defects

resulting from (a) improper or

inadequate maintenance or

calibration, (b) software, interfacing,

parts or supplies not supplied by

Agilent, (c) unauthorized

modification or misuse, (d) operation

outside of the published

environmental specifications for the

product, or (e) improper site

preparation or maintenance.

TO THE EXTENT ALLOWED BY

LOCAL LAW, THE ABOVE

WARRANTIES ARE EXCLUSIVE

AND NO OTHER WARRANTY OR

CONDITION, WHETHER

WRITTEN OR ORAL, IS

EXPRESSED OR IMPLIED AND

AGILENT SPECIFICALLY

DISCLAIMS ANY IMPLIED

WARRANTIES OR CONDITIONS

OF MERCHANTABILITY,

SATISFACTORY QUALITY, AND

FITNESS FOR A PARTICULAR

PURPOSE.

Agilent will be liable for damage to

tangible property per incident up to

the greater of $300,000 or the actual

amount paid for the product that is

the subject of the claim, and for

damages for bodily injury or death,

to the extent that all such damages

are determined by a court of

competent jurisdiction to have been

directly caused by a defective

Agilent product.

TO THE EXTENT ALLOWED BY

LOCAL LAW, THE REMEDIES IN

THIS WARRANTY STATEMENT

ARE CUSTOMER’S SOLE AND

EXCLUSIVE REMEDIES.

EXCEPT AS INDICATED ABOVE,

IN NO EVENT WILL AGILENT

OR ITS SUPPLIERS BE LIABLE

FOR LOSS OF DATA OR FOR

DIRECT, SPECIAL, INCIDENTAL,

CONSEQUENTIAL (INCLUDING

LOST PROFIT OR DATA), OR

OTHER DAMAGE, WHETHER

BASED IN CONTRACT, TORT, OR

OTHERWISE.

For consumer transactions in

Australia and New Zealand: the

warranty terms contained in this

statement, except to the extent

lawfully permitted, do not exclude,

restrict or modify and are in addition

to the mandatory statutory rights

applicable to the sale of this product

to you.

Assistance

Product maintenance agreements and

other customer assistance agreements

are available for Agilent

Technologies products.

For any assistance, contact your

nearest Agilent Technologies Sales

and Service Office.

Safety Considerations (contd)

WARNI NG

INSTRUCTIONS FOR

ADJUSTMENTS WHILE

COVERS ARE REMOVED

AND FOR SERVICING ARE

FOR USE BY SERVICETRAINED PERSONNEL

ONLY. TO AVOID

DANGEROUS ELECTRIC

SHOCK, DO NOT PERFORM

SUCH ADJUSTMENTS OR

SERVICING UNLESS

QUALIFIED TO DO SO.

WARNI NG

ANY INTERRUPTION OF THE

PROTECTIVE GROUNDING

CONDUCTOR (INSIDE OR

OUTSIDE THE PRODUCT'S

CIRCUITRY) OR

DISCONNECTING THE

PROTECTIVE EARTH

TERMINAL WILL CAUSE

A POTENTIAL SHOCK

HAZARD THAT COULD

RESULT IN PERSONAL

INJURY. (GROUNDING ONE

CONDUCTOR OF A TWO

CONDUCTOR OUTLET IS

NOT SUFFICIENT

PROTECTION.)

Whenever it is likely that the

protection has been impaired, the

instrument must be made inoperative

and be secured against any

unintended operation.

If this instrument is to be energized

via an autotransformer (for voltage

reduction) m ake sure the commo n

terminal is connected to the earthed

pole terminal (neutral) of the power

source.

Instructions for adjustments while

covers are removed and for servicing

are for use by trained-personnel only.

To avoid dangerous electric shock,

do not perform such adjustments or

servicing unless qualified to do so.

For continued protection against fire,

replace the line fuse(s) of the same

current rating and type (for example,

normal blow, time delay). Do not use

repaired fuses or short circuited

fuseholders.

Acoustic Noise Emissions

LpA<47 dB at operator position, at

normal operation, tested per

EN 27779. All data are the results

from type test.

Geräuschemission

LpA<47 dB am Arbeits

platz, normaler Betrieb, geprüft nach

EN 27779.

Die Angagen beruhen auf

Ergebnissen von Typenprüfungen.

7.NL.A.11.03.97.R1.P.CW6BC

Page 5

I

I

II

DECLARATION OF CONFORMITY

According to ISO/IEC Guide 22 and CEN/CENELEC EN 45014

Manufacturer’s Name:

Manufacturer’s Address:

Declares, that the product

Product Name:

Model Number:

Product Options: This declaration covers all options of the above product.

Conforms with the following European Directives:

The product herewith complies with the requirements of the Low Voltage Directive 73/23/EEC and the EMC Directive 89/336/EEC

(including 93/68/EEC) and carries the CE Marking accordingly.

EMC Standard

IEC 61326-1:1997+A1:1998 / EN 61326-1:1997+A1:1998

CISPR 11:1990 / EN 55011:1991

IEC 61000-4-2:1995+A1:1998 / EN 61000-4-2:1995

IEC 61000-4-3:1995 / EN 61000-4-3:1995

IEC 61000-4-4:1995 / EN 61000-4-4:1995

IEC 61000-4-5:1995 / EN 61000-4-5:1995

IEC 61000-4-6:1996 / EN 61000-4-6:1996

IEC 61000-4-11:1994 / EN 61000-4-11:1994

Canada: ICES-001:1998

Australia/New Zealand: AS/NZS 2064.1

Agilent Technologies, Incorporated

Santa Clara Site

5301 Stevens Creek Blvd

Santa Clara, California 95051

Universal Counter Frequency Counter

53131A, 53132A 53181A

Limit

Group 1 Class A

4kV CD, 8kV AD

3 V/m, 80-1000 MHz

0.5kV signal lines, 1kV power lines

0.5 kV line-line, 1 kV line-ground

3V, 0.15-80 MHz I cycle, 100%

[1]

Safety

Supplemental Information:

[1]

The product was tested in a typical configuration with Agilent Technologies test systems.

Authorized EU-representative: Agilent Technologies Deutschland GmbH, Herrenberger Stra

IEC 61010-1:1990+A1:1992+A2:1995 / EN 61010-1:1993+A2:1995

Canada: CSA C22.2 No. 1010.1:1992

July 31, 2001

Date Art Nanawa, Product Regulations Manager

For further information, please contact your local Agilent Technologies sales office, agent or distributor.

β

e 130, D 71034 Böblingen, Germany

Page 6

Contents

In This Guide

Contents and Organization xii

Related Documents xiii

Types of Service Available if Your Instrument Fails xiv

Standard Repair Services (Worldwide) xiv

Express Repair/Performance Calibration Service

(USA Only) xiv

Assembly-Level Service Guide xiv

Repackaging for Shipment xv

Description of the 225 MHz Universal Counter xvi

Options xviii

Hardware xviii

Support xviii

Accessories Supplied and Available xix

Accessories Supplied xix

Accessories Available xix

Supplied Manuals xix

Differences Between Prior and Current Revisions of the Agilent

53131A/132A xx

Agilent 53131A Containing Firmware Revisions (3317, 3335, or

3402) xx

Agilent 53132A Time Interval Delay Arming xxii

Calibrations xxi

Measurements xxi

Statistics xxii

GPIB Commands xxii

Operating Guide iii

Page 7

Contents

Agilent 53131A/132A Quick Reference Guide xxiii

1 Getting Started

The Front Panel at a Glance 1-2

The Front Panel Indicators at a Glance 1-3

The Front Panel Indicators at a Glance (Cont.) 1-4

The Front Panel Menus at a Glance 1-5

The Front Panel Menus at a Glance (Cont.) 1-6

The Front Panel Menus at a Glance (Cont.) 1-7

The Front Panel Menus at a Glance (Cont.) 1-8

The Display Annunciators at a Glance 1-9

The Display Special Character at a Glance 1-10

The Limit Test Graph Characters at a Glance 1-10

The Rear Panel at a Glance 1-11

Making Measurements 1-12

To Measure Frequency 1-13

To Select Input Coupling and Impedance 1-15

Selecting Input Coupling 1-15

Selecting Input Impedance 1-16

To Set Input Channel Trigger Level/Sensitivity 1-17

Changing Trigger Mode 1-17

Modifying Input Trigger Level 1-17

Selecting Input Trigger Slope 1-18

Selecting Input Sensitivity 1-19

Starting the Measurement 1-19

To Select Scale and Offset 1-19

Entering the Scale Value 1-20

Entering the Offset Value 1-21

Displaying the Math Results 1-22

Disabling Math 1-22

To Set Limits of Measurements 1-23

Setting the Upper Limit 1-24

Setting the Lower Limit 1-26

iv Operating Guide

Page 8

Contents

Setting the Counter to Flag and Stop Measuring On Out-of-Limit

Measurements 1-28

Setting the Counter to Flag On Limits But Continue

Measuring 1-29

Disabling Limit Testing 1-30

Disabling Math 1-30

To Perform Statistics on Measurements 1-31

Selecting the Type of Statistics (Stats) 1-31

Computing Stats on Filtered Data Only 1-32

Displaying Stats After Filtering Data of Input Signal 1-34

Disabling Stats and Math 1-35

To Control Measurement 1-36

2 Operating Your Universal Counter

Introduction 2-2

Chapter Summary 2-2

Where to Find Some Key Working Examples 2-3

How this Counter Works for You 2-4

Using the Measurement Control Keys (Run and Stop/Single) 2-5

Overview of the Measurement Control Keys 2-5

To Use the Measurement Control Keys 2-6

Using Entry/Select (Arrow) Keys 2-8

To Use During Numeric Entry 2-8

To Use When Sequencing Through the Measurement Function Menus

(Freq & Ratio, Time & Period, Other Meas) and the Recall

Menu 2-8

To Use During State Changing (ON/OFF, LO/MED/HI, etc.) 2-9

To Use on Prompted Event Messages (SET OFFSET ?, CAL: OFFS

n ?, TEST: ALL?, etc.) 2-9

To Use on Prompted Help Messages (MATH HELP ?, PRINT HELP

?) 2-9

Using the MEASURE Menu Keys 2-10

Overview of the MEASURE Menus 2-10

Operating Guide v

Page 9

Contents

To Measure Frequency 2-11

To Measure Frequency Ratio 2-12

To Measure Time Interval 2-13

To Measure Period 2-13

To Measure Rise/Fall Times 2-13

To Measure Positive/Negative Pulse Widths 2-14

To Measure Duty Cycle 2-14

To Make Totalize Measurements 2-14

To Make Phase Measurements 2-15

To Measure Positive/Negative Voltage Peaks 2-15

Using the Gate & External Arm Menu Key 2-16

Overview of Gate/External Arming Functions 2-16

Gate/External Arming Capabilities 2-16

AUTO Arming 2-16

EXTERNAL Arming 2-17

TIME Arming 2-17

DIGITS Arming 2-17

Agilent 53131A (and Agilent 53132A With S/N Prefix Below

3646) Time Interval DELAY Arming 2-17

Agilent 53132A (With S/N Prefix 3646 and Above) Time Interval

DELAY Arming 2-20

To Use the Gate and External Arm 2-24

Example Procedure for Gate and External Arm 2-24

Example Procedure for Changing the Number of

Digits of Resolution Displayed for More

Precise Measurements 2-25

Using the MATH Menu Keys 2-27

Overview of Scale/Offset Math Menu 2-27

To Use the Scale/Offset Math Menu 2-28

Example Procedure for Scale Function 2-28

Example Procedure for Offset Function 2-29

Example Procedure for Turning Off Math Mode 2-30

vi Operating Guide

Page 10

Contents

Example Procedure for Setting the Offset From

the Last Measurement Value 2-31

Overview of Statistics (Stats) Menu 2-32

To Use the Stats Menu for Automatic and Continuous Statistical

Analysis 2-33

Example Procedure for Computing Stats 2-33

Example Procedure for Easy Viewing of Stats 2-34

Example Procedure for Filtering Data (Using Limits) During

Stats 2-35

Example Procedure for Configuring SINGLE to Initiate

N Measurements 2-36

Example Procedure for Turning Off Stats Mode 2-36

Using the LIMITS Menu Keys 2-37

Overview of Limits Menus 2-37

To Set and Use Automatic Limit Testing 2-38

Limits Testing Example 1—Flag and Stop Measuring

On Limits 2-38

Limits Testing Example 2—Flag On Limits but

Continue Measuring 2-40

Limits Testing Example 3—Use Analog Graph Display While

Adjusting Input Signal 2-40

Limits Testing Example 4—Selecting Filtering Conditions of

Stats Computation 2-42

Limits Testing Example 5—Sending the Limit-Detect Output to

the RS-232 Serial Port 2-43

Using CHANNEL 1 and CHANNEL 2 Input

Conditioning Keys 2-44

Overview of Trigger/Sensitivity Menu 2-44

To Use the Trigger/Sensitivity Keys to Adjust Counter’s Triggering

Level 2-48

Example Procedure for Setting Trigger Voltage and Sensitivity

Levels 2-48

Example Procedure for Using Common 1 to Make Time Interval

(TI) Measurements on a Single Signal 2-51

Operating Guide vii

Page 11

Contents

Overview of Input Conditioning Toggle Keys 2-51

Using the Save and Recall Menus 2-52

Overview of Save and Recall Functions 2-52

To Use the Save Function 2-53

To Use the Recall Function 2-54

To Unsave a Measurement Setup 2-55

Using the Print Menu 2-56

Overview of the Print Menu 2-56

To Use the Print Menu 2-56

Using the Utility Menu 2-57

Overview of the Utility Menu 2-57

To Set the GPIB Address 2-58

Selecting Operating Mode (Talk/Listen, Talk-Only) 2-58

Setting the GPIB Address 2-58

To Choose the Timebase Source 2-59

To Run the Self-Test Routines 2-59

Overview of the Self-Test Routines 2-59

Example Procedure for Running the Self Test 2-61

To Configure the RS-232 Serial Port for Printing 2-61

Setting the Hardware Pacing 2-62

Setting the Baud Rate 2-62

Setting the Parity 2-63

Setting the Software Pace 2-63

To Configure the RS-232 Serial Port for Sending Limit-Detect

Output 2-64

To Select the Numerical Convention for the Display 2-65

To Connect the Counter to a Serial Printer via the RS-232 Port 2-65

To Connect the Counter to a Printer via GPIB 2-66

To Select the GPIB Talk-Only Mode for Printing 2-66

Using the Calibration Menu 2-67

Overview of the Calibration Menu 2-67

To View the Calibration Menu and Security Status 2-68

viii Operating Guide

Page 12

Contents

To Unsecure for Calibration 2-68

To Initiate the Calibration Routines 2-69

To Secure Against Calibration 2-71

To Change to a New Security Code 2-72

To View the Calibration Count 2-72

To Get Help With the Calibration Menu 2-72

Front Panel Display Messages 2-73

Measurement Result Displays 2-73

Power-Up/Self Test Messages 2-74

Menu Messages 2-75

GPIB Messages 2-77

Preset Values After Power-Up and *RST 2-78

Agilent 53131A (and Agilent 53132A With S/N Prefix Below 3646)

Preset Values for Functions Accessible Via Front Panel or

GPIB 2-79

Agilent 53132A (With S/N Prefix 3646 and Above) Preset Values for

Functions Accessible Via Front Panel or GPIB 2-85

Preset Values for Functions Accessible Via GPIB Only 2-91

Summary of the Measurement Sequence 2-93

Common Questions 2-94

Why is Stats result not available yet? 2-94

Why won’t printer work? 2-94

Why did Counter stop measuring? 2-94

Why did Counter go to its default state after I set up my RS-232

port? 2-94

Counter’s numeric display does not follow the numerical convention

for my country. 2-94

How do I display the 13th digit in my numerical result? 2-94

3 Specifications

Introduction 3-2

Instrument Inputs 3-2

Instrument Inputs (Continued) 3-3

Operating Guide ix

Page 13

Index

Contents

Time Base 3-4

Measurement Specifications 3-5

Measurement Specifications (Continued) 3-6

Measurement Definitions 3-12

Measurement Definitions (Continued) 3-13

Measurement Arming and Processing 3-14

Measurement Arming and Processing (Continued) 3-15

General Information 3-16

x Operating Guide

Page 14

In This Guide

This book is the operating guide for the Agilent 53131A and Agilent 53132A

225 MHz Universal Counters. It consists of a table of contents, this preface, a quick

reference guide, three chapters, and an index.

This preface contains the following information:

• Contents and Organization page xii

• Related Documents page xiii

• Types of Service Available if Your Instrument Fails page xiv

• Repackaging for Shipment page xv

• Description of the 225 MHz Universal Counter page xvi

• Options page xviii

• Accessories Supplied and Available page xix

– Supplied Manuals page xix

• Differences Between Prior and Current Revisions of the

Agilent 53131A/132A

Operating Guide xi

page xx

Page 15

In This Guide

Contents and Organization

Table of Contents

The Quick Reference Guide consists of a Menu Tree (cut-out sheet) that serves as a

device to trigger your memory or get you quickly reacquainted with the instrument,

and Menu Roadmaps that illustrate how to navigate through the menus. It is located

after this preface.

Chapter 1, “Getting Started,” is a quick start guide that gives you a brief overview of

the Counter’s keys, indicators, menus, display, and connectors. Last, a graphical

procedure for performing a complete measurement is provided.

Chapter 2, “Operating Your Universal Counter,” is an operator’s reference. You are

given an overview of each group of front-panel keys, operating functions, and menus

followed by a series of exercises that guide you through the operation of the Counter.

Chapter 3, “Specifications,” lists the specifications and characteristics of the Counter.

Index

xii Operating Guide

Page 16

In This Guide

Related Documents

For more information on universal counters refer to the following Series 200

Application Notes:

• Fundamentals of Electronic Frequency Counters

Application Note 200—Agilent part number 02-5952-7506.

• Fundamentals of Time Interval Measurements

Application Note 200-3—Agilent part number 02-5952-7561.

• Understanding Frequency Counter Specifications

Application Note 200-4—Agilent part number 02-5952-7522.

Operating Guide xiii

Page 17

In This Guide

Types of Service Available if Your Instrument Fails

If your Agilent 53131A/132A fails within one year of original purchase,

Agilent will repair it free of charge. If your instrument fails after your one-year

warranty expires, Agilent will repair it, or you can repair it yourself by ordering the

service guide (Agilent part number 53131-90039).

There are three types of repair services:

• Standard repair service—if downtime is not critical.

• Express Repair/Performance Calibration Service—if downtime is critical.

• Order the Assembly-Level Service Guide and repair unit yourself.

Standard Repair Services (Worldwide)

Contact your nearest Agilent Technologies Service Center. They will arrange to have

your Agilent 53131A/132A Universal Counter repaired.

Express Repair/Performance Calibration Service

(USA Only)

If downtime is critical, you can receive your repaired Agilent 53131A/132A via

overnight shipment. Just call 1-800-403-0801 and ask for Express

Repair/Performance Calibration Service. When your Counter is repaired, it will be

returned via overnight shipment.

Assembly-Level Service Guide

If your Agilent 53131A/132A 1-year warranty has expired and you choose to repair

the instrument yourself or would like more details on self test and calibration, refer to

the Agilent 53131A/132A Assembly-Level Service Guide, Agilent part number

53131-90039.

xiv Operating Guide

Page 18

In This Guide

Repackaging for Shipment

For the Express Repair/Performance Calibration Service described above, return your

failed Agilent 53131A/132A to the designated Agilent Technologies Service Center,

using the shipping carton of the instrument. Agilent will notify you when your failed

instrument has been received.

If the instrument is to be shipped to Agilent for service or repair, be sure you do the

following:

• Attach a tag to the instrument identifying the owner and indicating the required

service or repair. Include the instrument model number and full serial number.

• Place the instrument in its original container with appropriate packaging

material.

• Secure the container with strong tape or metal bands.

If the original shipping container is not available, place your unit in a container which

will ensure at least 4 inches of compressible packaging material around all sides of

the unit. Use static free packaging materials to avoid additional damage to your unit.

Agilent Technologies suggests that you always insure shipments.

Operating Guide xv

Page 19

In This Guide

Description of the 225 MHz Universal Counter

The Agilent 53131A and Agilent 53132A are universal counters capable of

measuring frequencies to 225 MHz on Channels 1 and 2. With an optional Channel 3

Option 030, Option 050, or Option 124, this capability is extended to 3.0, 5.0, or

12.4 GHz, respectively.

For the Agilent 53131A, frequency and time interval resolutions are 10 digits in one

second and 500 picoseconds, respectively. The Agilent 53131A provides users with a

GPIB measuring speed of up to 200 measurements per second, and is suitable for

bench-top operation and lower-volume ATE operation. The frequency and time

interval resolutions for the Agilent 53132A are up to 12 digits in one second and 150

picoseconds, respectively. The Agilent 53132A provides users with exceptional

resolution, and is ideal for ATE systems operation.

The Agilent 53131A/132A basic measurement functions include Frequency, Period,

Pulse Width, Duty Cycle, Rise/Fall Time, Time Interval, Frequency Ratio, Totalize,

Phase, and Peak Voltage. The Agilent 53131A/132A Counter has four arming modes:

auto, external, digits and time. However, the Agilent 53132A with serial number

prefix 3646 and above has expanded arming capabilities for Time Interval

measurements.

xvi Operating Guide

Page 20

In This Guide

The Agilent 53131A/132A include additional measurement functions and features

that are designed specifically for manufacturing and service applications:

• 1, 5, 10 MHz external reference capability—to match customer’s house standard

(however, the Agilent 53132A’s external reference capability is 10 MHz only),

• optional ultra high, high, or medium stability oven oscillators for high accuracy

needs and lengthened calibration cycles,

• external gating,

• statistics,

• automatic limit testing,

• SCPI programming capability, and

• analog display mode limit testing

Programmable control is performed via an GPIB. The GPIB and a talk-only RS-232C

serial port are standard for the Agilent 53131A and Agilent 53132A. The serial port is

for printing measured and analyzed data on serial printers, or for outputting an out-oflimit signal.

Operating Guide xvii

Page 21

In This Guide

Options

The options available for the Agilent 53131A/132A 225 MHz Universal Counter are

listed following this paragraph. Specifications for the options are listed in Chapter 3,

“Specifications.” If you’ve purchased an option with the initial order, it will be

installed at the factory and ready for operation at delivery. Refer to the “Retrofitting

Options” chapter in the Assembly-Level Service Guide for instructions on field

installation of the options.

NOTE The “0’s” and “1’s” in the following option numbers are numeric characters (that is,

they are not letters).

Hardware

• Medium Stability Oven Timebase, Option 001

• DC Power Input, Option 002

• High Stability Oven Timebase, Option 010

• Ultra-High Stability Oven Timebase, Option 012 (Agilent 53132A only)

• 3.0 GHz RF Input Channel (Channel 3), Option 030

• 5.0 GHz RF Input Channel (Channel 3), Option 050

• 12.4 GHz RF Input Channel (Channel 3), Option 124

• Rear Terminals

• Rack Mount Kit, Option 1CM. Also available under Agilent part number 5062-

9240.

• Lock-Link Kit (side-by-side) available under Agilent part number 5061-9694.

Also requires Flange Kit, part number 5062-3974.

1

, Option 060

Support

• 5-year Return to Agilent for Repair, Option W50

• 5-year Return to Agilent for Calibration, Option W52

1

The two standard input channels (1 and 2) will have both front an d rear terminals. Option 030 Channel 3 will

have a rear terminal only. Option 050 and Option 124 Channel 3 will have a front terminal only.

xviii Operating Guide

Page 22

In This Guide

Accessories Supplied and Available

Accessories Supplied

• Power cord, 2.3 meters

Accessories Available

• Agilent 34161A Accessory Pouch

• Agilent 34131A Transit Case

• Printer RS-232 Interface cables, Agilent 24542G or Agilent 24542H

• GPIB cables, Agilent 10833A/B/C/D

Supplied Manuals

• Agilent 53131A/132A Operating Guide—this guide

(Agilent P/N 53131-90055)

• Agilent 53131A/132A Programming Guide

(Agilent P/N 53131-90044)

• Agilent 53131A/132A Assembly-Level Service Guide

(Agilent P/N 53131-90039)

Operating Guide xix

Page 23

In This Guide

Differences Between Prior and Current Revisions of

the Agilent 53131A/132A

If you have an Agilent 53131A containing one of the prior firmware revisions (3317,

3335, or 3402), read the subsection below titled “Agilent 53131A Containing

Firmware Revisions (3317, 3335, or 3402)” to get an overview of the differences

between the earlier firmware revisions and current firmware revision.

If you have an Agilent 53132A with a serial number prefix below 3646, read the

subsection titled “Agilent 53132A Time Interval Delay Arming” on page xxii.

NOTE Note that throughout the guide, differences between the earlier and current firmware

revisions are noted where applicable.

Agilent 53131A Containing Firmware Revisions (3317, 3335, or

3402)

There are four main areas that differ:

• Calibrations

•Measurements

• Statistics

• GPIB Commands

xx Operating Guide

Page 24

In This Guide

Calibrations

If your Counter contains other than the current firmware revision, the following

calibration features are different:

• The calibration functions are in the Utility menu instead of the Calibration menu,

which is accessed by pressing and holding the front-panel Utility key and then

cycling POWER key.

• Calibrations are not protected by a security code.

• A calibration count does not exist to aid in monitoring the number of calibrations

performed.

• A more accurate Time Interval calibration (FINE TI) is not available.

See the section titled “Using the Calibration Menu” in Chapter 2 of the

Agilent 53131A/132A Operating Guide for details.

Measurements

If your Counter contains other than the current firmware revision, the following

measurement capabilities are different:

• Ratio channel selections Ratio 2 to 1 and Ratio 3 to 1 (for those counters

equipped with Channel 3) are not available.

• Ratio “AUTO-armed” does not automatically extends gate to capture sufficient

edges.

If Channel 1 input frequency is less than approximately 10 Hz, the Ratio gate

time is not extended to capture sufficient Channel 1 edges to produce a valid

measurement. Default gate time is 100 msec, which is not long enough to capture

two edges on a low-frequency signal. The user is required to extend the gate by

switching to TIME arming, and selecting a gate time appropriately long.

• Sensitivity for firmware revision below does not have adjusted controls to LO

and MED sensitivity.

In some Counters that contained firmware revision 3317, LO sensitivity fails to

correctly count very high frequency signals.

Operating Guide xxi

Page 25

In This Guide

Statistics

If your Counter contains other than the current firmware revisions, single-shot

statistics are not available using the ON SINGLE: menu item found in the Statistics

menu (use Stats key).

GPIB Commands

[:SENSe]:EVENt[1|2}:HYSTeresis:RELative

If your Counter contains firmware revisions 3402 and below, the input hysteresis

command and query does not operate in the conventional way. That is,

[:SENSe]:EVENt[1|2]:HYSTeresis:RELative sets high sensitivity when the

parameter is MINimum or 0 percent, and sets low sensitivity when the parameter is

MAXimum or 100 percent.

In the prior firmware revisions (3317, 3335, or 3402), MINimum or 0 percent

corresponded to low sensitivity, and MAXimum or 100 percent corresponded to high

sensitivity.

:CONFigure:TOTalize:TIMed

:CONFigure:TOTalize:CONTinuous

:MEASure:TOTalize:TIMed?

If your Counter contains firmware revisions 3402 and below, the Totalize

Measurement Instruction commands (shown above) are not available to disable autotrigger.

In the firmware revisions 3402 and below, these commands enabled auto-trigger at

the 50% level.

Agilent 53132A Time Interval Delay Arming

Agilent 53131A and Agilent 53132A Counters with a serial number prefix below

3646 are identical in their TI arming modes. Both only offer Time Interval Delay,

where the STOP trigger of a time interval measurement can be delayed by a

user-specified time.

xxii Operating Guide

Page 26

Agilent 53131A/132A Quick Reference Guide

The Quick Reference Guide is designed for experienced users of the

Agilent 53131A/132A Universal Counter. It is intended to be used as a tool to trigger

your memory. If you are using the Agilent 53131A/132A for the first time, Agilent

Technologies recommends that you at least read Chapter 1, “Getting Started,” in the

Operating Guide first.

The Quick Reference Guide follows this page, and consists of the following items:

• Menu Trees which may be torn out of the guide for external use (pages 1, 2, 3a,

and 3b).

• Menu Roadmaps which illustrate via key-press sequences how to navigate

through the menus under the menu keys (pages 4 through 11). Key-press

sequences are provided for the following menu keys:

– Freq & Ratio

– Time & Period

–Other Meas

–Gate & ExtArm

– Uppr & Lower

– Limit Modes

– Scale & Offset

–Stats

– Trigger/Sensitivity

Operating Guide xxiii

Page 27

xxiv Operating Guide

Page 28

Agilent 53131A/132A

Universal Counter

1

Freq &

Ratio

FREQUENCY 1

FREQUENCY 2

FREQUENCY 3

RAT I O 1 TO 2

RAT I O 1 TO 3

RAT I O 2 TO 1

RAT I O 3 TO 1

Uppr &

Lower

UPPR: 0.000000

LOWR: 0.000000

Time &

Period

T I 1 TO 2

PERIOD 1

RISETIME

FALLTIME

POS WIDTH 1

NEG WIDTH 1

Limit

Modes

LIM TEST: OFF

LIM TEST: ON

ON FAIL:GO ON

ON FAIL:

STOP

SHOW: NUMBER

SHOW:

GRAPH

1

1

Scale &

Offset

SCALE:1.000000

OFFS: 0.000000

SET OFFSET ?

MATH: OFF

MATH: ON

MATH HELP?

Other

Meas

T O T A L I Z E 1

PHASE 1 TO 2

DUTYCYCLE 1

VOLT PEAKS 1

VOLT PEAKS 2

Stats

SHOW: MEAS

SHOW: STD DEV

SHOW:

MEAN

SHOW:

MAX

SHOW:

MIN

N: 100

STATS: OFF

STATS: ON

USE: ALL MEAS

LIMIT

USE: IN

ON SINGLE: 1

ON SINGLE: N

(Agilent 53131A and Agilent 53132A)

Page 29

Agilent

53131A/132A

Universal Counter

2

Recall

NO REGISTERS

RECALL 0

RECALL 1

RECALL 2

RECALL 3

RECALL 4

RECALL 5

RECALL 20

50Ω

1MΩ

CH 1: 50 OHM

CH 1: 1M OHM

Save &

Print

SAVE:

UNSAVE:

PRINT: OFF

PRINT: ON

PRINT HELP?

DC

AC

CH 1: DC

CH 1: AC

Trigger

Sensitivity

AUTO TRG: ON AUTO TRG: OFF

LEVEL: 50 PCT

SLOPE: POS

SLOPE: NEG

SENSTVTY: HI

SENSTVTY: LO

SENSTVTY:MED

COMMON 1: OFF

COMMON 1: ON

X10

Attenuate

CH 1: X10 ATT

CH 1: X1 ATT

LEVEL: 0.000V

SLOPE: POS

SLOPE: NEG

SENSTVTY: HI

SENSTVTY: LO

SENSTVTY:MED

COMMON 1: OFF

COMMON 1: ON

100kHz

Filter

CH 1:

LP FILT

CH 1:

NO FILT

(Agilent 53131A and Agilent 53132A)

Page 30

Agilent 53131A and

Agilent 53132A

3a

Universal Counter

(Serial Number Prefix below 3646)

Gate &

ExtArm

Time &

Period

T I 1 TO 2

-- -- -- -- -- -- -- -- -- -- -- --

Gate &

ExtArm

ARM: AUTO

DELAY : NONE

DELAY : TIME

T IME : .01000

GATE:

TIME

TIME: .100 s

ARM : EXTERNL

SLOPE : POS

DELAY: NONE

GATE: AUTO

SLOPE : NEG

DELAY: TIME

TIME : .01000

GATE: EXTERNL

START: POS

START: NEG

STOP: AUTO

STOP: NEG

STOP: POS

STOP: TIME

TIME: .100 s

GATE: DIGITS

DIGITS: 4

(Agilent 53131A and Agilent 53132A S/N below 3646)

Page 31

Agilent 53132A

Universal Counter

(Serial Number Prefix 3646 and above)

Gate &

ExtArm

GATE:

Time &

Period

T I 1 TO 2

-- -- -- -- -- -- -- -- -- -- -- --

TIME: .100 s

Gate &

ExtArm

START: AUTO

DELAY : NONE

T : .1 E : 1

DELAY :TIME

DELAY : EVENT

TIME

GATE: AUTO

SLOPE : POS

DELAY: NONE

T : .1 E : 1

STOP : AUTO

SLOPE : POS

DELAY : NONE

GATE: EXTERNL

START: POS

START: NEG

STOP: AUTO

STOP: NEG

STOP: POS

STOP: TIME

TIME: .100 s

START: EXT

SLOPE : NEG

DELAY: TIME

STOP : EXT

DELAY : TIME

T : .1 E : 1

GATE: DIGITS

DIGITS: 4

DELAY: EVENT

SLOPE : NEG

DELAY : EVENT

(Agilent 53132A S/N 3646 and above)

3b

Page 32

Agilent 53131A/132A

4

Universal Counter

Freq &

Ratio

MEASURE

Time &

Period

Other

Meas

Freq &

Ratio

Freq &

Ratio

Freq &

Ratio

Freq &

Ratio

Freq &

Ratio

Freq &

Ratio

Freq &

Ratio

Freq &

Ratio

FREQUENCY 1

FREQUENCY 2

FREQUENCY 3

RATIO 1 TO 2

RATIO 1 TO 3

RATIO 2 TO 1

RATIO 3 TO 1

Time &

Period

Time &

Period

Time &

Period

Time &

Period

Time &

Period

Time &

Period

Time &

Period

1

T I 1 TO 2

PERIOD 1

RISETIME 1

FALLTIME 1

POS WIDTH 1

NEG WIDTH 1

Other

Meas

Other

Meas

Other

Meas

Other

Meas

Other

Meas

Other

Meas

TOTALIZE 1

PHASE 1 TO 2

DUTYCYCLE 1

VOLT PEAKS 1

VOLT PEAKS 2

(Agilent 53131A and Agilent 53132A)

Page 33

Agilent 53131A/132A

U

5

niversal Counter

Freq &

Ratio

FREQUENCY 1

MEASURE

– – – – – – – – – – – –

Gate &

ExtArm

Gate &

ExtArm

GATE: TIME

GATE: AUTO

GATE

: EXTERNL

Gate &

ExtArm

Gate &

ExtArm

GATE: DIGITS

STOP:

TIME: .100

Gate &

TIME: .100

ExtArm

TIME: .200

Gate &

START:

ExtArm

START: POS

START: NEG

STOP: AUTO

STOP: NEG

STOP: POS

STOP: TIME

TIME: .2000

Gate &

DIGITS: 10

ExtArm

Enter

Enter

Gate &

ExtArm

Gate &

ExtArm

Gate &

ExtArm

RUN

RUN

RUN

DIGITS: 5

Enter

RUN

(Agilent 53131A and Agilent 53132A)

Page 34

Agilent 53131A and

U

6a

Agilent 53132A

(Serial Number Prefix below 3646)

niversal Counter

Time &

Period

TI 1 TO 2

MEASURE

– – – – – – – – – – – –

Gate &

ExtArm

Gate &

ExtArm

Gate &

ExtArm

ARM:

Gate &

ExtArm

Gate &

ExtArm

Gate &

ExtArm

SLOPE:

DELAY:

TIME: .01000

ARM: AUTO

ARM: EXTERNL

SLOPE: POS

SLOPE: NEG

DELAY: NONE

DELAY:

TIME

TIME: .02000

RUN

RUN

RUN

RUN

Enter

(Agilent 53131A and Agilent 53132A S/N below 3646)

Page 35

Agilent 53132A

(Serial Number Prefix 3646 and above)

Universal Counter

Time &

Period

TI 1 TO 2

MEASURE

- - - - - - - - - - -

Gate &

ExtArm

Gate &

ExtArm

START:

Gate &

ExtArm

SLOPE:

START: EXT

START: AUTO

Gate &

ExtArm

SLOPE: POS

SLOPE: NEG

Gate &

DELAY:

ExtArm

DELAY :NONE

DELAY :TIME

DELAY :EVENT

Gate &

T : .1

ExtArm

T : 100.1

Gate &

E : 1

ExtArm

E : 1000

A

Enter

Enter

B C

(Agilent 53132A S/N 3646 and above)

6b

Page 36

Agilent 53132A

(Serial Number Prefix 3646 and above)

Universal Counter

Gate &

ExtArm

A

Gate &

ExtArm

STOP :

STOP :EXT

B C

STOP :AUTO

Gate &

SLOPE :

ExtArm

SLOPE : POS

SLOPE : NEG

Gate &

DELAY :

ExtArm

DELAY :NONE

Run

DELAY :TIME

DELAY :EVENT

Gate &

ExtArm

Gate &

ExtArm

T : .1

T : 100.1

E : 1

E : 1000

Run

Enter

Run

Enter

(Agilent 53132A S/N 3646 and above)

6c

Page 37

Agilent 53131A/132A

U

7

niversal Counter

Uppr &

Lower

LIMITS

Uppr &

Lower

Limit

Modes

Uppr &

Lower

Limit

Modes

Limit

Modes

UPPR: 0.000000

Uppr &

LOWR: 0.000000

Lower

LIM TEST:

Limit

ON FAIL:GO ON

Modes

Limit

SHOW: NUMBER

Modes

UPPR: 5.100000

LOWR: 4.900000

LIM TEST: OFF

LIM TEST: ON

ON FAIL:GO ON

ON FAIL: STOP

SHOW: NUMBER

SHOW: GRAPH

Enter

Enter

RUN

RUN

RUN

RUN

RUN

(Agilent 53131A and Agilent 53132A)

Page 38

Agilent 53131A/132A

U

8

niversal Counter

Scale &

Offset

Scale &

Offset

MATH

Scale &

Offset

Scale &

Offset

Scale &

Offset

Scale &

Offset

Scale &

Offset

SCAL:

1.000000

OFFS:

0.000000

SET OFFSET?

MATH:

MATH HELP ?

SCAL:

2.000000

OFFS:

0.500000

Enter

OFFS:-

nnnnnnn

MATH: OFF

MATH: ON

Enter

(MEAS X SCALE) + OFFS = RESULT

Enter

Enter

RUN

RUN

RUN

RUN

(Agilent 53131A and Agilent 53132A)

Page 39

Agilent 53131A/132A

U

9

niversal Counter

Stats

Stats

MATH

Stats

SHOW:

SHOW: MEAS

SHOW:

STD

DEV

SHOW: MEAN

SHOW: MAX

SHOW: MIN

Stats

Stats

Stats

Stats

N: 100

N: 200

STATS:

STATS: OFF

STATS: ON

USE:

USE: ALL MEAS

USE: IN LIMIT

ON SINGLE:

ON SINGLE: 1

ON SINGLE: N

Enter

RUN

RUN

Run

Run

(Agilent 53131A and Agilent 53132A)

Page 40

Agilent 53131A/132A

U

10

niversal Counter

Freq &

Ratio

– – – – – – – – – – – –

Trigger

Sensitivity

CHANNEL 1

CHANNEL 2

Trigger

Sensitivity

FREQUENCY 1

FREQUENCY 2

FREQUENCY 3

RATIO 1 TO 2

RATIO 1 TO 3

RATIO 2 TO 1

RATIO 3 TO 1

Time &

Period

PERIOD 1

RISETIME 1

FALLTIME 1

POS WIDTH 1

NEG WIDTH 1

Other

Meas

TOTALIZE

PHASE 1 TO 2

DUTY CYCLE 1

Trigger

Sensitivity

AUTO TRG:

Enter

Trigger

Sensitivity

Trigger

Sensitivity

Trigger

Sensitivity

Trigger

Sensitivity

AUTO TRG: ON

AUTO TRG: OFF

LEVEL: 0.000V

LEVEL: 2.000V

LEVEL: 50 PCT

LEVEL: 75 PCT

SLOPE:

SLOPE: POS

SLOPE: NEG

SENSTVTY:

SENSTVTY: HI

SENSTVTY: LO

SENSTVTY: MED

RUN

RUN

RUN

RUN

RUN

(Agilent 53131A and Agilent 53132A)

Page 41

Agilent 53131A/132A

U

niversal Counter

Time &

Period

TI 1 TO 2

CHANNEL 1

CHANNEL 2

– – – – – – – – – – – –

Trigger

Sensitivity

Trigger

Sensitivity

Trigger

Sensitivity

Trigger

Sensitivity

Trigger

Sensitivity

Trigger

Sensitivity

Trigger

Sensitivity

Trigger

Sensitivity

AUTO TRG:

LEVEL: 0.000V

LEVEL: 50 PCT

SLOPE:

SENSTVTY:

COMMON 1:

AUTO TRG: ON

AUTO TRG: OFF

LEVEL: 2.000V

LEVEL: 75 PCT

SLOPE: POS

SLOPE: NEG

SENSTVTY: HI

SENSTVTY: LO

SENSTVTY: MED

COMMON 1: OFF

COMMON 1: ON

RUN

RUN

Enter

RUN

RUN

RUN

RUN

(Agilent 53131A and Agilent 53132A)

11

Page 42

1

Getting Started

Page 43

Chapter 1 Getting Started

23

567

The Front Panel at a Glance

The Front Panel at a Glance

1

Remote

SRQ

POWER

Utility Menu:

Hold at power up

8

14

1

53131 A

UNIVERSAL COUNTER

Period Freq +Wid -Wid Rise Fall Time Ch 1 Ch 2 Ch 3 ExtRef

MEASURE LIMITS MATH CHANNEL 1 CHANNEL 2

Freq &

Ratio

Other

Meas

Recall

9

Time &

Period

Gate &

ExtArm

LocalUtility

Save &

Print

10

225 MHz

Uppr &

Lower

Limit

Modes

Run

11

Scale &

Offset

Stats

Stop/

Single

Limit

Trigger

Sensitivity

50Ω

1M Ω

DC

AC

X10

Attenuate

4

MHz

µs

Gate

Damage Lvl:

5V rms MAX.50Ω

100kHz

Filter

+/–

Trigger

Sensitivity

50Ω

1M Ω

!

DC

AC

X10

Attenuate

12 13

Enter

CHANNEL 3

100 MHz − 3 GHz

Damage Lvl:

5V rms MAX.50Ω

Damage Lvl:

5V rms MAX.50Ω

100kHz

Filter

!

!

Note: Unit shown with Option 030.

1 Measurement function menu keys

2 Limits menu keys

3 Math menu keys

4 Sign (+ or −) selection toggle key

5 Data Entry/Select (or arrow) keys

6 Enter numeric data (terminate) key

7 3.0/5.0/12.4 GHz RF input channel

(optional)

8 Utility menu key (Hold during power-up

to access Utility functions.)

9 Recall, Save and Print menu keys

10 Gate and External Arm menu key

11 Measurement control keys

12 Channel 1 Trigger/Sensitivity menu key

and input conditioning keys

13 Channel 2 Trigger/Sensitivity menu key

and input conditioning keys

14 Calibration menu key (Hold Scale &

Offset key during power-up to access

Calibration functions.)

NOTE It is normal operation for the fan in the Counter to continue to run after the Counter is

placed in Standby mode. Power to the timebase is continuous to maintain long term

measurement reliability, and the fan helps maintain timebase temperature stability.

1-2 Operating Guide

Page 44

Chapter 1 Getting Started

The Front Panel Indicators at a Glance

The Front Panel Indicators at a Glance

There are eight different groups of indicators or LEDs. They are listed and described

in the following table.

Indicators Description of the Indicators

Freq &

Ratio

Other

Meas

Scale &

Offset

Stats

Time &

Period

Limit

Modes

Local

Save &

Print

Trigger

Sensitivity

When one of these indicators is lit, it simultaneously

indicates which key’s menu (for example, Time & Period

key) and its menu item (for example, TI 1 to 2) is enabled.

When these indicators are lit, the key’s “enable” menu item

(that is, Limit Modes/LIM TEST, Scale & Offset/MATH,

Stats/STATS, and Save & Print/PRINT) is enabled.

When this indicator is lit, it indicates that you are in the

Trigger/Sensitivity menu for the corresponding channel.

When this indicator flashes, it indicates that the arrow keys

can be used to modify or enter data.

1

+/–

Run

Enter

Stop/

Single

When one of these indicators is lit, it indicates that the Run

or Single function is enabled.

Operating Guide 1-3

Page 45

Chapter 1 Getting Started

The Front Panel Indicators at a Glance (Cont.)

The Front Panel Indicators at a Glance (Cont.)

1

Indicators Description of the Indicators

When this indicator flashes, it indicates that the Counter is

triggering on the input signal. If the input signal is too high,

this indicator remains ON. If the input signal is too low, this

indicator is OFF.

50Ω

1MΩ

X10

Attenuate

SRQ

DC

AC

100kHz

Filter

When one of these indicators is lit, it indicates that the

adjacent choice (that is, 50Ω, DC, X10, or 100kHz Filter) is

enabled or active. Note that when these indicators are not lit,

then the other choice (that is, 1MΩ, AC, X1, or no filter) is

active.

A lit Remote indicator indicates that the Counter is in remote

mode (Note: In the remote mode, the Save & Print key

becomes the Local key.)

If (while in remote) an error occurs, the Remote indicator

will flash. The indicator will continue flashing until the

controller has read or cleared the error queue, or until the

front panel returns to local mode.

An unlit Remote indicator indicates that the Counter is in

local mode.

The SRQ indicator indicates that the Counter has requested

service from the controller. The SRQ indicator will remain lit

until the controller has recognized the service request and

serial polled the Counter, or taken specific action to cancel

the request (for example, *CLS command).

1-4 Operating Guide

Page 46

Chapter 1 Getting Started

The Front Panel Menus at a Glance

The Front Panel Menus at a Glance

Freq &

Ratio

Time &

Period

Other

Meas

1

Gate &

ExtArm

FREQUENCY 1

FREQUENCY 2

1

FREQUENCY 3

RAT I O 1 TO 2

1

RAT I O 1 TO 3

RAT I O 2 TO 1

1

RAT I O 3 TO 1

Uppr &

Lower

UPPR: 0.000000

LOWR: 0.000000

T I 1 TO 2

PERIOD 1

RISETIME

FALLTIME

1

1

POS WIDTH 1

NEG WIDTH 1

Limit

Modes

LIM TEST: OFF

LIM TEST: ON

ON FAIL:GO ON

ON FAIL:

STOP

SHOW: NUMBER

SHOW:

GRAPH

T O T A L I Z E 1

PHASE 1 TO 2

DUTYCYCLE 1

VOLT PEAKS 1

VOLT PEAKS 2

Scale &

Offset

SCALE:1.000000

OFFS: 0.000000

SET OFFSET ?

MATH: OFF

MATH: ON

MATH HELP?

2

GATE:

TIME

GATE: AUTO

GATE: EXTERNL

GATE: DIGITS

Stats

SHOW: MEAS

SHOW: STD DEV

SHOW:

MEAN

SHOW:

MAX

SHOW:

MIN

N: 100

STATS: OFF

STATS: ON

USE: ALL MEAS

LIMIT

USE: IN

ON SINGLE: 1

ON SINGLE: N

1

These menu items appear only if your Coun ter contains the optional Input Channel.

2

Refer to the Menu Tree in the Quick Reference Guide (which precedes this chapter) and/or th e Gate/External

Arming table in Chapter 2 for details on the Gate & ExtArm menu.

Operating Guide 1-5

Page 47

Chapter 1 Getting Started

The Front Panel Menus at a Glance (Cont.)

The Front Panel Menus at a Glance (Cont.)

1

Recall

3

NO REGISTERS

4

RECALL 0

RECALL 1

RECALL 2

RECALL 3

RECALL 4

RECALL 5

RECALL 20

50Ω

1MΩ

7

CH 1: 50 OHM

CH 1: 1M OHM

Save &

Print

SAVE:

5

UNSAVE:

PRINT: OFF

PRINT: ON

PRINT HELP?

Trigger

Sensitivity

AUTO TRG: ON

LEVEL: 50 PCT

SLOPE: POS

SLOPE: NEG

SENSTVTY: HI

AUTO TRG: OFF

LEVEL: 0.000V

SENSTVTY: LO

SENSTVTY:MED

6

COMMON 1: OFF

COMMON 1: ON

DC

AC

777

CH 1: DC

CH 1: AC

X10

Attenuate

CH 1: X10 ATT

CH 1: X1 ATT

100kHz

Filter

CH 1:

LP FILT

CH 1:

NO FILT

3

This appears when nothing can be recalled.

4

Only registers which can be recalled will appear in this menu.

5

This menu item only appears if an instrument setup has been saved.

6

COMMON 1 only appears when the Counter is operating in the Time Interval measurement function

(TI 1 TO 2).

7

Channel 2 is the same, except “CH 2” instead of “CH 1” is displayed. These menus will terminate after

two seconds.

1-6 Operating Guide

Page 48

Chapter 1 Getting Started

POWER

The Front Panel Menus at a Glance (Cont.)

The Front Panel Menus at a Glance (Cont.)

NOTE Turn power off, press and hold Recall (Utility) key, then press POWER key to access

this menu.

Utility

Recall

On / Stby

REV:

HP-IB: 3

TIMEBAS:

TIMEBAS:

AUTO

INT

TIMEBAS: EXT

CAL: HELP?

TEST LOOP: OFF

TEST LOOP: ON

TST PRINT:OFF

TST PRINT: ON

ALL?

8

TEST:

DISP?

CPU?

TEST:

TEST: ROM?

TEST: RAM?

TEST:

EEPROM?

TEST:

HP-IB?

TEST: QSPI?

TEST: FPGA?

TEST: FR END?

TEST: MEAS?

TEST: INTERP?

8

TEST:

KEYPAD?

TEST:

PRINT?

BAUD: 9600

BAUD:

19200

BAUD: 300

BAUD: 1200

BAUD: 2400

PARITY: OFF

PARITY:

EVEN

PARITY: ODD

SW PACE: XON

SW PACE: NONE

DTR: HIGH

DTR: LIMIT

HW PACE

DTR:

SHOW 9 AS: 9.0

TEST:

SHOW 9 AS: 9,0

1

8

These menu items appear only if TEST LOOP is OFF.

Operating Guide 1-7

Page 49

Chapter 1 Getting Started

The Front Panel Menus at a Glance (Cont.)

The Front Panel Menus at a Glance (Cont.)

1

NOTE Turn power off, press and hold Scale & Offset key, then press POWER key to access

this menu. (This menu does not exist in early versions of the Counter. In the early

versions of the Counter, the CAL: menu item resides in the Utility menu, and there is

no calibration security capability.)

POWER

Scale &

Offset

On / Stby

CAL SECURE CAL UNSECURE

9

CAL: OFFS1?

CAL: OFFS2?

CAL: GAIN1?

CAL: GAIN2?

CAL: TI QUIK?

CAL: TI FINE?

CAL: TIMEBAS?

10

CODE: 0

CAL COUNT?

HELP: CAL?

HELP: SECURE?

HELP: CODE?

9

This menu item appears and calibration is permitted only if calibration is unsecure. E nter in the correct code

to change calibration to se cure; refer to the section titled “Using the Calibration Menu” in Chapter 2 in this guide

for more information.

10

Timebase can be automatically calibrated only if the timebase option is installed.

1-8 Operating Guide

Page 50

Chapter 1 Getting Started

The Display Annunciators at a Glance

The Display Annunciators at a Glance

MHz

µs

Period Freq +Wid -Wid Rise Fall Time Ch 1 Ch 2 Ch 3 Limit ExtRef

Annunciator Indication

Period Counter is set to measure Period.

Freq Counter is set to measure Frequency.

+Wid Counter is set to measure Positive Pulse Width.

−Wid Counter is set to measure Negative Pulse Width.

Rise Counter is set to measure Rise Time. (The Time annunciator is also

turned on when the Rise annunciator is on.)

Fall Counter is set to measure Fall Time. (The Time annunciator is also

turned on when Fall annunciator is on.)

Time Counter is set to measure Time Interval. (The Time annunciator is

also turned on when the Rise or Fall annunciator are on.)

Ch 1 Counter’s channel 1 is selected to measure an input signal.

Ch 2 Counter’s channel 2 is selected to measure an input signal.

Ch 3 Counter’s channel 3 is selected to measure an input signal.

Limit Counter is limit testing and the current measurement exceeds the

user-entered limits.

ExtRef Counter is set to use the signal connected at rear panel Ref In

connector as the timebase (TIMEBAS: EXT); or Counter is set to

automatically (TIMEBAS: AUTO) select the timebase and has chosen

the signal connected at the rear panel Ref In connector.

Hz The displayed data is in units of Hertz.

M The prefix for the units of the displayed data is mega (10

µ The prefix for the units of the displayed data is micro (10

s The displayed data is in units of seconds.

Gate The gate is open. Before a measurement starts, this annunciator is

OFF, indicating the gate is closed. During a measurement, the

annunciator is ON, indicating the gate is open.

Gate

6

).

−6

).

1

Operating Guide 1-9

Page 51

Chapter 1 Getting Started

The Display Special Character at a Glance

The Display Special Character at a Glance

1

MHz

µs

Period Freq +Wid -Wid Rise Fall Time Ch 1 Ch 2 Ch 3 Limit ExtRef

Special Character Description

A placeholder that indicates this digit is not significant.

Gate

The Limit Test Graph Characters at a Glance

Freq Ch 1

Special Character Description

The colons represent the lower and upper limits.

The asterisk represents the last measurement.

These marks indicate that the last measurement was

or

significantly past the limit in the direction indicated.

1-10 Operating Guide

Page 52

Chapter 1 Getting Started

3

1 2

The Rear Panel at a Glance

The Rear Panel at a Glance

1

WARNING:

1

I

N

P

U

T

Ext

S

Arm

WARNING:

4

NO OPERATOR SERVICEABLE PARTS INSIDE, REFER SERVICING TO SERVICE TRAINED PERSONNEL.

50/60 Hz

50/60/400 Hz

60 VA

100 - 120 VAC

200 - 240 VAC

10 MHz Out

AC LINE:

ISM 1-A

FOR LABORATORY USE BY

QUALIFIED PERSONNEL

FOUR USAGE EN LABORATOIRE

PAR PERSONNEL QUALIFIE

OPTIONS

001 MS Oven

HP-IB

Talk Only

92

010 HS Oven

To Configure:

Hold Recall during turn-on.

Osc Adjust

SERIAL PLATE

RS - 232

2

3

!

Ref

In

FOR CONTINUED FIRE PROTECTION, USE SPECIFIED ~ LINE FUSE.

5 6 7 8 9

1 Rear-panel input connectors (optional)

2 Power module (Senses incoming voltage

and automatically selects proper setup.)

3 Fan

4 External Arm input connector

5 External Reference Input connector

6 10 MHz Output connector

7 GPIB (IEEE-488.1)

interface connector

8 Oscillator Adjust potentiometer (This

potentiometer is not present for options

001, 010, and 012.)

9 RS-232 interface or Limit

Output connector

NOTE It is normal operation for the fan in the Counter to continue to run after the Counter is

placed in Standby mode. Power to the timebase is continuous to maintain long term

measurement reliability, and the fan helps maintain timebase temperature stability.

Operating Guide 1-11

Page 53

Chapter 1 Getting Started

Making Measurements

Making Measurements

1

One of the first things you will want to do with your Agilent 53131A/132A Universal

Counter is to become acquainted with its front panel. Therefore, we have written the

procedures in this section to familiarize you with some of its controls. The following

procedures are provided:

• First you are shown how to turn on the Counter and measure the frequency of a

signal applied to the Counter’s input channels.

• Second, you are shown how to use the input coupling, impedance, and

trigger/sensitivity keys to set the input conditions of the appropriate input

channel to match the signal being measured.

• Third, you are shown how to scale and offset the measurement result.

• Fourth, you are shown how to set upper and lower limits for measurements.

• Fifth, you are shown how to enable the Counter to compute statistics (such as

standard deviation) and display statistics of measurements.

• Last, you are shown how to use the Run and Stop/Single keys to control

measurements.

The order of the procedures in this chapter is the recommended order for making

measurements with this Counter.

Study and refer to the following legend, as needed, to understand the meaning of the

icons which are used throughout this chapter.

1-12 Operating Guide

Page 54

Chapter 1 Getting Started

Making Measurements

Legend

12

34

1 Press key one time and

release

2 Press key two times and

release

3 Repeated key presses

To Measure Frequency

POWER

On / Stby

5

6

4 Press and hold

5 Result

6 Auto operation

7 Connect signal

Period Freq +Wid -Wid Rise Fall Time Ch 1 Ch 2 Ch 3 Limit ExtRef

78

91110

8 Disconnect signal

9 Indicator off

10 Indicator on

11 Indicator flashing

MHz

µs

Gate

1

Freq Ch 1

Freq Ch 1

Operating Guide 1-13

Page 55

Chapter 1 Getting Started

Making Measurements

NOTE Earlier versions of the Counter do not momentarily display the GPIB address at

turn-on.

1

Connect (for demonstration purposes) the Counter’s rear-panel 10 MHz Out signal to

CHANNEL 1 input as shown in the illustrated procedure, below.

CHANNEL 1

MHz

Damage Lvl:

5V rms MAX.50Ω

!

Freq Ch 1

Gate

The Counter will automatically display the measured frequency of the input signal.

Disconnect the demonstration signal from CHANNEL 1, and connect it to

CHANNEL 2 as shown in the following steps.

MEASURE

Freq &

Ratio

Other

Meas

Time &

Period

Gate &

ExtArm

CHANNEL 1

Damage Lvl:

5V rms MAX.50Ω

CHANNEL 2

Damage Lvl:

5V rms MAX.50Ω

Freq &

Ratio

!

!

Freq Ch 1

Freq Ch 1

Freq &

Ratio

Freq Ch 2

Freq

MHz

Ch 2

Gate

1-14 Operating Guide

Page 56

Chapter 1 Getting Started

Making Measurements

Again, the Counter will automatically display the measured frequency of the input

signal.

CHANNEL 2

Trigger

Sensitivity

50Ω

1MΩ

DC

AC

X10

Attenuate

Damage Lvl:

5V rms MAX. 50Ω

100kHz

Filter

If you need or want to change CHANNEL 2’s coupling, impedance, and triggering

conditions to match the input signal you are trying to measure, the next procedures

“To Select Input Coupling and Impedance” and “To Set Input Channel Trigger

Level/Sensitivity” demonstrate this. Perform these procedures whether or not you

want to customize the Counter’s input conditions to measure your signal; doing this

will help you become familiar with the DC/AC, 50Ω/1MΩ, and Trigger/Sensitivity

keys.

To Select Input Coupling and Impedance

Remember, the input signal is still connected to CHANNEL 2.

Selecting Input Coupling

DC

!

Channel 2’s input coupling is now set to dc.

If you want to change the coupling back to the default ac coupling, perform the

following step.

AC

Display 1, 7/13/92

1

DC

AC

Operating Guide 1-15

Page 57

Chapter 1 Getting Started

Making Measurements

Selecting Input Impedance

50Ω

1

Channel 2’s input impedance is now set to 50Ω.

NOTE The “arrow” keys can also be used to toggle the state of toggle keys (DC/AC,

50Ω/1MΩ, etc.) as indicated by the flashing indicator within the arrow keys. However,

for simplicity in this procedure, use the corresponding toggle key to change states.

If you want to change the input impedance back to the default 1 MΩimpedance,

perform the following step.

1MΩ

50Ω

1MΩ

MHz

Freq

Ch 2

Gate

1-16 Operating Guide

Page 58

+/–

Enter

Chapter 1 Getting Started

Making Measurements

To Set Input Channel Trigger Level/Sensitivity

Changing Trigger Mode

Trigger

Sensitivity

Press any one of these arrow keys to toggle to the next state of Auto Trigger.

Modifying Input Trigger Level

1

The leftmost “0” digit in the LEVEL display is highlighted, indicating that if you

press the d key once the displayed value will increase to 1.000 volt as shown in the

following step.

NOTE BE SURE to always press the Enter key to complete numeric data entries.

Channel 2’s trigger level is now set to +1V.

Operating Guide 1-17

Page 59

Chapter 1 Getting Started

Making Measurements

To set the trigger level to −0.05V, perform the following steps.

1

+/–

Enter

NOTE BE SURE to always press the Enter key to complete numeric data entries.

Channel 2’s trigger level is now set to −0.05V.

Selecting Input Trigger Slope

Trigger

Sensitivity

Display 1, 7/13/92

Display 1, 7/13/92

1-18 Operating Guide

Page 60

Chapter 1 Getting Started

Making Measurements

Selecting Input Sensitivity

Trigger

Sensitivity

Display 1, 7/13/92

Display 1, 7/13/92

Display 1, 7/13/92

Starting the Measurement

Run

Freq

Ch 2

The Run key initiates repetitive measurements, and is described in the section titled

“To Control Measurement” at the end of this chapter.

MHz

Gate

To Select Scale and Offset

1

The Scale & Offset key allows for multiplication and addition, respectively, of the

measurement by user-specified constants. Modification of the displayed measurement

by these Math operations is represented by the following equation:

(Measurement × Scale) + Offset = Displayed Results

The Scale and Offset Math operations can be used, for example, to subtract

systematic errors or display the percentage difference between signals.

Operating Guide 1-19

Page 61

Chapter 1 Getting Started

Making Measurements

Entering the Scale Value

Scale &

1

To demonstrate the Scale Math operation, set Scale to 10 as shown in the following

steps.

Press and hold the d key until the value of Scale is 10 as shown in the following step.

Offset

Enter

NOTE BE SURE to press the Enter key to enter the value of 10.

The Scale is now set to 10, and MATH has been enabled. The Scale & Offset

indicator is now lit to show that MATH is enabled. Since MATH is enabled, the

results are being scaled and offset.

1-20 Operating Guide

Page 62

Chapter 1 Getting Started

Making Measurements

Entering the Offset Value

To demonstrate the Offset Math operation, set the Offset to 1 MHz as shown in the

following steps.

Scale &

Offset

At this point, pressing the s key will cause the Counter to display the full display of

the Offset value as shown in the following step.

Press the s key six more times to cause the Counter to display your entry in Mega

units as shown in the following step.

1

The leftmost “0” digit in the OFFSet display is highlighted, indicating that if you

press d key once the displayed value will increase to 1 Mega (that is, 1E6) as shown

in the following step.

Enter

NOTE BE SURE to press the Enter key to enter the 1 Mega value.

The Offset is now set to 1 Mega.

Operating Guide 1-21

M

M

M

Page 63

Chapter 1 Getting Started

Making Measurements

Displaying the Math Results

1

Run

Freq Ch 2

M

The Counter displays the modified measurement results, which are based

on the scale and offset values that you selected in the previous steps. That is, the 101

represents the original 10, scale multiplied by 10, then offset by 1.

(For more details and real applications of the Math Scale and Offset operations, refer

to the appropriate section in Chapter 2, “Operating Your Universal Counter.”)

Disabling Math

Scale &

Offset

Display 1, 7/13/92

Display 1, 7/13/92

Note that the Scale & Offset key indicator is now off.

NOTE DO NOT cycle POWER because you will need to use these Scale and Offset values

in the following procedure “To Set Limits of Measurements.” Continue to the

following procedure.

1-22 Operating Guide

Page 64

Chapter 1 Getting Started

Making Measurements

To Set Limits of Measurements

To demonstrate how Math and Limits work together, use the Scale (10) and Offset (1

Mega) values selected in the previous procedure “To Select Scale and Offset.” Enable

Math by performing the following steps.

Scale &

Offset

Display 1, 7/13/92

Display 1, 7/13/92

1

Run

Freq Ch 2

M

The result of this Math operation is a measurement of 101 MHz.

(Measurement × Scale) + Offset = Result

(10 MHz × 10) + 1Mega = 101 Mega

Now, set the upper limit to 102 Mega and the lower limit to 100 Mega by performing

the following procedures. (Figure 1-1 and Figure 1-2 illustrate the limits settings.)

Operating Guide 1-23

Page 65

Chapter 1 Getting Started

Making Measurements

Setting the Upper Limit

LIMITS

1

Uppr &

Lower

Limit

Modes

Press the s key six more times to cause the Counter to display your entry in Mega

units as shown in the following step.

M

M

The leftmost “0” digit in the UPPR display is highlighted as shown above, indicating

that each press of the d key will increase the displayed value.

1-24 Operating Guide

Page 66

Chapter 1 Getting Started

Making Measurements

M

1

M

M

Enter

NOTE BE SURE to press the Enter key to enter the 102 Mega value.

1

2

1 102 Mega Upper Limit

2 101 Mega Scale/Offset Measurement

Figure 1-1. 102 Mega Upper Limit Setting

M

Operating Guide 1-25

Page 67

Chapter 1 Getting Started

Making Measurements

Setting the Lower Limit

1

Uppr &

Lower

Press the arrow keys as shown in the following steps to set the lower limit value.

Press the s key six more times to cause the Counter to display your entry in Mega

units as shown in the following step.

M

M

M

Enter

M

1-26 Operating Guide

Page 68

Chapter 1 Getting Started

Making Measurements

NOTE BE SURE to press the Enter key to enter the 100 Mega value.

Limits should now be set as shown in Figure 1-2.

1

2

3

1 102 Mega Upper Limit

2 101 Mega Scale/Offset Measurement

3 100 Mega Lower Limit

1

234

Figure 1-2. 100 Mega Lower and 102 Mega Upper Limits Settings

1

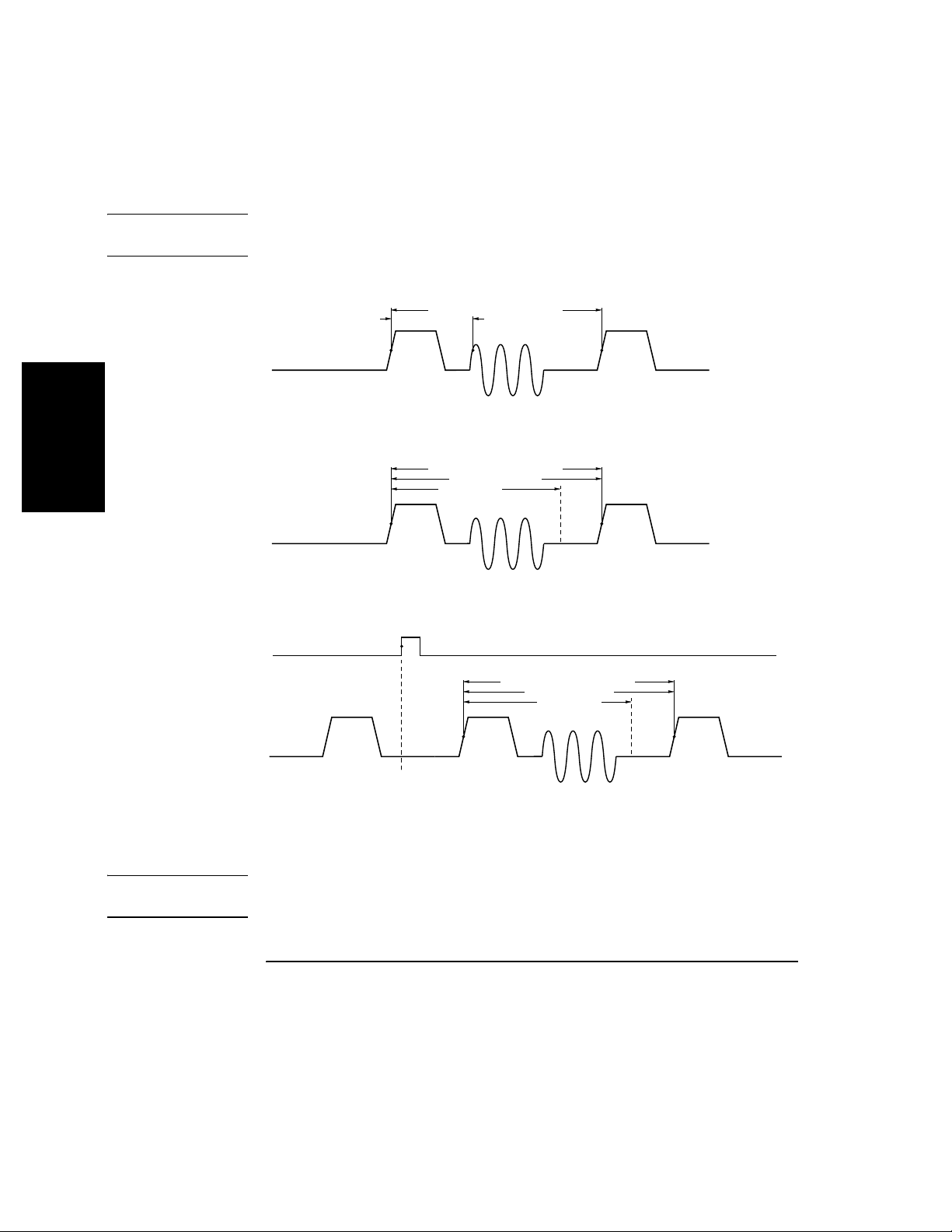

Figure 1-3 represents what transpired during this Math and Limits procedure.

1 Raw Measurements

2 Math

3 Limits

4 Measurements (Scale/Offset Results)

within Limits

Figure 1-3. Math and Limits Results

Operating Guide 1-27

Page 69

Chapter 1 Getting Started

Making Measurements

Setting the Counter to Flag and Stop Measuring On Out-of-Limit

Measurements

If you want the Counter to stop measuring when the signal exceeds the limits (102 to

1

100 Mega) that you entered in the previous procedure, perform the following steps to

select the STOP choice in the ON FAIL display. (Note that ON FAIL: GO ON is the

default state after power-up.)

Limit

Modes

Run

Freq Ch 2

M

Gate

The current modified measurement of the input signal applied to CHANNEL 2 is

displayed.

Since the Counter is now in the stop-on-fail mode, the Limit annunciator in the

display will light and the Counter will stop making measurements when a

measurement exceeds the limits you set.

1-28 Operating Guide

Page 70

Chapter 1 Getting Started

Making Measurements

Setting the Counter to Flag On Limits But Continue Measuring

Perform the following steps to select the GO ON choice in the ON FAIL display if

you want the Counter to continue measuring even though an measurement result

exceeds the limits previously entered.

Limit

Modes

1

Run

Freq Ch 2

M

Gate

The current modified measurement of the input signal applied to CHANNEL 2 is

displayed.

Since the Counter is now in the go-on-fail mode, the Limit annunciator in the display

will light each time a measurement exceeds the limits you set. However, the Counter

will continue to make measurements.

Operating Guide 1-29

Page 71

Chapter 1 Getting Started

Making Measurements

Disabling Limit Testing

Limit

1

Modes

The Counter is now making measurements without limit testing.

Disabling Math

The Counter is now making measurements without the scale/offset values calculated