Page 1

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176 - TestEquipmentDepot.com

Keysight 34970A/34972A

Data Acquisition/Switch Unit

Service Guide

Page 2

Notices

CAUTION

WARNING

Copyright Notice

© Keysight Technologies 2009 - 2019

No part of this manual may be repro-

duced in any form or by any means

(including electronic storage and

retrieval or translation into a foreign

language) without prior agreement and

written consent from Keysight Technologies as governed by United States and

international copyright laws.

Manual Part Number

34972-90010

Edition

Edition 7, April 2019

Printed in:

Printed in Malaysia

Published by:

Keysight Technologies

Bayan Lepas Free Industrial Zone,

11900 Penang, Malaysia

Trademarks

Adobe, the Adobe Logo, Acrobat and

the Acrobat Logo are trademarks of

Adobe Systems Incorporated.

Microsoft is either a registered trademark or a trademark of Microsoft Corporation in the United States and/or

other countries.

Windows and MS Windows are U.S.

registered trademarks of Microsoft Corporation.

Technology Licenses

The hardware and/or software

described in this document are furnished under a license and may be

used or copied only in accordance with

the terms of such license.

Declaration of Conformity

Declarations of Conformity for this

product and for other Keysight products may be downloaded from the

Web. Go to http://www.keysight.com/

go/conformity. You can then search by

product number to find the latest Declaration of Conformity.

U.S. Government Rights

The Software is “commercial computer

software,” as defined by Federal Acquisition Regulation (“FAR”) 2.101. Pursuant to FAR 12.212 and 27.405-3 and

Department of Defense FAR Supplement (“DFARS”) 227.7202, the U.S.

government acquires commercial computer software under the same terms

by which the software is customarily

provided to the public. Accordingly,

Keysight provides the Software to U.S.

government customers under its standard commercial license, which is

embodied in its End User License

Agreement (EULA), a copy of which can

be found at http://www.keysight.com/

find/sweula. The license set forth in the

EULA represents the exclusive authority

by which the U.S. government may use,

modify, distribute, or disclose the Software. The EULA and the license set

forth therein, does not require or permit, among other things, that Keysight:

(1) Furnish technical information

related to commercial computer software or commercial computer software

documentation that is not customarily

provided to the public; or (2) Relinquish

to, or otherwise provide, the government rights in excess of these rights

customarily provided to the public to

use, modify, reproduce, release, perform, display, or disclose commercial

computer software or commercial computer software documentation. No

additional government requirements

beyond those set forth in the EULA

shall apply, except to the extent that

those terms, rights, or licenses are

explicitly required from all providers of

commercial computer software pursuant to the FAR and the DFARS and are

set forth specifically in writing elsewhere in the EULA. Keysight shall be

under no obligation to update, revise or

otherwise modify the Software. With

respect to any technical data as defined

by FAR 2.101, pursuant to FAR 12.211

and 27.404.2 and DFARS 227.7102, the

U.S. government acquires no greater

than Limited Rights as defined in FAR

27.401 or DFAR 227.7103-5 (c), as

applicable in any technical data.

Warranty

THE MATERIAL CONTAINED IN THIS

DOCUMENT IS PROVIDED “AS IS,”

AND IS SUBJECT TO BEING

CHANGED, WITHOUT NOTICE, IN

FUTURE EDITIONS. FURTHER, TO THE

MAXIMUM EXTENT PERMITTED BY

APPLICABLE LAW, KEYSIGHT DISCLAIMS ALL WARRANTIES, EITHER

EXPRESS OR IMPLIED, WITH REGARD

TO THIS MANUAL AND ANY INFORMATION CONTAINED HEREIN, INCLUDING BUT NOT LIMITED TO THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. KEYSIGHT

SHALL NOT BE LIABLE FOR ERRORS

OR FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES IN CONNECTION

WITH THE FURNISHING, USE, OR

PERFORMANCE OF THIS DOCUMENT

OR OF ANY INFORMATION CONTAINED HEREIN. SHOULD KEYSIGHT

AND THE USER HAVE A SEPARATE

WRITTEN AGREEMENT WITH WARRANTY TERMS COVERING THE MATERIAL IN THIS DOCUMENT THAT

CONFLICT WITH THESE TERMS, THE

WARRANTY TERMS IN THE SEPARATE

AGREEMENT SHALL CONTROL.

Safety Information

A CAUTION notice denotes a hazard. It

calls attention to an operating procedure, practice, or the like that, if not

correctly performed or adhered to,

could result in damage to the product

or loss of important data. Do not proceed beyond a CAUTION notice until

the indicated conditions are fully

understood and met.

A WARNING notice denotes a hazard. It

calls attention to an operating procedure, practice, or the like that, if not

correctly performed or adhered to,

could result in personal injury or death.

Do not proceed beyond a WARNING

notice until the indicated conditions are

fully understood and met.

2 Keysight 34970A/34972A Service Guide

Page 3

Software Updates/Licenses

Periodically, Keysight releases software updates to fix known defects and

incorporate product enhancements. To search for software updates and the latest

documentation for your product, go to the product page at:

A portion of the software in this product is licensed under terms of the General

Public License Version 2 (“GPLv2”). The text of the license and source code can be

found at:

This product utilizes Microsoft Windows CE. Keysight highly recommends that all

Windows-based computers connected to Windows CE instruments utilize current

anti-virus software. For more information, go to the product page at:

Keysight 34970A/34972A Service Guide 3

Page 4

Safety Symbols

CAT I

The following symbols on the instrument and in the documentation indicate

precautions which must be taken to maintain safe operation of the instrument.

Alternating current (AC) Frame or chassis (ground) terminal

Caution, risk of electric shock

Standby supply. Unit is not completely

disconnected from AC mains when

switch is off.

IEC Measurement

Caution, risk of danger (refer to this

manual for specific Warning or Caution

information)

Protective earth (ground) terminal

4 Keysight 34970A/34972A Service Guide

Page 5

Safety Considerations

Read the information below before using this instrument.

The following general safety precautions must be observed during all phases of

operation, service, and repair of this instrument. Failure to comply with these

precautions or with specific warnings elsewhere in this manual violates safety

standards for design, manufacture, and intended use of the instrument. Keysight

Technologies assumes no liability for the customer’s failure to comply with these

requirements.

General

Do not use this product in any manner not specified by the manufacturer. The

protective features of this product may be impaired if it is used in a manner not

specified in the operation instructions.

Before Applying Power

Verify that all safety precautions are taken. Make all connections to the unit before

applying power and select the appropriate power line voltage on the fuse module.

Ground the Instrument

This product is provided with protective earth terminals. To minimize shock

hazard, the instrument must be connected to the ac power mains through a

grounded power cable, with the ground wire firmly connected to an electrical

ground (safety ground) at the power outlet. Any interruption of the protective

(grounding) conductor or disconnection of the protective earth terminal will cause

a potential shock hazard that could result in personal injury.

Do Not Operate in an Explosive Atmosphere

Do not operate the instrument in the presence of flammable gases or fumes.

Keysight 34970A/34972A Service Guide 5

Page 6

Do Not Remove the Instrument Cover

NOTE

Only qualified, service-trained personal who are aware of the hazards involved

should remove instrument covers. Always disconnect the power cable and any

external circuits before removing the instrument cover.

Do Not Modify the Instrument

Do not install substitute parts or perform any unauthorized modification to the

product. Return the product to an Keysight Sales and Service Office for service

and repair to ensure that safety features are maintained.

In Case of Damage

Instruments that appear damaged or defective should be made inoperative and

secured against unintended operation until they can be repaired by qualified

service personnel.

Maximum transients on all inputs are limited to 1500 Vpk, referenced to

earth.Measurement is rated for CAT ‘others’, and terminals are not to be

connected directly to mains. Do not use this equipment to measure circuits

where transient overvoltages could exceed this level.

6 Keysight 34970A/34972A Service Guide

Page 7

Environmental Conditions

The 34970A/34972A is designed for indoor use and in an area with low

condensation. The table below shows the general environmental requirements for

this instrument.

Environmental condition Requirement

Temperature

Humidity

Altitude Up to 2000 m

Pollution degree 2

Operating condition

– 0 °C to 55 °C

Operating condition

– 20% to 80% RH at 40°C or less (non-condensing)

Keysight 34970A/34972A Service Guide 7

Page 8

Regulatory Markings

1SM1-

The CE mark is a registered trademark

of the European Community. This CE

mark shows that the product complies

with all the relevant European Legal

Directives.

The RCM mark is a registered

trademark of the Australian

Communications and Media Authority.

This text indicates that the instrument

is an Industrial Scientific and Medical

Group 1 Class A product (CISPER 11,

Clause 4).

The CSA mark is a registered

trademark of the Canadian

Standards Association.

This symbol indicates the time period

during which no hazardous or toxic

substance elements are expected to

leak or deteriorate during normal use.

Forty years is the expected useful life

of the product.

ICES/NMB-001 indicates that this ISM

device complies with the

Canadian ICES-001.

Cet appareil ISM est conforme a la

norme NMB-001 du Canada.

8 Keysight 34970A/34972A Service Guide

Page 9

Waste Electrical and Electronic Equipment (WEEE) Directive

This instrument complies with the WEEE Directive marking requirement. This

affixed product label indicates that you must not discard this electrical or

electronic product in domestic household waste.

Product category

With reference to the equipment types in the WEEE directive Annex 1, this

instrument is classified as a “Monitoring and Control Instrument” product.

The affixed product label is as shown below.

Do not dispose in domestic household waste.

Keysight 34970A/34972A Service Guide 9

Page 10

NOTE

Unless otherwise indicated, this manual applies to all serial numbers.

The Keysight Technologies 34970A/34972A combines precision measurement

capability with flexible signal connections for your production and development

test systems. Three module slots are built into the rear of the instrument to accept

any combination of data acquisition or switching modules. The combination of

data logging and data acquisition features makes this instrument a versatile

solution for your testing requirements now and in the future.

Convenient Data Logging Features

– Direct measurement of thermocouples, RTDs, thermistors, DC voltage, AC

voltage, resistance, DC current, AC current, frequency, and period

– Interval scanning with storage of up to 50,000 time-stamped readings

– Independent channel configuration with function, Mx+B scaling, and al

limits available on a per-channel basis

– Intuitive user interface with knob for quick channel selection, menu navigation,

and data entry from the front panel

– Portable, ruggedized case with non-skid feet

®

– BenchLink Data Logger 3 Software for Microsoft

Windows ® included

arm

Flexible Data Acquisition/Switching Features

– 6½-digit multimeter accuracy, stability, and noise rejection

– Up to 60 channels per instrument (120 single-ended channels)

– Reading rates up to 500 readings per second on a single channel and scan

rates up to 250 channels per second

– Choice of multiplexing, matrix, general-purpose Form C switching, RF

switching, digital I/O, totalize, and 16-bit analog output functions

– GPIB (IEEE-488) interface and RS-232 interface are standard on the 34970A.

Local Area Network (LAN) and Universal Serial Bus (USB) are standard on the

34972A.

–SCPI (Standard Commands for Programmable Instruments) compatibility

10 Keysight 34970A/34972A Service Guide

Page 11

The Front Panel at a Glance

Denotes a menu key. See the next page for details on menu operation.

1 State Storage / Remote Interface Menus

2 Scan Start / Stop Key

3 Measurement Configuration Menu

4 Scaling Configuration Menu

5 Alarm / Alarm Output Configuration Menu

6 Scan-to-Scan Interval Menu

7 Scan List Single Step / Read Key

8 Advanced Measurement / Utility Menus

9 Low-Level Module Control Keys

10 Single-Channel Monitor On / Off Key

11 View Scanned Data, Alarms, Errors Menu

12 Shift / Local Key

13 Knob

14 Navigation Arrow Keys

Keysight 34970A/34972A Service Guide 11

Page 12

The Front-Panel Menu at a Glance

Several of the front-panel keys guide you through menus to configure various

parameters of the instrument (see previous page). The following steps

demonstrate the menu structure using the key.

1 Press the menu key. You are automatically guided

2 Press the same menu key again to move to the

to the first level of the menu. Rotate the knob to

view the other choices on the first level of the

menu.

The menu will automatically time out after about

20 seconds of inactivity. You will be returned to

the operation in progress prior to entering the

menu.

next item of the menu. Typically, this is where you

choose parameter values for the selected

operation.

12 Keysight 34970A/34972A Service Guide

Page 13

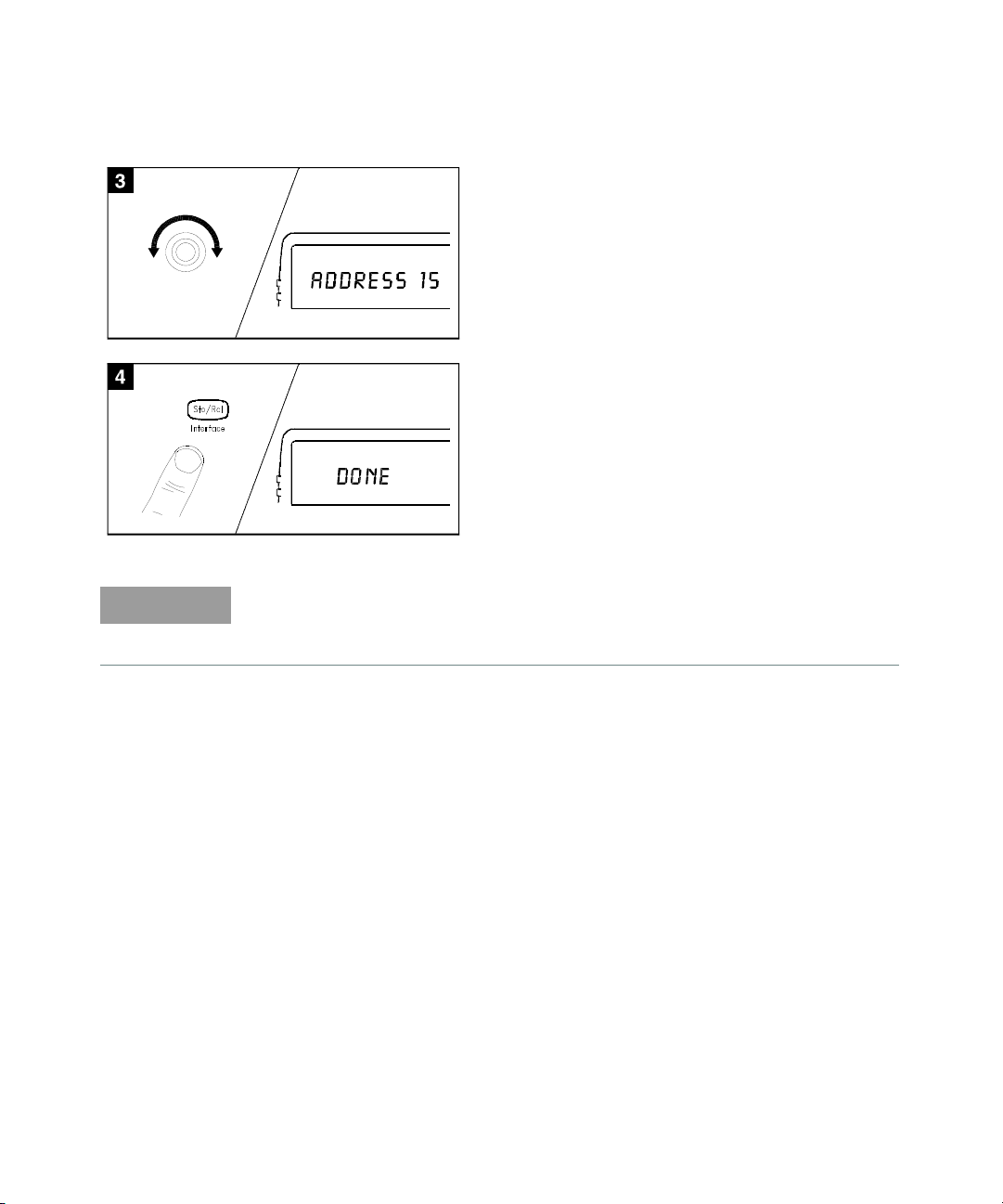

3 Rotate the knob to view the choices on this level

NOTE

of the menu. When you reach the end of the list,

rotate the knob in the opposite direction to view

all of the other choices.

The current selection is highlighted for emphasis.

All other choices are dimmed.

4 Press the same menu key again to accept the

change and exit the menu. A brief confirmation

message is displayed.

Tip: To review the current configuration of a specific menu, press the

menu key several times. A message NO CHANGES is displayed when you

exit the menu.

Keysight 34970A/34972A Service Guide 13

Page 14

Display Annunciators

SCAN

MON

VIEW Scanned readings, alarms, errors, or relay cycles are being viewed.

CONFIG Channel configuration is in progress on displayed channel.

ADRS Instrument is addressed to listen or talk over the remote interface.

RMT Instrument is in remote mode (remote interface).

ERROR

EXT Instrument is configured for an external scan interval.

ONCE

MEM (34970A) Reading memory overflow; new readings will overwrite the oldest readings.

MEM (34972A)

AUTO (34972A) USB logging is active.

LAST Viewed data is the last reading stored during most recent scan.

MIN Viewed data is the minimum reading stored during most recent scan.

MAX Viewed data is the maximum reading stored during most recent scan.

Scan is in progress or enabled. Press and hold again to turn off.

Monitor mode is enabled. Press again to turn off.

Measurement is in progress.

Hard ware or remote interface errors are detected. Press to read errors.

Scan Once mode is enabled. Press to initiate and hold key to disable.

A USB drive is connected to the instrument (annunciator on), or data is being

written to or read from the USB drive (annunciator flashing).

SHIFT

4W 4-wire function is in use on displayed channel.

OC Offset compensation is enabled on displayed channel.

has been pressed. Press again to turn off.

14 Keysight 34970A/34972A Service Guide

Page 15

Alarms are enabled on displayed channel.

Mx+B scaling is enabled on displayed channel.

HI or LO alarm condition has occurred on indicated alarms.

New serial number prefixes start with MY59000101 and SG59000101.

Keysight 34970A/34972A Service Guide 15

Page 16

The 34970A Rear Panel at a Glance

WARNING

1 Slot Identifier (100,200, 300)

2 Ext Trig Input / Alarm Outputs / Channel

Advance Input / Channel Closed Output

3 RS-232 Interface Connector

Use the Menu to:

– Select the GPIB or RS-232 interface (see Chapter 2).

– Set the GPIB address (see Chapter 2).

– Set the RS-232 baud rate, parity, and flow control mode (see Chapter 2).

4 Power-Line Fuse-Holder Assembly

5 Power-Line Voltage Setting

6 Chassis Ground Screw

7 GPIB (IEEE-488) Interface Connector

For protection from electrical shock, the power cord ground must not be

defeated. If only a two-contact electrical outlet is available, connect the

instrument’s chassis ground screw (see above) to a good earth ground.

16 Keysight 34970A/34972A Service Guide

Page 17

The 34972A Rear Panel at a Glance

WARNING

For serial number MY59000100 & SG59000100 and below.

Keysight 34970A/34972A Service Guide 17

1 Slot Identifier (100,200, 300)

2 Chassis Ground Screw

3 Ext Trig Input / Alarm Outputs / Channel

Advance Input / Channel Closed Output

Use the Menu to:

– Select and configure the LAN and USB interfaces (see Chapter 2).

[a] Under some conditions, while using the USB interface with the 34972A, you may experience connection or data

loss in the presence of an electrical transient from the main power line. You can re-establish the USB

communication by performing a reboot (cycle power) on the instrument. You can make the USB connection less

susceptible to a potential power line transient by inserting a USB hub in the connection between the computer and

the instrument.

4 Power-Line Fuse-Holder Assembly

5 LAN Connector

6 USB Drive Connector

7 USB Interface Connector

[a]

For protection from electrical shock, the power cord ground must not be

defeated. If only a two-contact electrical outlet is available, connect the

instrument’s chassis ground screw (see above) to a good earth ground.

Page 18

For serial number MY59000101 & SG59000101 and above.

WARNING

18 Keysight 34970A/34972A Service Guide

1 Slot Identifier (100,200, 300)

2 Chassis Ground Screw

3 Ext Trig Input / Alarm Outputs / Channel

Advance Input / Channel Closed Output

Use the Menu to:

– Select and configure the LAN and USB interfaces (see Chapter 2).

4 Power-Line Fuse-Holder Assembly

5 LAN Connector

6 USB Drive Connector

7 USB Interface Connector

For protection from electrical shock, the power cord ground must not be

defeated. If only a two-contact electrical outlet is available, connect the

instrument’s chassis ground screw (see above) to a good earth ground.

Page 19

The Plug-In Modules at a Glance

For complete specifications on each plug-in modules, refer to the module

sections in Chapter 1.

34901A 20-Channel Armature Multiplexer

– 20 channels of 300 V switching

– Two channels for DC or AC current measurements (100 nA to 1A)

– Built-in thermocouple reference junction

– Switching speed of up to 60 channels per second

– Connects to the internal multimeter

– For detailed information and a module diagram, see page 151.

Each of the 20 channels switches both HI and LO inputs, thus providing fully

isolated inputs to the internal multimeter. The module is divided into two banks of

10 two-wire channels each. When making four-wire resistance measurements,

channels from Bank A are automatically paired with channels from Bank B. Two

additional fused channels are included on the module (22 channels total) for

making calibrated DC or AC current measurements with the internal multimeter

(external shunt resistors are not required). You can close multiple channels on this

module only if you have not configured any channels to be part of the scan list.

Otherwise, all channels on the module are break-before-make.

34902A 16-Channel Reed Multiplexer

– 16 channels of 300 V switching

– Built-in thermocouple reference junction

– Switching speed of up to 250 channels per second

– Connects to the internal multimeter

– For detailed information and a module diagram, see page 153.

Use this module for high-speed scanning and high-throughput automated test

applications. Each of the 16 channels switches both HI and LO inputs, thus

providing fully isolated inputs to the internal multimeter. The module is divided

into two banks of eight two-wire channels each. When making four-wire

resistance measurements, channels from Bank A are automatically paired with

channels from Bank B. You can close multiple channels on this module only if you

Keysight 34970A/34972A Service Guide 19

Page 20

have not configured any channels to be part of the scan list. Otherwise, all

channels on the module are break-before-make.

34903A 20-Channel Actuator / General-Purpose Switch

– 300 V, 1 A actuation and switching

– SPDT (Form C) latching relays

– Breadboard area for custom circuits

– For detailed information and a module diagram, see page 155.

Use this module for those applications that require high-integrity contacts or

quality connections of non-multiplexed signals. This module can switch 300 V, 1 A

(50 W maximum switch power) to your device under test or to actuate external

devices. Screw terminals on the module provide access to the Normally-Open,

Normally-Closed, and Common contacts for each of the 20 switches. A

breadboard area is provided near the screw terminals to implement custom

circuitry, such as simple filters, snubbers, or voltage dividers.

34904A 4x8 Two-Wire Matrix Switch

– 32 two-wire crosspoints

– Any combination of inputs and outputs can be connected at a time

– 300 V, 1 A switching

– For detailed information and a module diagram, see page 156.

Use this module to connect multiple instruments to multiple points on your device

under test at the same time. You can connect rows and columns between multiple

modules to build larger matrices such as 8x8 and 4x16, with up to 96 crosspoints

in a single mainframe.

34905/6A Dual 4-Channel RF Multiplexers

– 34905A (50Ω) / 34906A (75Ω)

– 2 GHz bandwidth with on-board SMB connections

– 1 GHz bandwidth with SMB-to-BNC adapter cables provided

– For detailed information and a module diagram, see page 158.

20 Keysight 34970A/34972A Service Guide

Page 21

These modules offer wideband switching capabilities for high frequency and

pulsed signals. Each module is organized in two independent banks of 4-to-1

multiplexers. Both modules offer low crosstalk and excellent insertion loss

performance. To create larger RF multiplexers, you can cascade multiple banks

together. Only one channel in each bank may be closed at a time.

34907A Multifunction Module

– Two 8-bit Digital Input/Output ports, 400 mA sink, 42 V open collector

– 100 kHz Totalize input with 1 Vpp sensitivity

– Two 16-bit, ±12 V Calibrated Analog Outputs

– For detailed information and module block diagrams, see page 162.

Use this module to sense status and control external devices such as solenoids,

power relays, and microwave switches. For greater flexibility, you can read digital

inputs and the count on the totalizer during a scan.

34908A 40-Channel Single-Ended Multiplexer

– 40 channels of 300 V single-ended (common LO) switching

– Built-in thermocouple reference junction

– Switching speed of up to 60 channels per second

– Connects to the internal multimeter

– For detailed information and a module diagram, see page 160.

Use this module for high-density switching applications which require single-wire

inputs with a common LO. All relays are break-before-make to ensure that only

one relay is connected at any time.

Keysight 34970A/34972A Service Guide 21

Page 22

In This Book

Specifications

and plug-in modules.

Quick Start

front-panel features.

Front-Panel Overview

describes some of the instrument’s menu features.

Calibration Procedures

adjustment procedures for the instrument.

Theory of Operation

to the operation the instrument.

Service

Technologies for servicing, or for servicing it yourself. It also contains a list of

replaceable parts.

If you have questions relating to the operation of the 34970A/34972A, call

1-800-452-4844 in the United States, or contact your nearest Keysight

Technologies Sales Office.

If your 34970A/34972A fails within one year of original purchase, Keysight will

replace it free of charge. Call 1-800-829-4444 and select “Option 3” followed by

“Option 1”.

Chapter 6 provides guidelines for returning your instrument to Keysight

Chapter 1 lists the technical specifications for the mainframe

Chapter 2 helps you get familiar with a few of the instrument’s

Chapter 3 introduces you to the front-panel menus and

Chapter 4 provides calibration, verification, and

Chapter 5 describes block and circuit level theory related

22 Keysight 34970A/34972A Service Guide

Page 23

Table of Contents

Software Updates/Licenses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Before Applying Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Ground the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Do Not Operate in an Explosive Atmosphere . . . . . . . . . . . . . . . . . . .5

Do Not Remove the Instrument Cover . . . . . . . . . . . . . . . . . . . . . . . .6

Do Not Modify the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

In Case of Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Regulatory Markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Waste Electrical and Electronic Equipment (WEEE) Directive . . . . . . . .9

Product category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Sales and Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

The Front Panel at a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

The Front-Panel Menu at a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Display Annunciators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

The 34970A Rear Panel at a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . .16

The 34972A Rear Panel at a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . .17

The 34972A Rear Panel at a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . .18

The Plug-In Modules at a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

In This Book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

1Specifications

2Quick Start

Quick Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

To Prepare the Instrument for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

To Connect Wiring to a Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Keysight 34970A/34972A Service Guide 23

Page 24

To Set the Time and Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

To Configure a Measurement Channel . . . . . . . . . . . . . . . . . . . . . . . . . 37

To Monitor a Single Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

To Close a Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

If the Instrument Does Not Turn On . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

To Adjust the Carrying Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

To Rack Mount the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3 Front-Panel Overview

Front-Panel Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Front-Panel Menu Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

To Unsecure for Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

To Secure Against Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

To Change the Security Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

To Perform a Zero Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

To Apply Mx+B Scaling to Measurements . . . . . . . . . . . . . . . . . . . . . . . 57

To Read the Relay Cycle Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

To Read a Digital Input Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

To Write to a Digital Output Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

To Read the Totalizer Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

To Output a DC Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

4 Calibration Procedures

Calibration Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Keysight Technologies Calibration Services . . . . . . . . . . . . . . . . . . . . . 66

Calibration Interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Adjustment is Recommended . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Time Required for Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Automating Calibration Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

24 Keysight 34970A/34972A Service Guide

Page 25

Recommended Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Input Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Calibration Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

To Unsecure the Instrument Without the Security Code . . . . . . . . .72

Calibration Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

Calibration Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Aborting a Calibration in Progress . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Test Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Performance Verification Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Quick Performance Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Performance Verification Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Internal DMM Verification Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Zero Offset Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Gain Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

Optional AC Performance Verification Tests . . . . . . . . . . . . . . . . . . . . .87

Internal DMM Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Zero Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Gain Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

–10 VDC Adjustment Procedure (Optional) . . . . . . . . . . . . . . . . . . . . . .92

Plug-in Module Test Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . .94

Relay Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

Relay Cycle Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

(Optional) 34901A Relay Contact Resistance Verification . . . . . . . .97

(Optional) 34902A Relay Contact Resistance Verification . . . . . . .104

(Optional) 34903A Relay Contact Resistance Verification . . . . . . .109

(Optional) 34904A Relay Contact Resistance Verification . . . . . . .110

(Optional) 34905/06A Relay Contact Resistance Verification . . . .113

(Optional) 34908A Relay Contact Resistance Verification . . . . . . .114

Thermocouple Reference Junction (Optional) . . . . . . . . . . . . . . . . . . .120

Thermocouple Reference Junction Verification . . . . . . . . . . . . . . .120

Keysight 34970A/34972A Service Guide 25

Page 26

Thermocouple Reference Junction Adjustments . . . . . . . . . . . . . . 121

34907A Analog Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Analog Output Verification Test . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Analog Output Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

5Theory of Operation

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

System Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Floating Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Earth-Referenced Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Analog Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Digital Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Internal DMM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

DMM Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Input Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Ohms Current Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

AC Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

A-to-D Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Switch Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Switch Module Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Relay Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

34901A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

34902A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

34903A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

34904A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

34905A/34906A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

34908A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Multifunction Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

26 Keysight 34970A/34972A Service Guide

Page 27

Multifunction Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .162

Totalizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .164

Analog Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .165

Digital I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .166

6Service

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .170

Operating Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .171

Types of Service Available . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .172

Repackaging for Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .173

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .173

Electrostatic Discharge (ESD) Precautions . . . . . . . . . . . . . . . . . . . . .174

Surface Mount Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .174

To Replace the Power-Line Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175

Troubleshooting Hints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175

Self-Test Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .179

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .184

General Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .185

Internal DMM Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .186

Front Panel Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .187

Additional Chassis Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . .188

Plug-In Module Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .189

Recyclable Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .191

Replaceable Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .194

To Order Replaceable Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .194

Parts List for 34970A/34972A and 34901A . . . . . . . . . . . . . . . . . .194

Keysight 34970A/34972A Service Guide 27

Page 28

THIS PAGE HAS BEEN INTENTIONALLY LEFT BLANK.

28 Keysight 34970A/34972A Service Guide

Page 29

Keysight 34970A/34972A Data Acquisition/Switch Unit

Service Guide

1 Specifications

For the specifications and characteristics of the 34970A/34972A Data

Acquisition/Switch Unit, refer to the datasheet at

http://literature.cdn.keysight.com/litweb/pdf/5965-5290EN.pdf

29

Page 30

1 Specifications

THIS PAGE HAS BEEN INTENTIONALLY LEFT BLANK.

30 Keysight 34970A/34972A Service Guide

Page 31

Keysight 34970A/34972A Data Acquisition/Switch Unit

Service Guide

2 Quick Start

Quick Start 32

To Prepare the Instrument for Use 33

To Connect Wiring to a Module 34

To Set the Time and Date 36

To Configure a Measurement Channel 37

To Monitor a Single Channel 38

To Close a Channel 39

If the Instrument Does Not Turn On 41

To Adjust the Carrying Handle 44

To Rack Mount the Instrument 45

31

Page 32

2Quick Start

Quick Start

One of the first things to do with your instrument is to become acquainted with

the front panel. We have written the exercises in this chapter to prepare the

instrument for use and help you get familiar with some of its front-panel

operations.

The front panel has several groups of keys to select various functions and

operations. A few keys have a shifted function printed in blue below the key. To

perform a shifted function, press (the SHIFT annunciator will turn on). Then,

press the key that has the desired label below it. For example, to select the Utility

Menu, press .

If you accidentally press , just press it again to turn off the SHIFT

annunciator.

This chapter is divided into the following sections:

– “To Prepare the Instrument for Use” on page 33

– “To Connect Wiring to a Module” on page 34

– “To Set the Time and Date” on page 36

– “To Configure a Measurement Channel” on page 37

– “To Monitor a Single Channel” on page 38

– “To Close a Channel” on page 39

– “If the Instrument Does Not Turn On” on page 41

– “” on page 43

– “To Rack Mount the Instrument” on page 45

32 Keysight 34970A/34972A Service Guide

Page 33

To Prepare the Instrument for Use

1 Check the list of supplied items.

Verify that you have received the following items with your instrument. If

anything is missing, contact your nearest Keysight Technologies Sales Office.

–One power cord.

–One User’s Guide.

–This Service Guide.

–One Quick Reference Guide.

– Certificate of Calibration (if you ordered the internal DMM).

– BenchLink Data Logger 3 Software CD-ROM.

– Quick Start Package (if you ordered the internal DMM):

– One RS-232 cable.

– One J-type thermocouple and a flatblade screwdriver.

– Any plug-in modules that you ordered are delivered in a separate shipping

container.

2 Verify that the fuse on the back is set to the proper voltage range for your

AC power.

3 Connect the power cord and turn on the instrument.

Quick Start 2

The front-panel display will light up briefly while the instrument performs its

power-on self-test. The instrument initially powers up with all measurement

channels turned off. To review the power-on display with all annunciators

turned on, hold down

does not turn on properly, see page 41.

4 Perform a complete self-test.

The complete self-test performs a more extensive set of tests than those

performed at power-on. Hold down as you turn on the instrument and

hold down the key until you hear a long beep. The self-test will begin when

you release the key following the beep.

Keysight 34970A/34972A Service Guide 33

as you turn on the instrument. If the instrument

Page 34

2Quick Start

– For detailed information on each module, refer to the

34970A/34972A User’s Guide.

– To reduce wear on the internal DMM relays, wire like

functions on adjacent channels.

– Use shielded twisted pair PTFE insulated cables to

reduce settling and noise errors.

– The diagrams on the next page show how to connect

wiring to a multiplexer module for each measurement

function.

20 AWG Typical

6 mm

4 Replace the module cover.

2 Connect wiring to the screw terminals.

Wiring Hints...

Slot Channel

Channel Number:

1 Remove the module cover.

3 Route wiring through strain relief.

5 Install the module into mainframe.

Cable Tie Wrap

(optional)

To Connect Wiring to a Module

34 Keysight 34970A/34972A Service Guide

Page 35

Quick Start 2

Thermocouple

2-Wire Ohms / RTD / Thermistor

Thermocouple Types: B, E, J, K, N, R, S, T

See the 34970A/34972A User’s Guide for

Ranges: 100, 1 k, 10 k, 100 k, 1 M, 10 M, 100 M

Ω

RTD Types: 0.00385, 0.00391

Thermistor Types, 2.2 k, 5 k, 10 k

DC Current / AC Current

Valid only on channels 21 and 22 on the 34901A

Ranges: 10 mA, 100 mA, 1A

Channel n (source) is automatically paired with Channel n

+10 (sense) on the 34901A, or

Channel n +8 (sense) on the 34902A.

Ranges: 100, 1 k, 10 k, 100 k, 1 M, 10 M, 100 MΩ

RTD Types: 0.00385, 0.00391

DC Voltage / AC Voltage / Frequency

Ranges: 100 mV, 1 V, 10 V, 100 V, 300 V

4-Wire Ohms / RTD

thermocouple color codes.

Keysight 34970A/34972A Service Guide 35

Page 36

2Quick Start

To Set the Time and Date

All readings during a scan are automatically time stamped and stored in

non-volatile memory. In addition, alarm data is time stamped and stored in a

separate non-volatile memory queue.

1 Set the time of day.

Use and to select the field to modify and turn the knob to change the

value. You can also edit the AM/PM field.

TIME 03:45 PM

2 Set the date.

Use and to select the field to modify and turn the knob to change the

value.

JUN 01 2002

36 Keysight 34970A/34972A Service Guide

Page 37

To Configure a Measurement Channel

NOTE

NOTE

Use this general procedure to configure a measurement channel.

1 Select the channel.

Turn the knob until the desired channel is shown on the right side of

front-panel display. The channel number is a three-digit number; the left-most

digit represents the slot number (100, 200, or 300) and the two digits on the

right indicate the channel number (102, 110, etc.).

You can use and to skip to the beginning of the previous or next slot.

2 Select the measurement parameters for the selected channel.

Use the knob to scroll through the measurement choices on each level of the

menu. When you press to make your selection, the menu automatically

guides you through all relevant choices to configure a measurement on the

selected function. When you have finished configuring the parameters, you are

automatically exited from the menu.

The present selection (or default) is displayed in full bright for easy

identification. When you make a different selection, the new choice is shown in

full bright and it becomes the default selection. The order of the choices

always remains the same; however, you always enter the menu at the current

(full bright) setting for each parameter.

Quick Start 2

The menu will time-out after about 20 seconds of inactivity and any changes

made previously will take effect.

Keysight 34970A/34972A Service Guide 37

Page 38

2Quick Start

To Monitor a Single Channel

You can use the Monitor function to continuously take readings on a single

channel, even during a scan. This feature is used during front panel calibration

procedures.

1 Select the channel to be monitored.

Only one channel can be monitored at a time but you can change the channel

being monitored at any time by turning the knob.

2 Enable monitoring on the selected channel.

Any channel that can be “read” by the instrument can be monitored (the MON

annunciator turns on). This includes any combination of temperature, voltage,

resistance, current, frequency, or period measurements on multiplexer

channels. You can also monitor a digital input port or the totalizer count on the

multifunction module.

To disable monitoring, press again.

38 Keysight 34970A/34972A Service Guide

Page 39

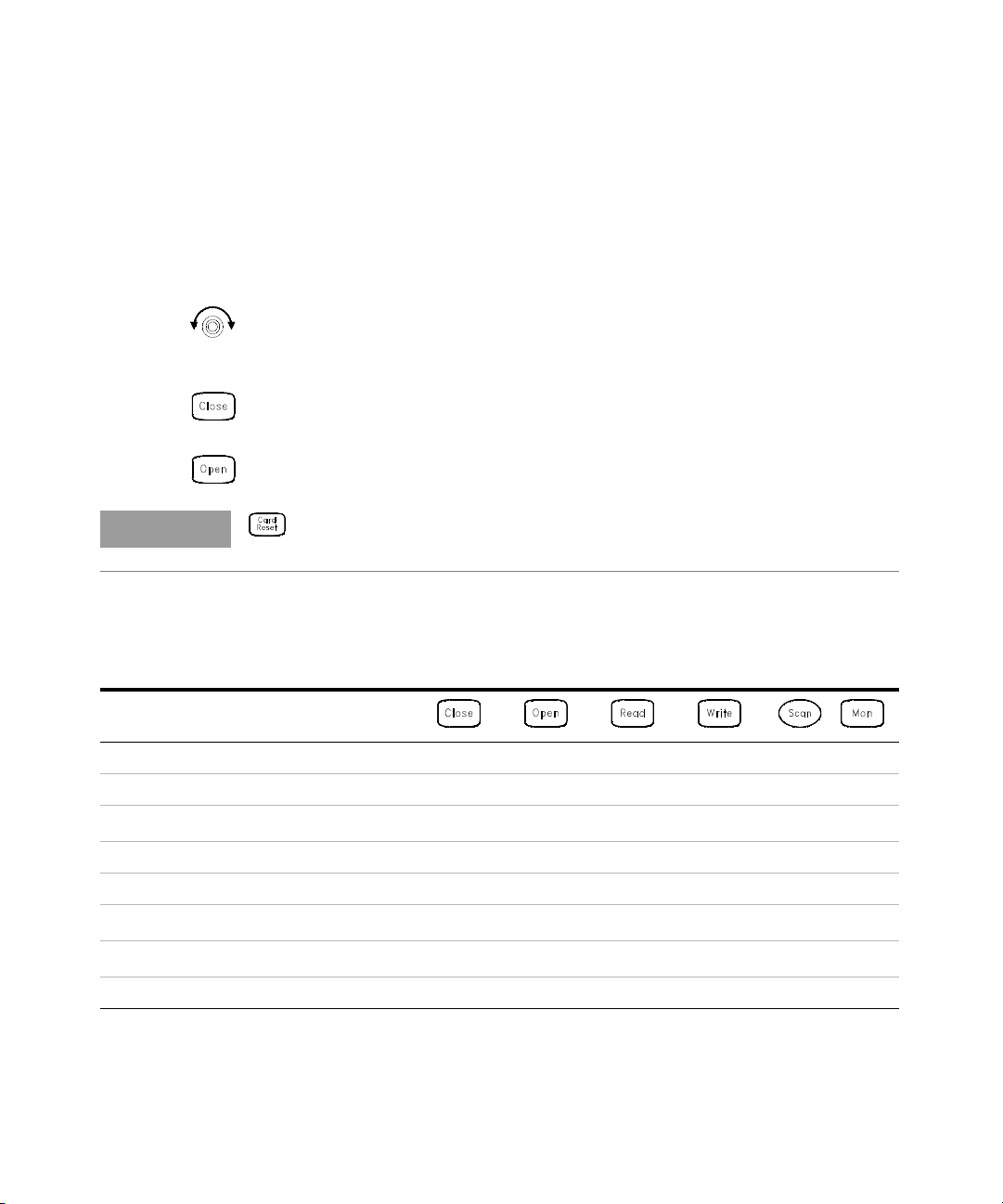

To Close a Channel

NOTE

,

On the multiplexer and switch modules, you can close and open individual relays

on the module. However, note that if you have already configured any multiplexer

channels for scanning, you cannot independently close and open individual relays

on that module.

1 Select the channel.

Turn the knob until the desired channel is shown on the right side of

front-panel display. For this example, select channel 213.

2 Close the selected channel.

3 Open the selected channel.

will sequentially open all channels on the mod ule in the selected slot.

The table below shows the low-level control operations available for each of

the plug-in modules.

Quick Start 2

Plug-In Mod ule

34901A 20-Channel Mux YYY Y

34902A 16-Channel Mux YYY Y

34908A 40-Channel Single-Ended Mux

34903A 20-Channel Actuator YY

34904A 4x8 Matrix YY

34905A Dual 4-Channel RF Mux (50Ω)

34906A Dual 4-Channel RF Mux (75Ω)

34907A Multifunction Module (DIO) YY Y

[a]

[b]

[b]

YYY Y

Y

Y

Keysight 34970A/34972A Service Guide 39

Page 40

2Quick Start

,

Plug-In Mod ule

34907A Multifunction Module (Totalizer) YY

34907A multifunction Module (DAC) Y

[a] Only one channel can be closed at a time on this module.

[b] Only one channel in each bank can be closed at a time on this module.

40 Keysight 34970A/34972A Service Guide

Page 41

If the Instrument Does Not Turn On

NOTE

NOTE

Use the following steps to help solve problems you might encounter when turning

on the instrument.

1 Verify that there is AC power to the instrument.

First, verify that the power cord is firmly plugged into the power receptacle on

the rear panel of the instrument. You should also make sure that the power

source you plugged the instrument into is energized. Then, verify that the

instrument is turned on.

The On/Standby switch is located on the lower left side of the front panel.

2 Verify the power-line voltage setting.

The line voltage is set to the proper value for your country when the

instrument is shipped from the factory. Change the voltage setting if it is not

correct. The settings are: 100, 120, 220, or 240 VAC.

– For 127 VAC operation, use the 120 VAC setting.

– For 230 VAC operation, use the 220 VAC setting.

Quick Start 2

See the next page if you need to change the line voltage setting.

3 Verify that the power-line fuse is good.

The instrument is shipped from the factory with a 500 mA fuse installed. This is

the correct fuse for all line voltages.

See the next page if you need to replace the power-line fuse.

To replace the 500 mAT, 250 V fuse, order Keysight part number 2110-0458.

Keysight 34970A/34972A Service Guide 41

Page 42

2Quick Start

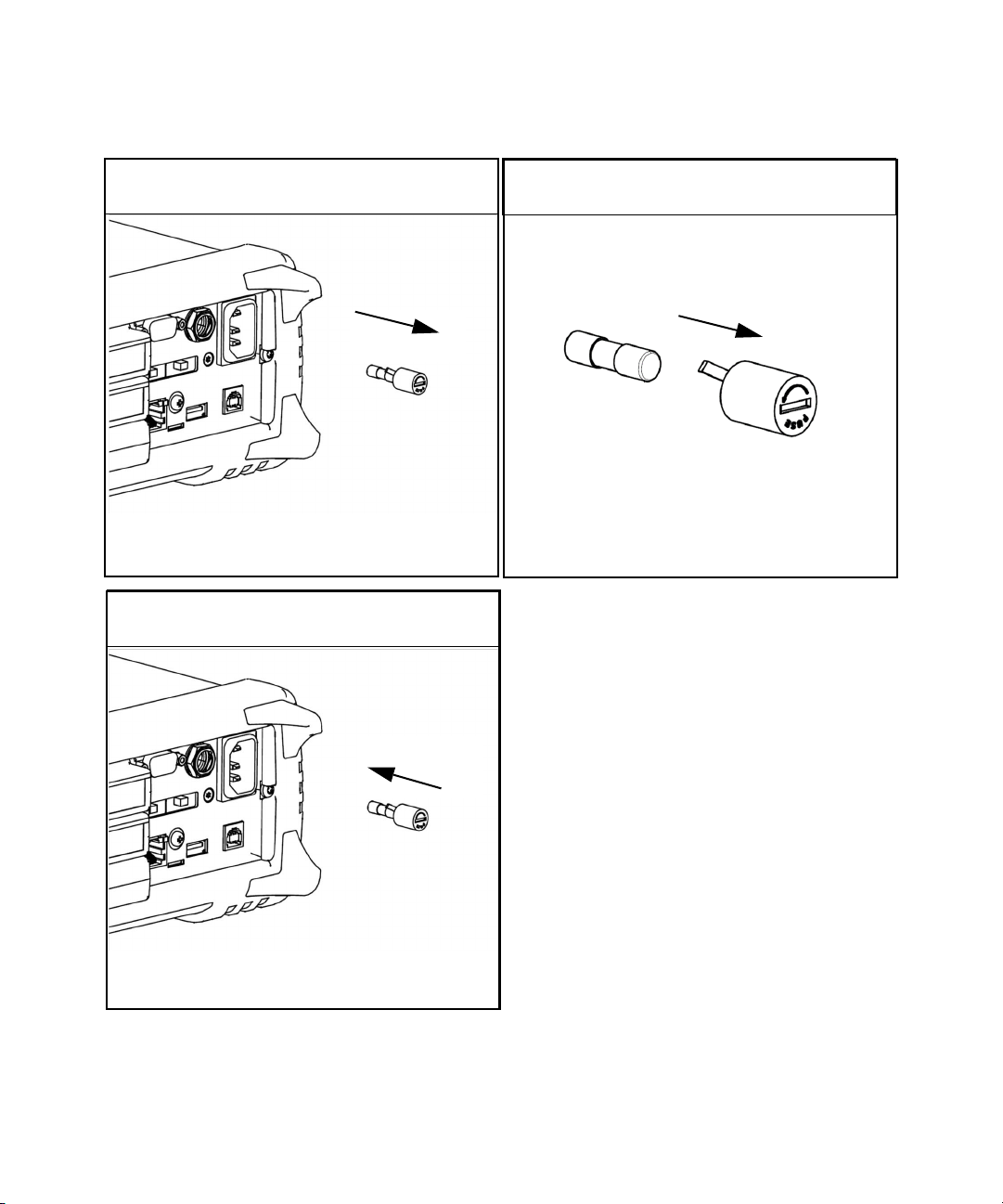

3 Rotate the line-voltage selector until the

correct voltage appears in the window.

1 Remove the power cord. Remove the

fuse-holder assembly from the rear panel.

100, 120 (127), 220 (230), or 240 VAC

2 Remove the line voltage selector from the

assembly.

4 Replace the fuse-holder assembly in the rear

panel.

Fuse: 500 mAT (for all line voltages)

Keysight Part Number: 2110-0458

Verify that the correct line voltage is selected and the power-line fuse is good.

42 Keysight 34970A/34972A Service Guide

Page 43

Quick Start 2

1 Remove the power cord. Remove the

fuse-holder assembly from the rear panel.

3 Replace the fuse-holder assembly in the rear

panel.

2 Remove the fuse from the assembly.

Fuse: 250 maT (for all line voltages)

Keysight Part Number: 2110-1704

New serial number prefixes start with MY59000101 and SG59000101.

Keysight 34970A/34972A Service Guide 43

Page 44

2Quick Start

Bench-top viewing position Carrying position

To Adjust the Carrying Handle

To adjust the position, grasp the handle by the sides and pull outward. Then,

rotate the handle to the desired position.

44 Keysight 34970A/34972A Service Guide

Page 45

To Rack Mount the Instrument

NOTE

To remove the handle, rotate it to the vertical position and pull the ends outward.

Front Rear (bottom view)

To remove the rubber bumper, stretch a corner and then slide it off.

You can mount the instrument in a standard 19-inch rack cabinet using one of

three optional kits available. Instructions and mounting hardware are included

with each rack-mounting kit. Any Keysight System II instrument of the same size

can be rack-mounted beside the 34970A/34972A.

Remove the carrying handle, and the front and rear rubber bumpers, before

rack-mounting the instrument.

Quick Start 2

Keysight 34970A/34972A Service Guide 45

Page 46

2Quick Start

To rack mount a single instrument, order adapter kit 5063-9240.

To rack mount two instruments side-by-side, order lock-link kit 5061-9694 and

flange kit 5063-9212. Be sure to use the support rails inside the rack cabinet.

To install one or two instruments in a sliding support shel f, order shelf 5063-9255,

and slide kit 1494-0015 (for a single instrument, also order filler panel 5002-3999).

46 Keysight 34970A/34972A Service Guide

Page 47

Keysight 34970A/34972A Data Acquisition/Switch Unit

Service Guide

3 Front-Panel Overview

Front-Panel Overview 48

Front-Panel Menu Reference 49

To Unsecure for Calibration 52

To Secure Against Calibration 53

To Change the Security Code 54

Error Messages 55

To Perform a Zero Adjustment 56

To Apply Mx+B Scaling to Measurements 57

To Read the Relay Cycle Count 58

To Read a Digital Input Port 59

To Write to a Digital Output Port 60

To Read the Totalizer Count 61

To Output a DC Voltage 62

47

Page 48

3 Front-Panel Overview

Front-Panel Overview

This chapter introduces you to the front-panel keys and menu operation. This

chapter does not give a detailed description of every front-panel key or menu

operation. It does, however, give you an overview of the front-panel menus and

many front-panel operations. See the Keysight 34970A/34972A User’s Guide for a

complete discussion of the instrument’s capabilities and operation.

This chapter is divided into the following sections:

– “Front-Panel Menu Reference” on page 49

– “To Unsecure for Calibration” on page 52

– “To Secure Against Calibration” on page 53

– “To Change the Security Code” on page 54

– “Error Messages” on page 55

– “To Perform a Zero Adjustment” on page 56

– “To Apply Mx+B Scaling to Measurements” on page 57

– “To Read the Relay Cycle Count” on page 58

– “To Read a Digital Input Port” on page 59

– “To Write to a Digital Output Port” on page 60

– “To Read the Totalizer Count” on page 61

– “To Output a DC Voltage” on page 62

48 Keysight 34970A/34972A Service Guide

Page 49

Front-Panel Menu Reference

This section gives an overview of the front-panel menus. The menus are designed

to automatically guide you through all parameters required to configure a

particular function or operation. The remainder of this chapter contains examples

of using the front-panel menus. New serial number prefixes start with

MY59000101 and SG59000101.

Configure the measurement parameters on the displayed channel.

– Select the measurement function (dc volts, ohms, etc.) on the displayed channel.

– Select transducer type for temperature measurements.

– Select units (°C, °F, or K) for temperature measurements.

– Select measurement range or autorange.

– Select measurement resolution.

– Copy and paste measurement configuration to other channels.

Configure the scaling parameters for the d isplayed channel.

Front-Panel Overview 3

– Set the gain (“M”) and offset (“B”) value for the displayed channel.

– Make a null measurement and store it as the offset value.

– Specify a custom label (RPM, PSI, etc.) for the displayed channel.

Configure alarms on the d isplayed channel.

– Select one of four alarms to report alarm conditions on the displayed channel.

– Configure a high limit, low limit, or both for the displayed channel.

– Configure a bit pattern that will generate an alarm (digital input only).

Keysight 34970A/34972A Service Guide 49

Page 50

3 Front-Panel Overview

Configure the four Alarm Output hardware lines.

– Clear the state of the four alarm output lines.

– Select the “Latch” or “Track” mode for the four alarm output lines.

– Select the slope (rising or falling edge) for the four alarm output lines.

Configure the event or action that controls the scan interval.

– Select the scan interval mode (interval, manual, external, or alarm).

– Select the scan count.

Configure the advanced measurement features on displayed channel.

– Set the integration time for measurements on the displayed channel.

– Set the channel-to-channel delay for scanning.

– Enable/disable the thermocouple check feature (T/C measurements only).

– Select the reference junction source (T/C measurements only).

– Set the low frequency limit (ac measurements only).

– Enable/disable offset compensation (resistance measurements only).

– Select the binary or decimal mode for digital operations (34907A only).

– Configure the totalizer reset mode (totalizer only).

– Select which edge is detected (rising or falling) for totalizer operations.

Configure system-related instrument parameters.

– Set the real-time system clock and calendar.

– Query the firmware revisions for the mainframe and installed modules.

– Select the instrument’s power-on configuration (last or factory reset).

– Enable/disable the internal DMM.

– Secure/unsecure the instrument for calibration.

50 Keysight 34970A/34972A Service Guide

Page 51

Front-Panel Overview 3

View readings, alarms, and errors.

– View the last 100 scanned readings from memory (last, min, max, and average).

– View the first 20 alarms in the alarm queue (reading and time alarm occurred).

– View up to 10 errors (34970A) or 20 errors (34972A) in the error queue.

– Read the number of cycles for the displayed relay (relay maintenance feature).

Store and recall instrument states.

– Store up to five instrument states in non-volatile memory.

– Assign a name to each storage location.

– Recall stored states, power-down state, factory reset state, or preset state.

Configure the remote interface (34970A).

– Select the GPIB address.

– Configure the RS-232 interface (baud rate, parity, and flow control).

Configure the remote interface (34972A).

– Configure the LAN settings (IP Address, Hostname, DHCP, etc.)

– Configure the USB settings (Enable, USB ID, etc.)

– Configure and use the USB drive (Logging, etc.)

Keysight 34970A/34972A Service Guide 51

Page 52

3 Front-Panel Overview

NOTE

To Unsecure for Calibration

You can unsecure the instrument either from the front panel or over the remote

interface. The instrument is secured when shipped from the factory and the

security code is set to “HP034970” or “AT034972”, depending on the product

number.

– Once you enter a security code, that code must be used for both front-panel

and remote operation. For example if you secure the instrument from the front

panel, you must use that same code to unsecure it from the remote interface.

– Press to enter the Utility menu.

When you first enter the Utility menu, the calibration entries toggle between CAL

SECURED and UNSECURE CAL. To unsecure the instrument, select UNSECURE

CAL and press . After entering the correct security code, press

When you return to the menu, you will see new choices CAL UNSECURED and

SECURE CAL.

If you enter the wrong secure code, NO MATCH is displayed and a new choice,

EXIT, is shown.

again.

52 Keysight 34970A/34972A Service Guide

Page 53

To Secure Against Calibration

You can secure the instrument either from the front panel or over the remote

interface. The instrument is secured when shipped from the factory and the

security code is set to “HP034970” or “AT034972”, depending on the product

number.

– Once you enter a security code, that code must be used for both front-panel

and remote operation. For example if you secure the instrument from the front

panel, you must use that same code to unsecure it from the remote interface.

– Press

When you enter the Utility menu, the calibration entries toggle between CAL

UNSECURED and SECURE CAL. To secure the instrument, select SECURE CAL

and press . After entering the desired security code, press

you return to the menu, you will see new choices CAL SECURED and UNSECURE

CAL.

to enter the Utility menu.

Front-Panel Overview 3

again. When

Keysight 34970A/34972A Service Guide 53

Page 54

3 Front-Panel Overview

To Change the Security Code

– To change the security code, you must first unsecure the instrument, and then

enter a new code. Make sure you have read the security code rules described

on page 71 before attempting to change the security code.

– To change the security code, first make sure that the instrument is unsecured.

Go to the SECURE CAL entry, enter the new security code, and press

instrument is now secured with the new code). Changing the code from the front

panel also changes the code as seen from the remote interface.

(the

54 Keysight 34970A/34972A Service Guide

Page 55

Error Messages

Error messages are retrieved in a first-in-first-out (FIFO) order.

Front-Panel Overview 3

When the ERROR annunciator is on, press

arrow keys to scroll the message in the display.

A list of the self-test errors messages and their meanings begins on page 179.

For a complete list of error messages and descriptions, see Chapter 6 in the

34970A/34972A User’s Guide.

to view error messages. use the

Keysight 34970A/34972A Service Guide 55

Page 56

3 Front-Panel Overview

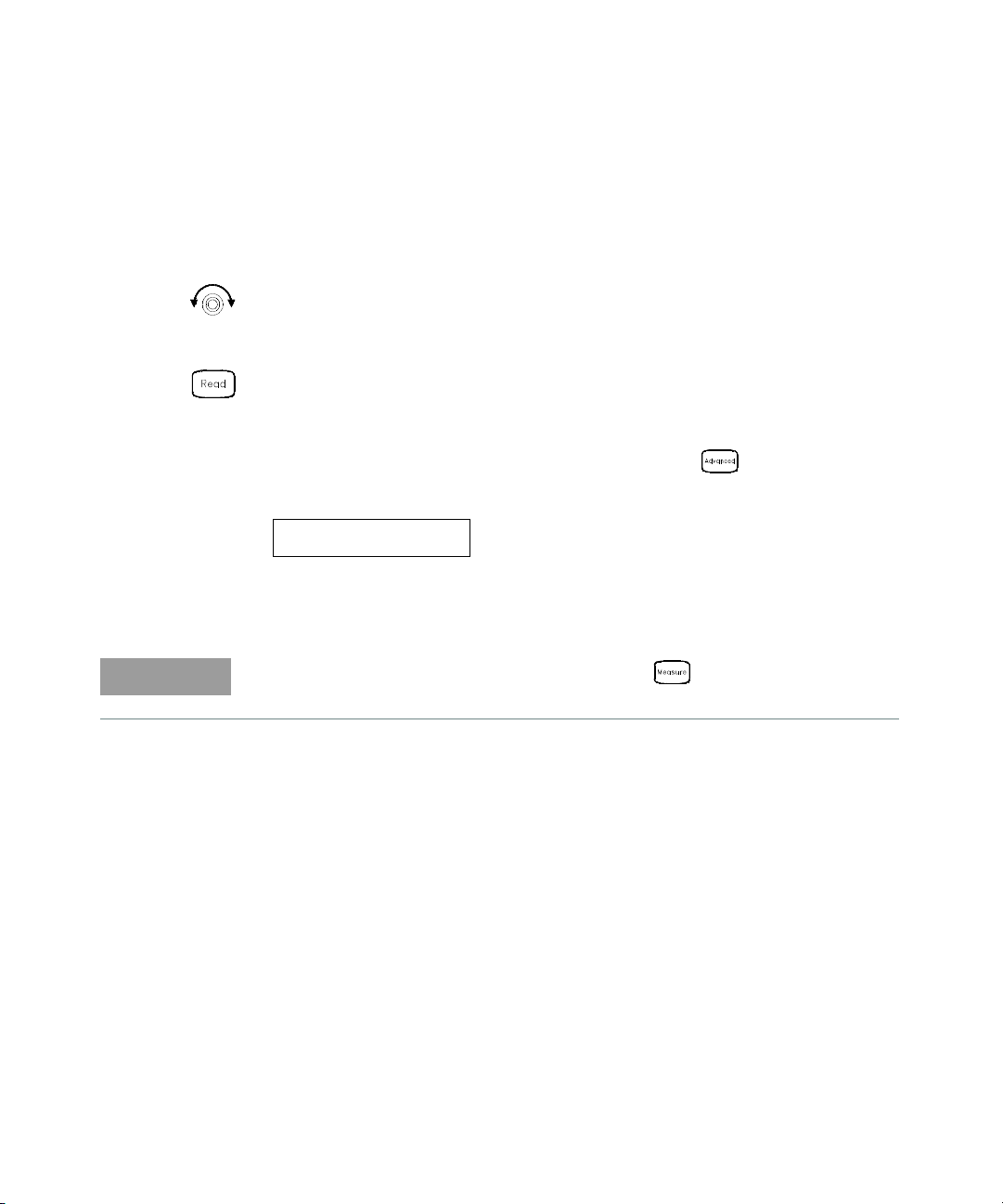

To Perform a Zero Adjustment

The instrument features closed case electronic calibration. No internal mechanical

adjustments are required. The instrument calculates correction factors based

upon an input reference value and stores the correction factors in non-volatile

memory. This procedure demonstrates making the zero adjustment from the front

panel. The gain adjustments are similar.

DO NOT perform this procedure before reading Chapter 4. Chapter 4 describes

this procedure, the required input connections, input signals, and test

considerations required for a valid adjustment.

1 Configure the channel.

You must configure a channel before applying performing the adjustment

procedure. Configure the channel to DC VOLTS and 6½ digits.

2 Apply the input signal.

In this example, the input signal is a copper short (see page 69).

3 Setup the calibration.

The display will show PERFORM CAL.

4 Set the adjustment value.

The display will show the a number. Edit the number to the actual input value.

For the Zero Adjustment, the input value is 0.000000.

+000.000,000 mVDC

5 Begin the adjustment.

The display will show the progress of the adjustment. When all the

adjustments are completed, the display will show done.

DONE

56 Keysight 34970A/34972A Service Guide

Page 57

To Apply Mx+B Scaling to Measurements

The scaling function allows you to apply a gain and offset to all readings on a

specified multiplexer channel during a scan. In addition to setting the gain (“M”)

and offset (“B”) values, you can also specify a custom measurement label for your

scaled readings (RPM, PSI, etc.).

1Configure the channel.

You must configure the channel (function, transducer type, etc.) before

applying any scaling values. If you change the measurement configuration,

scaling is turned off on that channel and the gain and offset values are reset

(M=1 and B=0).

2 Set the gain and offset values.

The scaling values are stored in non-volatile memory for the specified

channels. A Factory Reset turns off scaling and clears the scaling values on all

channels. An Instrument Preset or Card Reset does not clear the scaling values

and does not turn off scaling.

+1.000,000

Set Gain

Front-Panel Overview 3

-0.700,000 OHM

3 Select the custom label.

You can specify an optional three-character label for your scaled readings

(RPM, PSI, etc.). The default label is the standard engineering unit for the

selected function (VDC, OHM, etc.).

LABEL AS OHM

4 Scaling is now applied to the measurements.

Keysight 34970A/34972A Service Guide 57

Set Offset

Page 58

3 Front-Panel Overview

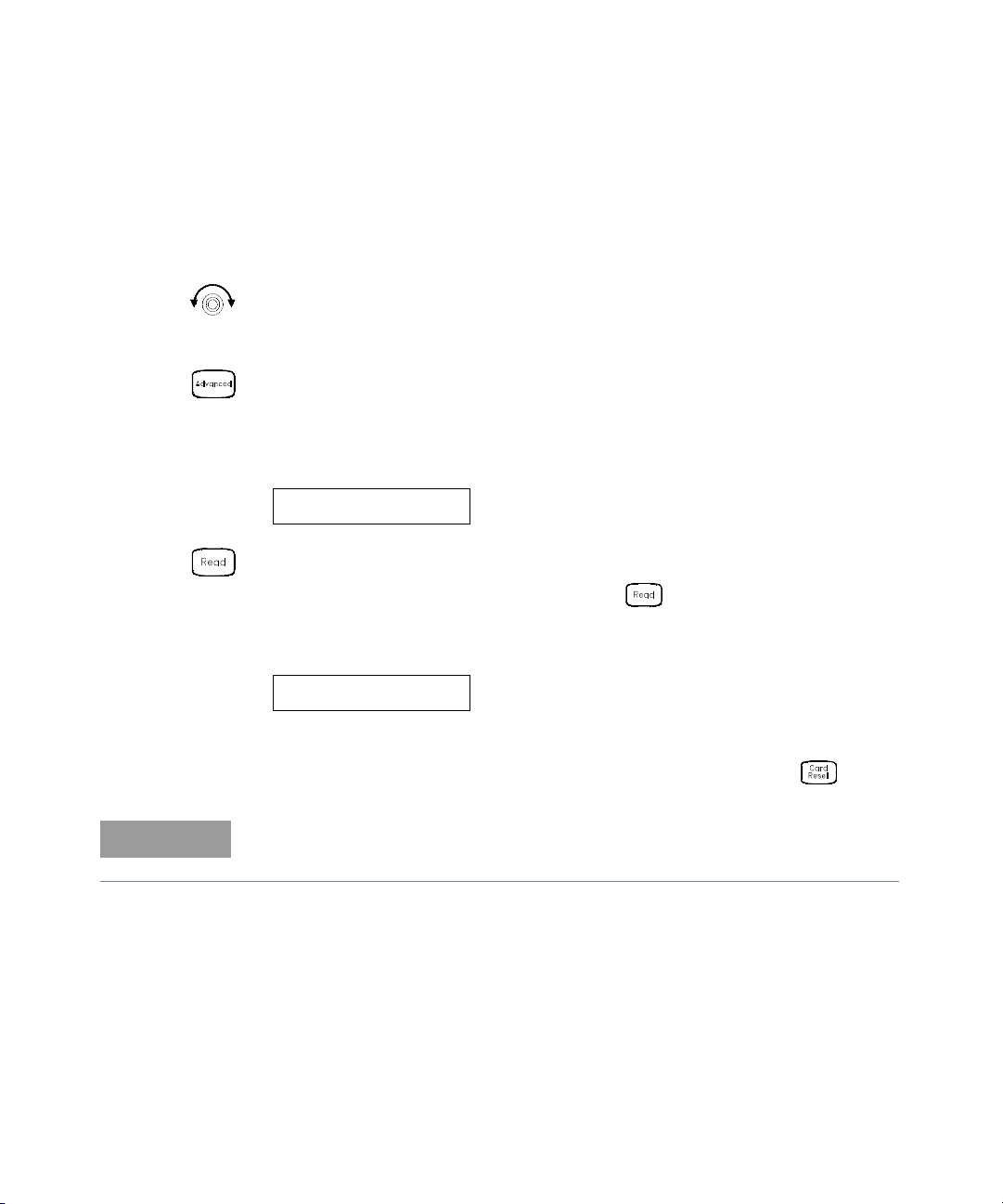

To Read the Relay Cycle Count

The instrument has a Relay Maintenance System to help you predict relay

end-of-life. The instrument counts the cycles on each relay in the instrument and

stores the total count in non-volatile memory on each switch module. You can use

this feature on any of the relay modules and the internal DMM.

– In addition to the channel relays, you can also query the count on backplane

relays and bank relays. Note that you cannot control the state of these relays

from the front panel but you can query the count.

– You can also query the state of the three relays on the internal DMM. These

relays are numbered “1”, “2”, and “3” (which correspond to relays K102, K103,

and K104 respectively). These relays open or close when a function or range is

changed on a module.

– The 34908A multiplexer contains 40 channels which are switched (HI only)

using only 20 relays. Each relay is used to switch HI on two different channels

(and only one channel can be closed at a time). The channels are arranged

such that channels 01 and 21 use different contacts on the same relay. The

remaining channels are also paired in the same manner (channels 02 and 22,

channels 03 and 23, etc.). Therefore, when you query the relay count on a

channel, the number reflects the number of times that the relay was closed.

For example, the relay count will always be the same on channels 01 and 21.

– For more information on relay life and load considerations, refer to “Relay Life

and Preventative Maintenance” in the 34970A/34972A User’s Guide.

– To read the count on the active channel, choose the following item and then

turn the knob. To read the count on the internal DMM relays, turn the knob

counterclockwise beyond the lowest numbered channel in the instrument. To

read the “hidden” relays, turn the knob clockwise beyond the highest

numbered channel in the current slot.

RELAY CYCLES

58 Keysight 34970A/34972A Service Guide

Page 59

To Read a Digital Input Port

NOTE

The multifunction module (34907A) has two non-isolated 8-bit input/output ports

which you can use for reading digital patterns. You can read the live status of the

bits on the port or you can configure a scan to include a digital read.

1 Select the Digital Input port.

Select the slot containing the multifunction module and continue turning the

knob until DIN is displayed (channel 01 or 02).

2 Read the specified port.

You can specify whether you want to use binary or decimal format. Once you

have selected the number base, it is used for all input or output operations on

the same port. To change the number base, press the key and select USE

BINARY or USE DECIMAL.

Front-Panel Overview 3

01010101 DIN

The bit pattern read from the port will be displayed until you press another key,

turn the knob, or until the display times out.

To add a digital input channel to a scan list, press and select the DIO READ

choice.

Binary Display Shown

Keysight 34970A/34972A Service Guide 59

Page 60

3 Front-Panel Overview

To Write to a Digital Output Port

The multifunction module (34907A) has two non-isolated 8-bit

input/output ports which you can use for outputting digital patterns.

1 Select the Digital Output port.

Select the slot containing the multifunction module and continue turning the

knob until DIN is displayed (channel 01 or 02).

2 Enter the bit pattern editor.

Notice that the port is now converted to an output port (DOUT).

00000000 DOUT

3 Edit the bit pattern.

Use the knob and or keys to edit the individual bit values. You can

specify whether you want to use binary or decimal format. Once you have

selected the number base, it is used for all input or output operations on the

same port. To change the number base, press the key and select USE

BINARY or USE DECIMAL.

240 DOUT

4 Output the bit pattern to the specified port.

The specified bit pattern is latched on the specified port. To cancel an output

operation in progress, wait for the display to time out.

Binary Display Shown

Decimal Display Shown

60 Keysight 34970A/34972A Service Guide

Page 61

To Read the Totalizer Count

NOTE

The multifunction module (34907A) has a 26-bit totalizer which can count pulses

at a 100 kHz rate. You can manually read the totalizer count or you can configure

a scan to read the count.

1 Select the totalizer channel.

Select the slot containing the multifunction module and continue turning the

knob until TOTALIZE is displayed (channel 03).

2 Configure the totalize mode.

The internal count starts as soon as you turn on the instrument. You can

configure the totalizer to reset the count to “0” after being read or it can count

continuously and be manually reset.

READ + RESET

3 Read the count.

The count is read once each time you press ; the count does not update

automatically on the display. As configured in this example, the count is

automatically reset to “0” each time you read it.

Front-Panel Overview 3

12345 TOT

The count will be displayed until you press another key, turn the knob, or until

the display times out. To manually reset the totalizer count, press .

To add a totalizer channel to a scan list, press and select the TOT READ choice.

Keysight 34970A/34972A Service Guide 61

Page 62

3 Front-Panel Overview

To Output a DC Voltage

The multifunction module (34907A) has two analog outputs capable of outputting

calibrated voltages between ±12 volts.

1 Select a DAC Output channel.

Select the slot containing the multifunction module and continue turning the

knob until DAC is displayed (channel 04 or 05).

2 Enter the output voltage ed itor.

+00.000 V DAC

3 Set the desired output voltage.

Use the knob and or keys to edit the individual digits.

+05.250VDAC

4 Output the voltage from the selected DAC.

The output voltage will be displayed until you press another key or turn the

knob. To manually reset the output voltage to 0 volts, press .

62 Keysight 34970A/34972A Service Guide

Page 63

Keysight 34970A/34972A Data Acquisition/Switch Unit

Service Guide

4 Calibration Procedures

Calibration Procedures 64

Keysight Technologies Calibration Services 66

Calibration Interval 66

Time Required for Calibration 67

Automating Calibration Procedures 67

Recommended Test Equipment 68

Input Connections 69

Calibration Security 71

Calibration Message 74

Calibration Count 74

Calibration Procedure 75

Aborting a Calibration in Progress 75

Test Considerations 76

Performance Verification Tests 77

Internal DMM Verification Tests 80

Optional AC Performance Verification Tests 87

Internal DMM Adjustments 88

–10 VDC Adjustment Procedure (Optional) 92

Plug-in Module Test Considerations 94

Relay Verification 96

Thermocouple Reference Junction (Optional) 120

34907A Analog Output 123

63

Page 64

4 Calibration Procedures

Calibration Procedures

This chapter contains procedures for verification of the instrument’s performance

and adjustment (calibration). These procedures are required only if the internal

DMM is installed. The chapter is divided into the following sections:

– “Keysight Technologies Calibration Services” on page 4

– “Calibration Interval” on page 4

– “Time Required for Calibration” on page 5

– “Automating Calibration Procedures” on page 5

– “Recommended Test Equipment” on page 6

– “Input Connections” on page 7

– “Calibration Security” on page 9

– “Calibration Message” on page 12

– “Calibration Count” on page 12

– “Calibration Procedure” on page 13

– “Aborting a Calibration in Progress” on page 13

– “Test Considerations” on page 14

– “Performance Verification Tests” on page 15

– “Internal DMM Verification Tests” on page 18

– “Optional AC Performance Verification Tests” on page 25

– “Internal DMM Adjustments” on page 26

– “–10 VDC Adjustment Procedure (Optional)” on page 30

– “Plug-in Module Test Considerations” on page 32

– “Relay Verification” on page 34

– “Thermocouple Reference Junction (Optional)” on page 58

– “34907A Analog Output” on page 61

64 Keysight 34970A/34972A Service Guide

Page 65

Calibration Procedures 4

Closed-Case Electronic Calibration

The instrument features closed-case electronic calibration. No internal

mechanical adjustments are required. The instrument calculates correction

factors based upon the input reference value you set. The new correction factors

are stored in non-volatile memory until the next calibration adjustment is

performed. Non-volatile EEPROM calibration memory does not change when

power has been off or after a remote interface reset.

Keysight 34970A/34972A Service Guide 65

Page 66

4 Calibration Procedures

Keysight Technologies Calibration Services

When your instrument is due for calibration, contact your local Keysight Service

Center for a low-cost recalibration. The 34970A/34972A is supported on

automated calibration systems which allow Keysight to provide this service at

competitive prices.

Calibration Interval

The instrument should be calibrated on a regular interval determined by the

measurement accuracy requirements of your application.

A 1-year interval is adequate for most applications. Accuracy specifications are

warranted only if adjustment is made at regular calibration intervals. Accuracy