Page 1

User’s Guide

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176 - TestEquipmentDepot.com

Publication Number 33220-90002 (order as 33220-90100 manual set)

Edition 4, May 2007

Copyright © 2003, 2005, 2007 Agilent Technologies, Inc.

Agilent 33220A

20 MHz Function/

Arbitrary Waveform Generator

Page 2

Agilent 33220A at a Glance

The Agilent Technologies 33220A is a 20 MHz synthesized function

generator with built-in arbitrary waveform and pulse capabilities.

Its combination of bench-top and system features makes this function

generator a versatile solution for your testing requirements now and in

the future.

Convenient bench-top features

• 10 standard waveforms

• Built-in 14-bit 50 MSa/s arbitrary waveform capability

• Precise pulse waveform capabilities with adjustable edge time

• LCD display provides numeric and graphical views

• Easy-to-use knob and numeric keypad

• Instrument state storage with user-defined names

• Portable, ruggedized case with non-skid feet

Flexible system features

• Four downloadable 64K-point arbitrary waveform memories

• GPIB (IEEE-488), USB, and LAN remote interfaces are standard

• LXI Class C Compliant

• SCPI (Standard Commands for Programmable Instruments) compatibility

Note:

Unless otherwise indicated, this manual applies to all Serial

2

Numbers.

Page 3

The Front Panel at a Glance

1 Graph Mode/Local Key

2 On/Off Switch

3 Modulation/Sweep/Burst Keys

4 State Storage Menu Key

5 Utility Menu Key

6 Help Menu Key

7 Menu Operation Softkeys

8 Waveform Selection Keys

9 Manual Trigger Key (used for

Sweep and Burst only)

10 Output Enable/Disable Key

11

Knob

12

Cursor Keys

13

Sync Connector

14

Output Connector

Note: To get context-sensitive help on any front-panel key or menu softkey,

press and hold down that key.

3

Page 4

The Front-Panel Display at a Glance

Menu Mode

Numeric

Readout

Mode

Information

Trigger

Information

Softkey Labels

Units

Output

Status

Graph Mode

To enter or exit the Graph Mode, press the key.

Parameter

Name

Parameter

Value

Display

Icon

Signal

Ground

In Graph Mode, only one parameter label

is displayed for each key at one time.

4

Page 5

Front-Panel Number Entry

1. Use the keys below the knob to move the cursor left or right.

1. Key in a value as you would on a typical calculator.

You can enter numbers from the front-panel using one of two methods.

Use the knob and cursor keys to modify the displayed number.

2. Rotate the knob to change a digit (clockwise to increase).

Use the keypad to enter numbers and the softkeys to select units.

2. Select a unit to enter the value.

5

Page 6

The Rear Panel at a Glance

1

External 10 MHz Reference Input Terminal

(Option 001 only)

2

Internal 10 MHz Reference Output Terminal

(Option 001 only)

3 External Modulation Input Terminal

Input: External Trig/FSK/Burst Gate

4

Output: Trigger Output

.

.

5 USB Interface Connector

6 LAN Interface Connector

7 GPIB Interface Connector

8 Chassis Ground

Use the menu to:

• Select the GPIB address (see chapter 2).

• Set the network parameters for the LAN interface (see chapter 2).

• Display the current network parameters (see chapter 2).

Note: The External and Internal 10 MHz Reference Terminals (1 and 2,

above) are present only if Option 001, External Timebase Reference, is

installed. Otherwise, the holes for these connectors are plugged.

WARNING For protection from electrical shock, the power cord ground must not be

defeated. If only a two-contact electrical outlet is available, connect the

instrument’s chassis ground screw (see above) to a good earth ground.

6

Page 7

In This Book

Quick Start Chapter 1 prepares the function generator for use and

helps you get familiar with a few of its front-panel features.

Front-Panel Menu Operation Chapter 2 introduces you to the frontpanel menu and describes some of the function generator’s menu features.

Features and Functions Chapter 3 gives a detailed description of the

function generator’s capabilities and o peration. You will find t his chapter

useful whether you are operating the function generator from the front

panel or over the remote interface.

Remote Interface Reference

to help you program the function generator over the remote interface.

Error Messages Chapter 5 lists the error messages that may appear

as you are working with the function generator. Each listing contains

information to help you diagnose and solve the problem.

Application Programs Chapter 6 contains several remote interface

application programs to help you develop programs for your application.

Tutorial Chapter 7 discusses the fundamentals of signal generation

and modulation techni ques.

Specifications Chapter 8 lists the function generator’s specifications.

Chapter 4 contains reference information

7

Page 8

You can contact Agilent Technologies at one of the following telephone

numbers for warranty, service, or technical support information.

In the United States: (800) 829-4444

In Europe: 31 20 547 2111

In Japan: 0120-421-345

Or use our Web link for information on contacting Agilent worldwide.

8

Page 9

Contents

Chapter 1 Quick Start 13

To Prepare the Function Generator for Use 15

To Adjust the Carrying Handle 16

To Set the Output Frequency 17

To Set the Output Amplitude 18

To Set a DC Offset Voltage 20

To Set the High-Level and Low-Level Values 21

To Select “DC Volts” 22

To Set the Duty Cycle of a Square Wave 23

To Configure a Pulse Waveform 24

To View a Waveform Graph 25

To Output a Stored Arbitrary Waveform 26

To Use the Built-In Help System 27

To Rack Mount the Function Generator 29

Chapter 2 Front-Panel Menu Operation 31

Front-Panel Menu Reference 33

To Select the Output Termination 35

To Reset the Function Generator 35

To Output a Modulated Waveform 36

To Output an FSK Waveform 38

To Output a PWM Waveform 40

To Output a Frequency Sweep 42

To Output a Burst Waveform 44

To Trigger a Sweep or Burst 46

To Store the I nstrument State 47

To Configure the Remote Int erface 48

Chapter 3 Features and Functions 53

Output Configuration 55

Pulse Waveforms 70

Amplitude Modulation (AM) 74

Frequency Modulation (FM) 79

Phase Modulation (PM) 85

Frequency-Shift Keying (FSK) Modulation 89

Pulse Width Modulation (PWM) 93

Frequency Sweep 99

Burst Mode 106

Contents

9

Page 10

Contents

Contents

Triggering 115

Arbitrary Waveforms 120

System-Related Operations 126

Remote Interface Configuration 135

External Timebase Reference (Option 001) 144

Calibration Overview 146

Factory Defa ul t Sett in gs 150

Chapter 4 Remote Interface Reference 153

SCPI Command Summary 155

Simplified Programming Overview 168

Using the APPLy Command 170

Output Configuration Commands 179

Pulse Configuration Commands 192

Amplitude Modulation (AM) Commands 197

Frequency Modulation (FM) Commands 200

Phase Modulation (PM) Commands 204

Frequency-Shift Keying (FSK) Commands 207

Pulse Width Modulation (P WM) Commands 210

Frequency Sweep Commands 215

Burst Mode Commands 223

Triggering Commands 231

Arbitrary Waveform Commands 234

State Storage Commands 245

System-Related Commands 249

Interface Configuration Commands 254

Phase-Lock Commands (Option 001 Only) 258

The SCPI Status System 260

Status Reporting Commands 270

Calibration Commands 274

An Introduction to the SCPI Language 276

Using Device Clear 281

10

Page 11

Contents

Chapter 5 Error Messages 283

Command Errors 285

Execution Errors 288

Device Dependent Errors 303

Query Errors 304

Instrument Errors 305

Self-Test Errors 306

Calibration Errors 308

Arbitrary Waveform Errors 309

Chapter 6 Application Programs 311

Introduction 312

Program Listings 314

Chapter 7 Tutorial 321

Direct Digital Synthesis 323

Creating Arbitrary Waveforms 326

Square Waveform Generation 328

Pulse Waveform Generation 329

Signal Imperfections 330

Output Amplitude Control 332

Ground Loops 333

Attributes of AC Signals 335

Modulation 337

Frequency Sweep 342

Burst 343

Contents

11

Page 12

Chapter 8 Specifications 345

Waveforms 346

Waveform Characteristics 346

Common Characteristics 347

Modulation 347

Sweep 348

Burst 348

Trigger Characteristics 348

Programming Times 348

General 349

Product Dimensions 350

Index 351

Contents

12

Page 13

1

1

Quick Start

Page 14

1

Quick Start

One of the first things yo u will want to do w ith your function ge nerator is

to become acquainted with the fron t panel. W e have written the exercises

in this chapter to prepare the instrument for use and help you get

familiar with some of its front-panel operations. This chapter is divided

into the following sections:

• To Prepare the Function Generator for Use, on page 15

• To Adjust the Carrying Handle, on page 16

• To Set the Output Frequency, on page 17

• To Set the Output Amplitude, on page 18

• To Set a DC Offset Voltage, on page 20

• To Set the High-Level and Low-Level V alues, on page 21

• To Select “DC Volts”, on page 22

• To Set the Duty Cycle of a Square Wave, on page 23

• To Configure a Pulse Waveform, on page 24

• To View a Waveform Graph, on page 25

• To Output a Stored Arbitrary Waveform, on page 26

• To Use the Built-In Help System, on page 27

• To Rack Mount the Function Generator, on page 29

14

Page 15

Chapter 1 Quick Start

To Prepare the Function Generator for Use

To Prepare the Function Generator for Use

1 Check the list of supplied items.

Verify that you have received the following items with your instrument.

If anything is missing, please contact your nearest Agilent Sales Office.

1

Power

Switch

• Power cord (for country of destination).

• Certificate of Calibration.

• Agilent 33220A Product Reference CD (product software,

programming examples, and manuals).

• Agilent Automation-Ready CD (Agilent IO Libraries Suite).

• USB 2.0 cable.

2 C onnect the power cord and turn on the function generator.

The instrument runs a short power-on self test, which takes a few

seconds. When the instrument is ready for use it displays a message

about how to obtain help, along with the current GPIB address and

USB identification string. The function generator powers up in the sine

wave function at 1 kHz with an amplitude of 100 mV peak-to-peak (into

a 50Ω termination).

enable the Output

If the function generator does not turn on, verify that the power cord is

firmly connected to the power receptacle on the rear p a ne l (t he po w er -line

voltage is automatically sensed at power-on). You should also make sure

that the function generator is connected to a power source that is energized

Then, verify that the function generator is turned on.

At power-on, the

connector, press the key

Output

connecto r

.

is disabled. To

4

.

If the power-on self test fails, “Self-Test Failed” is displayed along with an

error code. See the Agilent 33220A Service Guide for information on

error codes, and for

Agilent for service.

instructions on returning the function generator to

15

Page 16

1

Chapter 1 Quick Start

To Adjust the Carrying Handle

To Adjust the Carrying Handle

To adjust the position, grasp the handle by the sides and pull outward.

Then, rotate the handle to the desired position.

Retracted

Carrying

Position

Extended

16

Page 17

Chapter 1 Quick Start

To Set the Output Frequency

To Set the Output Frequency

At power-on, the function generator outputs a sine wave at 1 kHz with

an amplitude of 100 mV peak-to-peak (into a 50Ω termination).

The following steps show you how to change the frequency to 1.2 MHz.

1

1Press the “Freq” softkey.

The displayed frequency is either the power-on value or the frequency

previously selected. When you change functions, the same frequency is

used if the present value is valid for the new function. To set the

waveform period instead, press the Freq softkey again to toggle to the

Period softkey (the current selection is highlighted).

2 Enter the magnitude of the desired frequency.

Using the numeric keypad, enter the value “1.2”.

3 Select the desired units.

Press the softkey that corresponds to the desired units. When you select

the units, the function generator outputs a waveform with the displayed

frequency (if the output is enabled). For this example, press MHz

.

4

Note: Y

keys.

ou can also enter the desired value using the knob and cursor

17

Page 18

1

Chapter 1 Quick Start

To Set the Output Amplitude

To Set the Output Amplitude

At power-on, the function generator outputs a sine wave with an

amplitude of 100 mV peak-to-peak (into a 50Ω termination).

The following steps show you how to change the amplitude to 50 mVrms.

1Press the “Ampl” softkey.

The displayed amplitude is either the power-on value or the amplitude

previously selected. When you change functions, the same amplitude is

used if the present value is valid for the new function. To set the amplitude

using a high level and low level, press the Ampl softkey again to toggle to

the HiLevel and LoLevel softkeys (the current selection is highlighted).

2 Enter the magnitude of the desired amplitude.

Using the numeric keypad, enter the value “50”.

3 Select the desired units.

Press the softkey that corresponds to the desired units. When you select

the units, the functio n ge ner ator out puts the wave form w ith the disp layed

amplitude (if the output is enabled). For this example, press mV

Note: Y

keys.

18

ou can also enter the desired value using the knob and cursor

RMS

.

Page 19

Chapter 1 Quick Start

To Set the Output Amplitude

You can easily convert the displayed amplitude from one unit to another.

For example, the following steps show you how to convert the amplitude

from Vrms to Vpp.

4 Enter the numeric entry mode.

Press the key to enter the numeric entry mode.

5 Select the new units.

Press the softkey that corresponds to the desired units. The displayed

value is converted to the new units. For this example, press the Vpp

softkey to convert 50 mVrms to its equivalent in volts peak-to-peak.

1

4

To change the displayed amplitude by decades, press the right-cursor

key to move the cursor to the units on the right side of the display.

Then, rotate the knob to increase or decrease the displayed amplitude

by decades.

19

Page 20

1

Chapter 1 Quick Start

To Set a DC Offset Voltage

To Set a DC Offset Voltage

At power-on, the function generator outputs a sine wave with a dc offset

of 0 volts (into a 50Ω termination). The following steps show you how to

change the offset to –1.5 mVdc.

1Press the “Offset” softkey.

The displayed off set voltage is either the power-on value or the offset

previously selected. When you change functions, the same offset is used

if the present value is valid for the new function.

2 Enter the magnitude of the desired offset.

Using the numeric keypad, enter the value “–1.5”.

3 Select the desired units.

Press the softkey that corresponds to the desired units. When you select

the units, the functio n ge ner ator out puts the wave form w ith the disp layed

offset (if the output is enabled). For this example, press mV

Note: Y

keys.

20

ou can also enter the desired value using the knob and cursor

DC

.

Page 21

Chapter 1 Quick Start

To Set the High-Level and Low-Level Values

To Set the High-Level and Lo w-Level Values

You can specify a signal by setting its amplitude and dc offset values, as

described previously. Another way to set the limits of a signal is to

specify its high-level (maximum) and low-level (minimum) values. This

is typically convenient for digital applications. In the following example,

let's set the high-level to 1.0 V and the low-level to 0.0 V.

1 Press the "Ampl" softkey to select "Ampl".

2 Press the softkey again to toggle to "HiLevel".

Note that both the Ampl and Offset softkeys toggle together, to HiLevel

and LoLevel, respectively.

1

4

3 Set the "HiLevel" value.

Using the numeric keypad or the knob, select a value of "1.0 V". (If you

are using the keypad, you will need to select the unit, "V", to enter the

value.)

4 Press the "LoLevel" softkey and set the value.

Again, use the numeric keyp ad or the knob to enter a value of "0.0 V".

Note that these settings (high-level = "1.0 V" and low-level = "0.0 V") are

equivalent to setting an amplitude of "1.0 Vpp" and an offset of "500

mVdc".

21

Page 22

1

Chapter 1 Quick Start

To Select “DC Volts”

To Select “DC Volts”

You can select the "DC Volts" feature from the “Utility” menu, and then

set a constant dc voltage as an "Offset" value. Let's set "DC Volts" = 1.0

Vdc.

1 Press and then select the DC On softkey.

The Offset value becomes selected.

2 Enter the desired voltage level as an "Offset".

Enter 1.0 Vdc with the numeric keypad or knob.

You can enter any dc voltage from -5 Vdc to +5 Vdc.

22

Page 23

Chapter 1 Quick Start

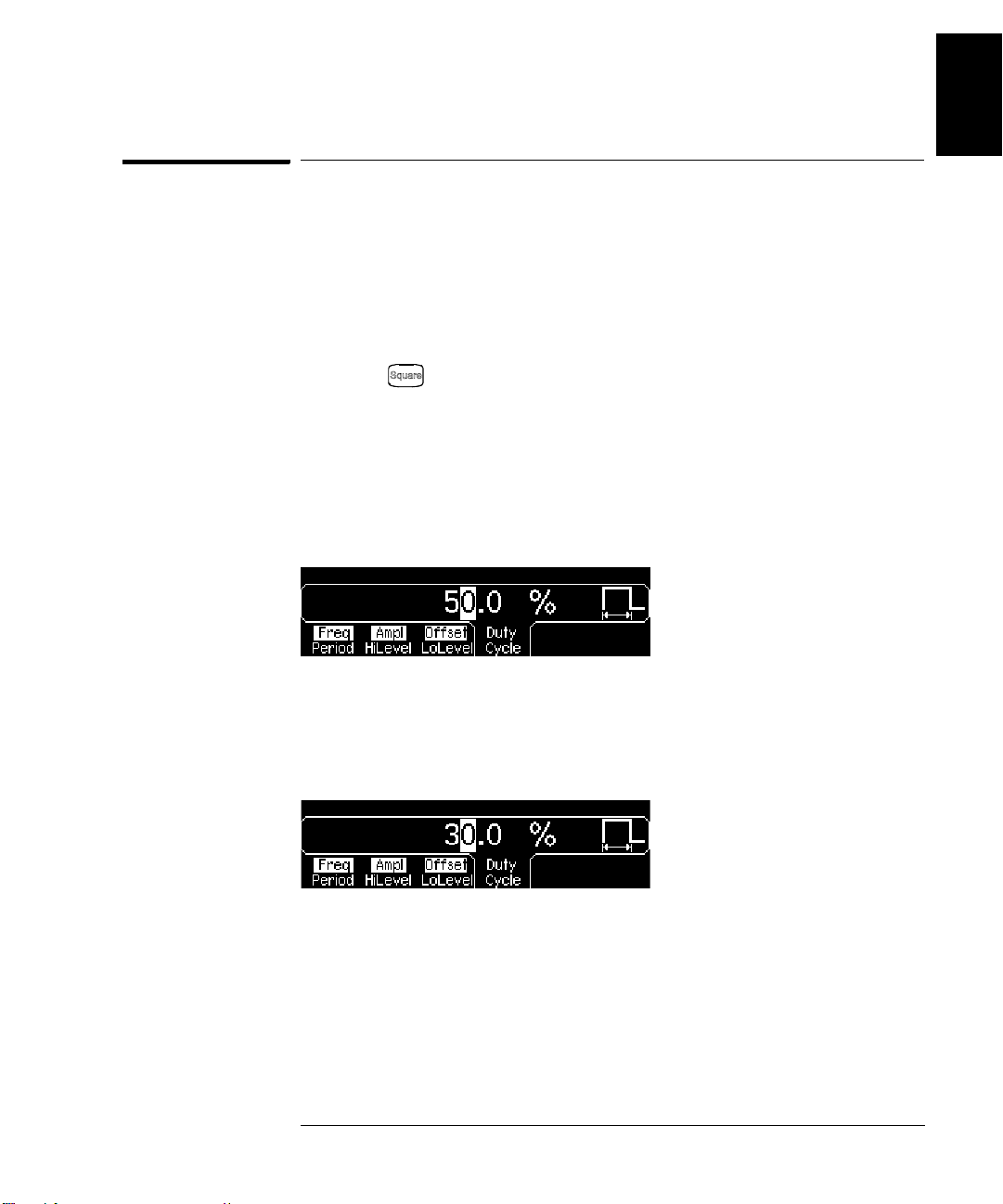

To Set the Duty Cycle of a Square Wave

To Set the Duty Cycle of a Square Wave

At power-on, the duty cycle for square waves is 50%. You ca n adjust the

duty cycle from 20% to 80% for output frequencies up to 10 MHz. The

following steps show you how to change the duty cycle to 30%.

1

1 Select the square wave function.

Press the key and then set the d esired output frequency to any

value up to 10 MHz.

2Press the “Duty Cycle” softkey.

The displayed duty cycle is either the power-on value or the percentage

previously selected. Th e duty cycle represents the amount of time per

cycle that the square wave is at a high level (note the icon on the right

side of the display).

3 Enter the desired duty cycle.

Using the numeric keypad or the knob, select a duty cycle value of “30”.

The function generator adjusts the duty cy cle immediately and outputs a

square wave with the specified value (if the output is enabled).

4

23

Page 24

1

Chapter 1 Quick Start

To Configure a Pulse Waveform

To Configure a Pulse Waveform

You can configure the function generator to output a pulse waveform

with variable pulse width and edge time. The following steps show you

how to configure a 500 ms pulse waveform with a pulse width of 10 ms

and edge times of 50 ns.

1 Select the pulse function.

Press the key to select the pulse function and output a pulse

waveform with the default parameters.

2 Set the pulse period.

Press the Period softkey and then set the pulse period to 500 ms.

3 Set the pulse width.

Press the Width softkey and then set the pulse width to 10 ms. The pulse

width represents the time from the 50% threshold of the rising edge to

the 50% threshold of the next falling edge (note the display icon).

4 Set the edge time for both edges.

Press the Edge Time softkey and then set the edge time for both the

rising and falling edges to 50 ns. The edge time represents the time from

the 10% threshold to the 90% threshold of each edge (note the display icon

24

).

Page 25

Chapter 1 Quick Start

To View a Waveform Graph

To View a Waveform Graph

In the Graph Mode, you can view a graphical representation of the

current waveform parameters. The softkeys are listed in the same order

as in the normal display mode, and they perform the same functions.

However, only one label (for example, Freq or Period) is displayed for

each softkey at one time.

1 Enable th e Graph Mode.

1

4

Press the key to enable the Graph Mode. The na me of the

selected

parameter’s numeric value field are both highlighted.

2 Select the desired paramet er.

To select a specific parameter, note the softkey labels at the bottom of

the display.

• As in the normal disp lay mode , you can e dit numb ers using either the

•

• To exit the Graph Mode, press again.

parameter,

For example

numeric keypad or the knob and cursor keys.

Param ete rs w h ic h n o rmally tog g le when you p re ss a key a seco nd t im e

also toggle in the Graph Mode. Howev er, you can see on ly on e label

for each softkey at one time (for example, Freq or Period).

The key also serves as a key to restore front-panel control

after remote interface operations.

shown in the up per-left corne r of the display, a nd the

, to select period, press the Period softkey.

currently

25

Page 26

1

Chapter 1 Quick Start

To Output a Stored Arbitrary Waveform

To Output a Stored Arbitrary Waveform

There are five built-in arbitrary waveforms stored in non-volatile memory

The following steps show you how to output the built-in “exponential fall”

waveform

For information on creating a custom arbitrary waveform, refer to

“To Create and Store an Arbitrary Waveform” on page 120.

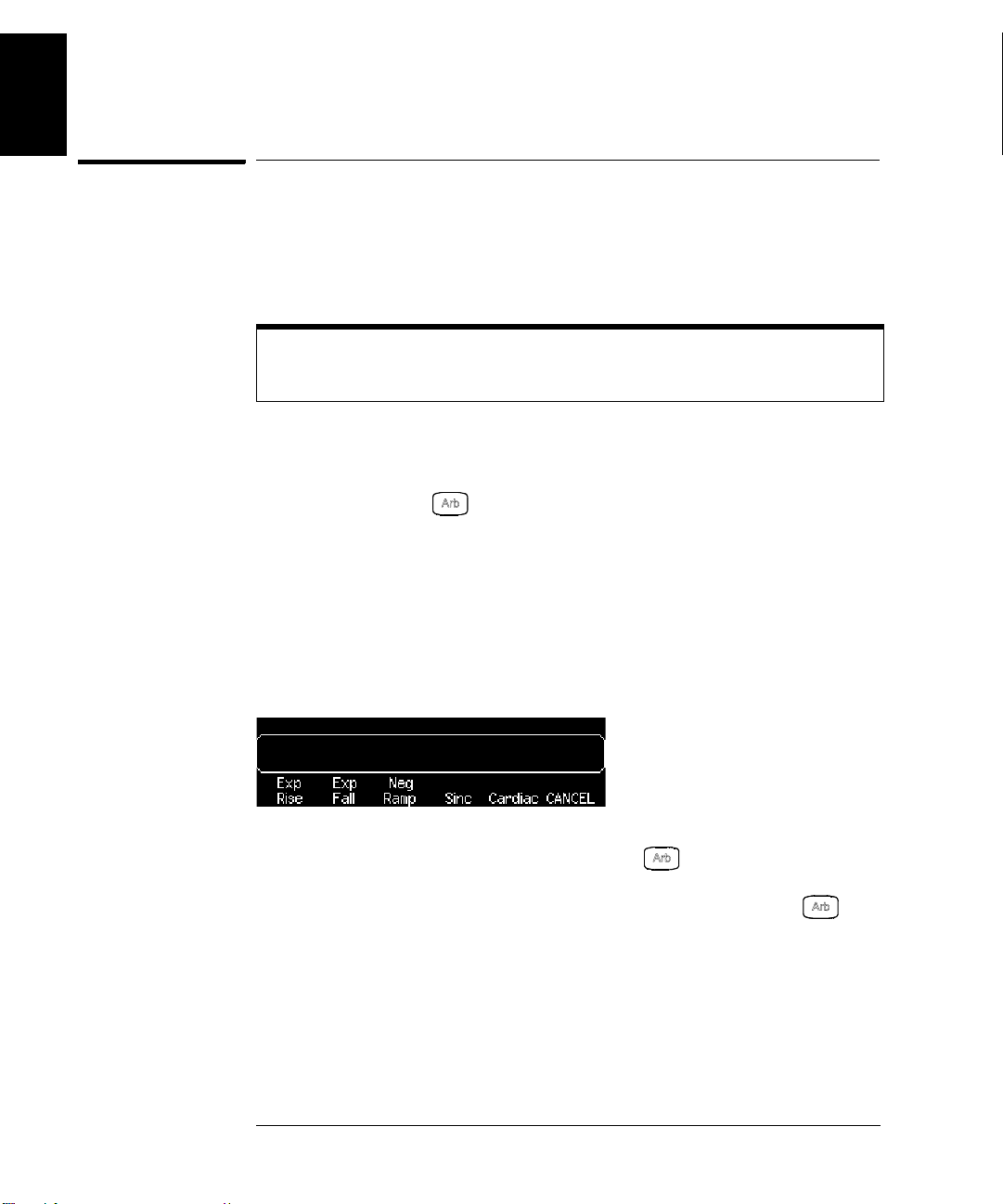

1 Select the arbitrary waveform function.

When you press the key to select the arbitrary waveform function,

a temporary message is displayed indicating which waveform is currently

selected (the default is “exponential rise”).

2 Select the active waveform.

Press the Select Wform softkey and then press the Built-In softkey to

select from the five built-in waveforms. Then press the Exp Fall softkey.

The waveform is output using the present settings for frequency,

amplitude, and offset unless you change them.

from the front panel.

.

The selected waveform is now assigned to the key. Whenever you

press this key, the selected arbitrary waveform is output. To quickly

determine which arbitrary waveform is currently selected, press .

26

Page 27

Chapter 1 Quick Start

To Use the Built-In Help System

To Use the Built-In Help System

The built-in help system is designed to provide context-sensitive

assistance on any front-panel key or menu softkey. A list of help topics

is also available to assist you with several front-panel operations.

1

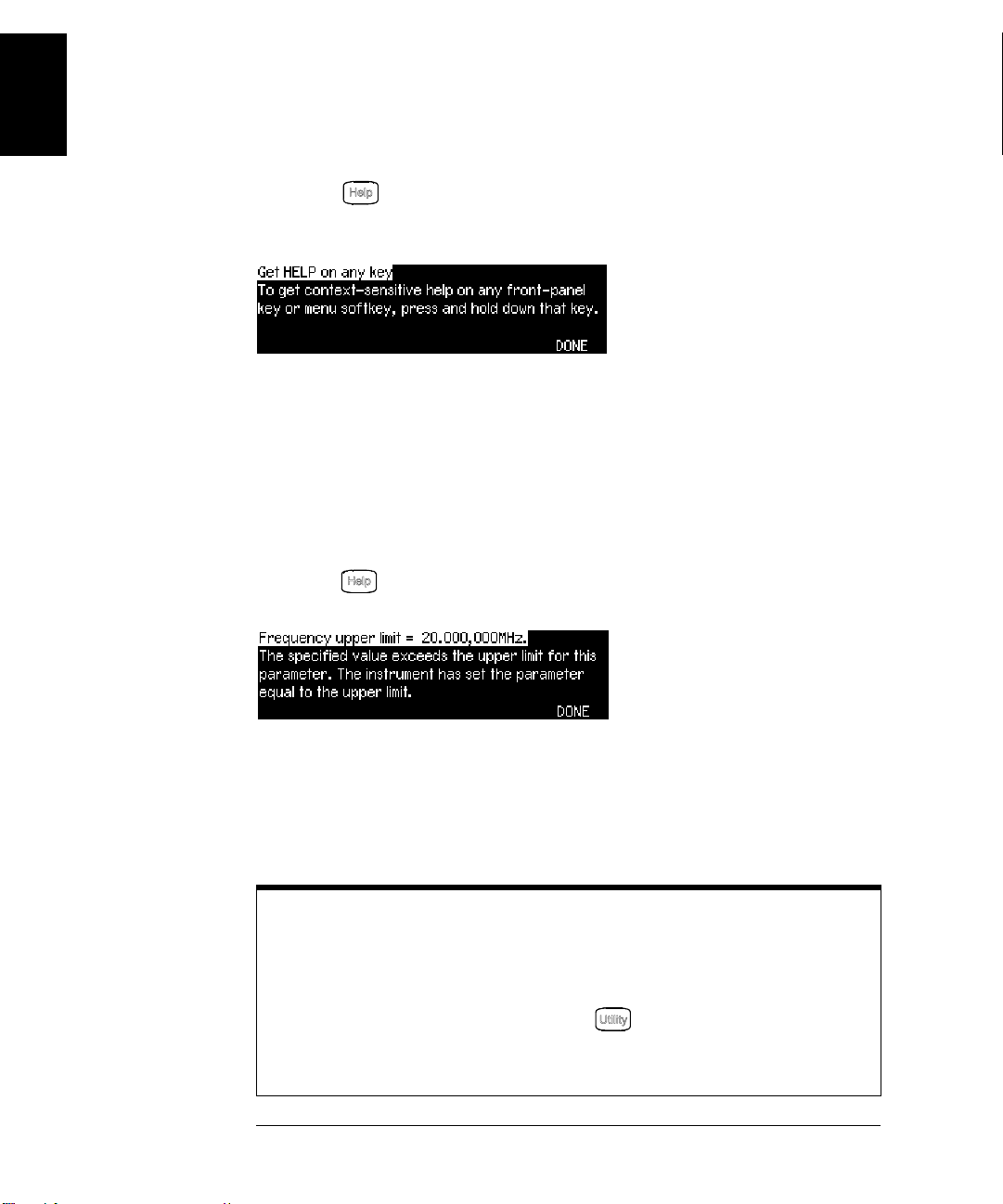

1 View the help information for a function key.

Press and hold down the key. If th e message contains

information than will fit on the di spla y, pre s s th e ↓ softkey or turn the

knob clockwise to view the remaining information.

Press DONE to exit Help.

2 View the help information for a menu softkey.

Press and hold down the Freq softkey.

information than will fit on the di spla y, pre s s th e ↓ softkey or rotate the

knob clockwise to view the remaining information.

Press DONE to exit Help.

If the message con tai ns

more

more

4

27

Page 28

1

Chapter 1 Quick Start

To Use the Built-In Help System

3 View the list of help topics.

Press the key to view the li st of available help topics. To scroll

through the list, press the ↑ or ↓ softkey or rotate the knob. Sele ct the

third topic “Get HELP on any key” and then press SELECT.

Press DONE to exit Help.

4 View the help information for displayed messages.

Whenever a limit is exceeded or an y other invali d config uration i s found,

the function generator will display a message. For example, if you enter

a value that exceeds the frequency limit for the selected function,

a message will be displayed. The built-in help system provides additional

information on the most recent message to be displayed.

Press the k ey, select the first top ic “

and then press SELECT.

Press DONE to exit Help.

Local Language Help: The built-in help system in available in multiple

languages. All messages, context-sensitive help, and help topics appear

in the selected language. The menu softkey labels and status line

messages are not translated.

To select the local language, press the key, press the System

softkey, and then press the Help In softkey. Select the desired

language.

View the last message displayed”,

28

Page 29

Chapter 1 Quick Start

To Rack Mount the Function Generator

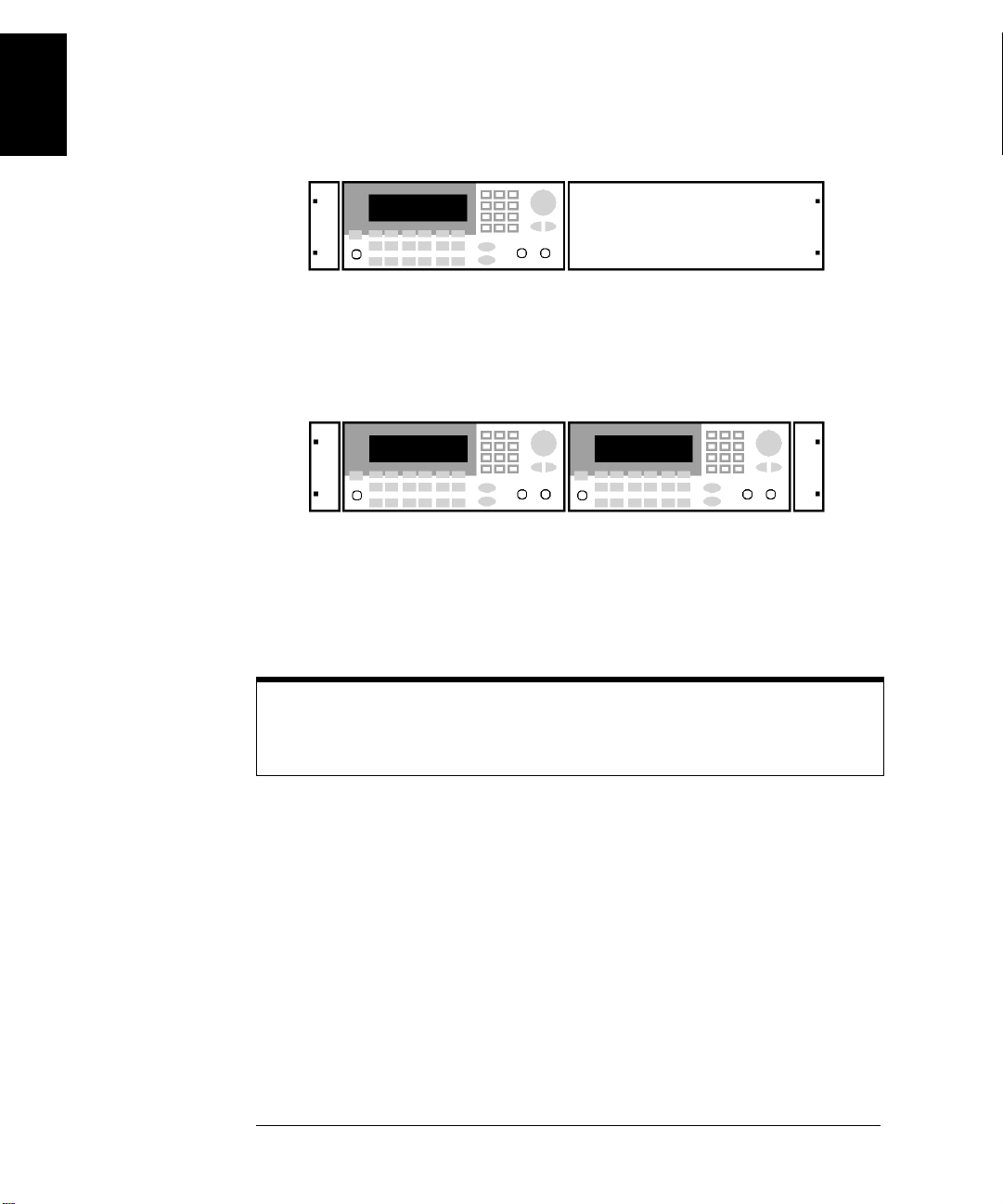

To Rack Mount the Function Generator

You can mount the Agilent 33220A in a standard 19-inch rack cabinet

using one of two optional kits available. Instructions and mounting

hardware are included with each rack-mounting kit. Any Agilent

System II instrument of the same size can be rack-mounted beside the

Agilent 33220A.

Note:

before rack-mounting the instrument.

Remove the carrying handle, and the front and rear rub ber bumpers

4

1

,

To remove the handle, rotate it to vertical and pull the ends outward.

Front

To remove the rubber bumper, stretch a corner and then slide it off.

Rear (bottom view)

29

Page 30

1

Chapter 1 Quick Start

To Rack Mount the Function Generator

To rack mount a single instrument, order adapter kit 5063-9240.

To rack mount two instruments side-by-side, order lock-link kit 5061- 8769

and flange kit 5063-9212. Be sure to use the support rails in the rack cabinet.

In order to prevent overheating, do not block the flow of air into or out of

the instrument. Be sure to allow enough clearance at the rear, sides, and

bottom of the instrument to permit adequate internal air flow.

30

Page 31

2

2

Front-Panel Menu Operation

Page 32

Front-Panel Menu Operation

This chapter introduces you t o the fro nt-pane l keys and menu oper ation.

This chapter does not give a deta iled descri ption of eve ry front-pa nel key

or menu operation. It does, however, give you an overview of the frontpanel menus and many front-panel operations. See chapter 3 “Features

and Functions,” starting on page 53, for a complete discussion of the

function generator’s capabilities and operation.

2

• Front-Panel Menu Reference, on page 33

• To Select the Output Termination, on page 35

• To Reset the Function Generator, on page 35

•To Output a Modulated Waveform, on page 36

• To Output an FSK Waveform, on page 38

•To Output a PWM Waveform, on page 40

• To Output a Frequency Sweep, on page 42

• To Output a Burst Waveform, on page 44

• To Trigger a Sweep or Burst, on page 46

• To Store the Instrument State, on page 47

• To Configure the Remote Interface, on page 48

32

Page 33

Chapter 2 Front-Panel Menu Operation

Front-Panel Menu Reference

Front-Panel Menu Reference

This section gives an overview of the front-panel menus. The remainder

of this chapter contains examples of using the front-panel menus.

2

Configure the modulation parameters for AM, FM, PM, FSK and PWM.

• Select the modulation type.

• Select an internal or external modulation source.

• Specify AM modulation depth, modulating frequency, and modulation shape.

Specify FM frequency deviation, modulating frequency, and modulation shape.

•

•

Specify PM phase deviation, modulating frequency, and modulation shape.

• Specify FSK “hop” frequency and FSK rate.

• Specify PWM deviation, modulating frequency, and modulation shape.

Configure the parameters for frequency sweep.

• Select linear or logarithmic sweeping.

• Select the start/stop frequencies or

• Select the time in seconds required to complete a sweep.

• Specify a marker frequency.

• Specify an internal or external trigger source for the sweep.

• Specify the slope (rising or falling edge) for an external trigger source.

• Specify the slope (rising or falling edge) of the “Trig Out” signal.

Configure the parameters for burst.

center/ span frequencies.

4

• Select the triggered (N Cycle) or externally-gated burst mode.

• Select the number of cycles per burst (1 to 50,000, or Infinite).

• Select the starting phase angle of the burst (-360° to +360°).

• Specify the time from the start of one burst to the start of the next burst.

• Specify an internal or external trigger source for the burst.

• Specify the slope (rising or falling edge) for an external trigger source.

• Specify the slope (rising or falling edge) of the “Trig Out” signal.

33

Page 34

2

Chapter 2 Front-Panel Menu Operation

Front-Panel Menu Reference

Store and recall instrument states.

• Store up to four instrument states in non-volatile memory.

• Assign a custom name to each storage location.

• Recall stored instrument states.

• Restore all instrument settings to their factory default values.

• Select the instrument’s power-on configuration (last or factory default).

Configure system-related parameters.

• Generate a dc-only voltage level.

• Enable/disable the Sync signal which is output from the “Sync” connector.

• Select the output termination (1Ω to 10 kΩ, or Infinite).

• Enable/disable amplitude autoranging.

• Select the waveform polarity (normal or inverted).

• Select the GPIB address.

• Specify the LAN configuration (IP address and network configuration).

Select how periods and commas are used in numbers displayed on the front panel.

•

• Select the local language for front-panel messages and help text.

• Enable/disable the tone heard when an error is generated.

• Enable/disable the display bulb-saver mode.

• Adjust the contrast setting of the front-panel display.

• Perform an instrument self-test.

• Secure/unsecure the instrument for calibration and perform manual calibrations.

• Query the instrument’s firmware revision codes.

View the list of Help topics.

• View the last message displayed.

• View the remote command error queue.

• Get HELP on any key.

• How to generate a dc-only voltage level.

• How to generate a modulated waveform.

• How to create an arbitrary waveform.

• How to reset the instrument to its default state.

• How to view a waveform in the Graph Mode.

• How to synchronize multiple instruments.

• How to obtain Agilent Technical Support.

34

Page 35

Chapter 2 Front-Panel Menu Operation

To Select the Output Termination

To Select the Output Termination

The Agilent 33220A has a fixed series output impedance of 50 ohms to

the front-panel Output connector. If the actual load impedance is

different than the value specified, the displayed amplitude and offset

levels will be incorrect. The load impedance setting is simply provided

as a convenience to ensure that the displayed voltage matches the

expected load.

1Press .

2 Navigate the menu to set the output termination.

Press the Output Setup softkey and then select the Load softkey.

2

4

3 Select the desired output termination.

Use the knob or numeric keypad to select the desired load impedance or

press the Load softkey again to choose “High Z”.

To Reset the Function Generator

To reset the instrument to its factory default state, press and then

select the Set to Defaults softkey. Press YES to confirm the operation.

For a complete listing of the instrument’s power-on and reset conditions,

see “Agilent 33220A Factory Default Settings” on page 151.

35

Page 36

2

Chapter 2 Front-Panel Menu Operation

To Output a Modulated Waveform

To Output a Modulated Waveform

A modulated waveform consists of a carrier and a modulating waveform.

In AM (amplitude modulation), the amplitude of the carrier is varied by

the amplitude of the modulating waveform. For this example, you will

output an AM waveform with 80% modulation depth. The carrier will

be a 5 kHz sine wave and the modulating waveform will be a 200 Hz

sine wave.

1 Select the function, frequency, and amplitude of the carrier.

Press and then press the Freq, Ampl, and Offset softkeys to

configure the carrier waveform.

with an amplitude of 5 Vpp.

2 Select AM.

Press and then select “AM” using the Type softkey. Notice that

a status message “AM by Sine” is shown in the upper-left corner of

the display.

3 Set the modulation depth.

Press the AM Depth softkey and then set the value to 80% using the

numeric keypad or the knob and cursor keys.

36

For this example, select a 5 kHz sine wave

Page 37

Chapter 2 Front-Panel Menu Operation

To Output a Modulated Waveform

4 Set the modu lating frequency.

Press the AM Freq softkey and then set the value to 200 Hz usi ng the

numeric keypad or the knob and cursor keys.

5 Select the modulating waveform shape.

Press the Shape softkey to select the shape of the modulating waveform.

For this example, select a sine wave.

At this point, the function generator outputs an AM waveform with the

specified modulation parameters (if the output is enabled).

6 View the waveform.

2

4

Press t

To turn off the Graph Mode, press

o view the waveform parameters.

again

.

37

Page 38

2

Chapter 2 Front-Panel Menu Operation

To Output an FSK Waveform

To Output an FSK Waveform

You can configure the function generator to “shift ” its output frequency

between two preset values using FSK modul ati on. The ra te at which the

output shifts between the tw o freq uencies (cal led the “ca rrier freq ue ncy”

and the “hop frequency”) is determined by the internal rate generator or

the signal level on the rear-panel Trig In connector. For this example,

you will set the “carrier” frequency to 3 kHz and the “hop” frequency to

500 Hz, with an FSK rate of 100 Hz.

1 Select the function, frequency, and amplitude of the carrier.

Press and then press the Freq, Ampl, and Offset softkeys to

configure the carrier waveform.

with an amplitude of 5 Vpp.

2 Select FSK.

Press and then select “FSK” using the Ty pe softkey. Notice that a

status message “FSK” is shown in the upper-left corner of the display.

38

For this example, select a 3 kHz sine wave

Page 39

Chapter 2 Front-Panel Menu Operation

To Output an FSK Waveform

3 Set the “hop” frequency.

Press the Hop Freq softkey and then set the value to 500 Hz using the

numeric keypad or the knob and cursor keys.

4 Set the FSK “shift” rate.

Press the FSK Rate softkey and then set the value to 100 Hz using the

numeric keypad or the knob and cursor keys.

At this point, the function generator outputs an FSK waveform (if the

output is enabled).

2

4

5 View the waveform.

Press t

To turn off the Graph Mode, press

o view the waveform parameters.

again

.

39

Page 40

2

Chapter 2 Front-Panel Menu Operation

To Output a PWM Waveform

To Output a PWM Waveform

You can configure the function generator to output a pul se wi dth

modulated (PWM) waveform. The Agilent 33220A provides PWM for

pulse carrier waveforms, and PWM is the only type of modulation

supported for pulse waveforms. In PWM, the pulse wi dth or duty cycle of

the carrier waveform is varied according to the modulating waveform.

You can specify either a pulse wi dth and widt h deviat ion, or a pulse duty

cycle and duty cycle deviation, the deviation to be controlled by the

modulating waveform.

For this example, you will specify a pulse width and pulse width

deviation for a 1 kHz pulse waveform with a 100 Hz sine wave

modulating waveform.

1 Select the carrier waveform parameters.

Press and then press the Freq, Ampl, Offset, Width, and Edge

Time softkeys to configure the carrier waveform. For this example, select

a 1 kHz pulse waveform with an amplitude of 1 Vpp, a zero offset, a pulse

width of 100 µs, and an edge time of 50 ns.

2 Select PWM.

Press (PWM is the only modulatio n typ e for Pulse). Notice that a

status message "PWM by Sine" is shown in the upper-left corner of the

display.

3 Set the width deviation.

Press the Width Dev softkey and set the va lue to 20 µs using the numeric

keypad or the knob and cursor keys.

40

Page 41

Chapter 2 Front-Panel Menu Operation

To Output a PWM Waveform

4 Set the modu lating frequency.

Press the PWM Freq softkey and then set the value to 5 Hz using the

numeric keypad or the knob and cursor keys.

5 Select the modulating waveform shape.

Press the Shape softkey to select the shape of the modulating waveform.

For this example, select a sine wave.

At this point, the function generator outputs a PWM waveform with the

specified modulation parameters (if the output is enabled).

6 View the waveform.

Press to view the waveform and paramet ers.

2

4

To turn off the Graph Mode, press again.

Of course, to really view the PWM wavef orm, you would need to ou tput it

to an oscilloscope. If you do this, you will see how the pulse width varies,

in this case, from 80 to 120 µs. At a modulation frequency of 5 Hz, the

deviation is quite visible.

41

Page 42

2

Chapter 2 Front-Panel Menu Operation

To Output a Frequency Sweep

To Output a Frequency Sweep

In the frequency sweep mode, the function generator “steps” from the

start frequency to the stop frequency at a sweep rate which you specify.

You can sweep up or down in frequency, and with either linear or

logarithmic spacing. For this example, you will output a swept sine wave

from 50 Hz to 5 kHz. You will not change the other parameters from their

default settings: internal sweep trigger, linear spacing, and 1 second

sweep time.

1 Select the function and amplitude for the sweep.

For sweeps, you can select sine, square, ramp, or arbitrary waveforms

(pulse, noise, and dc are not allowed) . For this example, select a sine wave

with an amplitude of 5 Vpp.

2 Select the sweep mode.

Press and then verify that the linear sweep mode is currently

selected. Notice that a status message “Linear Sweep” is shown in the

upper-left corner of the display.

3 Set the start frequency.

Press the Start softkey and then set the value to 50 Hz using the numeric

keypad or the knob and cursor keys.

42

Page 43

Chapter 2 Front-Panel Menu Operation

To Output a Frequency Sweep

4 Set the stop frequency.

Press the Stop softkey and then set the value to 5 kHz using the numeric

keypad or the knob and cursor keys.

2

At this point, the function generator outputs a continuous sweep from

50 Hz to 5 kHz (if the output is enabled).

Note: If desired, you can set the frequency boundaries of the sweep

using a center frequency and frequency span. These parameters are

similar to the start frequency and stop frequency and are included to

give you added flexibility. To achieve the same results, set the center

frequency to 2.525 kHz and the frequency span to 4.950 kHz.

5 View the waveform.

Press t

To turn off the Graph Mode, press

You can generate a single frequency sweep by pressing the key.

For more information, see “To Trigger a Sweep or Burst” on page 46.

o view the waveform parameters.

again

.

4

43

Page 44

2

Chapter 2 Front-Panel Menu Operation

To Output a Burst Waveform

To Output a Burst Waveform

You can configure the function generator to output a waveform with a

specified number of cycles, called a burst. You can output the burst at a

rate determined by the internal rate generator or the signal level on the

rear-panel Trig In connector. For this example, you will output a

three-cycle sine wave with a 20 ms burst period. You will not change the

other parameters from their default settings: internal burst source and

0 degree starting phase.

1 Select the function and amplitude for the burst.

For burst waveforms, you can select sine, square, ramp, pulse, or

arbitrary waveforms (noise is allowed only in the “gated” burst mode

and dc is not allowed). For this example, select a sine wave with an

amplitude of 5 Vpp.

2 Select the burs t mode.

Press and then verify that the “N Cycle” (inte rnally-triggered) mode

is currently selected. Notice that a status message “N Cycle Burst” is

shown in the upper-left corner of the display.

44

Page 45

Chapter 2 Front-Panel Menu Operation

To Output a Burst Waveform

3 Set the burst count.

Press the # Cycles softkey and then set the count to “3” u sing the

numeric keypad or knob.

4 Set the burst period.

Press the Burst Period softkey and then set the period to 20 ms using the

numeric keypad or the knob an d cursor keys. The burst period sets the

time from the start of one burst to the start of the next burst (note the

display icon).

2

4

At this point, the function generator outputs a continuous three-cycle burst

(if the output is enabled).

5 View the waveform.

Press t

To turn off the Graph Mode, press

You can generate a single burst (with the specified count) by pressing

the key. For more information, see “To Trigger a Sweep or Burst”

on page 46.

You can also use an external gate signal to either turn the burst signal

“on” or “off” based on the external signal applied to the rear-panel

Tri g In connector. For more information, see “Burst Mode” on page 106.

o view the waveform parameters.

again

.

45

Page 46

2

Chapter 2 Front-Panel Menu Operation

To Trigger a Sweep or Burst

To Trigger a Sweep or Burst

You can issue triggers from the front pa nel for sweeps and b ursts using a

manual trigger or an internal trigger.

• Internal or “automatic” triggering is enabled with the default settings

of the function generator. In this mode, the function generator

outputs continuously when the sweep or burst mode is selected.

• Manual triggering init iates one sweep o r outp uts one b urst each ti me

you press the key from the front-panel. Continue pressing this

key to re-trigger the function generator.

• The key is disabled when in remote (the remote icon turns on

while in remote) and when a function other than sweep or burst is

currently selected (or when the output is disabled). The key

flashes off momentarily when us ing a manual trigger.

46

Page 47

Chapter 2 Front-Panel Menu Operation

To Store the Instrument State

To Store the Instrument State

You can store the instrument state in one of four non-volatile storage

locations. A fifth storage location automatically holds the power-down

configuration of the instrument. When power is restored, the instrument

can automatically return to its state before power-down.

2

1 Select the desired storage location.

Press and then select the Store State softkey.

2 Select a custom name for the selected location.

If desired, you can assign a custom name to each of the four locations.

• The name can contain up to 12 characters. The first character

be a letter but the remaining cha racters can be letters, numbers

the underscore character (“_”).

• To add additional characters, press the right-cursor key until the

cursor is to the right of the existing name and then turn the knob.

• To delete all characters to the right of the cursor position, press .

• To use numbers in the name, you can enter them directly from the

numeric keypad. Use the de cimal point from the numeric keypad to

add the underscore character (“_”) to the name.

must

4

, or

3 St o re the instrument state.

Press the STORE STATE softkey. The instrument stores the selected

function, frequency, amplitude, dc offset, duty cycle, symmetry, as well

as any modulation parameters in use. The instrument does not store

volatile waveforms created in the arbitrary waveform function.

47

Page 48

2

Chapter 2 Front-Panel Menu Operation

To Configure the Remote Interface

To Configure the Remote Interface

The Agilent 33220A supports remote interface communication using a

choice of three interfaces: GPIB, USB, and LAN (LXI Class C compliant).

All three interfaces are "live" at power up. The following sections tell how

to configure the remote interface from the instrument front panel.

Note: Two CDs, provided with your instrument, contain connectivity

software to enable communications over the remote interfaces. See

“Connectivity Software and Product CDs” on page -135 for further

information on these CDs and the software they contain.

GPIB Configuration

You need only select a GPIB address.

1 Selec t the “I/O” menu.

Press and then press the

2 Set the GPIB address.

Use the knob and cursor keys or the numeric keypad to select a GPIB

address in the range 0 through 30 (the factory default is “10”).

The GPIB address is shown on the front-panel display at power-on.

3 Exit the menu.

Press the DONE softkey.

I/O

softkey.

USB Configuration

The USB interface requires no front panel configuration parameters.

Just connect the Agilent 33220A to your PC with the appropriate USB

cable. The interface will self configure. Press the Show USB Id softkey in

the “I/O menu” to see the USB interface identification string. Both USB

1.1 and USB 2.0 are supported.

48

Page 49

Chapter 2 Front-Panel Menu Operation

To Configure the Remote Interface

LAN Configuration

There are several parameters that you may need to se t to establish

network communication using the LAN interface. Primarily, you will

need to establish an IP address. You may need to contact your network

administrator for help in establishing communication with the LAN

interface.

2

1 Select the “I/O” menu.

Press and then press the

2 Selec t the “LA N” menu.

Press the

You can select

Config

Press

LAN

softkey.

Modify Settings

to view the current LA N settings (including the MA C address).

Modify Settings

.

I/O

softkey.

to chang e the LAN settings, or

4

Current

From this menu, you can select Reset LAN to restart the LAN, IP Setup

to set an IP address and related parameters, DNS Setup to configure

DNS, or Password to set a password for the Web Server Interface.

Note: To se t a password us e the kn ob and cursor keys (us e to delete

all characters to the right of the cursor position). The Web Server

Interface will prompt for the password to protect certain windows. See

“Agilent 33220A Web Interface” on page -143 for further information.

49

Page 50

2

Chapter 2 Front-Panel Menu Operation

To Configure the Remote Interface

3 Establish an “IP Setup.”

To use the Agilent 33220A on the network, you must first establish an IP

setup, including an I P addre ss, and pos sib ly a su bnet mask and gate way

address. Press the IP Setup softkey. By default, bo th DHCP and Auto IP

are set to On.

With DHCP On, an IP address will automatically be set by DHCP

(Dynamic Host Configuration Pr otocol) when you connect the Agilent

33220A to the network, provided the DHCP server is found and is able to

do so. DHCP also automatically deals with the subnet mask and gateway

address, if required. This is typically the easiest way to establish LAN

communication for your instrument. All you need to do is leave DHCP On.

With Auto IP On, if DHCP fails to assign an IP address, Auto IP will

attempt to do so after a time-out period.

However, if you cannot establish communication by means of DHCP or

Auto IP, you will need to manually set an IP address, and a subnet mask

and gateway address if they are in use. Follow these steps:

a. Set the “IP Address.” Press the softkeys to select DHCP Off and

Auto IP Off. The manual selection s oftkeys appea r and the current IP

address is displayed:

Contact your network administrator for the IP address to use. All IP

addresses take the dot-notation form "nnn.nnn.nnn.nnn" where "nnn"

in each case is a byte value in the range 0 through 255. You can enter

a new IP address using the numeric keypad (not the knob). Just type

in the numbers and the period delimiters using the k eypad. Use the

left cursor key as a backspace key. Do not enter leading zeros. For

further informati on, s ee “More about I P Address es and Do t Nota tion ”

at the end of this section.

50

Page 51

Chapter 2 Front-Panel Menu Operation

To Configure the Remote Interface

b. Set the “Subnet Mask.” The subnet mask is required if your

network has been divided into subnets. Ask your network

administrator whether a subnet mask is needed, and for the correct

mask. Press the Subnet Mask softkey and enter the subnet mask in

the IP address format (using the keypad).

4

c. Set the “Default Gateway.” The gateway address is the address of

a gateway, which is a device that connects two networks. Ask your

network administrator whether a gateway is in use and for the

correct address. Press the Default Gateway softkey and enter the

gateway address in the IP address format (using the keypad).

d. Exit the “IP Setup” menu. Press DONE to return to the "Modify

Settings" menu.

2

4 Configure the “DNS Setup” (optional).

DNS (Domain Name Service) is an Internet service that translates

domain names into IP addresses. Ask your network administrator

whether DNS is in use, and if it is, for the host name, domain name, and

DNS server address to use.

Start at the “Modify Settings” menu.

Press the DNS Setup softkey to display the “Host Name” field.

a. Set the “Host Name.” Enter the host name. The host name is the

host portion of the domain name, which is translated into an IP

address. The host name is entered as a string using the knob and

cursor keys to select and change characters. The host name may

51

Page 52

Chapter 2 Front-Panel Menu Operation

To Configure the Remote Interface

include letters, numbers, and dashes (“ -”). You can use the keypad for

the numeric characters only.

Press to delete all characters to the right of the cursor position.

2

b. Set the “Domain Name.” Press the Domain Name softkey and ent er

the domain name. The domain name is translated into an IP address.

The domain name is entered as a string using the knob and cursor

keys to select and change characters. The domain name may include

letters, numbers, dashes (“-”), and periods (“.“). You can use the

keypad for the numeric characters only.

Press to delete all characters to the right of the cursor position.

c. Set the “DNS Server” address. Press the DNS Server softkey and

enter the address of the DNS server in the IP address format (using

the keypad).

5 Exit the menus.

Press DONE to exit each menu in turn, or p

menu directly.

More about IP Addresses and Dot Notation

Dot-notation addresses ("nnn.nnn.nnn.nnn" where "nnn" is a byte value)

such as IP addresses must be expressed with care. This is because

most web software on the PC will interpret byte values with leading zeros

as octal numbers. Thus, "255.255.020.011" is actually equivalent to the

decimal "255.255.16.9" rather than "255.255.20.11" because ".020" is

interpreted as "16" expressed in octal, and ".011" as "9". To avoid

confusion it is best to use only decimal expressions of byte values (0 to

255), with no leading zeros.

ress

to exit the “Utility”

The Agilent 33220A assumes that all IP addresses and other dotnotation addresses are expressed as decimal byte values, and strips all

leading zeros from these byte values. Thus, if you try to enter

"255.255.020.011" in the IP address field, it becomes "255.255.20.11" (a

purely decimal expression). You should enter exactly the same

expression, "255.255.20.11" in your PC web software to address the

instrument. Do not use "255.255.020.011"—the PC will interpret that

address differently due to the leading zeros.

52

Page 53

3

3

Features and Functions

Page 54

3

Features and Functions

This chapter makes it easy to look up all the details about a particular

feature of the function generator. It covers both front panel and remote

interface operation. You may want to read chapter 2, “Front-Panel Menu

Operation” first. See chapter 4, “Remote Interface Reference” for a

detailed discussion of the syntax of the SCPI commands to program the

function generator. This chapter is divided into the following sections:

• Output Configuration, on page 55

•Pulse Waveforms, on page 70

• Amplitude Modulation (AM), on page 74

• Frequency Modulation (FM), on page 79

• Phase Modulation (PM), on page 85

• Frequency-Shift Keying (FSK) Modulation, on page 89

• Pulse Width Modulati on (PWM), on page 93

• Frequency Sweep, on page 99

•Burst Mode, on page 106

•Triggering, on page 115

• Arbitrary Waveforms, on page 120

• System-Related Operations, on page 126

• Remote Interface Configuration, on pa ge 135

• External Timebase Reference (Option 001), on page 144

• Calibration Overview, on page 146

• Factory Default Sett ing s, on page 150

Throughout this manual “default” states and values are identified. These

are the power-on default states provided you have not enabled the

power-down recall mode (see “Instrument State Storage” on page 126).

Throughout this manual, the following conventions are used for

SCPI command syntax for remote interface programming:

• Square brackets ( [ ] ) indicate optional keywords or parameters.

• Braces ( { } ) enclose pa rameters within a command string.

• Triangle brackets ( < > ) enclose parameters for which you must

substitute a value.

• A vertical bar ( | ) separates multiple parameter choices.

54

Page 55

Chapter 3 Features and Functions

Output Configuration

Output Configuration

This section contains information to help yo u configure the function

generator for outputting waveforms. You may nev er have to change some

of the parameters discussed here, but they are provided to give you the

flexibility you might need.

Output Function

The function generator can output five standard waveforms (sine,

square, ramp, pulse, and noise), plus dc. You can also select one of five

built-in arbitrary waveforms or create your own custom waveforms. You

can internally modulate sine, square, ramp, and arbitrary waveforms

using AM, FM, PM, or FSK. You can also modulate pulse using PWM.

Linear or logarithmic frequency sweeping is available for sine, square,

ramp, and arbitrary waveforms. You can generate a burst waveform

using any of the standard or arbi trary waveforms (but not dc). The

default function is sine wave.

3

• The table below shows which output functions are allowed with

modulation, sweep, and burst. Each “ • ” indicates a valid com bina tion

If you change to a function that is not allowed with modulation,

sweep, or burst, then t he modulation or mode is turned off.

Sine Square Ramp Pulse Noise DC Arb

AM, FM, PM, FSK

Carrier

PWM Carrier •

Sweep Mode •• • •

Burst Mode •• •• •

1

Allowed in the External Gated burst mode only.

•• • •

1

.

•

55

Page 56

3

Chapter 3 Features and Functions

Output Configuration

• Function Limitations: If you change to a function whose maximum

frequency is less than that of the current function, the frequency is

adjusted to the maximum value for the new function. For example,

if you are currently outputting a 20 MHz sine wave and then change

to the ramp function, the function generator will automatically

the output frequency to 200 kHz (the upper limit for ramps).

• Amplitude Limitations: If you change to a function whose maximum

amplitude is less than that of the current function, the amplitude is

automatically adjusted to the maximum value for the new function.

This may occur when the output units are Vrms or dBm due to the

differences in crest factor fo r the various output functions.

For example, if you output a 5 Vrms square wave (into 50 ohms) and

then change to the sine wave function, the function generator will

automatically adjust the output amplitude to 3.536 Vrms (the upper

limit for sine in Vrms).

• Front-Panel Operation: To select a function, press any key in the top

row of function keys. Press to output the arbitrary waveform

currently selected. To view the other arbitrary waveform choices,

press the Select Wform softkey.

adjust

To select dc volts from the front panel, press and then select the

DC On softkey. Press the Offset softkey to enter t he desired offset

voltage level.

• Remote Interface Operation:

FUNCtion {SINusoid|SQUare|RAMP|PULSe|NOISe|DC|USER}

You can also use the

amplitude, and offset with a single command.

56

APPLy

command to select the function, frequency

,

Page 57

Chapter 3 Features and Functions

Output Configuration

Output Frequency

As shown below, th e ou t pu t fr eq ue n c y rang e de p en d s on th e fu nc t i on

currently selected. The default frequency is 1 kHz for all functions.

Function Minimum Frequency Maximum Frequency

Sine

Square

Ramp

Pulse

Noise, DC

Arbs

1 µHz

1 µHz

1 µHz

500 µHz

Not Applicable

1 µHz

20 MHz

20 MHz

200 kHz

5 MHz

Not Applicable

6 MHz

• Function Limitations: If you change to a function whose maximum

frequency is less than that of the current function, the frequency is

adjusted to the maximum value for the new function. For example,

if you are currently outputting a 20 MHz sine wave and then change

to the ramp function, the function generator will automatically

adjust

the output frequency to 200 kHz (the upper limit for ramps).

• Burst Limitation: For internally-triggered bursts, the minimum

frequency is 2.001 mHz. For sine and square waveforms, frequencies

above 6 MHz are allowed only with an “infinite” burst count.

Duty Cycle Limitations

•

: For square waveforms, the function generato

may not be able to use the full range of duty cycle values at higher

frequencies as shown below.

20% to 80% (frequency <

10 MHz)

40% to 60% (frequency > 10 MHz)

If you change to a frequency that cannot produce the current duty cycle

the duty cycle is automatically adjusted to the maximum value for the

new frequency. For example, if you currently have the duty cycle set

to 70% and then change the frequency to 12 MHz, the function

generator will automatically adjust the duty cycle to 60% (the upper

limit for this frequency).

3

r

,

57

Page 58

Chapter 3 Features and Functions

Output Configuration

• Front-Panel Operation: To set the output frequency, press the Freq

softkey for the selected function. Then use the knob or numeric

keypad to enter the desired frequency. To set the waveform period

instead, press the Freq softkey again to toggle to the Period softkey.

• Remote Interface Operation:

FREQuency {<frequency>|MINimum|MAXimum}

3

You can also use the

amplitude, and offset with a single command.

APPLy

command to select the function, frequency

Output Amplitude

The default amplitude is 100 mVpp (into 50 ohms) for all functions.

• Offset Voltage Limitations: The relationship between output

amplitude and offset voltage is shown below. Vmax is the maximum

peak voltage for the selected output termination (5 volts for a 50Ω

load or 10 volts for a high-impedance load).

Vpp <

• Limits Due to Output Termination: If you change the output

termination setting, the displayed output amplitude will be adjusted

(and no error will be generated). For example, if you set the amplitude

to 10 Vpp and then change the output termination from 50 ohms to

“high impedance”, the amplitude displayed on the function

generator’s front-panel will double to 20 Vpp. If you change from

“high impedance” to 50 ohms, the displayed amplitude will drop

in half. For more information, see “Output Termination” on page 63.

• Limits Due to Units Selection: In some cases, the amplitude limits

are determined by the ou tput units selected . This may occur when the

units are Vrms or dBm due to the differences in crest factor for the

various output functions. For example, if you output a 5 Vrms square

wave (into 50 ohms) and then change to the sine wave function,

the function generator will automatically adjust the output amplitude

to 3.536 Vrms (the upper limit for sine waves in Vrms).

2 X (Vmax –|Voffset|)

,

58

Page 59

Chapter 3 Features and Functions

Output Configuration

• You can set the output amplitude in Vpp, Vrms, or dBm. For more

information, see “Output Units” on page 62.

• You cannot specify the output amplitude in dBm if the output

termination is currently set to “high impedance”. The units are

automatically converted to Vpp. For more information, see “Output

Units” on page 62.

• Arbitrary Waveform Limitations: For arbitrary waveforms, the

maximum amplitude will be limited if the waveform data points do

not span the

For example

of values between ±1 and therefore its maximum ampli tude is limite d

to 6.087 Vpp (into 50 ohms).

• While changing amplitude, you may notice a momentary disruption

in the output waveform at certain voltages due to switching of the

output attenuators. To prevent this disruption in the output, you can

disable the voltage autoranging feature as described on page 66.

full range of th e outpu t DAC (Digital- to-Analog Conve rter).

, the built-in “Sinc” waveform does not use the full range

3

• You can also set the amplitude (with an associated offset vo ltage)

by specifying a high level and low level. For example, if you set the

high level to +2 volts and the low level to -3 volts, the resulting

amplitude is 5 Vpp (with an offset voltage of -500 mV).

• For dc volts, the output level is actually controlled by setting the

offset voltage. You can set the dc level to any value between ±5 Vdc

into 50 ohms or ±10 Vdc into an open circuit. See “DC Offset Voltage”

on the following page for more information.

To select dc volts from the front panel, press and then select the

DC On softkey. Press the Offset softkey to set the desired offset

voltage level.

• Front-Panel Operation:

softkey for the selected function. Then use the knob or numeric

keypad to enter the desired amplitude. To set the amplitude using a

high level and low level, press the Ampl softkey again to to ggl e to t he

HiLevel and LoLevel softkeys.

To set the output amplitude, press the

Ampl

59

Page 60

Chapter 3 Features and Functions

Vpp

-

---

Output Configuration

• Remote Interface Operation:

VOLTage {<amplitude>|MINimum|MAXimum}

Or, you can set the amplitude by specifying a high level and low level

using the following commands.

VOLTage:HIGH {<voltage>|MINimum|MAXimum}

VOLTage:LOW {<voltage>|MINimum|MAXimum}

3

You can also use the

amplitude, and offset with a single command.

APPLy

command to select the function, frequency

DC Offset Voltage

The default offset is 0 volts for all functions.

Limits Due to Amplitude

•

output ampl itude i s sh own belo w. Vmax is the maximum peak vol tage

for the selected output termination (5 volts for a 50Ω load or 10 volts

for a high-impedance load).

|Voffset| <

If the specified offset voltage is not valid, the function generator will

automatically adjust it to the maximum dc voltage allowed with the

amplitude specified.

• Limits Due to Output Termination: The offset limits are determined

by the current output termination setting. For example, if you set the

offset to 100 mVdc and then change the output termination from

50 ohms to “high impedance”, the offset voltage displayed on the

function generator’s front-panel w ill double to 200 mVdc (and no error

will be generated). If you change from “high impedance” to 50 ohms,

the displayed offset will drop in half. See “Output Termination” on

page 63 for more information.

Vmax –

: The relatio nship between offs et voltage and

------2

,

60

Page 61

Chapter 3 Features and Functions

Output Configuration

• Arbitrary Waveform Limitations: For arbitrary waveforms, the

maximum

points do not

Converter).

the full range of values between ±1 and therefore its maximum offset

is limited to 4.95 volts (into 50 ohms).

• You can also set the offset by specifying a high level and low level.

For example, if you set the high level to +2 volts and the low level to

-3 volts, the resulting amplitude is 5 Vpp (with an offset voltage of

-500 mV).

offset and am p lit u d e w ill be lim it ed if the w aveform data

span the

For example, the built-in “Sinc” waveform does not use

full range of the output DAC (Digital-to-Analog

• For dc volts, the output level is actually controlled by setting the

offset voltage. You can set the dc level to any value between ±5 Vdc

into 50 ohms or ±10 Vdc into an open circuit.

To select dc volts from the front panel, press and then select the

DC On softkey. Press the Offset softkey to set the desired offset

voltage level.

• Front-Panel Operation:

for the selected function. Then use the knob or numeric keypad to

enter the desired offset. To set the offset using a high level and low

level, press the Offset softkey again to toggle to the HiLevel and

LoLevel softkeys.

• Remote Interface Operation:

VOLTage:OFFSet {<offset>|MINimum|MAXimum}

Or, you can set the offset by specifying a high level and low level

using the following commands.

VOLTage:HIGH {<voltage>|MINimum|MAXimum}

VOLTage:LOW {<voltage>|MINimum|MAXimum}

You can also use the

amplitude, and offset with a single command.

To set the dc offset, pre ss the

APPLy

command to select the function, frequency

Offset

softkey

3

,

61

Page 62

Chapter 3 Features and Functions

Output Configuration

Output Units

3

Applies to output amplitude only

amplitude are volts peak-to-peak.

• Output units: Vpp, Vrms, or dBm. The default is Vpp.

• The unit setting is stored in volatile memory. The units are set to

“Vpp”when power has been off or after a remote interface reset

(provided the Pow er On state is set to “default”).

• The function generator uses the current units selection for both front

panel and remote interface operations. For example, if you select

“VRMS” from the remote interface, the units are displayed as

“VRMS” on the front panel.

• The output units for amplitude cannot be set to dBm if the output

termination is currently set to “high impedance”. The units are

automatically converted to Vpp.

• Front-Panel Operation: Use the numeric keypad to enter the desired

magnitude and then press th e approp ria te so ftk ey to s elect the unit s.

You can also convert from one unit to another from the front panel.

For example, to convert 2 Vpp to its equivalent value in Vrms,

press and then press the V

707.1 mVrms for a sine wave.

• Remote Interface Operation:

. At power-on, the units for output

softkey. The converted value is

RMS

VOLTage:UNIT {VPP|VRMS|DBM}

62

Page 63

Chapter 3 Features and Functions

Output Configuration

Output Termination

Applies to output amplitude and offset voltage only. The Agilent 33220A

has a fixed series output i mpedance of 50 o hms to the front-panel Output

connector. If the actual load impedance is different than the value

specified, the displayed amplitude and offset levels will be incorrect.

• Output termination: 1Ω to 10 kΩ, or Infinite. The default is 50Ω. The

message line at the top of the display calls attention to output

termination settings other than 50Ω.

• The output termination setting is stored in non-volatile memory

and does not change when power has been off or after a remote

interface reset (assuming the Power On state is set to “default”).

• If you sp eci f y a 50- o hm te r mination but ar e a ctu a l ly te r mi nat i n g i nt o

an open circuit, the actual output will be twice the value specified.

For example, if you set the offset to 100 mVdc (and specify a 50-ohm

load) but are terminating the output into an open circuit, the actual

offset will be 200 mVdc.

3

• If you change the output termination setting, the displayed output

amplitude and offset levels are automatically adjusted (no error will

be generated). For example, if you set the amplitude to 10 Vpp and

then change the output termination from 50 ohms to “high

impedance” , the ampli tu de displayed on the fun ct i on ge n erator’s

front-pan el w ill

to 50 ohms, the displayed amplitude will drop in half.

• You cannot specify the output amplitude in dBm if the output

termination is currently set to “high impedance”. The units are

automatically converted to Vpp.

• Front-Panel Operation: Press and select the Output Setup

softkey. Then use the knob or numeric keypad to select the desired

load impedance or press the Load softkey again to choose “High Z”.

• Remote Interface Operation:

OUTPut:LOAD {<ohms>|INFinity|MINimum|MAXimum}

double

to 20 Vpp. If you change from “high impedance”

63

Page 64

3

Chapter 3 Features and Functions

Output Configuration

Duty Cycle (Square Waves)

The duty cycle of a square wave represents the amount of time per cycle

that the square wave is at a high level (assuming that the waveform is

not inverted).

20% Duty Cycle 80% Duty Cycle

(See Pulse Waveforms, on page 70 for information about duty cycle for

pulse waveforms.)

• Duty Cycle: 20% to 80% (frequency <

40% to 60% (frequency > 10 MHz)

• The duty cycle is stored in volatile memory; the duty cycle is set to

50% (the default) when powe r has been o ff o r af te r a remot e inte rfac e

reset (assuming the Power On state is set to “default”).

• The duty cycle setting is remembered when you change from square

wave to another function. When you return to the square function,

the previous duty cycle is used.

• Limits Due to Frequency: If the square wave function is selected and

you change to a frequency that cannot produce the current duty cycle,

the duty cycle is automatically adjusted to the maximum value for the

new frequency. For example, if you currently have the duty cycle set

to 70% and then change the frequency to 12 MHz, the function

generator will automatically adjust the duty cycle to 60% (the upper

limit for this frequency).

• The duty cycle setting does not apply to a square waveform used as

the modulating waveform for AM, FM, PM or PWM. A 50% duty cycle

is always used for a modulating square waveform. The duty cycle

setting applies only to a square waveform carrier.

• Front-Panel Operation: After selecting the square wave function,

press the Duty Cycle softkey. Then use the knob or numeric keypad

to enter the desired duty cycle.

10 MHz)

64

Page 65

Chapter 3 Features and Functions

Output Configuration

• Remote Interface Operation:

FUNCtion:SQUare:DCYCle {<percent>|MINimum|MAXimum}

The APPLy command automatically sets the duty cycle to 50%.

Symmetry (Ramp Waves)

Applies to ramp waves only. Symmetry represents the amount of time

per cycle that the ramp wave is rising (assuming that the waveform is

not inverted).

0% Symmetry 100% Symmetry

• The symmetry is st ored in volatile memory; the symmetry is set to

100% (the default) when power has been off or after a remote

interface reset (assuming the Power On state is set to “default”).

3

• The symmetry setting is remembered when you change from ramp

wave to another function. When you return to the ramp function,

the previous symmetry is used.

• If you select a ramp waveform as the modulating waveform for AM,

FM, PM, or PWM, the symmetry setting does not apply.

• Front-Panel Operation: After selecting the ramp function, press the

Symmetry softkey. Then use the knob or numeric keypad to enter the

desired symmetry.

• Remote Interface Operation:

FUNCtion:RAMP:SYMMetry {<percent>|MINimum|MAXimum}

The APPLy command automatically sets the symmetry to 100%.

65

Page 66

Chapter 3 Features and Functions

Output Configuration

Voltage Autoranging

3

Autoranging is

automatically selects the optimal settings for the output amplifier and

attenuators. With autoranging disabled, the function generator uses the

current

• You can disable autoranging to eliminate momentary disruptions

• Front-Panel Operation: Press and select the Output Setup

• Remote Interface Operation:

amplifier and attenuator settings.

caused by switching of the attenuators while changing amplitude.

However, turning autoranging off has side effects:

• The amplitude and offset accuracy and resolution (as well as

waveform fidelity) may be adversely affected when reducing the

amplitude below a range change that would occur with

autoranging on.

• You may not be able to achieve the minimum amplitude that is

available with autoranging on.