Useco 34-101-AF User Manual

Project: Quantity: Item #:

Rota-Chill™

Blast Chiller

Models

34-101-AF 34-101PT-AF

34-102-AF 34-102PT-AF

FEATURES

• Thoroughly and rapidly chills

prepared, cooked foods to minimize bacteria development and to

protect the quality of conventionally produced foods.

• Designed for accurate, rapid field

assembly. Complete set of installation instructions and assembly drawings are provided.

• Can be erected against a wall or

inside a room with close

tolerances.

• Food rack couples with RotaChill™ rack carousel. Food rack

rotates to provide quicker chilling.

Rotating rack also provides for

even distribution of cold air around

food so that there are no warm

pockets that allow bacteria growth.

PRODUCT INFORMATION

• “Hold-open” feature keeps door open when placing

or removing racks from Blast Chiller.

• 4” thick urethane insulation ensures optimum

chilling and minimizes operating noise.

• Single and double rack models available. Single rack

unit accommodates 200 to 260 lbs. of food weight.

Double rack unit accommodates 400 to 520 lbs. of

food weight.

• Pass-thru models with doors front and back

available.

• Average chilling cycle is one hour or less. Chilling

time is proportionate to weight and depth of food

in pans.

• The Rota-Chill™ Rack is recommended for food

storage as well as required for the Rota-Chill™

Blast Chiller. This reduces pan-handling.

• Supplied with refrigeration system designed to meet

blast chilling requirements. Available in air-cooled

or water-cooled models. HP depends on model

required.

• Patent number RE 34,047.

• Optional integral temperature probes with digital

readout available. Computer compatible.

• Optional diagnostic control panel available.

Savannah, TN 38372 www.americanfoodserviceco.com

731-925-2200 / 800-447-4693 / FAX 731-925-2840

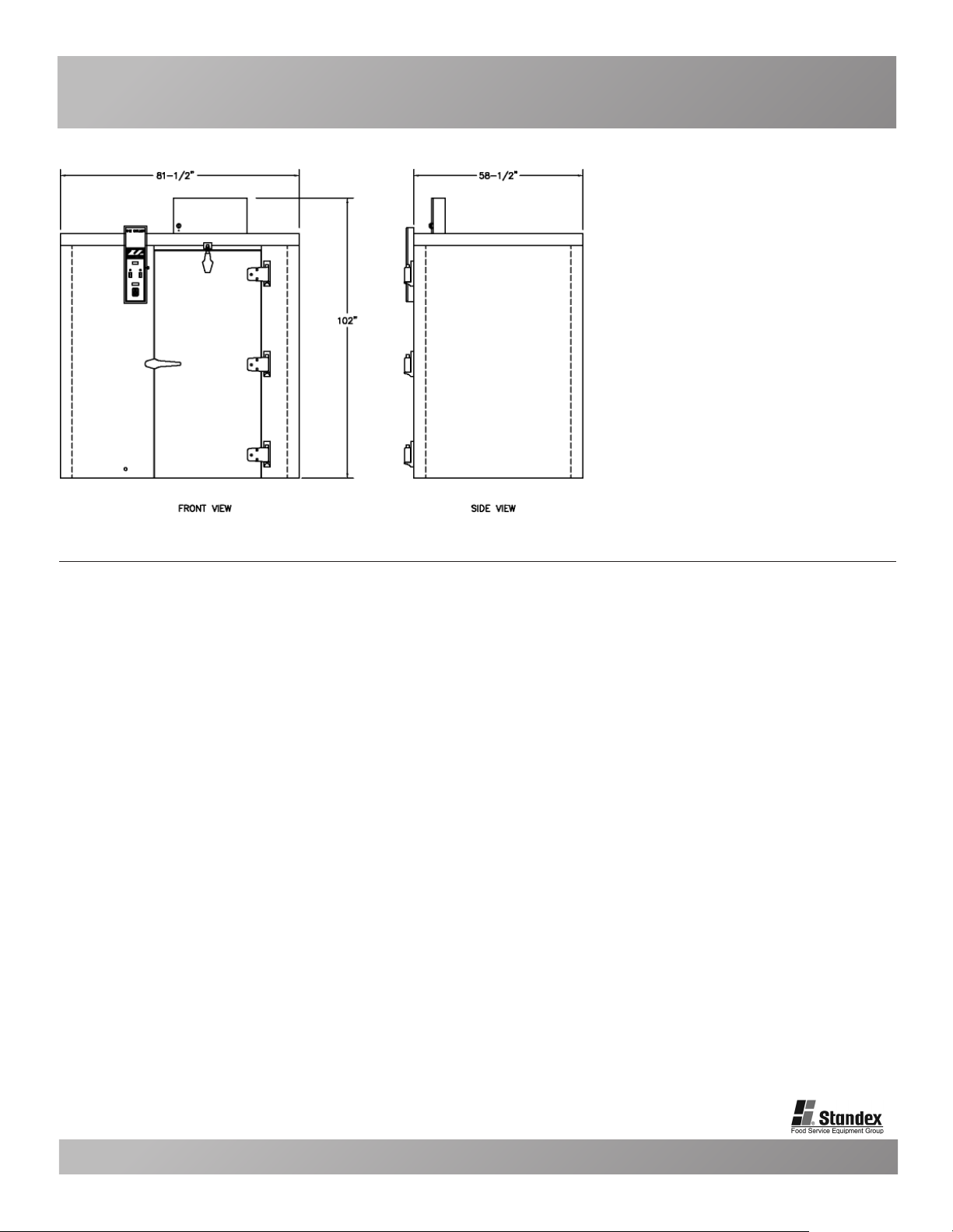

Rota-Chill™ Blast Chiller

34-101AF, 34-101PTAF; 34-102AF, 34-102PTAF

BID SPECIFICATIONS

Provide ____ USECO CATR System Rota-Chill Blast Chiller(s)

Model _______________. Chiller shall consist of stainless steel

modular insulated wall and ceiling panels; ceiling mounted

rotating mechanism, electronic control panel, refrigeration

system with ____________ (air or water) cooled condensing

unit and one mobile stainless steel pan chiller rack per rotating

position.

• Wall and Ceiling Panels shall be number 24 gauge Type

304 stainless steel interior and exterior with 4” thick Flame

spread 25 foamed in place urethane insulation. Panels shall be

secured in place with internal cam-action locking devices.

• Floor shall be no. 14 gauge Type 304 stainless steel with

angles to act as floor screeds to position wall panels.

• Door shall be 34” x 76” flush mounted in fitting type with

same thickness and construction as wall and ceiling panels.

Door opening shall be reinforced with a welded steel

perimeter channel and provided with a thermostatically

controlled electric warmer cable. Door shall be provided

with a thermo plastic, magnetic steel core gasket. Bottom of

door shall be provided with an adjustable vinyl wiper gasket.

Door shall be mounted on heavy duty strap type hinges with

cam-lift nylon bearings to provide “hold-open” capability

when opened 180º. Door shall be equipped with a heavy duty

pull handle with cylinder lock and inside safety latch. Safety

switch shall be provided to stop chiller rack rotation if door is

opened during chilling cycle.

• Rota-Chill Rotating Mechanism shall be provided on ceiling

exterior to provide rotation of pan chiller rack during chilling

cycle. Drive motor and speed reducer shall be attached to

vertical shaft which shall extend through ceiling panel. Shaft

shall be equipped with coupler to engage locking mechanism

on chiller rack.

• Pan Chiller Rack shall have no. 18 gauge tubing uprights and

no. 16 gauge base and pan support ledges of all stainless steel

welded construction. Rack shall accommodate (26) 12” x 20” x

1

2

⁄2” deep pans, two per ledge. Rack shall be equipped with 5”

diameter heavy duty swivel casters with

shall be equipped with top-mounted coupling device ice to

interface with Rota-Chill rotating mechanism.

• Refrigeration System shall consist of high-velocity forced

convection evaporator coil which shall extend from floor to

ceiling on interior wall adjacent to door opening with

integral condensate drain pan and _____ HP self-contained

compressor/condensing unit. Condensate drain line shall

extend through exterior wall. System shall include expansion

valve, drier and oil separator. R-404A refrigerant and

refrigerant lines for connection to remotely located

compressor/condensing unit to be provided by others.

• Control Panel shall be provided on exterior adjacent to latch

side of door opening. Panel shall provide for timed

activation of chilling cycle which shall include automatic

defrost cycle. Control panel shall include on/off, rotation and

manual defrost switches and indicator lights. Digital

thermometer shall indicate internal air temperature.

• Overall dimensions shall be ____ wide x ___ deep x ___ high.

• Electrical data — Blast Chiller controls and rotating

mechanism shall operate on 120/208 volt 1 Phase 60 Hertz.

15

⁄16” wide tires. Rack

Savannah, TN 38372 www.americanfoodserviceco.com

731-925-2200 / 800-447-4693 / FAX 731-925-2840

Due to continued product improvement, specifications are subject to change without notice. 2013 USA

Loading...

Loading...