Notes:

This is not the full manual, the assembly instructions have been removed.

The 17" wide double pages have been spit to a screen readable 8.5 x 11".

User Manual & Assembly Instructions

www.uscutter.com

www.uscutter.com

425.481.3555

425.481.3555

Connecting The Cutter To A Computer

Attach the power cord to the cutter and then plug in the

unit and turn on the power.

If using the Serial Cable to connect

your cutter to a computer:

If you are using a Serial Cable to connect your cutter to a computer then no further

setup is necessary. Simply connect one end of the cable to the cutter and the other end

to a computer and setup is complete. If you have more than one serial connection on

your computer or you are experiencing communication issues between your cutter and

computer then you may wish to verify that the correct COM port is being used in your

software setup, but for most users the COM port will be COM1.

If using the USB Cable to connect

your cutter to a computer:

You will need to download and install drivers for the USB connection to work properly.

Go to www.uscuttersupport.com/mh-support-page and select the driver that supports

your Windows version.

INSTALLING VINYL MASTER SOFTWARE

Your Titan Vinyl Cutter comes bundled with VinylMaster Cut

software, an easy to use software with the tools to help you take

your projects from concept to a ready to cut computer image le.

You can download and install the VinylMaster Cut software at

www.uscutter.com/download, and you will need the key code

packaged with this cutter to activate the software. You may need

to download drivers to support your operating system. Drivers are

available at http://support.uscutter.com

Training for VinylMaster is all done via short videos accessed

through the software. To access the videos, click on the SUPPORT

link, then HELP TOPICS.

12 13

10 11

www.uscutter.com

425.481.3555

If you are going to cut from a scrap or single sheet instead of a roll, then skip the next step on

placing a vinyl roll. All other steps will be the same.

1

Place the roll on top of the stand rollers.

For heat press vinyl, please ip the roll.

Setting up Media

2

Release the pinch rollers release levers.

www.uscutter.com

www.uscutter.com

425.481.3555

425.481.3555

3

Feed the vinyl underneath the pinch rollers (if

working from a single sheet instead of a roll, the

vinyl can also be feed from the front).

4

Adjust the pinch rollers so there is one roller located on each side of the vinyl (and, on

models with 3 or more rollers, one roller near the center). Avoid lowering a pinch roller

to the gap between the two feed rollers.

14 15

12

www.uscutter.com

425.481.3555

5

Leave a gap of between 1/2”-1 1/2” from the edge of

the roller and the edge of the vinyl on both sides.

Setting up MediaSetting up Media

6

Engage the Pinch Rollers by pushing down on the

Pinch Roller Release Levers.

If the cutter is not already on, turn it on now.

13

www.uscutter.com

www.uscutter.com

425.481.3555

425.481.3555

Blade Set Up

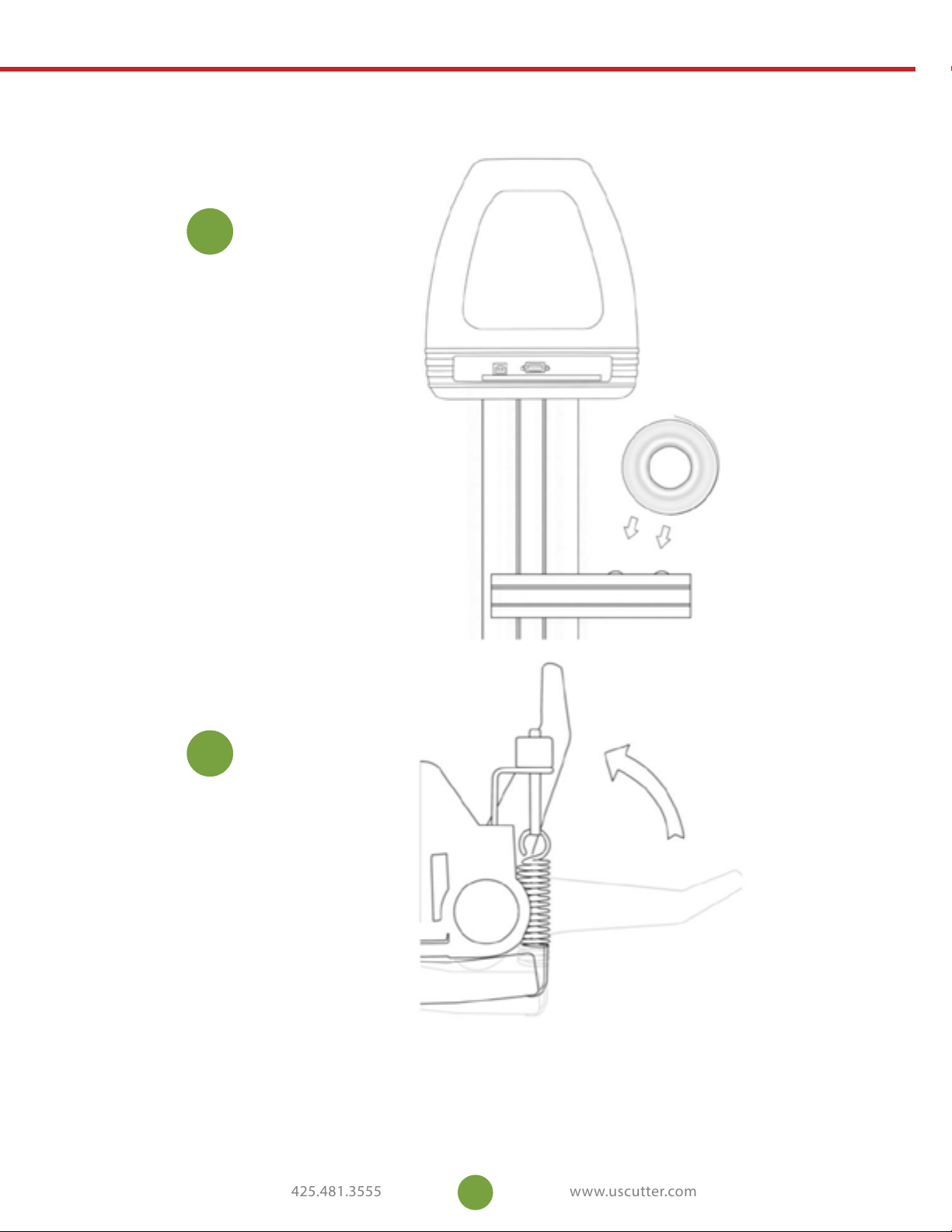

1

Unscrew the cap from the

Blade Carriage.

5 76

2 3 4

Set Brass Ring on Blade

Carriage to the fully down

position.

Remove the protective cover

from a new blade.

Insert the blade into the

top of the Blade Carriage.

Screw the cap back onto

the Blade Carriage.

Blades should be replaced every 6 months. Your blade may need to be replaced

more often if you are cutting thicker material such as ock, glitter, or reectives.

Adjust the carriage cap until the blade

is protruding approximately 1/64

inch.

th

of an

Adjust the Brass Ring until it ts snug

against the Cap. This will help keep

the cap in place during operation.

16 17

14 15

www.uscutter.com

425.481.3555

Control Panel

Setting the Origin for

LaserPoint2

To set the Origin of where the LaserPoint2 cutter will

begin cutting from press the “Enter” button on “Local”

while on the Home Screen using the “Select” button to

highlight it if needed. is will enter the cutter into “Jog

Mode” where the le and right arrows of the control

pad adjust the position of the carriage and the up and

down arrows advance and retreate the media via the

feed rollers. Once you have your media and carriage

in position press the “Select” button, while in the Local

Screen, to move the cursor to “Current” then press

“Enter” and the origin is set.

Home Screen

Changing LaserPoint2 Speed

and Force

To set speed and force of the LaserPoint2, make sure you

are back in the “Home” screen with “Local” highlighted.

Press “Enter”. Use the up and down arrows to adjust the

speed and the le and right arrows to adjust the cutting

force. A typical cutting speed is 500mm/s, and a typical

cutting force is 100.

Local Screen

SPD: 0mm/s PRS: 10g

LOCAL TEST COPY

Reset Select Enter

SPD: 0mm/s PRS: 10g

ORIGIN CURRENT ON

Reset Select Enter

www.uscutter.com

www.uscutter.com

425.481.3555

425.481.3555

BL A D E

MEDIA

CARRIER

60

BL AD E

MEDIA

CARRIER

60

Test Cut

Making Your First Test Cut

A Basic Guide To Vinyl Cutting

Now that you’ve got your system fully

assembled let’s take a moment to test it and

also take moment to learn a bit about how

to “ne tune” the machine so that it will do

quality cuts on the dierent materials you’ll be

cutting. To do this we’ll do a standard test cut,

which when competed will a simple triangle

inside of a square. Load the material roll and

adjust the pinch rollers. Remember to make

sure the top roller is placed so that there is a

bottom roller (called the “grit roller”) beneath

it. Remember to line the material up so that it

is moving straight through the feed area, and

resist the temptation to run the material close

to the edge of the cutter feed area or you

increase the risk of a mis-feed that will wrinkle

your vinyl. (See the graphic on the top of pg.

21 for an example.)

Assuming you’re cutting standard signage

vinyl, you’ll want to use your 45° blade. If

you received vinyl along with your cutter

package, chances are very good it’s a standard

GreenStar or Oracal signage vinyl. Now, nd

the TEST button on the cutter control pad and

press it. It should cut a pattern that looks like

this:

This Test Cut will help you to calibrate the

machine for this material. Examine this cut

and use a weeding tool or exacto knife to

weed the square out while keeping the

triangle on the paper. (“Weeding” is the word

for removing the cut vinyl in the design.)

Use this simple diagram to make adjustments.

There’s a certain amount of trial and error to it

at rst, but you’ll quickly get a feel for it.

CHOOSE BLADE

For thin and regular sized media,

o

use a 45

BL A D E

blade.

For thicker materials, such as Siser

60

StripFlock, Siser Glitter, and Hexis

MEDIA

CARRIER

CutFlex 600 Reflective,

o

blade is needed.

a 60

1

BLADE

Load the blade so

that the length of the

MEDIA

CARRIER

blade shown is not

longer than

thick.

the media is

MEDIA

CARRIER

2

LOAD MATERIAL

Most vinyl products are

loaded from over the top.

18 19

16

www.uscutter.com

425.481.3555

CUT SPEED

Test Cut

This setting determines how fast the design is cut out

and is usually measured in centimeters per second.

3

FORCE/PRESSURE

This setting determines how hard the blade comes down onto the material.

small intricate

designs

large simpler de-

signs

DECREASE CUT

SPEED

INCREASE

CUT SPEED

4

outer square

won’t weed

blade digging too far

into carrier

weeds easily with a light-

ly scored carrier

INCREASE

FORCE

DECREASE FORCE

PERFECT!

17

www.uscutter.com

www.uscutter.com

425.481.3555

425.481.3555

Contour Cutting Contour Cutting

1

Press “Enter” and use the arrow buttons to place the

carriage over a piece of paper. Insert plotter pen and

make an impact on the paper by pressing down and

twisting the pen cartridge.

2

Turn the cutter’s laser on by pressing the “Select” button

to highlight the word “On” and press “Enter”. e

cartridge and the paper should move immediately and

the laser should be exactly centered on your pen mark.

is shows that the oset between the laser and the pen/

blade is properly calibrated. If your laser doesn’t line

up exactly with the mark, your cuts will not land in the

proper lacation and you will need to adjust the oset.

Calibrating the laser

Testing the laser oset

Pen Mark

Laser centered

3

Start by placing the test paper ush against the right side

of the cutter and secure the pinch rollers. Hold down the

“Right” arrow and ress the “Reset” button or simply turn

the power o and then back on. If you are successful you

should see the word “OK” on the start up screen. If you

do not see the word “OK” repeat resetting the machine

until you do. Next, make a new impact mark with the

pen. Use the arrows to center the laser directly over

the pen mark and press the “Enter” button. Re-test the

laser oset by repeating step 2. Once you have nished

calibrating your laser it’s time to print your image.

Adjusting the oset

Flush on right edge

20 21

18

www.uscutter.com

425.481.3555

4

Load your image into the “Sure-Cuts_Allot” soware.

Make sure your art is centered and the size of the cutting

mat in your soware is the same size as the media you

are going to be using. Double check that you have the

correct printer selected by going to “File”, and select

“Print”. Select your printer and make sure you have

checked the box that says “Print Registration Marks”.

Press “OK” to send the job to your printer. You should

now have your printed image with three numbered

registration marks at the corners. Now back to your

cutter for the nal step.

Printing your image

5

Load your image with the registration mark number

“1” in the upper-le hand corner. Now set the position

of the pen/blade infront of, and to the right of your

printed image. Specically infront of the registration

mark. is insures the cutter has enough room to nd all

the registration marks located on the media. To set the

position, press “Enter” with “Local” highlighted and use

the “Arrow” keys to position the carriage. When the pen

is in it’s proper place press “Select” to highlight the word

“On”, and press “Enter”. Now use the “Select” button to

highlight the word “Current” and press “Enter”. e laser

will now be on and the cutter is ready. In the Sure-CutsAllot soware, click on the scissors icon to open your cut

settings window. Click on “Print and Cut” option and

click the “Next” tab twice. e cutter will move from it’s

current position to registration mark number “1”. Don’t

be alarmed if it stops short. Using the keys on your

computer’s keyboard, center the laser over the dot in the

registration mark, then click “Next”. e cutter will move

towards registration mark number “2”. Again, center the

laser over the dot using your computer’s keyboard and

click “Next”. Repeat this process for registration mark

number “3”. Click the “Cut” button and the cutter will

briey return to it’s home position and complete the cut.

Registering prints with the cutter

Laser centered on registration dot

19

www.uscutter.com

www.uscutter.com

425.481.3555

425.481.3555

Troubleshooting

PROBLEM SOLUTION

The cutter performs erratically

during cuts, stops cutting

before the cut is nished, or

cuts lines that do not appear in

the design.

After the rst cut is made,

subsequent cuts are made over

the top of the original, or vinyl

is fed backwards until it loses

contact with the rollers.

Cuts are jagged or inconsistent.

Slashes are made across the

vinyl from the blade movement

during cutting.

Some computers do not work well when connected via the USB port of the

cutters. If you are having problems while cutting and are using the USB cable

to connect from your cutter to computer, you may wish to try the serial cable

connection to avoid further problems. If a serial cable connection is not available

on your computer, you can try a third party USB to serial connector or a PCI card

serial adapter for your computer.

After a cut is made, you will need to reset the origin of the cutter. If the origin is

not set again, the rst origin will remain in the cutter and the cutter will return to

this position before making any further cuts. To reset the origin; from the main

screen of the cutter, press the Oine/Pause button on and then press the Origin

button.

The Blade may be dulled or damaged. Replace with a new blade and try again.

Make sure that the blade can turn freely (by attempting to turn it with your

ngers while the release button of the Blade Carriage is pressed).

Adjust the blade depth of the Blade Carriage (page 17) and Force setting on the

cutter (page 8) until you are getting solid, uniform cuts. Start with a blade depth

of around 1/64th of an inch and a pressure setting of 100g and try an increased

pressure setting before attempting to increase the blade depth.

If the blade is protruding too far from the Blade Carriage then it can score and

cut material during normal operations. If this is occurring, the blade needs to be

adjusted so that it is protruding a minimal distance from the carriage.

Vinyl not feeding straight and

the rightmost Pinch Roller will

not move.

Cuts are warped and

inconsistent.

Sometimes, during shipping or movement of the machine, the right pinch roller

will become stuck on a screw located on the back of the machine. If this occurs

and is aecting your cutting, press forcefully against the pinch roller until it

becomes dislodged from its position. If needed, remove the screw to reposition

the pinch roller in the desired position.

Sometimes, during shipping or movement of the machine, the Carriage Arm

can be dislodged from its track. Make sure that the 2 white wheels behind the

carriage arm are both resting securely on top of (not in front) of the track. If the

wheels are not on the track, gently lift the carriage arm and press back until both

wheels are resting on the track.

22 23

20

www.uscutter.com

425.481.3555

Common Cutting Issues

ISSUE

Cut has dashes or looks perforated.

EXAMPLE

CAUSE

Damaged cutting strip (groove in

strip) or too much blade is exposed

(friction build up).

SOLUTION

Replace the cutting strip or

decrease the blade depth.

ISSUE

Cut line tapers and not cutting

towards the end.

EXAMPLE

CAUSE

Dull blade or blade holder isn’t

secured properly in slot.

SOLUTION

Replace blade, check the

blade force, and secure the

blade holder.

ISSUE ISSUE

Blade is skipping turns and corners. Corners are not cutting correctly.

EXAMPLE EXAMPLE

ROUNDED CORNERS CORNERS WITH FLAGS

CAUSE CAUSE

Part of the blade is dragging on its

side during turns.

Oset setting is incorrect.

SOLUTION SOLUTION

Clean the inside of the blade holder by

coating the blade with WD40 and moving

it in and out of the blade holder. Clean o

any debris that comes out. Replacement

blade holder may be needed.

Change the oset setting.

RAISE OFFSET LOWER OFFSET

21

www.uscutter.com

www.uscutter.com

425.481.3555

425.481.3555

Maintenance For Your Cutter

Digital Printed

Graphics

Indoor Wall

Vinyl

Heat Press

Outdoor

Signage

Stencils &

Masks

You also need the right

media, blade, and

application tape to

ensure a professional job.

A good VINYL CUTTER

is just the start...

Main Tape

GFX-341

45°

Blade

45°

Blade

Oracal 3951 & 3651

HP Gloss & Matte

Glass Application

45°

Blade

Oracal 8300, 8500,

8510, & 8800

Main Tape

GXF-775 or

R-Tape AT65

Main Tape

GXP750 or

Oratape HT55

Oracal 631 or

GreenStar Wall Vinyl

30° Blade

(general)

60° Blade

(glitter/flock)

EasyWeed

(standard fabrics)

EasyWeed Extra

(nylons/water resistant)

R-Tape

4076RLA

60° Blade

Anchor BlastLite

Oramask

GreenStar

Layflat Classic or

Main Tape

GXF-775

45° Blade

(general)

60° Blade

(reflective)

Oracal 651 or GreenStar

Intermediate (calendered)

for short term

Oracal 751 or 951 (cast)

for long term

CUT & PLACE VINYL LIKE A PRO

60

60

Cutting Strips for your vinyl cutter will need

to be replaced periodically - we recommend it

be done every six months if you use your vinyl

cutter continuously.

You might need to change out your Cutting

Strips sooner if you start experiencing an uneven

depth of cut, or your material is peeling up even

on slow speeds.

To replace your Cutting Strip:

• USCutter stocks replacement

cutting strips. Go to

USCUTTER.com and search using

the keyword: Cutting Strip.

• Use a weeding tool or other pointed

tool to pry up the existing strip.

(For best results, start at either end

of the strip.)

Cutting Blades wear out with use and the

tips of the blades can snap just like the point of

a sharp pencil. (is is particularly true of the

60 degree blade.) You should also periodically

visibly inspect your blades and if you see visible

chips in the edge it’s best to replace the blade

with a new one. (is is also a good time to wipe

away any vinyl debris that has built up inside the

blade holder.)

You might also consider the replacement of your

blade if you develop problems weeding or otherwise experience problems with cut quality.

Refer to the manual section on Blade

Set-up for instructions on how to install re-

placement blades and remember to dispose of

your old blade safely by putting it in an aluminum can or other closed hard container.

• Lay replacement into the channel

and use a heat gun or hair dryer to

heat the strip up as you squeeegee it

into place.

• Use a knife to trim the ends of the

strip so that it ts in the channel.

24 25

22 23

Loading...

Loading...