U S Blindstitch 1099-CS, 1099-G, I099-FP, 1099-CS-I, I099-FP-1 User Manual

...

ILS.BLIIII

STnCH

EXPRESS

MMHME

STREET&SKYLINE

CABLE

ADDRESS:"BLINSTIT

1099

COVERING

STANDARD

DRIVE

1099-CS

1099-CS-I

1099-9

I099-DP

PLAINVIEW

TELEPHONE:

PLAINVIEW

SERffiS

THE

SUB

1099-G

CUR

N.Y.

11803

516-433^350

NEW

YORK"

FOLLOWING

CLASSES:

I099-FP

I099-FP-1

I099-KS

I099-KS-I

MAINTENANCE

PARTS

© 1979• U.S. BLIND STITCH MACHINE CORP.

CATALOG

&

ifWMAWc

ni-MAINTENANCE

INTRODUCTION

FOR

1118,1099

INSTRUCTIONS

&

1108

SERIES

A. Replacing

B. Replacing

C. Replacing

D. Replacing

the

the

the

the

Looper

Needle

Shoe

Feeder

Guide

MAINTENANCE

INTRODUCTION

INSTRUCTIONS

All U.S. BLIND STITCH machines are designed

installed

TIONS,

be required. These

cribed below, at which wear

worn

and

only

lubricated

the

minimum

in

accordance

maintenance

maintenance

requirements

maybeexpected

part

may be readily replaced by following

with

normally

for

the

INSTALLATION

will generallybeconfinedtothe

after

the

tion, andtoinsure satisfactory service, it is essential

and needles are used. They are

in long life

A.

and

excellent wearing characteristics typicalofthe

REPLACING

1.

Shoulditbecome

loosen

looper.

THE

the

Becauseofthe

necessarytoexertamoderate

the

new

looper

the

looper

2.

Any

timealooperismovedorchanged,

if

necessary.

formation.Asdescribedindetail

over

the

needleinthe

chain-off

the

pin,

looperisat

needle during

the

long

prongofthe

needle,

the

about

chain-off

approximately

same time,

1/64"

pin

the

LOOPER

looper

clamp

into

shoulder.

Proper

feeder,

the

the

needle

the

(.406mm)

(item

only

parts designed specifically for

necessarytoreplace

screw

(item

precise

fitofthe

amountofforcetopull

the

endofthe

looper

correct

looper

position

looper

3/32"

short

clearance,

"D"

in Figure

timingisabsolutely

return

prongofthe

rodasfarasit

below,aproperly

positiontopickupthe

slot,

and

where

the

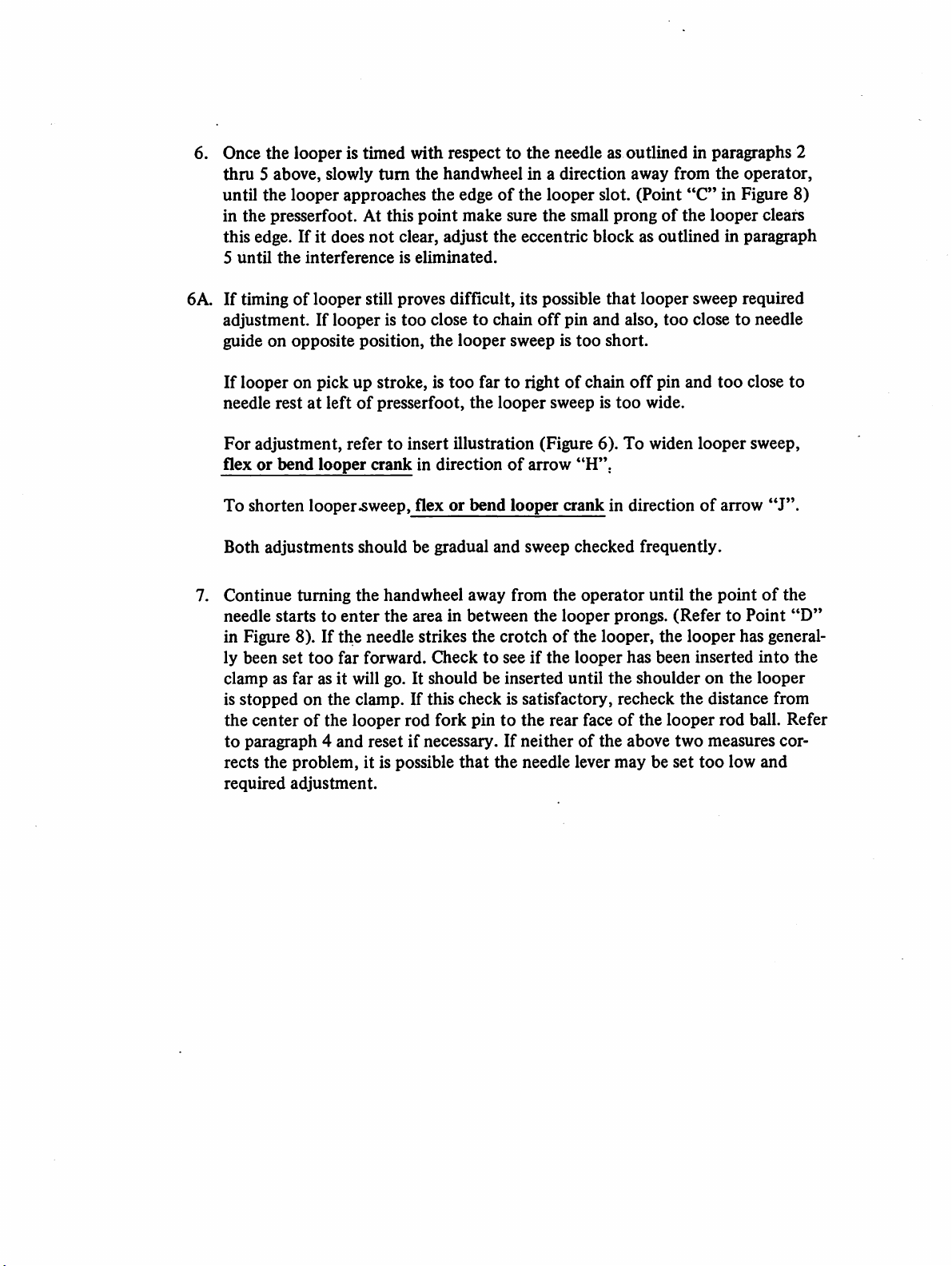

stroke. Referring to Figure 7,

should

(2.4mm)

and

7).

long life

associated

extended

and

trouble-free performance. When

AND

OPERATING

with

industrial

use. When

appropriate instructions.

that

only

genuine U.S. BLIND STITCH

the

U. S. BLIND STITCH machine.

the

looper

"A"

in Figure6)and

looperinthe

(item

looper

"B"inFigure

the

recheck

will go

the

essential

before

looper

for

timed

loop,

needle.

looper

pass

behind

looper

must

over

be so set

The

picks

and

the

should

first

check

the

thread

just

clear

endofthe

pass

over

thatitalso clears

sewing

four

such

wear does occur,

For

easeofinstalla

machine, with

remove

looper

the

roditmay

out.

bottoming

timing

correct

looper

and

will pass

also clear

point

loop

and

stitch

for

off

(Point

the

scarfofthe

needle eye.

the

needle

INSTRUC

machines

locations

the

6),

old

be

Insert

on

reset

the

timing

the

"C"),

At

with

the

will

des

the

parts

built-

3. To adjust

it

mayberotated

should be

and

out,

amount

the

made

the

looper

anddonot

of

travel

loopersothat

within

with

bottomed

attempttoforce

available.

its

the

looper

against its shoulder. Do

the

timing checks

clamp by a limited

clamp screw (item

the

loopertoturn

outasnoted

amount.

not

This

"A"

in Figure6)loosened,

move

beyond

in paragraph 2,

adjustment

the

the

looper

limited

in or

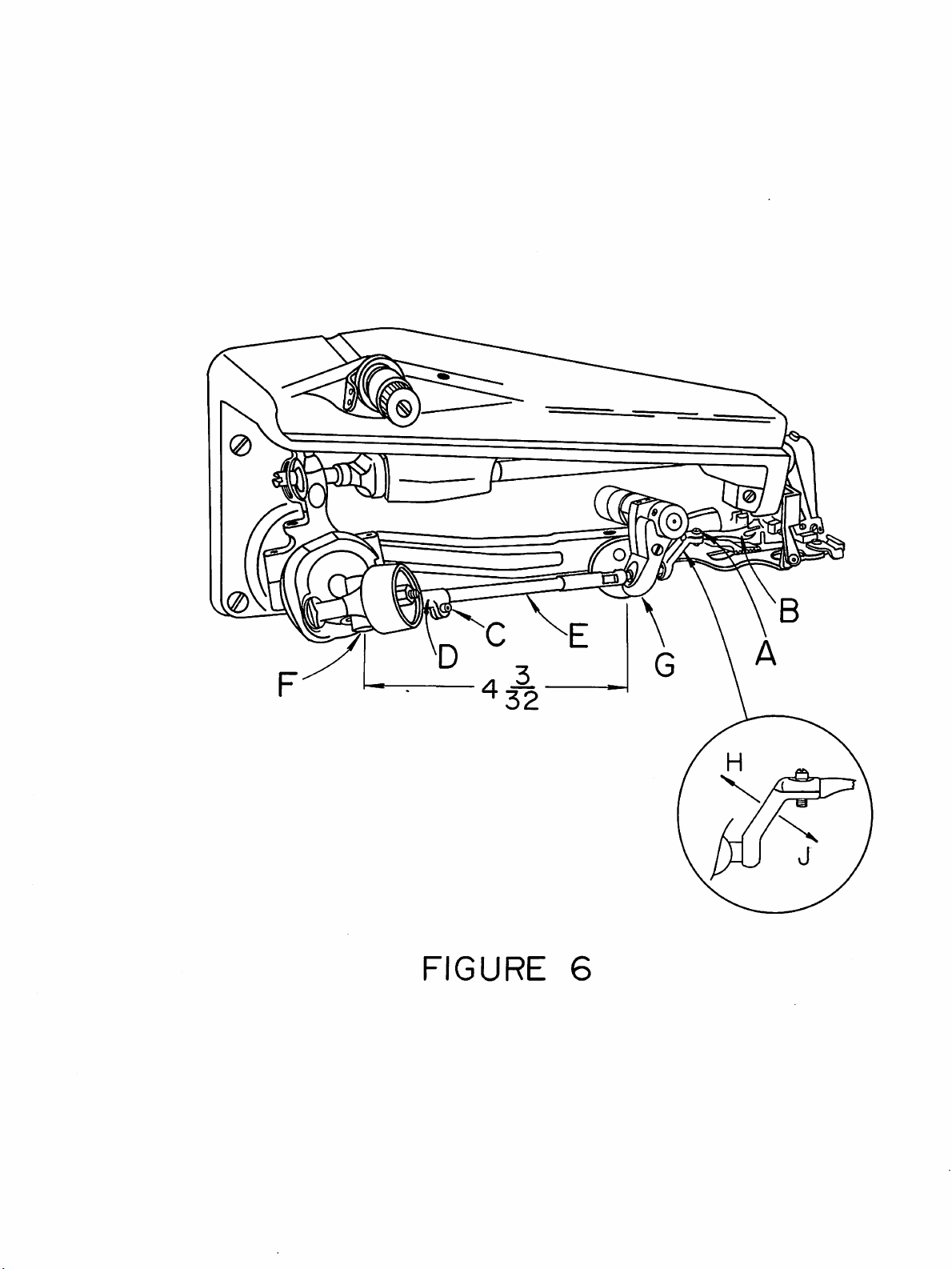

4. If the adjustment described in paragraph 3 is insufficient to provide the correct

timing,itwill be necessarytoturn

This

maybeaccomplishedbyloosening

in Figure 6). The

rodisthen

free to

the

looper

turn

rod

(item

with

looper

rod

in the looperrod fork (item

"E"

in Figure 6) itself.

clamp

screw

(item

"D"

"C"

in

Figure 6). It will normally be necessary to make only a very small adjustment

to

in order

get thelooper

If, for any reason, the rod has been removed or the basic setting

rod has been disturbed by a large amount,itmay be reset by noting

distance from the centerofthe looper rod fork pin (item

the

rear faceofthe

looper

into

the correct rotational position for proper timing.

of

the looper

"F"

in Figure 6) to

rod

ball (item

"G"

in Figure 6) is normally 4 &

that

the

3/32

inches (104mm) (refer to Figure 6). If the rod is settothis dimension then only

minor adjustment will be required

position. Note

variations

that

this dimension is merely a guidetoassist in setting a

maybeexpected

from

to

bring the looper into the correct timing

machinetomachine.

rod

and

5. If, after completing the above adjustments, it is found

too

lowortoo

the

two

set

slotofthe

raise or lower

to see

whether

high,itwill be necessarytoadjust

screws

eccentric

the

the

(item

stud

looper

looper

"A"

in Figure

(item

"B"

in Figure 7) and, using a slight turning

as required. Once

must

be movedtothe

7).

Place a

the

proper

that

the looper is either

the

eccentric

wide

blade screwdriver in

stud.

height is established, check

leftorto

the

right

priortoretight-

First

ening the eccentric block set screws.Ifsuch a movement is required, it may be ob

tainedbylightly

handle

ofascrewdriver.

tapping

the

eccentric

blockinthe

correct

direction

with

loosen

the

motion,

the

0

\

FIGURE

6

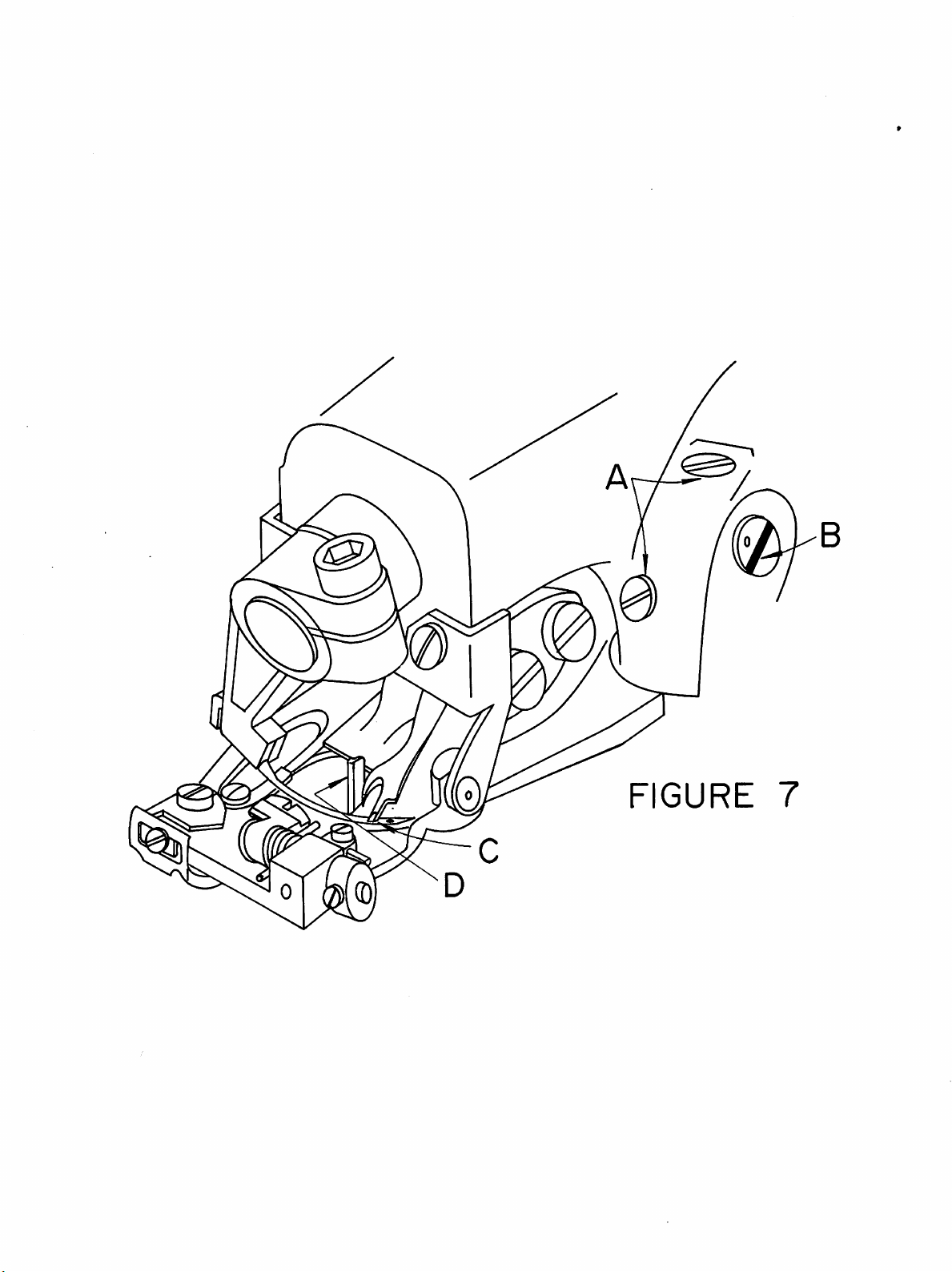

6. Once

the

looper

thru

5 above, slowly

until

the

looper

in

the

presserfoot. At this

this edge. If it does

5

until

the

is timed with respect to

turn

the

approaches

point

not

clear, adjust

interference

is

eliminated.

handwheel

the

edgeofthe

make

the

needle as outlined in paragraphs 2

in a direction away from

sure

the

looper

the

eccentric

slot. (Point

small

block

prongofthe

the

operator,

"C"

in Figure 8)

looper

clears

as outlined in paragraph

6A.Iftimingoflooper

adjustment. If looper is

guide on opposite position,

If

looperonpickupstroke, is

needle

For

restatleftofpresserfoot,

adjustment,

flexorbend

still proves difficult,

too

refertoinsert

looper

crank

its

possible

closetochain

the

looper

too

fartorightofchain

the

illustration

sweep is

looper

off

sweep is

(Figure

in directionofarrow

that

pin

and

too

short.

6).Towiden

"H".

also,

too

looper

off

wide.

too

pin

To shorten looper.sweep, flex or bend looper crank in directionofarrow

Both

7.

Continue

needle

in Figure 8). If

ly

been

clamp as

is

stopped

the

centerofthe

to

paragraph4and

rects

required

adjustments

turning

startstoenter

set

too

far

on the clamp. If this check is satisfactory, recheck

the

problem,

adjustment.

should

the

handwheel away from

the

the

needle strikes

far

forward.

as it will go. It

looper

rod

resetifnecessary.Ifneitherofthe

it is possible

be gradual

and

area in between

the

crotchofthe

Checktoseeifthe

shouldbeinserted

fork

pintothe

that

the

sweep

the

checked

the

operator

looper

looper

until

rear

faceofthe

needle lever

frequently.

until

prongs.

looper,

the

the

has

been

shoulderonthe

looper

above

maybeset

(RefertoPoint

two

sweep required

closetoneedle

and

too

close

looper

the

looper

inserted

the

too

sweep,

pointofthe

has general

into

looper

distance from

rod

ball. Refer

measures

low

and

to

"J".

"D"

the

cor

FIGURE

7

8. Onceclearance is established between the needle and the looper crotch,

continue

passes between the looper prongs, clearing

turning

the

handwheel away from

the

operator

both

the long and the

until

the

short

If difficulty is experienced at this point, it may be necessary to modify some

of

the previous adjustments to the eccentric block or the looper rod length.

If this is done, recheck

lished

which

will satisfy allofthe

the

previous

points

clearance

to insure

conditions.

that

a position is estab

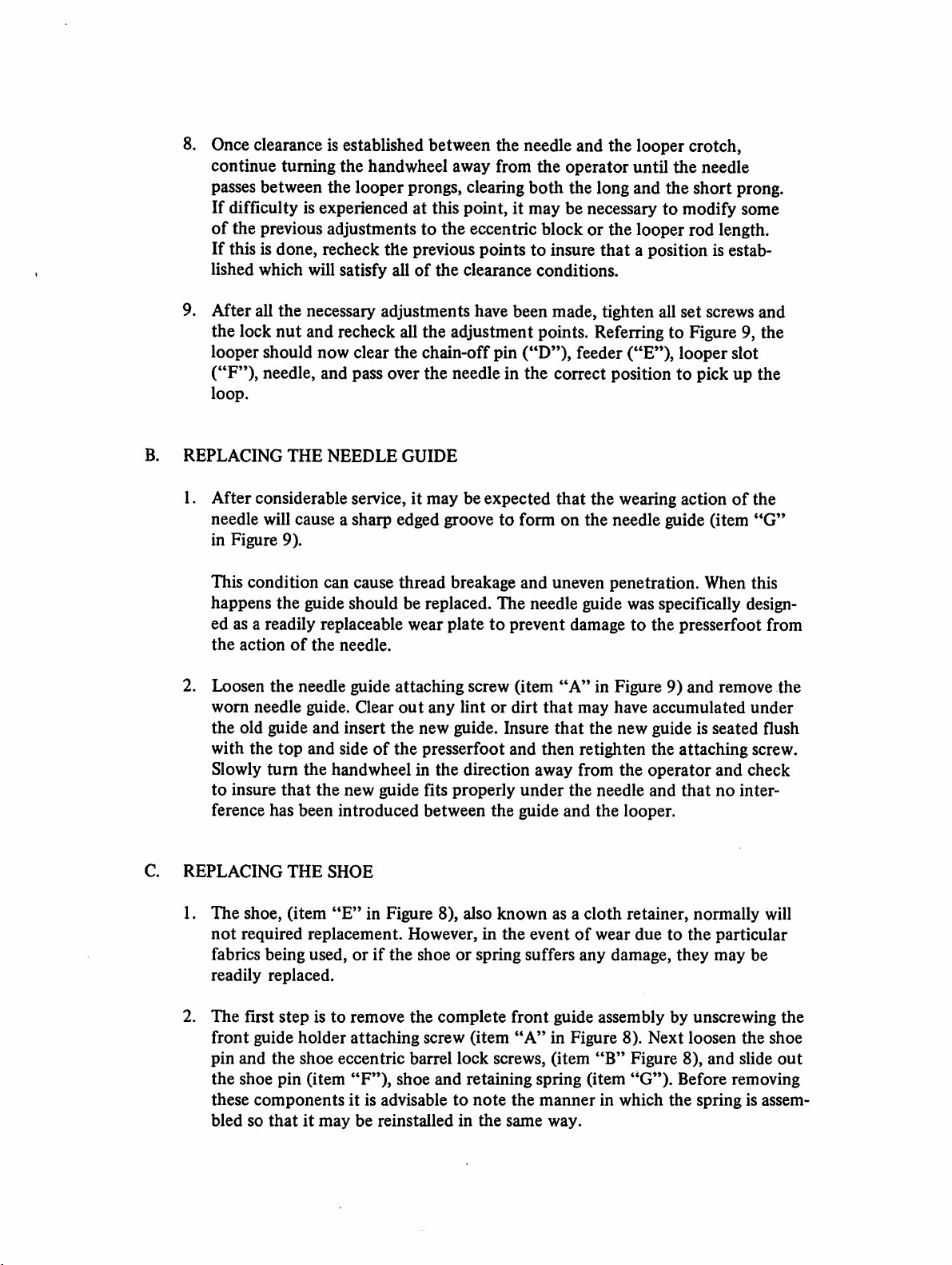

9. After all the necessary adjustments have been made, tighten all set screwsand

nut

and recheck all the adjustment points. Referring to Figure 9, the

should

now

clear

the

chain-offpin

("D"),

feeder

("E"),

looper

needle, and pass over the needle in the correct position to pick up the

THE

NEEDLE

GUIDE

B.

the lock

looper

("F"),

loop.

REPLACING

needle

prong.

slot

1. After considerable service, it may beexpected

needle will cause a sharp edged groove to form on

in

Figure

9).

This condition can cause thread breakage

that

the wearing actionofthe

the

needle guide (item

and

uneven penetration. When this

happens the guide should be replaced. The needle guide was specifically design

ed as a readily replaceable wear

the

action

2. Loosen

worn

the

old guide and insert

with

Slowly

to

insure

ference has

REPLACING

1.

The

not

required

fabrics being used,orif

readily

of

the

needle.

the

needle guide attaching screw (item

needle guide. Clear

the

top

and

sideofthe

turn

the

handwheel in the direction away from

that

the

new

been

introduced

THE

SHOE

shoe,

(item

"E"

replacement.

replaced.

in Figure

out

the

guide fits

the

platetoprevent damagetothe

"A"

any

lintordirt

new guide. Insure

presserfoot

properly

between

8),

However,inthe

shoeorspring suffers

the

also

that

and

then

under

guide

known

eventofwear

may

that

retighten

the

and

as a

any

presserfoot from

in Figure 9) and remove the

have

accumulated

the

new guide is seated flush

the

attaching screw.

the

needle

the

cloth

operator

and

looper.

retainer,

duetothe

damage,

and check

thatnointer

normally

particular

they

may

"G"

under

will

be

2.

The

first

step

is to remove

front

guide

holder

pin

and

the

shoe

the

shoe

pin

(item

these

components

bledsothatitmay

attaching

eccentric

"F'*),

it is advisabletonote

be reinstalled in

the

barrel

shoe

complete

screw

lock

and

front

(item

"A"inFigure

screws,

retaining

the

the

same

guide assembly by unscrewing

(item

spring

mannerinwhich

way.

"B"

(item

8).

Next

Figure 8),

"G*').

the

loosen

Before

the

and

slide

removing

spring is assem

the

shoe

out

e

F

CURE

8

FIGURE

9

3. When replacing an old shoe, make sure

pin

without

worn and does

as

the

tighten

is

linedupwith

the

openingofthe

binding

shoe-pin.

screws

and

without

not

fit the new shoe properly, it should be replaced at

After

replacing

(item

"B"

Figure 8),

the

centerofthe

presserfoot.

excessive looseness. In

the

shoe, shoe pin spring

and

rib.

that

the replacement shoe properly fits the

checktoinsure

Also

insure

that

the

the

event

that

the

the

into

shoe eccentric barrel, re-

that

the

centerofthe

shoe

clears

both

pin

has

same time

shoe

sides

of

4. In

and

out

positionofshoe should now be checked.

be as

closetoneedle

backasfaraspossible

(item

"F'

Figure 8). After the correct location is established, be sure to tighten

screws,

(item

"B"

4A. An additional shoe

controlled,

justedsothat

concerned.Bymoving

downonsome

control,itsometimes

tionofthe

ment

5.

REPLACING

1.

After

pin,

2.

Remove

out

using

side

shoe,

on

the

considerable

(Item

any

the

and

(item

the

fabrics

penetration

THE

"D"inFigure

the

lintordirt

screw previously

forward

as possible.

from

Figure 8).

adjustment

"H"

in Figure 8).

shoe,

whenever

the

which

will aid in

when

set

CHAIN

service, it

chain

off

that

edgeofthe

For

heavy

needle.

To

is also possible.

This

required,

tapered

properlyonmost

cycleonone

OFF

pininor

require

little,ifany

penetrationofdifficult

plyoffabric.

PIN

may

7).

pin

attaching

may

have accumulated.

removed.

slotinthe

For

light fabrics, shoe should

fabrics

move

is a

canbecontrolledasfaraselevation

out

become

screw

Insure

with

seam,

shoeinand

The

tapered

the

shoe

fabrics, is

necessarytoreplace

and

out

heightofthe shoe can now be

pin

and

shoe

canbekept

pressure.Byhaving

fabrics.

that

the

remove

the

Attach

that

the

chain

presserfoot,

and

shoe

turn

eccentric

position

The

shoe

chain

the

new chain

off

pin

then

tighten

shouldbeset

the

can

from

normal

will

show

chain

off

pin,

is against

barrel

be ad

pressing

this

posi

move

off

clean

off

the

screw.

is

pin,

the

Loading...

Loading...