Instructions

for

U.

S.

Blind

128-S • 138 • 448

Stitch

Models

and

parts

book

Machines

U.

S.

BLIND

312

SEVENTH

AVENUE

STITCH

LAckawanna

MACHINE

•

4-9144-5-6

NEW

YORK

CORP.

1,

N.

Y.

IMPORTANT

Unless

in

this

catalogue

however

specifically

It

is

always

the

machine

labeled,

are

model

when

for

advisable

number

the

parts

all

three

to

of

ordering

parts.

illustrated

U.S.

models,

state

your

YOU

CAN

DEPEND

U.

Simplicity

U.

S.

Blind

made

each

because

tion

behind

ordinary

mechanical

more

production

to

simplify

machine

Seldom

it

and

there

it.

amount

than

S.

Stitch

part

does a U.

is

rugged

are

Instructions

skill

pleased

you

receive

SERVICE

of

construction

Machines.

the

use

can

and

many

are

of

knowledge

is

necessary.

with

from

Every

of

this

be

easily

S.

Machine

uncomplicated

years

of

simply

You

quantity

your

ON

is

the

keynote

effort

catalogue

identified.

get

practical

given

is

used,

are

and

U.

has

so

out

of

order,

in

construc

experience

and

very

sure

quality

S,

Machines.

of

been

that

if

an

little

to

be

of

I.

When

Specify

Ordering

BE

SURE

Model

to

of

Parts

Machine

use

GENUINE

avoid

assures

trouble,

To

assure

the

U.

loss

best

VERY

the

proper

S.

NEEDLES

of

results.

IMPORTANT

operation

ONLY,

valuable

time,

of

this

is

costly

U.

S.

the

wise

repairs

Machines,

way

to

and

Standard

Used

#T0,

Each

needle

U.

S.

THROW

Good

needle.

eventually,

U.

screw

needle,

number

To

it

will

slowly

operate

penetration.

While

become

S.

needle

HOW

To

take

where

turn

the

of

times

insert a new

go

and

until

you

the

Needle

in

These

.#15,

has

B.

S.

is

stamped

AWAY

results

U.

of

TO

out

the

are

S.

needles

dull.

the

proper

INSERT

the

needle

Radio

so

the

needle;

tighten

reach

the

Radio

Dial

Sizes

Models

#20,

its

size

on

DULL

OR

obtained

give

Then

size.

NEW

old

needle,

sets.

Dial

Knob

needle

push

it

up

the

screw,

required

Knob

#25,

stamped

all

HOOKED

extra

discard

NEEDLE

slightly

Before

is

entirely

into

then

#30

U.

S.

only

long

inserting

to

the

the

turn

on

the

needles.

NEEDLE

by

using a sharp

service,

and

insert a new

CORRECTLY

loosen

right a sufficient

clear

groove

the

penetration.

which

regulates

shank.

they

the

the

of

the

as

dial

It

is

easy

do,

clamp

new

rib.

far

as

back

to

needle

Be

Sure

the

Needle

Trademark

on

the

Shank,

on

You

the

Box

Use

Has

and

Genuine

on

the

Envelope.

U.

S.

of

the

If

the

or

bottom

as

the

If

the

The

dial,

fabric,

needle

so

fails

layer,

arrow

needle

points

point

THE

of

course,

that

the

to

catch

turn

the

to

"MORE".

goes

DIAL

must

stitch

on

the

dial-a

down

too

be

adjusted

will

be

regular

right

side

little

at a time-to

Run a few

deep

and

to

the

thickness

and

even.

of

the

material,,

the

stitches

shows

to

too

left,

test.

much

impression

the

right

have

for

skilled

Dial

Showing

on

as

the

right

adjusting.

GUIDE

the

the

penetration.

"MORE"

right

arrow

FOR

PROPER

side

of

the

points

to

"LESS".

Only a little

NEEDLE

material,

turn

Then

test

patience

PENETRATION

Dial

Showing

the

dial

until

you

is

required

"LESS"

to

NEW

Rib

TYPE

Shaft

for

"MORE"

DIAL

NOW

Adiustment

USED

ON

Rib

ALL

U.

S.

Shaft

for

"LESS"

MODELS

Adjustment

HOW

Tliread

follows

rone

(A)

over

(ension

(C).

thru

(E)

then

TO

THREAD

from

thru

opening

(B),

under

openings

.thru

(D)

the

spool

or

and

bar

and

needle

THREAD

See

proper

firmly,

turn

tightly,

nut

threading

but

the

tension

shirring

(C)

away

without

After

to

cut a sharp

causing

replacing

thread

needle

Sometimes a groove

of

needle

cause

needle

clomp

thread

clamp:

BREAKAGE:

that

the

machine

causes

pull

or

nut

(C)

toward

the

material,

from

you

which

substantial

edge

in

breakage.

guide:

(E)

by

constant

breakage.

part

#36.

HOW

is

threaded

breakage.

interruption.

you.

or

if

will

loosen

service,

the

the

groove

When

part

#47.

will

thread

You

can

TO

The

If

If

the

it

breaks,

tension

needle

of

this

be

caused

friction;

avoid

thread

occurs,

AVOID

properly,

the

stitch

thread

turn

of

will

the

needle

in

the

this

this

by

as

should

feed

is

loose,

travels

the

tension

the

spring.

be

inclined

guide,

we

suggest

opening

also

changing

im

too

will

or

open

OIL

Be

SURE

holes

IS

THE

to

oil

are

located

LIFE

OF

every

movable

EVERY

THE

MACHINE

part

DAY,

wherever

especially

oil

cups

when

the

machine

Use

secure

into

representative

operator.

all

skip

from

is

new.

proper

lubricating

By

observing

satisfactory

any

trouble,

The

hand

Speed

(or

interval)

2,000

from

of

to

3,000

get

wheel

the

When

oiling,

oil.

these

results

from

in

touch

whom

HAND

you

must

SPEED

machine

stitch

machines,

stitches

insert

simple

your

with

bought

WHEEL

always

depends

the

instructions,

machine.

our

turn

we

per

minute.

oil

spout firmly.

you

If

you

do

main

office,

the

machine.

away

on

the

recommend

or

from

model.

speed

will

run

the

the

On

Very

Important:

speed

motors.

Do

not

mount

machine

on

high

REPLACING

LOOPER

Replacing

once

and

Loosen

looper

Is

looper

Then

reaches

should

needle

looper

guide.

certain

In

the

straight

clearing

turn

the

clear

Is

goes

Tighten

that

If,

looper

In

of

the

principle

the

same

and

the

the

hand

wheel

far

right

the

under

to

looper

the

for

some

the

proper

the

looper

Is

screw

and

slot

and

needle

looper

slowly

side

needle

the

looper

left

side

screw

looper

does

reason,

position,

(port

the

same

remove

turn

enters

prongs

away

of

the

just

in

without

also,

see

to

hold

not

you

note

#22)

on

all

the

old

with

fingers

between

without

from

presser

front

foot

of

touching

that

looper

touch

are

the

not

that

Is

of

utmost

machines.

looper.

so

the

touching

you

where

the

it

clears

In

feeder.

able

on

Insert

that

prongs

either

until

the

the

needle

It.

Then

the

position.

to

adjust

the

right

Import-

new

the

looper

of

one.

looper

looper

eye

when

needle

Make

side

the

and

the

of

machine

screws

tion.

looper

rect

is

the

eccentric

which

By

to

position,

hold

loosening

desired

position.

be

sure

block

(part

assembly

these

unit

three

screws,

When

to

tighten

10

#21).

of

the

the

the

screws

Here

entire

you

looper

looper

may

raise

Is

finally

again.

are

three

set

in

posi

or

lower

in

cor

To

of

feed

worn

new

feeder

replace

feeder

lever

from

is

feeder

and

in

REPLACING

(port

loosen

feed

lever

place,

move

FEEDER

#43-T),

inner

screw.

and

replace

hand

remove

Remove

with

wheel

away

only

front

the

new

from

screw

broken

one.

After

you

or

to

determine

press

tighten

touch

you

bend

assistance.

the

needle

that

feeder

screws

Do

not

the

knee

Do

not

the

When

removing

is

looper

down

on

feed

rest

on

lifter

try

to

help

needle.

out

of

clears

with

finger

lever.

D O N T >

knee

lifter.

while

the

the

machine

The

the

work

the

cloth.

above

feeder;

until

5

Be

sure

machine

by

machine

from

feeds

the

if

they

the

looper

that

the

is

in

operation.

pulling

the

the

machine,

do

clears

knee

does

fabric,

work

be

sure

touch,

and

not

lest

without

that

Do

not

run

the

machine

without

11

cloth.

NUMBER

NAME

6

6-B

7

9-B

10-B

23-B

32

33

85

97

99

100-B

110

Feed

Eccentric

Stitch

Needle

Rib

Rib

Main

Eccentric

Eccentric

Rib

Feed

Needle

Rib

Eccentric

Regulating

Connection

Lever

Connection

Shaft

Lever

Eccentric

Connection

Lever

Collar

Eccentric

(Models

Lever

Ball

Stud

Ball

Guard

Eccentric

Clamp

Ball

Screv/

Screw

Screw

Screw

Guard

128-S

(Models

Screw

128-S

and

and

448

448

only)

only)

12

NUMBER

NAME

8-B

30

34

35

36

38-B

43-T

87

90

100

100

116-L

Feed

Lever

Needle

Shaft

Needle

Needle

Needle

Feed

Lever

Feeder

Feeder

Screw

Needle

Needle

Needle

Feed

Shaft

Lever

Shaft

Clamp

Lever

Clamp

Rocker

Lever

Clamp

Clamp

Crank

Rocker

Pin

Screw

Pin

Collar

Screw

Screw

Collar

14

43-T

MODEL

138

ONLY

44-T

46

47

48

48

49-T

49-T-l

49-T-2

49-T-3

49-T-4

49-T-5

49-T-6

50-B

51

52

86

Presserfoot

Presserfoot

Needle

Needle

Front

Presserfoot

Right

Left

Compensating

Left

Compensating

Compensating

Compensating

Compensating

Presserfoot

Presserfoot

Presserfoot

Presserfoot

Eccentric

Guide

Guide

Guide

Screw

Holder

Shoe

Compensating

Shoe

Shoe

Shoe

Shoe

Shoe

Shoe

Clamp

Pin

Screw

Shoe

Shoe

Shoe

Spring

Regulating

Top

Spring

Bottom

Spring

Pin

Stud

Screw

Knob

Spring

87

92

111

125-T

126

Presserfoot

Front

Shoe

Front

Front

Guide

Pin

Holder

Guide

Guide

Brace

Screw

Holder

Screw

Holder

Clomp

16

Screw

44-T

49-T

49-T-4

W

47

49-T-l

49-T-2

49-T-5

48

49-T-3

49-T-6

WHEN

ORDERING

125

PARTS

17

-T

SPECIFY

MODEL

MODEL

128-S

ONLY

44-T

46

47

48

48

52

61-T

86

87

92

111

116-LR

125-T

126

300

301

Presserfoot

Presserfoot

Needle

Needle

Front

Presserfoot

Rib

Shaft

Presserfoot

Presserfoot

Front

Shoe

Left

Side

Front

Front

Left

Presserfoot

Right

Eccentric

Guide

Guide

Guide

Holder

Shoe

Clomp

Brace

Guide

Pin

Guide

Guide

Holder

Holder

Rib

Holder

Presserfoot

Screw

Stud

Screw

Screw

Screw

Shaft

Shoe

Shoe

Pin

Screw

Clamp

Collar

Screw

302

303

304

305

306

Left

Presserfoot

Right

Presserfoot

Penetration

Penetration

Presserfoot

Shoe

Adjusting

Adjusting

Shoe

Shoe

Pin

18

Spring

Spring

Knob

Knob

Stud

86

305

44-T

87

30^

92

126

46

47

II6-LR

125

III

.T

aoo

WHEN

ORDERING

302

PARTS

303

SPECIFY

19

304

MODEL

s

61

T

NUMBER

NAME

54

57-E

57-N

73

74

75

76

77

78

79

80

89

Main

Spring

Regulating

Regulating

Oil

Cup

Oil

Cup

Rear

Front

Tension

Tension

Tension

Tension

Thread

Knob

Knob

Thread

Thread

Stud

Disc

Spring

Nut

Guide

Screw

Guide

Guide

Screw

117

n7-A

117-B

117-C

118

119

Regulating

(128-S & 448

Spring

Spring

Main

Main

Feed

Fork

Knob

Link

Spring

Spring

Frame

Lock

Screw

Limit

and

only)

Screw

Screw

20

Rod

and

Complete

Nut

and

Nut

57-N

C

"7C

118

77

WHEN

ORDERING

PARTS

21

SPECIFY

MODEL

117

11

NUMBER

NAME

12

13

14

15

16

17

18

19

20

21

22

83

84

91

94

95

Looper

looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Eccentric

Rod

Rod

Rod

Rod

Rod

Rod

Rod

Rod

Rod

Block

Looper

Eccentric

Eccentric

Looper

Looper

Looper

Block

Block

Fork

Sleeve

Rod

Sleeve

Sleeve

Stud

Sleeve

Fork

Fork

Pin

Boll

Carrier

Carrier

Clamp

Clamp

Clamp

Ball

Pin

Screw

Screw

Srew

Clomp

Stud

Screw

Collar

98

99

ICQ

101

105

Eccentric

Looper

Sleeve

Looper

Looper

Rod

Collar

Clamp

Rod

Block

Screw

Carrier

Clamp

Screw

Nut

Clamp

Screw

22

Screw

WHEN

ORDERING

PARTS

SPECIFY

MODEL

PLEASE

WATCH

THESE

NUMBERS

CAREFULLY

11-L

11-R

n-3-L

11-3-R

53-B

61-T-l

63

64

65

66

67-R

67-1-L

67-2-L

67-3-L

67-3-R

68

Left

Flatten

Right

Flatten

Left

Flatten

Right

Flatten

Feed

Frame

Rib

Shaft

Rib

Shaft

Rib

Shaft

Rib

Shaft

Bracket

Right

Flatten

Left

Flatten

Left

Flatten

Left

Flatten

Right

Flatten

Flatten

Bracket

Bracket

(Model

Crank

Crank

Crank

Stud

(128-S

(138

(448

Screw

(128-S

Bracket

(128-S

(448

Bracket

Shaft

(448

448

Stud

Clamp

(128-S

and

only—Not

only)

only—Not

(448

only—Not

and

138

and

138

only—Not

only—Not

only)

Stud

138

only)

Illustrated)

Illustrated)

Illustrated)

only)

only)

Illustrated)

Illustrated)

69

100

103

104

108

116

116-A

Flatten

Rib

Bracket

Bracket

Flatten

Left

Right

Spring

Shaft

Limit

Limit

Screw

Rib

Rib

Collar

Screw

Screw

Nut

Shaft

Collar

Shaft

Clamp

Nut

Collar

24

Screw

103

104

61-T-l

53

ICQ

11-L

11-R

66

r

63

66

69

B

64

65

116

II6A

108

67-2-L

67-R

WHEN

ORDERING

PARTS

25

SPECIFY

MODEL

142

Supporting

Bracket

Lock

Washer

143

144

146

147

150-E

150-1-E

151-C

152

153

154

155-A

156

Supporting

Supporting

Knee

Knee

Large

Supporting

Front

Knee

Knee

Knee

Combination

Stop

Lifting

Bracket

Bracket

Lifter

Screw

Lifter

Lock

Front

Post

Plate

Lifter

Lifter

Pedal

Bracket

Rod

Bracket

Bracket

Bracket

Washer

Plate

for

Knee

and

Washer

Screw

150-E

Lifter

Lifting

Bracket

157

160

161

162

164

Knee

Lifter

(128-S

Hook

Knee

Front

Front

Lifter

Plate

Plate

Rod

and

448

Supporting

Screw

Screw

Support

only)

Spring

Nut

26

Collar

(138

only)

150-E

150-l-E

155-A

WHEN

ORDERING

PARTS

27

SPECIFY

MODEL

4

Side

Cover

5

24

24-V

72

85

97

98

100

109

167-L

168

Back

Cover

Hand

Hand

Belt

Belt

Hand

Hand

Cover

Belt

Cylinder

Cylinder

Wheel

Wheel V Belt

Guard

Guard

Wheel

Wheel

Screw

Guard

for

Screw

Screw

Screw

Screw

Washer

(Model

(Model

Drive

(Not

128-S

128-S

Illustrated)

only)

only)

28

167-L

WHEN

ORDERING

PARTS

SPECIFY

MODEL

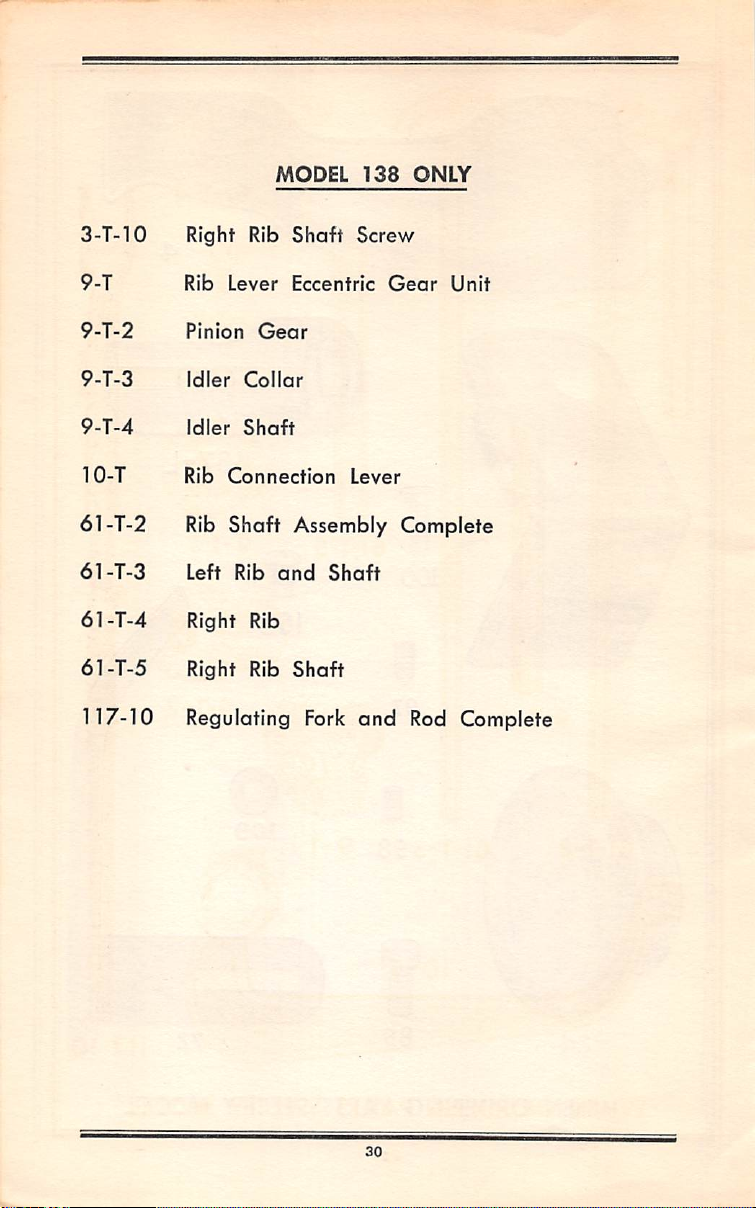

MODEL

138

ONLY

3-T-lO

9-T

9-T-2

9-T-3

9-T-4

10-T

61-T-2

61-T-3

61-T-4

61-T-5

117-10

Right

Rib

Pinion

Idler

Idler

Rib

Rib

Left

Right

Right

Regulating

Rib

Shaft

Lever

Connection

Shaft

Gear

Collar

Shaft

Rib

and

Eccentric

Assembly

Rib

Rib

Shaft

Fork

Screw

Lever

Shaft

and

Gear

Unit

Complete

Rod

Complete

30

6I-T-4

3-T-IO

6I-T-2

WHEN

9-T-4

6I-T-3

ORDERING

6hT-5

PARTS

9-T-3

9-T-2

SPECIFY

117-10

MODEL

MODEL

448

ONLY

44-B

46

47

48

86

87

89-T

101-T

301-T

302-T

303-T

304-T

Presserfoot

Presserfoot

Needle

Needle

Presserfoot

Presserfoot

Tape

Shoe

Right

Left

Shoe

Left

Channel

Pin

Shoe

Shoe

and

Pin

Eccentric

Guide

Guide

Clamp

Brace

Lock

Right

Pin

Screw

Screw

Screw

Tension

Screw

Shoe

and

Spring

Front

Guide

Screw

316-T

378-T

379-T

Tape

Tape

Tape

Channel

Channel

Screw

Tension—Specify

Channel—Specify

32

Size,

Va,

Size

5/16, % inch

■/

////////////A

378-T

316-T

□

379-T

44-B

303-T

301-T

86

WHEN

302-T

87

ORDERING

lOI-T

48

PARTS

33

47

SPECIFY

304-T

MODEL

MODELS

138

and

448

ONLY

3-T-l

3-T-2

3-T-3

3-T-5

3-T-6

3-T-7

3-T-8

3-T-9

3-T-l0

3-T-l 1 Regulating

3-T-l 2 Regulating

3-T-l3

Rib

Carrier

Rib

Carrier

Pinion

Regulating

Regulating

Loaded

Regulating

Regulating

Top

Layer

Shoulder

(Models

Pinion

Shaft

Link

Link

Rib)

Knob

Barrel

Feed

Screw

Stop

Spring

Regulating

Ball

(Models

Collar

Screw

Screw

Barrel

Collar

Frame

Screw

138 & 448)

138 & 448)

(Models

(Models

138 & 448)

138 & 448)

(Model

(Models

(Models

Regulating

138

Spring

138 & 448)

138 & 448)

Knob

(138 & 448)

3-T-l5

3-T-16

87

Rib

Carrier

Rib

Carrier

Rib

Carrier

(Model

448

Shaft

(Model

Shaft

Shaft

Shield

only)

Shield

34

(Mode!

Screw

448

only)

448

only)

3-T-9

I

3-j»7

3-T-6

3-T-5

3-T-I5

3-T-I2

3-T-I3

3-T-2

3-T-II

3-T-8

3-T-3

3-T-I6

3-T-IO

WHEN

ORDERING

PARTS

35

SPECIFY

MODEL

MEMORANDUM

36

Over

30

U.

SEE

S.

THE

Blind

U.

S.

Stitch

FIRST!

Models

,f>4

There

for

1

u.

is a U.

Every

s

5.

Blind

Stitch

r

Machine

Neecf

Printed

in

U.SA.

Loading...

Loading...