U S Blindstitch 1099-CS-l-HH, B1099-CS-1-HH, F1099-CS-1-HH, S1099-CS-1-HH, 1099-T User Manual

...

U.S.

BUND

STITCH

EXPRESS

IMGHINE

STREET

&

SKYLINE

CABLE

ADDRESS:"BLiNSTlT

1099

COVERING

STANDARD

1099-CS-l-HH

B1099-CS-1-HH

F1099-CS-1-HH

S1099-CS-1-HH

DRIVE

TELEPHONE:

1099-PBW-I

CORP.

PLAINVIEW

PLAINVIEW

SERIES

THE

SUB

N.V.

11803

516-433-4350

NEW

YORK"

FOLLOWING

CLASSES;

1099-T

1099-T-l

1099-WB

1099-WB-l

EST.1925

MAINTENANCE

PARTS

©

1979•U.S.

CATALOG

BLIND

STITCH

MACHINE

&

CORP.

ni-MAINTENANCE

FOR

INTRODUCTION

A.

1118,1099

Replacing

the

INSTRUCTIONS

& 1108

Looper

SERIES

B. Replacing

C. Replacing

D. Replacing

the

the

the

Needle

Shoe

Feeder

Guide

MAINTENANCE

INTRODUCTION

INSTRUCTIONS

All U.S. BLIND STITCH machines are designed for long life and trouble-free performance. When

installed

and

lubricated

in

accordance

with

the

INSTALLATION

AND

OPERATING

INSTRUC

TIONS, only the minimum maintenance normally associated with industrial sewing machines will

be.required. These maintenance requirements will generally be confined to the four locations des

cribed below, at which wear may be expected

worn part may be readily replaced by following the appropriate instructions.

tion, and to insure satisfactory service, it is essential

after

extended

that

use. When such wear does occur, the

For

easeofinstalla

only genuine U.S. BLIND STITCH parts

and needles are used. They are the only parts designed specifically for the machine, with the built-

in long life and excellent wearing characteristics typicalofthe U. S. BLIND STITCH machine.

A.

REPLACING

THE

LOOPER

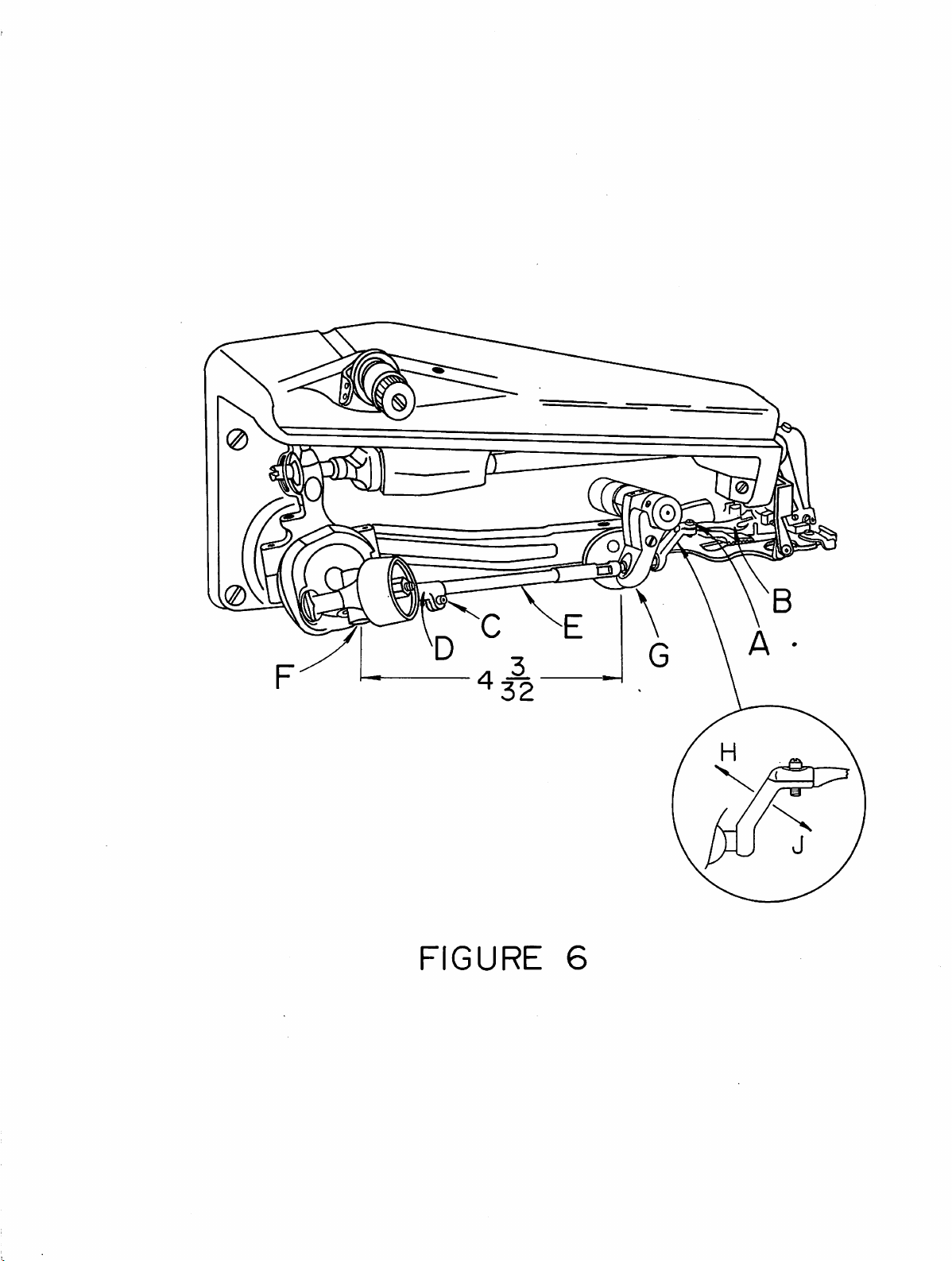

1. Should it become necessary to replace the looper (item

loosen the looper clamp screw (item

looper. Becauseofthe

precise fitofthe

necessary to exert a moderate

"A"

in Figure 6) and remove the old

looper

in the

amountofforce to pull the looper

"B"

looper

in Figure 6),

rod

it may be

out.

Insert

the new looperinto the endofthe rod as far as it will go before bottoming on

the

looper

shoulder.

2. Any time a looper is moved or changed, recheck the looper timing and reset

if necessary. Proper looper timing is absolutely essential for correct stitch

formation. As described in detail below, a properly timed

over the needle in the correct position to pick up

the

chain-off pin, feeder, looper slot, and needle. The first check

the looper is at the position where the looper picks the thread loop

looper

will pass

loop, and also clear

point

for timing

off

the

the

needle during the needle return stroke. Referring to Figure 7, (Point "C"),

the long prongofthe looper should pass over and

needle, approximately

the

same time, the

about

chain-off

1/64"

pin

(.406mm)

(item

3/32"

short

prongofthe

clearance, and

"D"

in Figure 7).

(2.4mm)

behind

looper should pass over

must

just

clear the scarfofthe

the

endofthe needle eye. At

be so

set

that

it also clears the

the

needle with

3. To adjust the looper so

it

mayberotated

shouldbemade

and

the

looper

out,

anddonot

amount

4.

If

timing, it will be necessarytoturn

This

in Figure 6).

Figure

in

If, for

rod

distance

the

inches

minor

of

the

adjustment

may

6).

ordertoget

any

has

been

from

rear faceofthe

(104mm)

adjustment

position. Note

variations

with

bottomed

attempttoforce

travel

be accomplished by loosening

The

It will

normally

the

reason,

disturbedbya large

the

(refer to Figure 6).Ifthe

that

maybeexpected

that

within

the

available.

describedinparagraph

rodisthen

looper

the

rod

centerofthe

looper

will be

this dimension is merely a guidetoassist in setting a

the timing checks

its

clampbya

looper

against

clamp

freetoturninthe

be necessarytomake

into

the

limited

screw

its

shoulder.

the

loopertoturn

3 is

the

looper

with

correct

(item

insufficienttoprovide

looper

rotational

has been removedorthe

amount,itmayberesetbynoting

rod

looper

ball (item

rod

fork

"G"

rod is

requiredtobring

from

machinetomachine.

the

out

as noted in paragraph 2,

amount.

Do

not

rod

looper

only

pin

This

adjustment

"A"

in Figure6)loosened,

move

the

looperinor

beyond

(item

rod

position

the

limited

"E"

in Figure6)itself.

clamp screw (item

rod

fork

(item

a very small

for

basic settingofthe

(item

"F"

in Figure6)to

the

"D"

adjustment

proper

looper

that

in Figure 6) is normally 4 &

settothis dimension

looper

into

the

correct

then

timing

correct

"C*

in

timing.

the

3/32

only

rod

and

5. If,

after

too

lowortoo

the two

slotofthe

raiseorlower

to see

ening

tained

handle

completing the above adjustments, it is found

high,itwill be necessarytoadjust

set

screws (item

eccentric

the

whether

the

by lightly

ofascrewdriver.

the

eccentric

tapping

looperasrequired.

stud

looper

block

"A"

in Figure 7). Place a wide blade screwdriver in the

(item

"B"

in Figure 7) and, using a slight

Once

the

proper

mustbemovedtothe

set

screws.Ifsuchamovementisrequired,itmaybeob

the

eccentric

blockinthe

that

the

eccentric stud.

height

leftorto

correct

the

looperiseither

turning

is established,

the

right

direction

First

loosen

motion,

check

priortoretight-

with

the

\

FIGURE

6

6.

Once

the

looperistimed

thru 5 above,slowly turn the handwheel in a direction awayfrom the operator,

untilthe

inthe

this

5

until

looper

approaches

presserfoot.Atthis

edge.

Ifit

does

the

interferenceiseliminated.

not

with

point

clear,

respect

the

adjust

edge

make

to the

of the

sure

the

needleasoutlinedinparagraphs

looper

the

eccentric

slot.

small

(Point

prong

"C" in

of the

looper

blockasoutlinedinparagraph

Figure

clears

2

8)

,

6A.Iftiming

adjustment.Iflooper

guideon opposite position, the looper sweep is too short.

If looper on pickup stroke, istoo far to right of chain off pin and too closeto

needle rest at leftofpresserfoot, the looper sweep is too wide.

For adjustment, refer to insert illustration (Figure 6). To widen looper sweep,

flex or bend looper crank in directionofarrow

To shorten looper

Both adjustments should be gradual and sweep checked frequently.

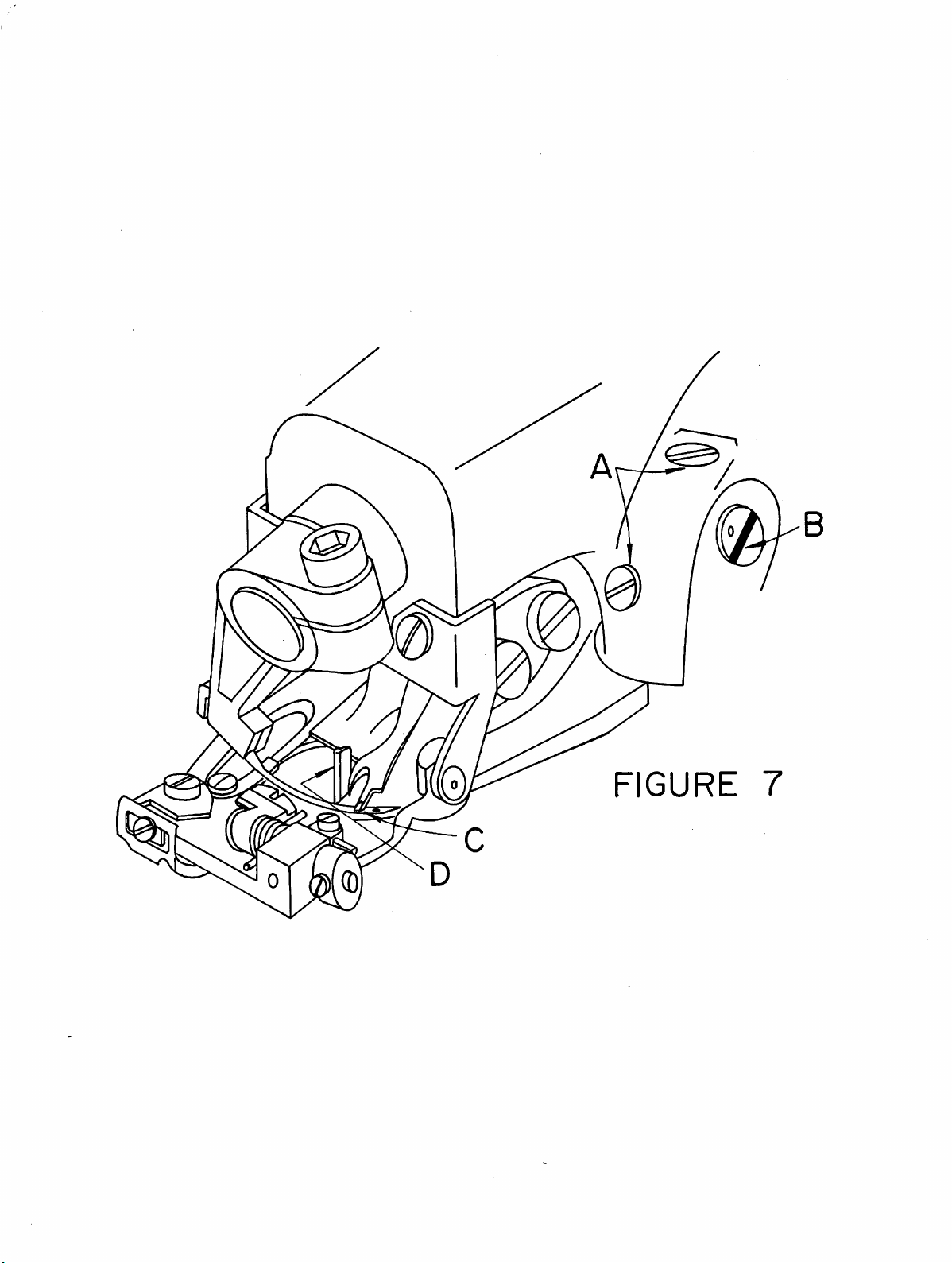

7. Continue turning the handwheel away from the operator until the point of the

needle starts to

in Figure 8). If the needlestrikes the crotch of the looper, the looper has general

ly beenset too far forward. Checkto seeif the looperhas beeninserted into the

clamp

isstopped on the clamp. If this check issatisfactory,recheck the distancefrom

the center of the looperrod fork pin to the rearface of the looper rod ball. Refer

to paragraph 4 and reset if necessary. If neitherofthe above two measures cor

rects the problem, it is possible that the needle levermay be set too low and

required

oflooper still

enter

asfar asit

adjustment.

proves

istoo

.sweep,

the area in between the looper prongs. (Refer to Point

will

go. It shouldbe inserteduntil the shoulder on the looper

difficult, its

closetochain

flex or bend looper crank in direction of arrow

possible

that

offpinand

"H".

looper

also,

sweep

too

closetoneedle

required

"J".

"D"

FIGURE

7

B.

8.

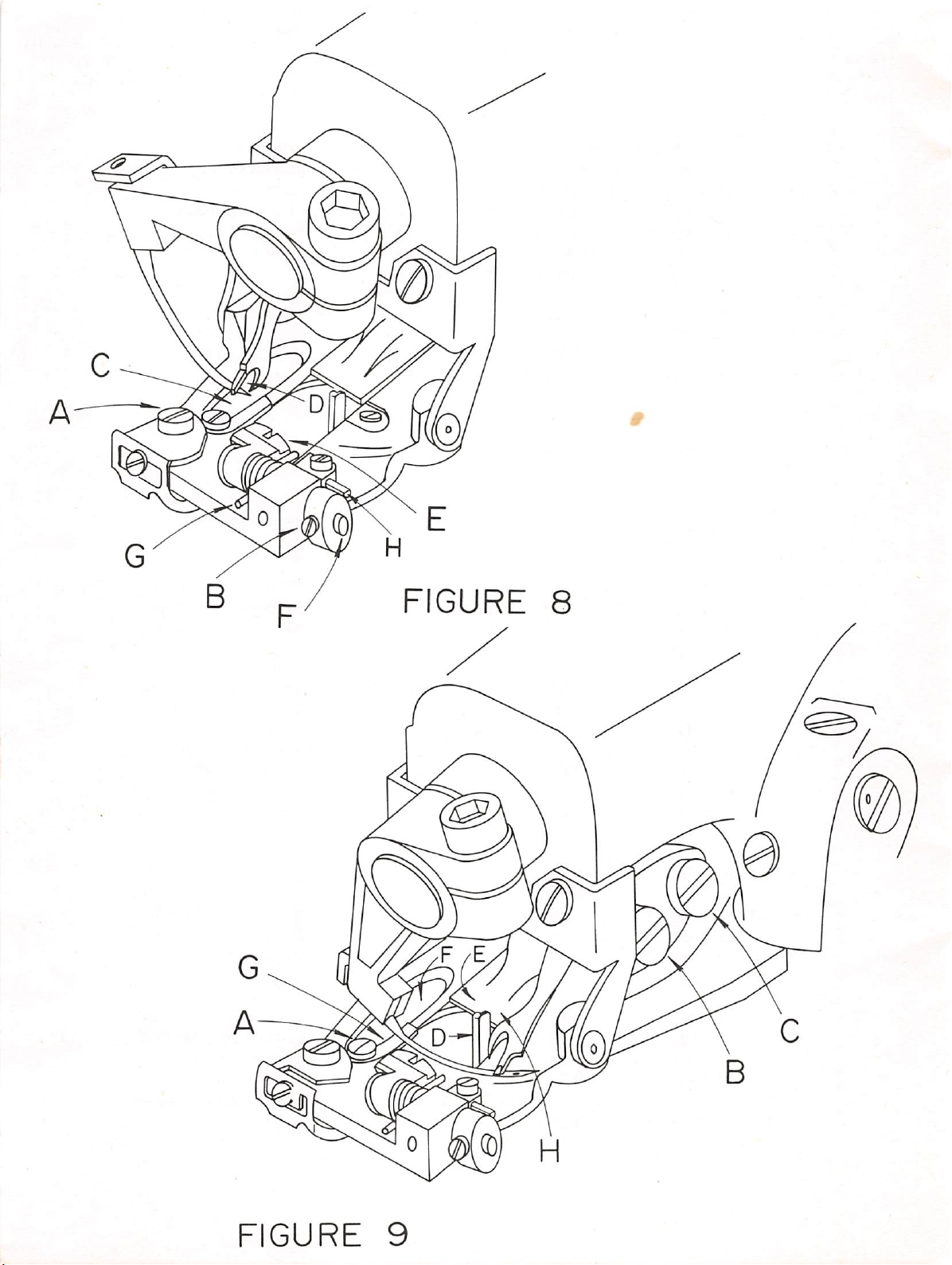

Once

clearanceisestablished

continue

passes

If

difficultyisexperiencedatthis

of

the

turning the handwheel away from the

between

previous

the

adjustmentstothe

If this is done, recheck

lished

9.

After

the

looper

("F"),

loop.

REPLACING

1.

lock

After

which

all

will satisfy allofthe

the

necessary

nut

and

recheck

should now clear the chain-off pin

needle,

considerable

THE

and

NEEDLE

looper

pass over

service,itmaybeexpected

between

prongs, clearing

the

previous

adjustments

all

the

adjustment

the

needleinthe

GUIDE

the

needle

both

point,itmay

eccentric

points

clearance

have

blockorthe

to insure

conditions.

been

points.

("D"),

and

the

looper

operator

the

long

until

and

be necessary to

looper

that

a position is estab

made,

tighten

ReferringtoFigure 9,

feeder

correct

that

("E"),

positiontopickupthe

the

wearing

the

all

needle will cause a sharp edged groove to form on the needle guide (item

in

Figure

This

happens

ed as a readily replaceable wear

the

9).

condition

the

action

of

guide

the

can cause

should

needle.

thread

breakage

be replaced.

plate

and

uneven

The

needle guide was specifically design

penetration.

to prevent damage to the presserfoot from

crotch,

the needle

short

prong.

modify

rod

set

looper

actionofthe

some

length.

screws

slot

When

and

the

"G"

this

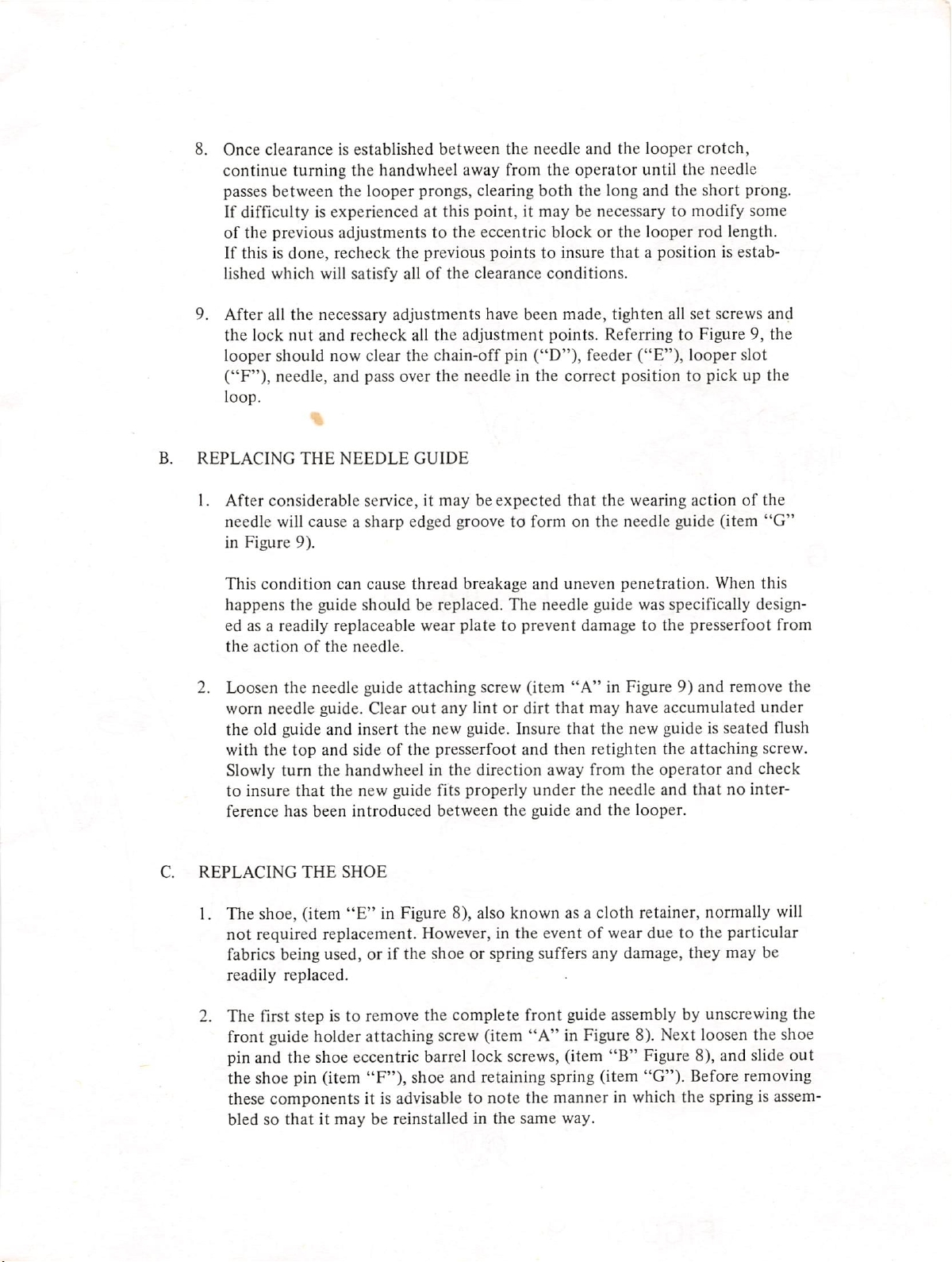

2. Loosen the needle guide attaching screw (item

worn needle guide. Clear

out

any

lint or dirt

"A"

in Figure 9) and remove the

that

may have accumulated

the old guide and insert the new guide. Insure that the new guide is seated flush

with

the

top

and

sideofthe

presserfoot

and

then

retighten

the

attaching

Slowly turn the handwheel in the direction away from the operator and check

to

insure

ference has

C.

REPLACING

1. The shoe, (item

not

that

the

new

been

THE

guide fits

introduced

SHOE

"E"

in Figure 8), also known as a cloth retainer, normally will

properly

between

the

under

guide

the

and

needle

the

looper.

and

thatnointer

required replacement. However, in the eventofwear due to the particular

fabrics being used, or if the shoe or spring suffers any damage, they may be

readily

replaced.

2. The first step is to remove the complete front guide assembly by unscrewing the

front guide holder attaching screw (item

pin and the shoe eccentric barrel lock screws, (item

"A"

in Figure 8). Next loosen the shoe

"B"

Figure 8), and slide

the shoe pin (item "F")» shoe and retaining spring (item "G"). Before removing

these components it is advisable to note the manner in which the spring is assem

bledsothatitmaybereinstalledinthe

same

way.

under

screw.

out

FIGURE

8

FIGURE

9

3. When replacing an old shoe, make sure that the replacement shoe properly fits the

pin without binding and without excessivelooseness. In the event that the pin has

worn and does not fit the new shoe properly, it should be replaced at the same time

as the shoe-pin.After replacingthe shoe, shoe pin springinto shoe eccentric barrel, re-

tighten screws (item

is linedupwith

the

openingofthe

"B"

the

centerofthe

presserfoot.

Figure 8), and check to insure

rib. Also insure

that

the

that

shoe

the

centerofthe

clears

both

shoe

sides

4. In and out position of shoeshould now be checked. For lightfabrics, shoeshould

be as close to needle as possible. For heavy fabrics with seam, shoe should be set

back

as far as possible from needle. To move shoe in

(item

"I"

screws,

Figure

(item

8). After the correct location isestablished, be sure to tighten

"B"

Figure 8).

and

out

turn

eccentric barrel

4A. An additionalshoe adjustment isalsopossible. The height of the shoe can now be

controlled, (item *'H"in Figure8). This is a tapered pin and position can be ad

justed so

concerned.

downon some

that

the shoe, whenever required, can be controlled as far as elevation is

By

moving

fabrics

the taperedpin in or out the shoe can be kept

whichrequire little, if any shoe pressure. By

from

having

pressing

this

control, it sometimes willaid in penetration of difficult fabrics. The normal posi

tionofthe shoe, when set properly on most fabrics, is that the shoe willshow move

ment

on the penetration cycle on one plyoffabric.

of

5.

REPLACING

THE

CHAIN

OFF

PIN

1. After considerableservice, it may become necessary to replacethe chain off

pin,

(Item

"D"

in Figure 7).

2. Remove the chain off pin attaching screwand remove the chain off pin, clean

out

any lint or dirt that may have accumulated. Attach the new chain

off

using the screw previously removed. Insure that the chain

of

the

side and forward edge

slot in the presserfoot, and then tighten the screw.

pin is against the

off

pin,

D.

REPLACING

THE

FEEDER

1. In the event that the machine

work, a worn feederis frequently found to be the cause.After considerableservice,

especially

dull, and the feeder should be replaced. In order to remove the old feeder, remove

the front feeder attaching screw (item

attaching screw (item

place. Insert the new feeder under the rear screwand replace the front screw.

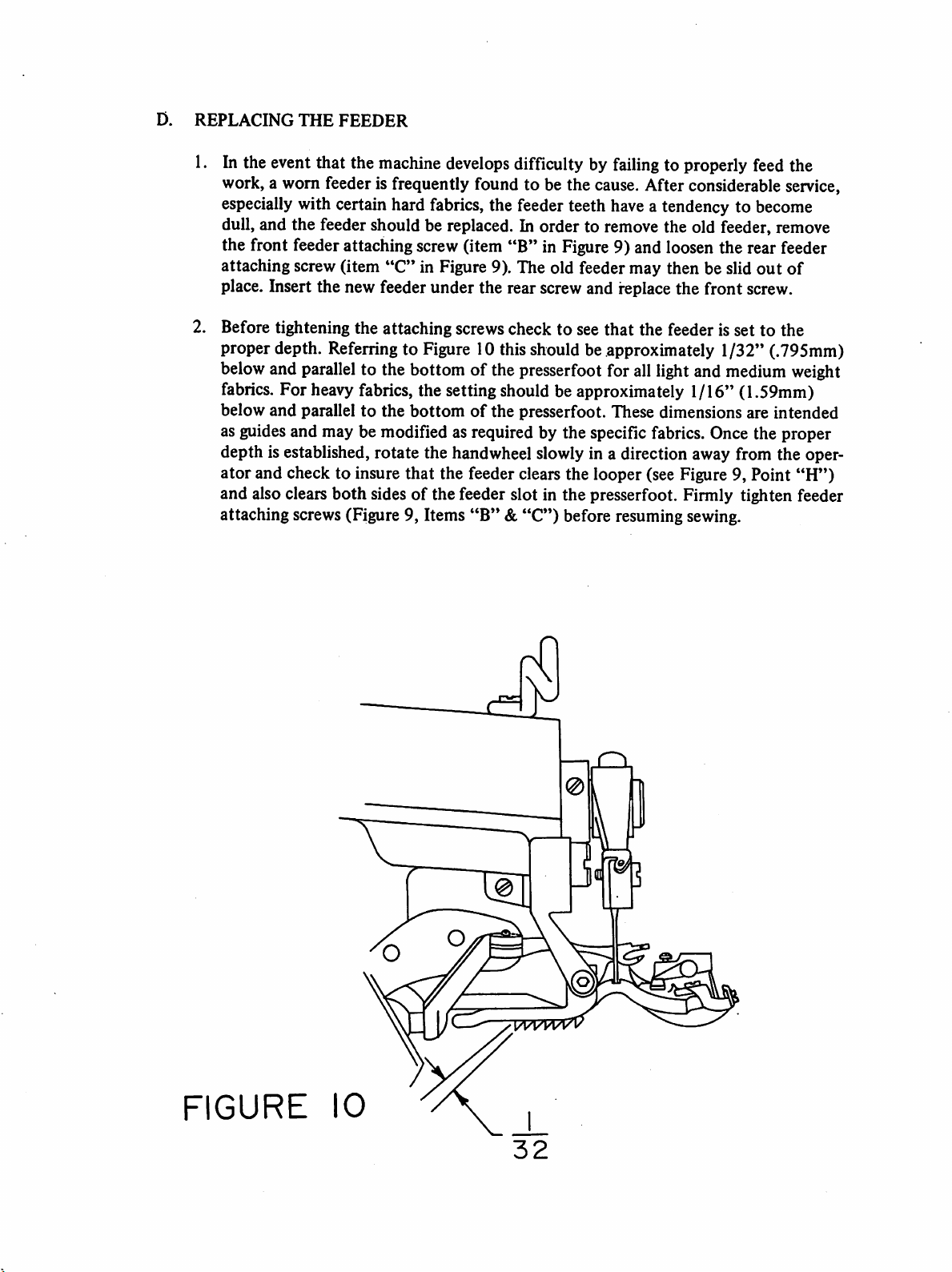

2. Before tightening the attaching screwscheck to see that the feeder is set to the

proper depth. Referring to Figure 10 this should be approximately 1/32" (.795mm)

belowand parallel to the bottom of the presserfoot for all lightand

fabrics. For heavy fabrics, the setting should be approximately 1/16" (1.59mm)

below and parallel to the bottomofthe presserfoot. These dimensions are intended

as guidesand may be modified as required by the specific fabrics. Once the proper

depth is established, rotate the handwheel slowlyin a direction away from the oper

ator

and also clears

attaching screws (Figure 9, Items

withcertainhard

"C"

and check to insure that the feeder clears the looper (see Figure 9, Point

both

sidesofthe feeder slot in the presserfoot. Firmly tighten feeder

develops

fabrics,

in Figure 9). The old feeder may then be slid

difficulty by

the

feeder

"B"

in Figure 9) and loosen the rear feeder

"B"&"C")

failing

teeth

have

before resuming sewing.

to properly

a tendency to

medium

feed

the

become

out

of

weight

"H")

FIGURE

cC

10

COVERING

1099

THE

SERIES

PARTS

FOLLOWING

CATALOGUE

STANDARD

SUB-CLASSES

5182

1401

5019

7004

1069

5174

3021

Side

Washer,

Screw,

Guard,

Screw,

Thread

Consists

7023

1324

1330

1329

7022

1811

Screw,

Cover

Side

Belt

Guard

Tension

Feed

1099-CS-l-HH

B1099-CS-1-HH

F1099-CS-1-HH

S1099-CS-1-HH

Assembly

Clamp

Cover

of:

Thread

Disc.

Post,

Spring,

Nut,

Pin,

Lever

r4AIN

Screw

Regulating

Guide

Thread

Thread

Tension

Tension

Spring

Plate

FRAME

Tension

Tension

1099PBW-1

1099-T

1099-T-l

1099-WB

1099-WB-l

GROUP

Ass'y.

1005

1006

1093

1289

1240

1089

7028

1096

1107

3281

1108

1080

1070

1054*

Tube,

Wick,

Screw,

Screw,

Pin,

Screw,

Plate,

Screw,

Screw,

Washer,

Screw,

Thread

Screw,

Washer

Oil

Oil

Set

Set

Presserfoot

Set

Top

Cover

Top

Cover

Bridge

Clamp

Clamp

Guide

Thread

Mtg.

Screw

Guide

♦Models

Do

not

1099-T,

have

washer

1099-WB

1054

and

1099

-WB-1

ASS

I

070

1

080

I

005

Y

324

5

74

006

I

096

006

7004

1054

328

MAIN

I

FRAME

50

19

I

093

GROUP

MAIN

SHAFT

GROUP

7012

5003-1*

See

Table*

*Sold

as

Main

Rib

1974

1973

1880

Needle

1072

1134-1

1132

1131-1

an

Assembly

**The

Shaft

Connection

Connection

Following

Screw

Screw

Screw,

Screw

Guard

Screw

Screw

Only

5188.-1

5240

5253

Lever

Eccentric

For

Cleunp

Ass*y.

Optional

&

Eccentric

Stud

Handwheel

Handwheel

Handwheel

Handwheel,

Positioner

Ass'y.

Ass'y.

With

Double

Double

Hub

Position

Pulley

Ass'y.

Are

Pulley

1845

5226**

See

Table

Available

Hub

Ass'y.

and

Collar

1971

Handwheel

3290

3291

3032

Stitch

Regular

1834

Ass*y.

Screw

Ass'y.

Handwheel

Screw

Pulley

Collar

Set

1121

1069

Screw

Ass'y.

Screw

Screw

Ass'y.,

Model

1099-CS-l-HH

B1099-CS-1-HH

F1099-CS-1-HH

S1099-CS-1-HH

1099PBW-1

1099T

1099T-1

1099-WB

1099-WB-l

Table

Needle

Ass'y.

5004-1

5004-1

5004-1

5004-1

5004-1

5004-1

5004-1

5041-1

5004-1

Connection

Stitch

Ass

5232

5232

5232

5232

5232

5231

5232

5231

5231

Collar

'y

2)I072

013-

>SEE

(2

086-

1013-

1014-

331-

I

013-1

1072

TABLE

701

(2)1834

SEE

5228

ASS'Y

C3C^

2

TABLE

SEE

FEED

(2)I974

p5003-l

y

//

DRIVE

GROUP

^1806

/ I069

ASS'Y-|

^

0

(2)197

(3)

l30-33n

3290

3032

i

!

1015

ASST

MAIN

SHAFT

I

880

GROUP

51

75

ASS'Y

ASS'^

5226-

ASS'Y

See

See

Table

Table

3019

3021

1821

See

Table

Feed

Feed

Feed

Screw

Thrust

1870

Feeder

1119

Lever

(Sold

Rocker

Lever

FEED

-

Lever

Collar

DRIVE

&

as

Plate

Set

Feeder

Stitch

Ass'y,

Ass'y.

Plate

Ass'y.

Screw

GROUP

Screw

Collar

only)

Ass

*y

Model

1099-CS-l-HH

B1099-CS-1-HH

F1099-CS-1-HH

S1099-CS-1-HH

1099PBW-1

1099T

1099-T-l

1099-WB

1099-WB-l

*Types

Feed

Rocker

Ass'y•

5023

5023

5023

5023

5016

5016

5023

5016

5016

of

Armoloyd

Carbide

Feed

Feeders

Table

Lever

Stitch

Collar

Ass'y.

5211

5211

5211

5211

5208

5208

5209

5208

5208

2125

2119

Available

Feed

Lever

Ass'y.

5229

5229

5229

5229

5228

5228

5228

5228

5228

Stitch

Collar

Ass'y.

5232

5232

5232

5232

5232

5231

5232

5231

5231

Feeder

2106

2106

2106

2106

2106

2100*

2106

2100*

2100*

SEE

TABLE

2

1

1834

SEE

TABLE

SEE

523

ASS'Y

TABLE

ASS

301

302

I

Y

9

SEE

(2)

TABLE

I I

19

FEED

DRIVE

GROUP

NEEDLE

DRIVE

GROUP

Short

5082

Needles

0

1

1

2

2

3

3

4

4

5

1/2

1/2

1/2

1/2

1/2

Needle

1076

3050

1137

1243

1136

Lever

Use

Long

Regular

Screw

Screw

Clamp

Pin

Lever

Genuine

Needles

Sizes

00

10

15

20

25

30

35

40

55

Ass'y.

Point

NEEDLE

U.S.B.S.

-

SIZES

System

AVAILABLE

Needles

251

Ball

Sizes

10

15

20

25

Point

5135

1095

For

Best

Collar

1089

Shaft

1118

Results

Spear

Ass'y.

Screw

Screw

Point

Sizes

10

15

20

25

30

35

65

^1

37

IMS

5082

J

ASS-Y^

'243

II36

076

NEEDLE-SPECIFY

SIZE

(2)1

REQUIRED

089

3050

NEEDLE

DRIVE

GROUP

LOOPER

DRIVE

GROUP

Part

2200*

1150

5233

5230

5213

5186

5206

No

Description

Looper

Stud,

Looper

Collar

1870

Looper

Consists

1154

1155

3049

1979

1123

1146

5006

1094

Looper

Consists

5185

1154

3049

1979

Looper

Consists

5017

1117

5185

Looper

Consists

5186

1154

3049

1979

Ass*y.

Set

Rod

of:

Fork

Pin

Screw

Nut

Stud

Nut

Looper

(Not

Screw

Rod

of:

Looper

Fork

Screw

Nut

Rod

of:

Looper

Screw

Looper

Rod,

of:

Ass'y.

Fork

Screw

Nut

Adjustment

Screw

Fork,

sold

&

Fork

&

Carrier

Fork

Sleeve

Rod

Sleeve

separately)

Ass'y.

Rod &

Rod

Rod &

&

Carrier

&

Ball

Ass'y.

Carrier

Ball

Stud

Ass'y

Ass'y.

Ass'y.

Ass'y.

Ass'y.

Ass'y

*2201

Looper

Used

with

S1099-CS-1-HH

ASSY

5006

ASSY

094

1979

I

23

ASS'Y

5

86

ASSY

LOOPER

DRIVE

GROUP

FEED

FRAME

I

GROUP

Model

1099-CS-l-HH

B1099-CS-1-HH

*F1099-CS-1-HH

*S1099-CS-1-HH

1099-FBW-l

1099-T

1099-T-l

1099-WB

1099-WB-l

***1262

See

See

**Rib

*1995

***In

Table

Table

Rib

Ass'y.

Ass'y.

8086

8024

8017

8021

place

5179

1836

5167

7018

1864

1056

1244-4

1146

1029

1167

Shaft

8067-1

8096

8096

8096

8086**

8024**

8024**

8017**

8021**

Shaft

Roller

Feed

Collar

1079

Rib

1117

Plate,

Screw,

Post,

Nut

Flatten,

Screw,

Nut

Nut

Screw,

Nut,

Flatten

Left

2400

Roller*

7140

2436

2422

2400

2400 2401

2400

2400

2400

Rib

2081

2020

2017-1

2017

Screw

of

1710

Frame

Shaft

Spring

Flatten

&

Ass'y.

Ass*y.

Set

Crank

Screw

Window

Plate

L.H.

Flatten

Cylinder

Flatten

Right

2401

2435

2437

2423

2401

2401

2401

2401

Rib

Pawl

2083

1262

Screw

Lock

Fin

Fin

use

Ass'y.

Flatten

Bkt

Left

2473

2473-1

2482-1

2482-1

2473

2473

2473

2466

2466

Rib

Hub

——

2021

2018-1

2019

part

3013

3013

n

/

TABLE

Flatten

Bkt

Right

Fin

Fin

Collar

1373

nos.

See

See

See

See

Table

Table

Table

1069

1021

Table

***1710

1055

See

Table

1113

1105

See

Table

7014

Spring

2474

2474

2481-1

3013

2481-1

3013

2474

2474

2474

2465

2465

3062

3065

1172

4

1172

4

3062

3062

3062

3062

3062

Req'd

Req'd

Spring

1376

1306

1307

1307

1132(2), 1114(2),

Stud

1379

1379-1

1379-1

•

1379

•

1379

1379

1379

1379

1379

Screw

1377

1935

1377

1377

BKT,

BKT,

Stud

Set

Screw

Spacer:-

Spring

Screw,

Post

Flatten,

Screw,

Screw

Cylinder

Shaft,

Cylinder

1168(2)

L.H.

R.H.

7025

7025

7025

7025

7025

Nut

1881

1881

1881

Flatten

Flatten

1021-1

Limit

R.H.

Frame

Rocker

and

=

-2

=

Cylinder

Screw

1966

1966

1966

1966

1966

7150

2017-1

2021^

^2020

2081

(2017)

2018-

(2019)

8017

(8021

ASS'Y

ASS'Y)

(2)1244-4

SEE

SEE

(2)1167

1307

TABLE

TABLE

SEE

SEE

TABLE

TABLE

SEE

TABLE

(2)

1373

5167

1935

—

8024

ASS'Y

1306

ASS'Y

SEE

(2)1864

7019

TABLE

1836

2083

ASS

8086

Y

1376

ASS'Y

SEE

SEE

TABLE-

TABLE

1055

(2)1262

(2)1710

SEE

TABL

FEED

FRAME

069

7014

GROUP

1836

ASS'Y

5179

ASS'Y

1146

I

FEED

FRAME

GROUP

II

5020

1146

1177

1184

*1190

5163

3055

1061

5235

7013

1060

1838

4544

5162-H

131-31

Spring

1176

Nut,

Ret'ng.

Screw,

Nut,

Main

Lift

Spring

Spring

Arm

1335

1855

1334

1120

1035

1008

Collar

1992

Spring

Knee

Pedal

1208

1037

Key

Vertical

Nut

Pad,

Pedal

Horizontal

Pin

Link

Pin

Link

Ass*y.

Lift

Screw

Hook

Screw

Screw

Nut

Ass'y.

Set

Knee

Screw

Offset

Ass'y.

Arm

Screw

Ass'y.

Pedal

Rod,

Rod

Knee

Press

♦Subclasses

use

Spring

See

last

classes

S1099-CS-1-HH.

F1099-CS-1-HH

1660

page

B1099-CS-1-HH,

for

diagram

and

S1099-CS-1-HH

of

lifter

F1099-CS-1-HH

for

and

sub

51

79

ASS'Y

5I62H

(2

1 I

20

5163

ASS'Y

I

06

3055

ASS'Y

I

131-3

S)

70

I

838

1060

46

I

177

I

184

3

5020

ASS'Y

4544

FEED

FRAME

GROUP

H

REGULATING

GROUP

1186

5012

1025

5177

Regulating

Push

Rod

1023

1024

Pin

Regulator

1109

5173

5178

1223

1222

1977

Fork

Ass'y.

Pin

Spring

Ass'y.

Screw,

Dial

Dial

Shoe

Screw

Screw

-

Regulator

&

Ratchet

Plate

Complete

Ass'y,

Ass'y.

1223

1222

5178

5177

ASS*Y

<1

ASS

ASS

5173

Y

Y

(2)

1109

REGULATING

5012

ASS'Y

1024

GROUP

Partial

Ass'y.*

See

PRESSERFOOT

Table

GROUP

Presserfoot

Consists

See

1238

1933

See

1866

1102

Table

Table

of:

Presserfoot

Pin

Screw

Needle

Screw

Screw

Ass'y•

-

"Chain-Off"

Guide

(Partial)

Model

1099-CS-l-HH

B1099-CS-1-HH

F1099-CS-1-HH

S1099-CS-1-HH

1099-PBW-l

1099-T

1099-T-l

1099-WB

1099-WB-l

Complete

Ass'y•**

Shoe

2540

2541

2540

2541

2521-1

2511

2521

2510

2517

Shoe

Ass'y,

5215

5216

5215

5216

5078-

5074-

5078

5064

5077

See

1308

1075

1133

See

See

1099

1079

7026

Anchor

3024-1

3024-1

3024-1

3024-1

3024-1

Fitted

1418-B

3024-1

Bracket

1242

3024

Table

Table

Table

Shoe

Pin

3294

3294

3294

3294

3294

3294

3294

1237

3294

Shoe

Screw

Screw

Screw

Pin

Bracket

Screw

Screw

Bridge

Bushing

7210

7210

7210

7210

7210

7210

7210

3068-1

3068-1

1372

1305

3067

See

3025

1976

See

1107

1864

TABLE

Guide

2606

2606

2606

2606

2606

2606

2606

2606

Table

Table

Spring

Spring

Wedge

Bushing,

Spring

Set

Guide

Screw,

Screw

Chain-Off

Pin

1831

1831

1831

1831

1831

2900

2900

2900

2900

Screw

Shoe

Bridge

Presserfoot

2373

2373

2373

2373

2359

2358

2359

23

2350

Adjustment

Mtg.

52

Partial

Ass'y.*

8503

8503

8503

8503

8509

8508

8509

8502

8500

Complete

Ass'y.**

8603

8616

8603

8616

8618

8619

8620

8621

8617

2

1075

1308

1305

(2)^107

1864

075

054

SEE

3025

SEE

1099

SEE

SEE

1079

TABLE

TABLE

TABLE

TABLE

PARTIAL

ASS'Y

SEE

I I

SEE

TABLE-

33

TABLE

SEE

TABLE

SEE

866

1933

TABLE

I

108

COMPLETE

PRESSERFOOT

ASS'Y

SEE

GROUP

TABLE

See

Table

1051

5015

1227

1052

1053

1051

3016

FRONT

Swing

Screw

Stop

Stop

Screw

Washer

Set

Spring

Pin

Plate

Screw

PLATE

Plate

Ass'y.

Washer

TABLE

GROUP

1225

3026

7009***

1103

1230

1229

1226

Pivot

Retaining

Support

Screw

Washer,

Washer

Collar

1992

Pin

Bracket

Flat

,

Lock

Ass'y.

Ring

Set

Screw

Model

1099CS-1-HH

***B1099-CS-1-HH

F1099-CS-1-HH

S1099-CS-1-HH

1099-PBW-l

1099-T

1099-T-l

1099-WB

1099-WB-l

***Board

Support

r

under

Bracket

Swing

Plate

7006

7006

7037

7006

7037

7037

machine

7060

7200

Swing

Plate

Ass

*5251

*5251

**5265

*5251

**5265

**5265

'y.

Stationary

Plate

7036

Stationary

Plate

Ass

'y.

5264

SEE

TABLE

30

6

5015

ASS'Y

2

1053

2

1230

(2

1229

(2)1103

ASS

7009.

Y

+

COMPLETE

*•

COMPLETE

FRONT

ASS'Y

ASS'Y

PLATE

GROUP

NO.

NO.

5251

5265

132

(2)4533

7

1326

i

1037

3

7-

(2)1230

(2)1229

(2)

1103

7035

'M

2)1230

(2)1229

COMPLETE

FRONT

ASS

PLATE

Y.

NO

GROUP

(2)1341

5264

REAR

OF

70

1 3

5179

m

I

ASS

Y

MAIN

WALL

FRAME

•

II

I

177

879

1008

17

r

fc

5020

ASS'Y

4544

MAI

FRAME

\

ASS

N

(21414

(2I393

I

271

Y

120^

FEED

FRAME

GROUP

5235

n

ASS'Y

A

MachineisOnly

as

Good

as

its

NEEDLE!

Don't

Top-quality

with

wash

saved on

U. S. specifications of the finest materials and workmanship available.

recognition

in U. S. needles is the knowledge

foremost

unequalled.

and

quality

curvature

top-quality

Peak

and

wear

and

performance.

Imitations

inferior

U. S.

The

and

in

our

For

Their

Take

needles

efficiency

fabrics

or

needles only prove to be expensive dollars in

Blind

quality

cannot

products.

durability

uniform

assure

efficient,

Chances—Avoid

sewing

to

is

accomplished

substitutes

Stitch

of U. S. Needles is, in

be

duplicated.

and

demands

achieve

in

today's

needles

that

freedom

construction,

economical

top-quality

perfect

high-speed

only

areacostly

are

made

The

confidence

quality is and always has been

from

carefully

stitching.

Trouble

machines

results.

sewing

with

needles

compromise.

in

the

fact,amatter

of

breakage,

controlled

of

of

United

our

U. S.

equipped

synthetic

superior

Pennies

the

long

States

of

world-wide

customers

Needles

finish

and

run.

to

are

BE

GENUINE

Lix^

on

The

perfection exists in all U. S. Machine Parts.

BE

SURE

fot

ail

same

SURE

TO

U.

S.

fhk

parts

precision

TO

GET

USE

ONLY

NEEDLES

ldi>e/

construction

U.

S.

—

and

working

ACCEPT

GENUINE

U.S.

NEEDLES

U.S.

BUND

MACHINE

Express

and

Skyline

Plainview.NewYofk 11803

Made

NO

SUBSTITUTE

in

STITCH

CORP.

Street

Dfive

U.S.A.

#4452/6-80

PREVTON,

LITHO

U.S.A.

Loading...

Loading...