U.ii.BUNDiSTITCH

EXPRESS

MACHINE

STREET

&

CABLE

SKYLINE

ADDRESS:"BLINSTIT

DRIVE

TELEPHONE:

CORP.

PLAINVIEW

PLAINVIEW

INSTALLATION

OPERATING

INSTRUCTIONS

MAINTENANCE

PARTS

CATALOG

N.Y.

U803

516-433-4350

NEW

YORK"

AND

&

for

EST.1925

Model

U.S.

Blind

1979•U.S.

Stitch

BLIND

Machine

STITCH

MACHINE

099SF/1200SF

CORP.

NOTE

FOR

PARTS

CATALOG

The

1200SF

modified

However,

changed.

to

this

unit,

numbers

Please

when

ing

service

and

only

parts

just

have

indicate

ordering

has

renamed

a

You

may

book

note

been

parts

information.

recently

few

still

where

changed.

serial

10099SF.

parts

for

or

been

are

refer

either

part

number

request

MACHINE

MODEL

NO.

a

o

000000

PARTS

BE

CATALOGS

SURE

OF

MACHINE

TO

ARE

SPECIFY

WHEN

AVAILABLE

MODEL

ORDERING

AND

MACHINE

SERIAL

UPON

SERIAL

PARTS.

NO.

REQUEST

NO.

1099SF/1200-SF

All

U.S.

trouble-free

accordance

only

the

sewing

ments

below,

such

following

tion,

will

wear

and

INSTALLATION,

Blind

performance.

with

minimum

machines

generally

at

which

does

the

to

insure

Stitch

the

INSTALLATION

maintenance

will

wear

occur,

appropriate

satisfactory

OPERATING

INSTRUCTIONS

Machines

be

required.

be

confined

may

be

the

worn

instructions.

When

normally

expected

part

are

installed

AND

to

service,

AND

MAINTENANCE

designed

OPERATING INSTRUCTIONS,

associated

These

the

after

may

for

and

lubricated

maintenance

five

be

extensive

readily

For

it

locations

ease

is

long

life

with

require

replaced

of

installa

essential

industrial

use.

and

in

described

When

by

that

only

They

with

typical

genuine

are

the

the

built-in

of

the

U.S.

only

U.S.

Blind

parts

long

Blind

Stitch

designed

life

Stitch

and

parts

specifically

excellent

Machine.

and

needles

wearing

are

for

the

characteristics

used.

machine,

I.

UNPACKING

A.

UNPACKING

1.

AND

INSTALLING

Cardboard

INSTALLATION

THE

Carton:

INSTRUCTIONS

MACHINE

Open

the

carton

and

remove

the

B.

C.

corrugated

the

carded.

plywood

attaching

for

FITTING

1.

The

LOCATING

1.

The

table

machine

accessories

Lift

base

the

use

in

THE

MACHINE

machine

THE

MACHINE

1200-SF

top.

as

liner.

is

the

still

plywood

mounting

TO

should

is

set

After

noted

Insure

not

misplaced

machine

attached.

base,

the

THE

TABLE

be

mounted

WITH

RESPECT

even

establishing

above,

that

out

and

machine.

TOP

with

move

the

of

Next,

on

TO

the

the

it

envelope

or

accidentally

the

carton

remove

set

the

a

blank

THE

front

position

sideways

bolts

TABLE

edge

containing

with

the

table

EDGE

of

of

until

dis

the

bolts

aside

top.

the

the

the

machine

The

belt

the

belt

has

been

in

the

the

table

place

table

and

install

Insure

the

bolts

handwheel

slot

to

established.

base

top.

the

felt

top,

that

securely

may

insure

of

replace

the

the

lines

now

that

the

machine,

Drill

pad,

attaching

machine

be

Mark

3/8"

supplied

the

machine

fastened.

up

the

is

cut

bolts,

with

in

correct

the

and

holes

with

firmly

the

the

center

remove

for

in

washers

motor

table

machine

the

each

its

proper

clamped

drive

top.

location

of

the

the

machine

mounting

machine,

and

in

pulley.

Install

bolt

on

location

nuts.

position

holes

from

bolts,

the

and

2,

Position

the

thread

stand

behind

the

machine

to

the

D.

MOTOR

1.

2.

right

supplied

The

of

DRIVE

machine

bination

the

correct

ing

recommendations.

unit

rated

a

Either

When

is

at

2-1/2"

V-belting

installing

the

handwheel,

wood

is

which

speed

employed,

1/3

HP

pulley

screws.

shipped

is

properly

when

it

and

should

or

the

and

with

used

When

is

recommended

1750

be

round

belt,

secure

a

handwheel

sized

in

accordance

an

individual

RPM. On

used.

leather

use

just

in

to

insure

that

all

belting

enough

place

and

operation

with

motor

the

standard

may

tension

with

pulley

the

and

motor

models,

be

the

com

at

follow

clutch

be

used.

to

prevent

belt

wear

slippage.

and

can

Excessive

possibly

tension

damage

the

will

machine

cause

rapid

II.

OPERATING

A.

LUBRICATING

1.

INSTRUCTIONS

Before

THE

MACHINE

operating

the

machine,

it

is

extremely

important

B.

that

following

2.

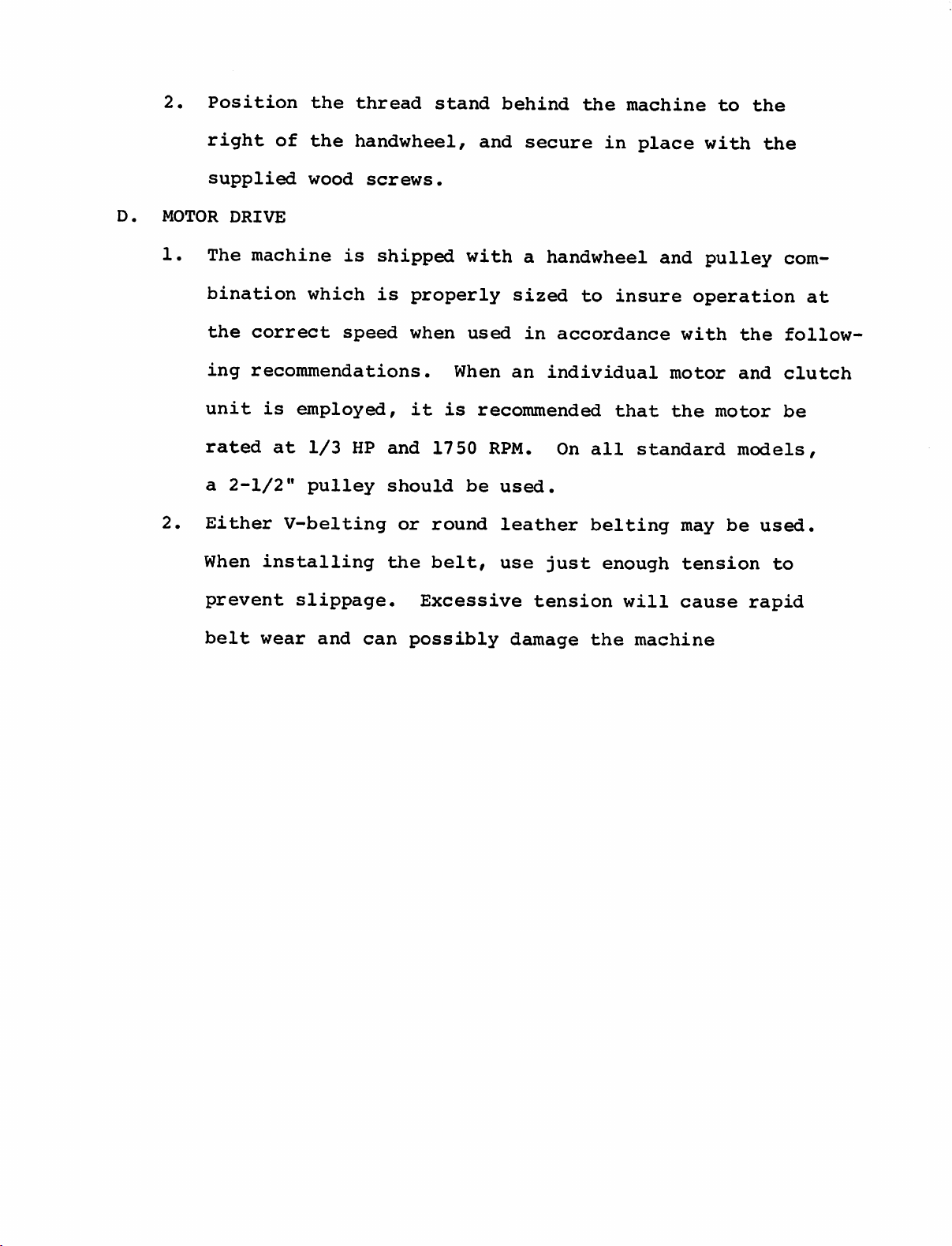

Place

oiling

on

Then

the

3.

In

daily

Item

ADJUSTING

1.

In

lifter

it

be

a

few

chart

Figure

place

oiling

prpduction

basis

2

above.

THE

order

to

may

properly

instructions.

drops

in

Figure

1

by

loosening

a

few

drops

chart

in

use,

in

accordance

KNEE

insure

be

LIFTER

adjusted.

lubricated

of

oil

Figure

the

optimum

at

all

1.

Remove

the

of

oil

2.

machine

with

operator

in

the

cover

at

should

the

accordance

points

the

table

attaching

all

the

be

instructions

comfort,

shown

cover

points

oiled

with

bolt

on

the

the

on

shown

"A".

shown

a

in

knee

the

on

C.

2.

To

(Item

lifter

then

THREADING

1,

Use

being

ized

2.

Prior

should

until

of

position

place

tighten

any

00/2,

it's

E,

pad

THE

type

sewn.

to

be

the

swing.

lifter

Fig.

is

screws.

MACHINE

of

This

70/2

starting

turned

needle

for

threading.

pad

1)

and

in

comfortable

thread

includes

and

the

in

reaches

This

in

proper

push

which

nylon

threading

the

will

down

mercerized,

K15

direction

the

put

position,

on

position

is

suitable

or

K13.

operation,

extreme

it

into

rod

away

(Item

for

nymo

from

right

the

loosen

operator

for

the

hand

most

two

F)

until

the

000,

handwheel

the

convenient

screws

the

knee,

work

mercer

operator

portion

SIDE

COVER

DIRECTION

HANDWHEEL

ROTATION

OF

OIL

a,

FIGURE

OIL-

1

OIL

0

OIL

FIGURE

2

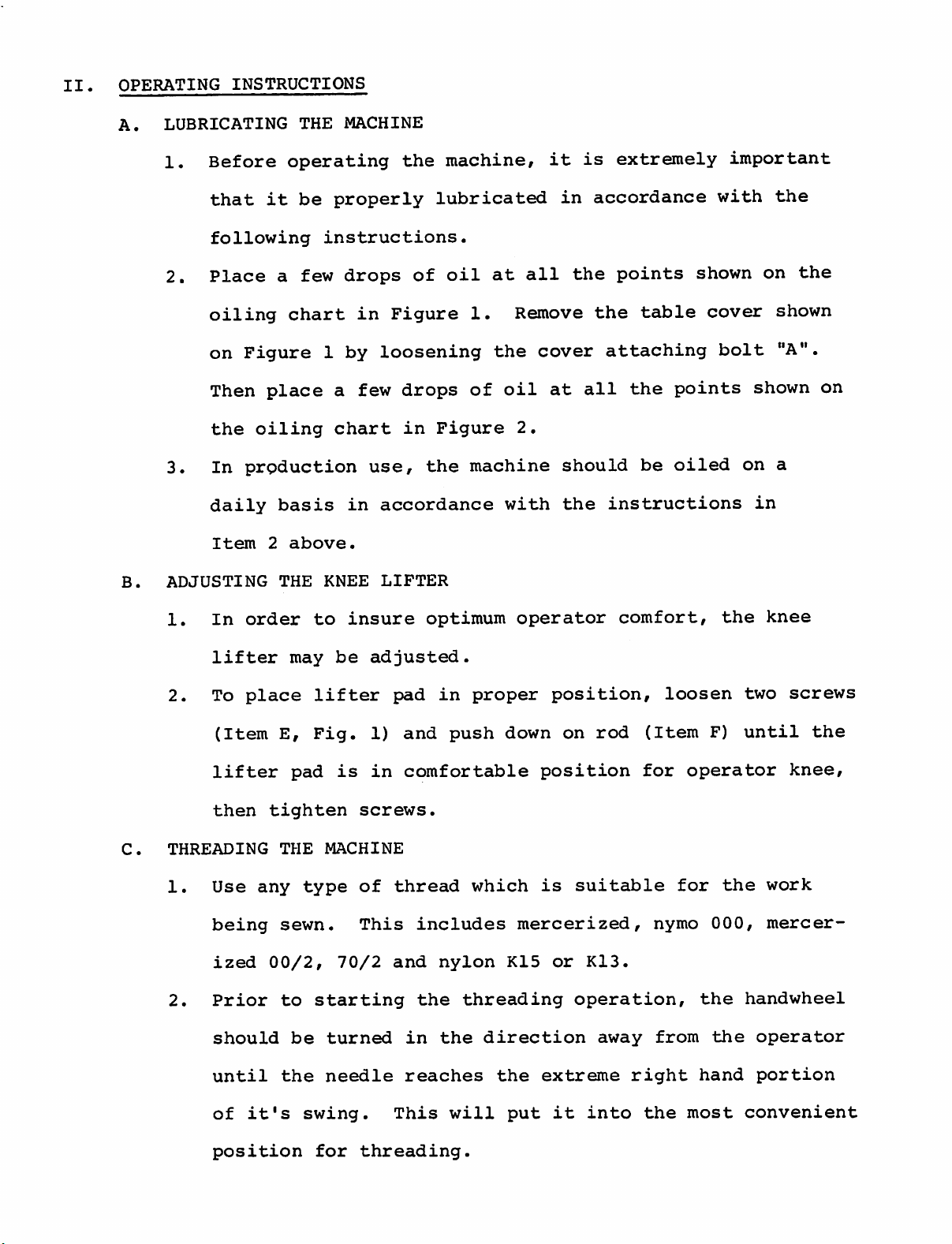

3.

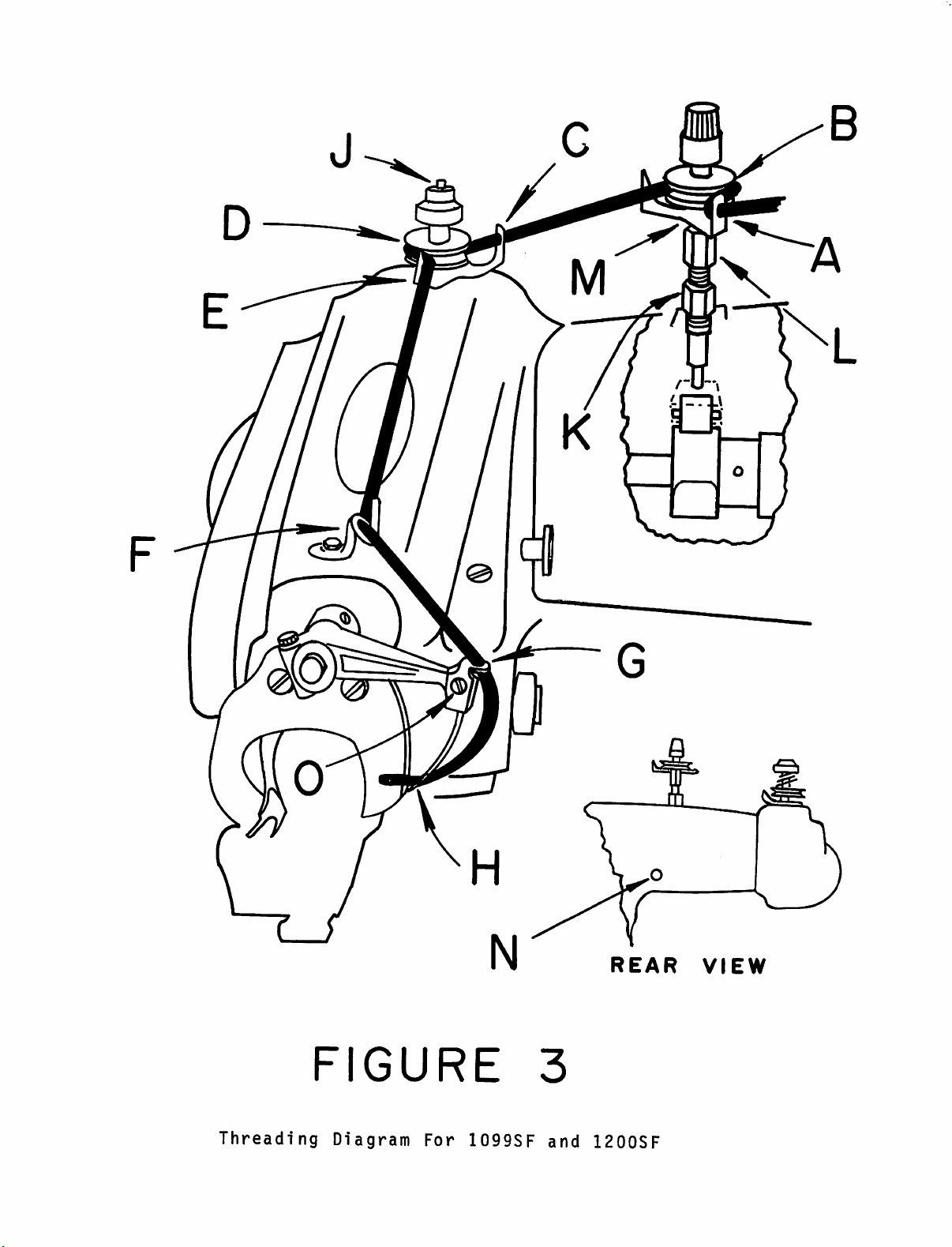

Referring

to

the

threading

chart

in

Figure

3,

it

can

be

D.

seen

thread

"A".

and

then

brought

"F".

hole

ing

the

past

INSERTING

that

is

slides

"G",

on

top.

the

is

It

carried

forward

It

the

THE

the

passed

then

between

then

then

underside

The

eye

of

WORK

threading

from

slides

to

the

along

is

passed

through

thread

the

IN

THE

front

between

left

the

"E"

the

of

should

needle

MACHINE

procedure

to

the

through

two

tension

through

through

eye

the

needle

be

by

back

the

of

pulled

a

few

is

two

the

the

a

through

tension

guide

discs

front

needle

needle

and

through

inches.

simple

hole

"D"

being

one.

guide

discs

"C".

and

thread

clamp

"H",

removed

to

The

hole

"B"

It

is

guide

guide

enter

at

extend

1.

2.

3.

Prior

to

turned

needle

swing.

The

knee

the

feed

and

the

The

work

edge

loaded

of

leased

important

operator's

inserting

in

the

reaches

lifter

frame

plattens.

is

the

cloth

which

to

direction

inserted

lining

retainer

locks

insure

knee

the

is

and

is

the

work,

away

extreme

then

pressed

creates

underneath

fold

the

or

or

work

that

not

permitted

right

a

with

"shoe".

in

during

the

from

to

gap

the

the

position.

machine

handwheel

the

operator

hand

portion

the

between

presser

center

The

lifter

to

rest

should

right

the

which

presser

foot

of

is

It

is

operation,

against

until

of

the

be

its

and

spring-

then

very

the

the

drops

foot

the

re

the

knee

lifter.

non-uniform

4.

A

trial

This

run

can

stitch

should

effect

quality.

be

made

needle

along

penetration

and

result

a

few

inches

of

work.

in

m

Threading

FIGURE

Diagram

For

1099SF

3

and

REAR

1200SF

VIEW

E.

Do

the

The

it

ADJUSTING

1.

If,

not

machine

operator

against

THE

on

attempt

the

STITCH

the

trial

will

merely

to

feed

edge

LINE

run,

pull

the

it

needs

guide

LOCATION

it

work

through

automatically

to

guide

located

is

found

the

on

that

the

the

at

work

presser

the

machine

the

by

stitch

proper

resting

foot.

as

rate.

forma

F.

G.

tion

edge

foot,

2.

If

the

be

ADJUSTING

The

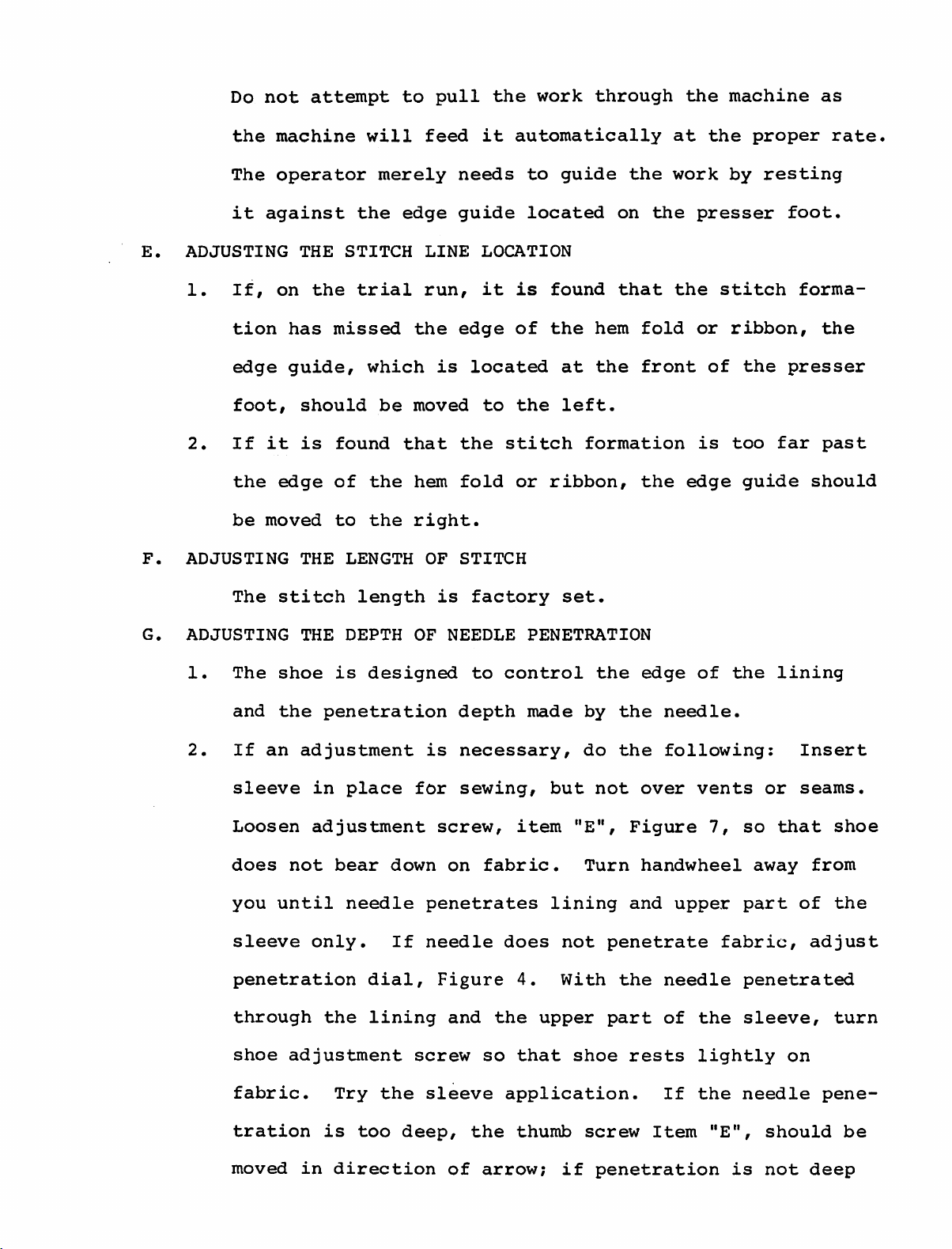

ADJUSTING

1.

The

and

2.

If

has

guide,

should

it

is

edge

moved

THE

stitch

THE

shoe

the

an

adjustment

missed

which

be

found

of

the

to

the

LENGTH

length

DEPTH

is

designed

penetration

the

moved

that

hem

right.

OF

OF

is

edge

is

located

the

fold

STITCH

is

factory

NEEDLE

to

depth

necessary,

to

stitch

control

of

the

at

the

left.

or

ribbon,

set.

PENETRATION

made

do

hem

fold

the

front

formation

the

the

edge

by

the

the

or

of

is

edge

of

needle.

following;

ribbon,

the

too

guide

the

presser

far

lining

Insert

the

past

should

sleeve

Loosen

does

you

sleeve

penetration

through

shoe

fabric.

tration

moved

in

adjustment

not

bear

until

only.

the

adjustment

Try

is

in

direction

place

needle

dial.

lining

the

too

for

down

If

screw

deep,

sewing,

screw,

on

fabric.

penetrates

needle

Figure

and

so

sleeve

the

of

arrow;

but

item

lining

does

the

4.

not

With

upper

that

application.

thumb

shoe

if

not

"E",

Turn

penetrate

the

part

screw

penetration

over

Figure

handwheel

and

upper

needle

of

rests

If

Item

vents

7,

fabric,

the

lightly

the

"E",

is

or

seams.

so

that

away

part

of

adjust

penetrated

sleeve,

on

needle

should

not

deep

shoe

from

the

turn

pene

be

PENETRATION

DIAL

RIB

ADJUSTMENT

FOR

SHAFT

-

MORE

FIGURE

-

RIB

ADJUSTMENT

FOR-LESS-

4

SHAFT

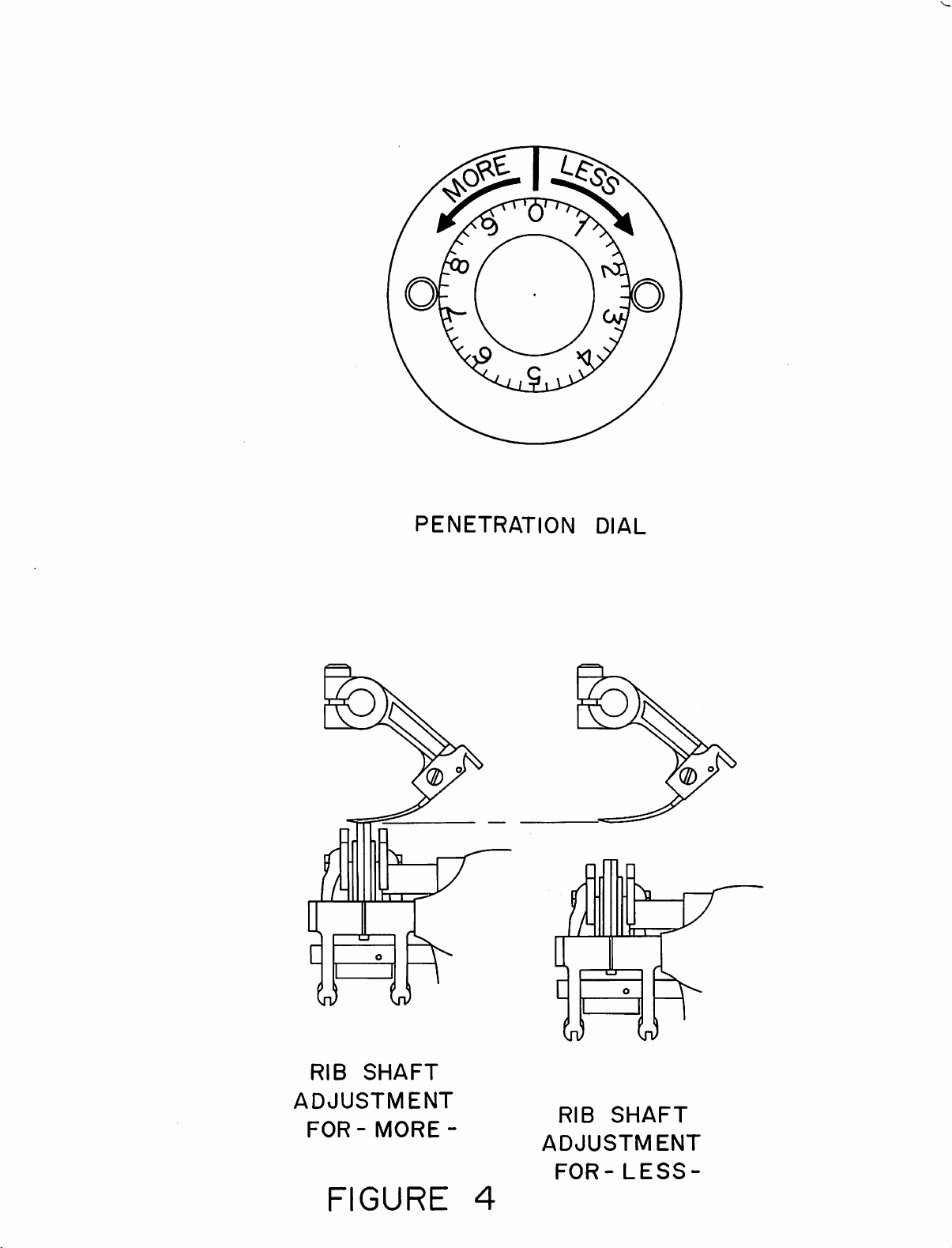

enough,

the

alignment

turn

screw

of

the

in

opposite

lining

edge

direction

is

not

of

arrow.

correct,

If

then

H.

guide

if

going

ments

ADJUSTING

1.

This

rib

2.

This

Figure

ance

wrench.

counter

Item

there

from

are

SPRING

machine

which

adjustment

1,

hole

clockwise

"F"

is

an

a

required

can

which

of

Turn

should

extreme

tropical

LOADED

is

equipped

be

adjusted

is

is

the

cylinder

the

on

RIB

made

reached

screw

for

be

moved

fabric

to

a

the

-

with

by

clockwise

less

thickness

heavy

dial.

SERVICE

a

for

a

turning

through

using

tension.

to

correspond.

tweed,

MAN

spring

desired

screw.

the

a

1.5

for

ONLY

MM

more

This

change,

further

loaded

load.

Item

right

(.059)

screw

Naturally,

fall-away

hand

tension,

such

adjust

"D",

alien

has

as

clear

been

I.

sealed

However,

be

REPLACING

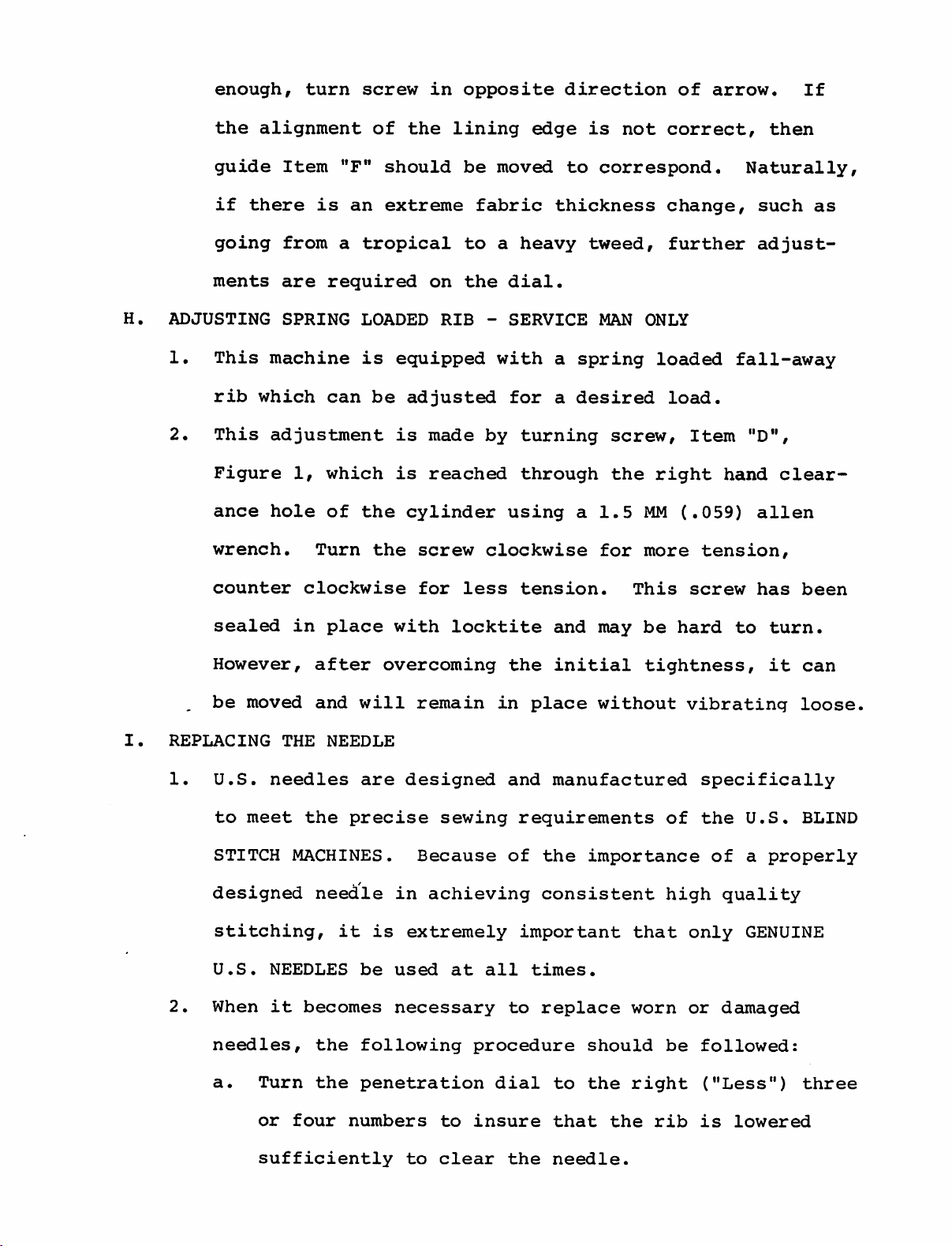

1.

U.S.

to

STITCH

designed

stitching,

U.S.

2.

When

needles,

a.

moved

THE

needles

meet

NEEDLES

it

Turn

in

place

after

and

will

NEEDLE

are

the

precise

MACHINES.

needle

it

is

be

becomes

the

following

the

penetration

with

locktite

overcoming

remain

designed

sewing

Because

in

achieving

extremely

used

at

necessary

the

in

place

and

requirements

of

important

all

times.

to

procedure

dial

and

may

initial

without

manufactured

the

importance

consistent

replace

should

to

the

be

hard

tightness,

of

high

that

worn

be

right

to

vibrating

specifically

the

U.S.

of

a

quality

only

or

GENUINE

damaged

followed:

("Less")

turn.

it

can

loose.

BLIND

properly

three

or

four

sufficiently

numbers

to

to

clear

insure

the

that

needle.

the

rib

is

lowered

b.

Loosen

the

needle

clamp

screw

(Item

"C"

in

Figure

1),

slide

old

new

needle

the

the

the

making

needle

c.

Readjust

previous

3.

Needles

the

needle,

needle

lever

flat

needle

needle

sure

guide

clamp

remove

and

as

on

the

is

clamp

that

on

the

needle

section,

forward

push

far

shank

properly

screw

the

the

prior

sufficiently

and

discard

it

up

as

it

of

seated

and

needle

presserfoot

penetration

to

into

will

the

turn

passes

resuming

it.

the

go.

needle

in

the

the

and

as

to

release

Insert

groove

Make

faces

groove.

handwheel

lightly

clears

described

operation.

the

of

sure

forward

over

the

the

the

that

Tighten

slowly

the

looper

in

a

and

Use

Long

Genuine

Needles

NEEDLE

U.S.B.S.

-

SIZES

System

Sizes

AVAILABLE

Needles

251

30,

35

for

Best

Results

III.

MAINTENANCE

A.

REPLACING

1.

Should

in

Fig.

of

the

of

the

INSTRUCTIONS

THE

LOOPER

it

become

6)

do

foot,

needle

the

turn

is

necessary

following:

the

handwheel

in

the

to

middle

replace

with

clockwise

of

the

the

the

looper

foot

looper

at

until

opening.

(Item

the

the

"B"

left

point

2.

Loosen

the

looper

clockwise

reverse

Any

time

timing

absolutely

described

pass

the

over

loop,

looper

the

looper

the

the

a

and

slot,

looper

out

upside

above

looper

reset

essential

in

detail

the

and

and

is

clamp

approximately

down

if

and

procedure.

is

moved

necessary.

for

below,

needle

also

in

clear

needle.

at

the

position

screw

pull

correct

the

the

The

(Item

1/8

or

changed,

a

properly

correct

chain-off

first

where

of

out.

Proper

stitch

A,

Fig.

an

inch.

To

replace

recheck

looper

formation.

timed

position

pin,

check

the

looper

6)

looper

feeder,

point

and

Turn

the

timing

to

picks

the

pick

for

pull

looper

looper,

looper

is

As

will

up

timing

the

3.

thread

stroke.

prong

scarf

the

prong

1/64"

clears

In

the

crank

end

the

crank

loop

Referring

of

the

of

the

of

the

of

the

(.406MM)

the

chain-off

event

cam

cam

(Item

off

looper

needle,

needle

looper

clearance,

that

can

the.needle

to

should

approximately

should

pin

the

be

adjusted.

B,

Figure

Figure

eye.

and

(Item

timing

5)

during

7,

pass

At

pass

must

of

is

over

the

over

"D"

the

The

the

the

(Point

3/32"

same

be

in

looper

normal

timing

needle

"C"),the

and

just

(2.4MM)

time,

the

needle

so

set

Figure

return

clear

the

that

7).

must

setting

mark

long

behind

short

with

it

be

changed,

of

on

the

the

about

also

the

5

(Z)

FIGURE

5

FIGURE

6

cam

corresponding

to

the

notch

in

the

rim

of

the

feed

B.

eccentric

speed

it

movement

looper.

REPLACING

1.

After

wearing

groove

This

tration.

The

up

down

THE

considerable

to

condition

needle

Item

the

on

the

of

NEEDLE

action

form

When

guide

looper

the

C.

right

cam

of

on

can

this

was

Turning

on

will

GUIDE

service,

the

the

cause

happens

the

the

left

side

of

produce

it

needle

needle

thread

the

specifically

crank

the

may

will

guide

clockwise

side

breakage

foot.

a

reverse

be

cause

of

(Item

guide

designed

the

Reversing

expected

a

sharp

"G"

and

should

foot

action

in

uneven

be

as

will

and

that

edged

Figure

replaced

a

readily

the

of

slow

the

the

9).

pene

2.

replaceable

foot

from

Loosen

Figure

any

lint

old

guide

guide

foot

turn

is

and

the

operator

properly

been

introducted

the

the

needle

9)

and

or

and

seated

then

handwheel

and

under

wear

action

remove

dirt

insert

flush

retighten

check

the

plate

of

guide

the

that

may

the

with

in

the

to

insure

needle

between

to

prevent

the

needle.

attaching

worn

have

new

the

the

attaching

direction

and

the

damage

screw

needle

accumulated

guide.

top

that

the

that

guide

guide.

Insure

and

screw.

away

new

no

interference

and

(Item

side

the

to

under

of

from

guide

looper.

the

"A"

Clear

that

Slowly

presser-

in

the

the

the

the

fits

out

new

presser-

has

C.

REPLACING

1.

The

retainer,

in

shoe,

the

THE

event

SHOE

(Item

"E"

normally

of

wear due

in

will

Figure

not

to

8),

require

the

also

known

replacement.

particular

as

a

fabrics

cloth

However,

being

(^0

MORE

0)

FIGURE

ai

7

FIGURE

8

2.

used,

may

The

be

first

or

readily

if

step

the

shoe

replaced.

is

to

or

spring

loosen

the

suffers

complete

any

damage,

front

they

guide

3.

assembly

screw

pin

locking

shoe

Before

the

may

K

When

ment

out

worn,

pin

manner

be

and

replacing

shoe

excessive

by

(Item

(Item

removing

reinstalled

L.

Attach

properly

it

should

unscrewing

"A"

in

screw

"F"),

these

in

which

these

an

looseness.

be

Figure

(Item

shoe

components

the

in

the

old

shoe,

fits

replaced.

the

"B",

spring

items

the

front

8).

and

same

make

pin

In

guide

Next,

Figure

retaining

it

is

way.

to

the

sure

without

the

event

After

holder

loosen

8)

and

spring

is

advisable

assembled

Remove

new

shoe.

that

binding

that

replacing

the

slide

so

Items

the

the

attaching

shoe

out

(Item

to

that

H,

replace

and

pin

the

shoe,

the

"G").

note

it

J,

with

has

D.

shoe

and

the

sure

the

REPLACING

1.

After

replace

2.

Remove

chain-off

accumulated.

screw

is

against

pin

spring

"B",

Figure

shoe

presserfoot.

that

THE

is

the

CHAIN-OFF

considerable

the

the

chain-off

pin,

previously

the

and

8),

lined

up

shoe

chain-off

clean

Attach

removed.

side

shoe

and

check

with

clears

PIN

service,

pin,

pin

out

the

and

pin,

to

the

both

it

(Item

attaching

any

lint

new

chain-off

Insure

forward

retighten

insure

center

sides

of

of

may become

"D"

in

screw

or

dirt

that

edge

of

screws

that

the

the

necessary

Figure

and

that

pin,

the

the

(Items

the

center

rib.

opening

7).

remove

may

using

chain-off

slot

in

Also

have

the

the

"A"

of

in

of

to

the

pin

presserfoot,

and

then

tighten

the

screw.

(^RE

y

FIGURE

0

]

PW17

9

22

figure

10

E.

REPLACING

1.

In

the

THE

event

FEEDER

that

the

machine

develops

difficulty

by

2.

failing

frequently

service,

feeder

feeder

feeder,

(Item

attaching

may

then

under

Before

that

the

to

properly

especially

teeth

should

remove

"B"

in

screw

be

the

rear

tightening

feeder

found

have

Figure

slid

be

the

(Item

screw

is

feed

to

be

with

a

tendency

replaced.

front

9)

"C"

out

of

and

the

attaching

set

the

certain

and

place.

replace

to

the

cause.

In

feeder

loosen

in

the

work,

to

become

order

attaching

Figure

Insert

screws,

proper

After

hard

the

the

a

9).

worn

fabrics,

dull,

to

remove

rear

the

front

check

depth.

feeder

considerable

the

and

the

screw

feeder

The

old

new

feeder

screw.

to

Referring

is

the

old

feeder

see

to

Figure

below

all

the

and

light

setting

parallel

and

10,

parallel

and

dimensions

required

by

is.,established,

away

clears

both

tighten

"C")

from

the

sides

feeder

before

the

this

medium

should

to

are

intended

the

operator

looper

of

the

attaching

resuming

should

to

be

the

bottom

specific

rotate

(see

feeder

be

the

bottom

weight

fabrics.

approximately

of

as

guides

fabrics.

the

handwheel

and

check

Figure

slot

screws

sewing.

approximately

of

the

For

1/16"

the

presserfoot.

and

may

Once

slowly

to

insure

9,

Point

in

the

presserfoot.

(Figure

1/32"

presserfoot

heavy

(1.59

be

modified

the

proper

in

that

"H")and

9,

Items

(.795MM)

fabrics,

MM)

These

a

direction

the

also

"B"

for

below

as

depth

feeder

clears

Firmly

and

F.

THREAD

1.

The

TENSION

purpose

RELEASE

of

the

thread

tension

release

is

to

obtain

uniform

thread

tension

over

seams

and

vents.

This

tension

off.

thread.

should

wheel.

do

the

nut

Item

so

that

(using

and

counter

keep

locking

is

Turn

be

In

following

the

a

release

nut

A

felt

"K"

1/2

factory

the

handwheel

distinct

twice

the

event

(using

tension

open

clockwise

of

Item

adjusted

locking

referring

a

assembly

end

thread

"K".

with

a

minor

9/16

wrench)

for

to

if

necessary

when

clockwise

and

each

revolution

adjustment

to

Figure

open

can

clockwise

less

a

release.

minimum.

the

machine

as

releasing

end

wrench)

be

moved.

to

you

pull

of

of

must

3,

release

for

For

Retighten

reposition

is

the

the

be

just

Turn

more

best

sewed

on

thread

hand-

made,

locking

enough

Item

release

release

thread

the

"L"

results,

G.

TIMING

1.

2.

guide

OF

The

thread

3/8

of

(Figure

needle

foot.

If

an

directly

Open

alien

Item

turn

THREAD

an

inch

7).

stroke

adjustment

under

the

top

wrench

"N"

Figure

Item

RELEASE

should

This

window

through

from

is

the

"M"

moving

is

3,

(using

-

SERVICE

release

the

left

measurement

towards

needed,

release

plate,

the

opening

and

loosen

a

when

the

tension

looking

3/8

MAN

the

edge

is

the

open

ONLY

needle

of

to

the

tension

assembly

in,

in

unmarked

the

be

left

back

end

presserfoot

taken

side

lift

place

of

wrench).

is

located

when

of

cam

can

a

3/32"

the

screw.

the

the

located

be

reset.

machine.

Insert

the

same

and

hold

eye

of

presserfoot

the

3/32"

in

needle

place.

and

alien

tighten

is

wrench

Turn

in

the

line

screw.

into

the

handwheel

with

Check

the

marked

clockwise

right

the

screw,

edge

timing

until

of

of

loosen

the

the

the

thread

release

as

described

in

Paragraph

1.

If

the

needle

presserfoot

cam.

screws•

After

is

not

3/8

when

all

of

an

the

thread

adjustments

inch

from

is

are

the

released,

made,

edge

readjust

tighten

of

the

the

both

TO

MAINTAIN

PARTS

EFFICIENCY

CATALOG

OF

THE

ORIGINAL

EQUIPMENT

GENUINE

U.S.

PARTS

AND

NEEDLES

ARE

RECOMMENDED

1099SF/1200-SF

*5001

1401

5019

*1068

1069

5198

1005

1006

1093

1289

1240

1089

*1081

1096

1107

1054

1108

1080

1070

5197

MAIN

Side

Washer,

Screw,

Guard,

Screw,

Thread

Consists

1084

1083

1082

1329

1994

Tube,

Wick,

Screw,

Screw,

Pin,

Screw,

Plate,

Screw,

Screw,

Washer,

Screw,

Thread

Screw,

Thread

5217

1953-

1954

1959

1955-

1084

1957

1021-

1083

3046

1085

1011

3069

FRAME

Cover

GROUP

Assembly

Clamp

Side

Belt

Guard

Tension

of

Disc.

Oil

Oil

Set

Set

Presserfoot

Set

Top

Cover

Top

Cover

Bridge

Clamp

Clamp

Guide

Thread

Tension

Regulator

1

Rod

Spring

Nut

1

Sleeve

Thread

Post

6

Spacer

Disc

Disc

Spring

Ratchet

Nut

Screw

Cover

(for

:

Thread

Post,

Spring,

Nut,

Mtg.

Screw

Guide

(for

1200SF

Regulating

Guide

Thread

Thread

Tension

Tension

(for

Release

Ass'y

Guide

1200SF

only)

Ass'y.

Tension

Tension

1200SF

Ass'y.

only)

only)

*For

5182

7028

7004

the

1099SF

Side

Top

Belt

use

Cover

Cover

Guard

the

following

Assembly

Plate

51

97

51

ASS'Y

500

ASS'Y

98

ASS

1955-

1994

082

1084

I

1959

953-1

52

ASSY

7

Y

I

02

084

-6

1080

08

1096

006

§

I

068

MAIN

FRAME

GROUP

1099SF/1200-SF

***1964

5003-1*

5194-1*

*Sold

as

Main

Rib

Needle

an

Shaft

Connection

1974

1973

1880

1072

1134

1132

3061

3276

1946

Assembly

**The

(for

Screw

Screw

Screw,

Connection

Screw

Guard

Screw

Screw

Screw

Crank

Only

Following

1200SF

Lever

Eccentric

For

Stud

Clamp

Ass'y.

Optional

MAIN

only)

&

Eccentric

SHAFT

Handwheel

GROUP

Ass'y,

Ass'y.

1845

5226**

5232

5224

is

Available

Collar

1971

Handwheel

3290

3291

3032

Stitch

Regular

1834

Cam

Ass'y.

1814

Ass'y.

Screw

Handwheel

Screw

Pulley

Collar

Set

Screw

Ass'y.

1121

1069

Ass'y.

Screw

Screw

Ass'y.,

Screw

***For

7012-1

the

5188-1

1099SF

Main

use

Shaft

Handwheel

the

With

following;

Position

Hub

2 I

(2)

I I

I

072

32

34

(2I834

2

18

14

2

306

(2I072

5232

ASS'Y

5207

ASS'Y

5224

ASST

(2)1974

5003-1

%

ASS'Y

01

1069

o-(

e-

845

0

ASS

(2I97

ASST

(3)

3291

3290

3032

ASS'Y

5194-1

ASS'Y

MAIN

SHAFT

GROUP

1099SF/1200-SF

5184

Use

System

Needle

1076

3050

1945

1243

1944

Genuine

251

Lever

Screw

Screw

Clamp

Pin

Lever

U.S.B.S.

Size

NEEDLE

Ass'y.

NEEDLE

35

SIZES

or

DRIVE

Needles

Size

GROUP

5135

1095

AVAILABLE

For

40

for

Best

Heavy

Collar

Shaft

Results

Sleeves

1089

1118

Ass'y.

Screw

Screw

(2)1089

095

•5184

ASS'Y

3050

944

243

5 I

35

ASS'Y

ASS'Y

\

NEEDLE-SPECIFY

SIZE

REQUIRED

NEEDLE

DRIVE

GROUP

1099SF/1200-SF

5212

1834

5023

1821

2124

FEED

Feed

Screw

Feed

Thrust

Feeder

Lever

(Sold

Rocker

1870

1119

DRIVE

Collar

&

as

Set

Feeder

GROUP

Stitch

Ass'y.

Ass'y.

Ass'y.

Screw

Screw

Collar

only)

Ass'y.

5212

ASSV

(2)1834

5232

AS

AS

_

ST

ST

ASST

(2)

2

24

I I

19

FEED

DRIVE

GROUP

(2

1870

ASSY

1099SF/1200-SF

Part

2203

1150

5233

5195

5213-1

5186-1

5206-1

No.

LOOPER

Description

Looper

Stud,

Collar

1870

Looper

Consists

1154

1155

3049

1979

3297

1094

Looper

Consists

5185-1

1154

3049

1979

Looper

Consists

5017

1117

5185-1

Looper

Consists

5186-1

1154

3049

1979

DRIVE

Looper

Ass'y.

Set

Rod

of

Fork

Pin

Screw

Nut

Stud

Screw

Rod

of:

Looper

Fork

Screw

Nut

Rod

of

Looper

Screw

Looper

Rod,

of:

Ass'y.

Fork

Screw

Nut

GROUP

Adjustment

Screw

Fork,

:

&

Fork

&

Carrier

;

Fork

Sleeve

Ass'y.

Rod

Rod

Rod

&

&

Ball

Ass'y.

Carrier

&

Ball

Carrier

&

Stud

Ass'y.

Ass'y.

Ass'y.

Ass'y.

Ass'y.

ASS

2

094-

3297

ASST

5195

870

Y

5186-1

ASS'Y

1870

835

ASS'Y

3049

LOOPER

DRIVE

GROUP

1099SF/1200-SF

*5046-1 Feed Frame

1836-1

5167

*1205

*1030

3057

1262

2434

1244-4

1146

1966

1167

1836

6098

Collar

1077

Rib

1117

Plate,

Screw,

Post,

Nut

Platten,

Screw,

Nut

Screw,

Nut,

Collar

1079

Rib

2086

1158

1881

*6095

Ass'y.

Shaft

Window(for

Plate(for

Spring

L.H.

Platten

Cylinder

Platten

Ass'y,

Set

Shaft

Ass'y.(for

Set

Screw

Crank

Screw

Lock

Screw

Pawl

Rib

Pawl

Screw,

Nut

Rib

Shaft

(for

1200SF

Ass'y.

1200SF

Ass'y

Pawl

1200SF

1200SF

Ass'y.

only)

FEED

only)

only)

FRAME

only)

GROUP

2483

2484

1379

1069

1021

3062

1710

3056

2435

1113

*1213

*1066

3027

1004-1

3280

3065

3063

3059

3058

3064

I

BKT,

BKT,

Stud

Set

Spacer

Spring

Screw,

Post

Platten,

Screw,

Cylinder(for

Shaft,

Plate

Stud

Set

Spring

Spring

Retaining

Yoke

Retaining

L.H.

R.H.

Screw

:-1021-l

Cover

Screw

Platten

Platten

12

Limit

R.H.

Frame

Rocker(for

Pin

Ring

Ring

=

=

1200SF

.010";

.015",

only)

1200SF

etc.

only)

*For

5179

7019

1864

1099SF

Feed

Window

(2)

use

Plate

the

Frame

Plate

following;

Ass'y.

Screw

7014

1213-1

8095

Rocker

Cylinder

Rib

Shaft

Shaft

Ass'y.

5167

ASS

Y

836

ASS'Y

(2)1244-4

2434

(2)1167

(2)3062

(2)

1262

3056

6098

ASS

Y

(2

3059

1205

3

1966

1069

1079

3064

1030

(2)1004-1

1836-

ASS

1077

Y

(2)1710

1066

FEED

FRAME

GROUP

5046-1

I

ASS'Y—J

1099SF/1200-SF

5020

1146

1177

1184

1191

5235

7013

3079

4544

5237

1882

3047

1117

1271

1393

1414

1839

1879

1008

1117

FEED

FRAME

Spring

1176

Nut,

Screw,

Nut,

Main

Knee

1208

1037

Key

Knee

Pad,

Knee

1841

3048

1815

3299

1054

Washer

Block

Screw

Knee

Screw

Washer

Bracket

Screw

Nut

Screw

GROUP

Link

Ret'ng,

Link

Spring

Spring

Pedal

Lift

Pedal

Lifter

Lifter

Ass'y.

Pin

Ass'y.

Knee

Screw

Rod

Bracket

Screw

Link

Bracket

Screw

Washer

Spring

II

Pedal

(For

Ass'y.

3299

Screw)

70

I 3

REAR

OF

MAIN

WALL

FRAME

3047

5046-1

ASS'Y

5020

ASS'Y

3079

4544

MAI

FRAME

1117

I

177

1879

I

176

008

1841

5237

/

ASS'Y

N

1839

(21414

(2)1

393

20^

FEED

FRAME

GROUP

5235

n

ASS'Y

1099SF/1200-SF

1186

5012-1

1025

5018

*For

5173

5178

1977

REGULATING

Regulating

Push

Pin

Regulator

the

1099SF

Dial

Dial

Screw

Rod

1023

1024

1109

*5039

*5010

1223

1222

*1039

&

Ratchet

Plate

Ass*y.

Pin

Spring

Screw,

Dial

Dial

Shoe

Screw

Screw

use

Ass'y.

GROUP

Fork

Ass'y.

the

Ass'y.

-

Regulator

&

Ratchet

Plate

(for

following;

Complete

Ass'y.

Ass'y.

1200SF

(for

only)

(for

1200SF

1200SF

only)

only)

1223

,5010

5018

ASS'Y

ASS'Y

5039

AS

U039

(2)1

ST

109

REGULATING

GROUP

501

ASS'Y

2-1

1099SF/1200-SF

5214

1099

1943

1967

2620

1079

1237

1106

6194

1054

1108

1107

PRESSERFOOT

Shoe

Ass'y,

1075

1372

1308

1305

2542

Screw

Spring

Bracket

Edge

Screw

Pin

Set

Guide

Screw

Presserfoot

1866

1961

1102

1960

Washer

Screw

Screw

ASS'Y.

Screw

Lock

Screw

Spring

Shoe

Ass'y.

Screw

Pin,

Screw

Guide

Spring

Chain

Off

-5214

1075

1372

1099

cfT

I960

2

6

194

ASSY

1054

1967

1079

COMPLETE

PRESSERFOOT

ASS'Y

5259

GROUP

(2)I107

Notes

A

MachineisOnly

as

Good

as

its

NEEDLE!

with

wash

U. S.

recognition

in

foremost

unequalled.

and

quality

saved

U. S.

top-quality

and

and

on

inferior

specifications

needlesisthe

curvature

Don't

Top-quality

Peak

wear

in

fabrics

performance.

Imitations

U.

S.

The

quality

and

cannot

our

products.

For

durability

Their

assure

Take

sewing

needles

efficiehcy

is

or

needles

Blind

Stitch

of

the

of

be

knowledge

uniform

efficient,

Chances—Avoid

demands

to

achieve

in

today's

accomplished

substitutes

only

prove

needles

finest

U. S.

duplicated.

and

construction,

perfect

high-speed

areacostly

to

be

are

materials

Needles

The

that

freedom

economical

only

quality

from

Trouble

top-quality

results.

with

expensive

made

and

workmanship

is,infact,amatter

confidence

is

breakage,

carefully

stitching.

machines

sewing

needles

compromise.

dollars

in

the

United

of

our

and

always

U. S.

controlled

of

synthetic

of

superior

in

the

available.

of

customers

has

equipped

Pennies

long

States

world-wide

been

Needles

finish

and

run.

to

are

BE

SURE

GENUINE

Lo(dc

on

The

perfection exists in all

BE

fot

all

TO

U.

fhk

parts

S.

USE

ONLY

NEEDLES

U6e/

same precision construction and working

U.

S. Machine Parts.

SURE

TO

GET

U.

S. —

ACCEPT

NO

GENUINE

U.S.

NEEDLES

U.S. BUND

MACHINE

Express

and

Plainview,NewYork 11803

Made

Skyline

In

STITCH

CORP.

Street

Drive

U.S.A.

SUBSTITUTE

500/885

PREVTON,

LITHO

U.S.A.

Loading...

Loading...