Page 1

Urschel® Model M6 Dicer

Versatile Dicer/Strip Cutter/Shredder

APPLICATIONS

The two-dimensional cutter, Urschel Model M6, is a versatile machine

designed for dicing, strip cutting, or shredding a variety of products

through a wide range of sizes from product of a predetermined

thickness. In addition to cutting frozen-tempered, fresh-chilled, or hotcooked meat and poultry, the M6 also processes leafy vegetables, pork

skins, pet food, sh, bread for croutons, and bakery goods. The Model

M6 operates continuously at high production capacities, and is designed

for easy cleanup and maintenance.

TYPES OF CUTS

DICES: Many sizes of cuts are possible by combining the various

selections of circular knife spacings with different crosscut knife spindles.

• Circular knives: 3/16 to 1-1/2" (4.8 to 38 mm)

• Crosscut knives: 1/8 to 3" (3.2 to 76.2 mm) standard sizes, up to

5.66" (144 mm) available with alternate gearing.

STRIP CUTS: Strip cuts can be made by removing the crosscut knife

spindle from the machine. The length and thickness of the strips will

depend upon the size of the original product.

SHREDS: Many types available. Due to variables in applications, it is

highly recommended that processors work with Urschel Laboratories to

achieve optimum results.

2

1

6

4

8

7

3

5

MODEL M6 (DICING)

OPERATING PRINCIPLE

Product of predetermined thickness is delivered onto a high speed

feed belt [ 1 ]. This belt carries the product to the dicing unit. Product

is pinched between a feed roll [ 2 ] and the drive roll [ 3 ] at the end

of the feed belt. The feed roll, which is spring loaded and adjustable,

allows product of varying thicknesses to move through the dicing unit

without being crushed. Product is forced into circular knives [ 4 ] which

run in narrow grooves in the rotating feed drum [ 5 ]. The resulting strips

are then removed from the circular knives by a stripper plate [ 6 ] which

also acts as a shear edge for the crosscut knives [ 7 ]. The strips move

directly into the rotating crosscut knives producing cubes or rectangular

pieces [ 8 ] of predetermined size.

The machine can also be equipped with a top belt assembly. With this

assembly, the feed roll is replaced by the top belt drive roll and top feed

belt [ 9 ].

The machine can also be set up for shredding. In this application, a feed

spindle [ 10 ] replaces the circular knife spindle, and a shredding spindle

replaces the crosscut knife spindle. There are two types of shredding

spindles. One spindle design uses shredding discs [ 11 ] and spacers

stacked on a spindle. The other spindle design uses blunt edge knives

[ 12 ] on a crosscut spindle. Both spindles will produce shreds [ 13 ] on

various meat products.

9

10

45584 URSCHEL USA

45584 URSCHEL USA

45584 URSCHEL USA

45584 URSCHEL USA

45584 URSCHEL USA

45584 URSCHEL USA

45584 URSCHEL USA

45584 URSCHEL USA

45584 URSCHEL USA

45584 URSCHEL USA

11

MODEL M6 WITH OPTIONAL TOP BELT

If your product application is not mentioned on this page, contact your local Urschel representative to determine the most effective solution to your size reduction needs.

MODEL M6 (SHREDDING)

13

10

12

(over)

13

Page 2

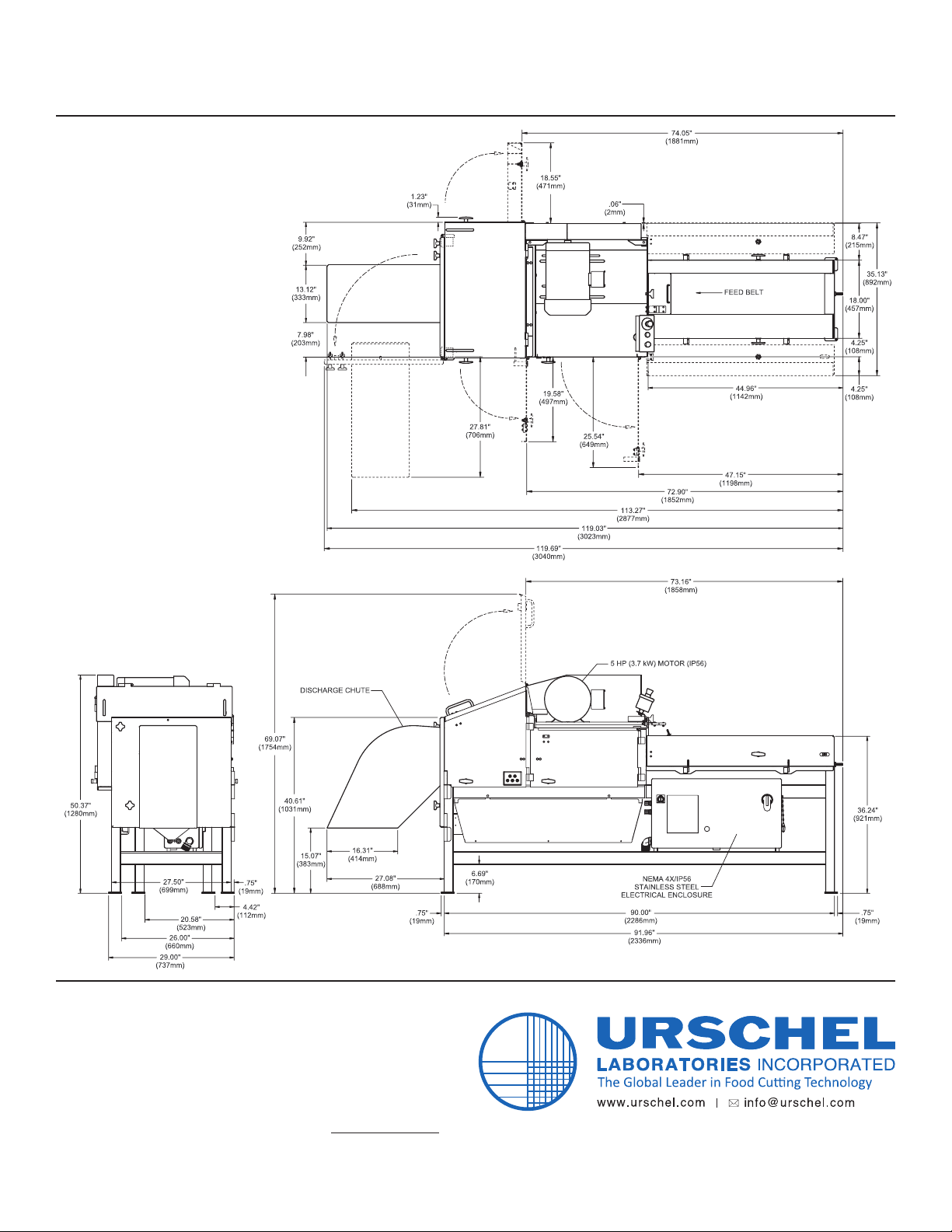

SPECIFICATIONS

Length. . . . . . . . . . . . . . . 119.03" (3023 mm)

Width. . . . . . . . . . . . . . . . . .33.48" (850 mm)

Height . . . . . . . . . . . . . . . .50.37" (1280 mm)

Net Weight . . . . . . . . . . . . . 1642 lb (745 kg)

Motor. . . . . . . . . .5 or 7.5 HP (3.7 or 5.6 kW)

Urschel® Model M6

Dimensional Drawing

You Are Invited to Test Cut Your Product

Urschel Laboratories has a complete network of test facilities and

experienced service and sales representatives around the world

ready to work for you on any size reduction application. Contact your local Urschel Laboratories’ representative to schedule

a comprehensive, no-obligation test today at www.urschel.com.

®Urschel is a registered trademark of Urschel Laboratories, Inc. | L2582 November 2013 (s.s. L2275)

Loading...

Loading...