Page 1

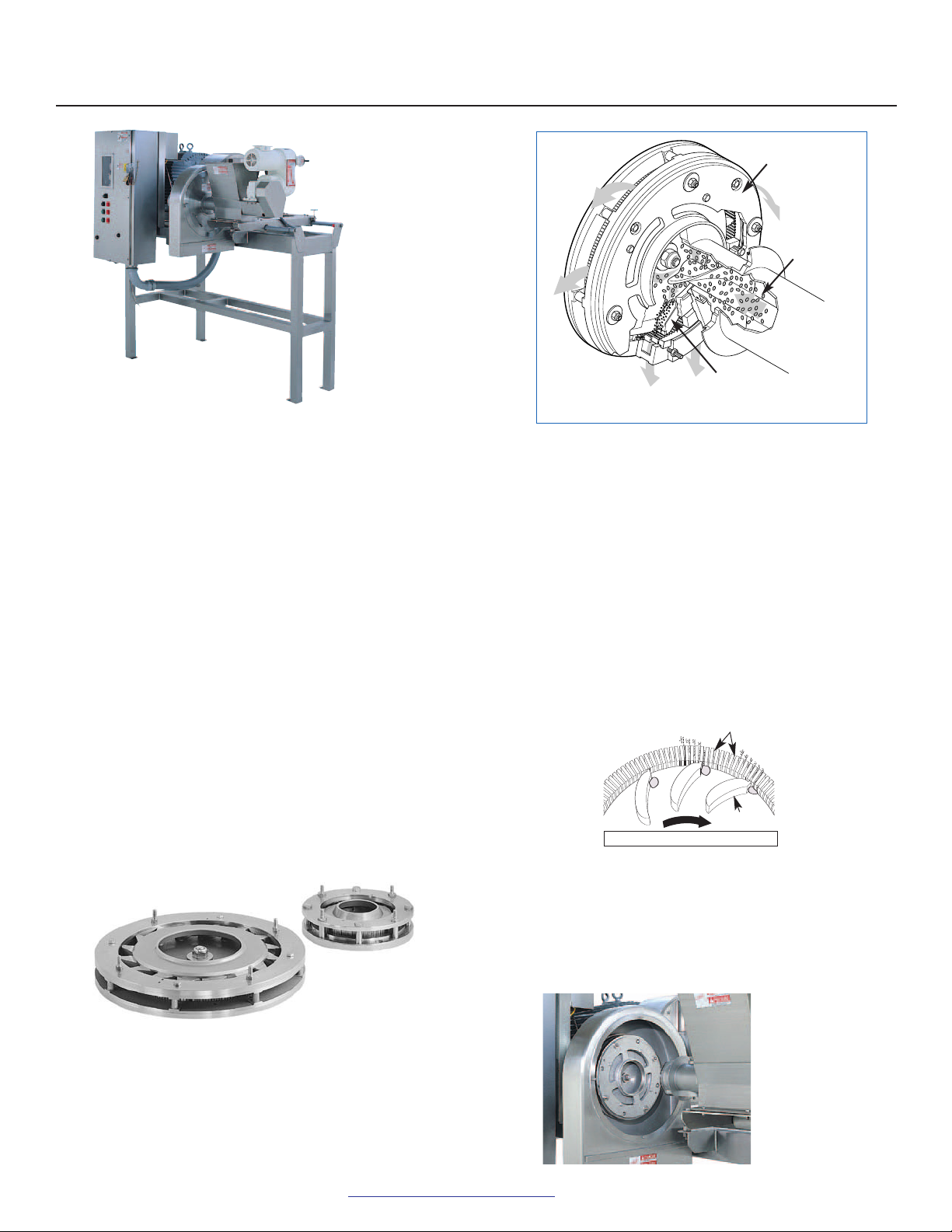

Comitrol® Processor Model 9300 with Feeder

High Capacity Controlled Particle Size Reduction

Microcut

Head

Feed

Screw

SPECIFICATIONS

Length: . . . . . . . . . . . . . . . . . . . . . . 94.06" (2389 mm)

Width: . . . . . . . . . . . . . . . . . . . . . . . 60.06" (1526 mm)

Height: . . . . . . . . . . . . . . . . . . . . . . 88.00" (2235 mm)

Net Weight: . . . . . . . . . . . . . . . . . . . 3500 lb (1587 kg)

Motor: . . . . . . . . . . . 150 or 200 HP (112 or 149.1 kW)

APPLICATIONS

The ¥patented Comitrol Processor Model 9300 is recommended for

particle size reduction when the final product will be a slurry, paste, or liquid. Equipped with a 12" (304.8 mm) microcut head and impeller, the

9300 is designed for one-pass size reduction of products such as fruits

and meats for the production of baby food and peanuts for peanut butter.

The machine features a screw feeder, continuous operation for uninterrupted production, and simplified design for easy cleanup and maintenance.

Product

COMITROL® PROCESSOR MODEL 9300 WITH FEEDER

Impeller

OPERATING PRINCIPLE

Product received by the feed hopper is uniformly delivered by a

variable speed feed screw to a rotating impeller. The high rotational

speed of the impeller causes centrifugal force. This force moves the

product radially outward to the impeller tips. The impeller tips combined with centrifugal force, carry the product past the cutting edges of

the stationary microcut head.

The microcut head is a ring of closely spaced blades. Product

strikes the exposed cutting edges of the blades with great velocity.

This action results in the removal of small particles until reduction is

completed. Particles are discharged through the spaces between the

blades. Because of high impeller speeds, product remains in the

microcut head only a fraction of a second. The product is reduced in

precise increments, emerging a uniform size.

Blades

Product

Impeller

MICROCUT HEAD ASSEMBLY

TYPES OF CUTS

Particle sizes ranging from coarse to fine emulsions are possible. To

ensure the proper combination of cutting parts, Urschel Laboratories, Inc.

recommends your product be tested in one of our worldwide Product Test

Cutting Facilities free-of-charge to find the most efficient solution to your

size reduction needs.

The 12" (304.8 mm) diameter microcut head and

impeller compared to the 6" (152.4 mm) microcut head

(used on other Comitrol Processors)

¥

The COMITROL Processor Model 9300 may contain parts protected by U.S. Patent 5201469.

If your product application is not mentioned on this page, contact your local Urschel representative to

determine the most effective solution to your size reduction needs.

Cutting unit with cutting

enclosure removed.

(Shown for illustration

purposes only)

(over)

Loading...

Loading...